Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

171results about How to "Shorten manufacturing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

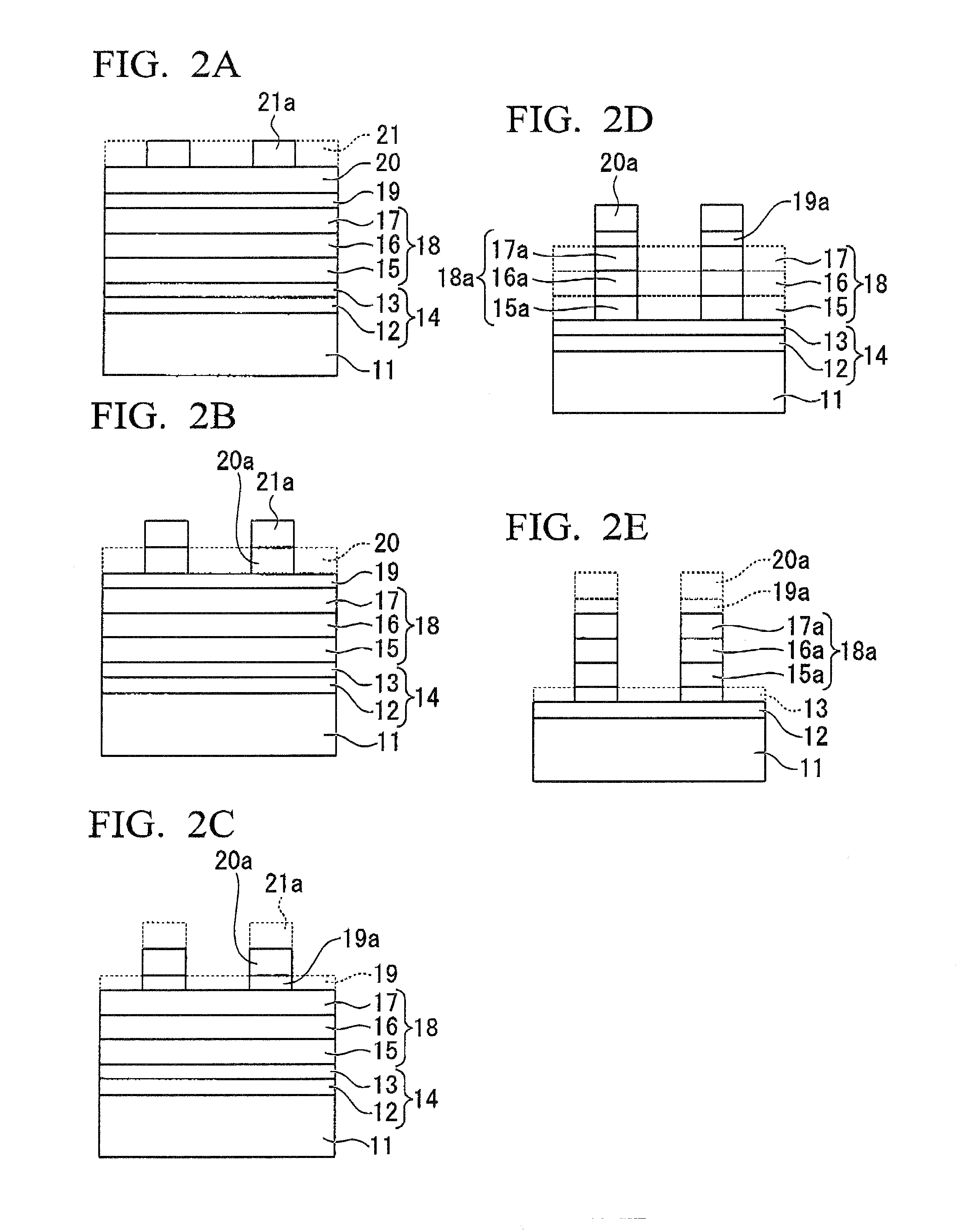

Method and apparatus for manufacturing device

InactiveUS20090275146A1Low costShorten production timeSemiconductor/solid-state device manufacturingCapacitorsOptoelectronicsElectrode

A method for manufacturing a device, includes: (A) forming a first electrode layer on a substrate; (B) forming a ferroelectric layer on the first electrode layer; (C) forming a second electrode layer on the ferroelectric layer; (D) forming a mask having a predetermined pattern on the second electrode layer; (E) forming a memory element by selectively removing the first electrode layer, the ferroelectric layer, and the second electrode layer using the mask; and (F) removing the mask, where at least, the processes (D) and (E), or the processes (E) and (F) are continuously performed under a reduced pressure.

Owner:ULVAC INC +1

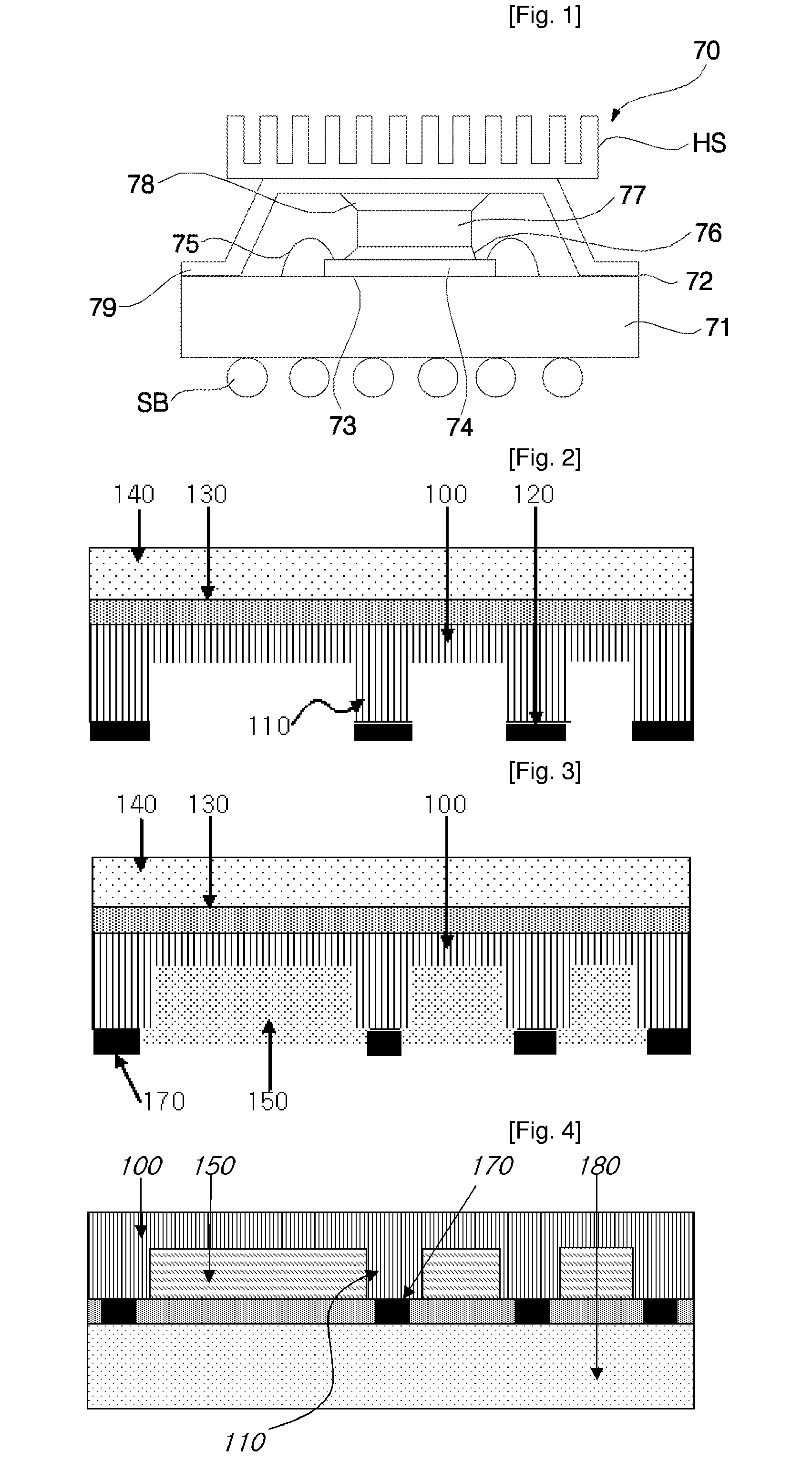

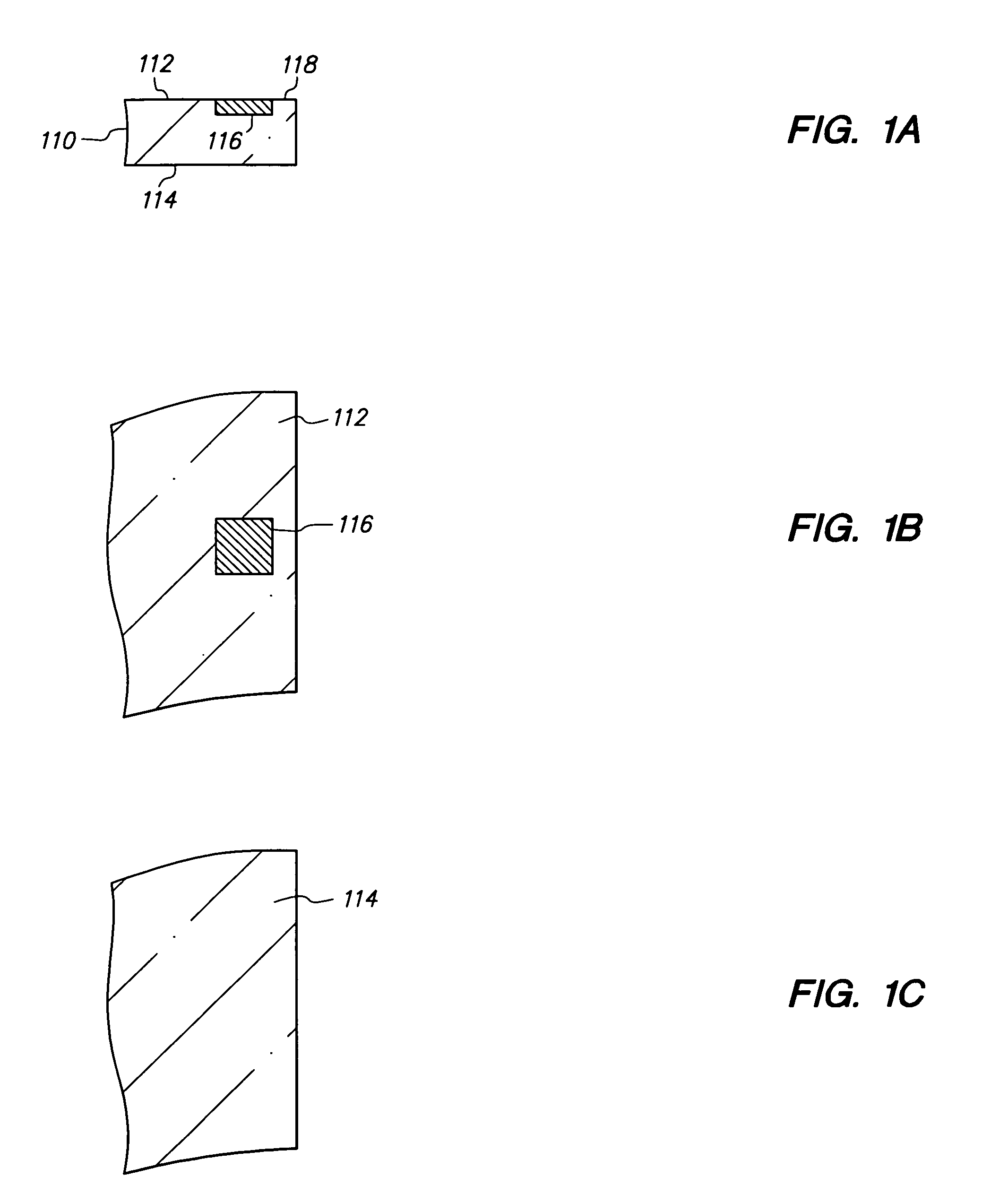

Semiconductor chip assembly with embedded metal particle

InactiveUS7009297B1Enhancing mechanical supportImprove protectionSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipMetal particle

A semiconductor chip assembly includes a semiconductor chip that includes a conductive pad, a conductive trace that includes a routing line and a metal particle, a connection joint that electrically connects the routing line and the pad, and an encapsulant. The routing line extends laterally beyond the metal particle towards the chip, and the chip and the metal particle are embedded in the encapsulant and extend vertically beyond the routing line in the same direction.

Owner:BRIDGE SEMICON

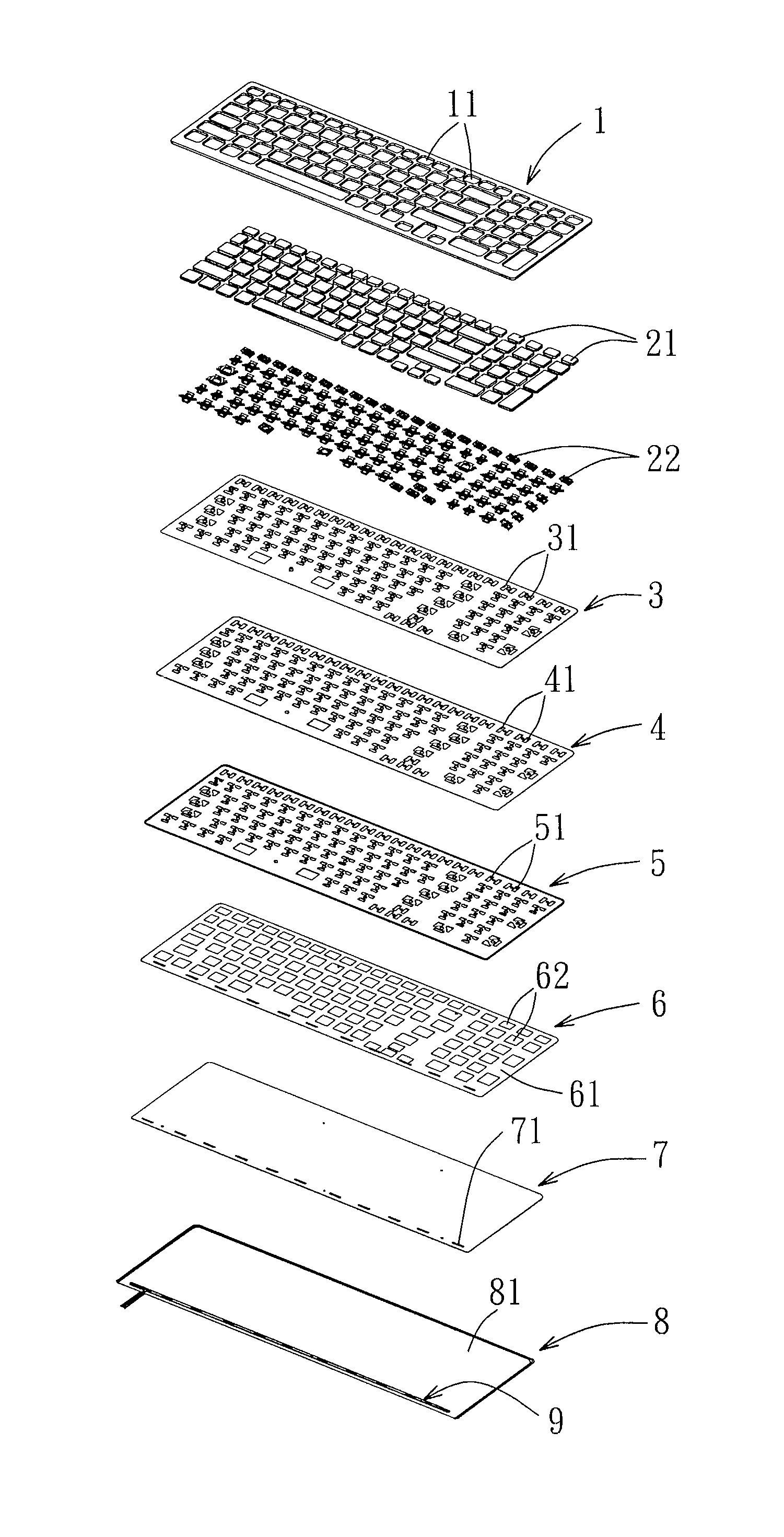

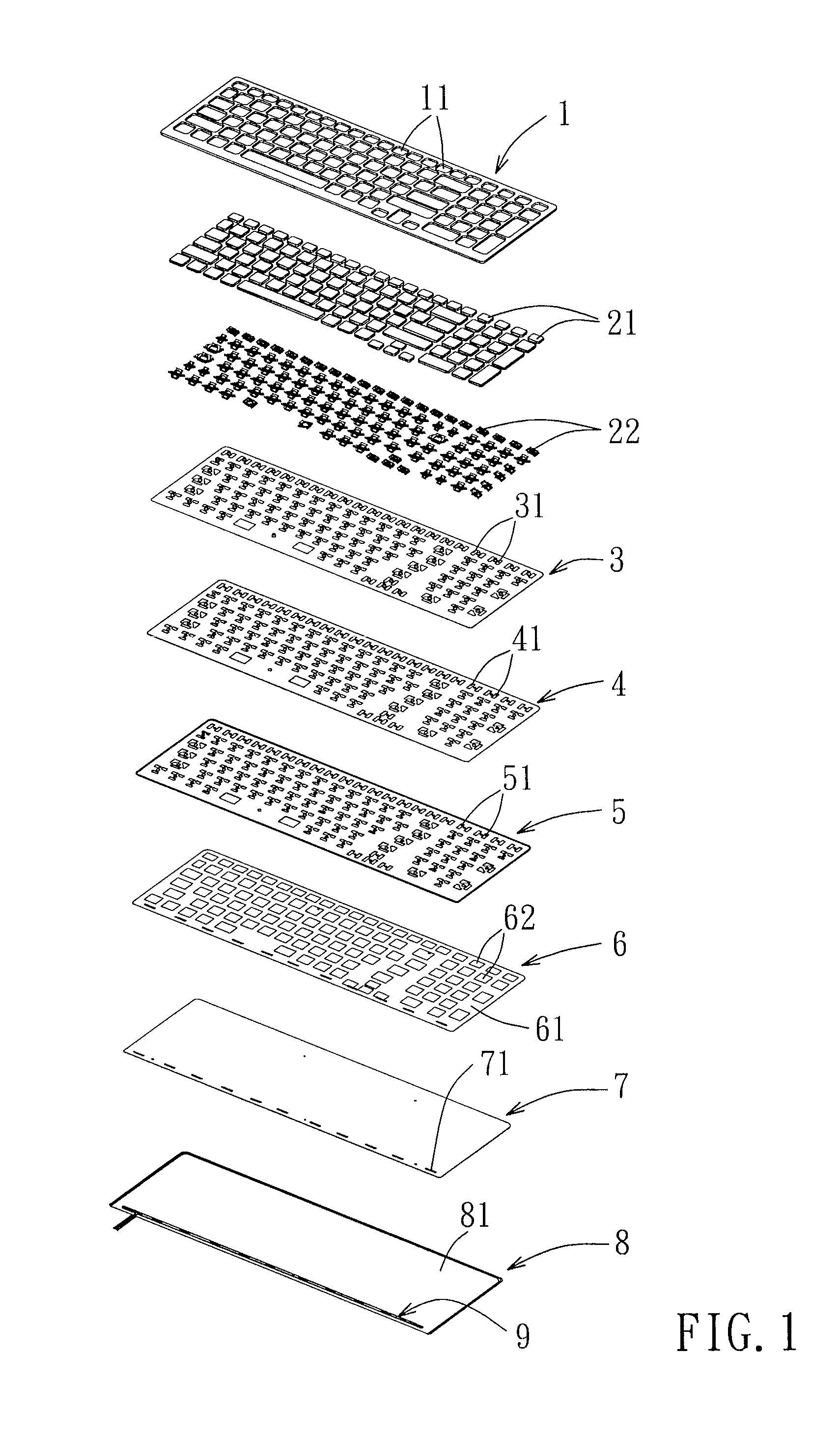

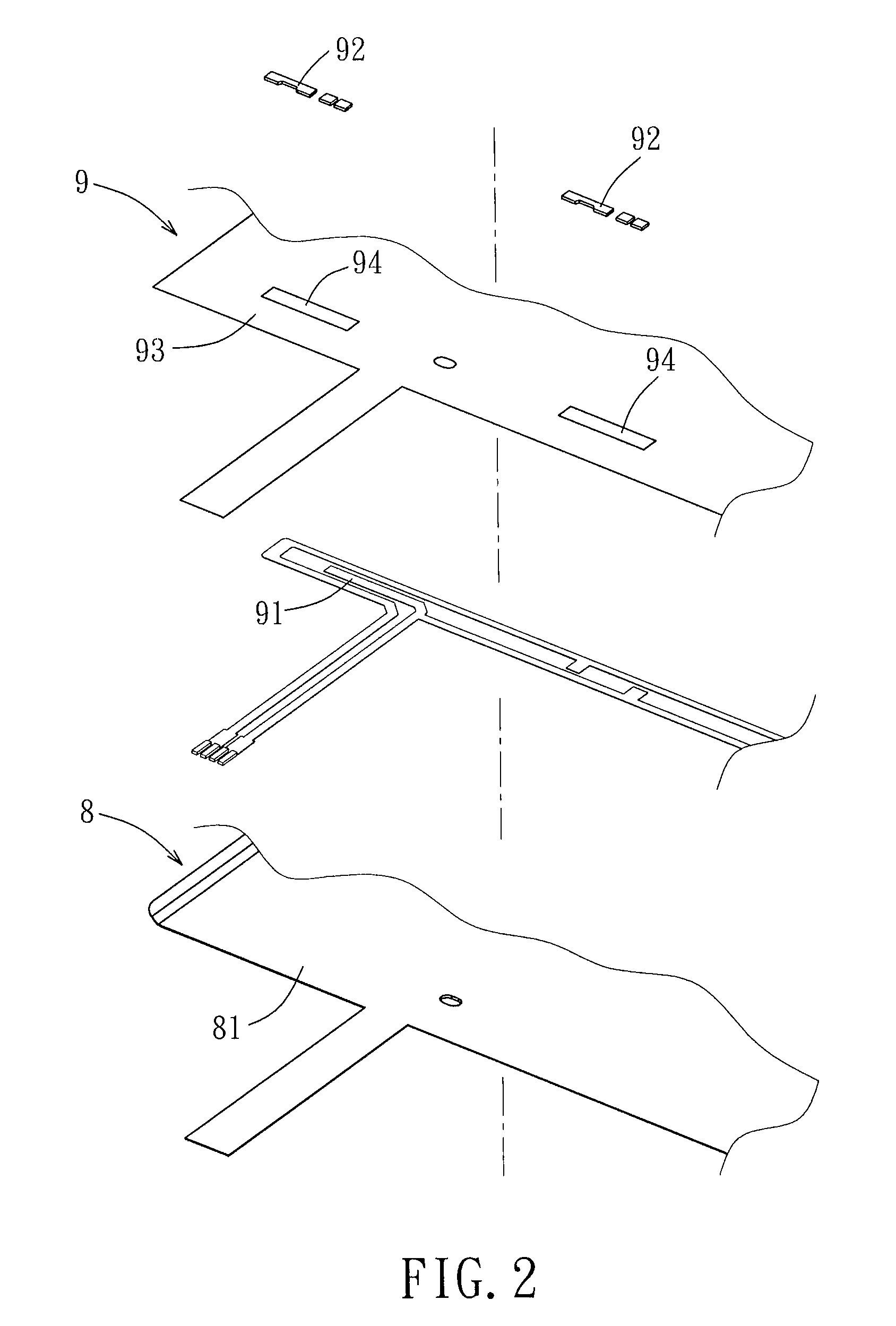

Luminous keyboard

InactiveUS20140151211A1Small sizeSimplify manufacturing stepsContact mechanismsLegendsLight guideConductive polymer

A luminous keyboard includes: a plurality of key caps; a light guiding plate disposed under the key caps; a reflector disposed under the light guiding plate; a masking layer disposed between the key caps and the light guiding plate; a membrane circuit unit disposed under the key caps and on the masking layer; and a luminous unit having a conductive lead, and an illuminant electrically connected to the conductive lead. The conductive lead is made of a material including a conductive polymer gel and a conductive powder and is formed directly on one of the reflector, the masking layer and the membrane circuit unit.

