Preparation of sulfur-modified magnetic chitosan and method for treating heavy metal wastewater

A technology of chitosan and chitosan acetic acid, which is applied in chemical instruments and methods, alkali metal compounds, water/sewage treatment, etc., to achieve the effects of small footprint, simple preparation method, and improved adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

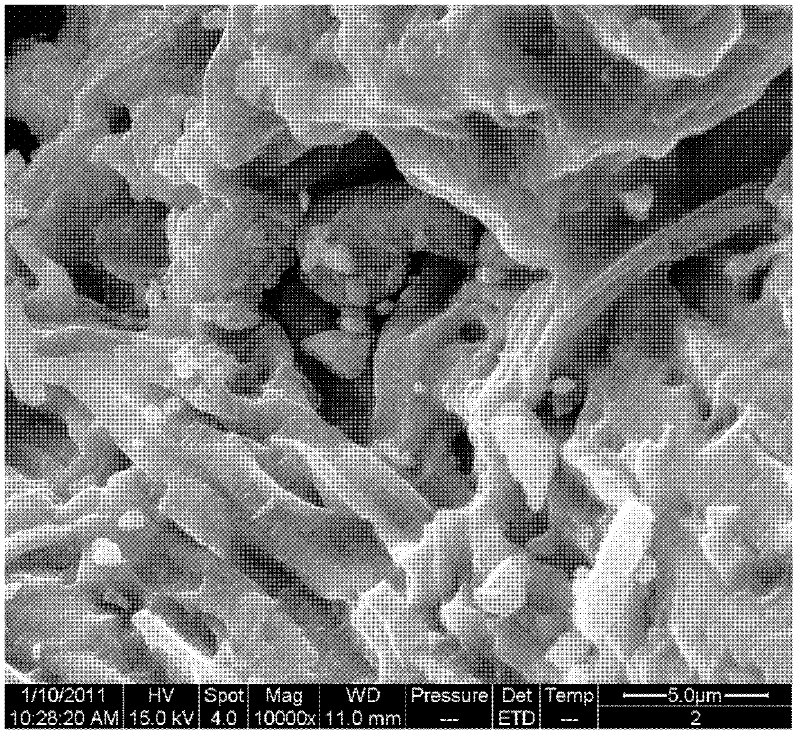

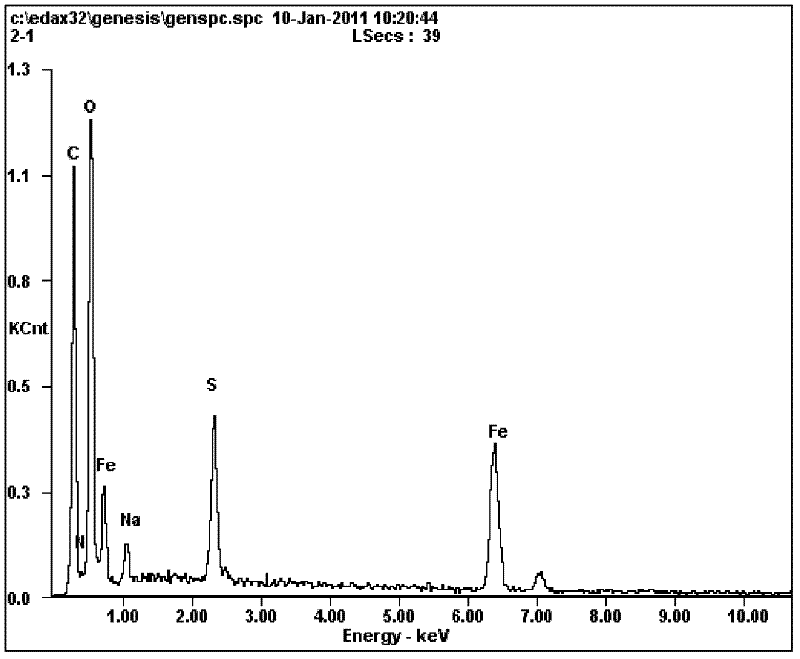

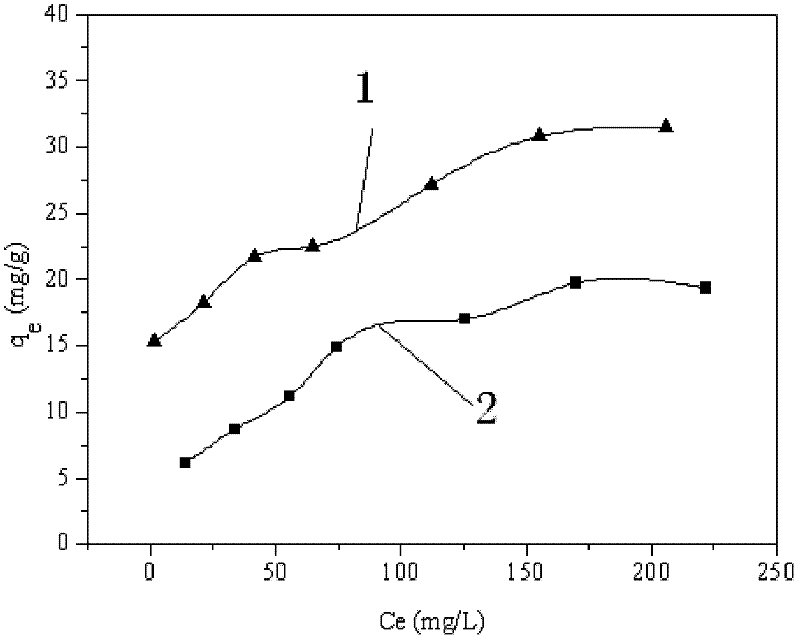

Image

Examples

Embodiment 1

[0022] The preparation method of vulcanized modified magnetic chitosan is carried out according to the following steps:

[0023] (1) 2g chitosan was dissolved in 100mL acetic acid solution to make chitosan acetic acid solution, and then 2.7g FeCl 3 . 6H 2 O and 2.8 g FeSO 4 .7H 2 O (molar ratio 1:1) was dissolved in chitosan acetic acid solution, stirred for 1 h to make it evenly mixed, and left for 0.3 hours;

[0024] (2) The solution obtained in step (1) is slowly dripped into the NaOH solution with a mass fraction of 30% with a syringe, stirred for 1h, and the chitosan gel nanoparticles are solidified to form magnetic chitosan beads, which are then deionized Water repeatedly washes the magnetic chitosan beads until the washing liquid becomes neutral;

[0025] (3) Suspend the magnetic chitosan beads washed to neutral in 0.01M glutaraldehyde solution and stir slowly for 12h, then wash the cross-linked magnetic chitosan beads with deionized water to neutral and vacuum Dr...

Embodiment 2

[0028] The preparation method of vulcanized modified magnetic chitosan is carried out according to the following steps:

