Heavy pure cotton fabric cold padding and stacking pretreatment method

A thick fabric and cold pad-batch technology, which is applied in the field of dyeing and finishing, can solve the problems of not too much weight of linen fabrics, adverse effects on the wastewater environment, and unsatisfactory treatment effects, so as to maintain excellent mechanical properties, reduce sewage treatment costs, good gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

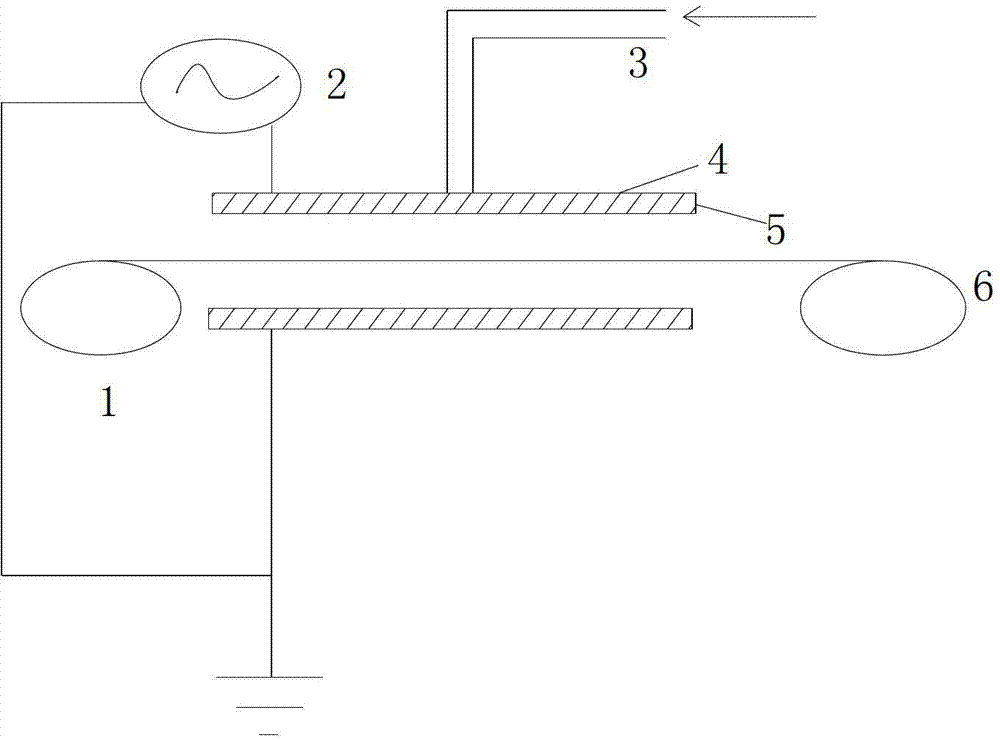

[0038] Embodiment 1: Atmospheric pressure plasma treatment of pure cotton thick and heavy fabric rolling enzyme stacking pretreatment process

[0039] combined with figure 1 , the atmospheric pressure plasma treatment process is as follows:

[0040] The pure cotton heavy gray cloth 1 to be processed passes between the two discharge electrodes 4 of the plasma device, and then is wound on an automatic winding machine 6 . The automatic winding machine 6 can wind up the processed pure cotton heavy fabric on-line, and adjust the line speed of the pure cotton heavy fabric by adjusting the rotation speed of the winding shaft.

[0041] Adjust the distance between the two discharge electrodes 4 to be 2 centimeters, first feed the mixed gas from the air guide tube 3, the mixed gas is argon and oxygen with a volume ratio of 99 / 1, and adjust the intake speed to be 4 liters / minute; then Turn on the power supply, close the switch of the plasma generator 2, adjust the plasma discharge powe...

Embodiment 2

[0044] Example 2: Atmospheric pressure plasma treatment of pure cotton thick and heavy fabric rolling enzyme stacking pre-treatment process

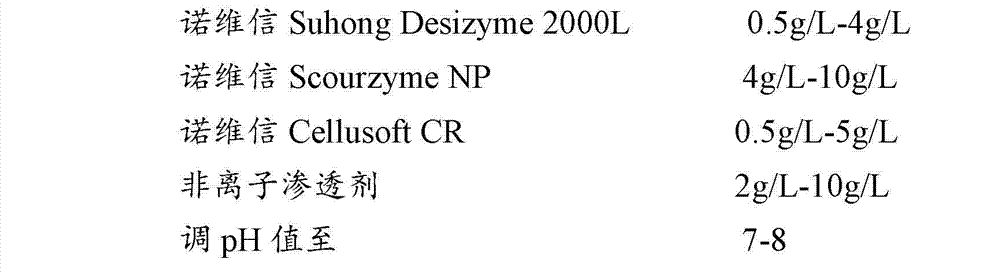

[0045] Singed pure cotton thick twill yarn card gray fabric (C10×10 74×44 3 / 1↖ 43" / 57" 283 g / m 2 ) placed between two discharge electrodes of dielectric barrier discharge, carry out normal pressure dielectric barrier discharge plasma treatment, normal pressure dielectric barrier discharge plasma treatment condition is: the gap between the discharge electrodes is 2 centimeters; 99.5 / 0.5 argon and oxygen, the gas inlet speed is 10 liters / minute; the discharge power of the plasma discharge is 100 watts, the discharge frequency is 10 kHz, the line speed of the pure cotton heavy fabric is 15 m / min, the plasma discharge The body processing time is 40 seconds. The pure cotton heavy fabric after plasma treatment is subjected to enzyme solution padding, and the enzyme solution composition is: Novozymes Suhong Desizyme 2000L 0.5g / L, Novozymes Sco...

Embodiment 3

[0047] Example 3: Atmospheric pressure plasma treatment of pure cotton thick and heavy fabrics with enzymatic enzyme stacking pre-treatment process

[0048] Singed pure cotton thick twill thread card gray fabric (C40 / 2×40 / 2 141×76 2 / 2↗ 43" / 57" 260g / m 2 ) placed between two discharge electrodes of dielectric barrier discharge, carry out normal pressure dielectric barrier discharge plasma treatment, normal pressure dielectric barrier discharge plasma treatment condition is: the gap between the discharge electrodes is 2 centimeters; 99.5 / 0.5 argon and oxygen, the gas inlet speed is 10 liters / minute; the discharge power of the plasma discharge is 100 watts, the discharge frequency is 10 kHz, the line speed of the pure cotton heavy fabric is 15 m / min, the plasma discharge The body processing time is 40 seconds. The pure cotton heavy fabric after plasma treatment is subjected to enzyme solution padding. The enzyme solution composition is: Novozymes Suhong Desizyme 2000L 0.5g / L, Nov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com