Owner:CHANGSHU SUNREX TECH

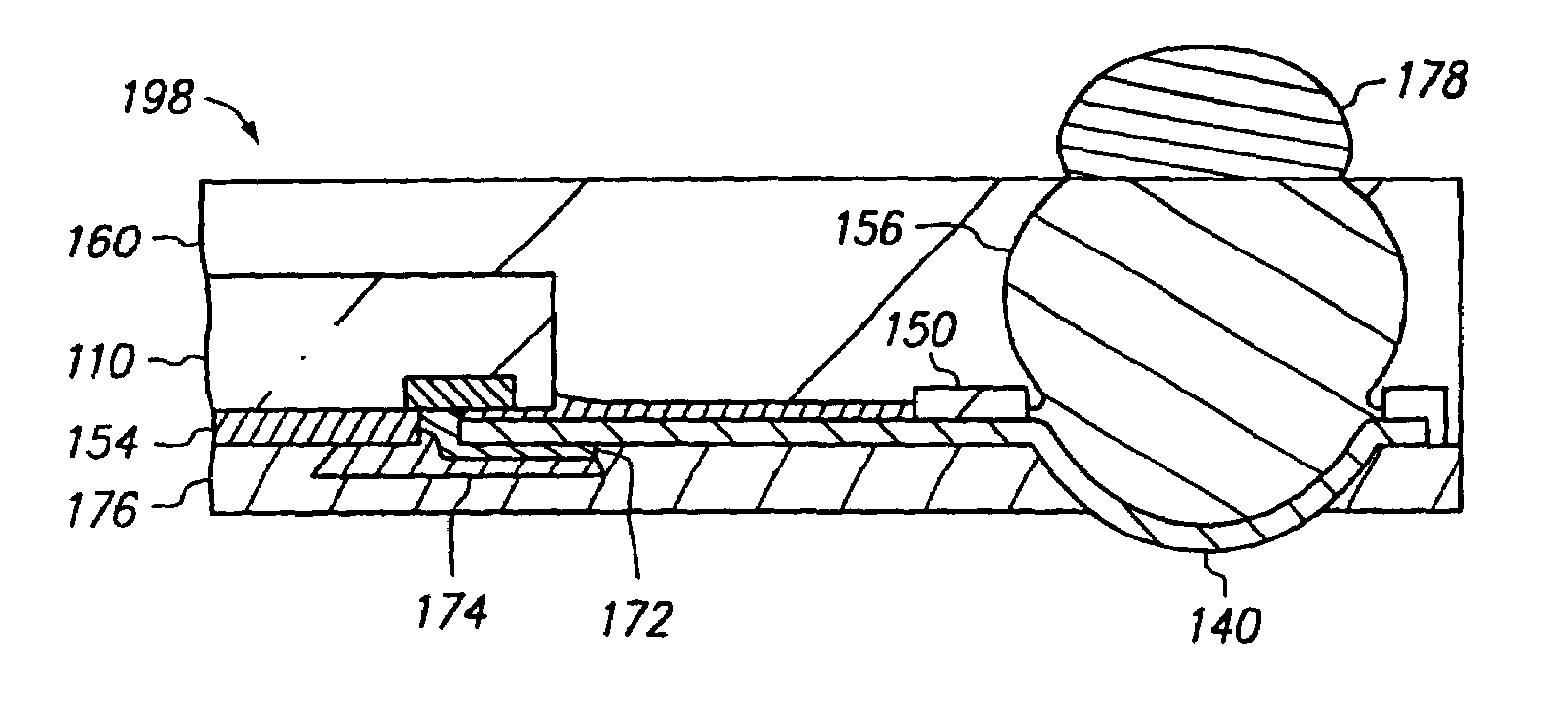

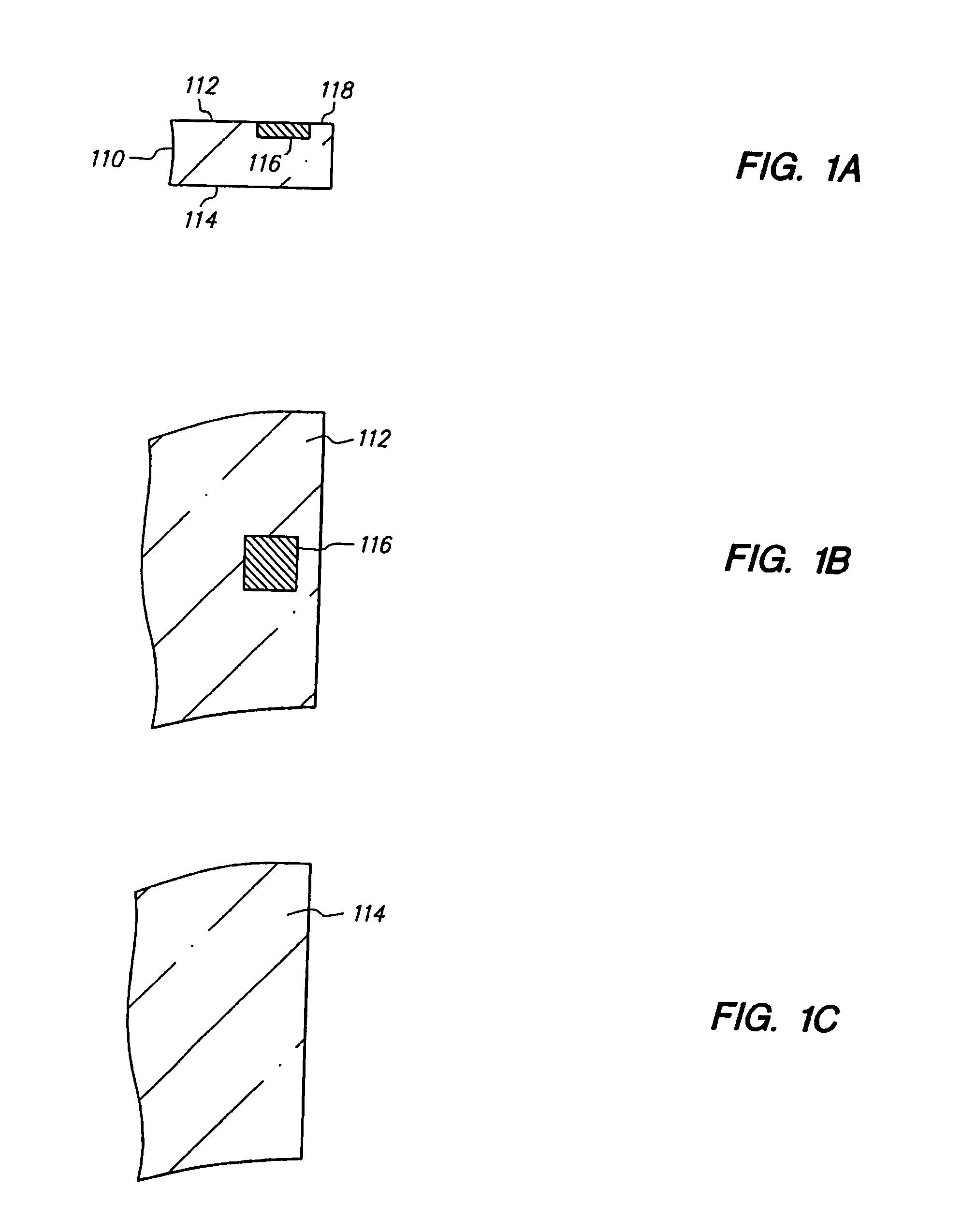

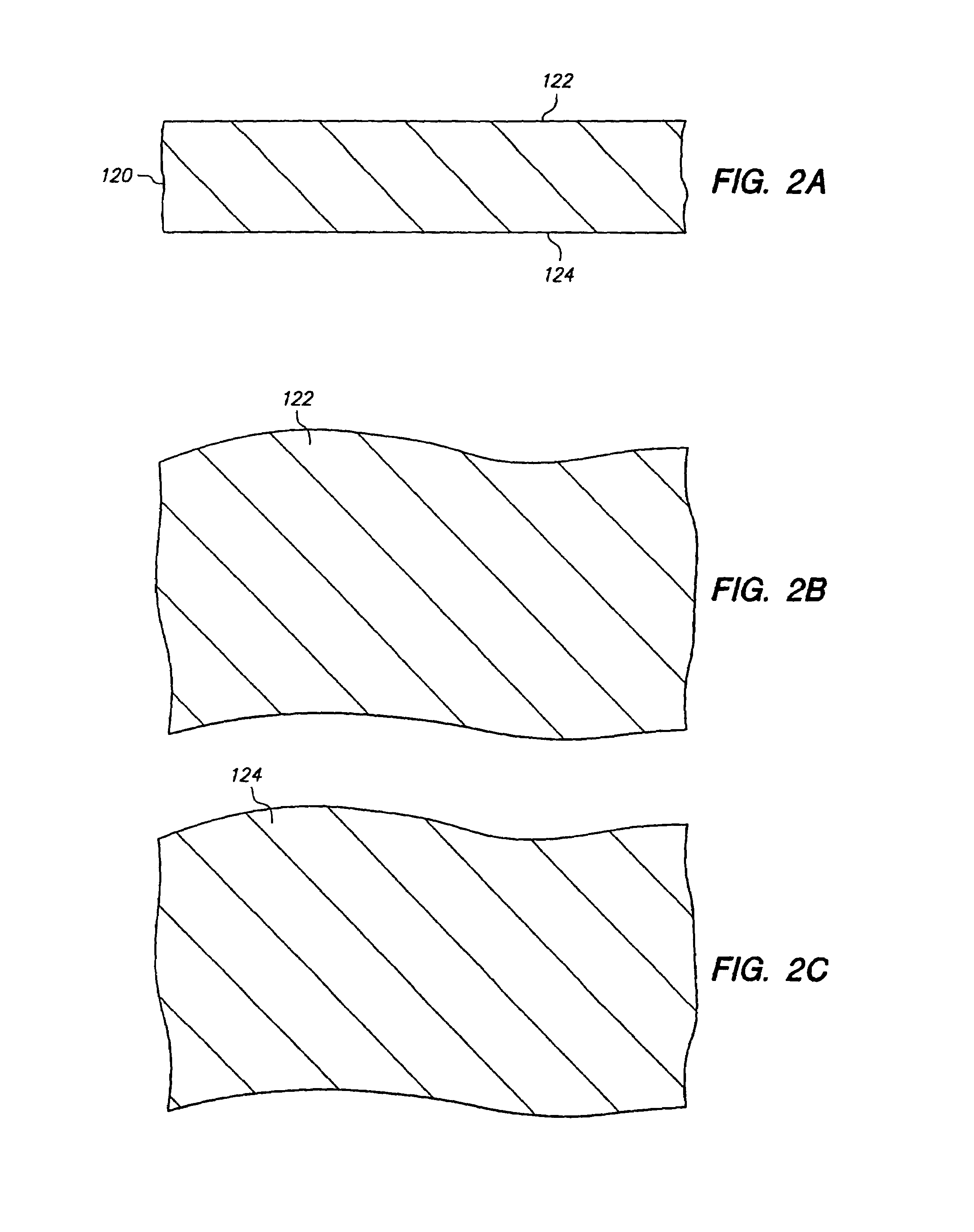

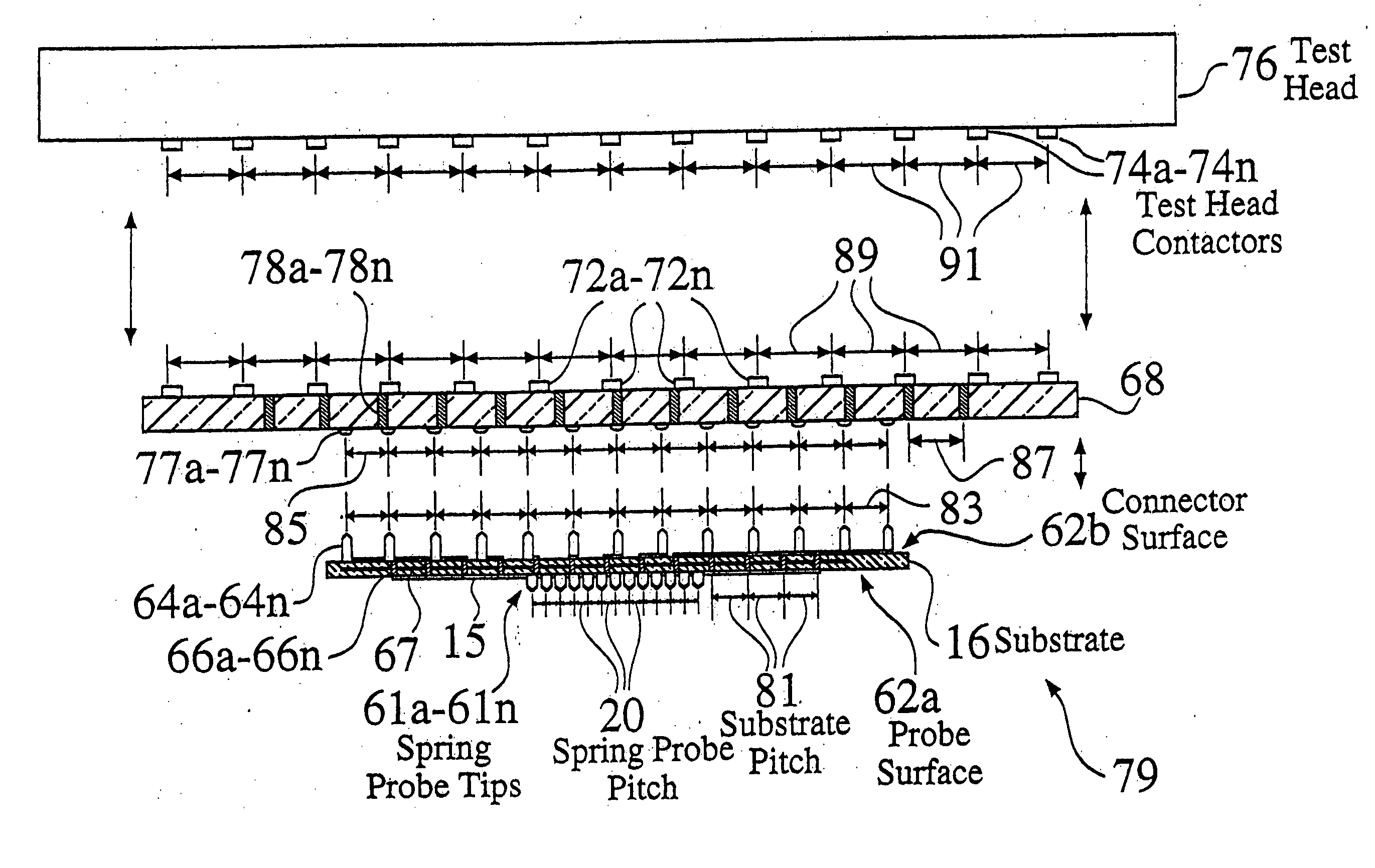

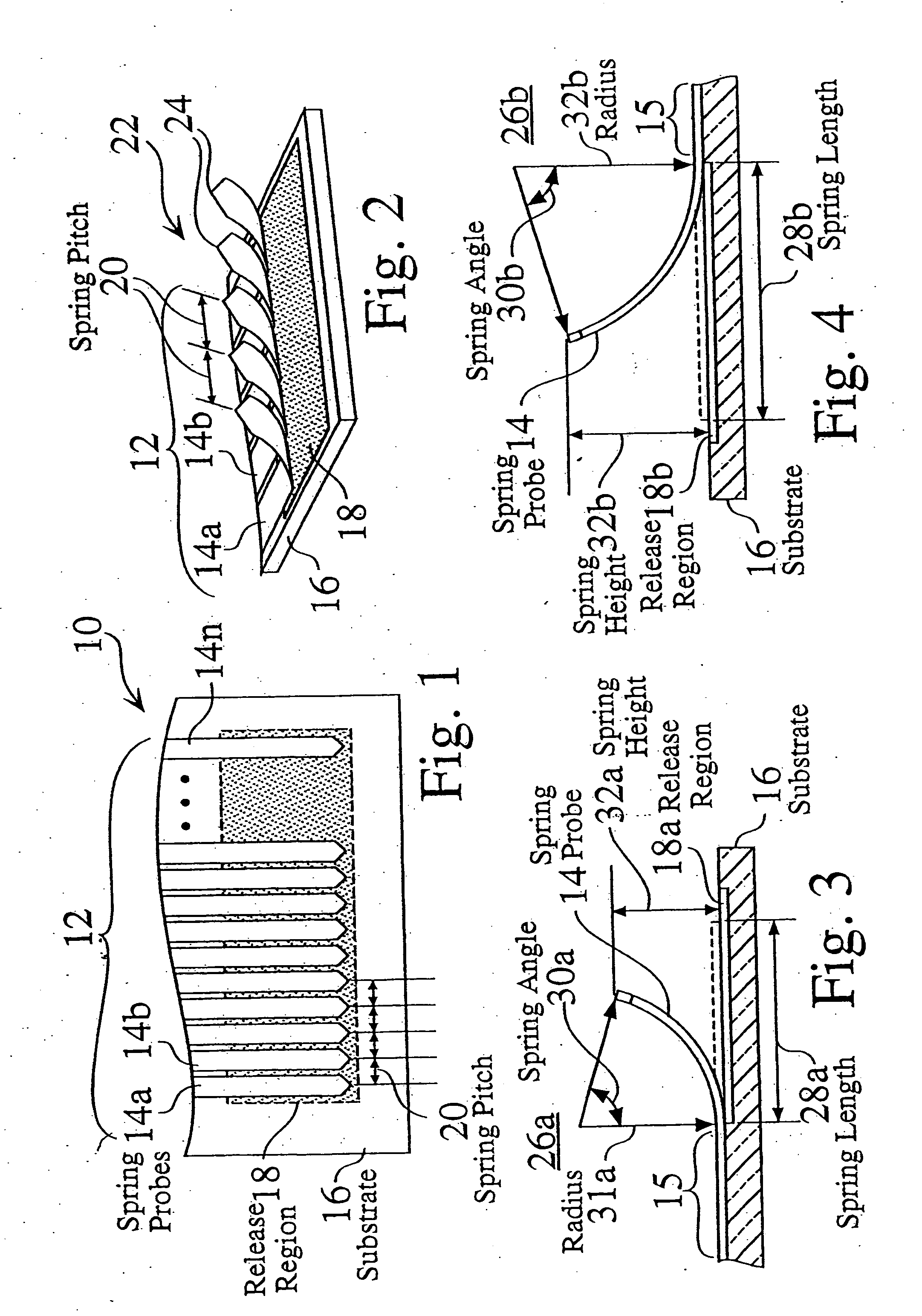

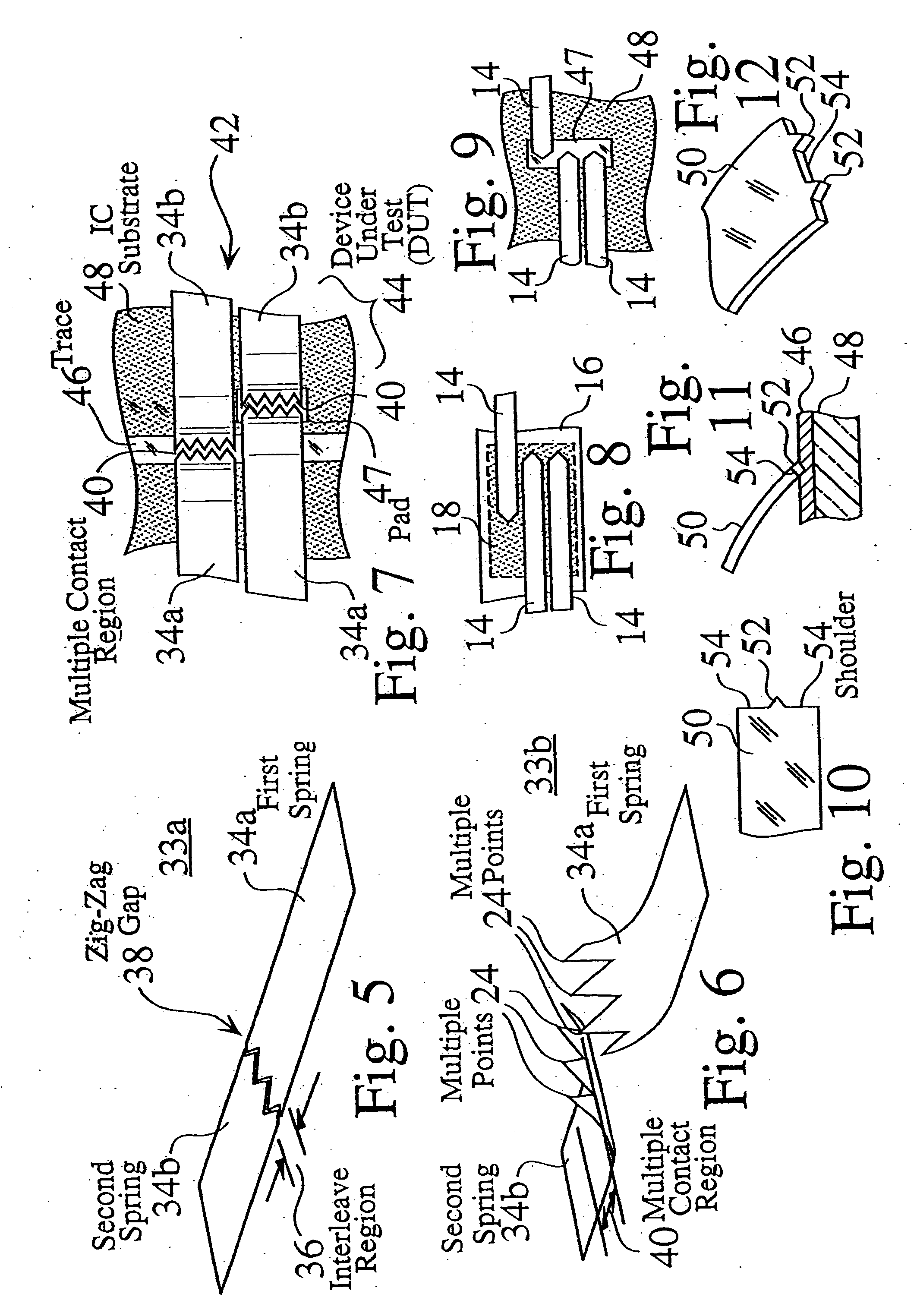

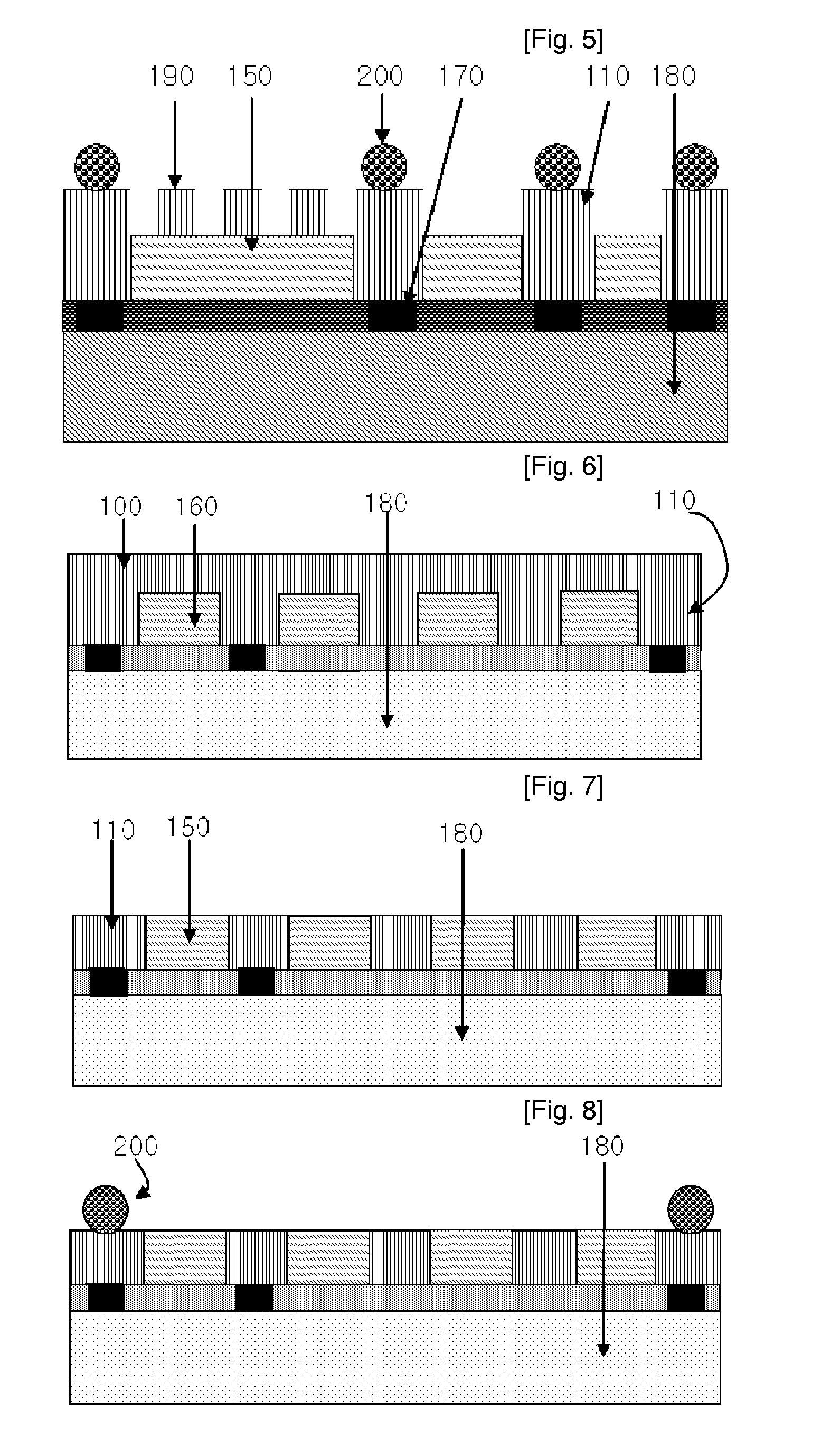

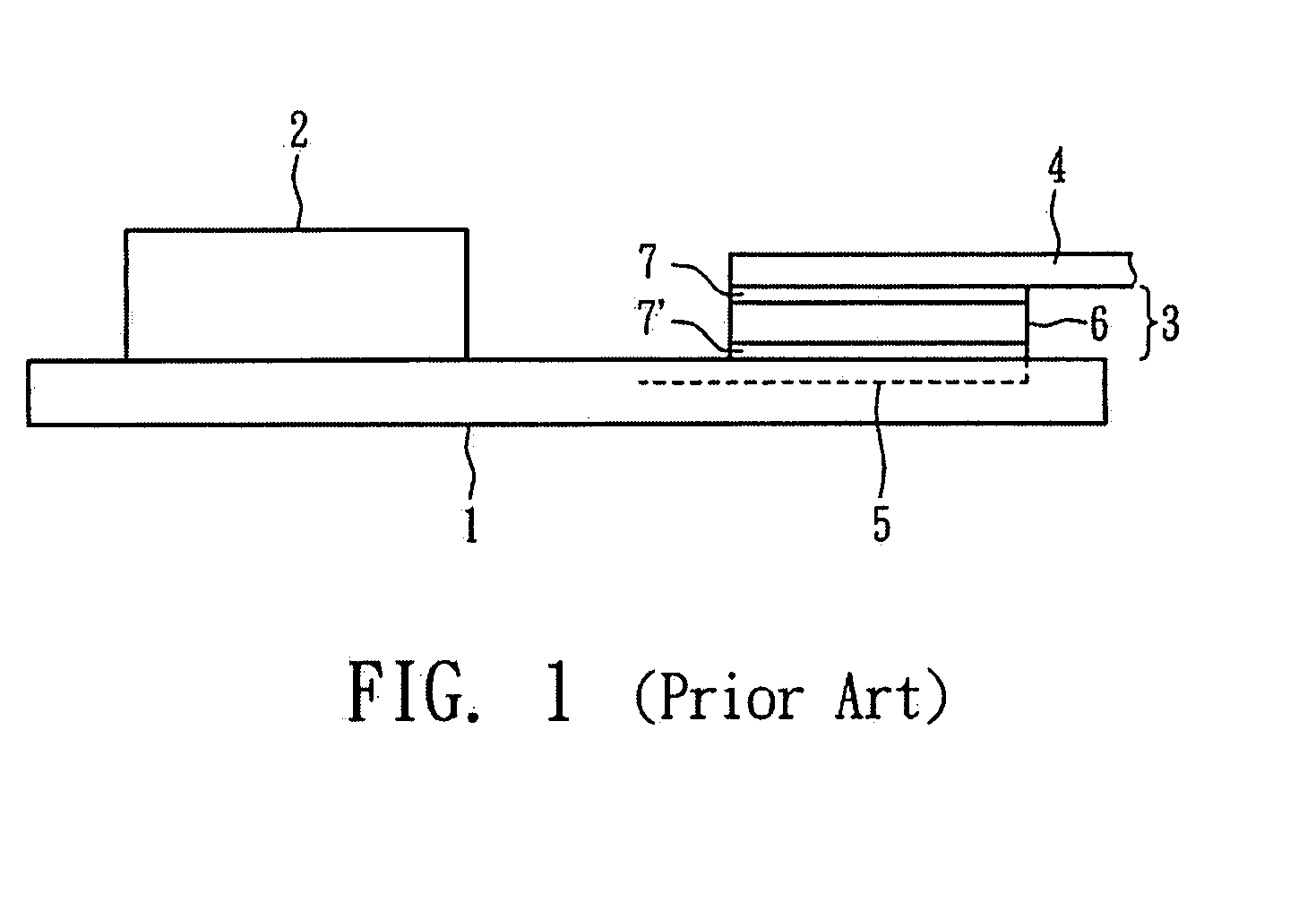

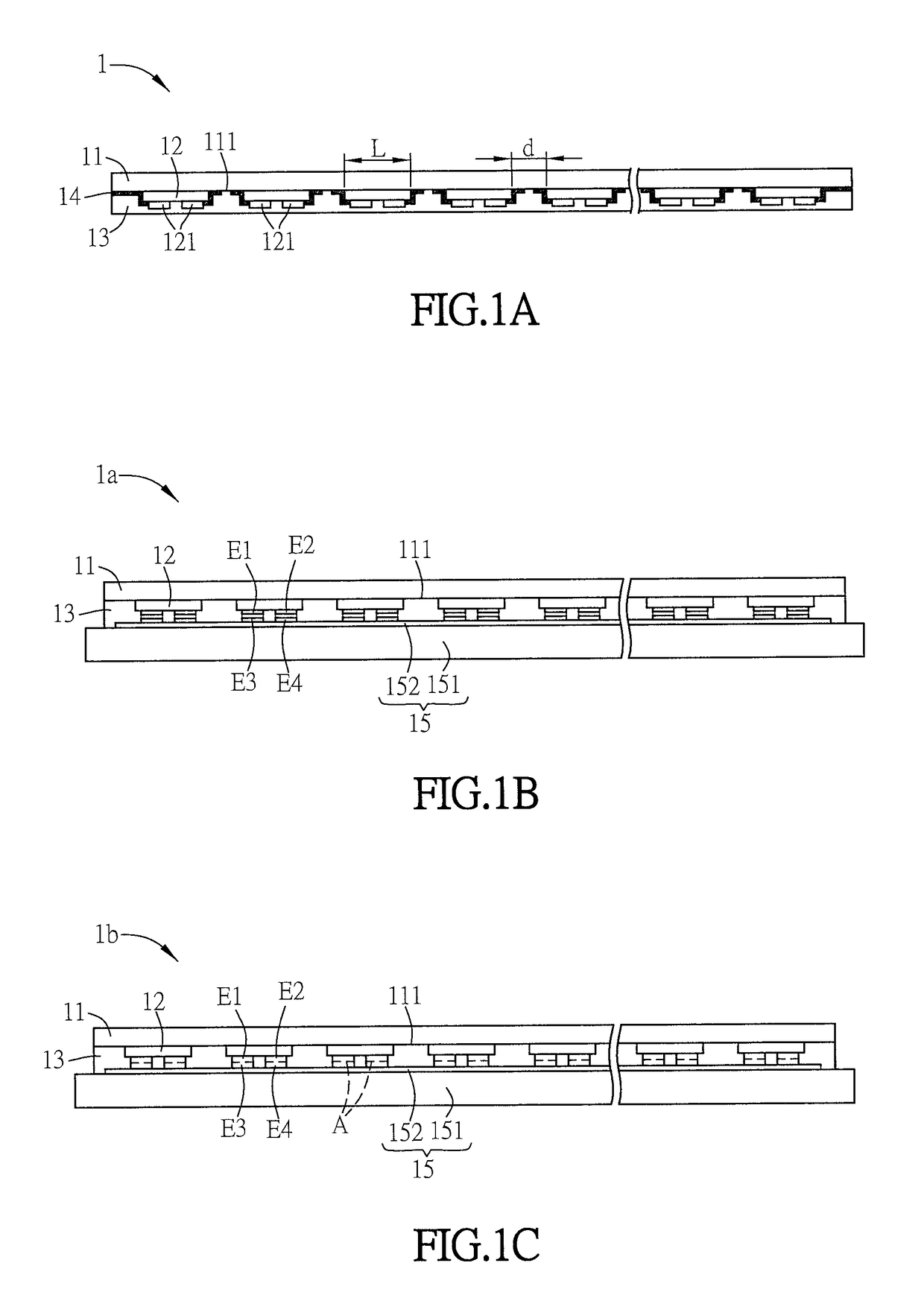

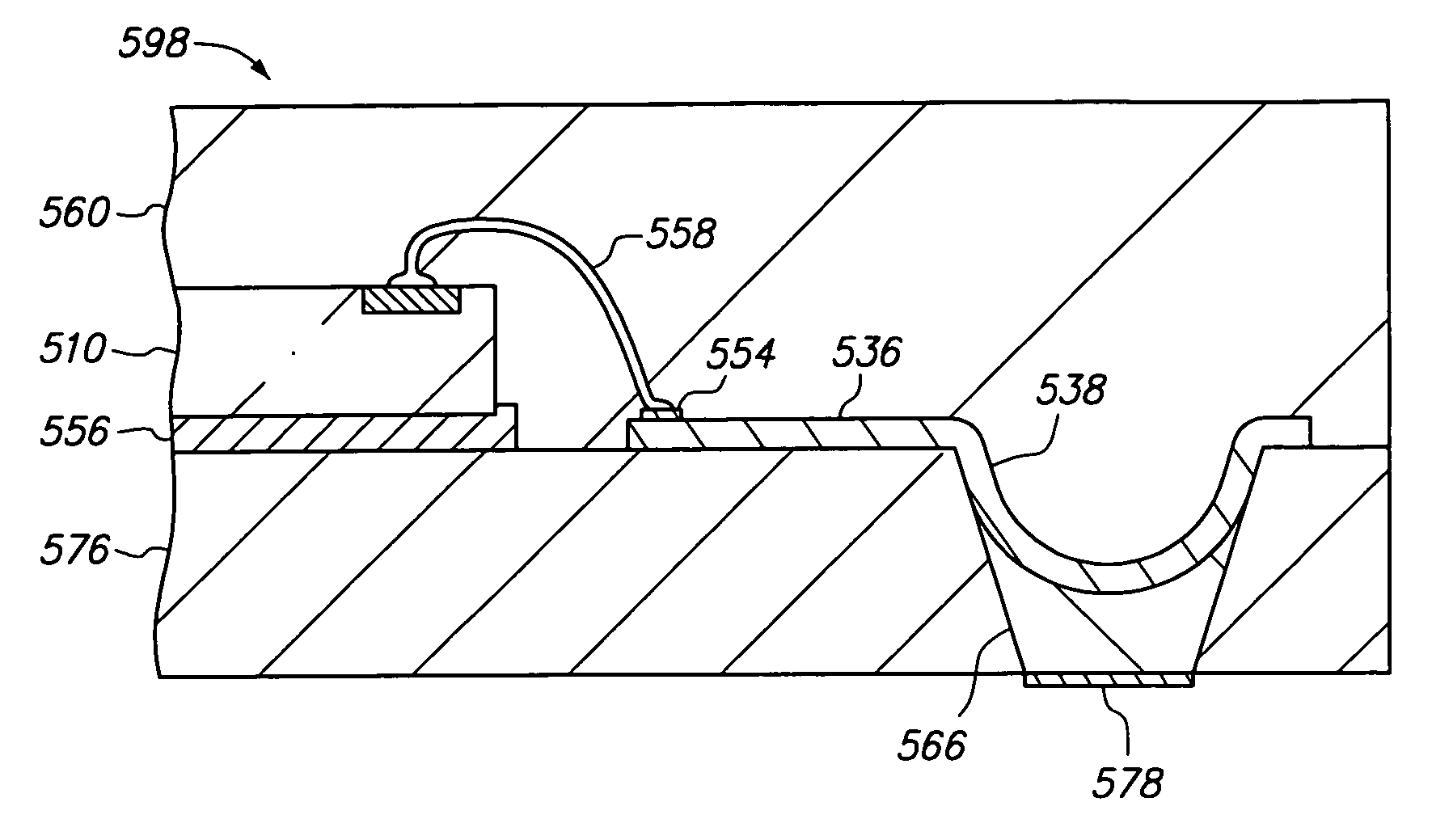

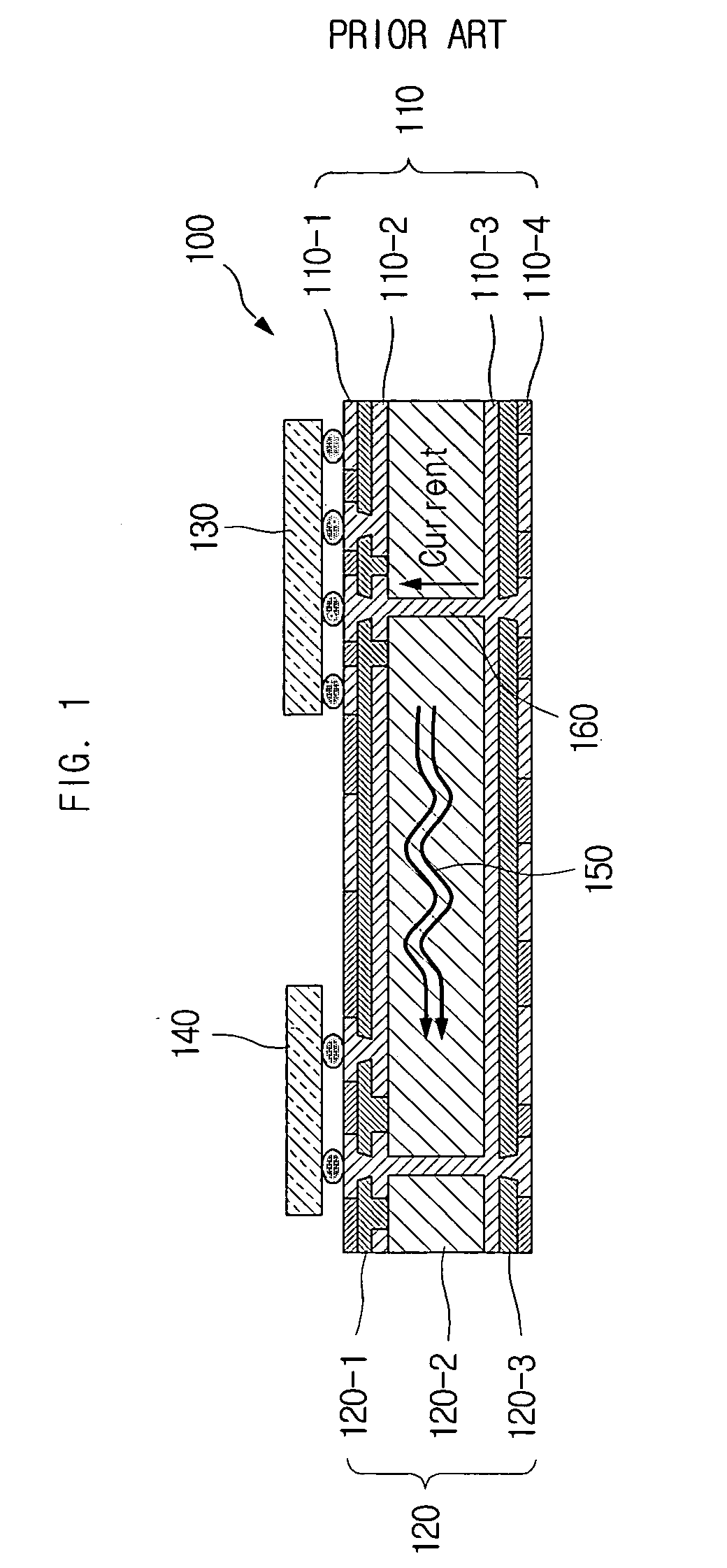

Construction structures and manufacturing processes for integrated circuit wafer probe card assemblies

InactiveUS20050042932A1Increase mechanical complianceReduces assembly manufacturing costElectronic circuit testingElectrical measurement instrument detailsProbe cardManufacturing technology

Several embodiments of integrated circuit probe card assemblies are disclosed, which extend the mechanical compliance of both MEMS and thin-film fabricated probes, such that these types of spring probe structures can be used to test one or more integrated circuits on a semiconductor wafer. Several embodiments of probe card assemblies, which provide tight signal pad pitch compliance and / or enable high levels of parallel testing in commercial wafer probing equipment, are disclosed. In some preferred embodiments, the probe card assembly structures include separable standard components, which reduce assembly manufacturing cost and manufacturing time. These structures and assemblies enable high speed testing in wafer form. The probes also have built in mechanical protection for both the integrated circuits and the MEMS or thin film fabricated spring tips and probe layout structures on substrates. Interleaved spring probe tip designs are defined which allow multiple probe contacts on very small integrated circuit pads. The shapes of probe tips are preferably defined to control the depth of probe tip penetration between a probe spring and a pad or trace on an integrated circuit device. Improved protective coating techniques for spring probes are also disclosed, offering increased reliability and extended useful service lives for probe card assemblies.

Owner:ADVANTEST SINGAPORE PTE LTD

Novel low-sugar low-fat shortbread type biscuit and the preparation technics thereof

InactiveCN101095420AThe texture is crispy and oilyShorten manufacturing timeBakery productsYeastLow fat biscuit

The invention relates to a kind of low-sugar and low-fat biscuit and the preparation method. The method comprises following steps: preparing flour dough with yeast and medium-strength (or high-strength)flour, getting fermented flour dough, adding egg, sugar and oil and other findings into flour dough, mixing with fermented flour dough and enzyme agent, adding low-strength flour, shaping through roll marking, cutting or roll cutting, drying, cooling and getting finished product. The invention employs low-sugar and low-fat formulation, combines biological techniquie such as fermentation and enzyme agent and produces crisp biscuit.

Owner:TIANJIN UNIV OF SCI & TECH

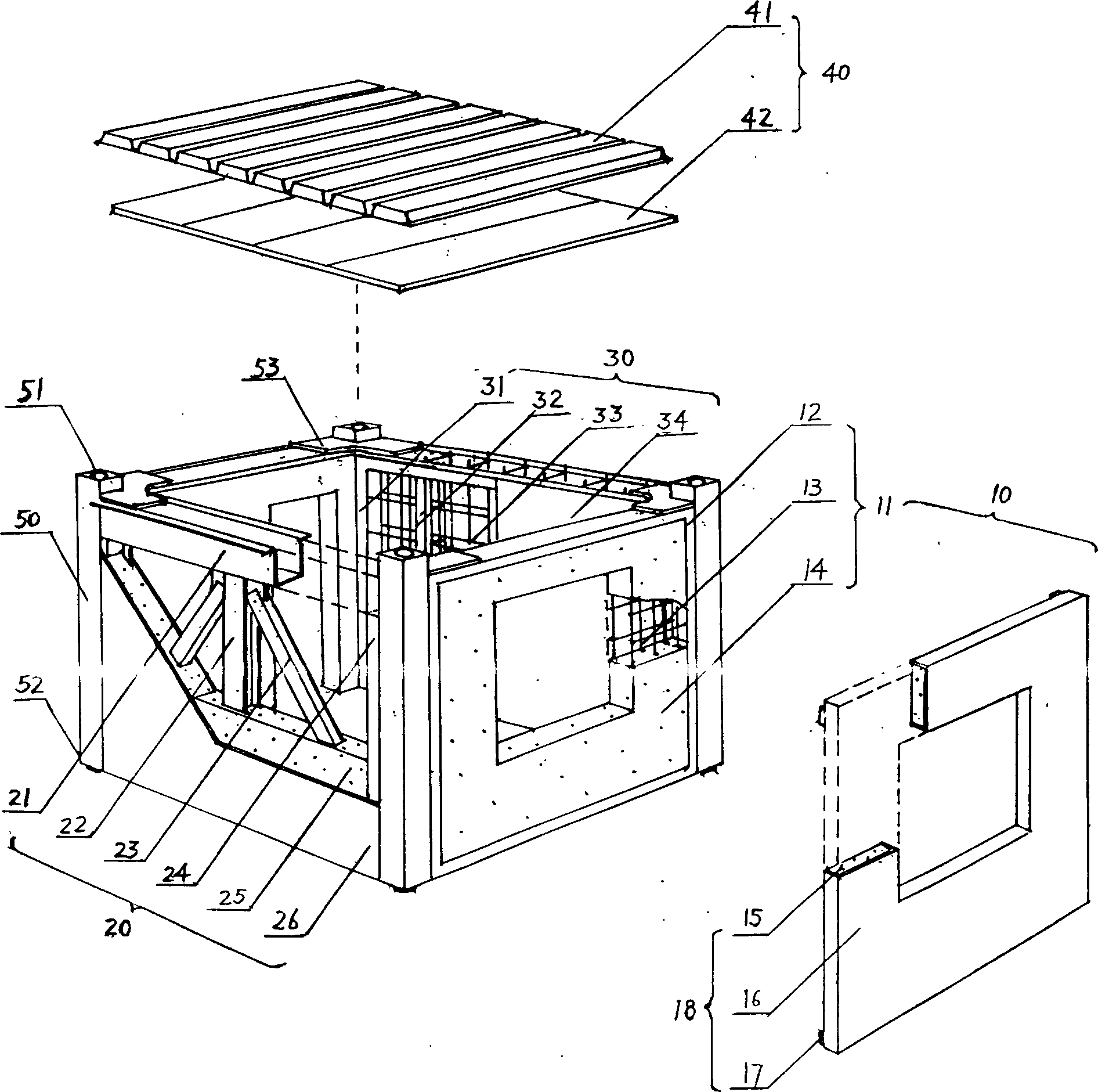

Box shaped house model of construction and fabricating method

A box type of house mould used on building consists of outer wall formed by steel frame, steel screen frame and aero ¿C concrete plate; inner wall formed by hollow wall plate and composite frame wall plate; top plate mould formed by pressed steel bearing plate and light thin plate and steel tube. It is featured as enclosing box type of house mould by one outer wall and three inner walls and furthermore forming stereo structure house mould with five surfaces by welding said box type of house mould with top plate mould.