[0029] (1) 4g chitosan was dissolved in 100mL acetic acid solution to make chitosan acetic acid solution, and then 5.4g FeCl 3 . 6H 2 O and 2.8 g FeSO 4 .7H 2 O (molar ratio 2:1) was dissolved in chitosan acetic acid solution, stirred for 4 hours to make it evenly mixed, and left for 2 hours;

[0030] (2) The solution obtained in step (1) is slowly dripped into the NaOH solution with a mass fraction of 30% with a syringe, stirred for 5h, and the chitosan gel nanoparticles are solidified to form magnetic chitosan beads, which are then deionized Water repeatedly washes the magnetic chitosan beads until the washing liquid becomes neutral;

[0031] (3) Suspend the magnetic chitosan beads washed to neutrality in 0.1M glutaraldehyde solution and stir slowly for 36h, then wash the cross-linked magnetic chitosan beads to neutrality with deionized water and vac...

Embodiment 3

[0035] The preparation method of vulcanized modified magnetic chitosan is carried out according to the following steps:

[0036] (1) 6g chitosan was dissolved in 100mL acetic acid solution to make chitosan acetic acid solution, and then 10.8g FeCl 3 . 6H 2 O and 2.8 g FeSO 4 .7H 2 O (molar ratio 4:1) was dissolved in the chitosan acetic acid solution, stirred for 2 hours to make it evenly mixed, and left for 1 hour;

[0037] (2) The solution obtained in step (1) is slowly dripped into the NaOH solution with a mass fraction of 30% with a syringe, stirred for 3h, and the chitosan gel nanoparticles are solidified to form magnetic chitosan beads, which are then deionized Water repeatedly washes the magnetic chitosan beads until the washing liquid becomes neutral;

[0038] (3) Suspend the magnetic chitosan beads washed to neutrality in 0.05M glutaraldehyde solution and stir slowly for 36h, then wash the cross-linked magnetic chitosan beads with deionized water to neutrality an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com