Method for preparing drug sustained release nanofibers

A nanofiber and drug technology, applied in fiber processing, pharmaceutical formulations, fiber chemical characteristics, etc., can solve the problems of inability to meet the needs of drug efficacy, reduce the effect of porous structure, and large carrier size, so as to improve the efficiency of drug use and save time. and material cost, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Prepare polylactic-co-glycolic acid (PLGA, 50 / 50, MW40000Da) microspheres with a diameter of about 20 nm loaded with heparin by using the existing emulsification and solidification method, and place it in 10 ml of dichloromethane, Stirring and oscillating to mix evenly to prepare the core layer spinning solution;

[0036](2) Dissolve 1.0g of PGA (intrinsic viscosity: 1.4-1.8dL / g, melt index at 190°C: 0.4-0.7g / min) in 20ml of dichloromethane solvent, stir and oscillate evenly, and make a cortical spinning solution;

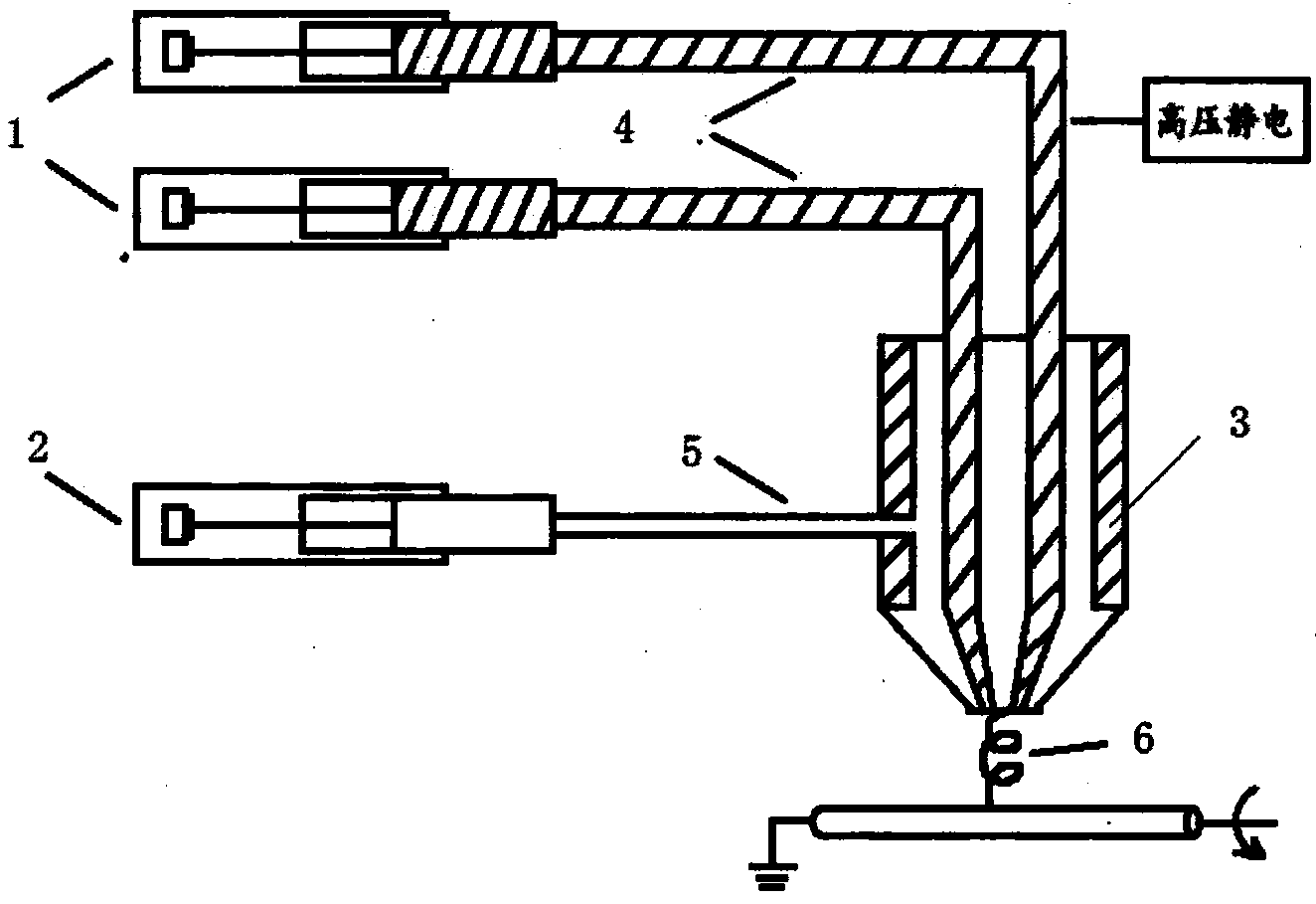

[0037] (3) Put the cortex spinning liquid and the core layer spinning liquid into the cortex liquid storage tank 2 and the core layer liquid storage tank 1 respectively, the flow rate of the cortex spinning liquid is 1.0mL / h, and the spinneret aperture is 1.2mm; The flow rate of the core layer spinning solution is 0.6mL / h, the diameter of the spinneret is 0.45mm; the applied voltage is 17kV, the receiving distance is 12cm, and electrospinning is carried ...

