Pure cotton heavy fabric pretreatment method

A heavy-duty fabric and pure cotton technology, applied in the field of pre-treatment of pure cotton heavy-duty fabrics, can solve the problem of incomplete effect and other problems, and achieve the effects of good mechanical properties, good process treatment effect and reduced dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

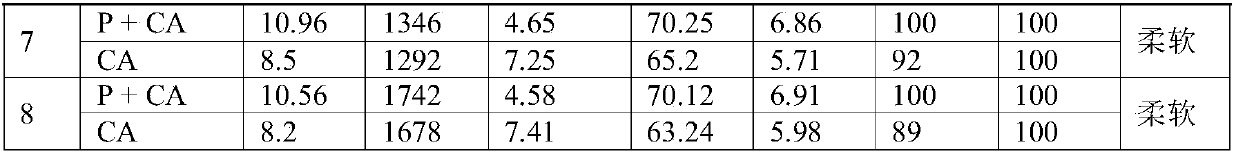

Embodiment 1

[0040] Pure cotton thick plain weave gray fabric after singeing (C12×12 52×50 1 / 1 63"197g / m 2 ) placed between the two discharge electrodes of the corona discharge plasma, and then wound on an automatic winder for corona discharge plasma treatment, the automatic winder can wind the treated pure cotton heavy fabric online , by adjusting the speed of the winding shaft to adjust the line speed of the pure cotton fabric. The corona discharge plasma treatment conditions are: the gap between the discharge electrode and the corona roller is 2.5 mm; the plasma discharge power is 800 watts, the discharge frequency is 20 kHz, and the line speed of the pure cotton fabric is 20 m / min , the plasma treatment time is 30 seconds. The pure cotton heavy fabric scouring and bleaching liquid after plasma treatment is pad-rolled, and its scouring and bleaching liquid is composed of: scouring agent 2g / L, sodium hydroxide 15g / L, hydrogen peroxide (35%) 4g / L, oxygen bleaching stabilizer Sodium sili...

Embodiment 2

[0043] Singeing pure cotton thick twill yarn card gray fabric (C10×10 74×44 3 / 1↖43" / 57" 283g / m 2 ) is placed between two discharge electrodes of corona discharge plasma to carry out corona discharge plasma treatment, and the corona discharge plasma treatment condition is: the gap between the discharge electrode and the corona roller is 2 millimeters; the plasma discharge power The discharge frequency is 500 watts, the discharge frequency is 20 kHz, the line speed of pure cotton fabric is 15 m / min, and the plasma treatment time is 40 seconds. The pure cotton heavy fabric scouring and bleaching liquid after plasma treatment is pad-rolled, and its scouring and bleaching liquid is composed of: scouring agent 10g / L, sodium hydroxide 8g / L, hydrogen peroxide (32%) 12g / L, oxygen bleaching Stabilizer sodium silicate 5g / L, non-ionic penetrant fatty alcohol polyoxyethylene ether 4g / L, excess rate 100%, cold stack time 0.5h. The piled pure cotton heavy fabrics were steamed at a steaming ...

Embodiment 3

[0046] Singeing pure cotton thick twill thread card gray fabric (C40 / 2×40 / 2 141×76 2 / 2↗43" / 57" 260g / m 2 ) is placed between two discharge electrodes of corona discharge plasma to carry out corona discharge plasma treatment, and the corona discharge plasma treatment condition is: the gap between the discharge electrode and the corona roller is 2 millimeters; the plasma discharge power The discharge frequency is 300 watts, the discharge frequency is 20 kHz, the line speed of pure cotton fabric is 3.3 m / min, and the plasma treatment time is 180 seconds. The pure cotton heavy fabric scouring and bleaching liquid after plasma treatment is pad-rolled, and its scouring and bleaching liquid is composed of: scouring agent 10g / L, sodium hydroxide 2g / L, hydrogen peroxide (30%) 15g / L, oxygen bleaching Stabilizer sodium silicate 5g / L, non-ionic penetrant fatty alcohol polyoxyethylene ether 6g / L, excess rate 100%, cold stack time 1h. The piled pure cotton heavy fabrics were steamed at a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com