Owner:张东川

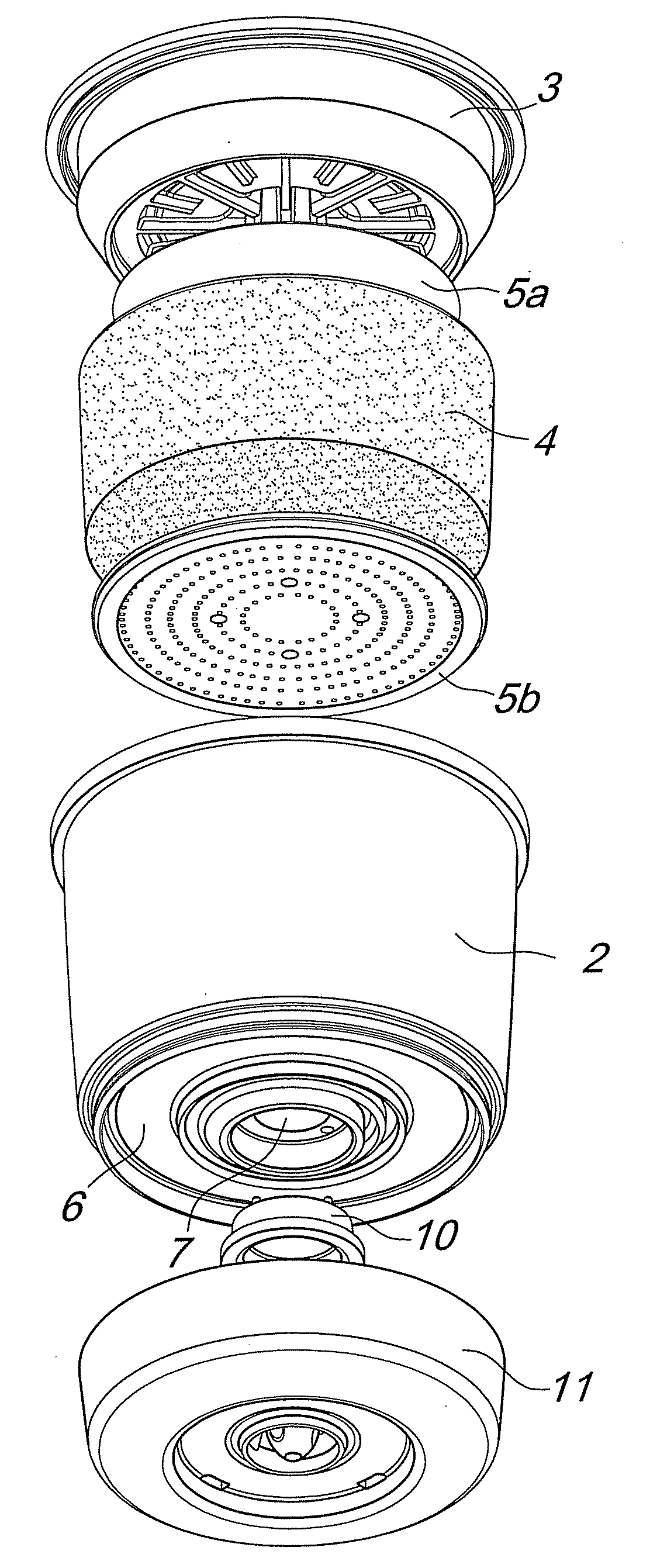

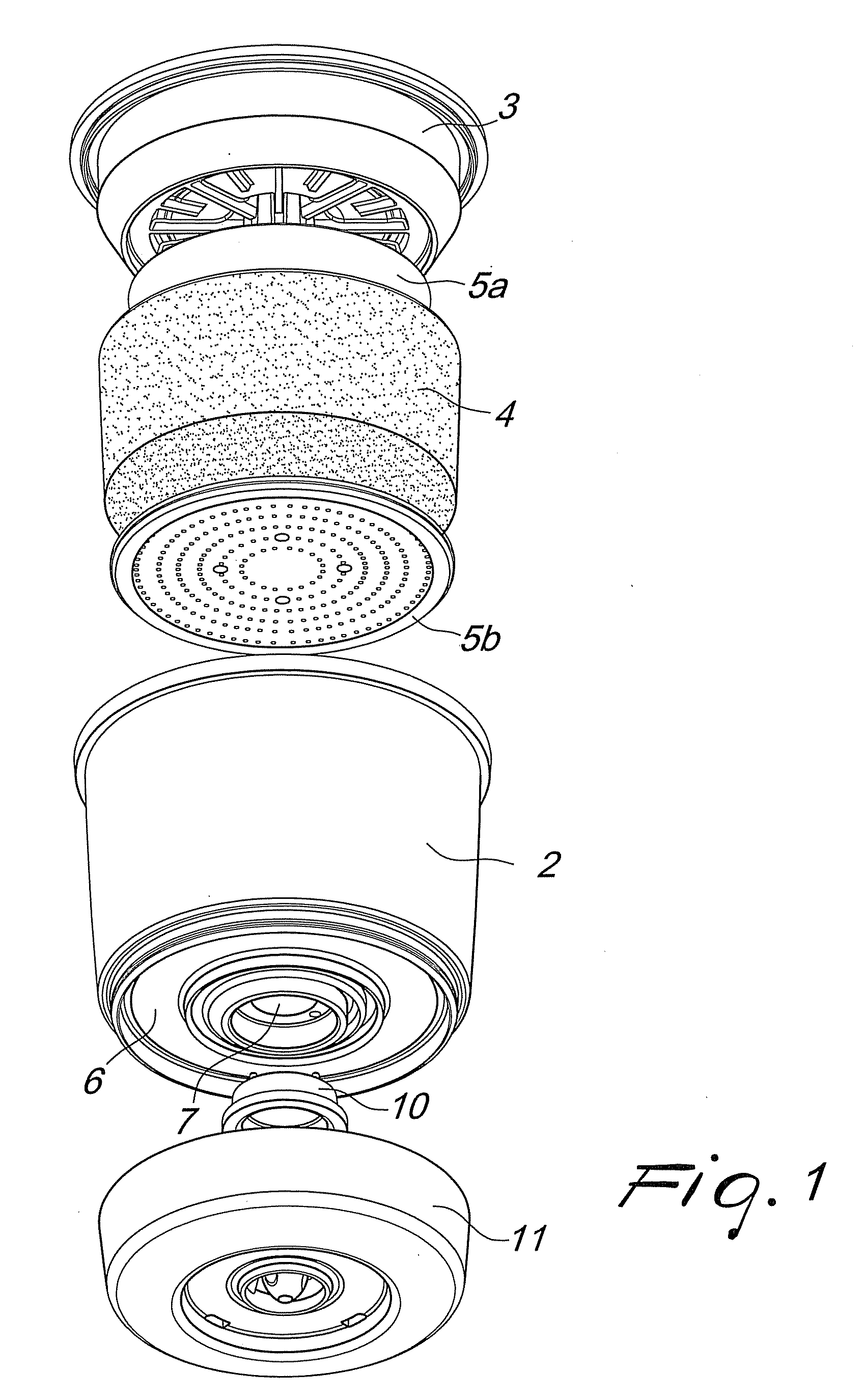

Rigid filter for capsules suitable for extracting beverages, particularly espresso coffee

ActiveUS20080257165A1Shorten manufacturing timeLow costReady-for-oven doughsBeverage vesselsSolid massEspresso coffee

A rigid filter for capsules suitable for extracting beverages, comprising a flat body having a plurality of through filtering holes, which are sized so as to block the passage of solid particles and allow passage of brewed water or beverage, wherein the holes have a substantially symmetrical shape with respect to the middle plane of the flat body, so that the filter can be inserted into a capsule without taking care of the orientation of such holes with respect to the powdered substance within the capsule.

Owner:ILLYCAFFE SPA

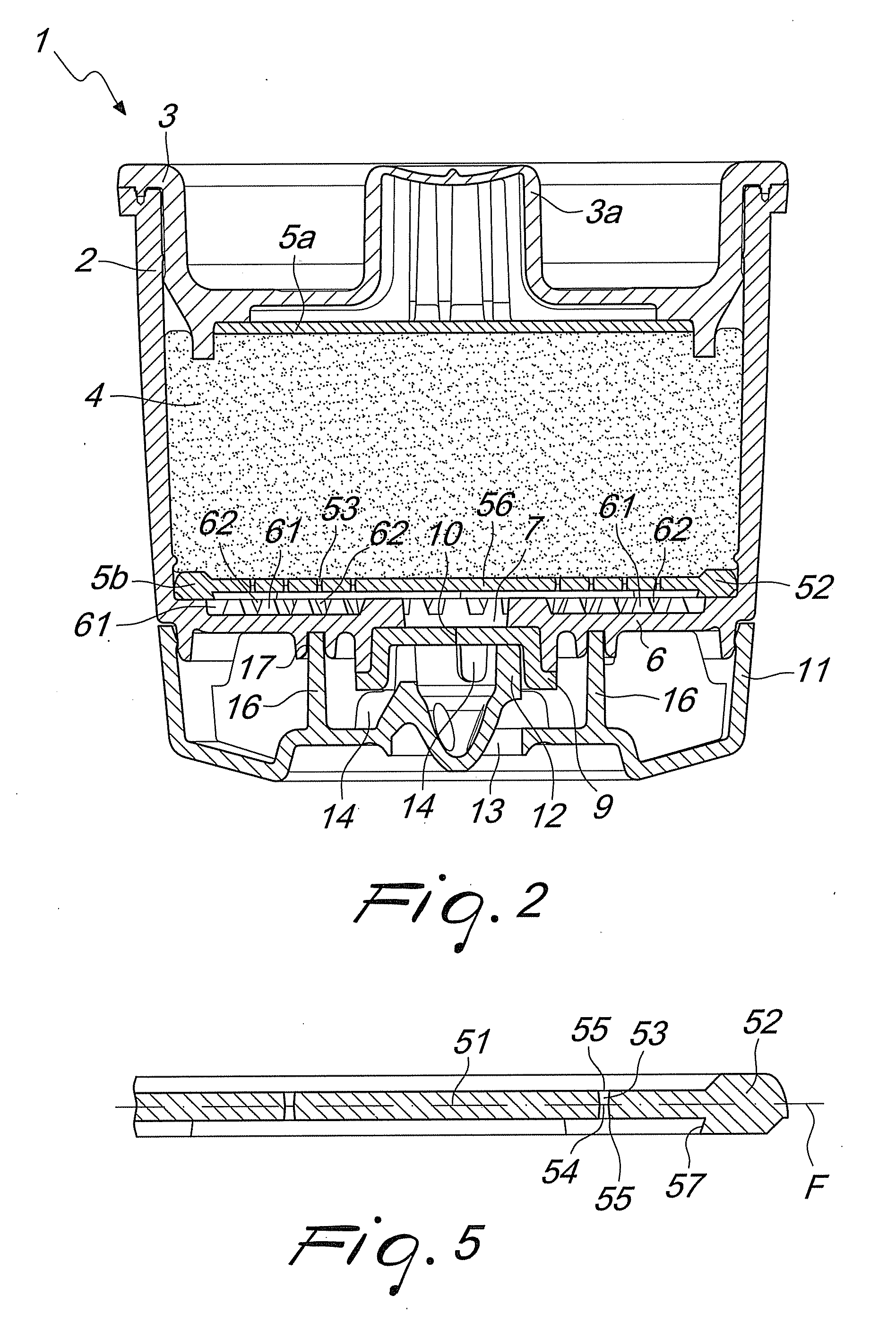

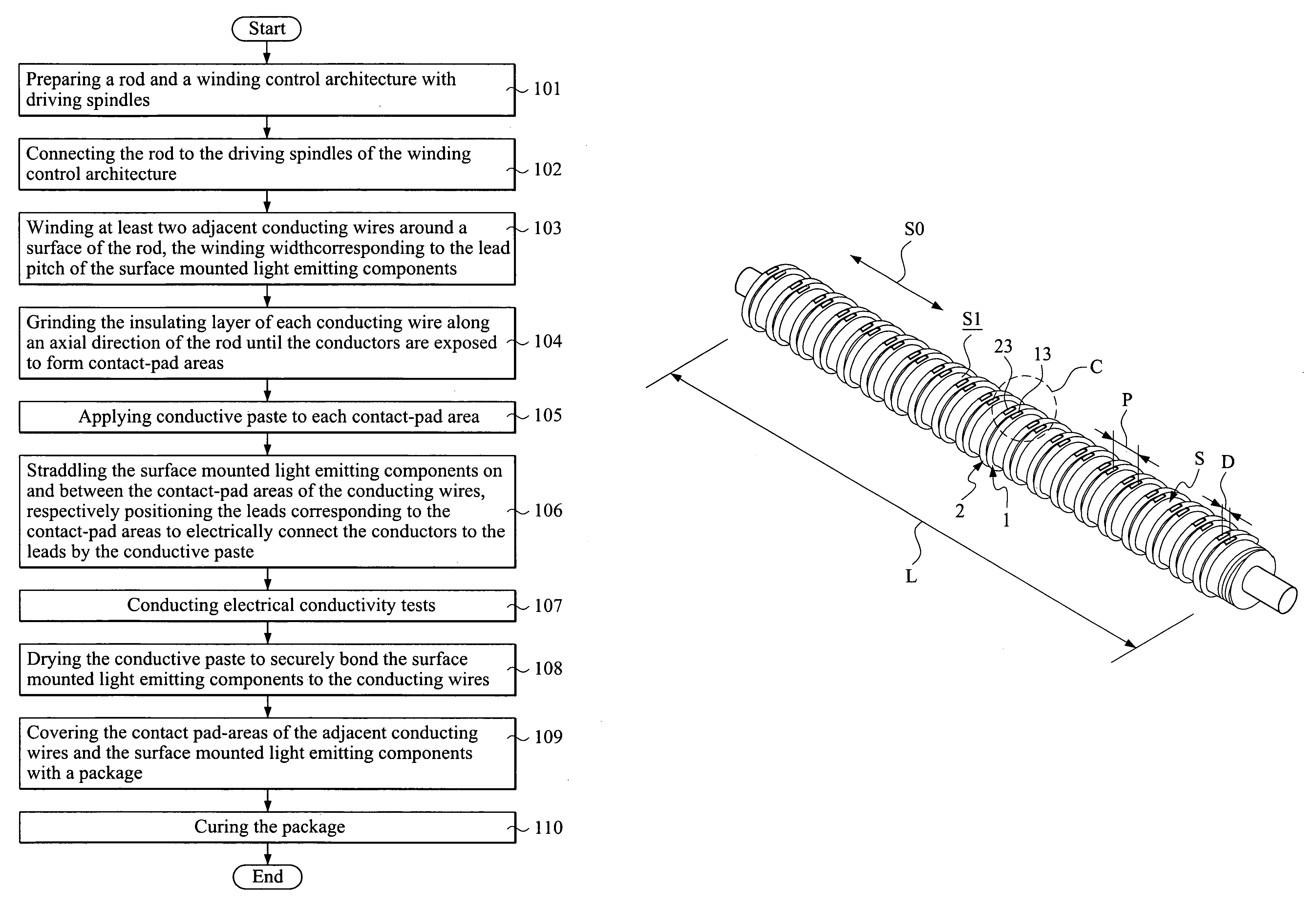

Method for manufacturing light set with surface mounted light emitting components

ActiveUS8397381B2Quickly and accurately manufactureShorten production timeLighting support devicesPoint-like light sourceConductive pasteWinding machine

A method for manufacturing a light set with surface mounted light emitting components is disclosed. A rod having a predetermined length and a winding control architecture with corresponding driving spindles are prepared first. The rod is driven to rotate by a winding machine via driving spindles to wind conducting wires. The insulating layer of each conducting wire is then ground along an axial direction of the rod to expose the conductor of each conducting wire to form contact-pad area. A conductive paste is applied to each contact-pad area, and the surface mounted light emitting components are straddled thereon. Each lead of the surface mounted light emitting components is respectively positioned corresponding to the contact-pad areas, and is electrically connected to the conductors by the conductive paste. The contact-pad areas and the surface mounted light emitting component are then covered with a package.

