White ceramic product capable of being used for open fire and preparation method thereof

A technology of ceramic products and open flames, which is applied in the field of white ceramic products and its preparation, can solve the problems of easy cracking, color absorption, use, etc., achieve high temperature resistance to expansion coefficient, not easy to crack and fall off, and broaden the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

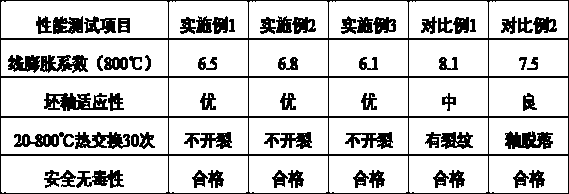

Examples

Embodiment 1

[0025] This embodiment provides a white ceramic product that can be used in an open flame, wherein the green body includes the following components in parts by weight: 20 parts of kaolin, 30 parts of potassium feldspar, 15 parts of quartz, 15 parts of high-permeability silica powder, and 4 parts of cordierite , 5 parts of zirconia and 3 parts of yttrium oxide;

[0026] The glaze includes the following components in parts by weight: 10 parts of petalite, 20 parts of potassium feldspar, 8 parts of spinel, 5 parts of fused quartz, 3 parts of burnt talc, 2 parts of fumed silica, high temperature and low expansion melting 4 parts of block, 4 parts of mica hematite and 2 parts of titanium dioxide.

[0027] This embodiment also provides a preparation method for the above-mentioned white ceramic product, comprising the following steps:

[0028] (1) Ingredients: Mix the components of the green body evenly according to the ratio, first use mechanical stirring to mix, and then use a thr...

Embodiment 2

[0034] This embodiment provides a white ceramic product that can be used in an open flame, wherein the green body includes the following components in parts by weight: 40 parts of kaolin, 15 parts of potassium feldspar, 15 parts of quartz, 8 parts of high-permeability silica powder, and 10 parts of cordierite , 2 parts of zirconia and 1 part of yttrium oxide;

[0035] The glaze includes the following components in parts by weight: 20 parts of petalite, 5 parts of potassium feldspar, 8 parts of spinel, 10 parts of fused quartz, 5 parts of burnt talc, 6 parts of fumed silica, high temperature and low expansion melting 8 parts of block, 8 parts of mica hematite and 5 parts of titanium dioxide.

[0036] This embodiment also provides a preparation method for the above-mentioned white ceramic product, comprising the following steps:

[0037] (1) Ingredients: Mix the components of the green body evenly according to the ratio, first use mechanical stirring to mix, and then use a thre...

Embodiment 3

[0043] This embodiment provides a white ceramic product that can be used in an open flame, wherein the green body includes the following components in parts by weight: 30 parts of kaolin, 20 parts of potassium feldspar, 20 parts of quartz, 10 parts of high-permeability silica powder, and 7 parts of cordierite , 3 parts of zirconia and 2 parts of yttrium oxide;

[0044] The glaze includes the following components by weight: 15 parts of petalite, 15 parts of potassium feldspar, 5 parts of spinel, 7 parts of fused quartz, 4 parts of calcined talc, 4 parts of fumed silica, high temperature and low expansion melting 6 parts of block, 6 parts of mica hematite and 3 parts of titanium dioxide.

[0045] This embodiment also provides a preparation method for the above-mentioned white ceramic product, comprising the following steps:

[0046] (1) Ingredients: Mix the components of the green body evenly according to the ratio, first use mechanical stirring to mix, and then use a three-rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com