Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Reduce internal diffusion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

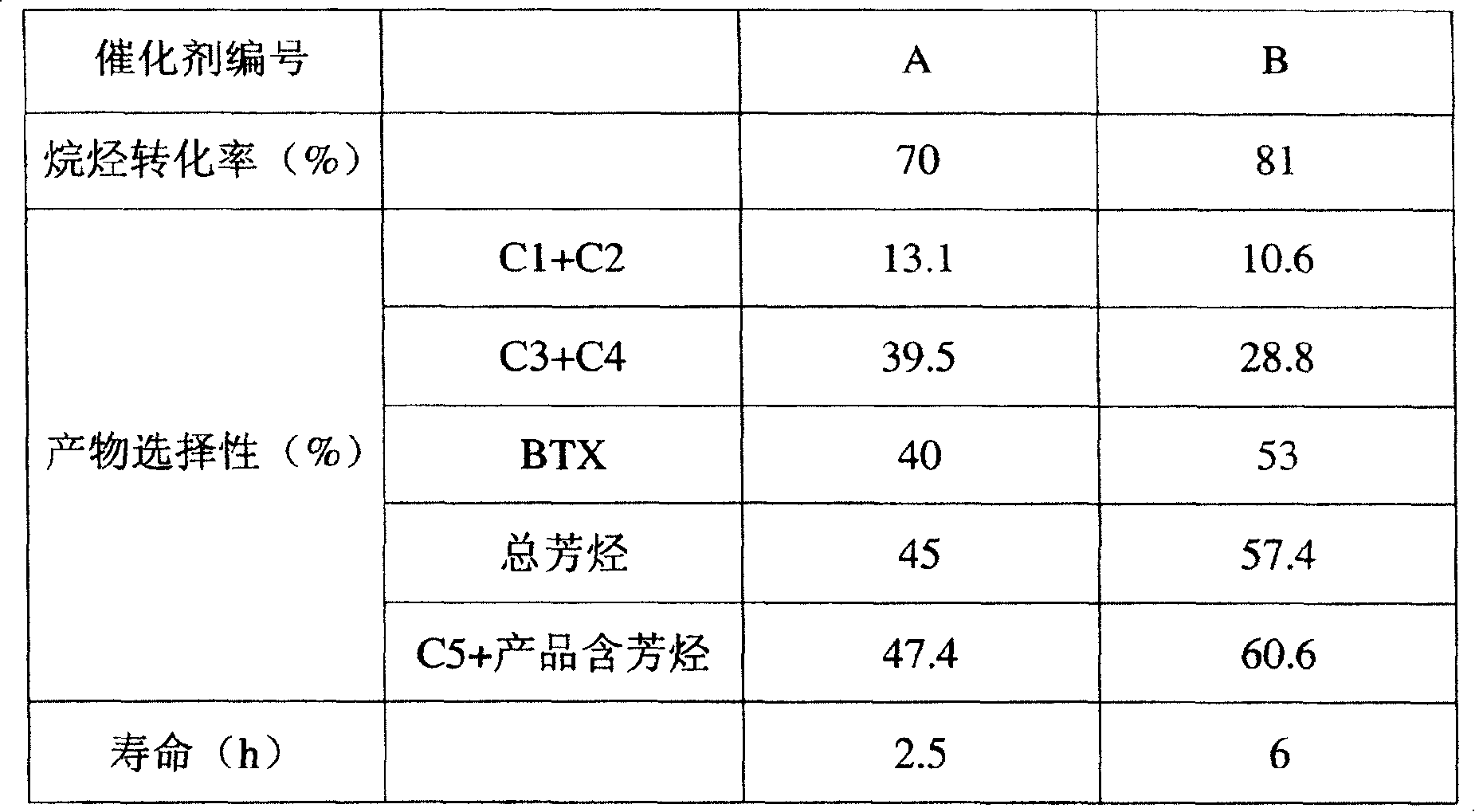

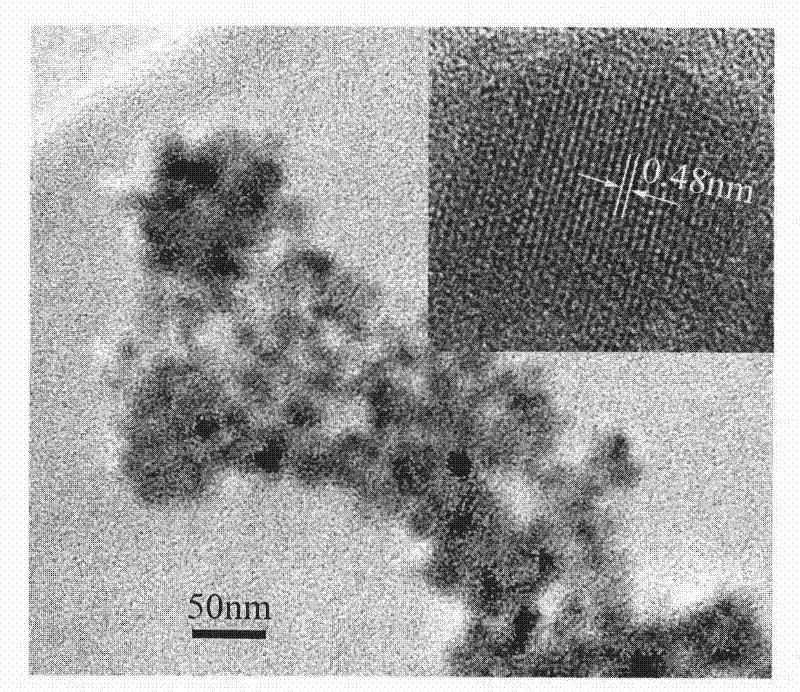

Paraffinic hydrocarbon aromatization catalyst and its preparation method

InactiveCN1830558AHigh surface energyImprove surface activityMolecular sieve catalystsRefining to change hydrocarbon structural skeletonMolecular sieveDiffusion resistance

A catalyst for aromatizing paraffin is a non-noble metal modified nano-class zeolite molecular sieve, which is composed of MFI-type zeolite molecular sieve as carrier and the Zn and Ga as active component. It has high catalytic activity, selectivity and stability. Its preparing process is also disclosed.

Owner:BEIJING UNIV OF CHEM TECH

Molybdenum nitride hydrodeoxygenation catalyst as well as preparation method and application thereof

ActiveCN107456988AHigh reactivityHigh activityPhysical/chemical process catalystsHydrocarbon from oxygen organic compoundsBenzeneActive component

The invention researches a loaded molybdenum nitride catalyst and a preparation method thereof. The preparation method comprises the following steps: with mesoporous carbon (MC) as a carrier, loading an active component onto the carrier according to an equivalent-volume impregnation method, drying to obtain a catalyst precursor, and carbonizing and then nitriding the obtained precursor to obtain the loaded molybdenum nitride catalyst. The loaded molybdenum nitride catalyst prepared by the preparation method has relatively high activity during a hydrodeoxygenation reaction of guaiacol and has relatively high benzene selectivity.

Owner:CHANGZHOU UNIV

Application of hydrogenation catalyst to preparation of 1,4-cyclohexanediamine

InactiveCN102491904AEasy to recycleHigh yieldOrganic compound preparationAmino compound preparationReaction temperatureBULK ACTIVE INGREDIENT

The invention relates to an application of a hydrogenation catalyst to preparation of 1,4-cyclohexanediamine. A method for preparing the 1,4-cyclohexanediamine comprises the following steps of: adding a ruthenium catalyst consisting of an active ingredient and a carrier into a stainless steel high-pressure reaction kettle with a stirring function; adding para-phenylene diamine; adding a solvent and an aid; closing the reaction kettle; replacing air in the reaction kettle with nitrogen for at least three times; replacing nitrogen in the reaction kettle with hydrogen for at least three times; charging hydrogen till a reaction pressure in the reaction kettle is 1-10 MPa; heating the reaction kettle till a reaction pressure is 80-180 DEG C; and performing catalytic hydrogenation to prepare the 1,4-cyclohexanediamine. In the method for preparing the 1,4-cyclohexanediamine by performing catalytic hydrogenation with the para-phenylene diamine, a hydrogenation reaction technology for using the stainless high-pressure reaction kettle with the stirring function is adopted, and a catalyst carrier is pretreated, so that the activity of the catalyst is raised, the consumption of the catalyst is lowered, and catalyst cost is reduced greatly; and process conditions are optimized, so that high transformation ratio of the para-phenylene diamine is kept, and the high selectivity of the 1,4-cyclohexanediamine serving as a product is raised.

Owner:CHANGZHOU UNIV

Pt-load catalyst taking mesoporous carbon as carrier, as well as preparation method and usage thereof

InactiveCN102671656AAdvantages of preparation methodHigh reactivityHydrazine preparationMetal/metal-oxides/metal-hydroxide catalystsO-nitrochlorobenzenePretreatment method

The invention relates to a Pt-load catalyst taking mesoporous carbon as a carrier, which is characterized in that the mesoporous carbon is pretreated before Pt is loaded; the pretreatment method comprises one in the following steps of: (1) adding the mesoporous carbon into a 10-30% hydrogen dioxide solution, soaking for 1-24hours, washing and removing hydrogen peroxide; (2) adding the mesoporous carbon into a 1-6M hydrochloric acid or nitric acid solution, soaking for 1-24hours, washing and removing hydrochloric acid or nitric acid; and (3) adding the mesoporous carbon into a 1-6M sodium hydroxide solution, soaking for 1-24hours, washing and removing alkali, wherein the load quantity of Pt is 0.5-5%. The invention also relates to the application of the Pt-load catalyst in preparation of 2, 2'-dichloro hydroazobenzene (DHB) from ortho-nitrochlorobenzene through hydrogenation. The catalyst uses the mesoporous carbon as the carrier, so that the internal diffusion resistance can be better reduced, and the reaction speed is accelerated. The Pt-load catalyst is high in reaction activity and selectivity, and can be repeatedly used for more than eight times, so that the using cost of the catalyst is lowered.