Owner:REAL BONUS

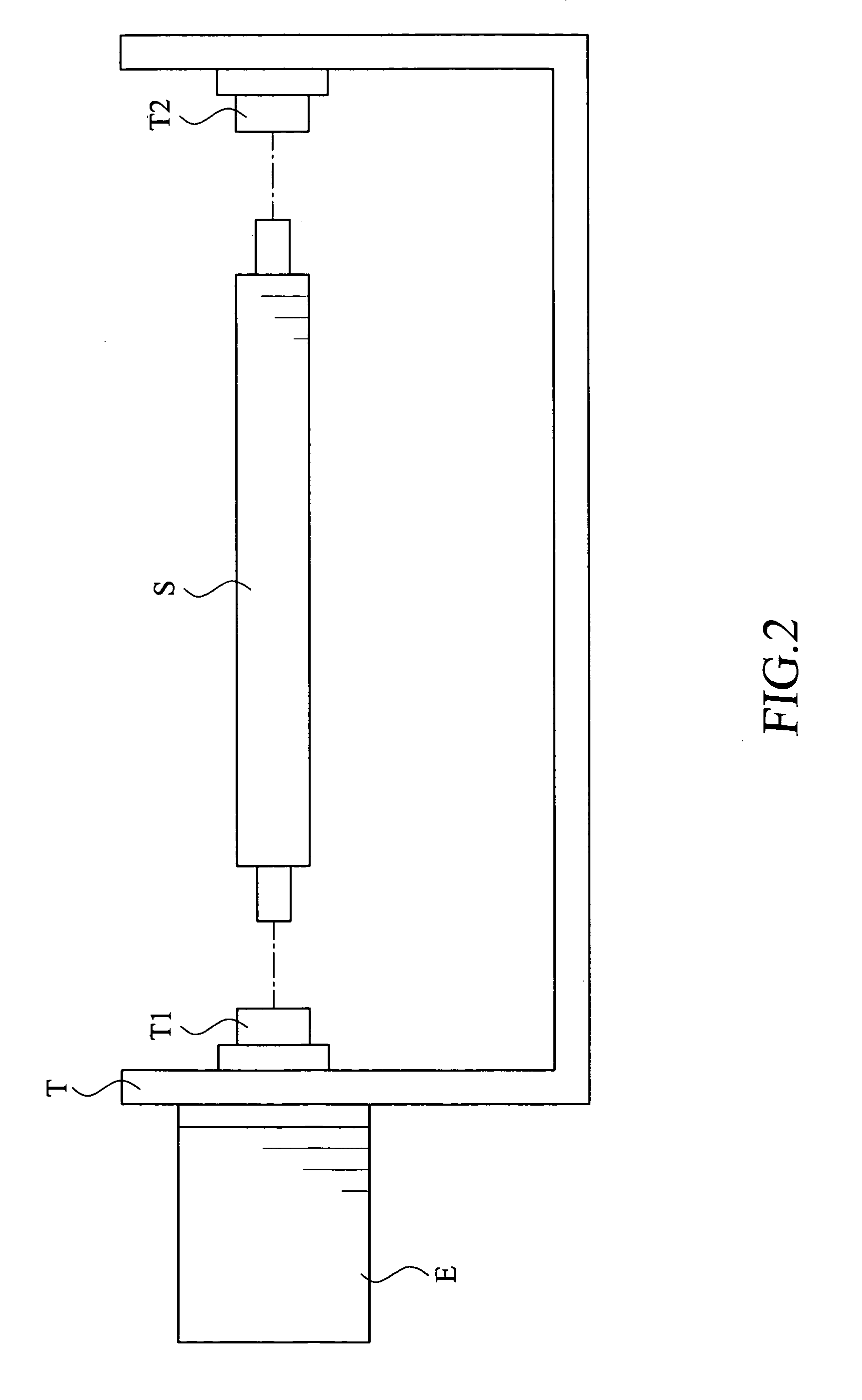

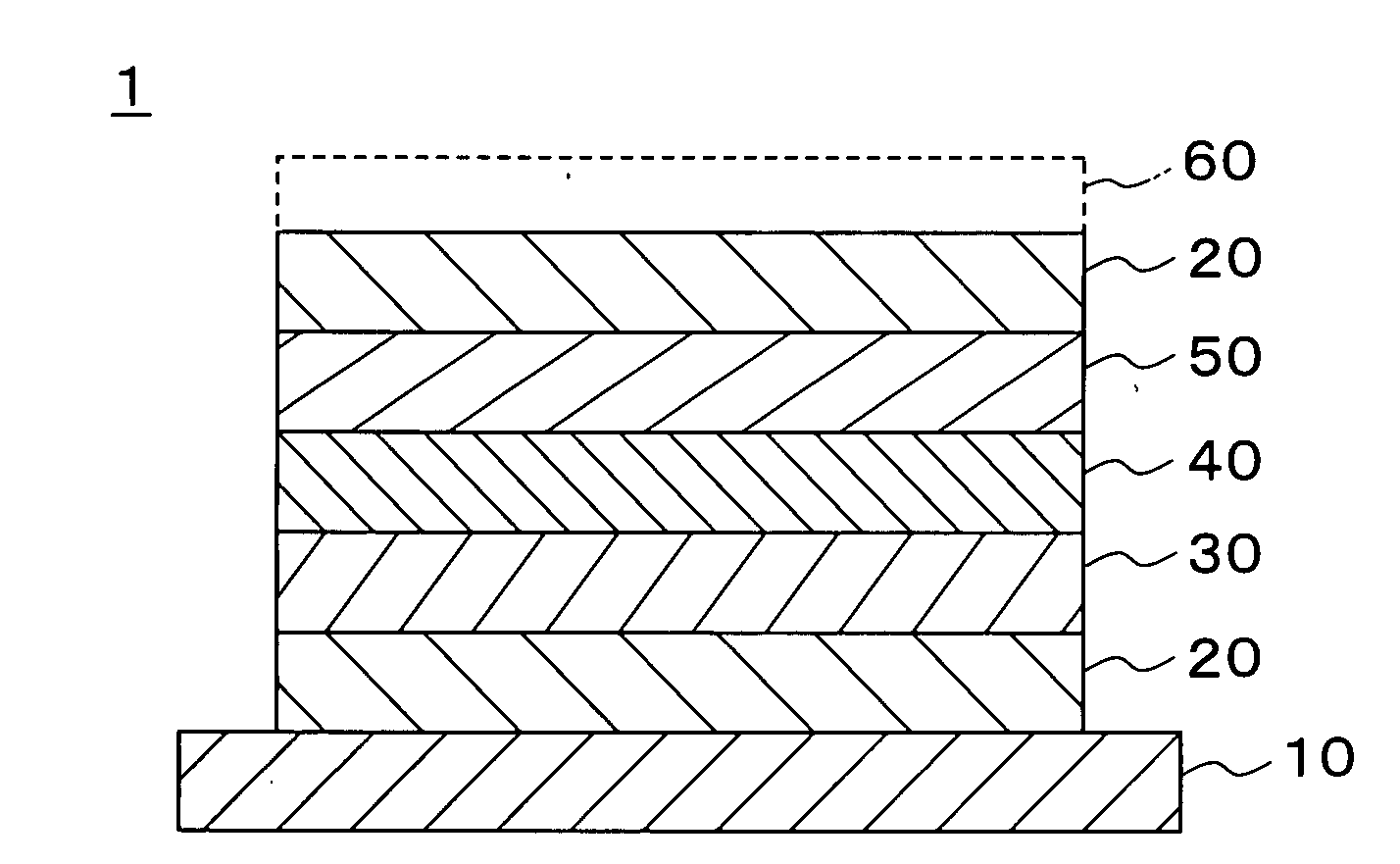

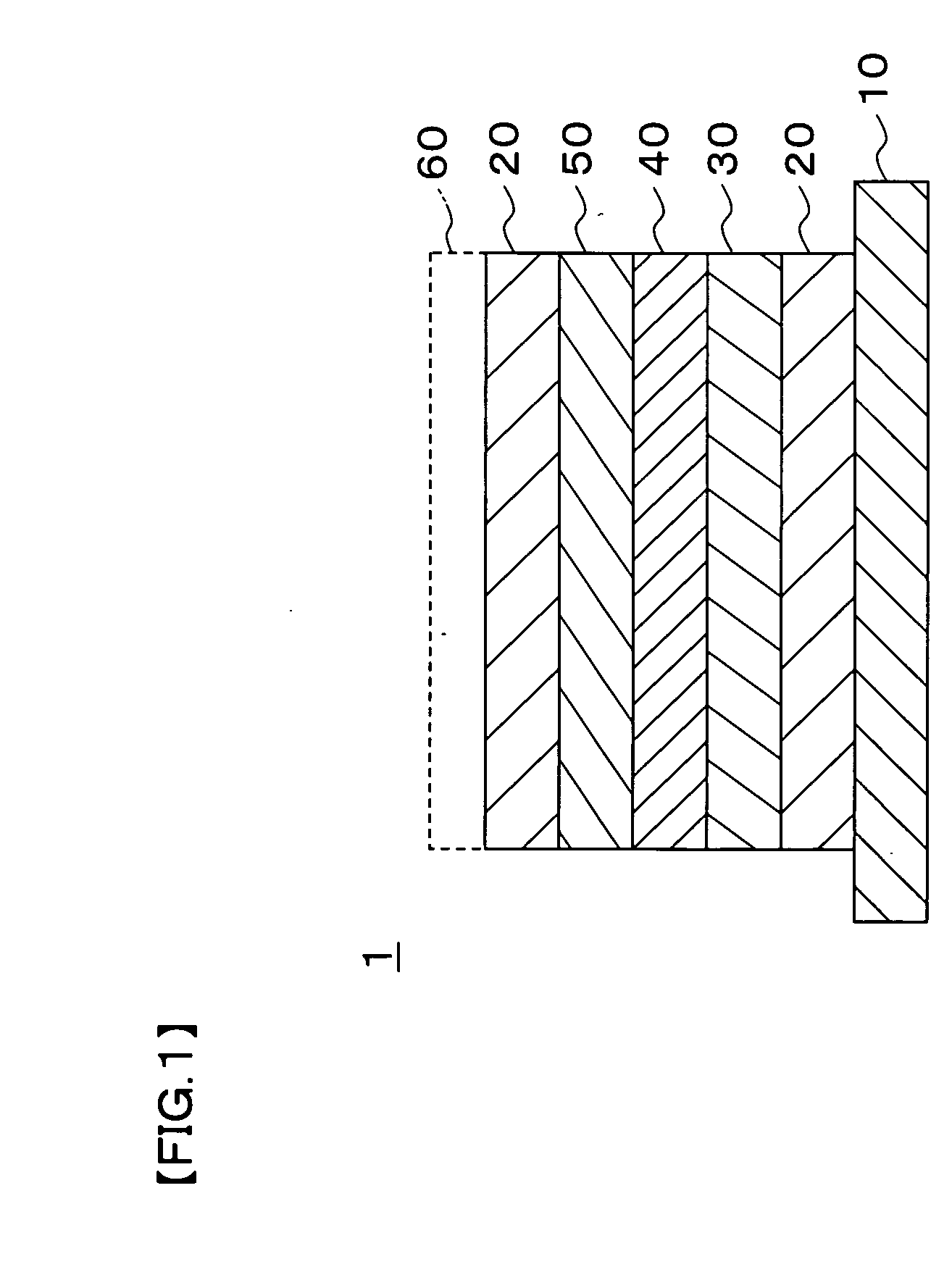

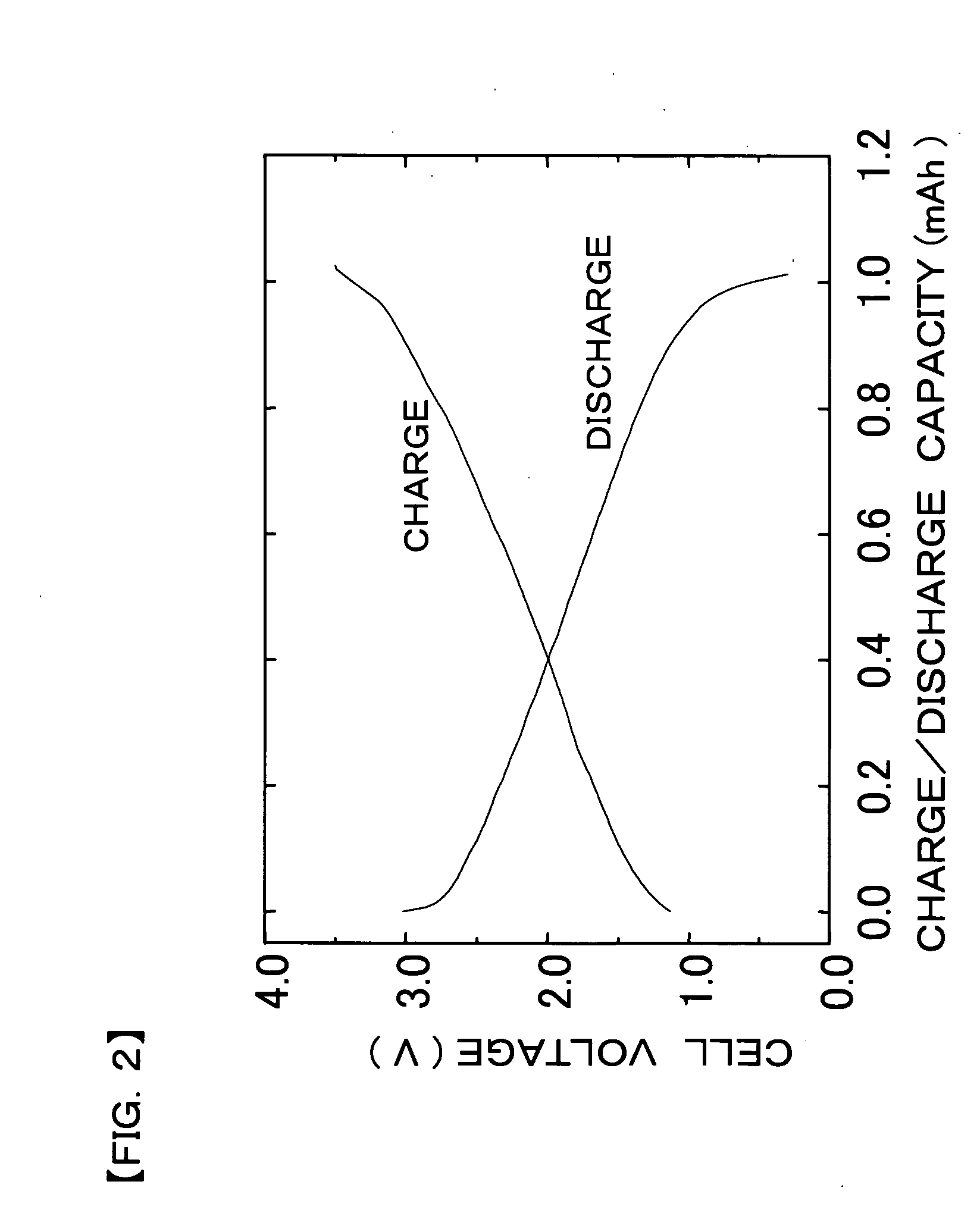

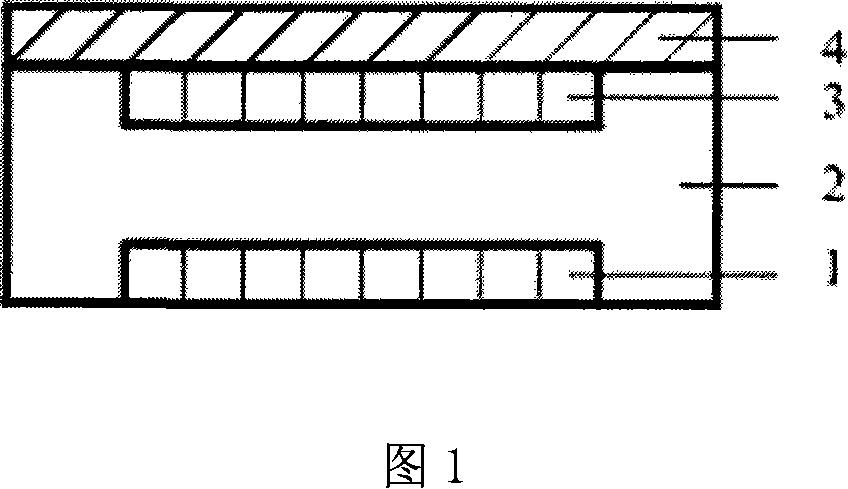

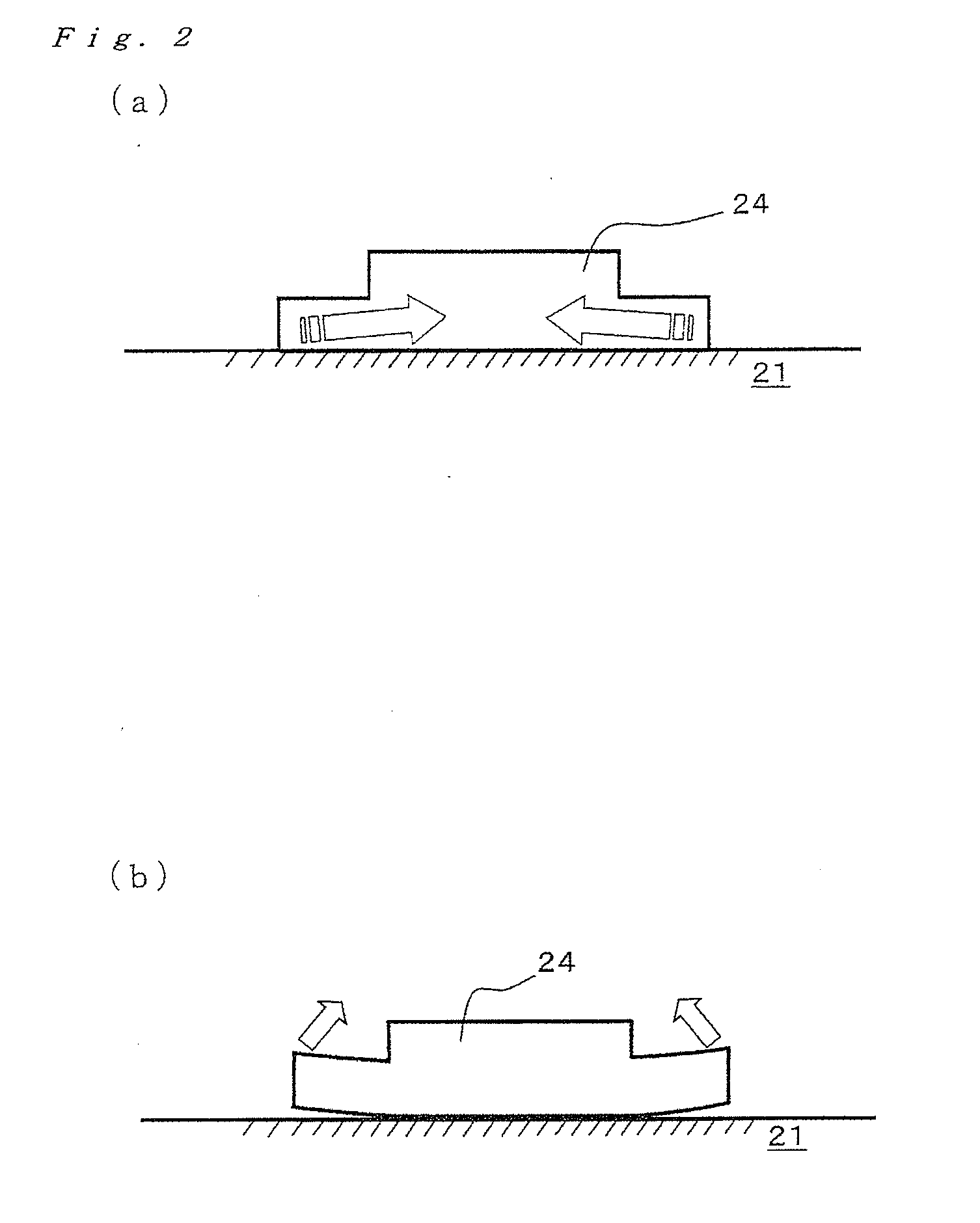

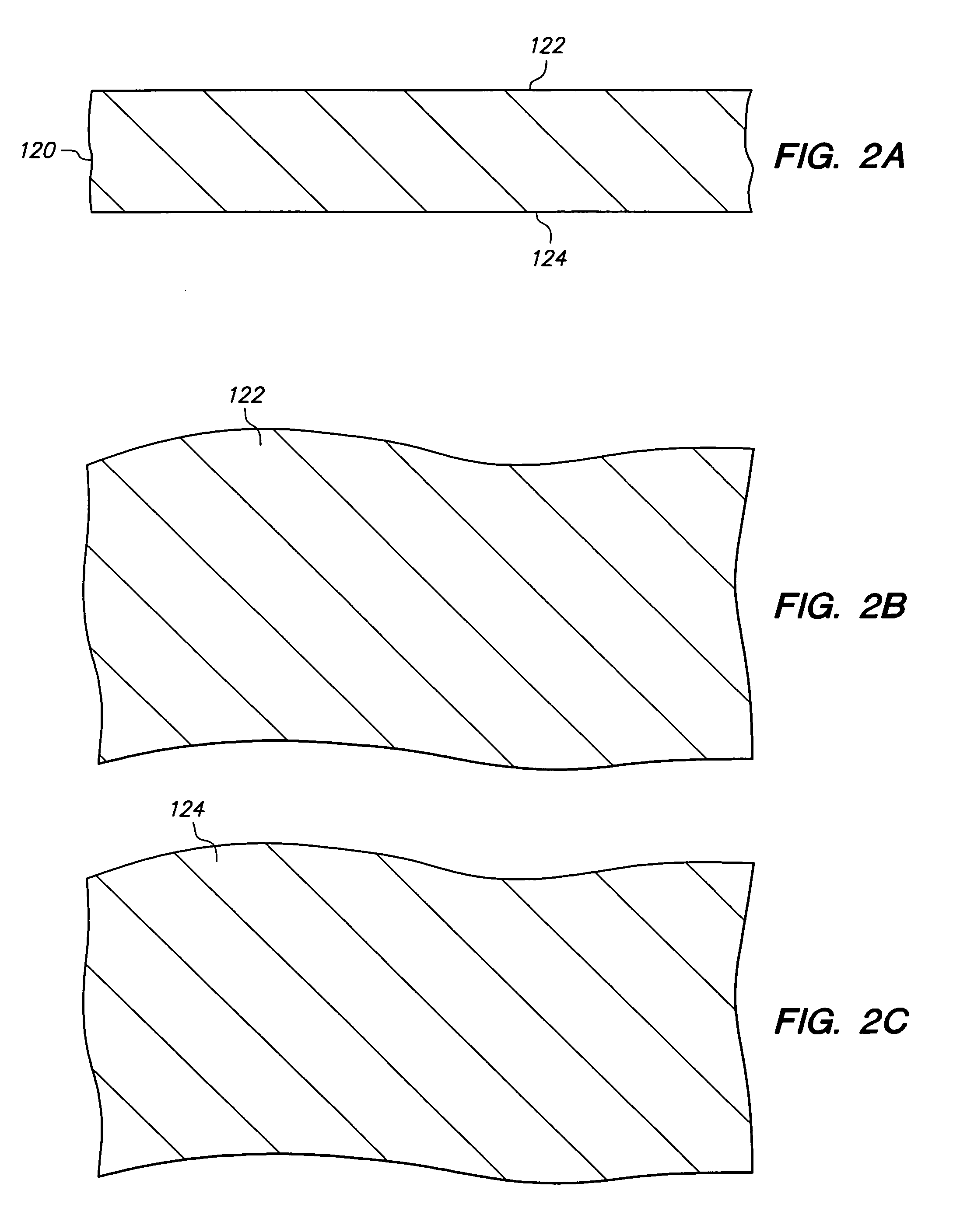

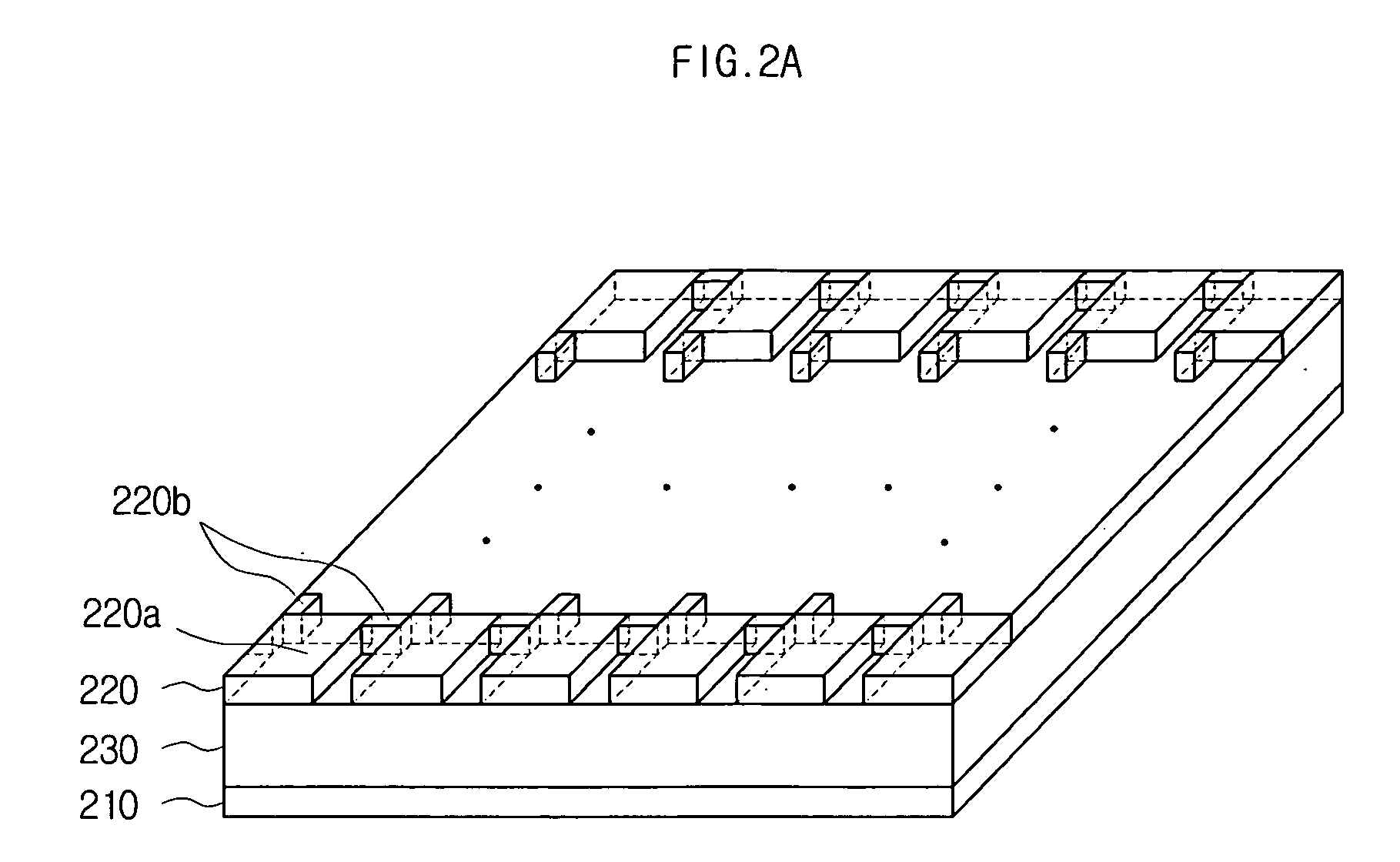

Thin-Film Solid Secondary Cell

InactiveUS20090029264A1Shorten manufacturing timeReduce stepsFinal product manufactureCell electrodesNitrogenLITHIUM PHOSPHATE

Disclosed is a thin-film solid secondary cell (1) wherein a positive electrode collector layer (20), a positive electrode active material layer (30), a solid electrolyte layer (40), a negative electrode active material layer (50) and a negative electrode collector layer (20) are arranged on a substrate (10). The positive electrode active material layer (30) is a thin film composed of a metal oxide containing a transition metal and lithium, while the negative electrode active material layer (50) is a thin film composed of a semiconductor, a metal, an alloy or a metal oxide other than vanadium oxide. At least layers other than collector layers (20) are amorphous thin films. The substance constituting the solid electrolyte layer (40) is lithium phosphate (Li3PO4) or lithium phosphate added with nitrogen (LIPON).

Owner:GEOMATEC

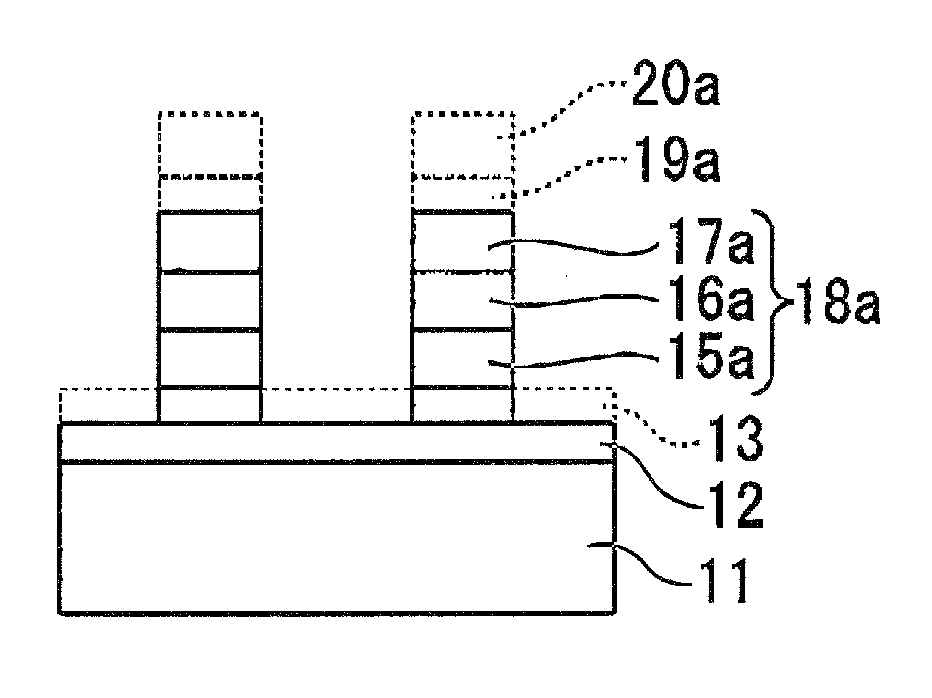

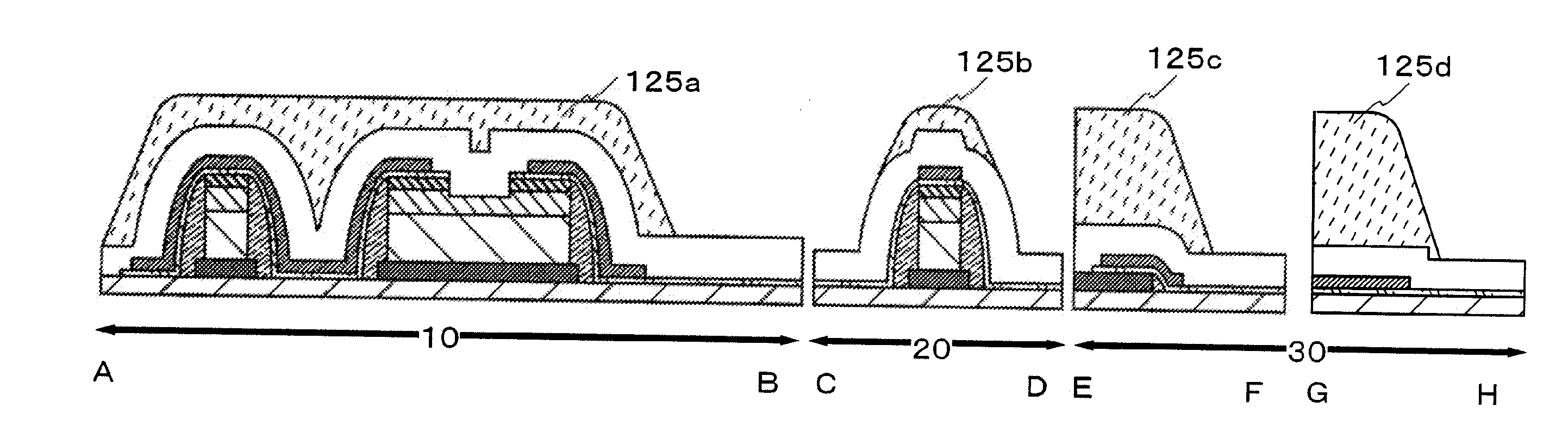

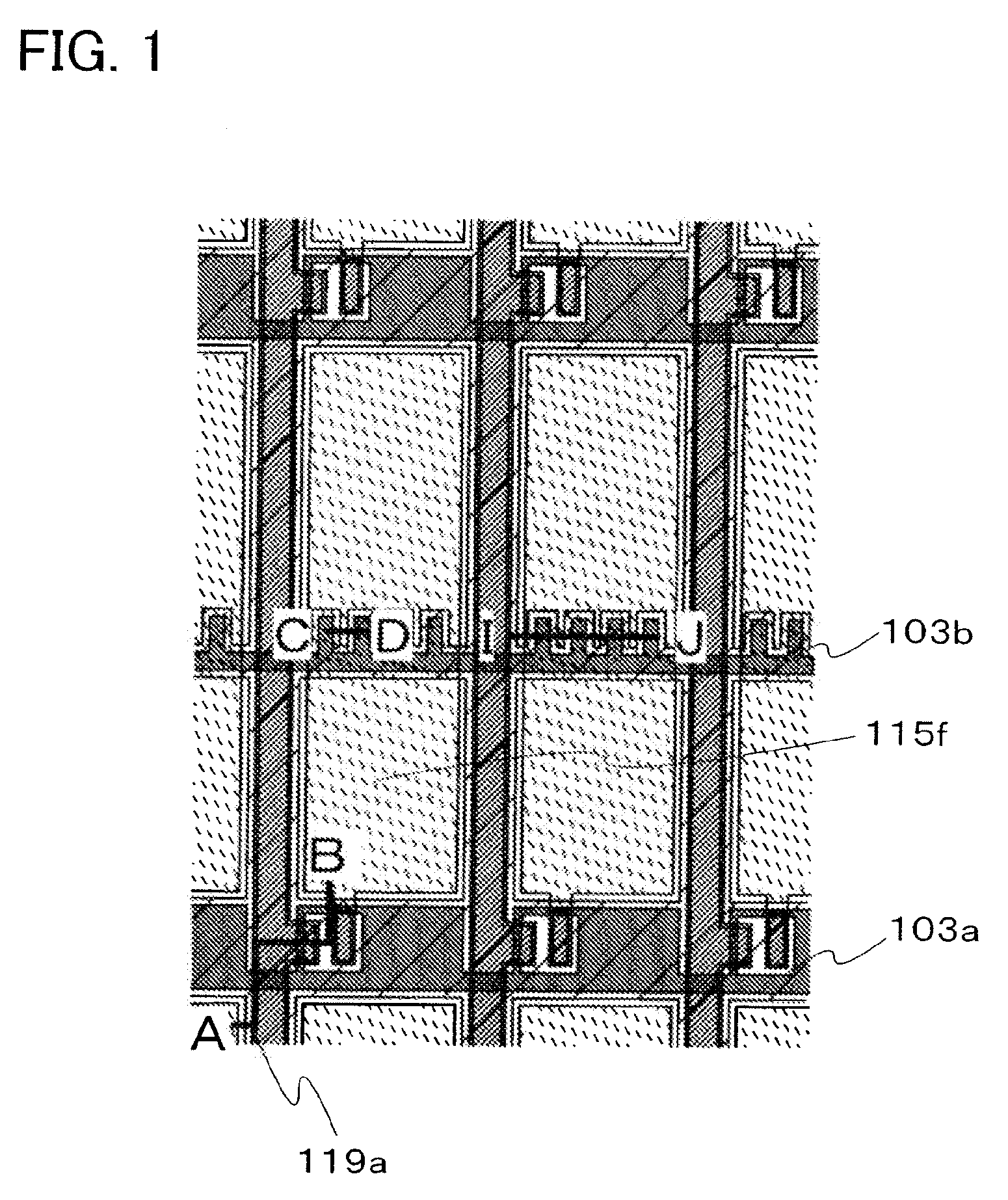

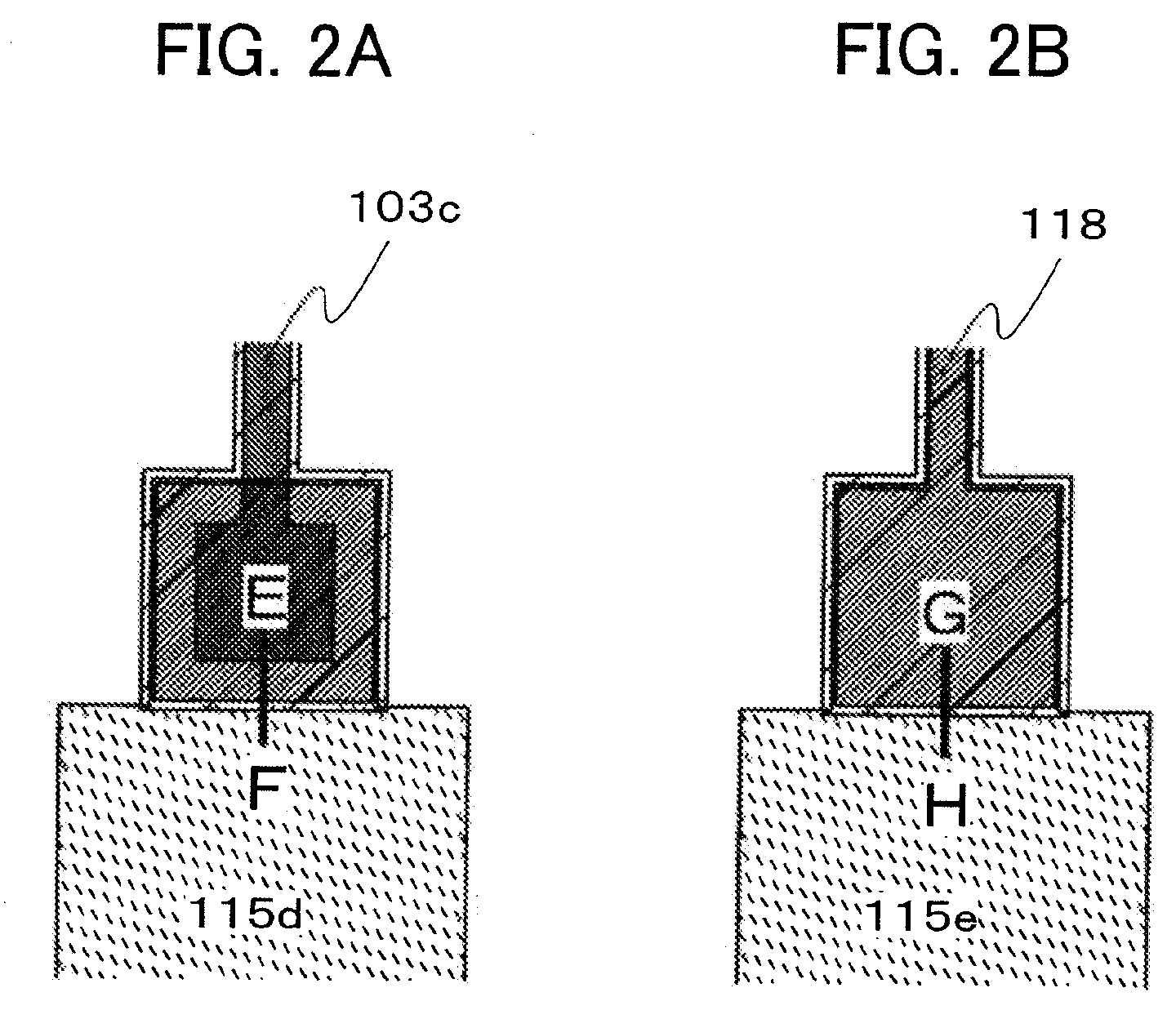

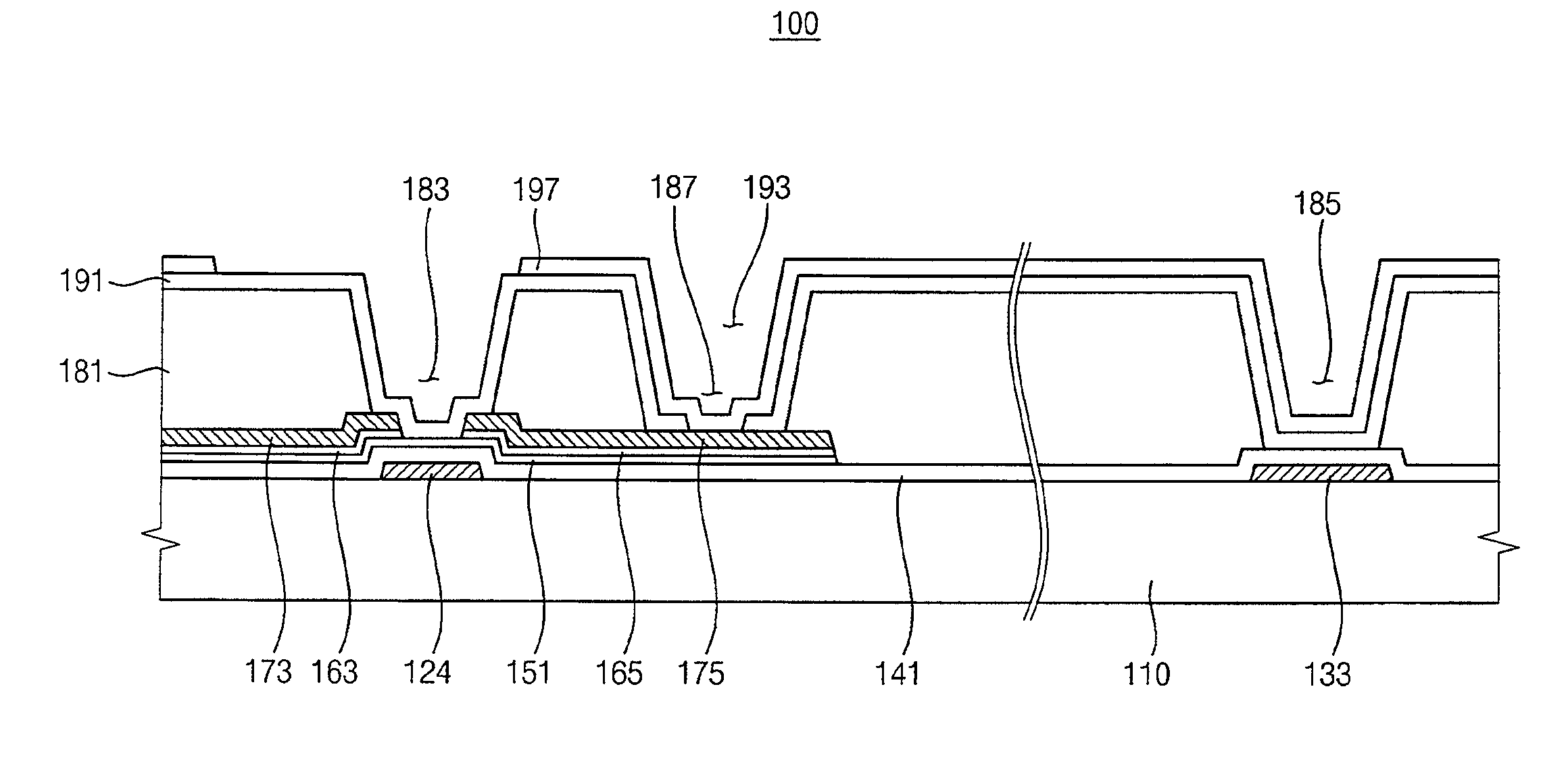

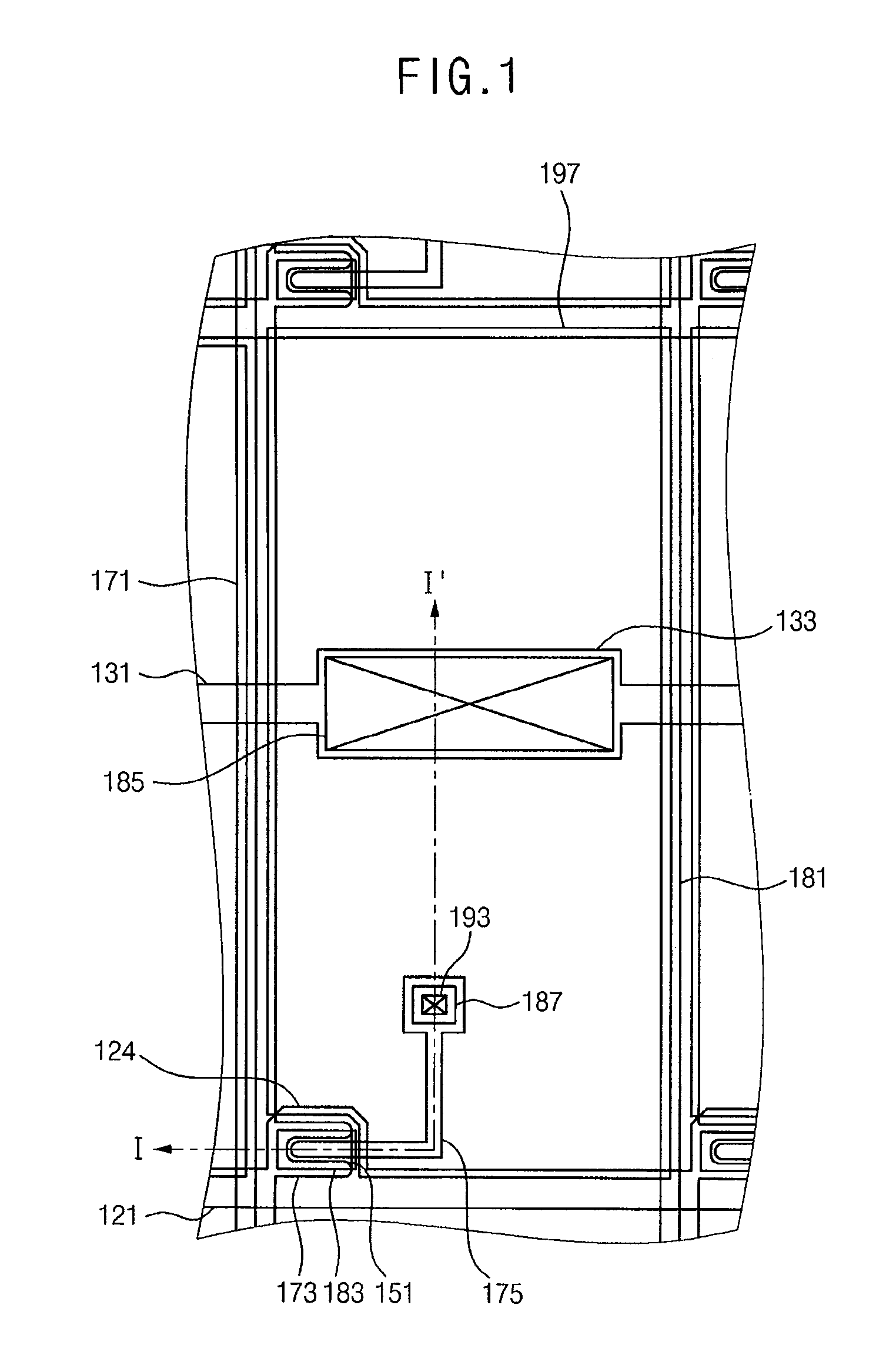

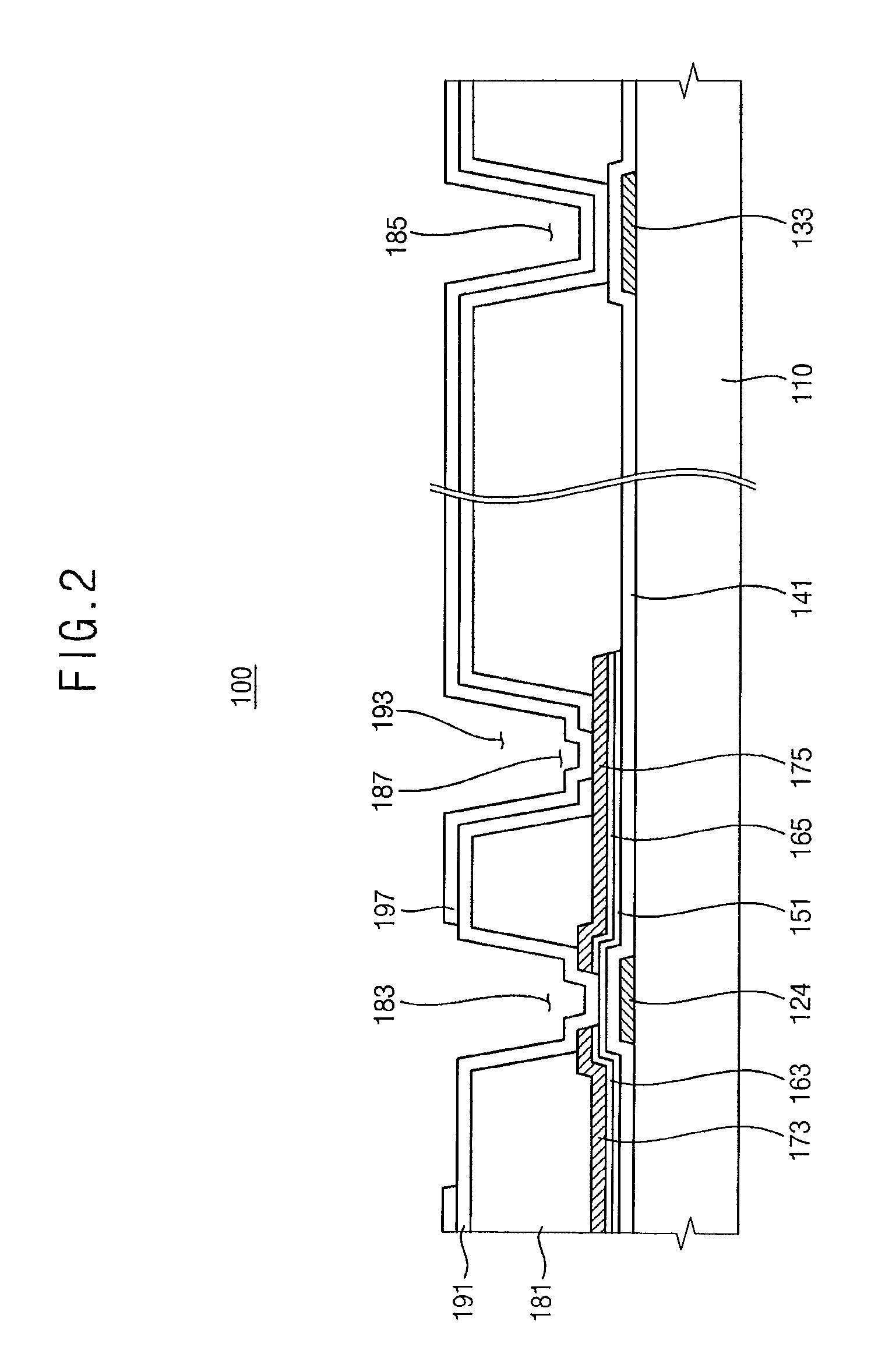

Semiconductor device and method for manufacturing semiconductor device

ActiveUS20090101906A1Shorten manufacturing timeIncrease the aperture ratioTransistorSolid-state devicesResistElectrical conductor

A first resist pattern is formed by exposure using a first multi-tone photomask, and a first conductive layer, a first insulating layer, a first semiconductor layer, and a second semiconductor layer are etched, so that an island-shaped single layer and an island-shaped stack are formed. Here, sidewalls are formed on side surfaces of the island-shaped single layer and the island-shaped stack. Further, a second resist pattern is formed by exposure using a second multi-tone photomask, and a second conductive layer and the second semiconductor layer are etched, so that a thin film transistor, a pixel electrode, and a connection terminal are formed. After that, a third resist pattern is formed by exposure from a rear side using metal layers of the first conductive layer and the second conductive layer as masks, and the third insulating layer are etched, so that a protective insulating layer is formed.

