Microbial lysozyme microcapsule as well as preparation and application of microbial lysozyme microcapsule

A lysozyme and microcapsule technology, applied in the field of microbial preparations and aquaculture, can solve the problems of preparing microbial lysozyme microcapsules, etc., and achieve the effect of solving the problems of drug resistance and drug residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Take 100ml 40g / L sodium alginate solution and 100ml 2mg / mL lysozyme solution (the activity of lysozyme is 5000U / mg) and mix evenly, and drop the above mixed solution into 200ml containing 20g / L calcium chloride and 50g / L chitosan (90% degree of deacetylation) and 5mL / L acetic acid aqueous solution, and stirred at a speed of 180rpm, the peristaltic pump dropping rate is 100 drops / min (about 4 ~ 6mL / min).

[0022] After about 40 minutes, the dropwise addition was completed, and the stirring was stopped. After solidification for 1 hour, the solid was washed twice with distilled water, and drained with gauze.

[0023] Pre-freeze at -20°C for 12 hours, freeze-dry at -25°C and 80pa for 24 hours. 2% calcium chloride and 0.5% chitosan (90% degree of deacetylation) in 0.5% (v / v) acetic acid aqueous solution with constant stirring, 10^6U / 4

[0024] The obtained lysozyme microcapsules use sodium alginate / chitosan as a wall material, and the content of lysozyme is 23000-27000U / g. ...

Embodiment 2

[0026] The above-mentioned lysozyme microcapsules that are made carry out heterogeneous gibel crucian carp culture test:

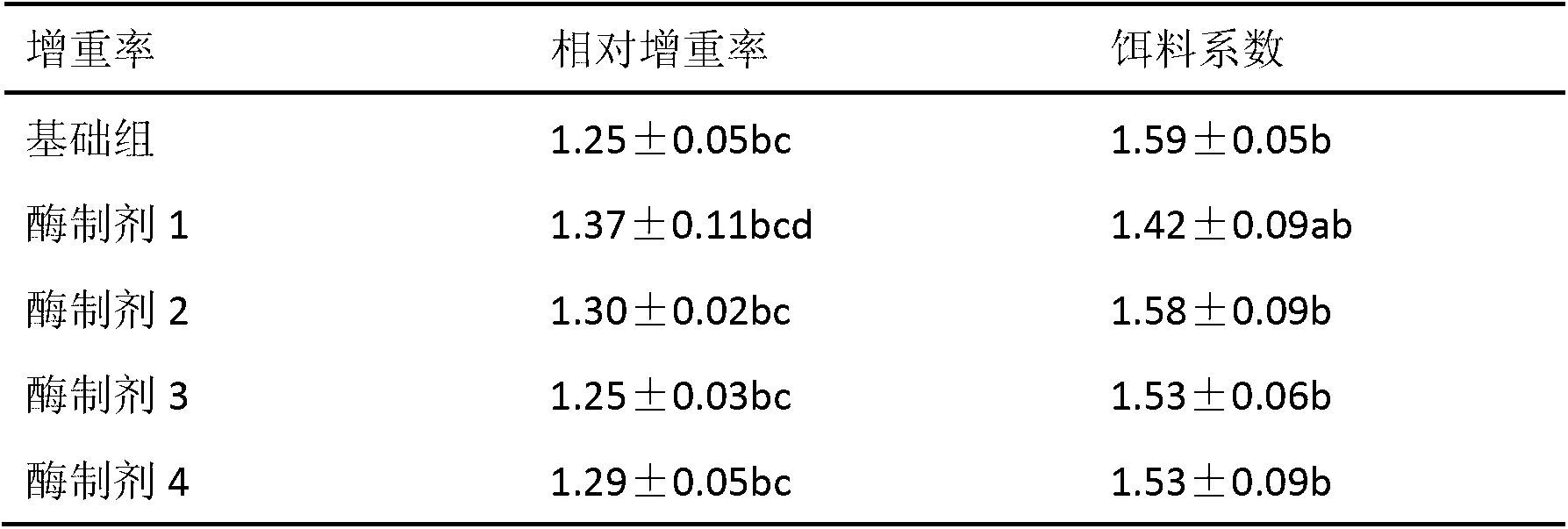

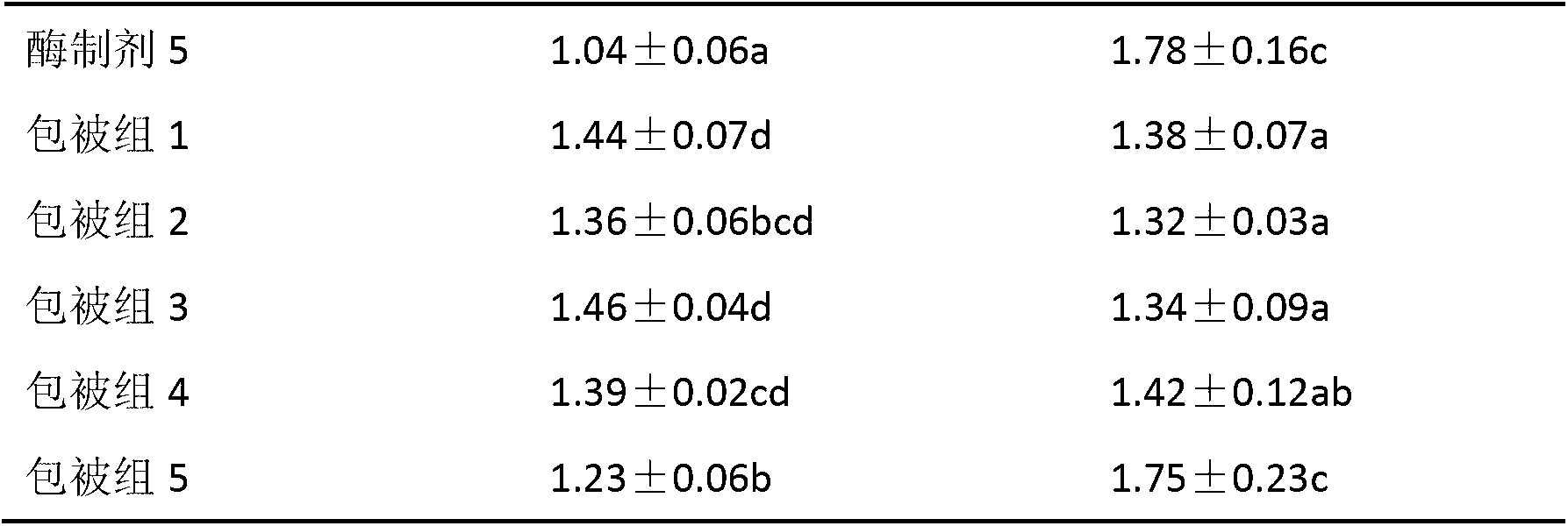

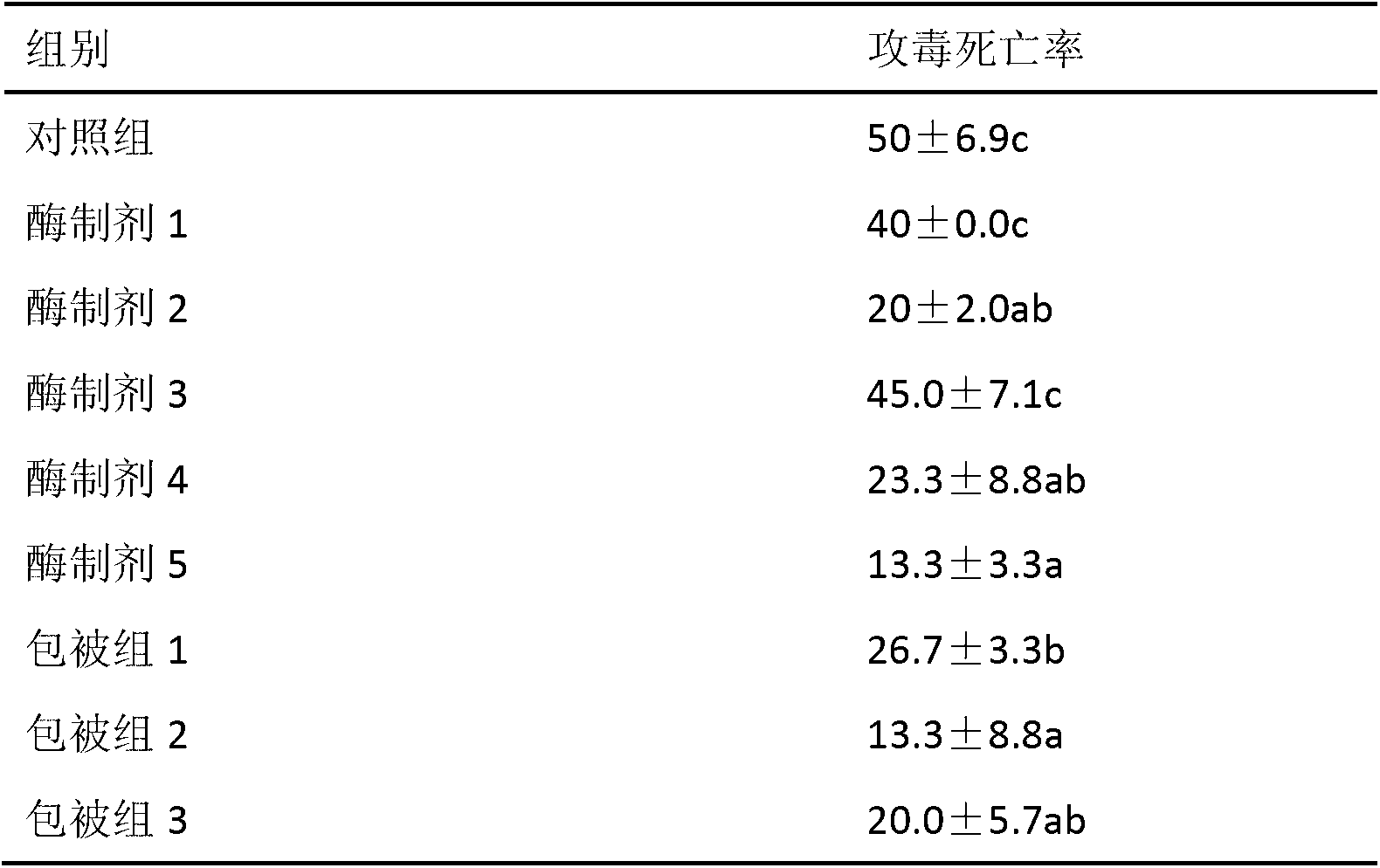

[0027] 1 Materials and methods

[0028] 1.1 Test fish and feed preparation

[0029] The experiment was carried out in the special aquaculture farm of Shanghai Ocean University from July to September 2011. The heterogeneous gibel crucian carp was selected in the same year, and it was cultured for 40 days with basic feed in the test pond to make it adapt to the test conditions and eliminate the differences caused by the nutrition and environment of the test fish. The experiment was divided into 11 groups with 4 repetitions in each group and 30 tails in each repetition (initial weight 28.11±2.14g). According to the nutritional requirements of heterogeneous gibel crucian carp, formulate feed formula and make basic feed. Add lysozyme product and its coating product respectively in basic feed, wherein lysozyme product is the microbial lysozyme crystal powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com