Embodiment 2

[0040] (1) Using the existing emulsification-solvent evaporation method to prepare polycaprolactone-polyethylene glycol-polycaprolactone triblock copolymer (PCL-PEG-PCL) nanoparticles with a diameter of about 20 nm loaded with curcumin Microspheres are placed in 10ml of aqueous solution solvent, stirred and oscillated to mix evenly to obtain the core layer spinning solution;

[0041] (2) 0.6g poly-L-lactic acid (PLLA) was dissolved in 10ml chloroform solvent, after stirring and oscillating evenly, a cortical spinning solution was made;

[0042] (3) Put the cortex spinning solution and the core layer spinning solution into the cortex liquid storage tank 2 and the core layer liquid storage tank 1 respectively, the flow rate of the cortex spinning solution is 1.0mL / h, and the diameter of the spinneret is 1.0mm; The flow rate of the core layer spinning solution is 0.4mL / h, the diameter of the spinneret is 0.9mm; the applied voltage is 18kV, the receiving distance is 12cm, and the ...

Embodiment 3

[0045] (1) Using the existing solvent evaporation method to prepare polylactic acid (PLA) microspheres with a diameter of about 36nm loaded with doxorubicin, disperse 3mg of the microspheres in 5ml of aqueous solution;

[0046] (2) 1.0g PLGA is dissolved in 10ml dichloromethane solvent, after stirring and oscillating evenly, make cortex spinning solution;

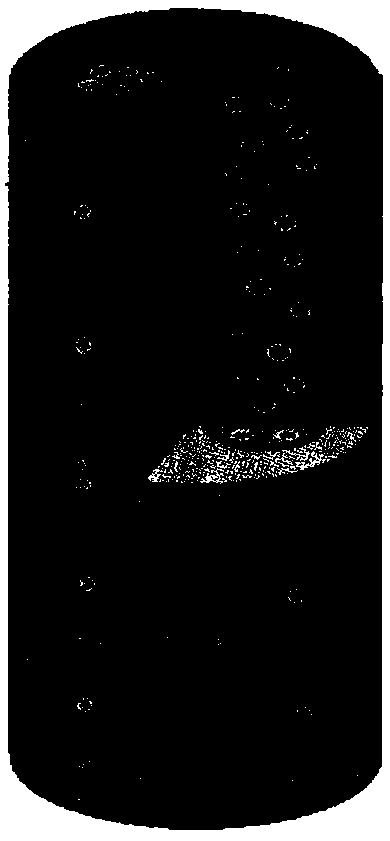

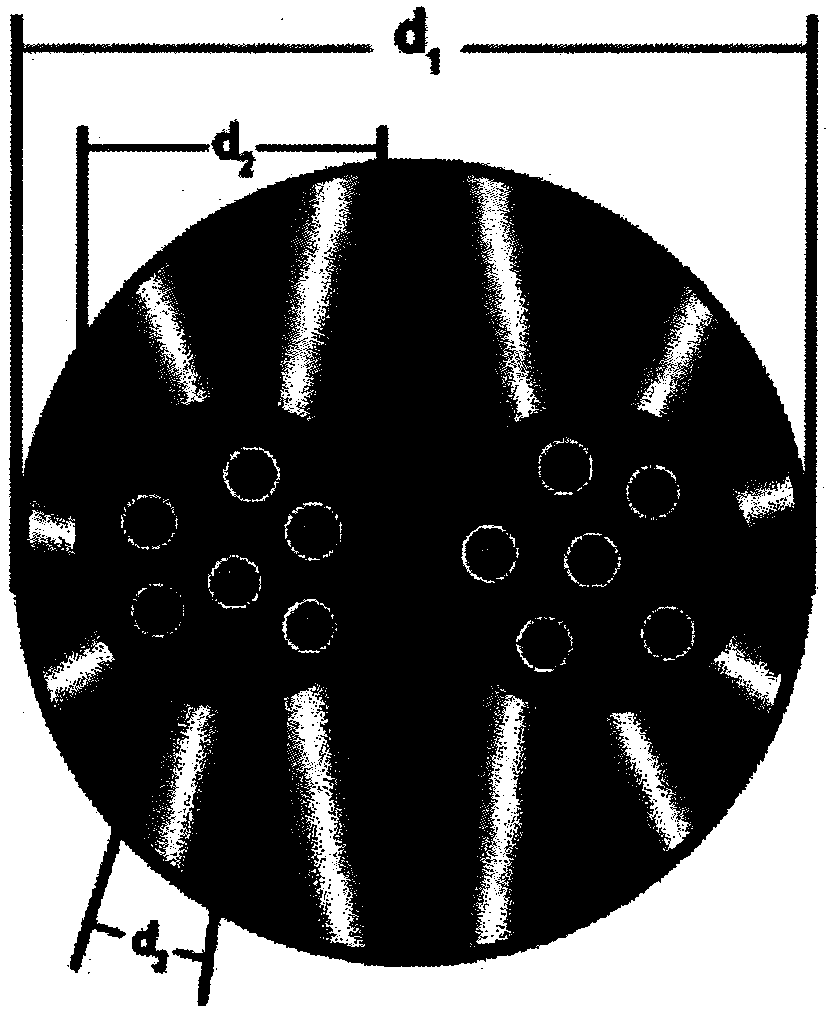

[0047] (3) Put the cortex spinning solution and the core layer spinning solution into the cortex storage tank 2 and the core layer storage tank 1 respectively, the flow rate of the cortex spinning solution is 1.2mL / h, and the diameter of the spinneret is 1.2mm; The flow rate of the core layer spinning solution is 0.5mL / h, the diameter of the spinneret is 0.8mm; the applied voltage is 18kV, the receiving distance is 15cm, and spinning is carried out. During the spinning process, the volatile solvent in the cortex spinning solution volatilizes to form a through hole holes, get as figure 2 The shown drug slow-release nanofib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com