Owner:SEMICON ENERGY LAB CO LTD

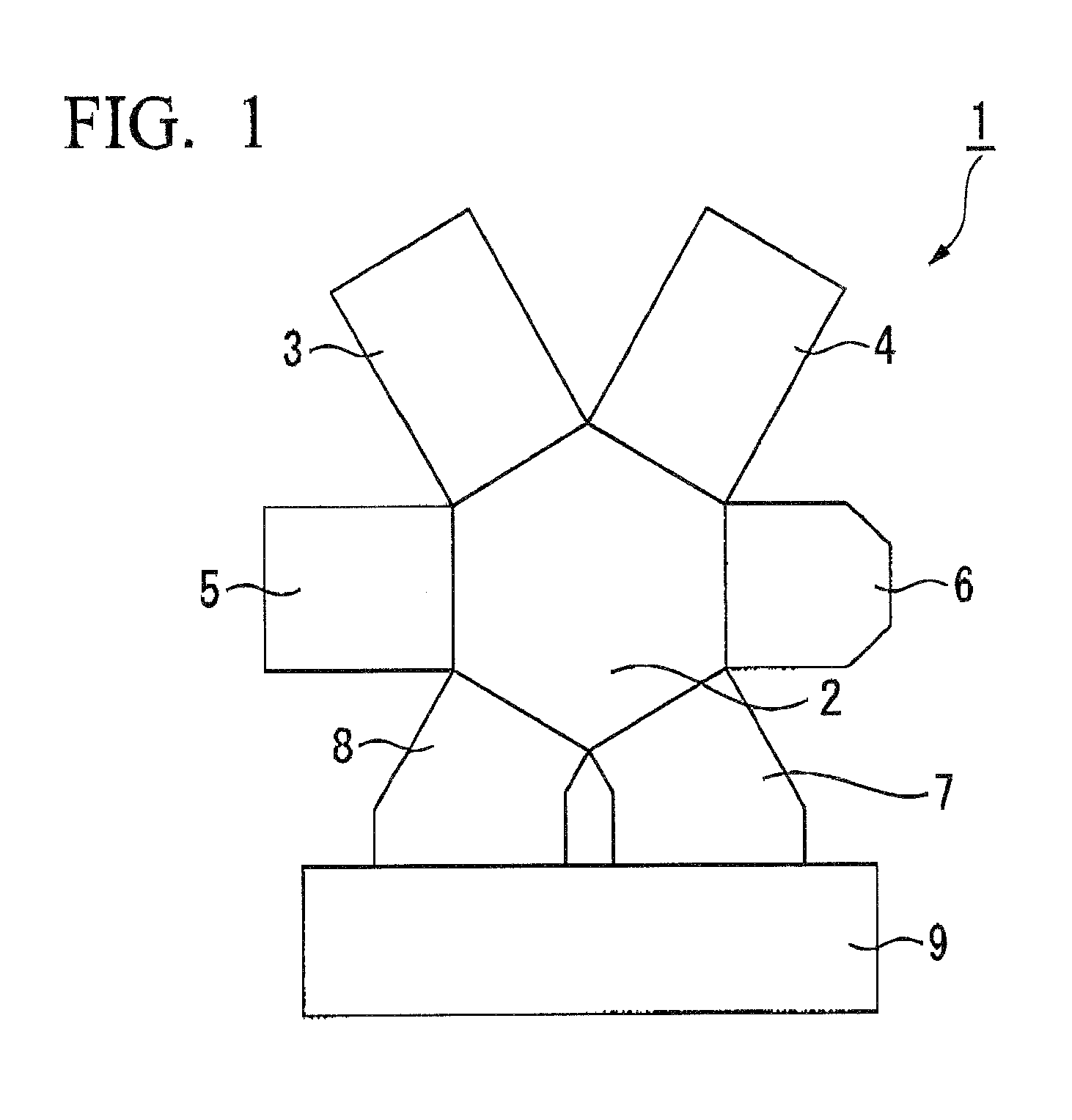

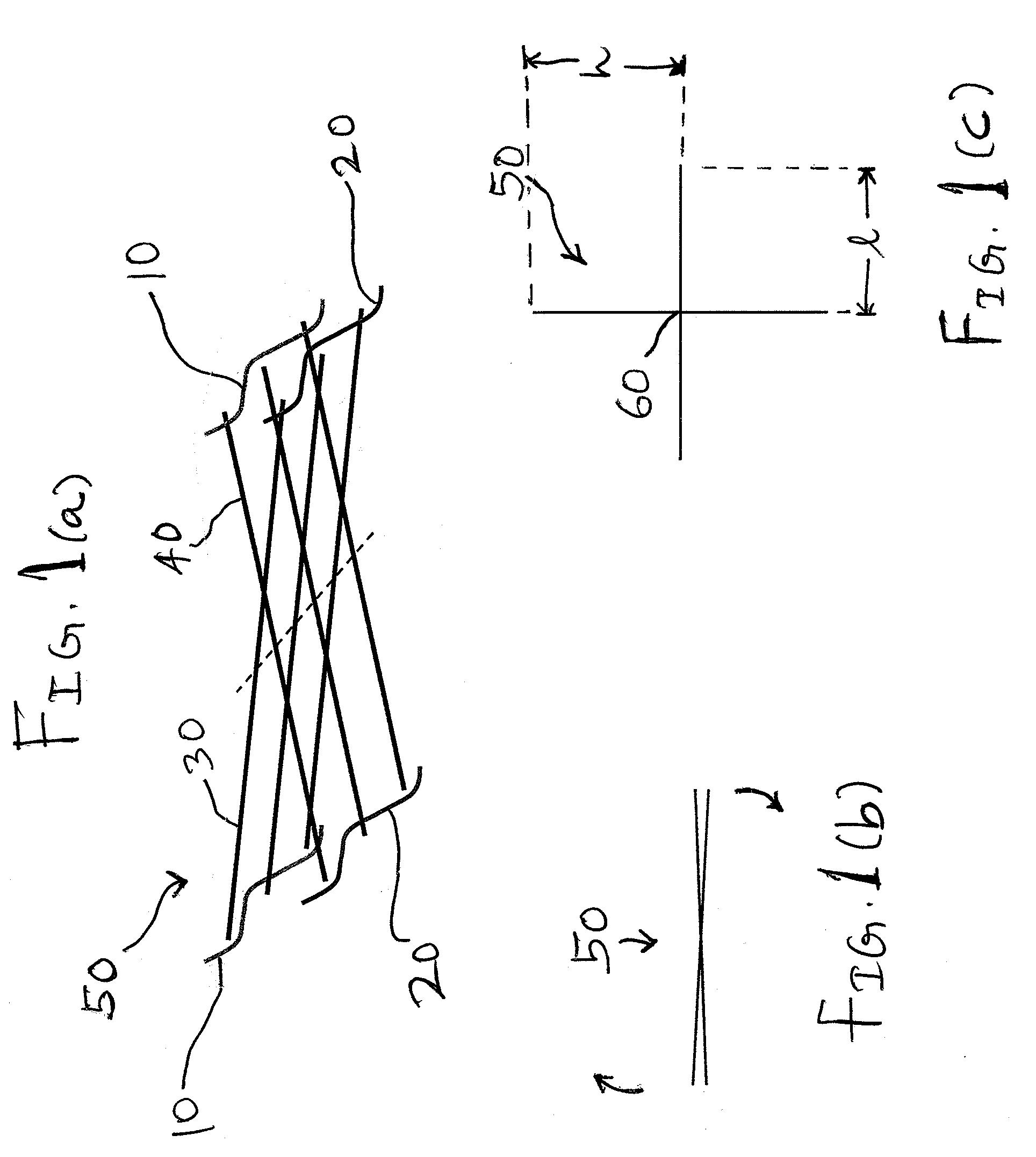

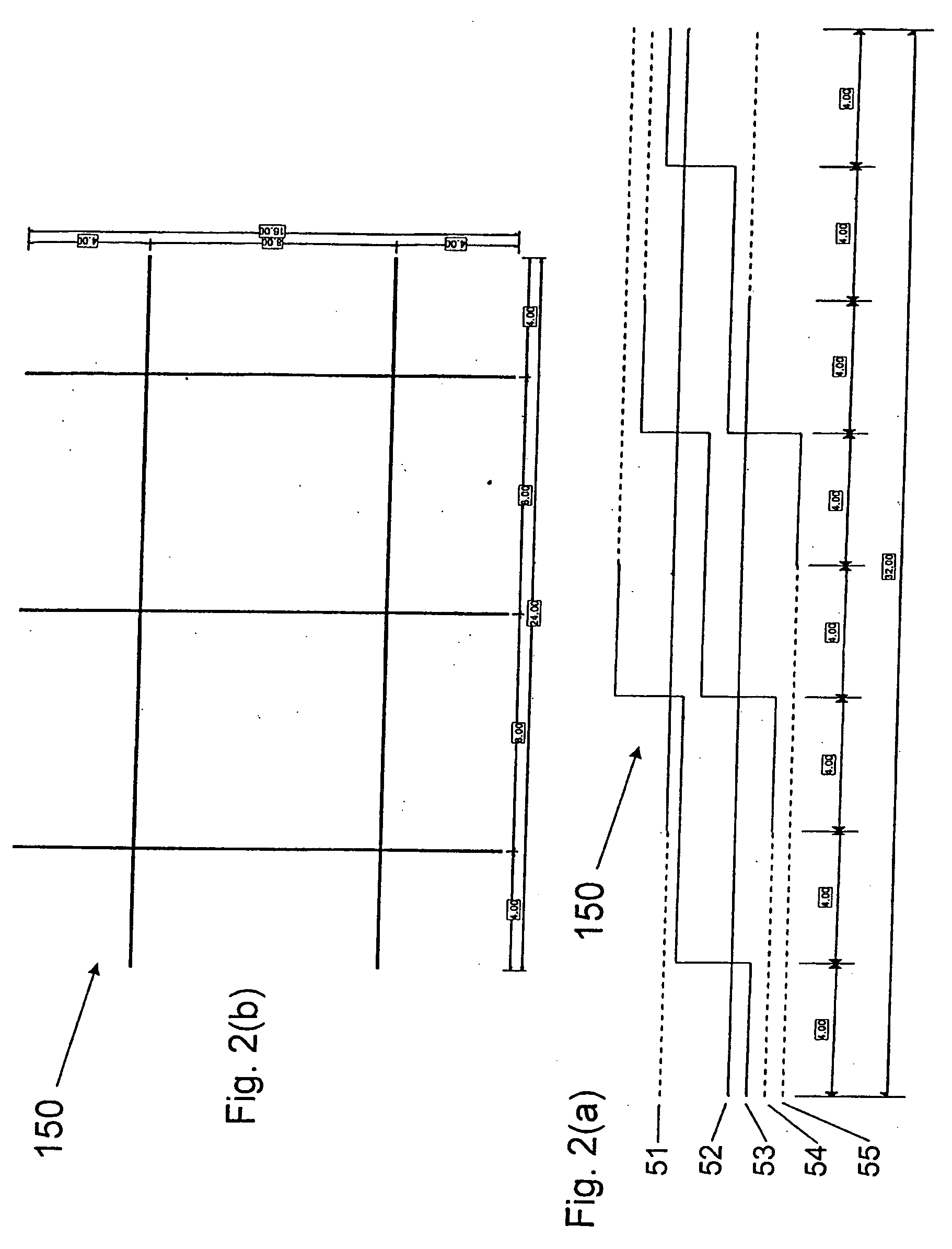

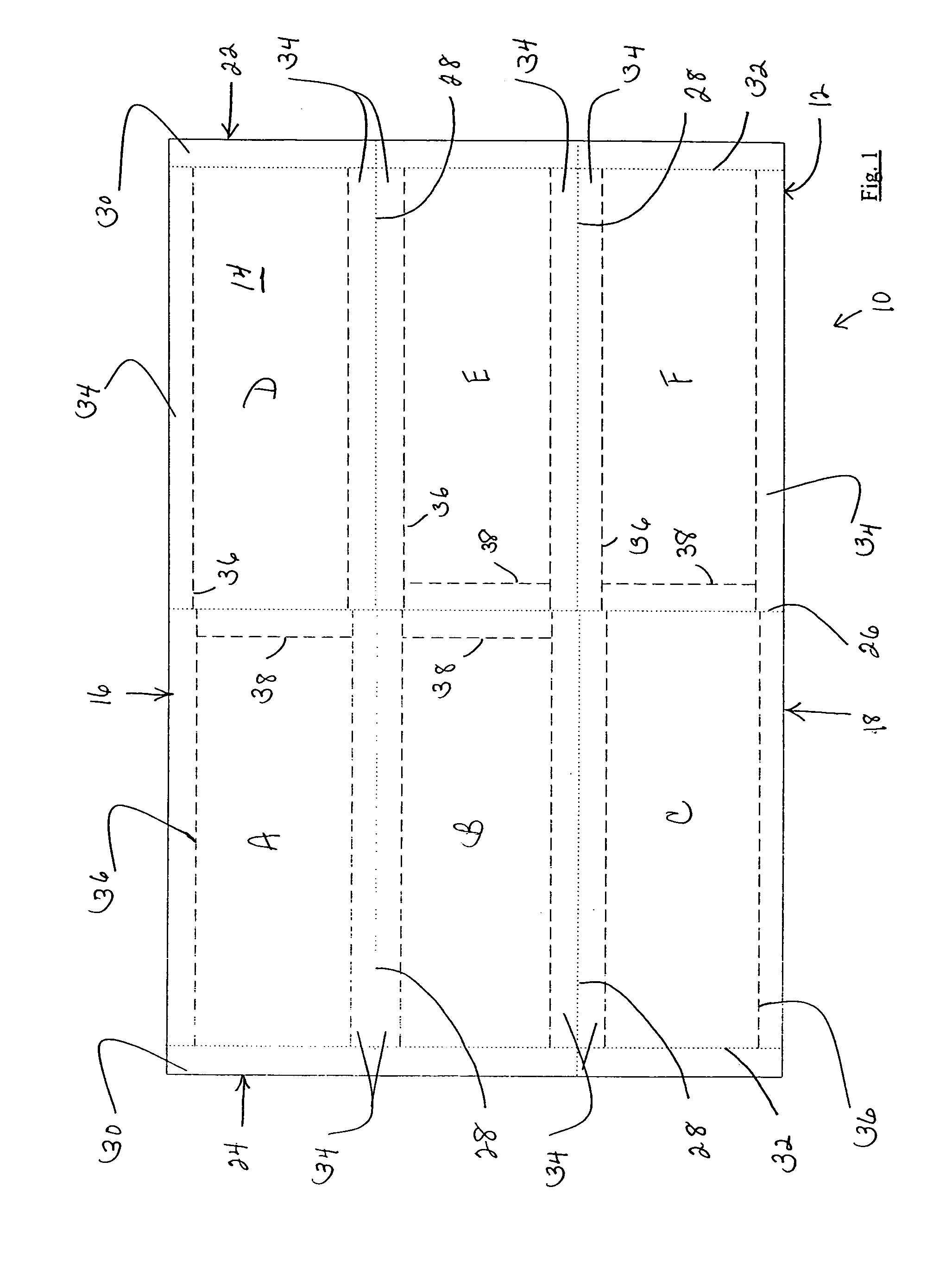

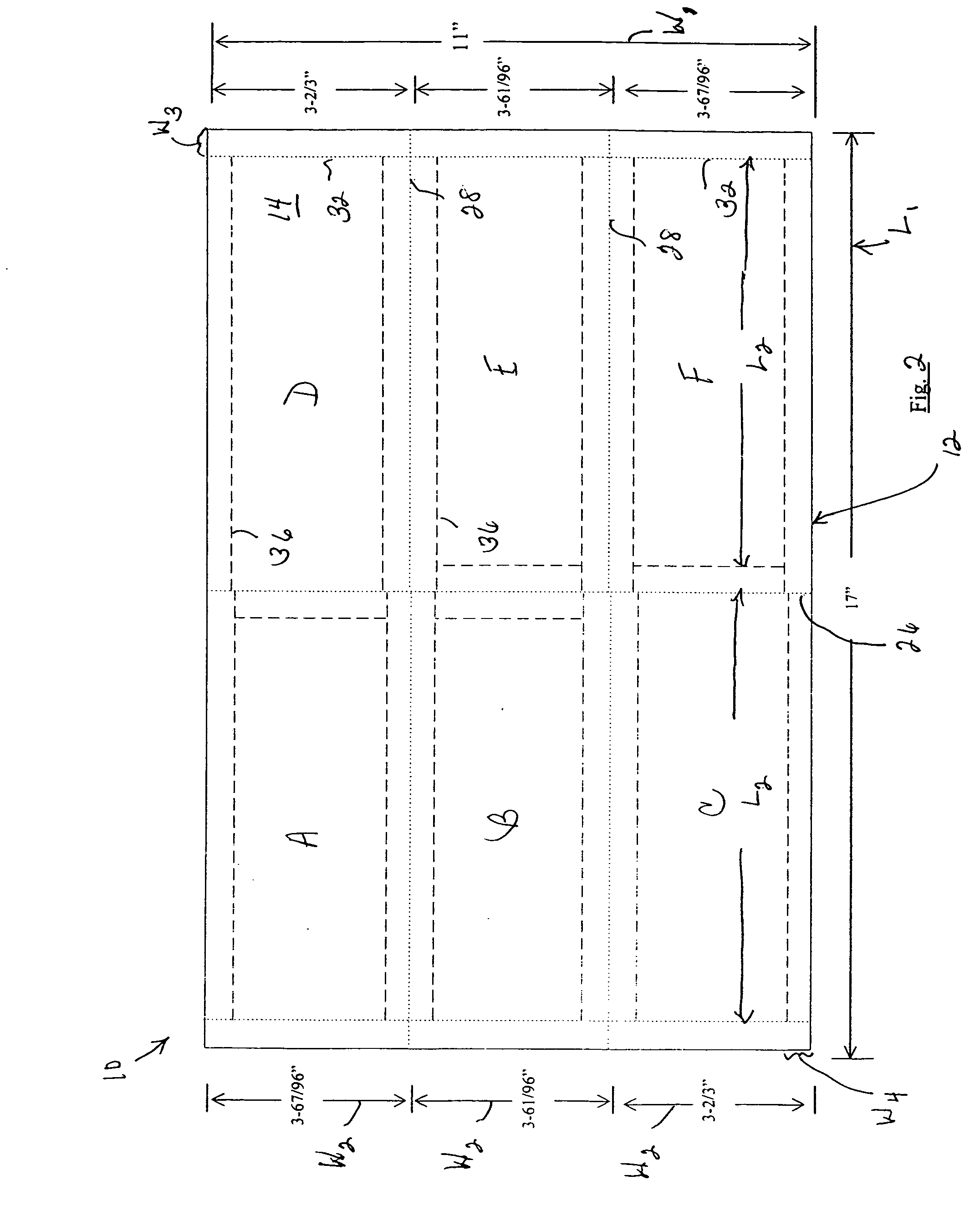

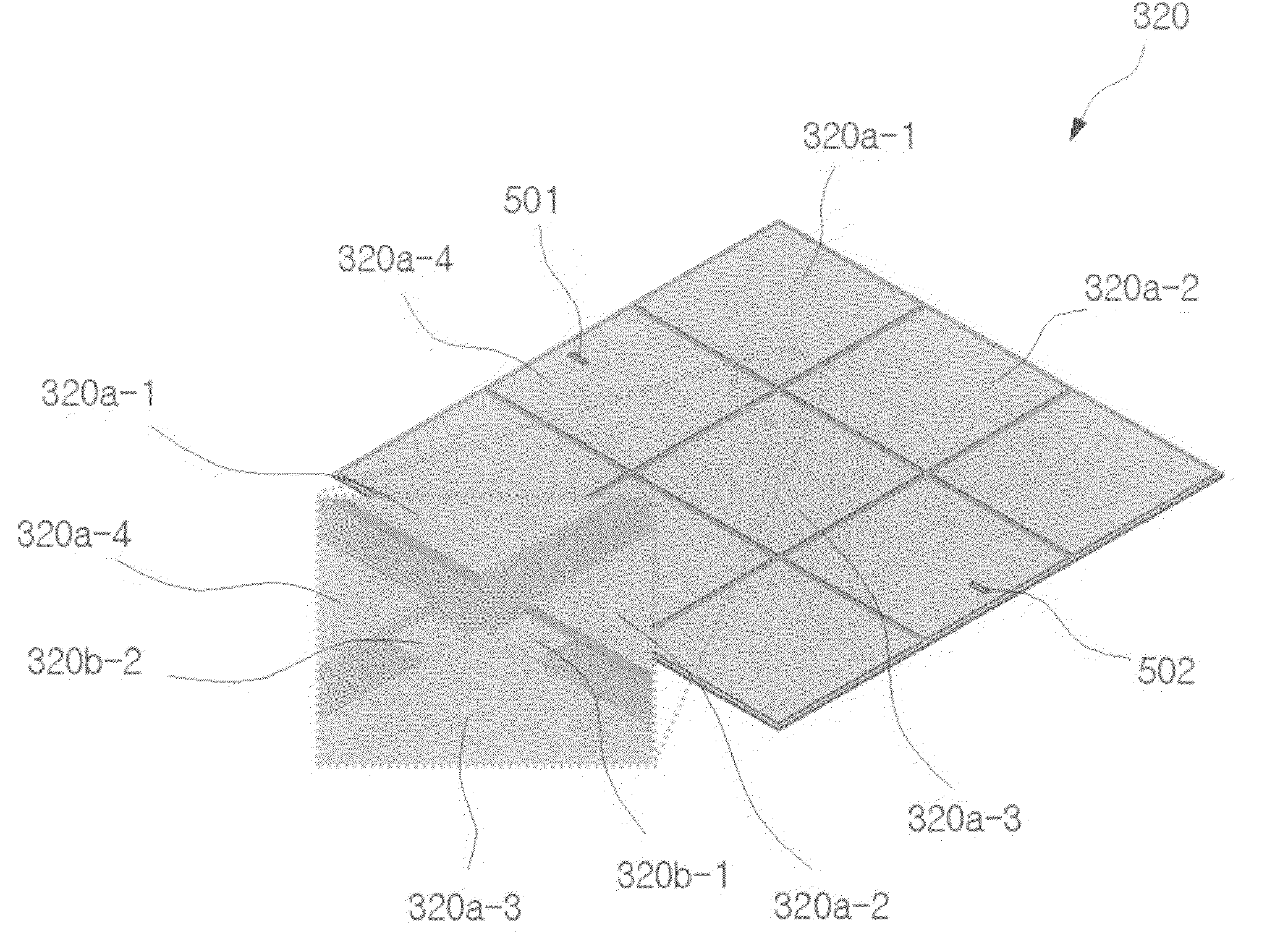

Method for Weaving Closed Structures with Intersecting Walls

ActiveUS20090149100A1Shorten manufacturing timeLow costSmallware loomsOrnamental textile articlesShell moldingTransfer molding

The present invention generally relates to a woven preform for reinforced composite materials and a method of making thereof. Specifically, the present invention is a method of machine weaving fiber preforms for polymer matrix composites that consist of closed perimeters with multiple intersecting members in their interiors. More specifically, the invention is a woven preform and a method of forming thereof with closed cells at the outer edges with continuous hoop reinforcement in each cell of the preform. The woven preform is woven flat in both the warp and weft directions, and then unfolded to achieve the final shape of the structure, and can be processed into composite structural components using known methods such as resin transfer molding or chemical vapor infiltration. Thus, complicated shapes of all sizes can be woven on a conventional loom using the instant method.

Owner:ALBANY ENGINEERED COMPOSITES

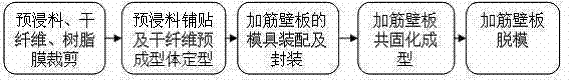

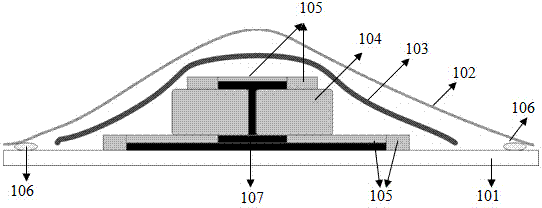

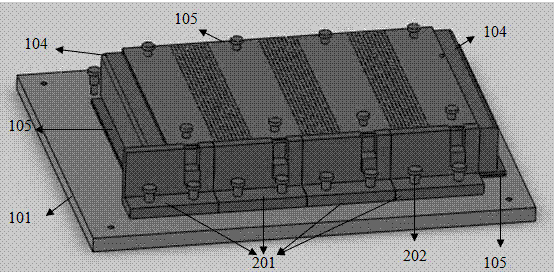

Prepreg/resin film infiltration co-curing forming method for composite stiffened wallboards

The invention discloses a prepreg / resin film infiltration co-curing forming method for composite stiffened wallboards. The method comprises the following steps: 1, tailoring prepregs, dry fibers and resin films; 2, spreading the prepregs and sizing dry fiber preforms; 3, assembling and packaging a mould for the stiffened wallboards; 4, co-curing and forming the stiffened wallboards; and 5, demolding the stiffened wallboards. According to the method, a skin is prepared by adopting prepreg spreading, ribs are prepared by the dry fiber preforms and the resin films, and in combination with the characteristics of a prepreg autoclave process and a resin film melting process, the ribs, the skin and the adhesive interface of the ribs and the skin are cured in an autoclave at the same time, thus realizing the co-curing forming of the stiffened wallboards with different rib forms and different material systems. The method can significantly improve the forming efficiency of the stiffened wallboard structure, reduce the manufacture cost, improve the quality of products and improve the flexibility and designability of the manufacturing process and is of great significance to the efficient low-cost manufacture of the composite material stiffened wallboard structure.

Owner:SHANGHAI AIRCRAFT MFG +1

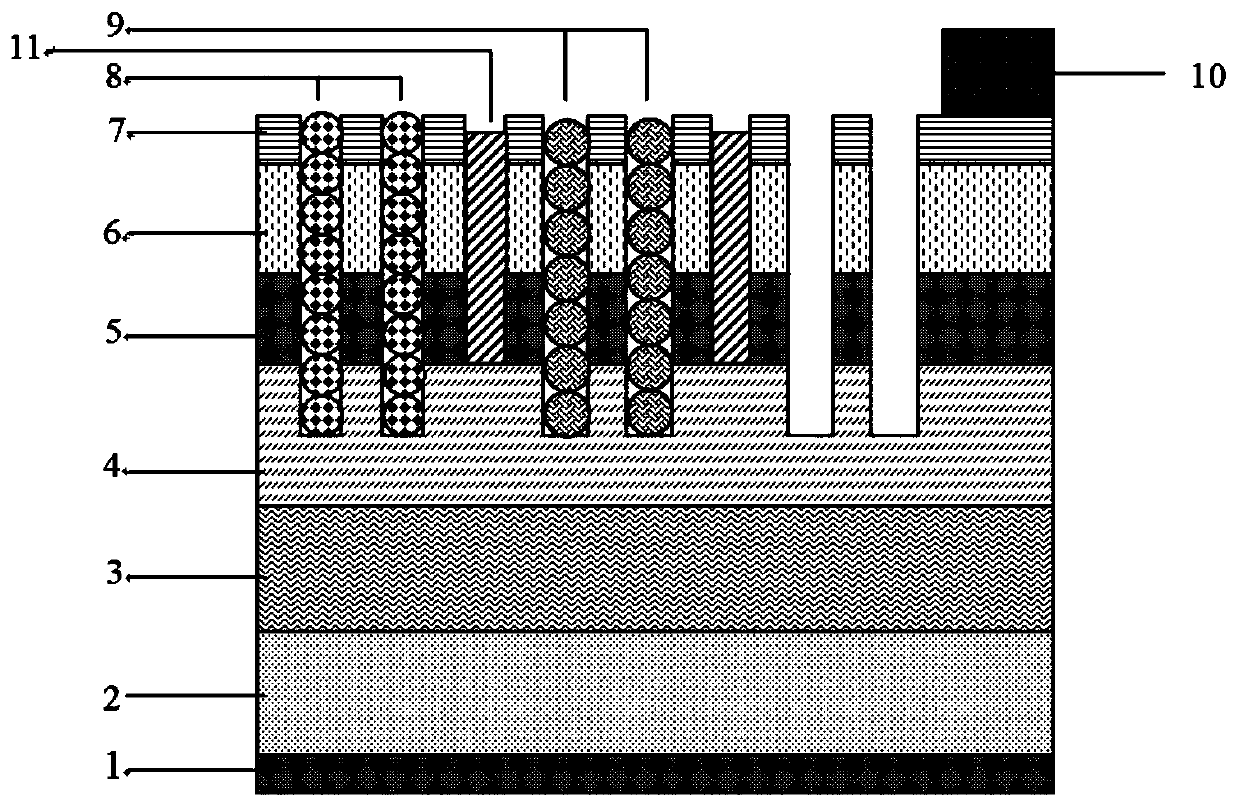

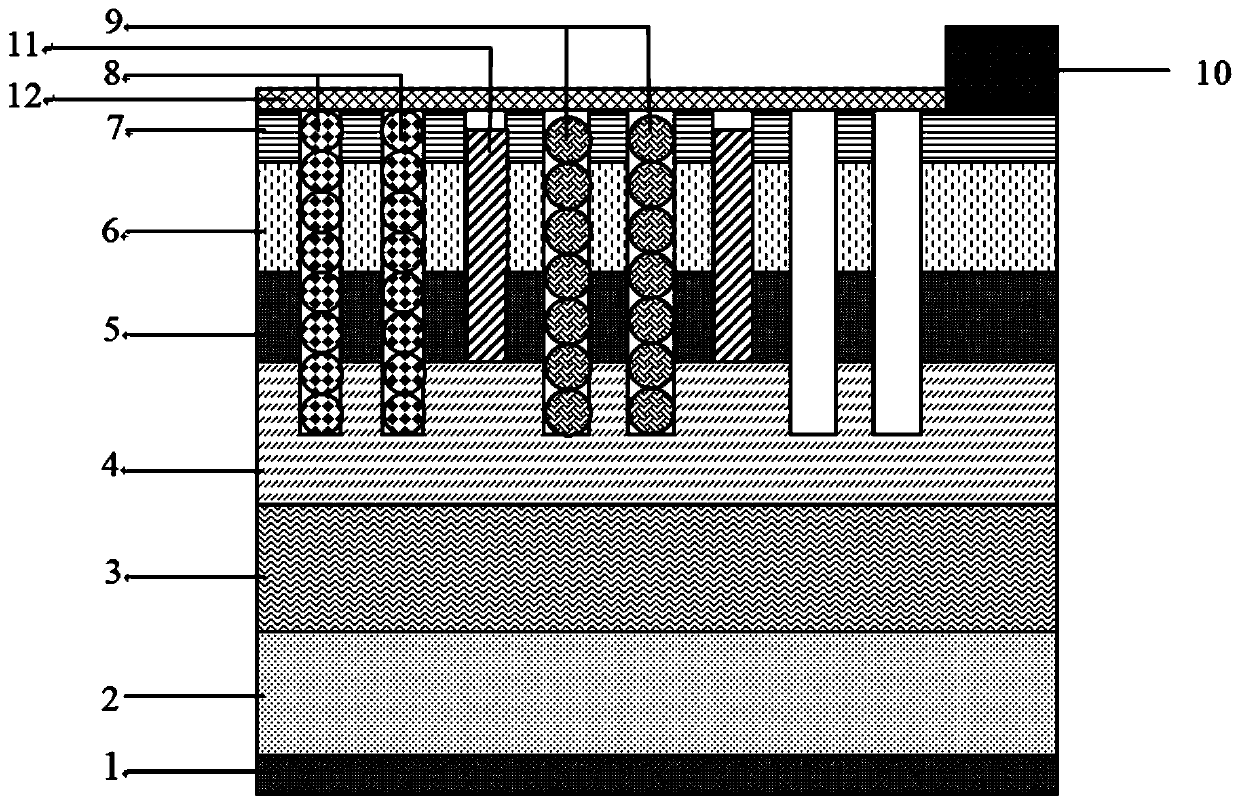

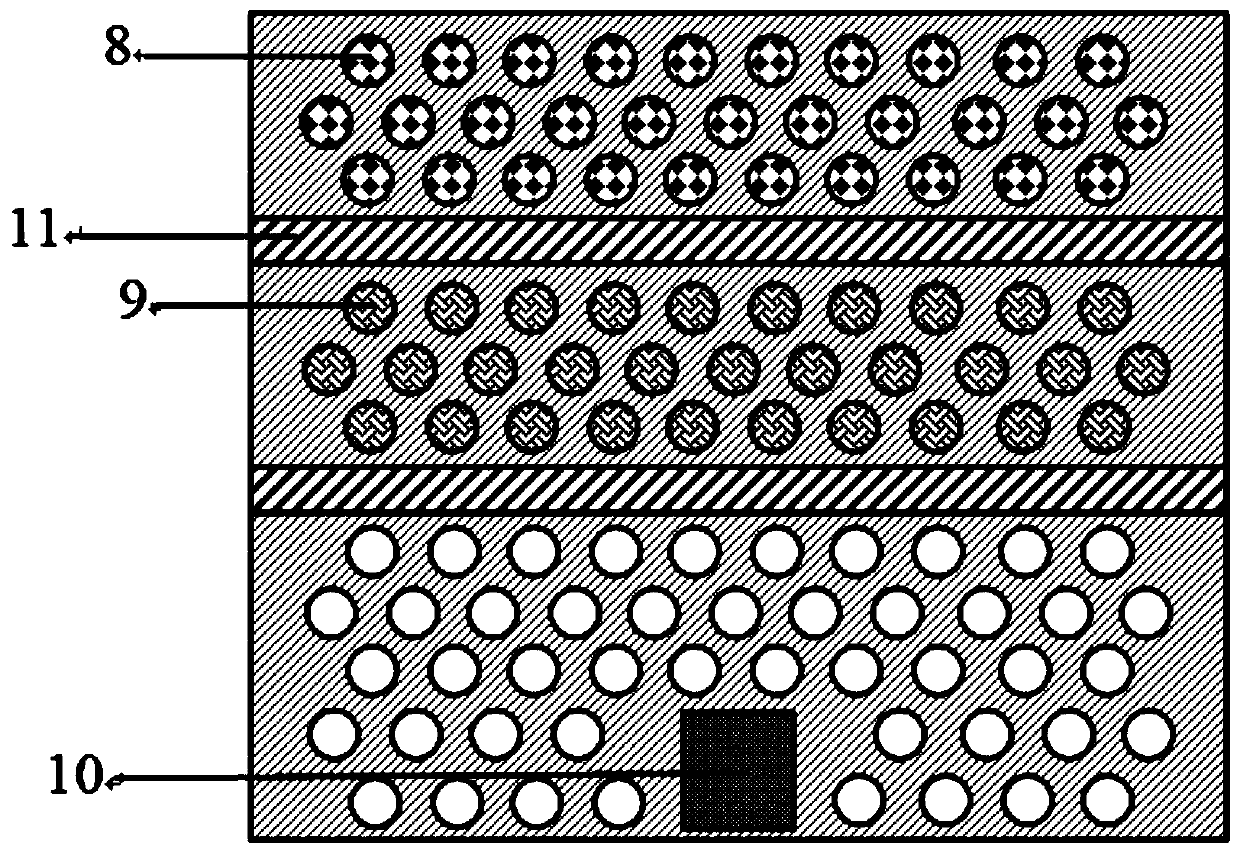

Panchromatic micrometer LED display chip based ona gallium nitride nanopore array/quantum dot composite structure and preparation method thereof

ActiveCN110112172AShorten manufacturing timeImprove manufacturing efficiencyMaterial nanotechnologySolid-state devicesHigh contrastNanopore

The invention discloses a panchromatic micrometer LED display chip based on a gallium nitride nanopore array / quantum dot composite structure. On the GaN blue-light LED epitaxial layer of a silicon substrate, an array rectangular mesa structure penetrating through a p-type GaN layer and a quantum well active layer to a n-type GaN layer is disposed. Each rectangular mesa structure constitutes one RGB pixel unit. In each rectangular pixel unit, a red-light rectangular sub-pixel region, a green-light rectangular sub-pixel region and a blue-light rectangular sub-pixel region are included. The adjacent sub-pixel regions are isolated by an isolation trench. Each sub-pixel region is provided with a nanopore array structure and is filled with red and green quantum dots. Panchromatic display is realized by quantum dot color conversion. A preparation method of the panchromatic micrometer LED display chip is also disclosed. The panchromatic micrometer LED display chip utilizes a nanopore structureto improve the stability and lifetime of the quantum dots, and utilizes the energy resonance transfer between quantum dots to improve the internal quantum efficiency and color conversion efficiency,and achieve panchromatic display with high resolution, high color gamut, and high contrast.

Owner:NANJING UNIV

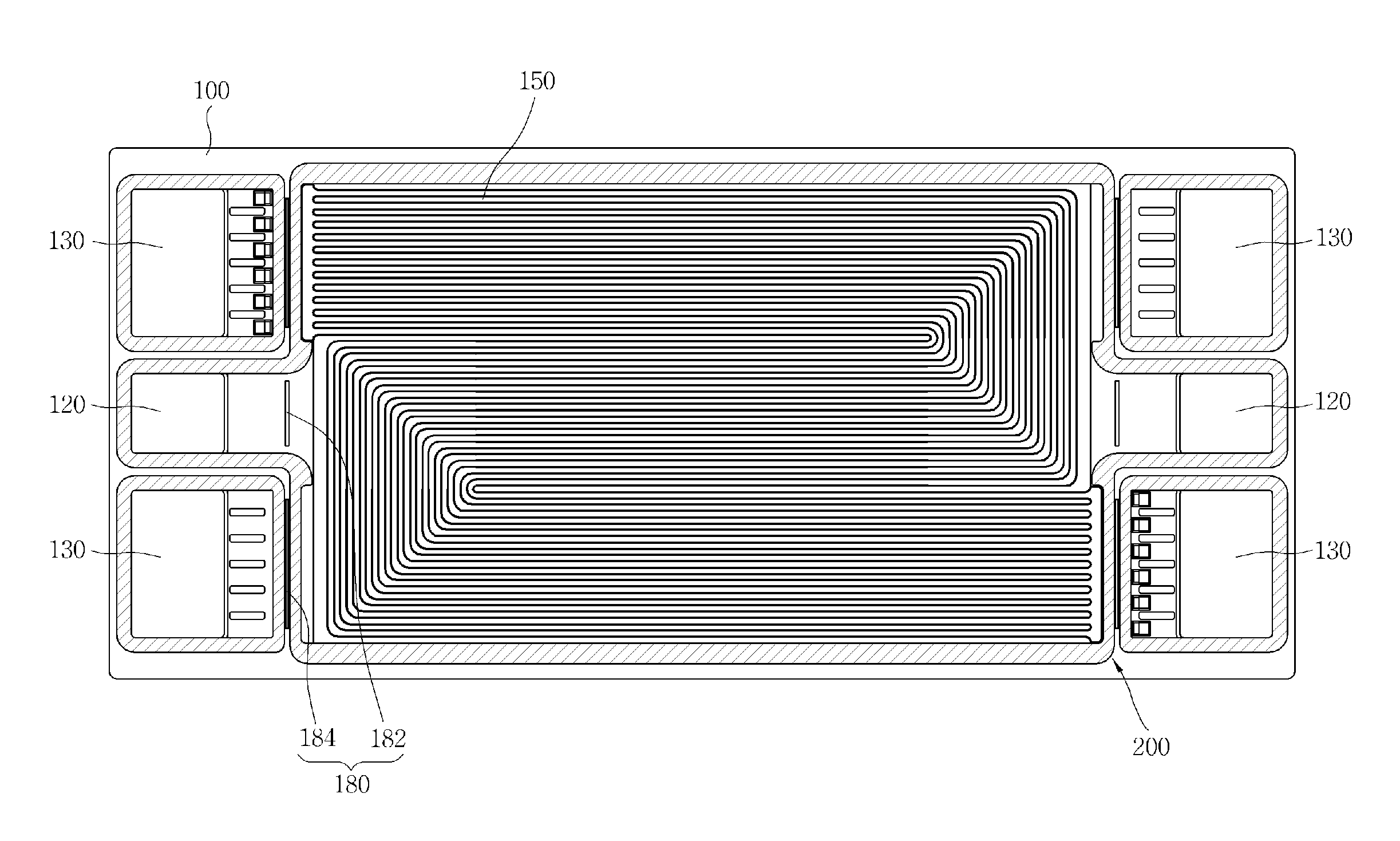

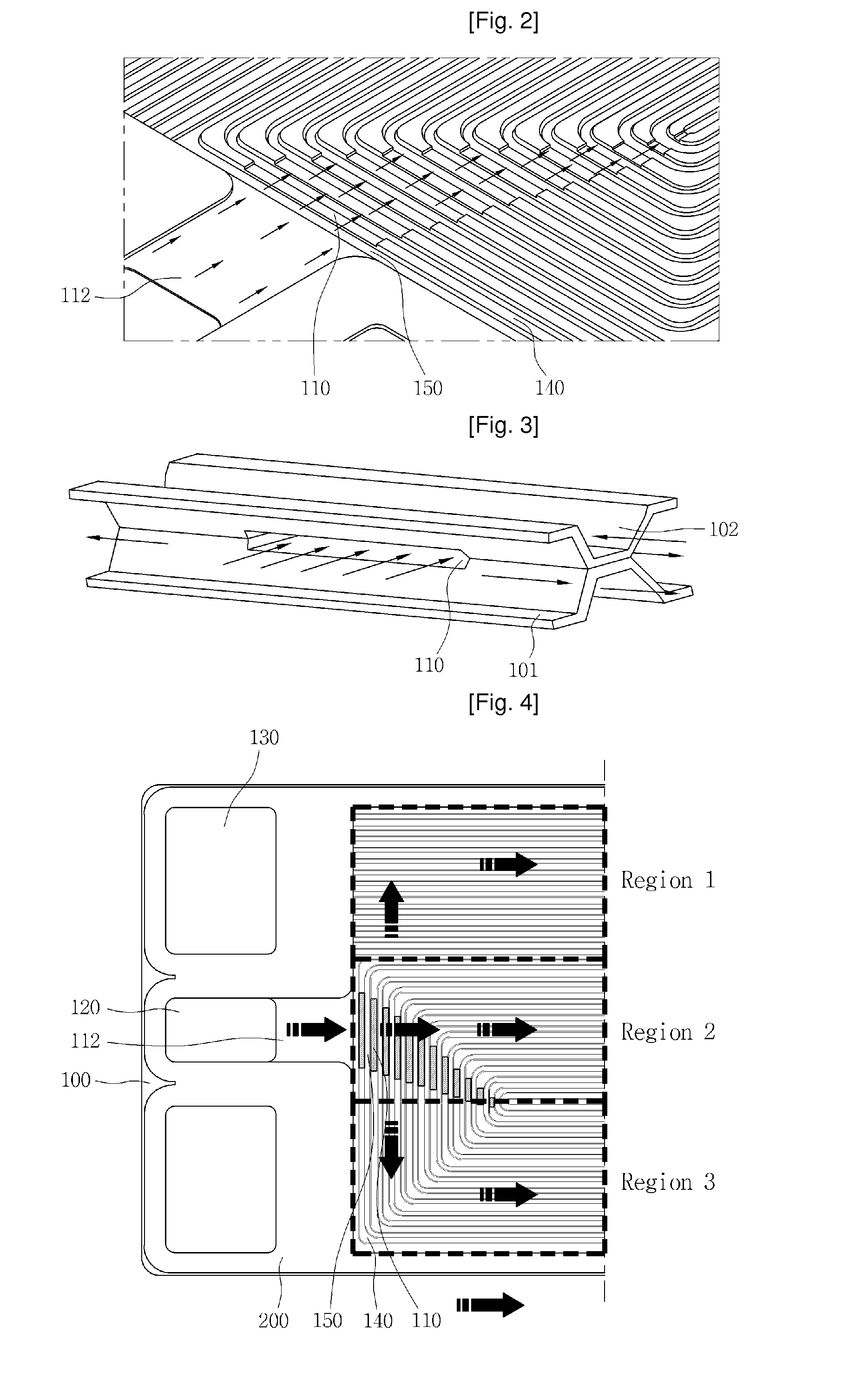

Metal separator for fuel cell and fuel cell stack having the same

ActiveUS20100028742A1Improve cooling effectShorten manufacturing timeFuel cells groupingFinal product manufactureFuel cellsCoolant flow

The present invention discloses a metal separator for a fuel cell including a reaction gas channel formed to protrude from a first face of the metal separator to a second face thereof, a coolant channel formed between the reaction gas channels protruding from the second face of the metal separator, a reaction gas manifold opened to introduce a reaction gas into the metal separator, a coolant manifold opened to introduce a coolant into the metal separator, and a stepped portion positioned at any one of the space between the reaction gas channel and the reaction gas manifold, and the reaction gas channel. This configuration serves to widen the reaction gas flowing portion and the coolant flowing portion on the metal separator, and prevent deformation of the reaction gas flowing portion and the coolant flowing portion, thereby improving efficiency of the fuel cell.

