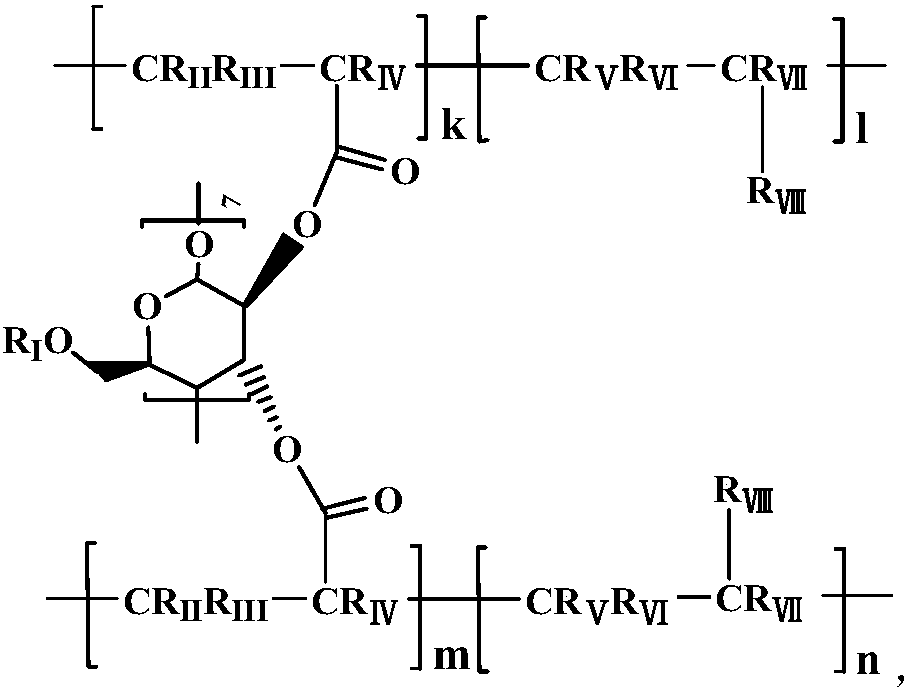

Beta-cyclodextrin polymer adsorbent, and preparation method and application thereof

A cyclodextrin polymer and adsorbent technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, water pollutants, etc., can solve problems such as insufficient adsorption capacity, achieve excellent adsorption effect, and enhance inclusion effect , the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Preparation of modified β-cyclodextrin: Dissolve 2 parts by weight of β-cyclodextrin in 40 parts by volume of dry pyridine under stirring, and when the temperature of the above solution drops below 0°C, 1.5 parts by weight are dissolved 30 parts by volume of dry pyridine solution of trimethylchlorosilane was slowly added dropwise to the solution, and reacted for 12 hours at room temperature. After the reaction, the pyridine was removed, the solid product obtained was dissolved in 40 parts by volume of chloroform and 50 parts by volume of 1mol / L KHSO 4 The residual pyridine in the organic solvent is washed with an aqueous solution and 50 parts by volume of deionized water, the organic phase is collected and the solvent is removed to obtain a white solid product, which is vacuum dried to obtain the first cross-section silane-protected β-cyclodextrin derivative. 2 parts by weight of the first cross-section silane-protected β-cyclodextrin derivative, 0.6 parts by volume o...

Embodiment 2

[0052] (1) Preparation of modified β-cyclodextrin: Dissolve 7 parts by weight of β-cyclodextrin in 120 parts by volume of dry pyridine under stirring, and when the temperature of the above solution drops below 0°C, 4.9 parts by weight are dissolved 40 parts by volume of dry pyridine solution of trimethylchlorosilane was slowly added dropwise to the solution, and reacted for 19 hours at room temperature. After the reaction, the solvent was removed, the solid product obtained was dissolved in 60 parts by volume of dichloromethane and 100 parts by volume of 1mol / L KHSO 4 The residual pyridine in the organic solvent is washed with an aqueous solution and 80 parts by volume of deionized water, the organic phase is collected and the solvent is removed to obtain a white solid product, which is vacuum dried to obtain the first cross-section silane-protected β-cyclodextrin derivative. 7.7 parts by weight of the first cross-section silane-protected β-cyclodextrin derivative, 12 parts by v...

Embodiment 3

[0056] (1) Preparation of modified β-cyclodextrin: 10 parts by weight of β-cyclodextrin were stirred and dissolved in 180 parts by volume of dry pyridine, and when the temperature of the above solution dropped below 0°C, 11 parts by weight were dissolved 100 parts by volume of dry pyridine solution of tert-butyldimethylchlorosilane was slowly added dropwise to the solution, and reacted at room temperature for 21 hours. After the reaction, the solvent was removed, the solid product obtained was dissolved in 150 parts by volume of chloroform and 100 parts by volume of 1mol / L KHSO 4 The residual pyridine in the organic solvent is washed with an aqueous solution and 100 parts by volume of deionized water, the organic phase is collected and the solvent is removed to obtain a white solid product, which is vacuum dried to obtain the first cross-section silane-protected β-cyclodextrin derivative. 6.1 parts by weight of the first cross-section silane-protected β-cyclodextrin derivative, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com