Heavy pure cotton fabric corona discharge plasma and enzyme cold padding and stacking pretreatment method

A corona discharge and heavy fabric technology, applied in the field of dyeing and finishing, can solve the problems that the gram weight of linen fabric cannot be too large, which is unfavorable for continuous industrial production, and the removal of impurities is not clean, so as to maintain excellent mechanical properties and reduce sewage treatment costs. , good gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: corona discharge plasma treatment pure cotton heavy fabric rolling enzyme stacking pretreatment process

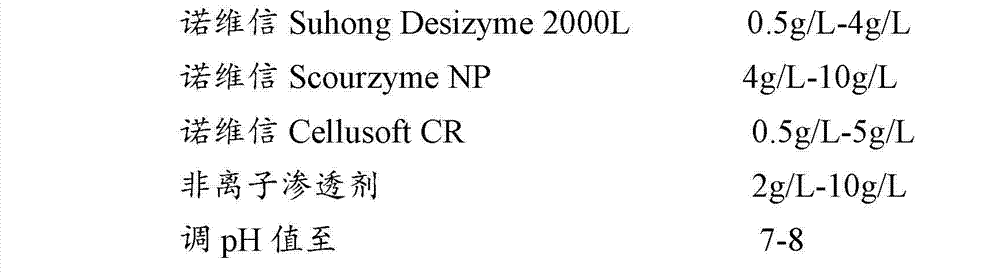

[0035] Pure cotton heavyweight plain gray fabric after singeing (C12×12 52×50 1 / 1 63" 197g / m 2 ) placed between the two discharge electrodes of the corona discharge plasma, and then wound on an automatic winder for corona discharge plasma treatment, the automatic winder can wind the treated pure cotton heavy fabric online , by adjusting the speed of the winding shaft to adjust the line speed of the pure cotton fabric. The corona discharge plasma treatment conditions are: the gap between the discharge electrode and the corona roller is 2.5 mm; the plasma discharge power is 800 watts, the discharge frequency is 20 kHz, and the line speed of the pure cotton fabric is 20 m / min , the plasma treatment time is 30 seconds. The pure cotton heavy fabric after plasma treatment is padded with enzyme treatment solution, the composition of enzyme treatment solutio...

Embodiment 2

[0037] Example 2: Corona discharge plasma treatment of pure cotton heavy fabric rolling enzyme stacking pre-treatment process

[0038] Singed pure cotton thick twill yarn card gray fabric (C10×10 74×44 3 / 1↖ 43" / 57" 283 g / m 2 ) is placed between two discharge electrodes of corona discharge plasma to carry out corona discharge plasma treatment, and the corona discharge plasma treatment condition is: the gap between the discharge electrode and the corona roller is 2 millimeters; the plasma discharge power The discharge frequency is 500 watts, the discharge frequency is 20 kHz, the line speed of pure cotton fabric is 15 m / min, and the plasma treatment time is 40 seconds. The pure cotton heavy fabric after plasma treatment is subjected to enzyme solution padding, and the enzyme solution composition is: Novozymes Suhong Desizyme 2000L 0.5g / L, Novozymes Scourzyme NP 8g / L, Novozymes Cellusoft CR 2g / L, non-ionic penetrant JFC 2g / L, using 10% NaOH to adjust the pH value to 8, the enzy...

Embodiment 3

[0040] Example 3: Corona discharge plasma treatment of pure cotton thick and heavy fabric rolling enzyme stacking pre-treatment process

[0041] Singed pure cotton thick twill thread card gray fabric (C40 / 2×40 / 2 141×76 2 / 2↗ 43" / 57" 260g / m 2 ) is placed between two discharge electrodes of corona discharge plasma to carry out corona discharge plasma treatment, and the corona discharge plasma treatment condition is: the gap between the discharge electrode and the corona roller is 2 millimeters; the plasma discharge power The discharge frequency is 300 watts, the discharge frequency is 20 kHz, the line speed of pure cotton fabric is 3.3 m / min, and the plasma treatment time is 180 seconds. The pure cotton heavy fabric after plasma treatment is subjected to enzyme solution padding. The enzyme solution composition is: Novozymes Suhong Desizyme 2000L 0.5g / L, Novozymes Scourzyme NP 8g / L, Novozymes Cellusoft CR 1g / L L. Non-ionic penetrant JFC 3g / L, using 10% NaOH to adjust the pH value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com