Owner:CHANGZHOU UNIV +1

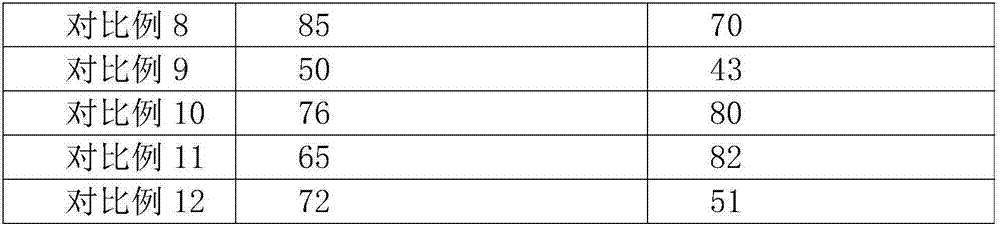

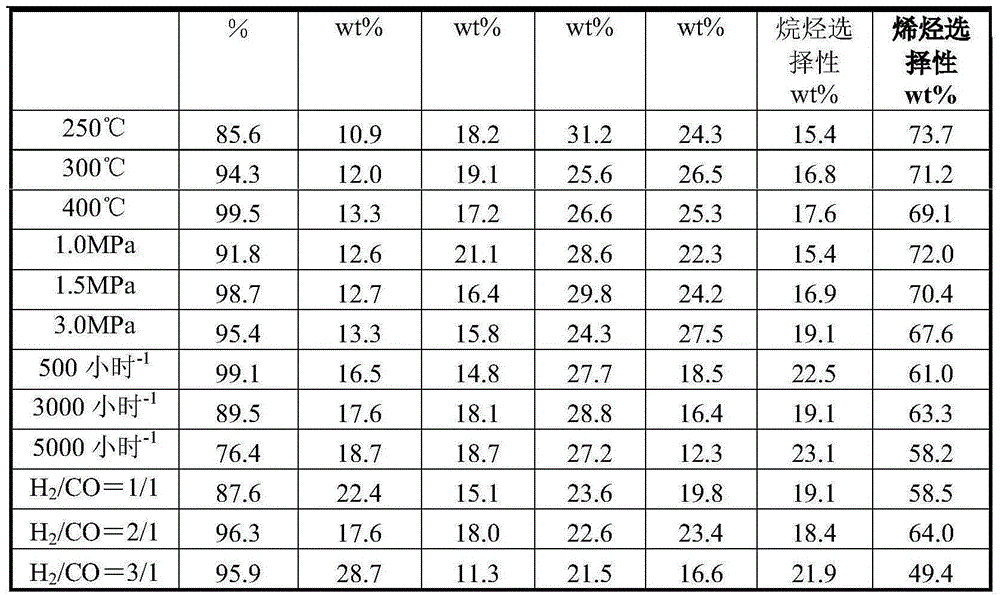

Iron-based catalyst for preparing low-carbon alkane as well as preparation method and using method of iron-based catalyst for preparing low-carbon alkane

ActiveCN104437524AHigh activityActive releaseHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsAlkanePtru catalyst

The invention relates to an iron-based catalyst for preparing low-carbon alkane as well as a preparation method and a using method of the iron-based catalyst for preparing the low-carbon alkane. The iron-based catalyst for preparing the low-carbon alkane is mainly used for solving the problems that the reaction of preparing low-carbon alkane from a synthesis gas in the prior art is low in CO conversion rate and low in low-carbon alkane selectivity, and the catalyst is poor in strength and thermal stability under a using condition. The problems are solved very well by adopting a technical scheme that the catalyst comprises the following components in parts by weight: a) 20-80 parts of an iron element or oxides thereof; b) 1-15 parts of a cobalt element and oxides thereof; c) 10-30 parts of at least one element selected from molybdenum and vanadium or oxides thereof; d) 5-20 parts of at least one element selected from magnesium and barium or oxides thereof; e) 5-20 parts of at least one element selected from tin and aluminum or oxides thereof; and f) 0.5-10 parts of a scandium element or oxides thereof. The catalyst can be used for industrial production of preparing low-carbon alkane from the synthesis gas by virtue of a one-step process.

Owner:CHINA PETROLEUM & CHEM CORP +1

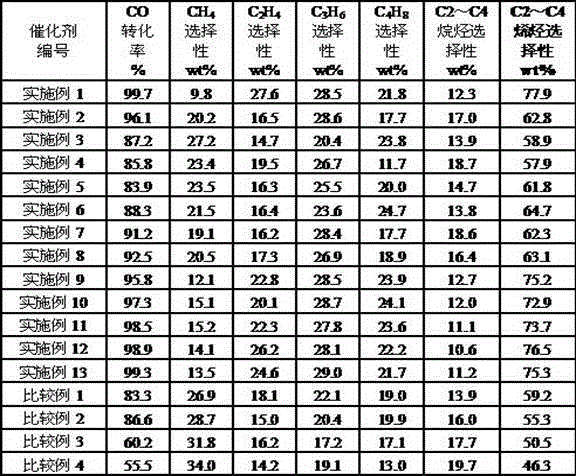

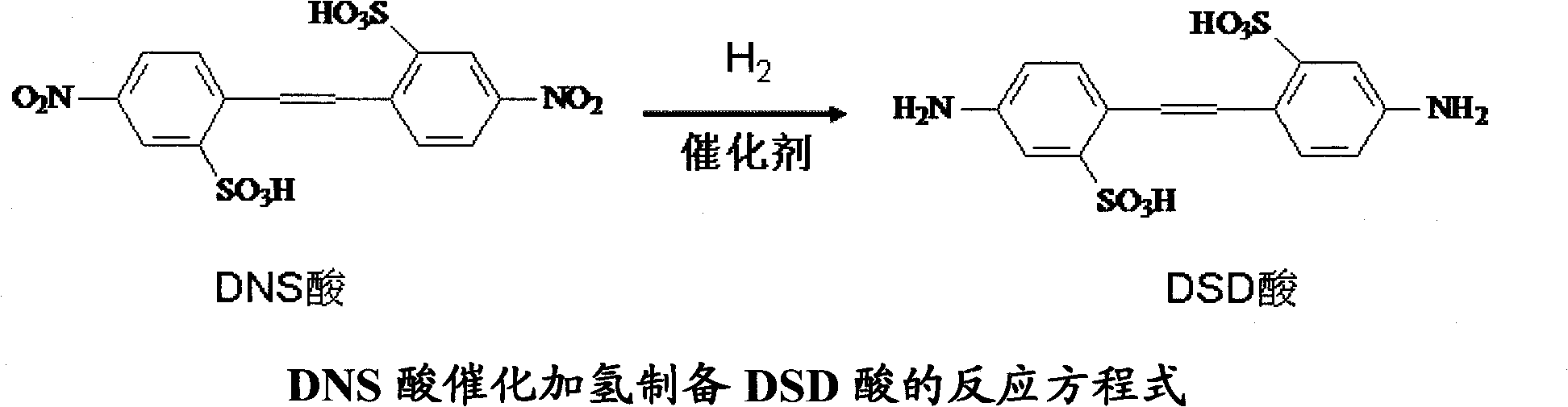

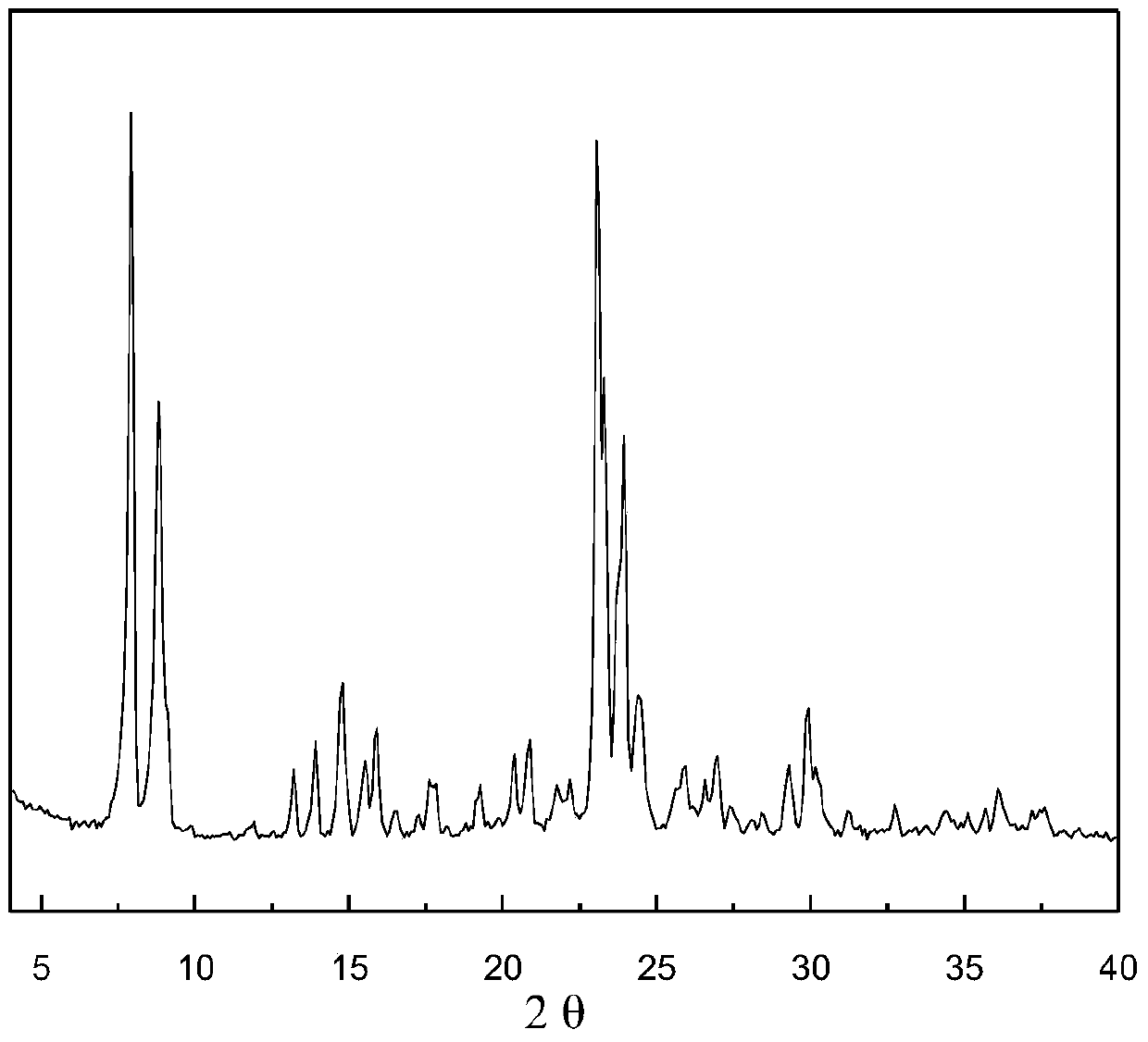

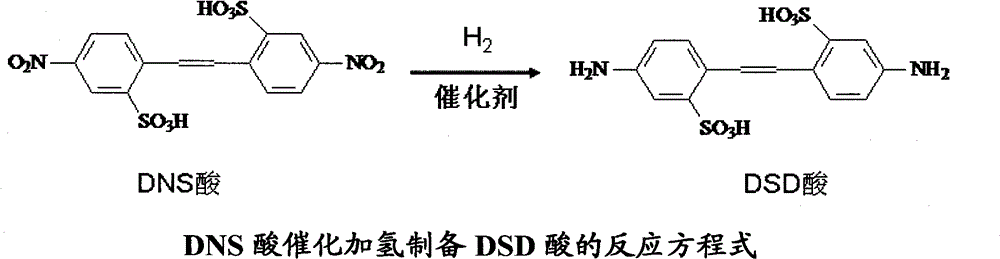

Mesoporous carbon catalyst with load palladium (Pd) and application of mesoporous carbon catalyst

InactiveCN102631916AHigh reactivityHigh selectivitySulfonic acid preparationMetal/metal-oxides/metal-hydroxide catalystsProcess conditionsPalladium

The invention relates to a mesoporous carbon catalyst with load palladium (Pd). The mesoporous carbon catalyst is characterized by preprocessing mesoporous carbon before processing the load Pd. A processing method comprises one or combination of the following steps of: adding and immersing the mesoporous carbon in 10% to 30% peroxide solution for 1 hour to 24 hours, and washing and removing peroxide; and adding and immersing the mesoporous carbon in 1M to 6M of hydrochloric acid solution for 1 hour to 24 hours, and washing and removing hydrochloric acid. In addition, the invention also relates to application of the mesoporous carbon catalyst in preparation of 4,4'-aminostilbene-2,2'-disulfonic acid (DSD acid). According to the invention, as the catalyst carrier is preprocessed, the catalyst activity is improved, and the catalyst consumption is reduced; and as technological conditions are optimized, the conversion rate of 4,4'-diaminostilbene-2,2'-disulfonic acid (DNS acid) to the DSD Acid is improved effectively, and the high selectivity of the product DSD acid is maintained.

