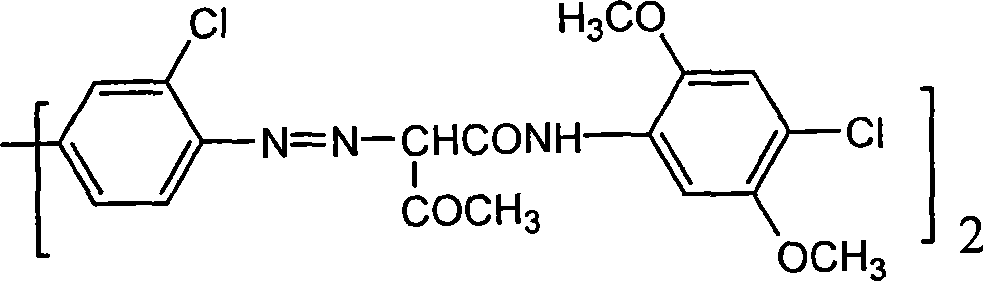

Method for preparing pigment yellow

A pigment yellow and pigment technology, which is applied in the field of pigment preparation, can solve the problems such as the effect is not very obvious, and achieve the effect of bright color, easy dispersion and good coloring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

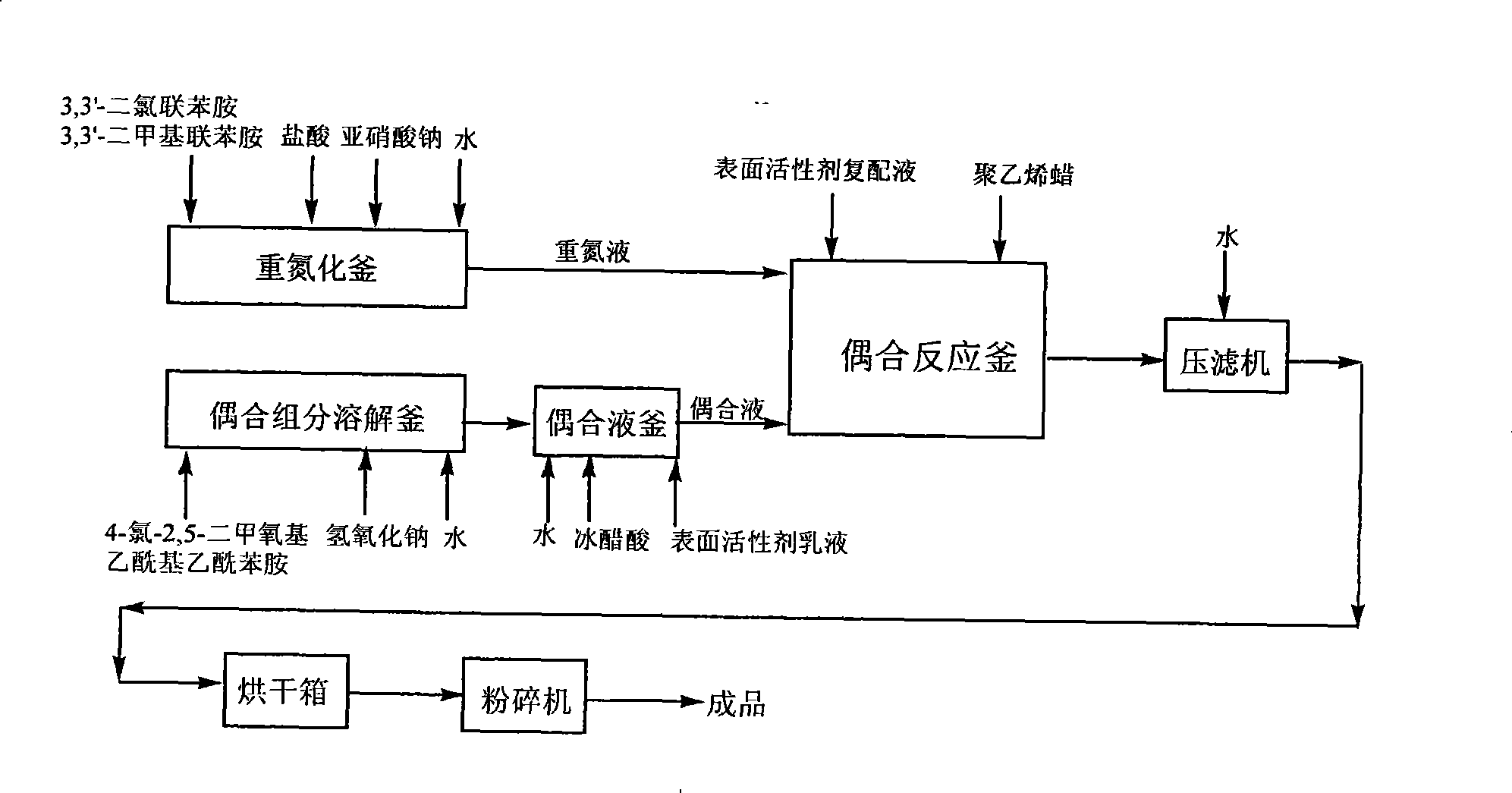

[0031] exist figure 1 , 2 In, the preparation method of Pigment Yellow 83, it is water 200ml, add 30% hydrochloric acid 8.6g, 3,3'-dichlorobenzidine 4.7g, 3,3'-dimethylbenzidine 0.094g, stir to dissolve 0.5 h, add ice and cool down to 3°C, add 9.67g of 30% sodium nitrite, carry out diazotization reaction for 0.5h, use sulfamic acid to remove excess nitrous, and prepare diazonium salt for later use.

[0032] 200ml of water and 2.8g of sodium hydroxide were heated up to 35°C, 11.6g of 4-chloro-2,5-dimethoxyacetylacetanilide was added and stirred until clear to obtain a solution of the coupling component.

[0033] Add 200ml of water, add 5.3g of glacial acetic acid, 0.2g of ethylenediaminetetraacetic acid, add 0.1g of Pingpingjia O, 0.1g of Zhakai powder, 2.0g of xylene and 20g of water and mix well, and stir evenly. Put the coupling component solution in 0.5h for acid analysis, the acid analysis temperature is 20°C, add 2.4g of sodium acetate to prepare the coupling solution. ...

Embodiment 2

[0036] The preparation of diazonium salt is with embodiment 1.

[0037] 200g of water and 2.8g of sodium hydroxide were heated up to 40°C, 11.6g of 4-chloro-2,5-dimethoxyacetylacetanilide was added, stirred until clear, and a solution of the coupling component was obtained.

[0038] Add 200g of water, add 5.3g of glacial acetic acid, 0.3g of ethylenediaminetetraacetic acid, add 0.15g of Pingpingjia O, 0.1g of pull-off powder, 3.0g of xylene and 20g of water and mix well, and stir evenly. Put the solution of the coupling component in 0.5h for acid analysis, the acid analysis temperature is 30°C, add 2.4g of sodium acetate after analysis to obtain the coupling solution. The pH value of the coupling solution is 5-6.

[0039] Add the diazonium salt dropwise into the coupling solution in 4 hours, the coupling temperature is 30°C, the pH value after the coupling is 3~4, add the emulsion dissolved by Pingpingjia OS-15 0.1g, solsperse17000 0.3g and water 10g, and stir to react 1h, h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com