Owner:HYUNDAE STEEL CO LTD

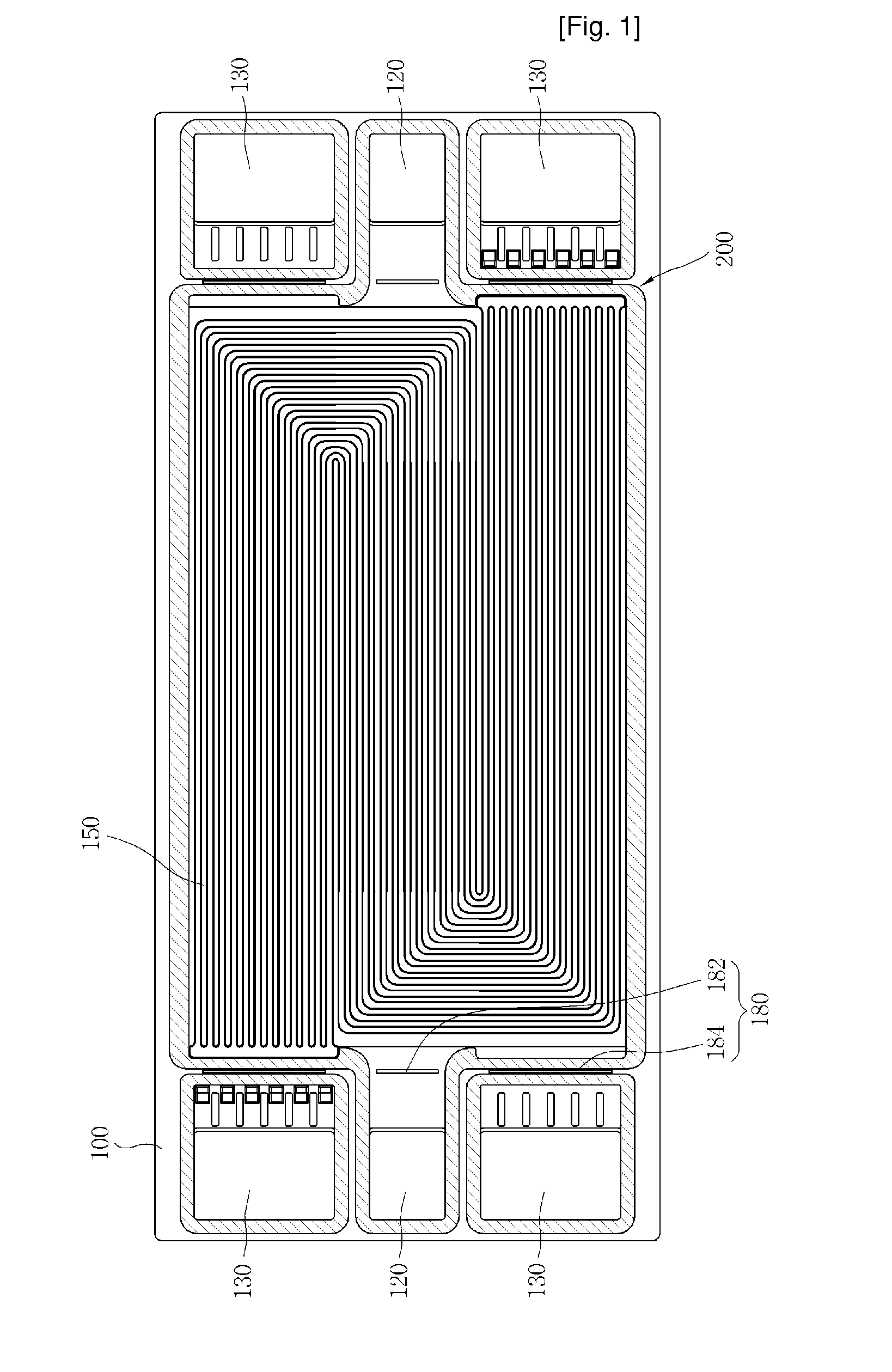

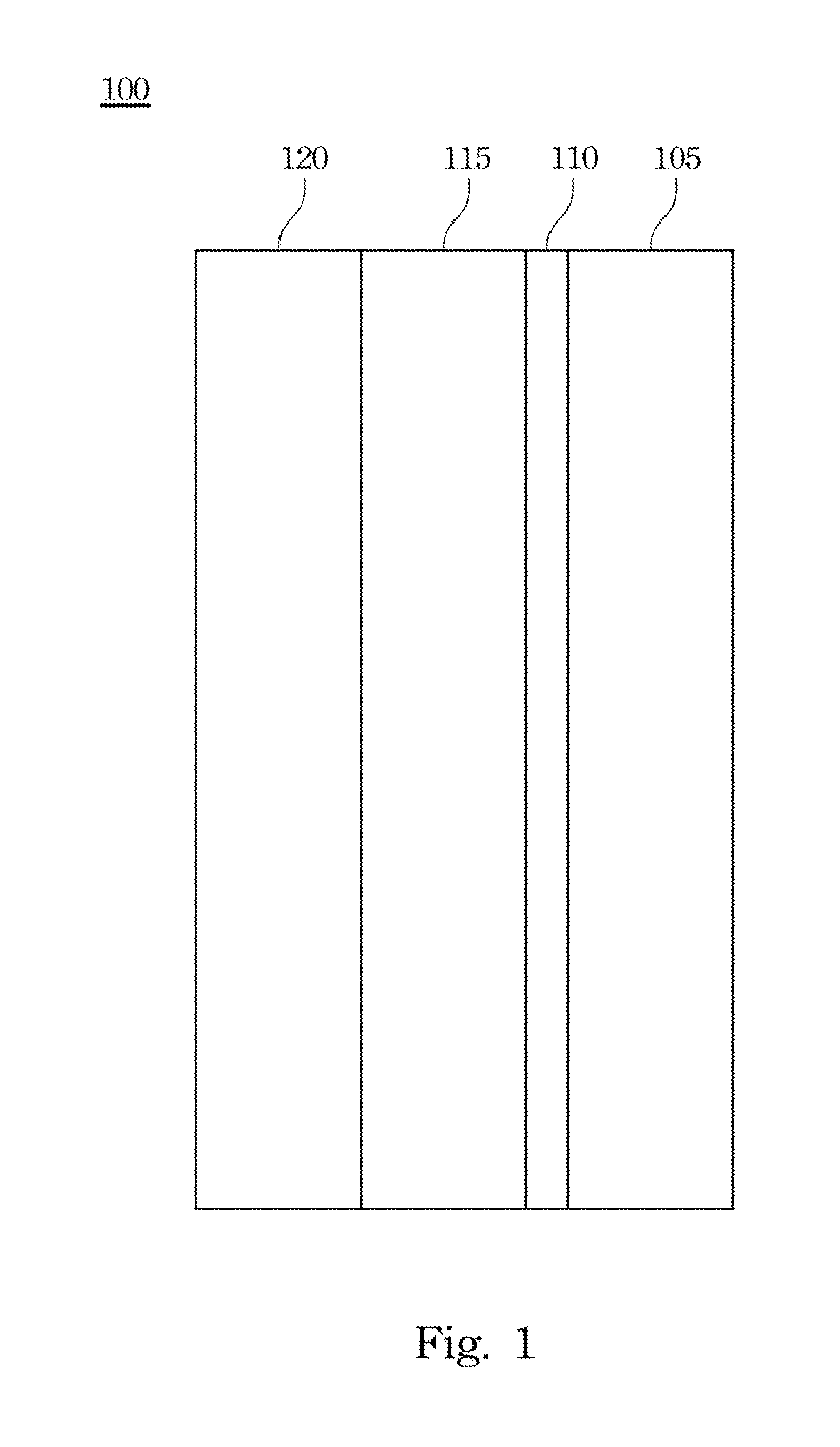

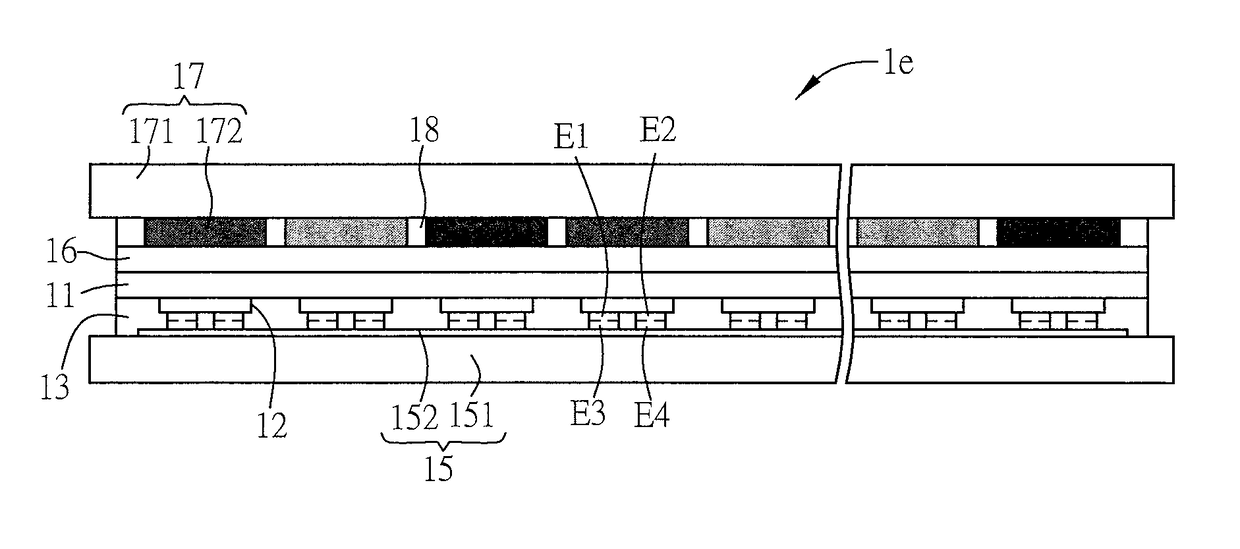

Thin-film transistor substrate, method of manufacturing the same and display apparatus having the same

ActiveUS20080042135A1Reduce display defectsAvoid impuritiesSolid-state devicesSemiconductor/solid-state device manufacturingOrganic layerSemiconductor

In a thin-film transistor (TFT) substrate, a gate insulating layer is disposed on a gate electrode electrically connected to a gate line. A semiconductor layer is disposed on the gate insulating layer. A source electrode is electrically connected to a data line that intersects the gate line. A drain electrode faces the source electrode and defines a channel area of a semiconductor layer. An organic layer is disposed on the data line and has a first opening exposing the channel area. An inorganic insulating layer is disposed on the organic layer. A pixel electrode is disposed on the inorganic insulating layer and electrically connected to the drain electrode. The inorganic insulating layer covers the first opening, and thickness of the inorganic insulating layer is substantially uniform.

Owner:SAMSUNG DISPLAY CO LTD

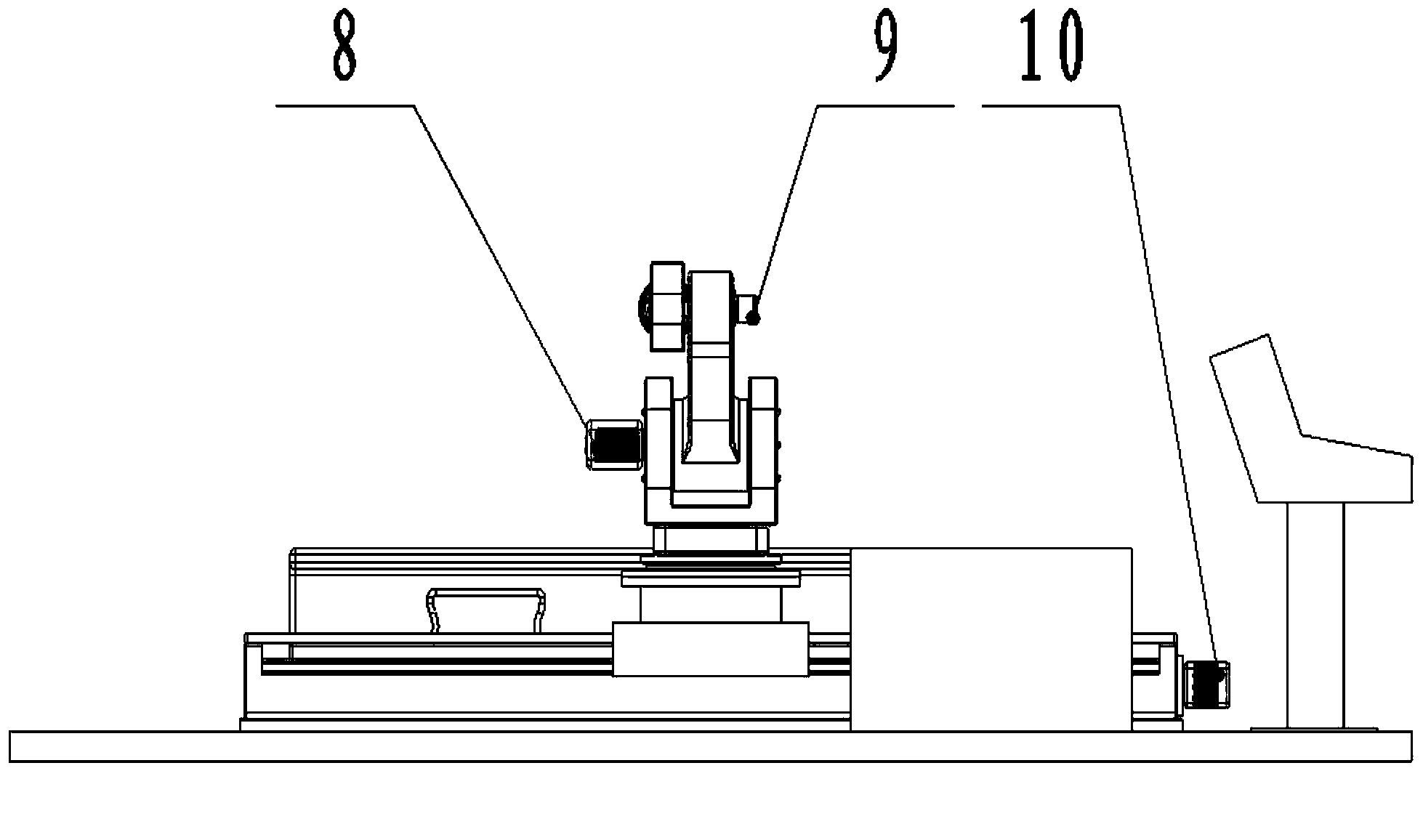

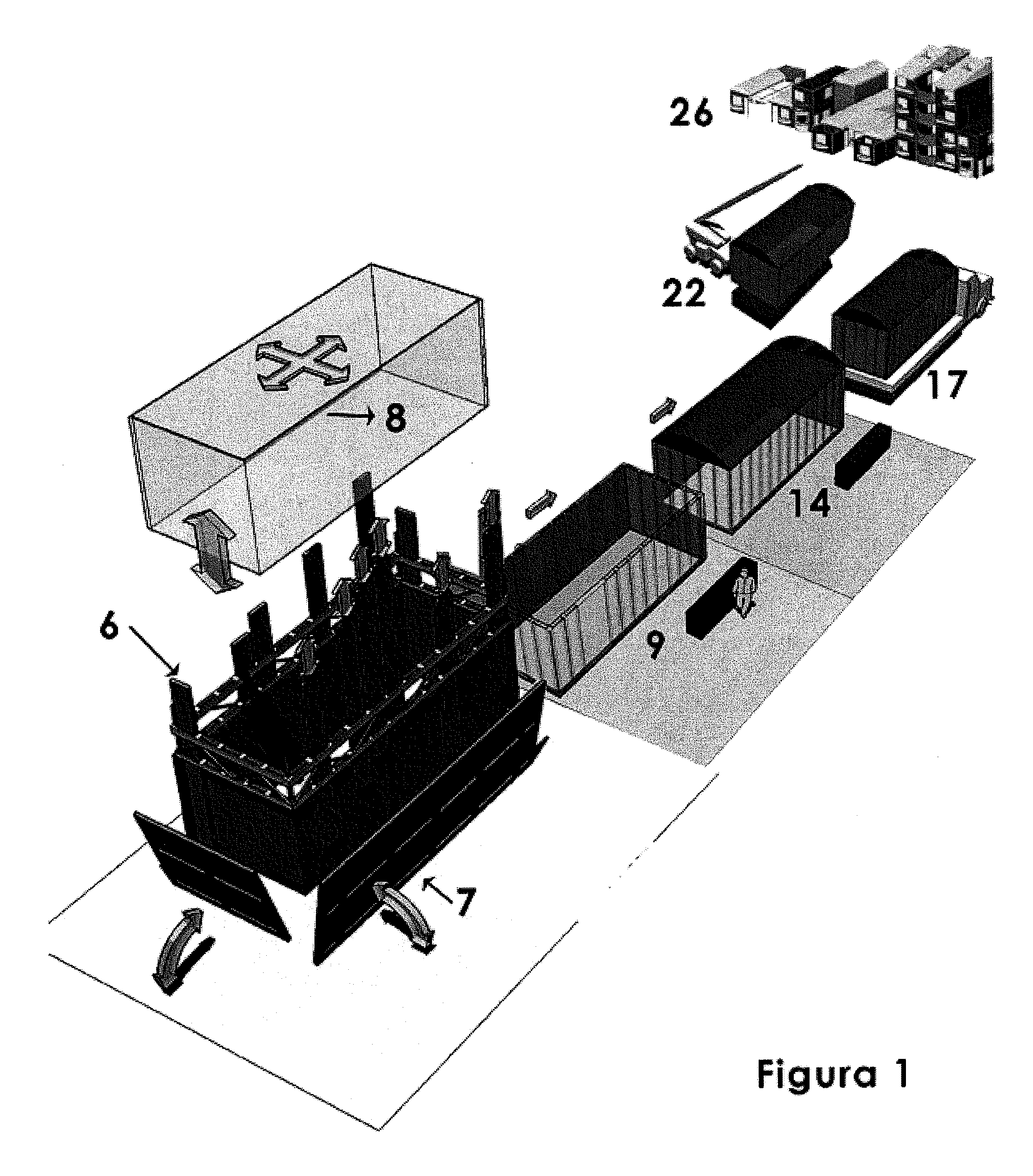

Calculus 3D (three Dimensional) constructing method and device

InactiveCN103465475ABreaking the limitations of difficult 3D manufacturingReduce difficultyData processing systemMathematical Calculus

The invention relates to a calculus 3D (three Dimensional) constructing method and device. The calculus 3D constructing method mainly comprises the steps: carrying out unit partitioning on large and complex product moulds into small limited polyhedron units by using a mathematical calculus idea, respectively manufacturing the small limited polyhedron units and storing the small limited polyhedron units in a classifying manner, combining the small limited polyhedron units into a large product by a mechanical arm action executing mechanism under the control of a data processing system, and spraying a hot melting polymer on the surfaces of the small limited polyhedron units in the forming process so as to obtain products integrated into a whole. The calculus 3D constructing device mainly comprises an engine base, the mechanical arm action executing mechanism, a multi-freedom-degree bulb connecting device, a hot melting nozzle device, a manipulator executing end and the data processing system, wherein the machine base and the mechanical arm action executing mechanism commonly form a movement main body which is capable of rotating by 360 DEG, and the mechanical arm action executing mechanism is capable of reciprocating on the machine base horizontally. By adopting the method and the device provided by the invention, the processing and manufacturing time can be greatly shortened, the processing cost is lowered, and the labor intensity of an operator is lightened.

Owner:BEIJING UNIV OF CHEM TECH

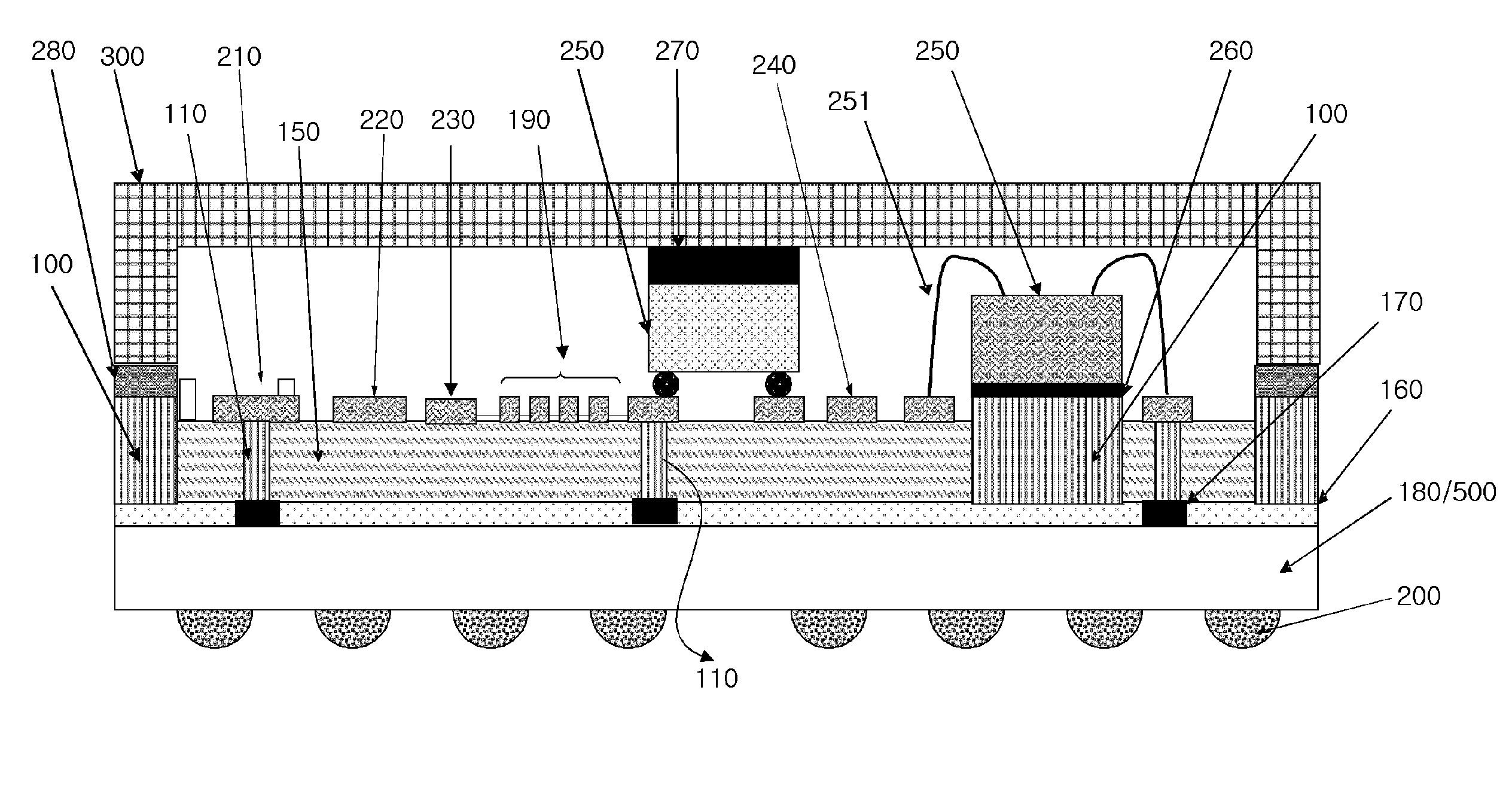

Method for Manufacturing Passive Device and Semiconductor Package Using Thin Metal Piece

InactiveUS20080194058A1Quality improvementShorten manufacturing timeSemiconductor/solid-state device detailsSolid-state devicesThin metalSurface mounting

A method for manufacturing passive devices and semiconductor packages using a thin metal piece is provided. According to the method, an adhesive layer is formed on a dummy substrate; a thin metal piece is bonded on the adhesive layer; a masking material is attached to the thin metal piece, a region where vias are to be formed is patterned, the thin metal piece is etched at a predetermined depth; the masking material is removed, the etched portion is filled with polymer to form a flat polymer layer, a masking material is attached on the polymer layer, a region that is to be attached to an IPD or an IC chip is patterned, a metal pad is formed, and the formed devices are attached to a lower substrate using the metal pad; the adhesive layer and the dummy substrate are removed, a masking material is attached on a surface exposed, a region where passive devices are to be formed is patterned, and the thin metal piece is etched at a predetermined depth; and solder bumps for surface mounting are formed.

Owner:WAVENICS +1

Integrated preparing method for molten carbonate fuel cell electrolyte membrane

InactiveCN101071872ALow manufacturing costShorten manufacturing timeElectrolyte holding meansFinal product manufactureSolventPlasticizer

A fuses the carbonate fuel cell electrolyte membrane integrated preparation method, belongs to the field of fuel cell technology, that is as follows: use sub-micro-grade alpha-LiAlO2 powder or gamma -LiAlO2 powder as raw material, take water as solvent, after the ball grinding dispersion, add electrolyte salt, continue ball grinding mix, again add Al2O3 fiber, ball grinding mix to form a pulp containing substrate diaphragm material and the electrolyte saltm, directly spread this pulp on the double pole plate fitted with electrode, dry to obtain a fused carbonate fuel cell electrolyte membrane. As the pulp contains no dispersant, binder and plasticizer, the height of cell pile assembled under room temperature and the height of cell pile at working temperature will not change. In the course of preparation and primary operation, it dose not discharge organic solvent and waste gases.

Owner:SHANGHAI JIAO TONG UNIV

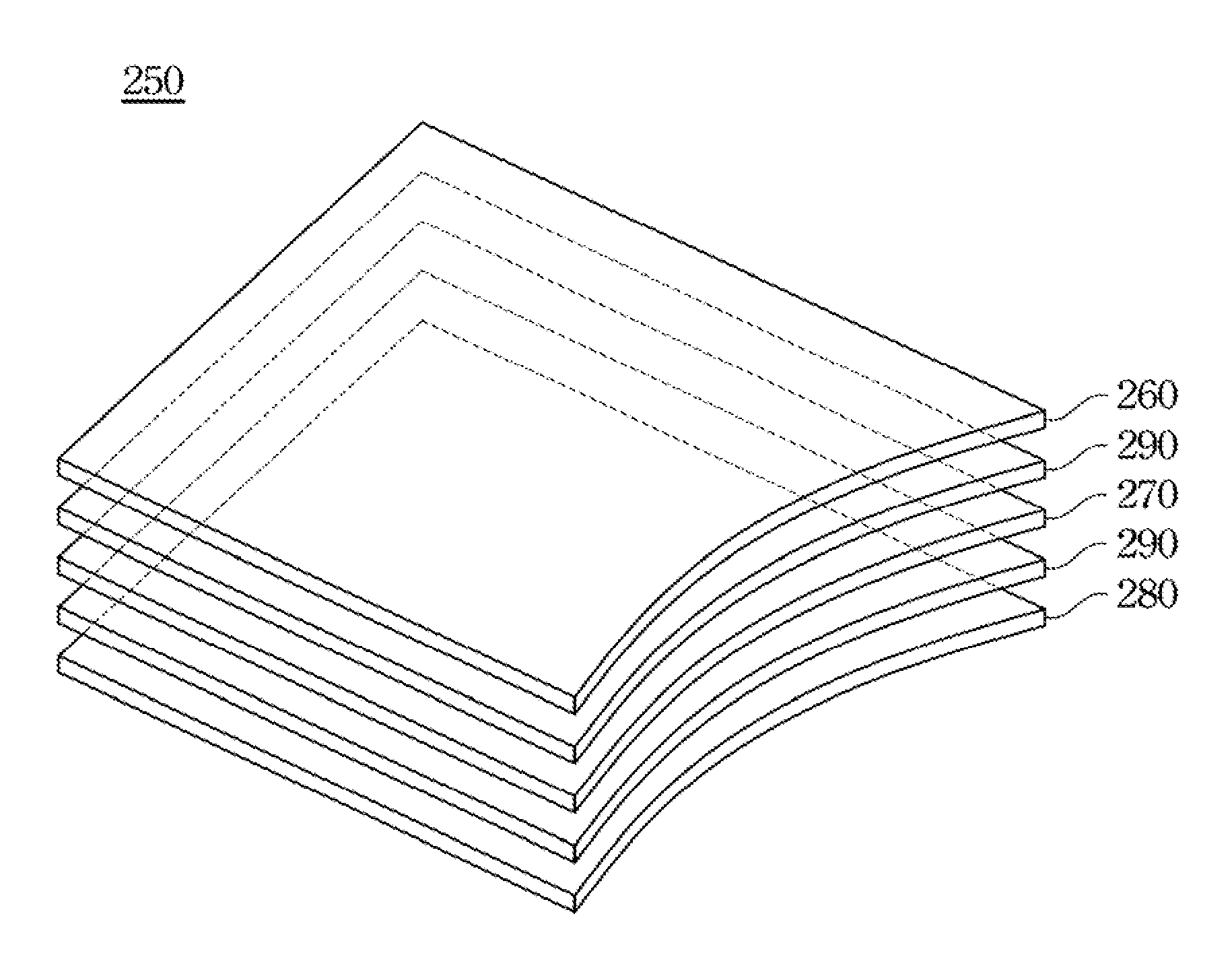

Powder coating for photovoltaic module

InactiveUS20120090778A1Shorten manufacturing timeLow costAbrasion apparatusLaminationDielectric layerPowder coating

Disclosed herein is a backsheet for a photovoltaic module. The backsheet includes a dielectric layer, an adhesive layer disposed on the dielectric layer, a barrier layer disposed on the adhesive layer and bonded to the dielectric layer via the adhesive layer, and a weather resistant layer directly disposed on and bonded to the barrier layer by a powder coating method.

Owner:DU PONT APOLLO

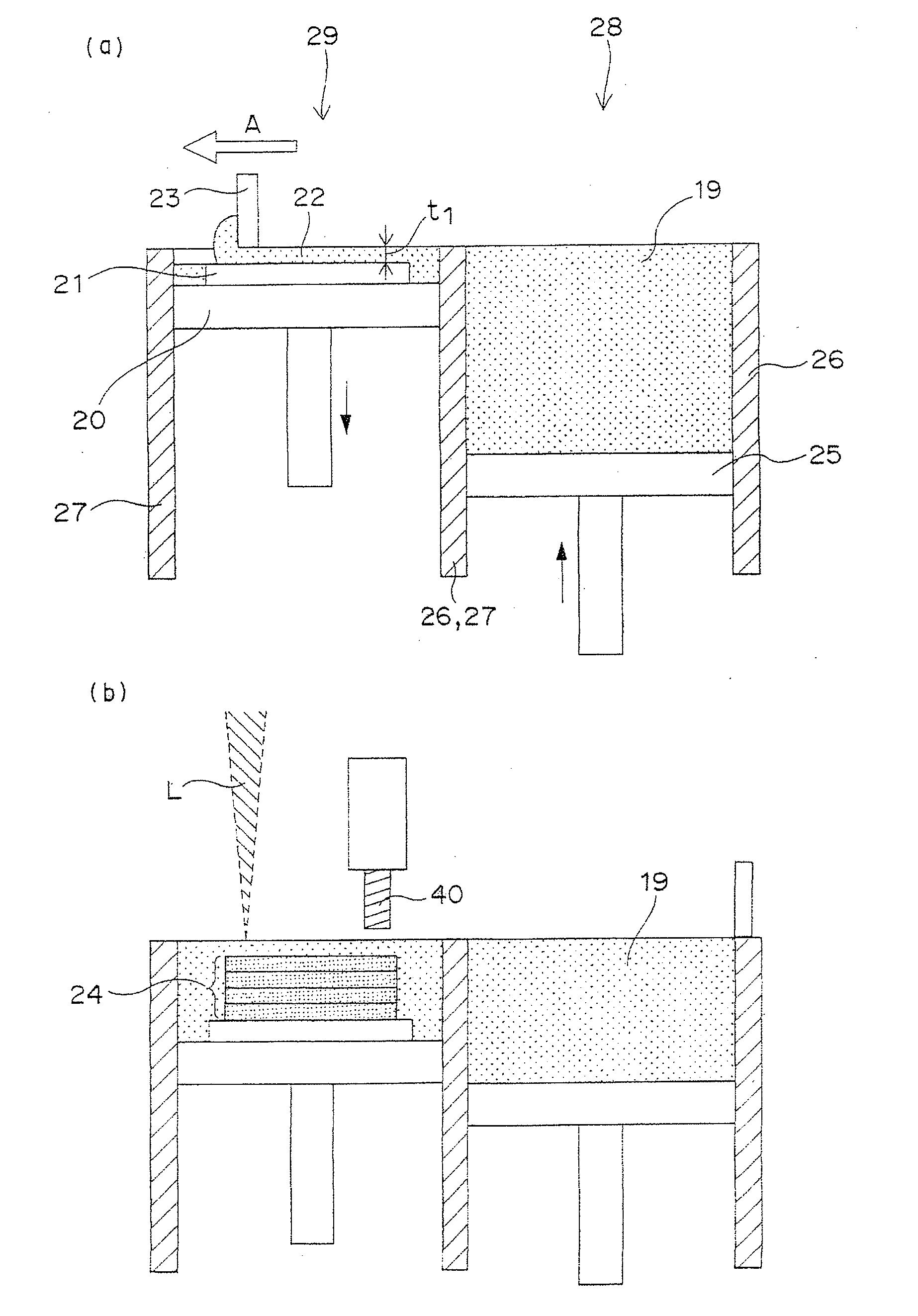

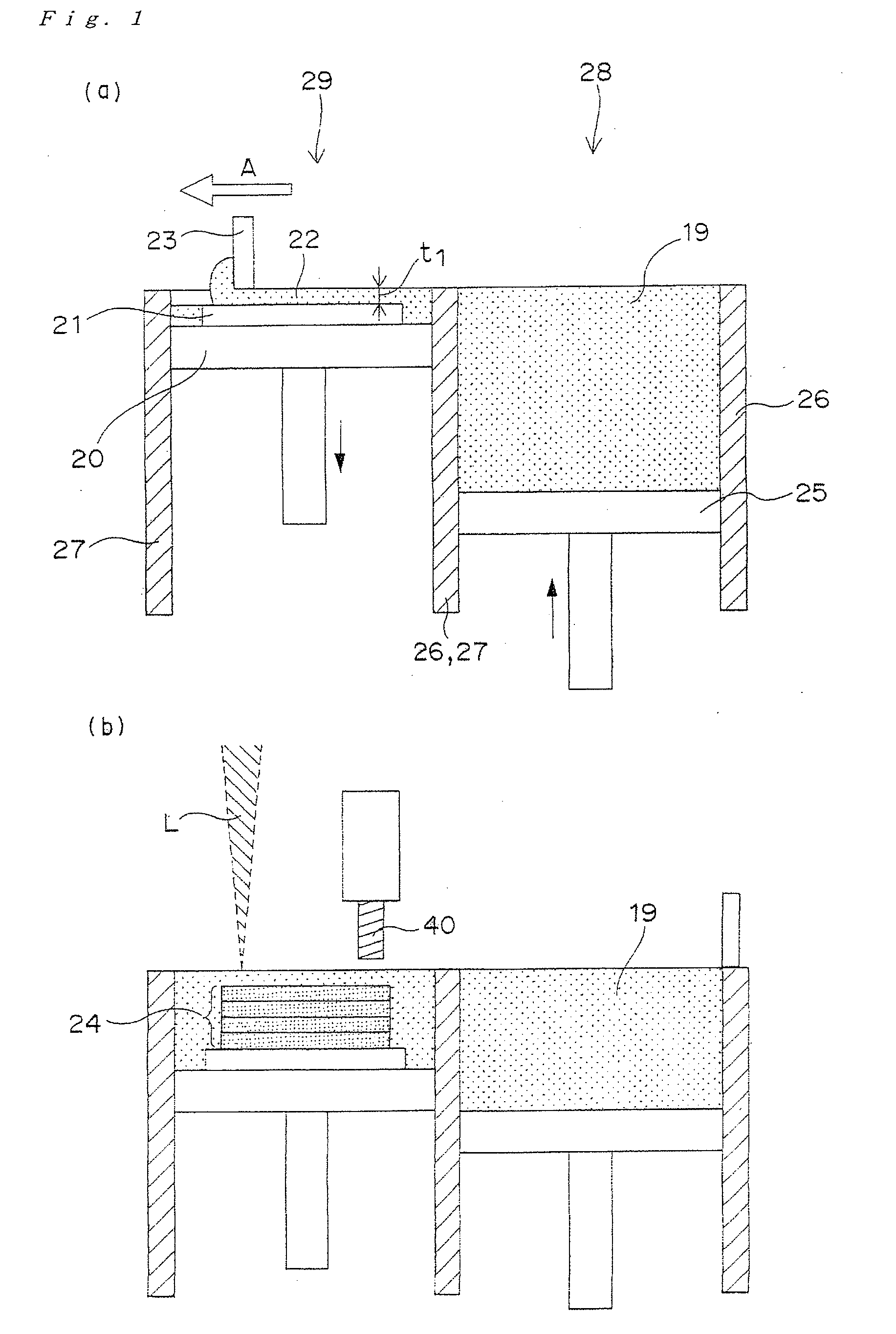

Method for manufacturing three-dimensional shaped object and three-dimensional shaped object obtained by the same

InactiveUS20120041586A1Shorten production timeReduce the ratioAdditive manufacturing apparatusFoundry mouldsLight beamHigh density

There is provided a method for manufacturing a three-dimensional shaped object. The method of the present invention comprises the repeated steps of: (i) forming a solidified layer by irradiating a predetermined portion of a powder layer on a base plate with a light beam, thereby allowing a sintering of the powder in the predetermined portion or a melting and subsequent solidification thereof; and (ii) forming another solidified layer by newly forming a powder layer on the resulting solidified layer, followed by the irradiation of a predetermined portion of the powder layer with the light beam; wherein the solidified layers are formed such that they have a high-density portion whose solidified density is 95 to 100% and a low-density portion whose solidified density is 0 to 95% (excluding 95%); and wherein the high-density portion is a portion of the three-dimensional shaped object, to which the force is applied when the three-dimensional shaped object is used.