Owner:CHANGZHOU UNIV +1

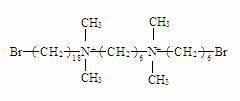

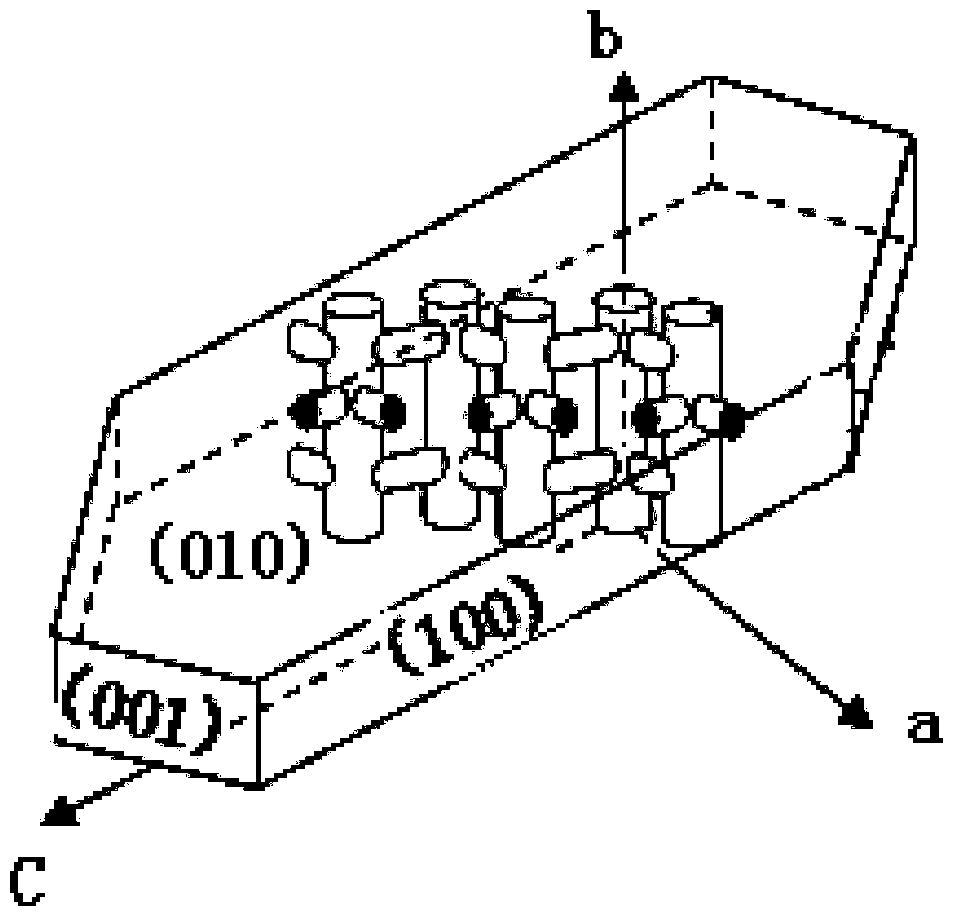

Method for preparing MFI catalyst carrying transition elements and MFI catalyst application

InactiveCN102380412AAvoid inactivationHigh activityMolecular sieve catalystsDispersed particle separationNucleationSodium silicate

Disclosed are a method for preparing an MFI catalyst carrying transition elements and MFI catalyst application. Cationic gemini surfactant- dibromide-1-(dimethyl hexyl ammonium)-6-(dimethyl octodecyl ammonium) hexane is used as structure directing agent of the MFI catalyst, sodium silicate is used as a silicon source and is subjected to low-temperature hot crystallization under self-generated pressure in a rotationally dynamic manner, and after directional polycondensation, rearrangement, nucleation and growth of inorganic atom Si-Al-Na-O on a two-dimensional plane, and single-structure-cell nano-layer MFI catalytic materials which are in mesoporous and microporous structure with the thickness ranging from 2 nanometers to 5 nanometers only are synthetized. Activity center point number of the MFI catalyst is increased evidently by utilizing two-dimensional single-structure-cell nano MFI carrying transition elements of Fe and Mo, the thickness of the catalyst crystal is reduced effectively, diffusion path is shortened, and molecular diffusion is speeded up. In addition, according to the result of a test of utilizing the selective catalytic reduction (SCR) process to remove tail gas of automobiles, NOx removal rate reaches 99.5%.

Owner:TAIYUAN UNIV OF TECH

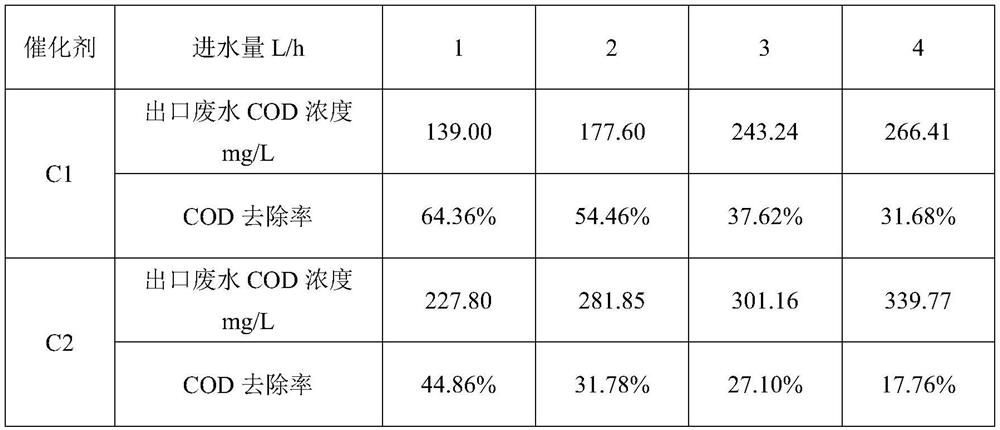

Heterogeneous ultraviolet-Fenton oxidation catalyst and preparation and application thereof

ActiveCN104383958AImprove the bactericidal effectImprove effluent qualityPhysical/chemical process catalystsWater/sewage treatment by irradiationDiffusion resistanceActive component

The invention discloses a heterogeneous ultraviolet-Fenton oxidation catalyst and preparation and application thereof. Prussian blue is used as iron sources, the Prussian blue is deposited on an amino-functional SiO2 mesoporous film with vertical hole passages in an automatic assembly manner, the Prussian blue is fixed through the physical absorption and the interaction force between the positive and negative charges, the bonding is firm, and the loosing is avoided; the prepared catalyst is the film catalyst, the specific surface area is large, the utilization efficiency of active components is high, the catalytic efficiency is high, and compared with the powdery and granular catalysts, the separation and the recovery are easy. Because the catalyst is provided with the mesoporous passages which are vertically distributed, the internal diffusion resistance is little, and many organic matters are suitable for being treated; at the same time, the Prussian blue loaded by the catalyst contains various states of iron, so that the Prussian blue has a cooperating function; in addition, the preparation method disclosed by the invention is simple in technology and wild in condition, so that the preparation method is suitable for popularization and application.

