Method for comprehensive harmless recovery and utilization of waste lithium ion power battery

A lithium-ion battery and power battery technology, applied in battery recycling, recycling technology, recycling by waste collectors, etc., can solve the problems of low added value of products, waste of resources, unfeasible, etc., and achieve a favorable workshop working environment. , avoid burning or explosion, reduce the effect of harm to human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

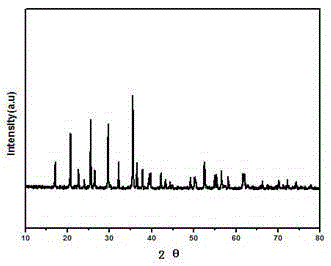

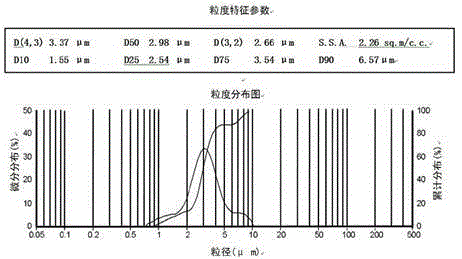

Image

Examples

Embodiment 1

[0042] (1) Take a set of 320V60Ah waste lithium iron phosphate lithium-ion power battery packs (graphite negative electrodes) for electric vehicles, disassemble the waste power battery packs, measure the performance of each battery, the capacity is more than 60% of the original nominal capacity and Single batteries whose resistance does not exceed 3 times the original nominal value shall be reconfigured according to the rules of capacity error within ±2%, internal resistance error within ±30%, leakage current error within ±20%, and charge-discharge curve coincidence degree greater than 95%. into a 72V100Ah battery pack, and the reassembled battery is used for low-speed electric vehicles;

[0043] (2) Discharge the waste power batteries eliminated in (1) until the voltage is <0.5V;

[0044] (3) In an oxygen-isolated environment, cut the battery along the top of the battery by cutting, cut off the connection between the core pack and the terminal, open the battery and take out t...

Embodiment 2

[0055] (1) Take a set of 370V100Ah waste ternary lithium-ion power battery packs (lithium titanate negative electrode) for electric vehicles, disassemble the waste power battery packs, and measure the performance of each battery. The capacity is more than 60% of the original nominal capacity and within Single batteries whose resistance does not exceed 3 times the original nominal value shall be reconfigured according to the rules of capacity error within ±2%, internal resistance error within ±30%, leakage current error within ±20%, and charge-discharge curve coincidence degree greater than 95%. into a 74V160Ah battery pack, and the reassembled battery is used for low-speed electric vehicles;

[0056] (2) Discharge the waste power batteries eliminated in (1) until the voltage is <0.5V;

[0057] (3) In an oxygen-isolated environment, cut the battery along the top of the battery by cutting, cut off the connection between the core pack and the terminal, open the battery and take o...

Embodiment 3

[0067] (1) Take a set of 370V100Ah waste lithium manganese oxide power battery packs (graphite negative electrodes) for electric vehicles, disassemble the waste power battery packs, and measure the performance of each battery. The capacity is more than 60% of the original nominal capacity and the internal resistance does not exceed The single battery with 3 times the original nominal value shall be re-made into 74V160Ah according to the rules of capacity error within ±2%, internal resistance error within ±30%, leakage current error within ±20%, and charge-discharge curve coincidence degree greater than 95%. Battery packs, repackaged batteries for low-speed electric vehicles;

[0068] (2) Discharge the waste power batteries eliminated in (1) until the voltage is <0.5V;

[0069] (3) In an oxygen-isolated environment, cut the battery along the top of the battery by cutting, cut off the connection between the core pack and the terminal, open the battery and take out the core pack;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com