Owner:PANASONIC CORP

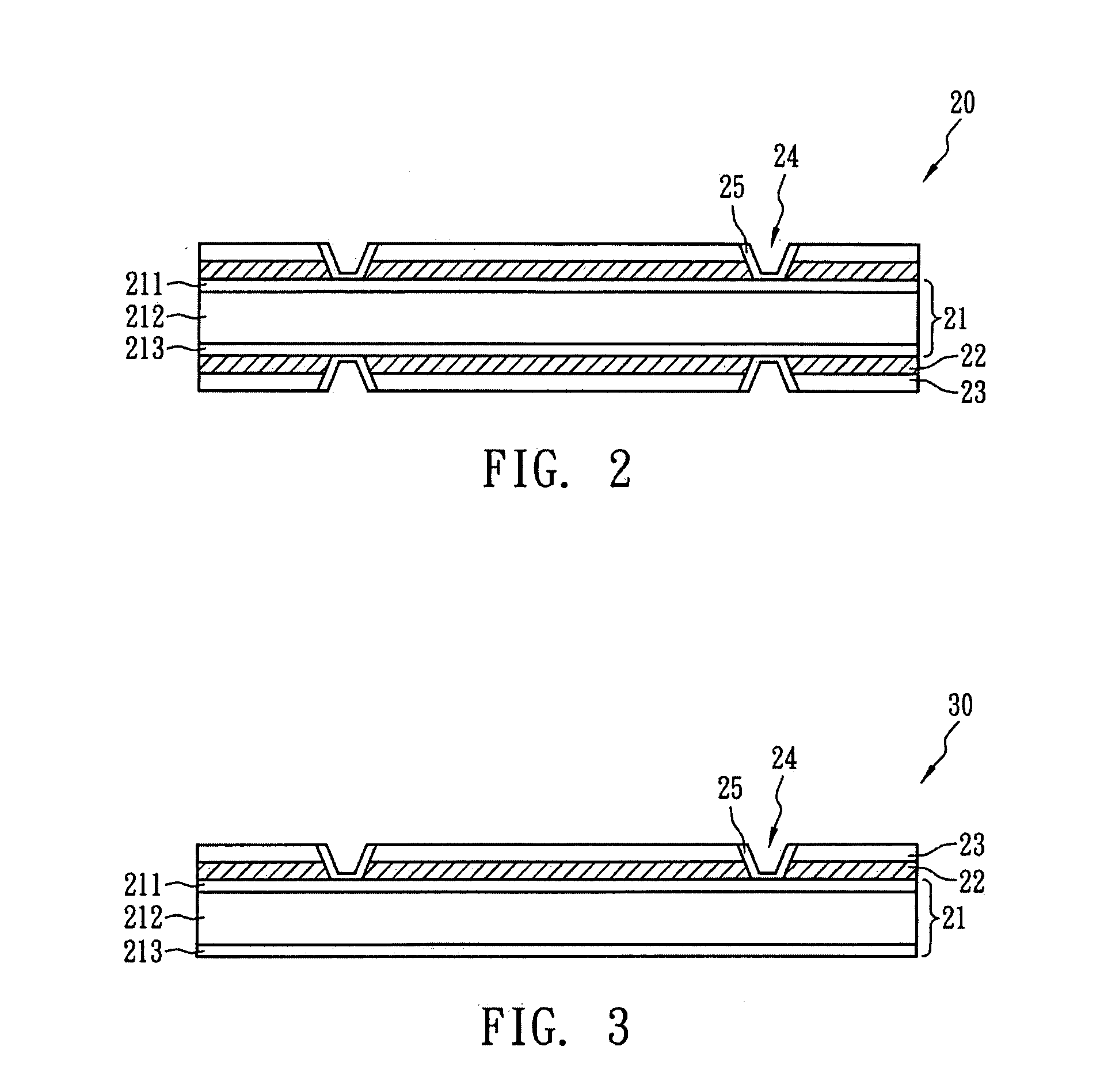

Protective circuit board and overcurrent protection device thereof

ActiveUS20080253050A1Ease of mass productionShorten manufacturing timeCells structural combinationResistor mounting/supportingInsulation layerEngineering

The over-current protection device of the present invention can be used for over-current protection to PCM. The over-current protection device comprises a PTC device, at least one insulation layer; at least one electrode layer and at least one conductive channel. The insulation layer is placed on a surface of the PTC device, and the electrode layer is formed on the insulation layer afterwards. As a result, the insulation layer is between the electrode layer and the PTC device. The electrode layer serves as a surface of the over-current protection device. The conductive channel electrically connects the PTC device and the electrode layer. In an embodiment, the conductive channel is a blind hole penetrating through the electrode layer and the insulation layer and ending at the surface of the PTC device, and the surface of the blind hole is coated with a conductive layer to electrically connect the PTC device and the electrode layer.

Owner:POLYTRONICS TECH

Optoelectronic semiconductor device

ActiveUS20170365588A1Shorten manufacturing timeLow costSolid-state devicesPrint image acquisitionElectronSemiconductor device

An optoelectronic semiconductor device includes an epitaxial substrate and a plurality of microsized optoelectronic semiconductor elements. The microsized optoelectronic semiconductor elements are disposed separately and disposed on a surface of the epitaxial substrate. A length of a side of each of the microsized optoelectronic semiconductor elements is between 1 μm and 100 μm, and a minimum interval between two adjacent microsized optoelectronic semiconductor elements is 1 μm.

Owner:LG DISPLAY CO LTD

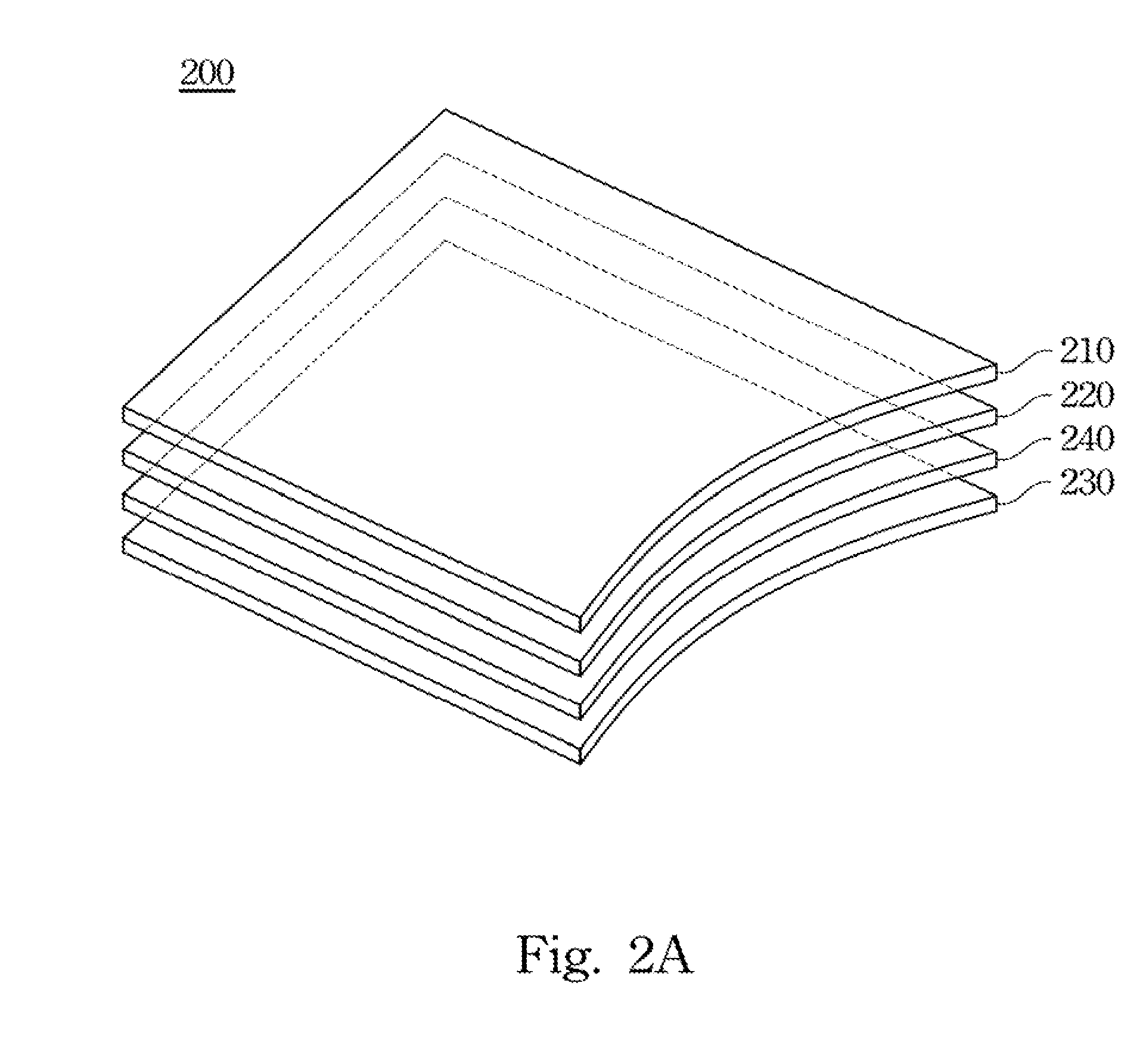

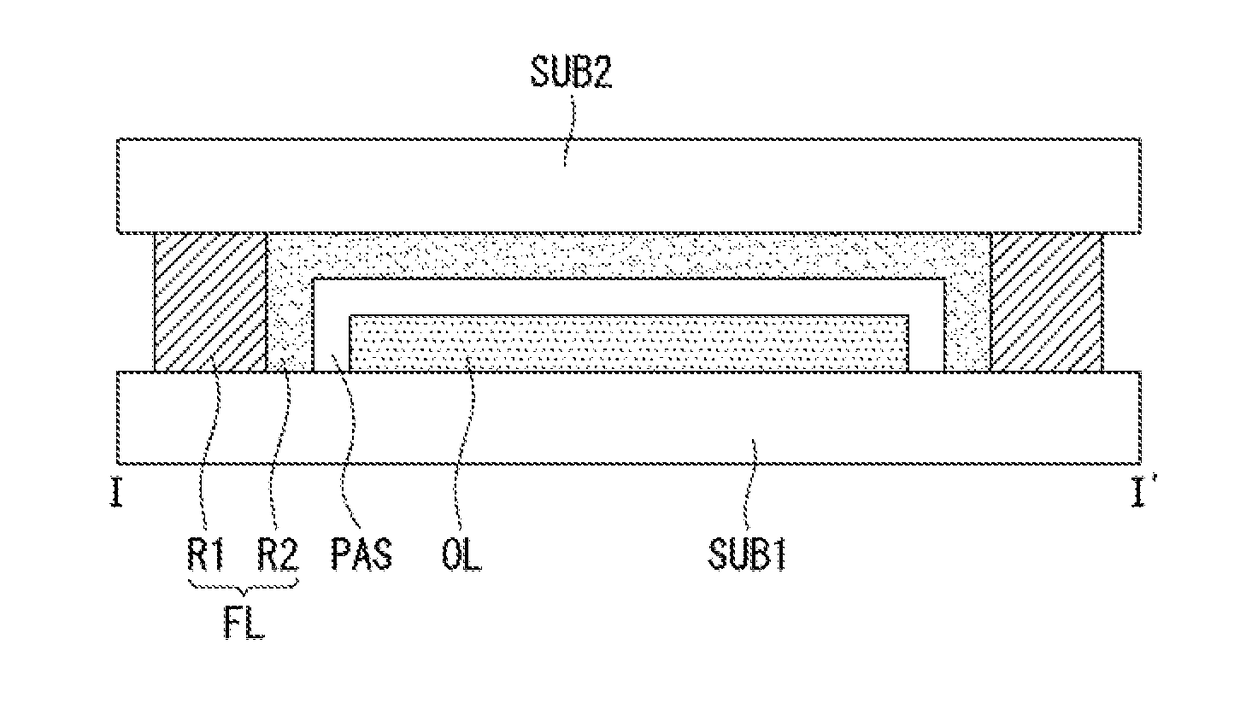

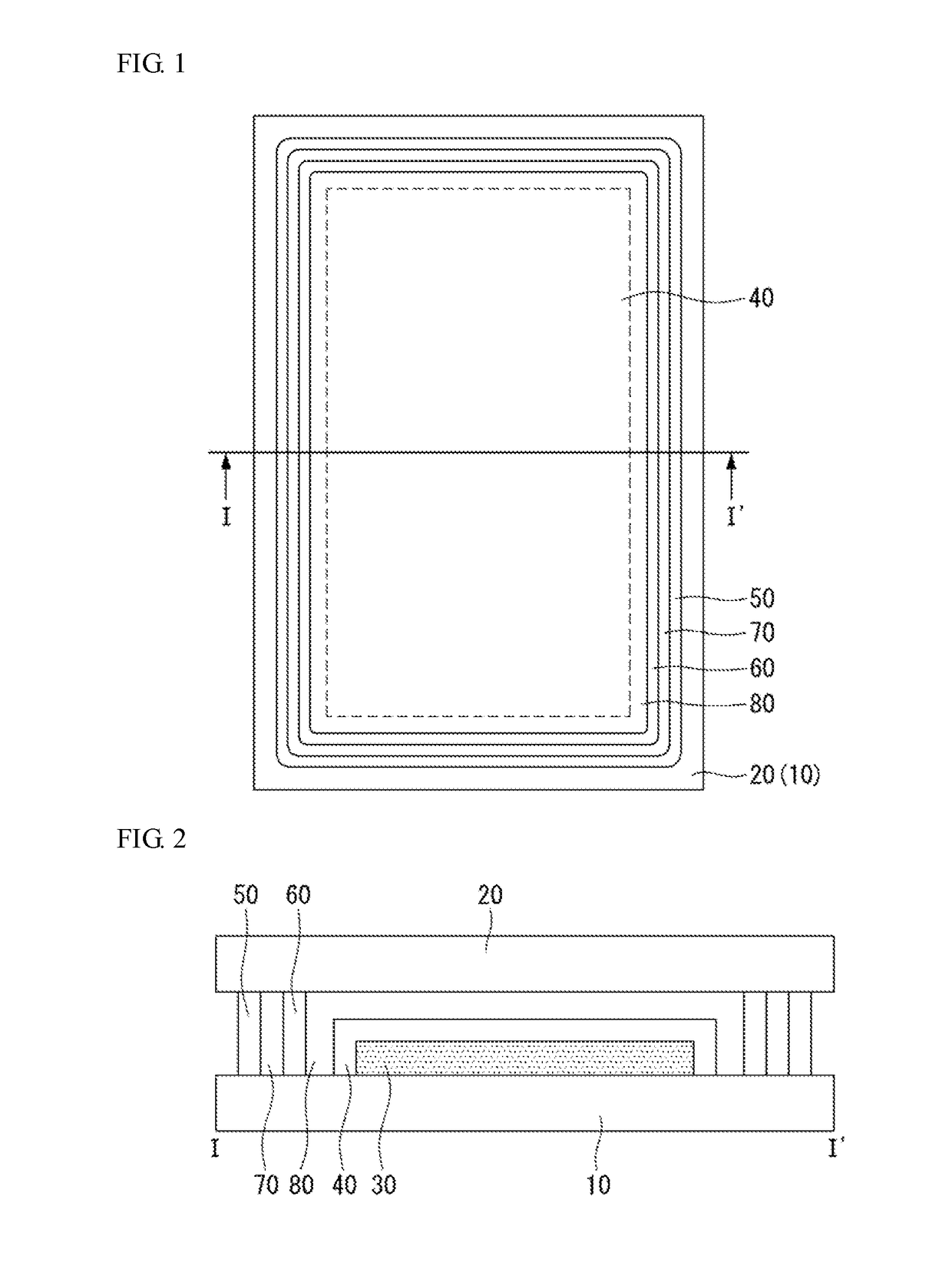

Organic electroluminescent display device and method of sealing the same

ActiveUS20170331072A1Inhibited DiffusionReduce misalignmentFinal product manufactureSolid-state devicesHardnessOrganic electroluminescence

This disclosure relates to an organic electroluminescent display device and a method of sealing the same capable of reducing a manufacturing time and a complexity of manufacturing process. The organic electroluminescent display device comprises a first substrate including an active area and a bezel area outside the active area, the first substrate including an organic light emitting layer and a passivation film covering the organic light emitting layer thereon; a second substrate facing to the first substrate; and a filling layer in a space between the first substrate and the second substrate, wherein the filling layer includes; a first region having a first hardness, and spaced apart at a predetermined distance from the a passivation film to surround the protective layer in the bezel area; and a second region having a second hardness lower than the first hardness, and positioned inside the first region to be contacted with the first region.

Owner:LG DISPLAY CO LTD

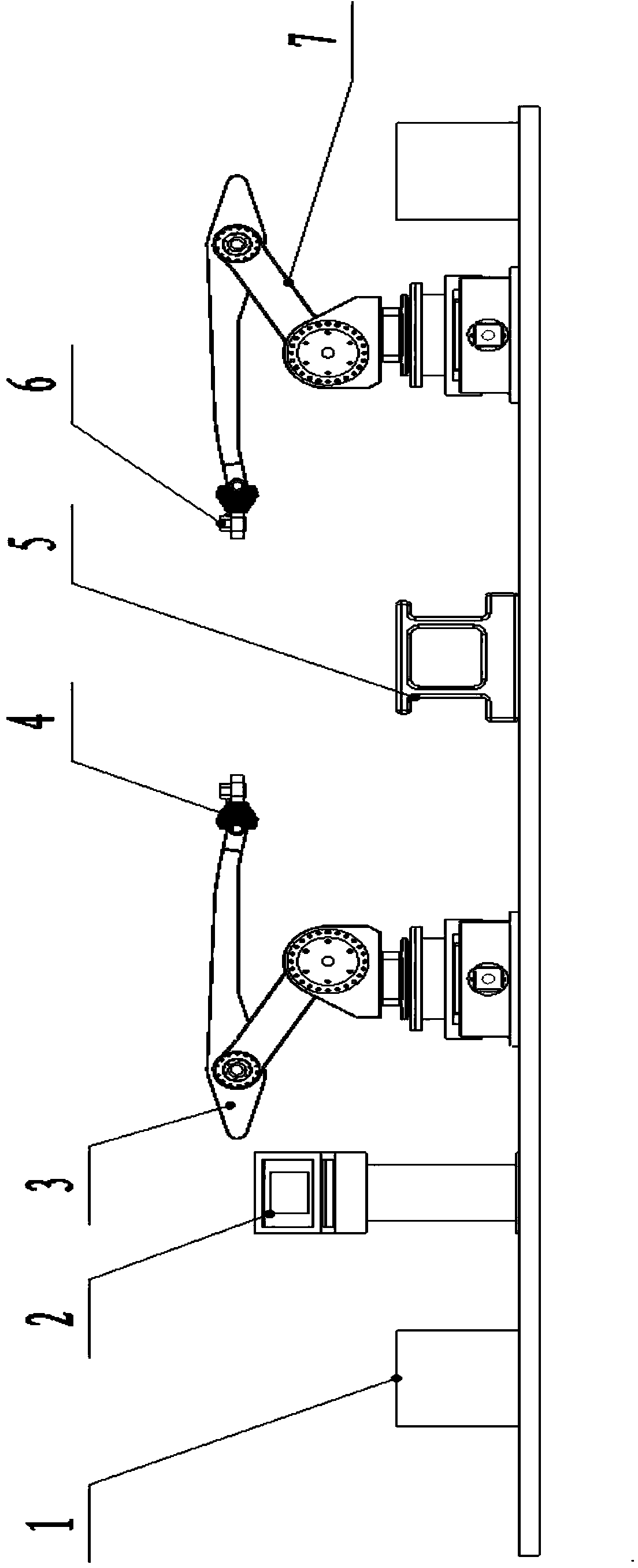

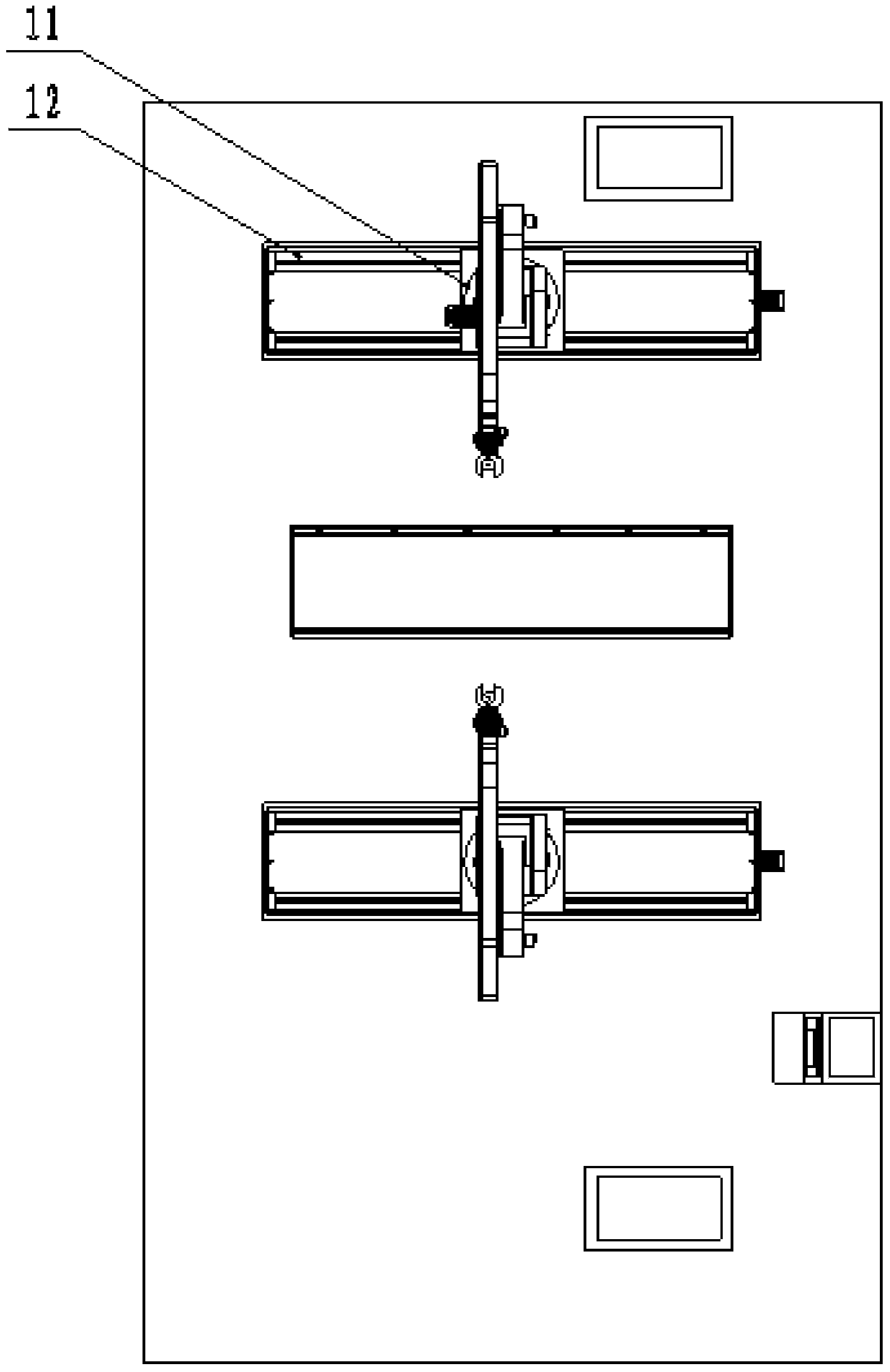

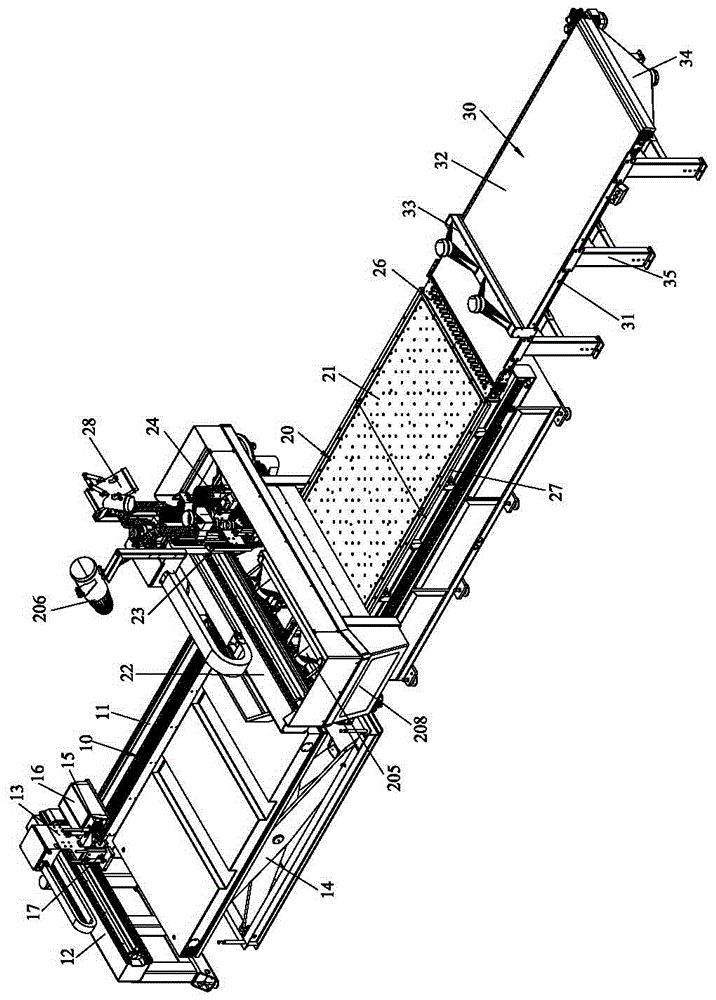

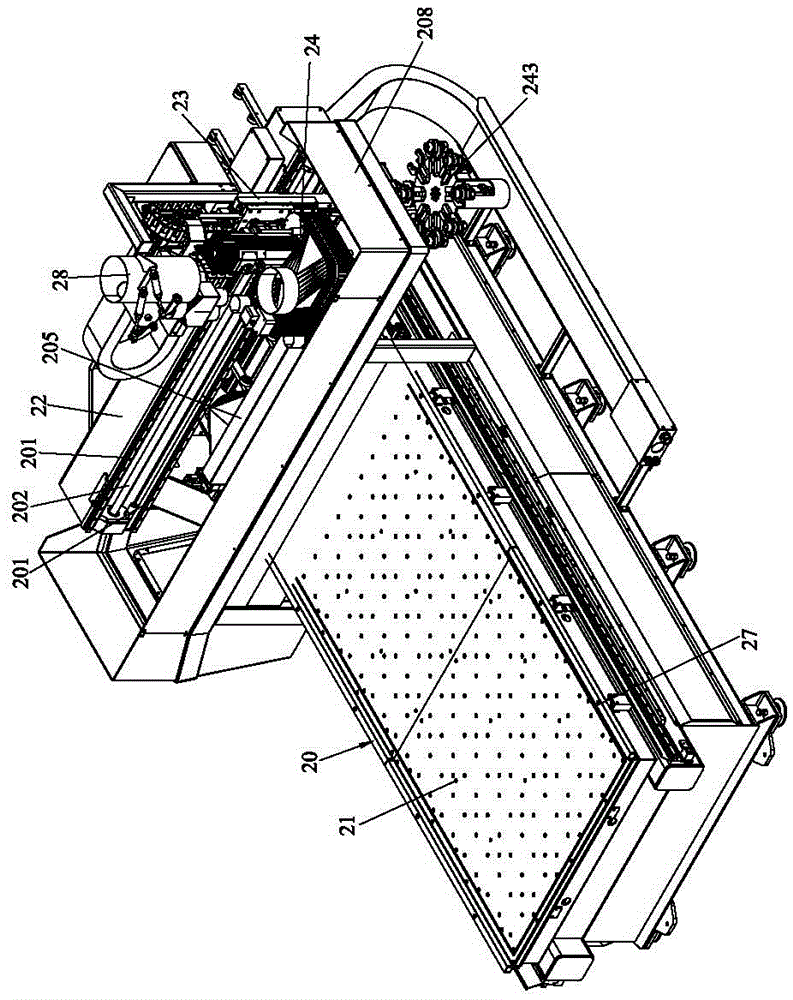

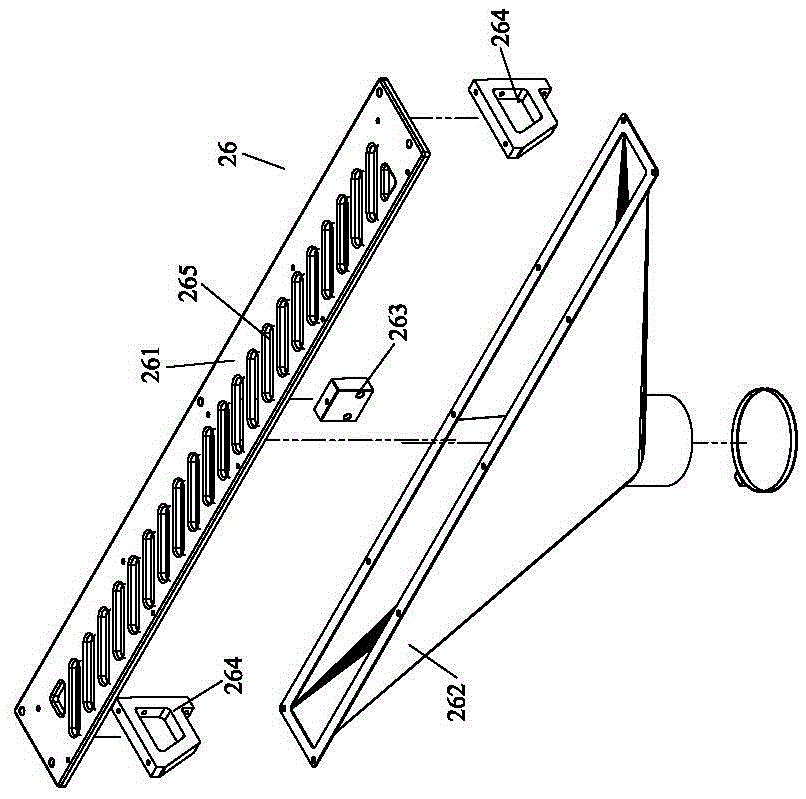

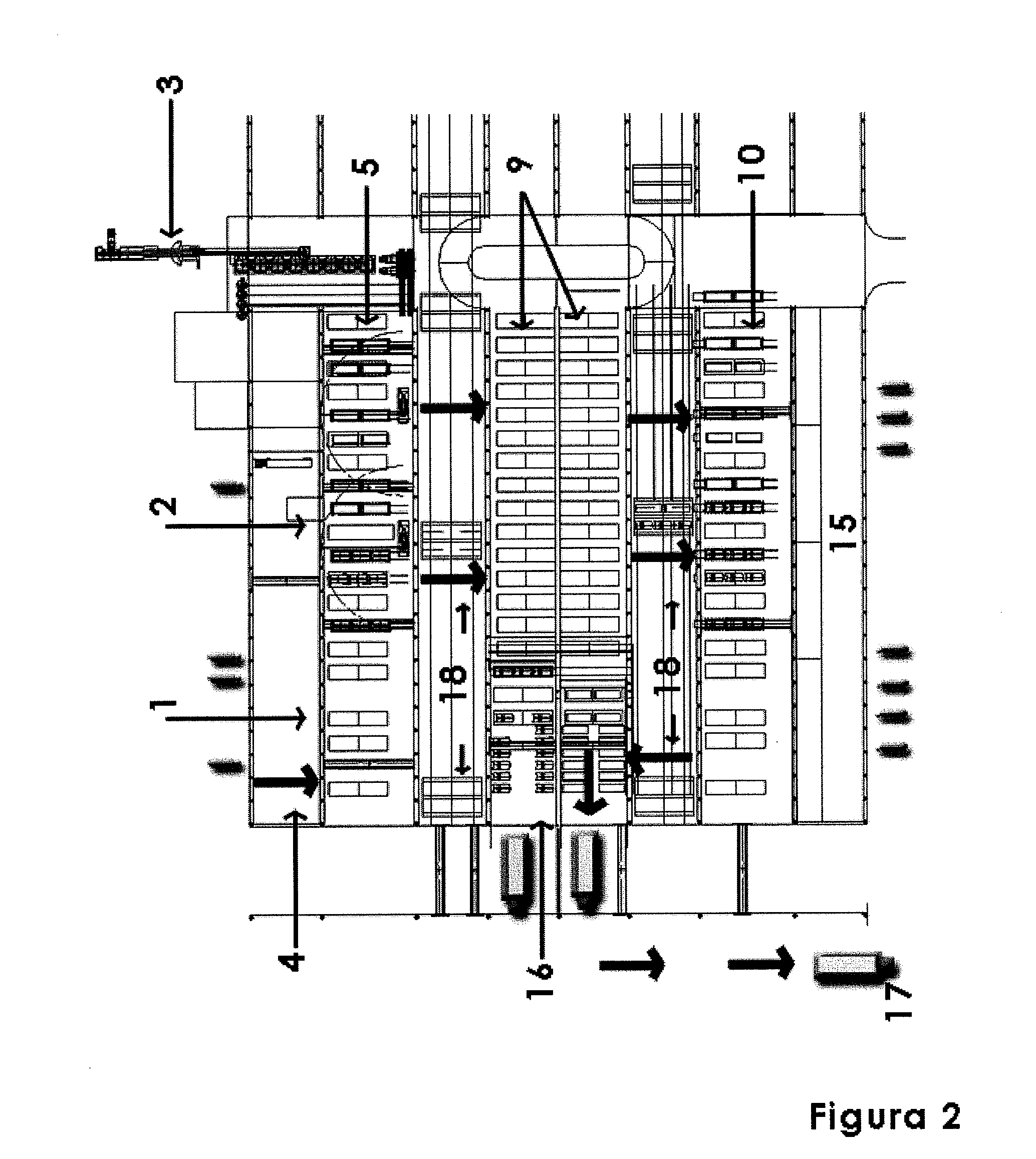

Automatic loading and unloading processing center production line

ActiveCN105479241AShorten manufacturing timeImprove work efficiencyMetal working apparatusMaintainance and safety accessoriesProduction lineEngineering

The invention discloses an automatic loading and unloading processing center production line which comprises a loading machine, a processing center and an unloading machine, wherein the loading machine, the processing center and the unloading machine are sequentially transversely arranged side by side; the loading machine comprises a loading lathe bed, a cantilever beam and a sliding base, wherein a labeling head and a bar code printer are arranged on the sliding base; the processing center comprises a processing lathe bed, a portal frame, a sliding table and a machine head; and the unloading machine comprises an unloading rack, a conveying mechanism, an upper dust absorbing mechanism, a lower dust absorbing mechanism and a plurality of supporting pin mechanisms. According to the automatic loading and unloading processing center production line disclosed by the invention, the loading machine, the processing center and the unloading machine are arranged in a matched mode, so that the equipment can automatically and sequentially complete processes of loading, automatic bar code sticking, once milling type drilling and slotting, unloading and the like, can remarkably improve the working efficiency, can save wood processing manufacturing time, and can effectively increase the yield.