Owner:SHANGHAI JIAO TONG UNIV

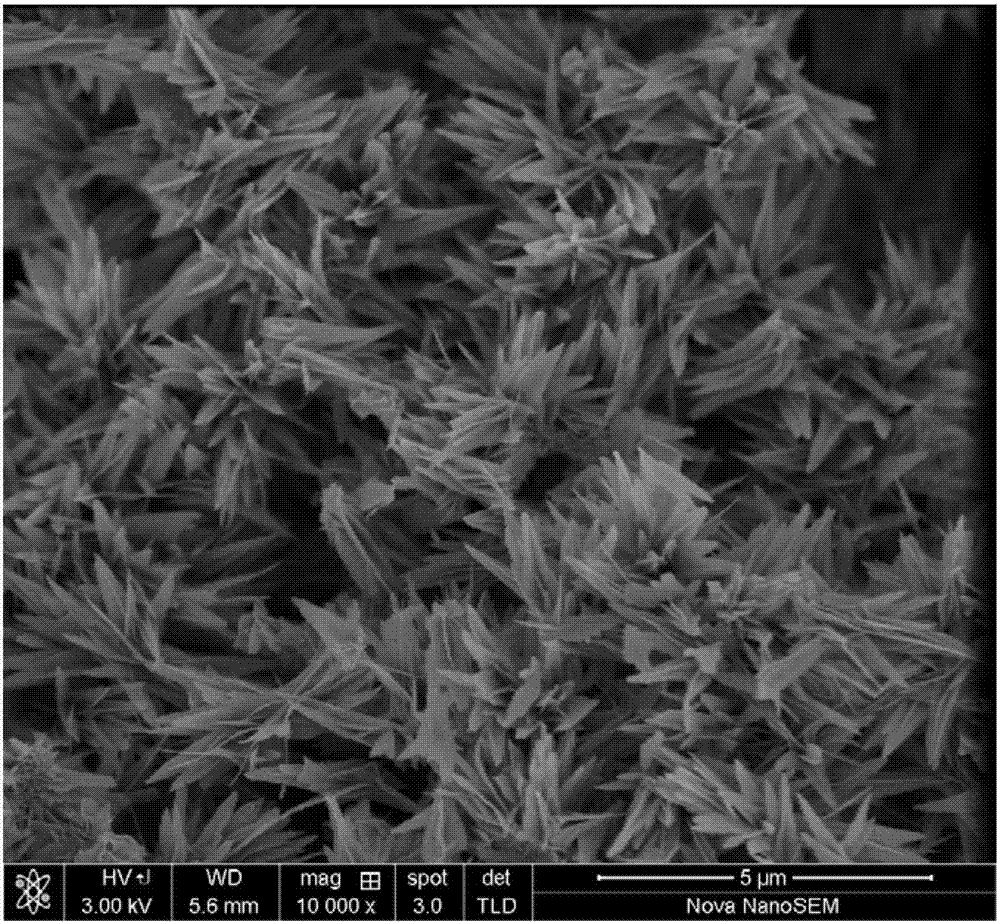

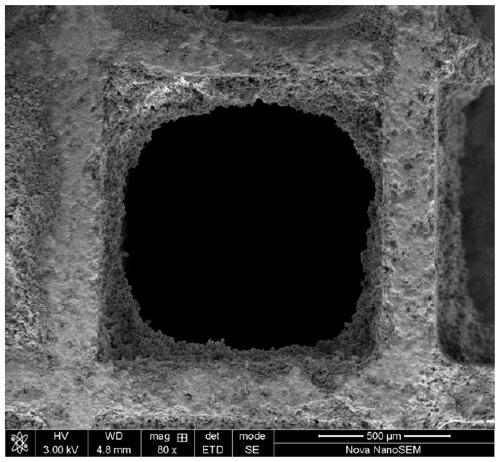

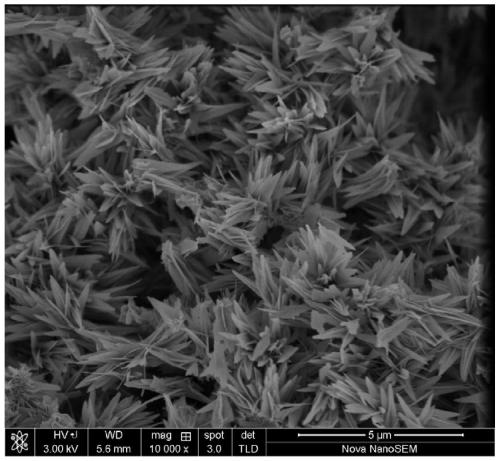

Monolithic cluster alumina supported catalyst and application thereof

ActiveCN107497499AImprove high temperature resistanceReduce internal diffusion resistanceCatalyst carriersHeterogenous catalyst chemical elementsFlower likeMetallurgy

The invention discloses a monolithic cluster alumina supported catalyst and an application thereof. A supporter contains a hierarchical-structure alumina coating and a monolithic porous ceramic matrix, wherein the hierarchical-structure alumina coating is a micron-sized cluster substance formed by laminating blades with nano-thickness and is of a flower-like structure.

Owner:EAST CHINA UNIV OF SCI & TECH

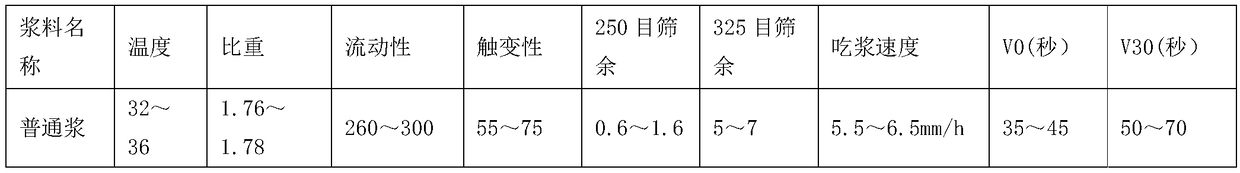

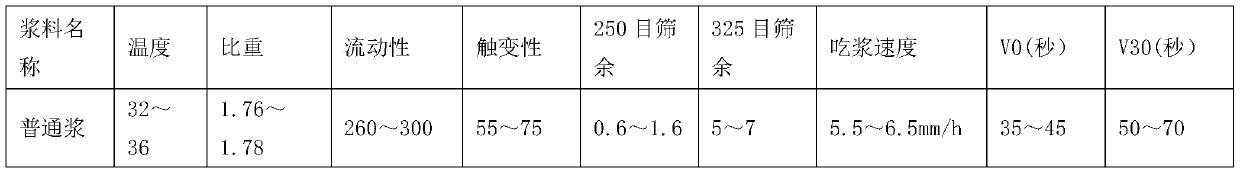

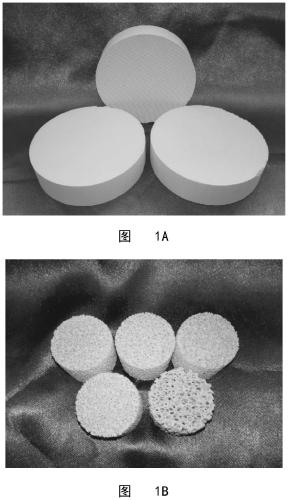

Rapid sanitary appliance production method

ActiveCN108892474AShorten drying cycleIncrease productivityCeramic shaping apparatusCeramic materials productionMicrowaveSlurry

The invention discloses a rapid sanitary appliance production method which includes the steps: grouting and forming: pouring slurry into a mold, demolding to form a sanitary appliance mud blank; microwave drying: conveying the sanitary appliance mud blank into a microwave drying oven to dry the mud blank for 3-6 hours. Microwave drying stages sequentially include a slow drying stage, an accelerated drying stage, a rapid drying stage and a cooling stage. The sanitary appliance mud blank is dried by the aid of a microwave drying mode, a drying period is controlled within the range from 3 hours to 6 hours and reduced to a large extent, and the production efficiency is improved. The method adopts four microwave drying stages, so that the sanitary appliance mud blank is slowly dried, dried in an accelerated manner, rapidly dried and cooled, and the drying qualification rate of sanitary appliances is effectively increased and reaches 97%.

Owner:FOSHAN DONGPENG SANITARY WARE +2

ZSM-5 molecular sieve and preparation method thereof

InactiveCN110156040ANot easy to reuniteAvoid easy cloggingPentasil aluminosilicate zeoliteCrystallinitySolid like

The invention provides a preparation method of a sheet ZSM-5 molecular sieve. The method includes: in a gel preparation process, mixing a silicon source, an aluminum source, a template agent and an additive, and performing stirring at 10-50DEG C for 1-20h; conducting standing aging for 10-30h at 10-90DEG C; putting the prepared gel reaction mixture into a reaction kettle, then putting the reactionkettle into an oven, conducting crystallization at 100-220DEG C for 4-30h, then taking the product out, and carrying out filtering, washing and drying to obtain the ZSM-5 molecular sieve product. Themethod provided by the invention synthesizes the ZSM-5 molecular sieve under a solid like phase condition, and the obtained ZSM-5 molecular sieve product is sheet shaped, and has a relative crystallinity of 90-110%, and an SiO2 / Al2O3 molar ratio of less than or equal to 100.

