Preparation method of composite antioxidant for better improving yellowing of polymer caused by processing and long-term aging

A compound antioxidant, long-term aging technology, applied in the field of antioxidant compounding, can solve the problems of changing color, poor color complementation, uneven distribution, etc., and achieve the effect of reducing viscosity, preventing sedimentation and agglomeration, and eliminating yellow light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing a compound antioxidant that better improves polymer processing and long-term aging and yellowing, the specific method is as follows:

[0032] (1) First grind phthalocyanine blue and ultramarine blue respectively, and filter with 800-900 mesh filter screen to obtain phthalocyanine blue powder and ultramarine blue powder, and set aside;

[0033] (2) Mix 20g of antioxidant 1010 and 40g of antioxidant 168, heat and stir, gradually raise the temperature to 250°C, then keep it for 30-60min, then lower the temperature to 230°C, stir for 40-50min, and the stirring speed is 1000~1500r / min to obtain the composite antioxidant mixture Ⅰ;

[0034] (3) Weigh 11.25g of calcium stearate, add it to the composite antioxidant mixture I in the above step (2), stir at a temperature of 230°C for 30-40min, mix well, lower the temperature to 200°C, and stir for 40 ~50min to obtain the composite antioxidant mixture II;

[0035] (4) Keep the temperature of the composite ...

Embodiment 2

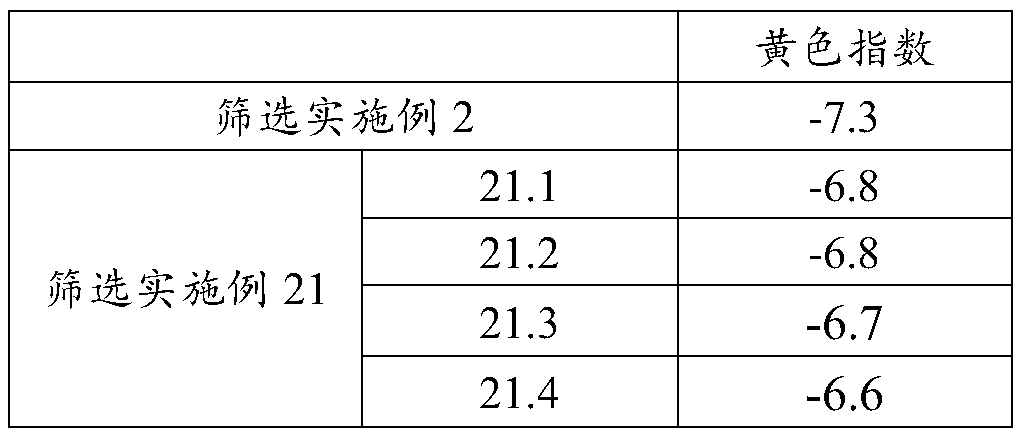

[0038] All steps (1), (2), (3), (5) in this screening embodiment are exactly the same as all steps (1), (2), (3), (5) in screening embodiment 1, The difference is that in (4) of this screening example, the composite antioxidant mixture II in the above step (3) is ultrasonically treated under ultrasonic waves, the ultrasonic power is 1000-1200W, the frequency is 20KHz, and the temperature is 190-200°C. Add 3.60g of phthalocyanine blue powder in the above-mentioned step (1), and add 0.15g of ultramarine blue powder in the above-mentioned step (1) after the ultrasonic time is 2 to 3min, continue ultrasonic treatment, disperse evenly, and the ultrasonic time is 3 to 4min, and obtain Complex antioxidant emulsion.

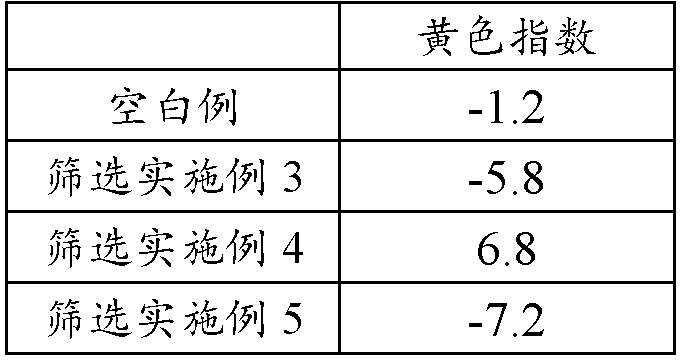

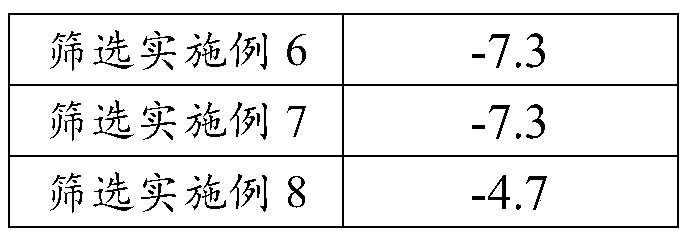

[0039]After the above experiments, take 2g of the composite antioxidant granules prepared in each screening example, add them to 1000ml of polypropylene resin emulsion, mix evenly, and inject them at 180-210°C to extrude and granulate to obtain improved Polypropylene re...

Embodiment 3

[0044] A method for preparing a compound antioxidant that better improves polymer processing and long-term aging and yellowing, the specific method is as follows:

[0045] (1) First grind phthalocyanine blue and ultramarine blue respectively, and filter with 800-900 mesh filter screen to obtain phthalocyanine blue powder and ultramarine blue powder, and set aside;

[0046] (2) Mix 22.5g of antioxidant 1010 and 45g of antioxidant 168, heat and stir, gradually raise the temperature to 250°C, then keep it for 30-60min, then lower the temperature to 230°C, stir for 40-50min, the stirring speed 1000~1500r / min, to obtain the composite antioxidant mixture I;

[0047] (3) Weigh 4.5g of calcium stearate, add it to the composite antioxidant mixture I in the above step (2), stir at a temperature of 230°C for 30-40min, mix well, lower the temperature to 200°C, and stir for 40 ~50min to obtain the composite antioxidant mixture II;

[0048] (4) Ultrasonic treatment of the composite antiox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com