Semiconductor ceramic with negative resistance temperature coefficient and negative temperature coefficient thermistor

A technology with negative temperature coefficient and temperature coefficient, which is applied in the field of semiconductor ceramics and negative temperature coefficient thermistors, can solve the problems of molded body expansion, deterioration of plasticity, etc., and achieve the effect of expansion suppression and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] mn 3 o 4 with BaCO 3 Raw materials were prepared by mixing so that the atomic ratio of Ba / M became 1. After firing at 1300°C for 2 hours, the raw materials were crushed with a pulverizer, and then finely ground with a ball mill for 20 hours to obtain BaMnO 3 powder.

[0023] Then as listed in Table 1, the BaMnO 3 Powder was added to Mn with a weight ratio of 50:30:20 3 o 4 , NiO and Fe 2 o 3 In, mixed with a ball mill for 16 hours. The raw material was fired at 900°C for 2 hours and crushed with a pulverizer. Next, 10% by weight of polyvinyl alcohol as an organic binder, 0.5% by weight of glycerin as a plasticizer and 1.0% by weight of a polyethylene dispersant were added to the crushed raw material and mixed for 16 hours. Then, coarse particles were removed with a 250-mesh sieve to obtain sheet-shaped pulp. This slurry was formed into a 50 μm thick ceramic green sheet with a doctor blade.

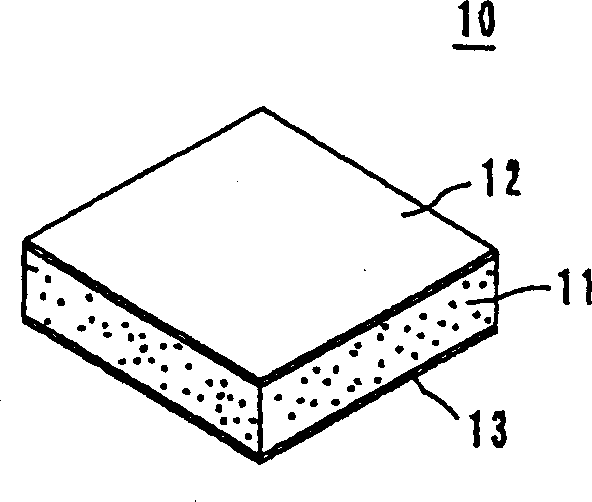

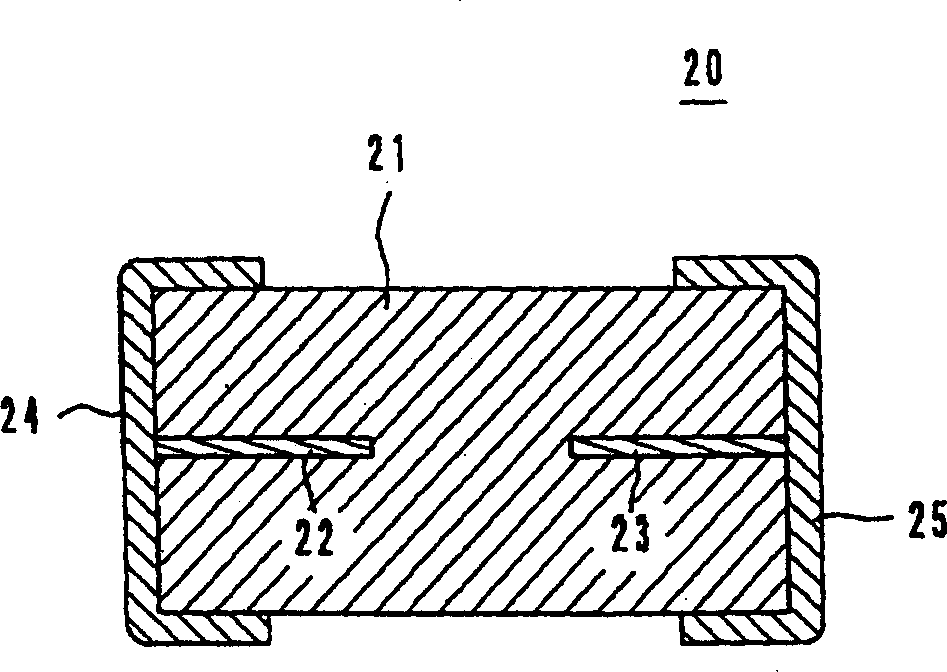

[0024] Punch the ceramic green sheet into a fixed size, and stack t...

Embodiment 4

[0041] La 2 o 3 , SrCO 3 with MnCO 4 Raw materials were prepared by mixing so that the atomic ratio Sr:La:Mn=0.05:0.95:1. After firing at 800°C for 2 hours, crush the raw material with a pulverizer, and then finely grind it with a ball mill for 20 hours to obtain Sr 0.5 La 0.95 MnO 3 powder.

[0042] Next, the Sr listed in Table 4 0.5 La 0.95 MnO 3 Powder was added to Mn with a weight ratio of 45:25:30 3 o 4 , Fe 2 o 3 with Co 3 o 4 Li, and mixed with a ball mill for 16 hours. The raw material was fired at 900°C for 2 hours and crushed with a pulverizer. Next, 10% by weight of polyvinyl alcohol as an organic binder, 0.5% by weight of glycerin as a plasticizer and 1.0% by weight of a polyethylene dispersant were added to the crushed raw material and mixed for 16 hours. Then, coarse particles were removed with a 250-mesh screen to obtain a sheet-shaped slurry, which was formed into a 50-μm-thick ceramic green sheet with a doctor blade.

[0043] The ceramic gree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com