Owner:PETROCHINA CO LTD

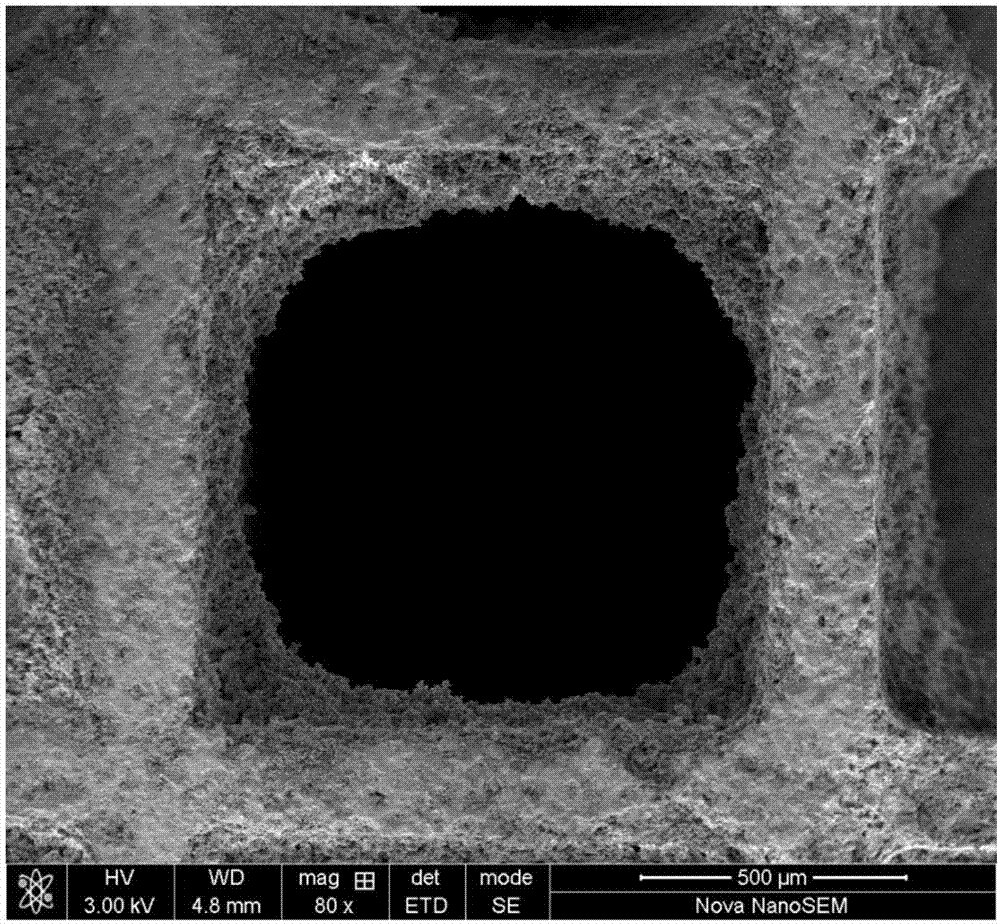

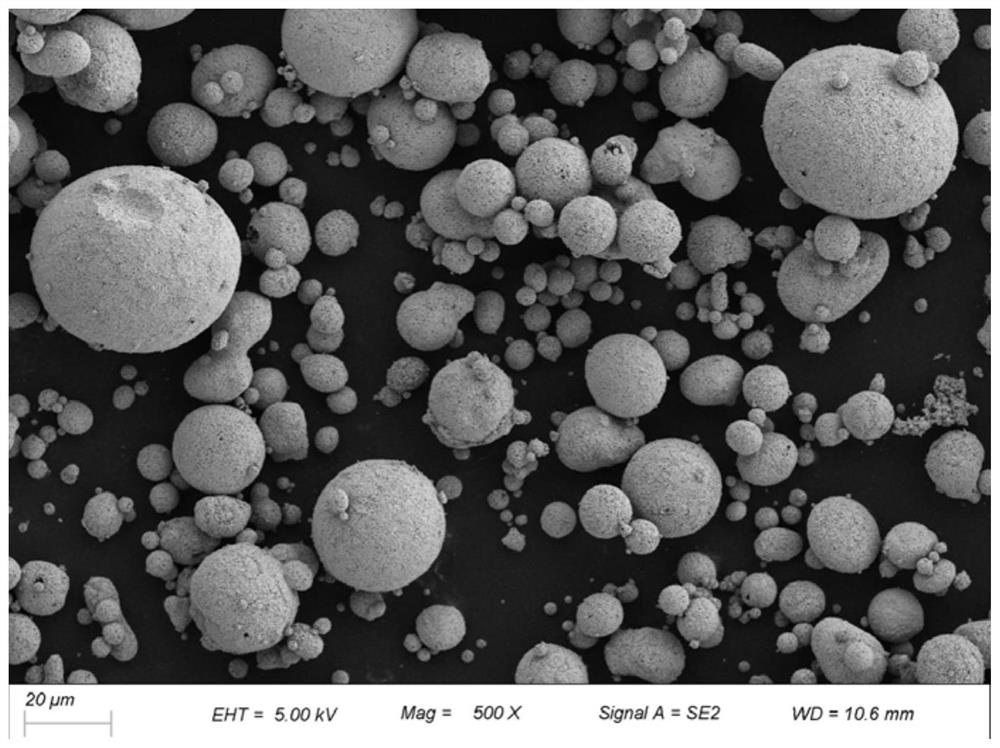

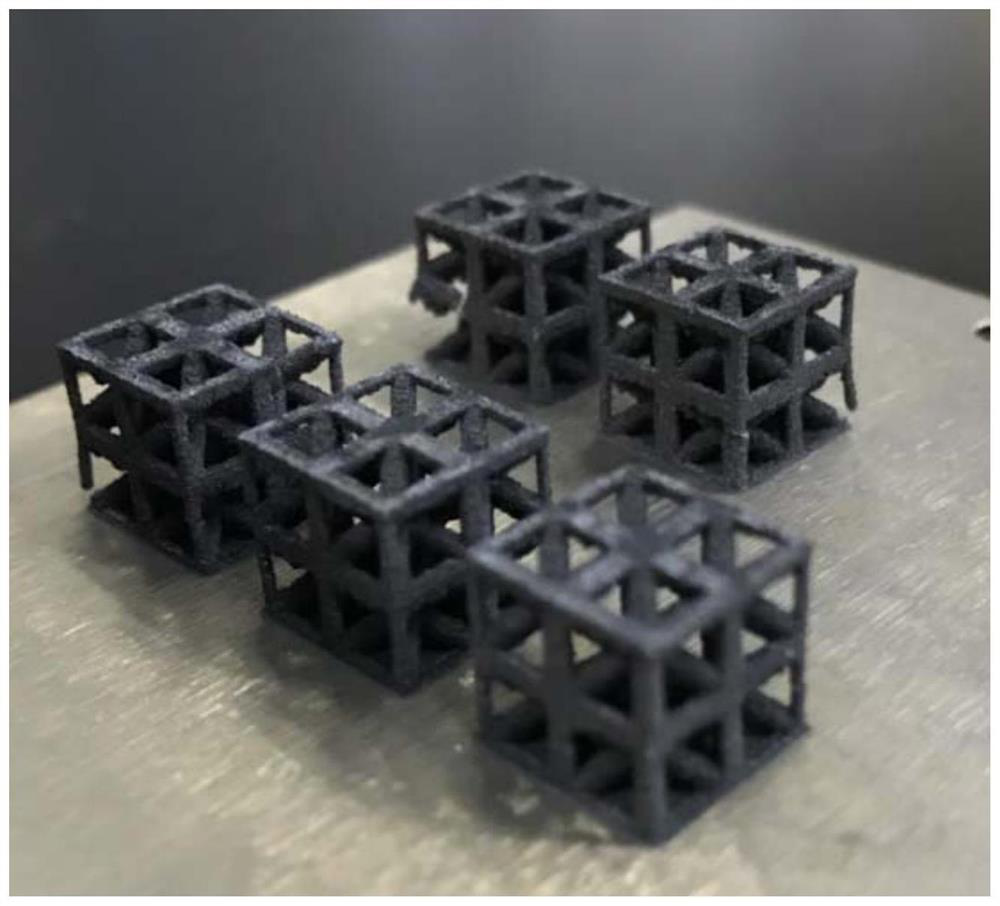

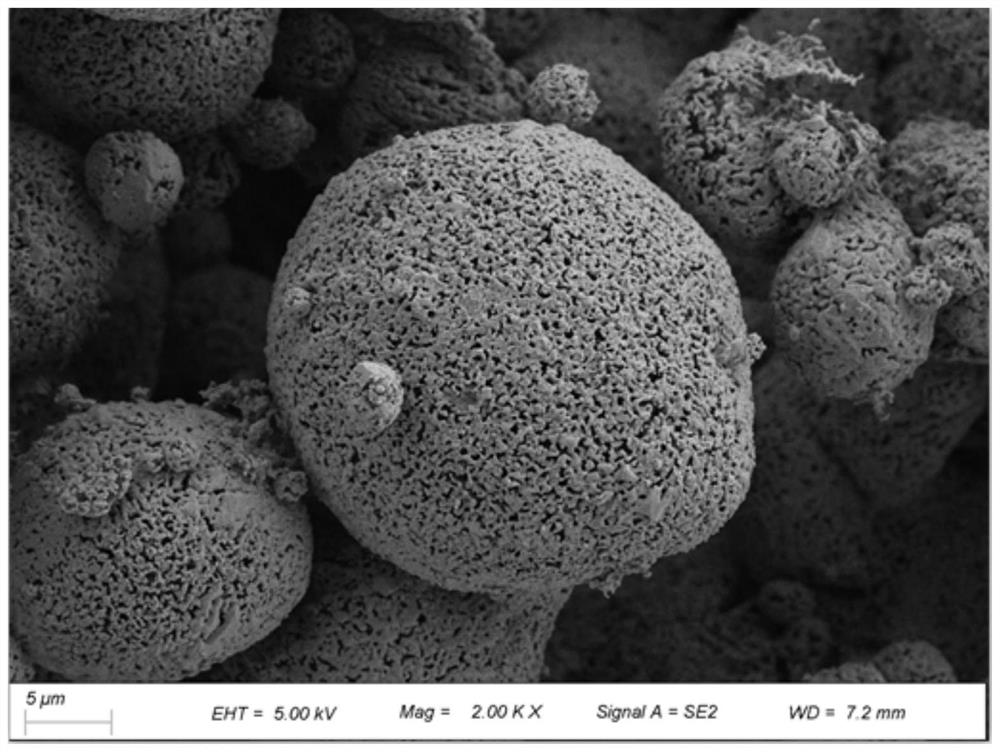

Hydrogen production catalyst based on 3D printing dealloying process, preparation method and application

PendingCN114192148ALarge specific surface areaIncrease loadHydrogenAdditive manufacturing apparatus3d printPtru catalyst

The invention discloses a hydrogen production structure catalyst based on a 3D printing dealloying process, a preparation method and application. The preparation method comprises the steps that (1) alloy raw materials are smelted, an alloy material is obtained, pre-alloy powder for 3D printing is prepared, and the pre-alloy powder is screened; (2) the pre-alloyed powder is subjected to 3D printing, and a macroscopic grid porous structure framework is prepared; (3) the 3D printing grid porous structure framework is subjected to annealing treatment; (4) the annealed 3D printing grid porous structure framework is placed in an alkaline or acid solution for chemical dealloying; (5) repeatedly cleaning the dealloyed 3D printing grid porous structure framework by using deionized water and absolute ethyl alcohol; and (6) reducing the 3D printing grid porous structure framework in a tubular furnace by using H2 to obtain the catalyst for hydrogen production by methanol reforming. The hydrogen production catalyst has the advantages of good mass and heat transfer, no need of coating, high conversion rate, good CO selectivity and large-scale production.

Owner:EAST CHINA UNIV OF SCI & TECH

Paraffinic hydrocarbon aromatization catalyst and its preparation method

InactiveCN100393415CHigh surface energyImprove surface activityMolecular sieve catalystsRefining to change hydrocarbon structural skeletonMolecular sieveDiffusion resistance

A catalyst for aromatizing paraffin is a non-noble metal modified nano-class zeolite molecular sieve, which is composed of MFI-type zeolite molecular sieve as carrier and the Zn and Ga as active component. It has high catalytic activity, selectivity and stability. Its preparing process is also disclosed.

Owner:BEIJING UNIV OF CHEM TECH

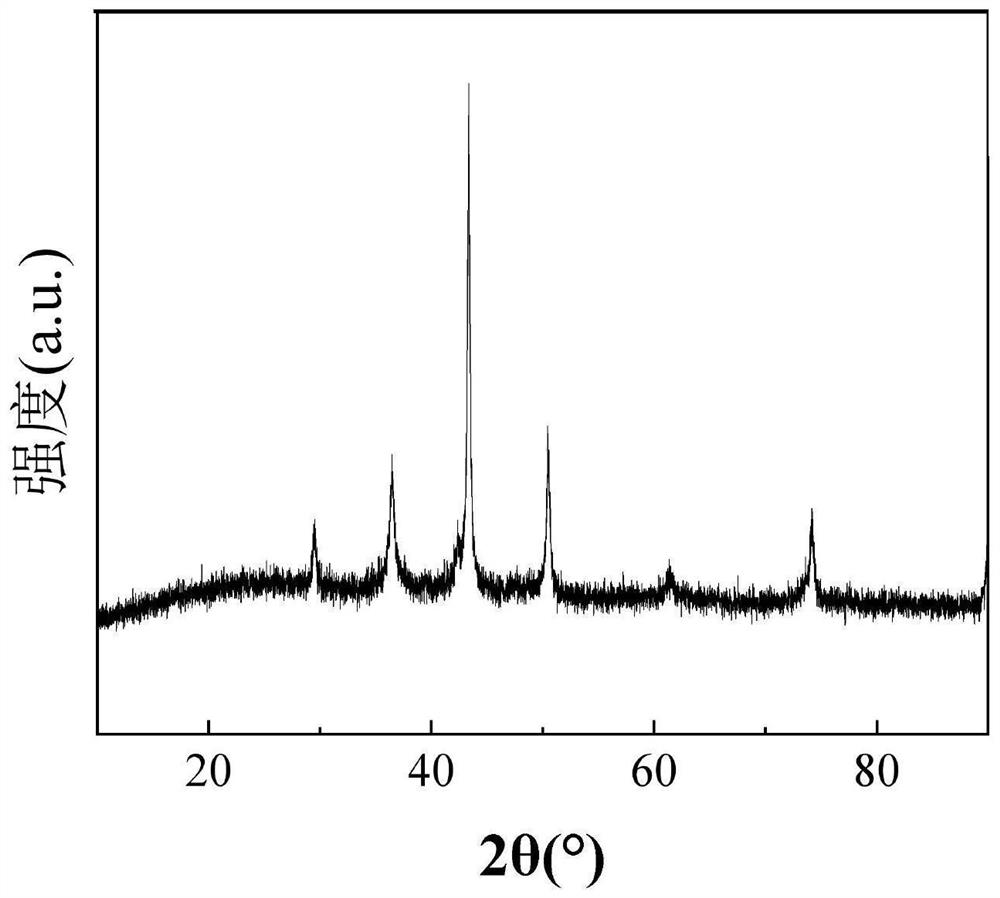

Method for removing organic cationic dyes from waste water by magnetic nano adsorption material

InactiveCN101670266BReduce internal diffusion resistanceImprove adsorption capacityOther chemical processesWater/sewage treatment by magnetic/electric fieldsDesorptionSorbent

The invention relates to preparation of a magnetic nano adsorbent and a method for removing organic cationic dyes from waste water by the same, and belongs to the technical field of wastewater treatment. The magnetic nano adsorbent uses Fe3O4 particles as a carrier, and coated humic acid as an active adsorbing component. The method comprises the following steps: adding mixed solution of ferric chloride and ferrous sulfate to alkaline humic acid solution, reacting under anaerobic, heating and stirring conditions, and obtaining the magnetic nano adsorbent after magnetic separation, washing, drying and grinding. The removal rate of methylene blue and neutral red reaches more than 95% by treating organic cationic dye wastewater with the magnetic nano adsorbent. The magnetic nano adsorbent after magnetic solid-liquid separation is regenerated by methanol-acetic acid solution, a desorption solvent recovers methanol and acetic acid by distillation for recycling use. The magnetic nano adsorbent has the advantages of nanoscale size, high active surface radicals, extremely high adsorption removal rate for cationic dyes, simple process, high efficiency and easy control.