Owner:NANXING MACHINERY CO LTD

Preparation method of solar cell for reutilizing diffusion oxide layer

InactiveCN102364698AQuick removalShorten manufacturing timeFinal product manufactureSemiconductor devicesHydrofluoric acidSilicate glass

The invention relates to a preparation method of a solar cell for reutilizing a diffusion oxide layer. The method comprises the following steps of: not removing a silicon oxide layer (such as BSG (Boron Silicate Glass) and PSG (Phosphosilicate Glass)) formed by diffusion on a front face immediately but plating a layer of film on the oxide layer after a diffusion process is completed to form a double-layer film for serving as a mask for quickly removing back face junctions subsequently and for use in a procedure for making a back face electric field by back diffusion; and removing the film and the silicon oxide layer on the front face, and a silicon oxide layer on the back face together with hydrofluoric acid in a post cleaning procedure. Due to the adoption of the method, back junctions formed by diffusion can be removed quickly, the production process flow is optimized, the cell producing and manufacturing time is shortened greatly, and mass production is available.

Owner:TRINASOLAR CO LTD

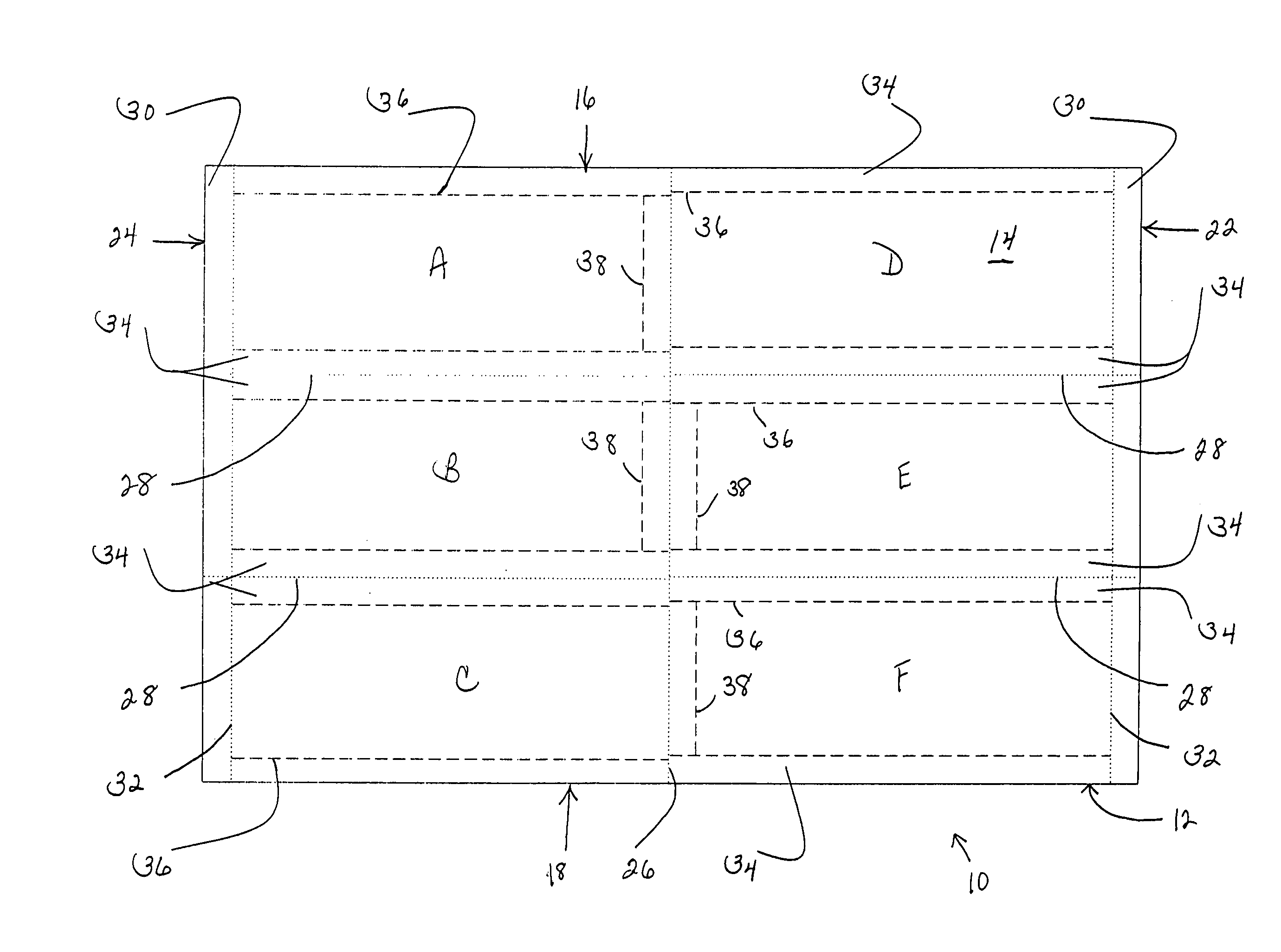

Cross folded, pressure sealed multi-page paper assembly and methods of making same

InactiveUS7219828B2Shorten manufacturing timeLow costOther printing matterEnvelopesMaterial PerforationCost savings

A cost effective, pressure-sealed, multi-page paper assembly is configured as a mailer-type of assembly for use as a business form, direct mail piece or other document to distribute information to end-users. The multi-page paper assembly is formed from a single ply or sheet of paper that permits use of such cost-saving technologies as laser printing and imaging of the single ply or sheet. The multi-page paper assembly includes a central transverse line of cross fold perforations and a plurality of lines of fold assist perforations that permit the single ply or sheet to be folded into a desired Z-fold, C-fold, eccentric C-fold, V-fold, double parallel-fold or other folded configuration having a number of inboard panels to serve as pages of the assembly. Deposits of pressure-activated cohesive along one or both surfaces of the single ply or sheet are placed to define those panels to serve as inboard boards and to adhere portions of the ply or sheet when folded. Cohesive deposits can form seals and thereby a secure seal multi-page paper assembly when pressure-sealed to protect contents. Use of low-tack deposits can form unsecured seals for use with direct mail pieces. Removal of stub portions of the paper assembly permits the sealed assembly to be opened in a book-like manner along the sealed cross fold perforations and access provided to the multiple of pages contained therein.

Owner:INFOSEAL

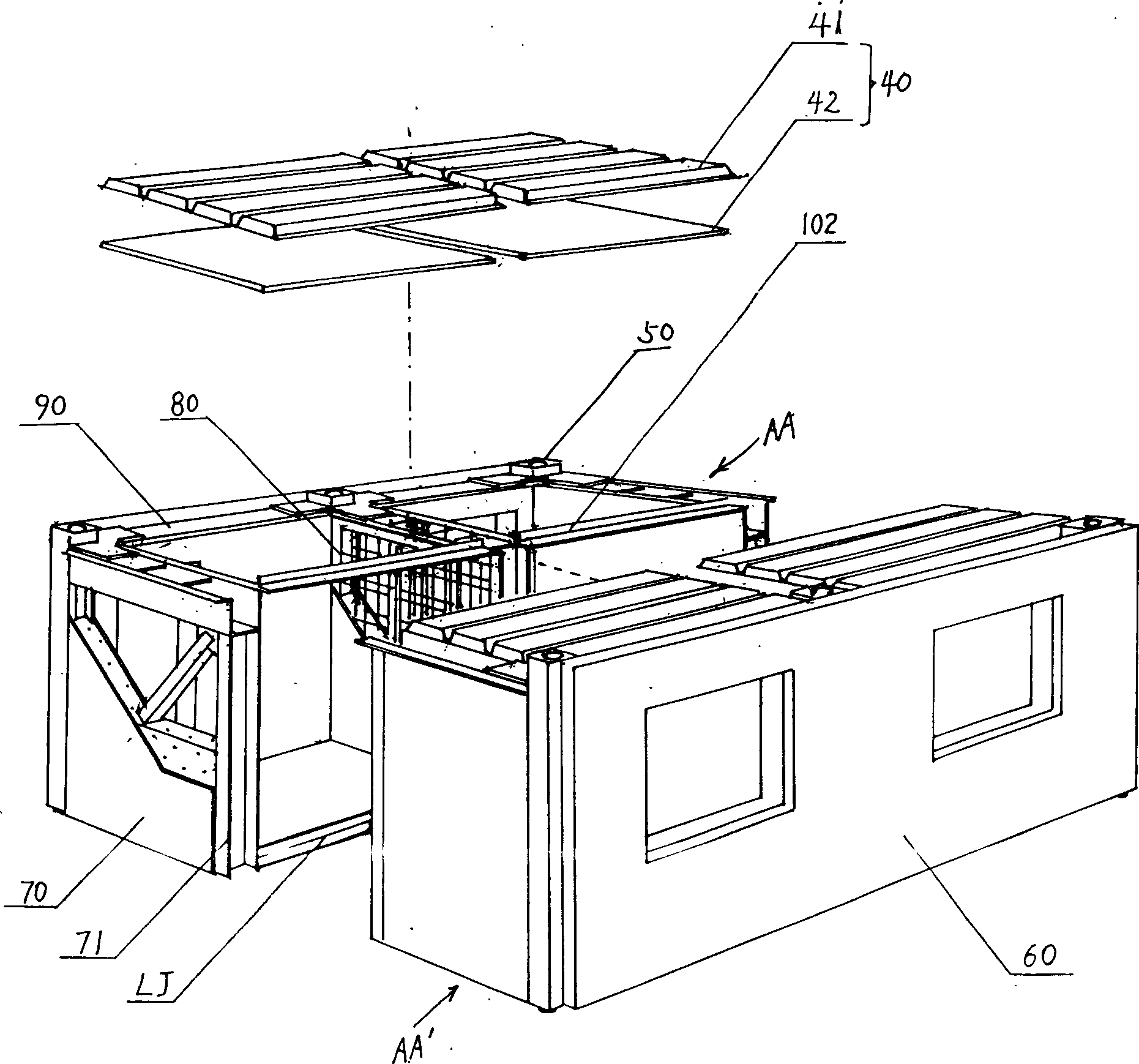

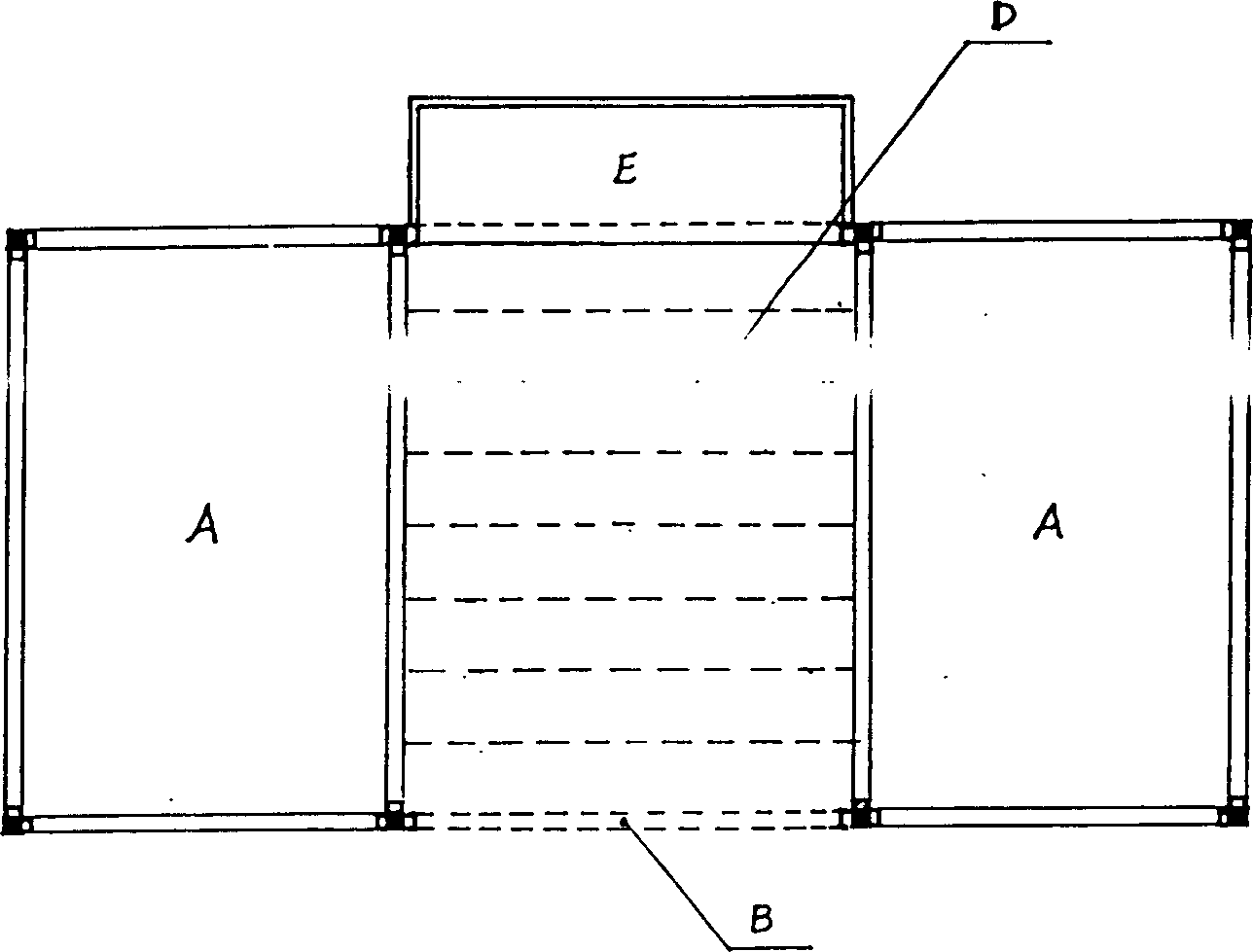

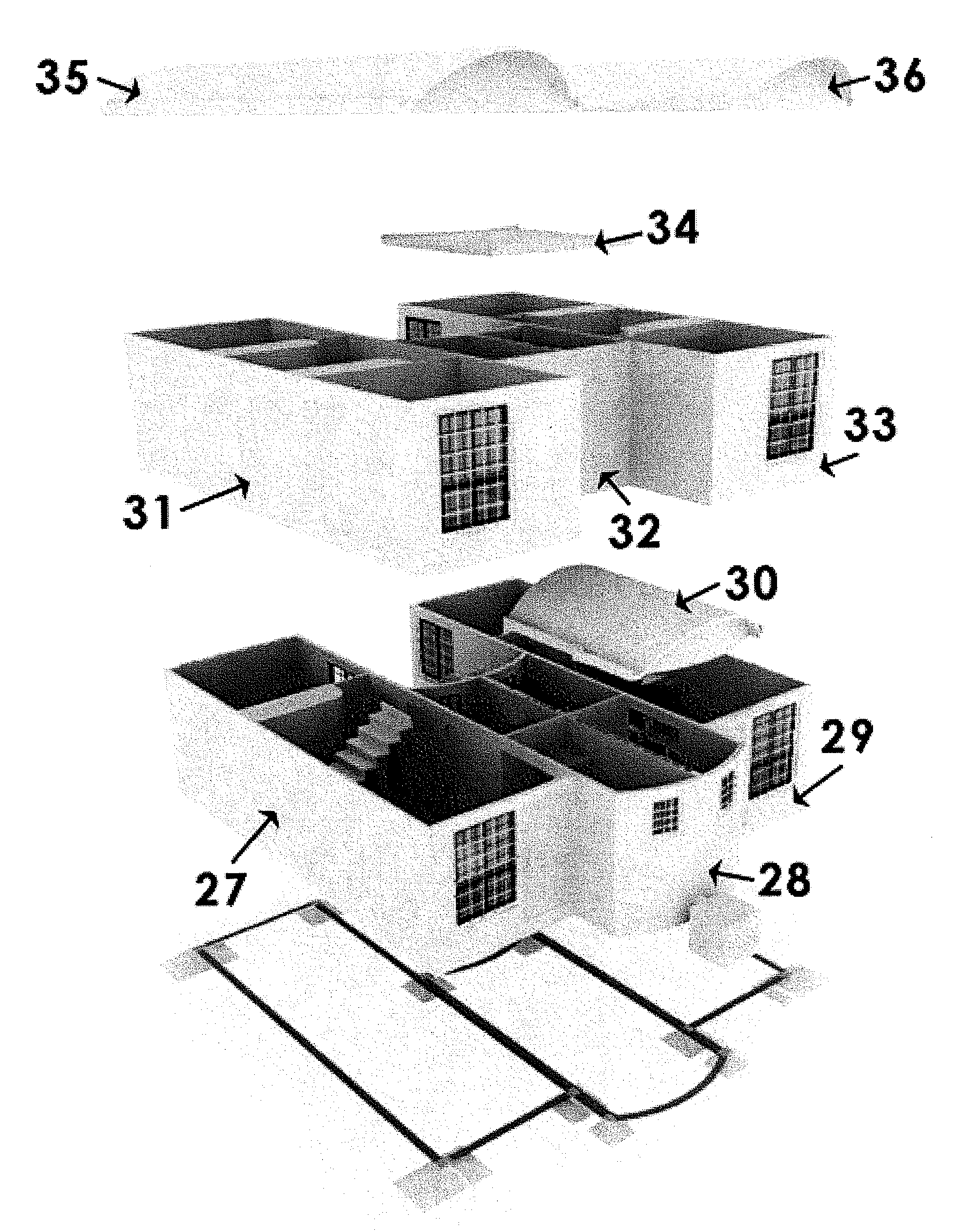

Integral, industrialised modular dwelling system

ActiveUS20090145079A1Reduce material consumptionShorten production timeBuilding roofsMouldsReinforced concreteModularity

The invention relates to an integral, industrialized, modular dwelling system which is based on modular, multi-functional, three-dimensional modules that are made from reinforced concrete. The modules, roofing and components are produced in a semi-automated covered plant in which the modules are first cast and set and subsequently provided with integrated finishes, installations, accessories, partitions and details. The invention also relates to a method for constructing the modules, a retractable flexible mold for casting said modules and a method for the on-site building of dwellings using the inventive three-dimensional modules.

Owner:GARCIA VELEZ & CORTAZAR CARLOS

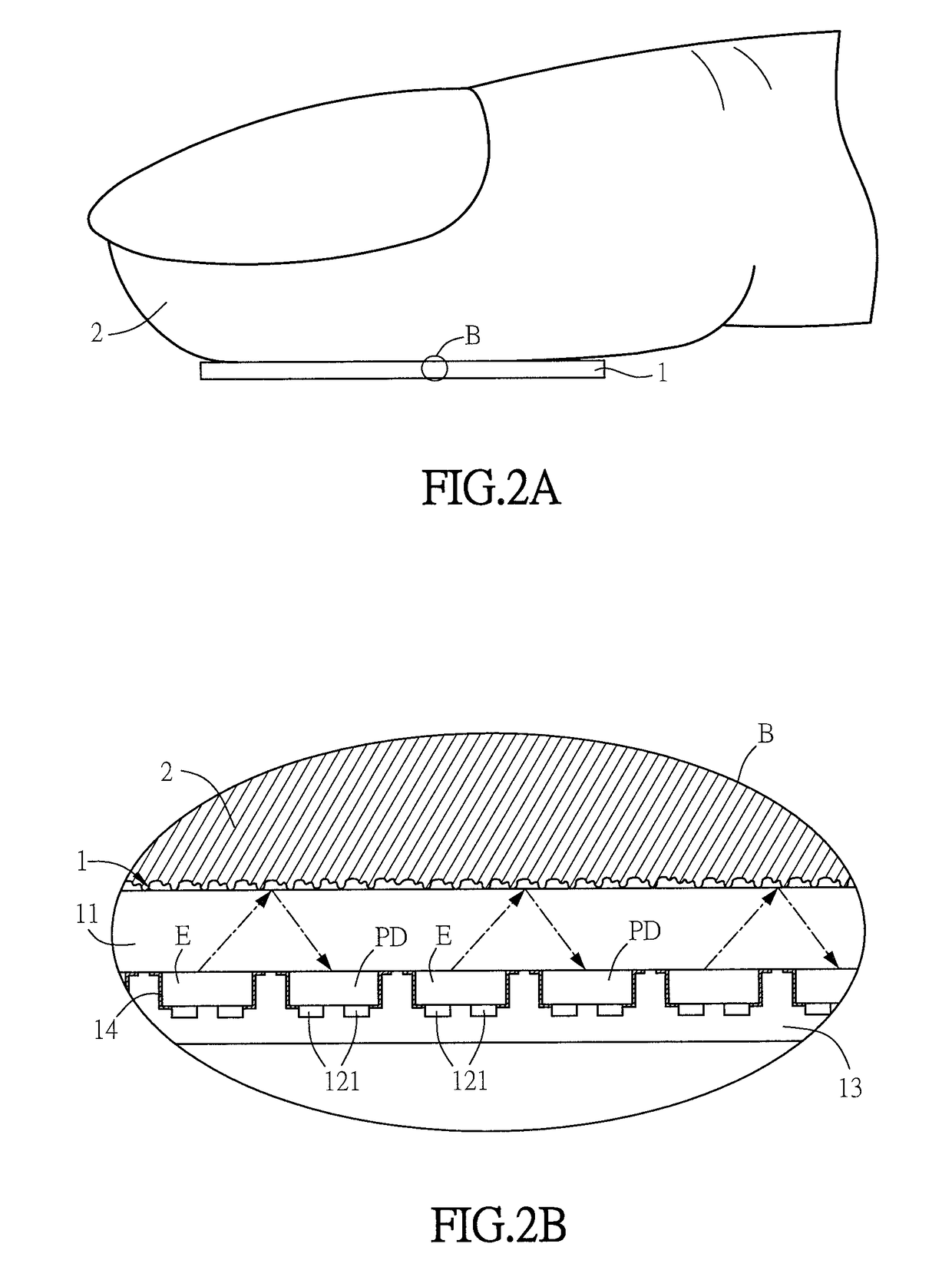

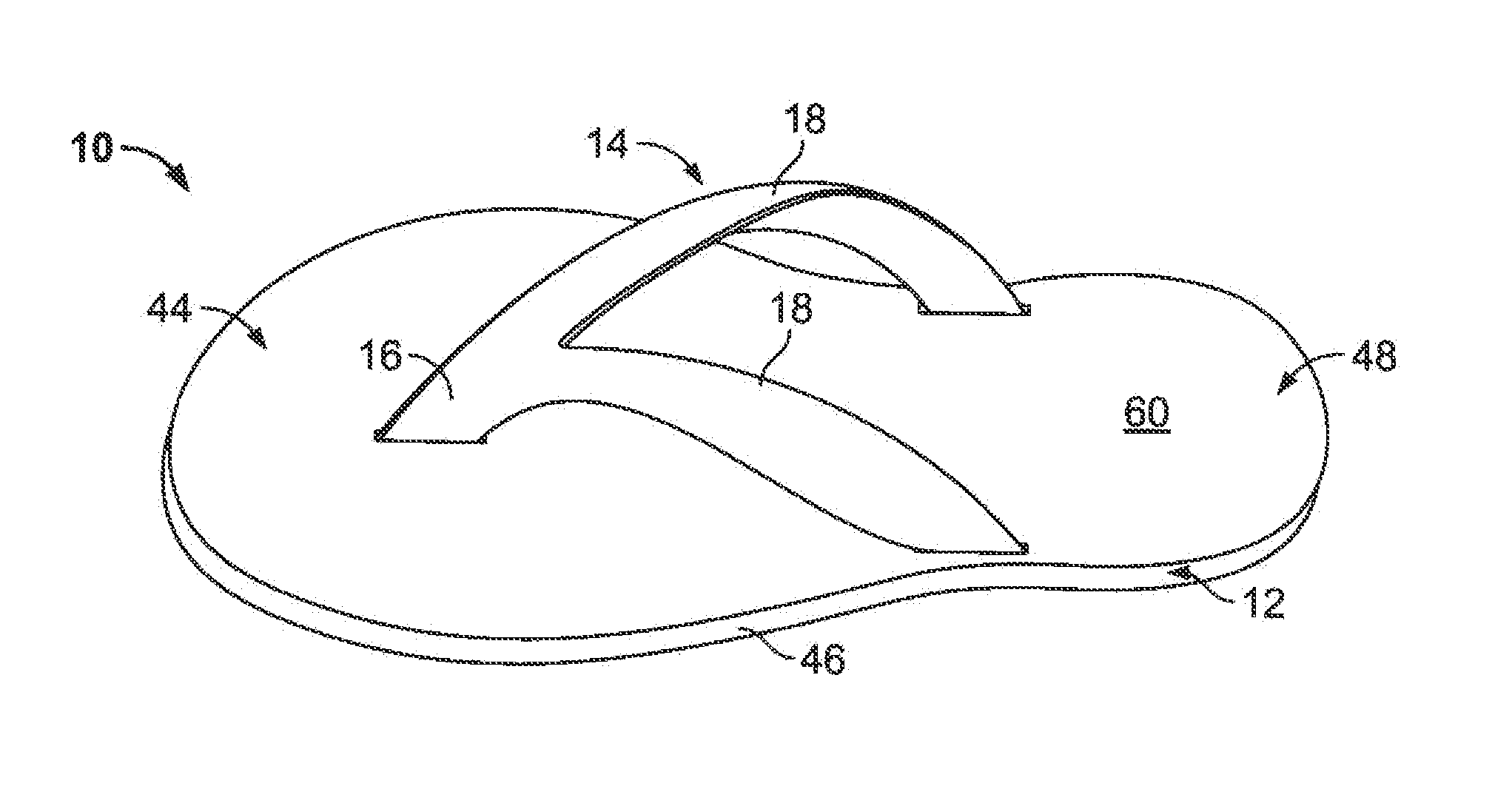

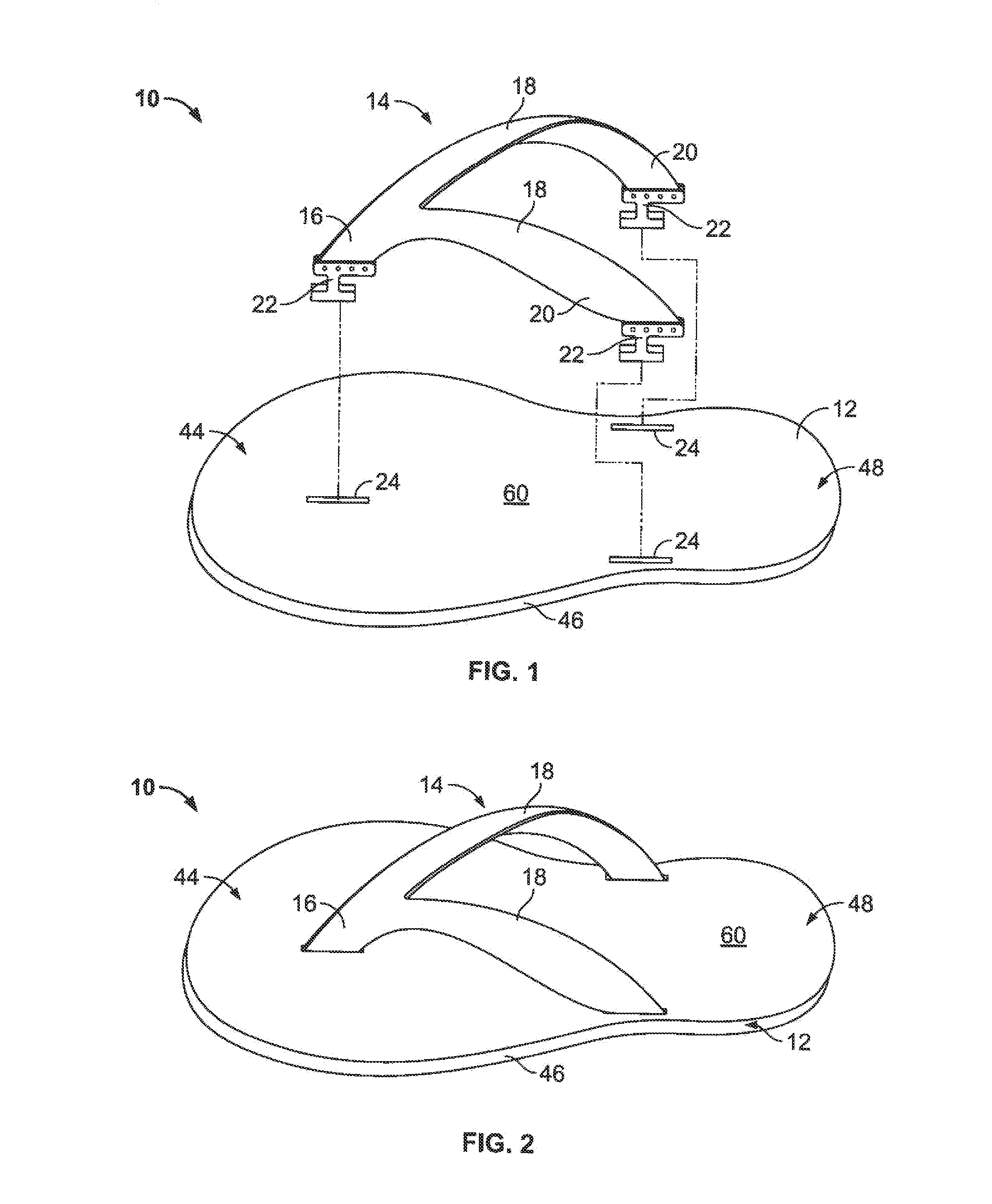

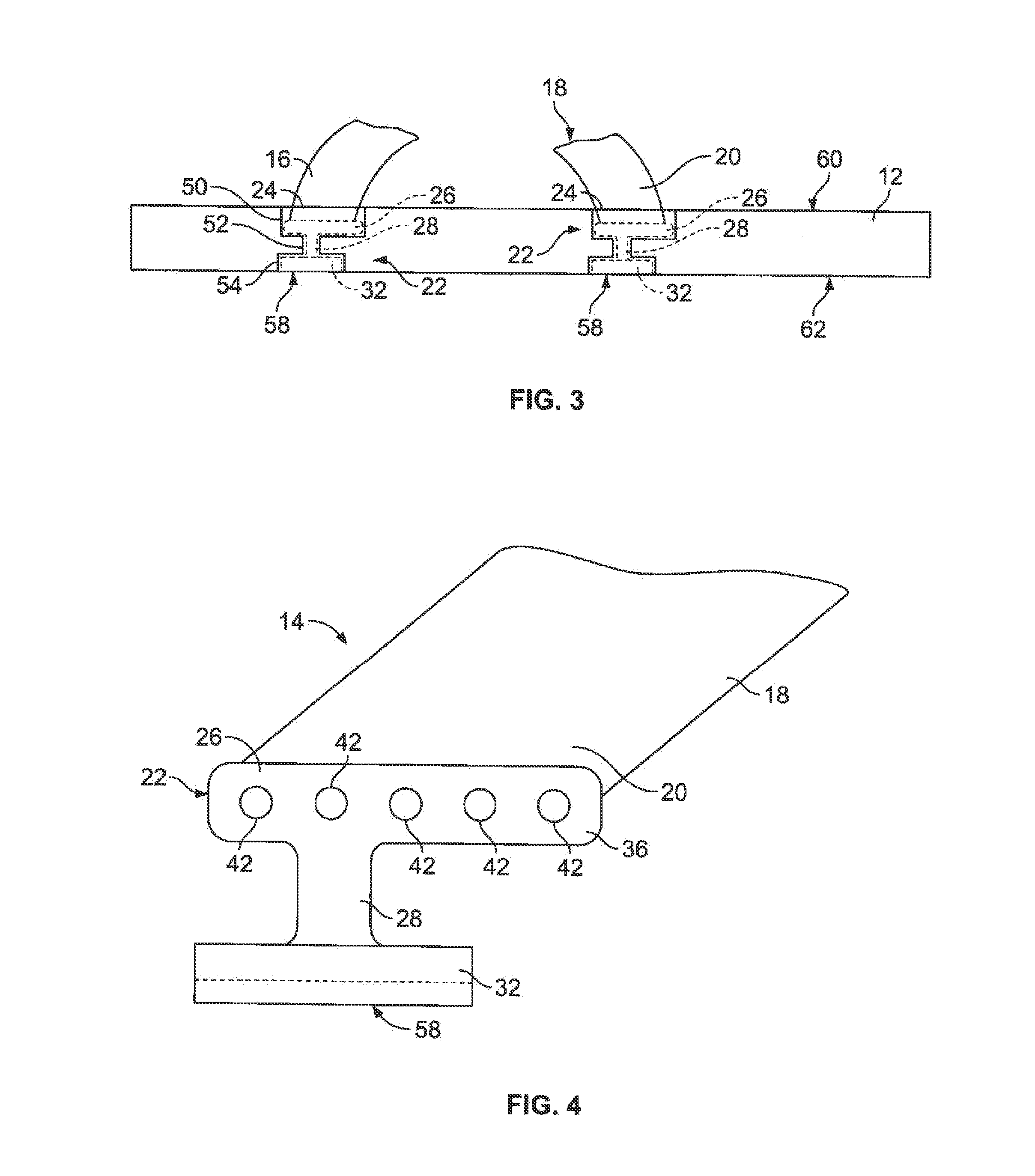

Footwear including a removable and replaceable upper

InactiveUS20140352171A1Shorten manufacturing timeReduce material costsDomestic footwearFootwearEngineeringMechanical engineering

Owner:DECKERS OUTDOOR CORPORATION

Method of making a semiconductor chip assembly with a bumped metal pillar

InactiveUS7112521B1Enhancing mechanical supportImprove protectionSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

A method of making a semiconductor chip assembly includes providing a metal base, a routing line and a bumped terminal, then mechanically attaching a semiconductor chip to the metal base, the routing line and the bumped terminal, then forming an encapsulant, and then etching the metal base to form a metal pillar that contacts the bumped terminal.

Owner:BRIDGE SEMICON

Printed circuit board having stepped conduction layer

InactiveUS20090084582A1Shorten manufacturing timeReduce manufacturing costCross-talk/noise/interference reductionPrinted circuit aspectsEngineeringPrinted circuit board

A printed circuit board having a stepped conduction layer is disclosed. In one embodiment of the invention, a printed circuit board is provided in which at least one conduction layer configured for use as a signal transmission layer is divided into at least two base regions and at least one connecting region connecting any adjacent two of the base regions, where the connecting region is stepped to a lower height than those of the base regions. The stepped conduction layer in the printed circuit board can be used to resolve the problem of mixed signals in a printed circuit board equipped with various parts and components, including an analog circuit and digital circuit, etc.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com