A high-performance low-expansion crucible and a preparing method thereof

A low-expansion, high-performance technology, used in the field of refractory materials, can solve the problems of short service life, high labor intensity, and low use times, and achieve the effects of improving thermal shock resistance, improving production qualification rate, and low production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

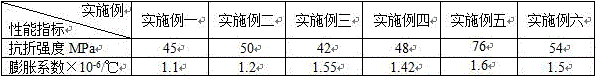

Examples

Embodiment 1

[0021] A high-performance low-expansion crucible, which is composed of a crucible base material and a crucible coating material. The mass percentage of the crucible base material is: 45% of pyrophyllite, 10% of spodumene, 10% of Suzhou soil, and Zimujie 1% soil, 4% black talc, 20% Guizhou soil, 0% white carbon black, 10% zirconia micropowder; the mass percentage of the crucible coating material is composed of: 15% pyrophyllite, zirconia after calcined at 800°C 85% micropowder, plus 0.1% polyacrylamide and 0.1% hydroxypropyl methylcellulose; the fineness of the zirconia micropowder is 10µm.

[0022] After the raw materials of the crucible base are mixed, ball milling, sieving, dehydration by pressure filtration, vacuum mud refining, molding and drying are carried out to obtain the crucible body, and then the crucible coating material is prepared into a slurry with good fluidity after batching , sprayed onto the inner surface of the crucible base, and finally fired to obtain a h...

Embodiment 2

[0024] A high-performance low-expansion crucible, which is composed of a crucible base material and a crucible coating material. The mass percentage of the crucible base material is: 58% of pyrophyllite, 5% of spodumene, 5% of Suzhou soil, and Zimujie 2% soil, 1% black talc, 22% Guizhou soil, 1% white carbon black, and 6% zirconia micropowder. The mass percentage of the crucible coating material is composed of: 12% pyrophyllite, praseodymium oxide calcined at 850°C 88% fine powder, plus 0.2% polyethylene glycol and 0.2% polyvinyl alcohol; the fineness of the zirconia fine powder and praseodymium oxide fine powder is 15 μm.

[0025] After the raw materials of the crucible base are mixed, ball milling, sieving, dehydration by pressure filtration, vacuum mud refining, molding and drying are carried out to obtain the crucible body, and then the crucible coating material is prepared into a slurry with good fluidity after batching , sprayed onto the inner surface of the crucible bas...

Embodiment 3

[0027] A high-performance low-expansion crucible is composed of a crucible base material and a crucible coating material. The mass percentage of the crucible base material is: 50% of pyrophyllite, 15% of spodumene, 5% of Suzhou soil, and Zimujie 1% soil, 1% black talc, 15% Guizhou soil, 3% white carbon black, 10% zirconia micropowder, the mass percentage of the crucible coating material is composed of: 10% pyrophyllite, lanthanum oxide after calcining at 1000°C 90% fine powder, plus 0.3% polyacrylic acid and 0.1% polyvinyl alcohol; the fineness of the zirconia fine powder and lanthanum oxide fine powder is 20µm.

[0028] After the raw materials of the crucible base are mixed, ball milling, sieving, dehydration by pressure filtration, vacuum mud refining, molding and drying are carried out to obtain the crucible body, and then the crucible coating material is prepared into a slurry with good fluidity after batching , sprayed onto the inner surface of the crucible base, and fina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com