Owner:BEIJING FORESTRY UNIVERSITY

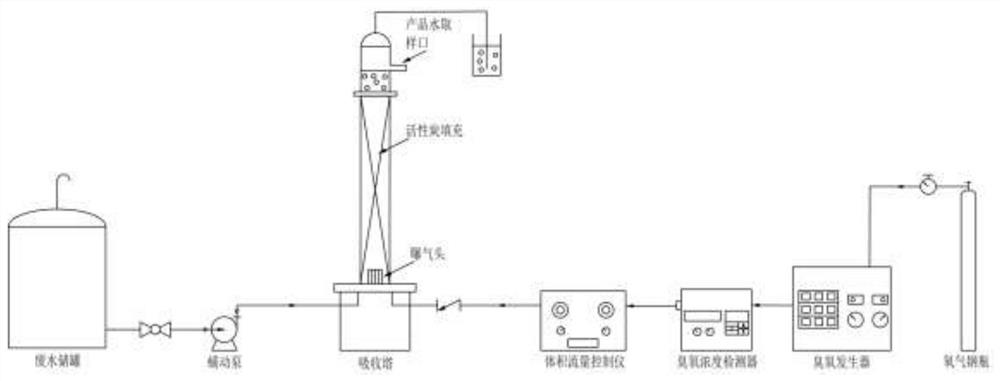

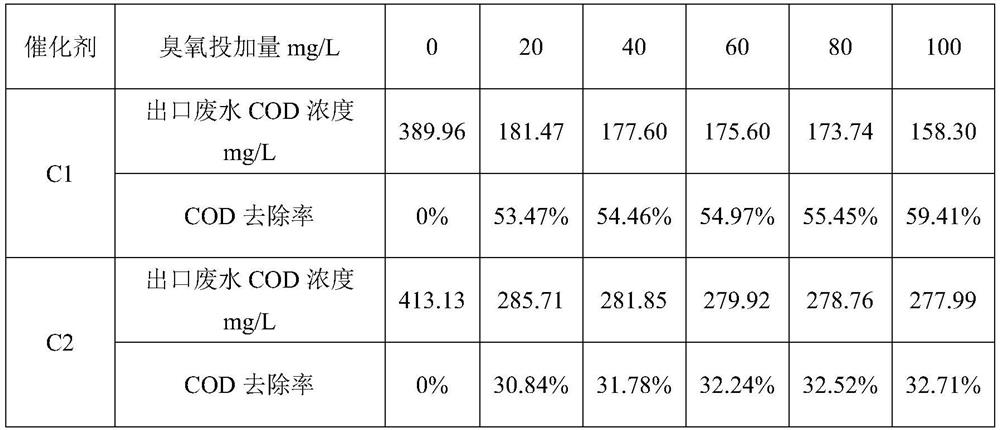

Method for ozonizing organic matters in wastewater by using activated carbon structured catalyst

PendingCN112403457AEasy accessReduce internal diffusion resistanceWater treatment parameter controlWater contaminantsActivated carbonOrganic matter

The invention discloses a method for ozonizing organic matters in wastewater by using an activated carbon structured catalyst, and belongs to the technical field of sewage purification. The catalyst is composed of a carrier, an active component and an auxiliary agent, the carrier is honeycomb activated carbon, the active component is one or more of Mn, Fe, Co, Ni, Cu, Zn, Y and Zr, and the auxiliary agent is one or more of La and Ce. The preparation method comprises the following steps: (1) washing and drying the carrier; (2) preparing an impregnation liquid containing the active component andthe auxiliary agent; (3) placing the carrier in the impregnation liquid for impregnation to obtain a catalyst precursor; and (4) washing, drying and calcining the catalyst precursor to obtain the activated carbon structured catalyst. The catalyst is applied to treatment of organic wastewater, has the characteristics of small bed pressure drop, uniform gas distribution, small internal diffusion resistance, high COD removal rate and the like, and has a good application prospect.

Owner:BEIJING UNIV OF CHEM TECH

Hydrogenation catalyst, preparation method thereof and application thereof to preparation of 10-hydroxydecanoate

ActiveCN103272594AEasy to recycleHigh yieldOrganic compound preparationChemical recyclingFiltrationReaction rate

The invention relates to the fields of catalyst technologies and fine chemical engineering, and in particular relates to a hydrogenation catalyst. The catalyst comprises a carrier and active components, wherein the carrier is mesoporous carbon pretreated by a sodium hypochlorite solution; and the active components comprise metal ruthenium and metal tin. A preparation method of the hydrogenation catalyst comprises the following steps of: soaking the mesoporous carbon in the sodium hypochlorite solution, washing the soaked mesoporous carbon by distilled water, and then filtering the washed mesoporous carbon; and soaking the carrier, namely the mesoporous carbon, by a salty solution containing the metal ruthenium and the metal tin, then washing the soaked carrier by distilled water, and performing suction filtration on the washed carrier. The invention also discloses application of the hydrogenation catalyst to preparation of 10-hydroxydecanoate. The hydrogenation catalyst has the advantages that the catalyst carrier adopts the mesoporous carbon, and compared with active carbon, the mesoporous carbon enables the target product yield to be obviously improved; compared with a catalyst with an inorganic oxide carrier, the catalyst has the advantage that the active components, namely the ruthenium and the thin, in the waste catalyst are easy to recycle; due to proper passageways, the inner diffusion resistance can be reduced, and the reaction rate is improved; by pretreatment of the sodium hypochlorite, the activity of the catalyst is obviously improved; and the hydrogenation catalyst has great industrial prospect.

Owner:恒光新材料(江苏)股份有限公司

High-temperature sintering type sulfur-containing iron-based catalyst and preparation method thereof

ActiveCN106607052AHigh activityActive releaseHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionSulfur containingChromium

The present invention relates to a high-temperature sintering type sulfur-containing iron-based catalyst and a preparation method thereof. A purpose of the present invention is to mainly solve the problems of low CO conversion rate and low low-carbon olefin selectivity in the low-carbon olefin preparation reaction with synthesis gas, and poor strength and poor thermal stability of the catalyst under the use condition in the prior art. The catalyst comprises, by weight, a) 5-50 parts of iron or an oxide thereof; b) 1-15 parts of ruthenium or an oxide thereof; c) 10-30 parts of calcium or an oxide thereof; d) 10-30 parts of at least one element selected from vanadium and chromium, or an oxide thereof; e) 10-75 parts of aluminum or an oxide thereof; and f) added trace amount calcium sulfate, wherein the catalyst contains 20-200 ppm sulfur based on the total weight of the iron-based catalyst. With the technical scheme, the problems in the prior art are well solved. The catalyst of the present invention can be used for the low-carbon olefin preparation with synthesis gas in industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-temperature combustion-supporting environment-friendly additive for natural gas and preparation method thereof

The invention relates to the field of environment-friendly auxiliaries, and particularly discloses a low-temperature combustion-supporting environment-friendly additive for natural gas and a preparation method thereof. The low-temperature combustion-supporting environment-friendly additive for natural gas comprises the following substances in parts by weight: 10-50 parts of dimethyl carbonate, 0-10 parts of methyl tert-butyl ether, 10-20 parts of methanol and 15-20 parts of dispersed catalytic particles, wherein the dispersed catalytic particles are carbon aerogel adsorbed with nanometer Pt particles. According to the low-temperature combustion-supporting environment-friendly additive for natural gas, dimethyl carbonate, methyl tert-butyl ether and methyl alcohol are selected as liquid matrixes, a carbon aerogel material adsorbed with precious metal Pt is taken as a catalytic material, the environment-friendly additive material is effectively wrapped and loaded in a boiling gas phase,and a uniform combination form is formed between the gas phase environment-friendly additive and natural gas, so a hydrogen-oxygen bond in the natural gas is opened under the effect of the environmental-friendly additive at a temperature of 80-100 DEG C; and thus, the combustion of the natural gas in an oxygen-enriched state is effectively catalyzed, and the activity of the natural gas in a low temperature environment is further improved.

Owner:江苏沃特优新能源科技有限公司

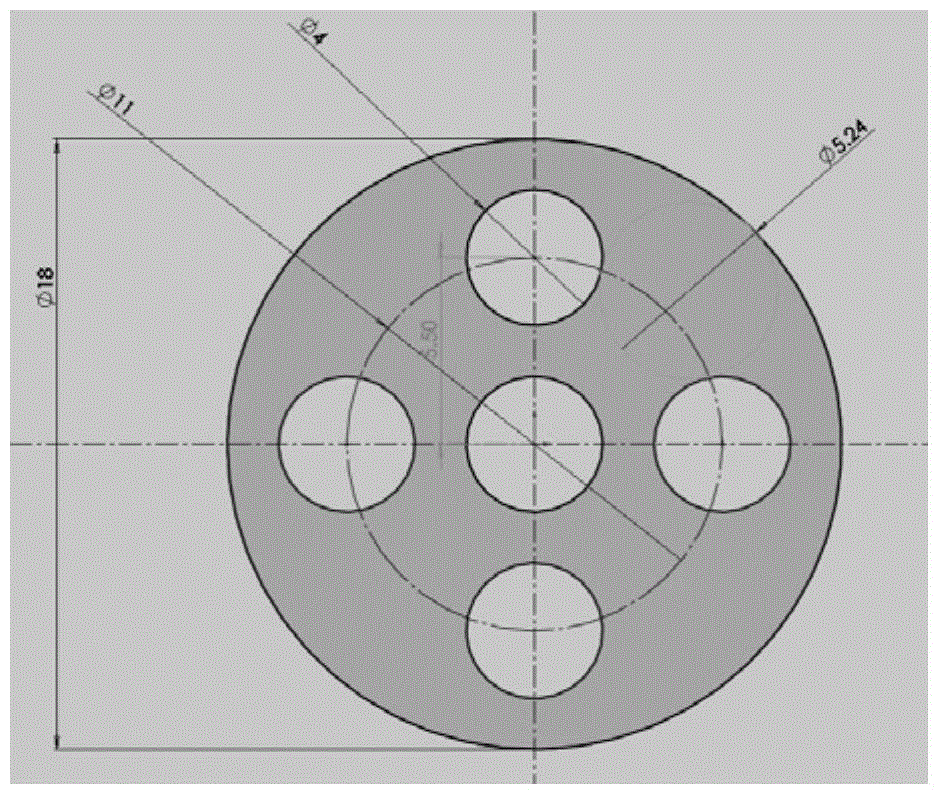

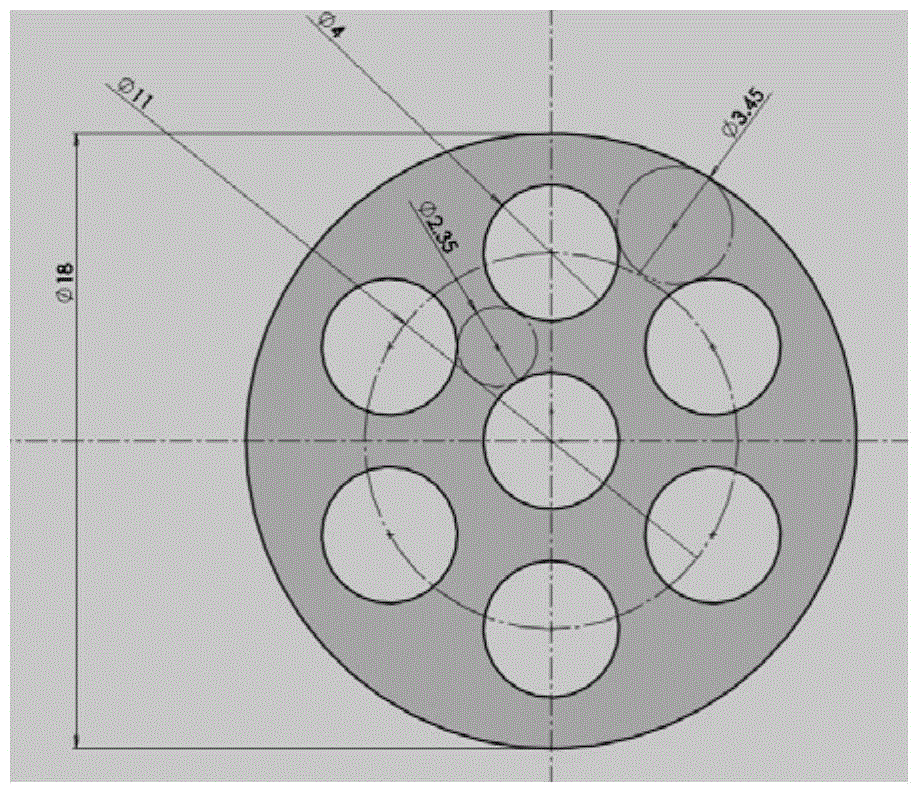

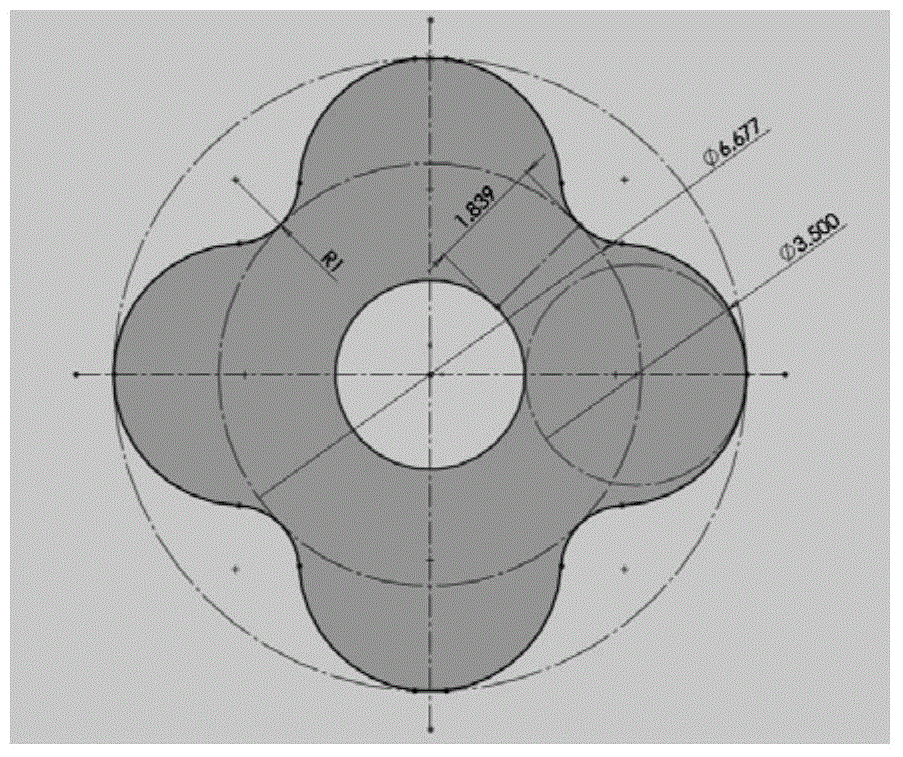

Hetero-type methanation catalyst and molding process and application thereof

ActiveCN105709794AHigh particle surface area/skeleton volume ratioSmall radial mass transfer distanceHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsActive componentMethanation

The present invention discloses a hetero-type methanation catalyst and a molding process and application thereof. The process is as follows: nickel-based synthesis gas methanation catalyst powder is prepared into porous cylinder particles by compression or squeezing, wherein diameter Phi of a profile circumscribed circle of the porous cylinder particles is 3-22mm, height is 3-12mm, ratio of surface area / grain skeleton volume is 0.8-1. 6mm<2> / mm<3>, the maximum radial mass transfer distance is 1.4-4.0mm, and the geometric shape of the porous cylinder particles is regular and symmetrical. The molding process of the hetero-type methanation catalyst aims at process characteristics and requirements of various stages of the synthesis gas methanation process, the utilization efficiency of catalyst active components can be improved, and the hetero-type methanation catalyst has an important role for reducing bed resistance drop and improving long-time operational stability of the catalyst.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Nickel catalyst for hydrogenation of C5 petroleum resin and preparation method of nickel catalyst

ActiveCN106268824AReduced Diffusion ResistanceReduce dosageHeterogenous catalyst chemical elementsCatalyst activation/preparationNickel catalystPolyvinyl acetate

The invention belongs to the field of preparation of a metal catalyst, and particularly relates to a nickel catalyst for hydrogenation of C5 petroleum resin and a preparation method of the nickel catalyst. The catalyst comprises a diatomaceous earth carrier treated with a reaming agent, and a catalyst Ni loaded on the carrier, wherein the reaming agent is selected from one or several kinds of sodium citrate, polyvinylpyrrolidone and polyvinyl acetate. In addition, the invention further discloses the preparation method of the catalyst. When the catalyst is used for the hydrogenation of the C5 petroleum resin, in-diffusion can be reduced, the dosage is small, the activity is high, the life is long, and water-white high-quality C5 hydrogenation petroleum resin can be prepared; and besides, the preparation technology is simple, and the catalyst is suitable for industrialized production.

Owner:抚顺华兴石油化工有限公司

Copper/porous carbon catalyst and preparation method and application thereof

PendingCN113318737ALarge specific surface areaUniform responseHydrogenCatalyst activation/preparationSteam reformingMethanol water

The invention provides a copper / porous carbon catalyst and a preparation method and application thereof, belonging to the field of catalytic materials. According to the preparation method provided by the invention, all the components are subjected to a uniform reaction and form a stable structure in a subsequent roasting and reduction process by utilizing aging; bio-based porous carbon has a high specific surface area, and the loading capacity and dispersity of the active component copper are improved, so active sites are increased, and catalytic activity is improved; a developed pore channel and a three-dimensional communicated hierarchical pore structure are beneficial to reducing the internal diffusion resistance of reactants and products and effectively reducing CO selectivity; and meanwhile, the porous carbon contains more microcrystals, and has certain reaction activity and catalytic activity similar to crystal defects, and a large number of various functional groups on the surface of the porous carbon further improve the catalytic activity. When the catalyst is applied to hydrogen production by methanol steam reforming, the conversion rate of methanol can reach 92%, and CO selectivity is as low as 0%.

Owner:DALIAN UNIV

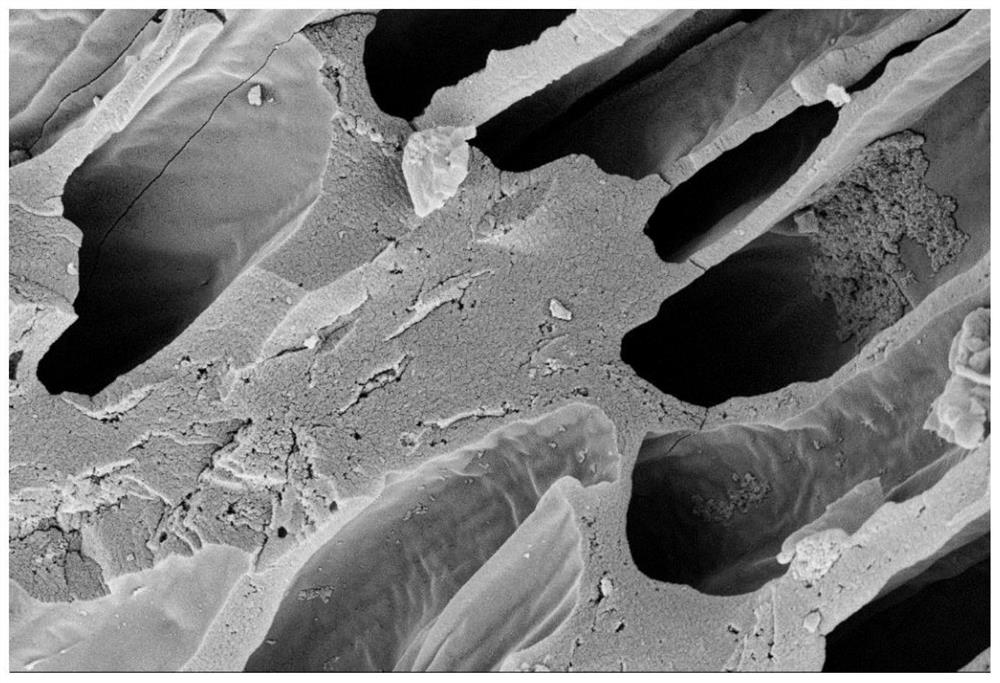

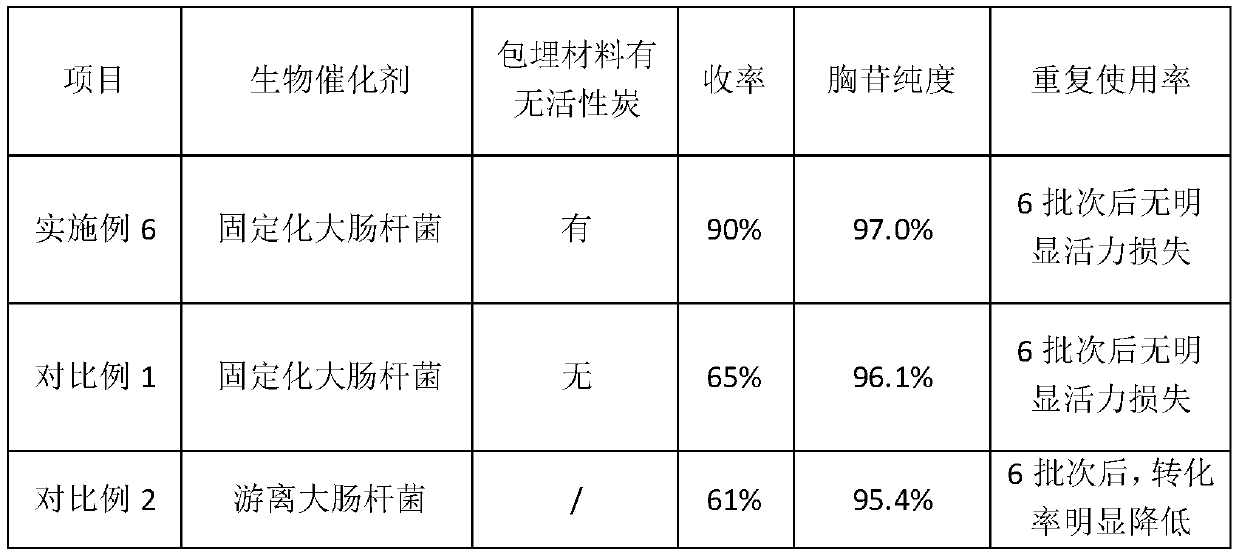

Method for preparing thymidine by immobilized Escherichia coli

ActiveCN109706204AHigh yieldImprove toleranceMicroorganism based processesOn/in organic carrierEscherichia coliActivated carbon

The invention belongs to the field of biological catalysis, and in particular relates to a method for preparing thymidine by immobilized Escherichia coli. The method adopts PVA and carrageenan as theembedding substrates, takes activated carbon as an additive, and immobilizes the phosphorylase-producing Escherichia coli to obtain the immobilized Escherichia coli; in the preparation of thymidine, immobilized Escherichia coli is used as a catalyst, a phosphate buffer solution is used as a solvent, 2-deoxy-alpha-D-ribose-1-dicyclohexylamine phosphate and thymine are used as a reaction substrate,and thymidine is prepared. The method adopts the immobilized Escherichia coli to prepare thymidine, and can better improve the tolerance of the bacteria to the substrate, and the stability thereof isimproved, so that the yield of thymidine is improved; The results show that after purification, the purity of thymidine is more than 97%, and the yield is more than 90%. After 6 batches of reaction, no significant loss of viability in immobilized Escherichia coli is generated.

Owner:JIANGSU UNIV OF TECH

Hydrogenation catalyst, preparation method thereof and application thereof to preparation of 10-hydroxydecanoate

ActiveCN103272594BEasy to recycleHigh yieldOrganic compound preparationCarboxylic compound preparationFiltrationReaction rate

The invention relates to the fields of catalyst technologies and fine chemical engineering, and in particular relates to a hydrogenation catalyst. The catalyst comprises a carrier and active components, wherein the carrier is mesoporous carbon pretreated by a sodium hypochlorite solution; and the active components comprise metal ruthenium and metal tin. A preparation method of the hydrogenation catalyst comprises the following steps of: soaking the mesoporous carbon in the sodium hypochlorite solution, washing the soaked mesoporous carbon by distilled water, and then filtering the washed mesoporous carbon; and soaking the carrier, namely the mesoporous carbon, by a salty solution containing the metal ruthenium and the metal tin, then washing the soaked carrier by distilled water, and performing suction filtration on the washed carrier. The invention also discloses application of the hydrogenation catalyst to preparation of 10-hydroxydecanoate. The hydrogenation catalyst has the advantages that the catalyst carrier adopts the mesoporous carbon, and compared with active carbon, the mesoporous carbon enables the target product yield to be obviously improved; compared with a catalyst with an inorganic oxide carrier, the catalyst has the advantage that the active components, namely the ruthenium and the thin, in the waste catalyst are easy to recycle; due to proper passageways, the inner diffusion resistance can be reduced, and the reaction rate is improved; by pretreatment of the sodium hypochlorite, the activity of the catalyst is obviously improved; and the hydrogenation catalyst has great industrial prospect.

Owner:恒光新材料(江苏)股份有限公司

A rapid production method for sanitary ware

ActiveCN108892474BShorten drying cycleIncrease productivityCeramic shaping apparatusCeramic materials productionProcess engineeringSlurry

The invention discloses a rapid sanitary appliance production method which includes the steps: grouting and forming: pouring slurry into a mold, demolding to form a sanitary appliance mud blank; microwave drying: conveying the sanitary appliance mud blank into a microwave drying oven to dry the mud blank for 3-6 hours. Microwave drying stages sequentially include a slow drying stage, an accelerated drying stage, a rapid drying stage and a cooling stage. The sanitary appliance mud blank is dried by the aid of a microwave drying mode, a drying period is controlled within the range from 3 hours to 6 hours and reduced to a large extent, and the production efficiency is improved. The method adopts four microwave drying stages, so that the sanitary appliance mud blank is slowly dried, dried in an accelerated manner, rapidly dried and cooled, and the drying qualification rate of sanitary appliances is effectively increased and reaches 97%.

Owner:FOSHAN DONGPENG SANITARY WARE +2

Preparation method of oxalate by CO gas phase coupling synthesis using regular catalyst

ActiveCN101851160BImprove apparent activityReduce resistancePreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsOxalateNitrite

The invention relates to a preparation method of oxalate by CO gas phase coupling synthesis using a regular catalyst. In the method, a fixed bed reactor is adopted, a catalyst bed consists of a regular structural catalyst loaded with noble metal; CO and vaporized nitrite are introduced into a reactor for reacting on the regular catalyst so as to generate the oxalate at the conditions that the pressure is 0.1-2MPa, the reaction temperature is 80-200 DEG C, and N2 is taken as a carrier gas, wherein the volume ratio of the materials is as follows: N2:CO:nitrite is 20-80:5-60:10-40, and the retention time is 0.5-10 hours. The method of the invention improves mass transfer efficiency of the reaction materials between the gas phase and the solid phase or among the gas phase, the liquid phase and the solid phase, increases the contact area of the reaction materials and the catalyst and reduces the usage amount of the catalyst in the noble metal, wherein the usage amount of the catalyst noble metal Pd is saved by more than 86%. The method of the invention has the characteristics of high catalyst activity, low cost, convenient and fast replacement and the like, and is beneficial for realizing large-scale engineered application.

Owner:TIANJIN UNIV +2

Process for preparing sulfuric acid by blending combustion of pyrite concentrate with ferrous sulfate

PendingCN114671412AIncrease contact areaIncrease oxygen contentSulfur compoundsCatalytic transformationCombustion

The invention discloses a process for preparing sulfuric acid by blending and burning pyrite concentrate with ferrous sulfate. The process comprises the following steps: S1, preparing preparation equipment; s2, raw material treatment; s3, roasting is carried out; s4, a purification step; s5, carrying out dry suction; s6, carrying out conversion; and S7, preparing a finished product. According to the process for preparing sulfuric acid by blending combustion of pyrite concentrate with ferrous sulfate, the internal diffusion resistance can be reduced and the contact area between air and ore can be increased due to the small particle size of the pyrite concentrate with the particle size of 3mm, the measure is most effective for controlling the total roasting rate through oxygen diffusion, and the total roasting rate can be controlled by increasing the oxygen content of furnace entering gas; the oxygen concentration in the atmosphere is high, external diffusion and internal diffusion cone power of oxygen is large, the diffusion rate of the oxygen is high, the oxygen content in the furnace gas can be increased, catalytic conversion of So2 is facilitated, the process is simple and convenient, the cost is low, and sulfuric acid with high purity can be prepared.

Owner:SICHUAN DONGLI TECH CO LTD

A monolithic clustered alumina-supported catalyst and its application

ActiveCN107497499BImprove high temperature resistanceReduce internal diffusion resistanceCatalyst carriersHeterogenous catalyst chemical elementsMicron scalePtru catalyst

The invention discloses an integral clustered alumina supported catalyst and its application. The carrier includes a hierarchical structure alumina coating and a monolithic porous ceramic matrix; the hierarchical structure alumina coating is a micron-scale cluster of leaves with a thickness of nanometers, forming a flower-like structure.

Owner:EAST CHINA UNIV OF SCI & TECH

A kind of ZSM-5 molecular sieve and synthetic method thereof

ActiveCN106904634BAdaptableSynthesis fastPentasil aluminosilicate zeoliteAluminium chlorideMetallic aluminum

The invention discloses a ZSM-5 molecular sieve and a synthesizing method thereof. The synthesizing method comprises the following steps of (1) adjusting the activity of an aluminum source, performing inert treatment on the active aluminum source, and activating the inert aluminum source; (2) adding a template agent into a silicon source solution, stirring the treated aluminum source solution, dripping into the silicon source solution, adding a crystal seed, and preparing into a uniform gel; (3) hydrothermally crystallizing the prepared gel for 1 to 200h at the temperature of 100 to 200 DEG C, filtering a crystallized solid, washing, drying, and calcining, so as to obtain the ZSM-5 molecular sieve, wherein the active aluminum source is one or several of a group formed by aluminum sulfate, aluminum chloride, aluminum nitrate and aluminium isopropoxide; the inert aluminum source is one or several of a group formed by pseudo-boehmite, sodium metaaluminate, aluminium hydroxide and metal aluminum. Thin sheet type ZSM-5 zeolite has the advantages that the straight pore channel is very short, the inner diffusion drag is small, the agglomeration of crystal grains is avoided, and the thin sheet type ZSM-5 zeolite is favorable for processing wearproof catalysts.

Owner:PETROCHINA CO LTD

Catalyst for preparing 1-aminoanthraquinone by hydrogenation of 1-nitroanthraquinone and its preparation method and application

ActiveCN107020083BReduce dosageImprove stabilityOrganic chemistryOrganic compound preparationEthylenediamineSaline solutions

The invention belongs to the technology of catalysts in the field of fine chemical engineering, and particularly relates to a catalyst used for preparing 1-amino-anthraquinone from 1-nitroanthraquinone by hydrogenation and a preparation method and application of the catalyst. Mesoporous carbon is added into ethylenediamine aqueous solution to be dipped, then, saline solution containing palladium and silver is used for dipping a carrier which is mesoporous carbon, and reduction, washing and filtering are carried out to obtain a Pd-Ag / mesoporous carbon catalyst. The above hydrogenation catalyst is used for preparing the 1-amino-anthraquinone from the 1-nitroanthraquinone by hydrogenation, a reaction condition is moderate, and product selectivity is high.

Owner:CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com