Lightweight ceramisite prepared from coal ashes and gasification slag as well as preparation method and application thereof

A technology of lightweight ceramsite and fly ash, which is applied in the field of building materials, can solve the problems of density, strength, water absorption and other quality indicators that need to be improved, limited raw material sources, and high energy consumption in production, so as to achieve good environmental protection benefits and good economics. Benefits, the effect of high carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

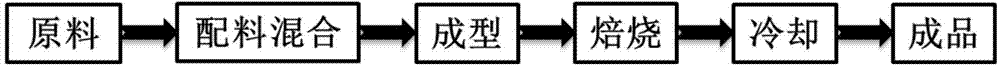

Method used

Image

Examples

Embodiment 1

[0070] The preparation of lightweight ceramsite with fly ash and gasification slag comprises the following steps:

[0071] a. Pretreatment: Dry the fly ash and gasification slag raw materials in a blast drying oven at 100°C, conduct appropriate ball milling on the dried fly ash and gasification slag raw materials, and then pass the fly ash and gasification slag raw materials through 100 Mesh sieve (standard sieve made by Taylor), the sieve residue is less than 5%, packaged for use; other raw materials pass through 200 mesh sieves, packaged for use;

[0072] B. Mixing of ingredients: composition according to weight percentage: base material: 50% of fly ash, 30% of gasification slag, 14% of potassium feldspar, 6% of albite feldspar, additive: 1% of silicon carbide (additional, silicon carbide quality account for 1% of the base material) to weigh, the total mass of the base material is 50g, and the fly ash, gasification slag, potassium feldspar, albite feldspar, and silicon carbi...

Embodiment 2

[0094] Utilize fly ash and gasification slag to prepare lightweight ceramsite, comprise the following steps:

[0095] a. Pretreatment: Dry the fly ash and gasification slag raw materials in a blast drying oven at 100°C, conduct appropriate ball milling on the dried fly ash and gasification slag raw materials, and then pass the fly ash and gasification slag raw materials through 100 Mesh sieve, the sieve residue is less than 5%, packaged for use;

[0096] b, batching mixing: composition according to weight percentage: base material: fly ash 60%, gasification slag 10%, potassium feldspar 20%, albite 10%, auxiliary agent: silicon carbide 0.8% (extra, silicon carbide quality account for 0.8% of the base material) to weigh, the total mass of the base material is 50g, and the fly ash, gasification slag, potassium feldspar, albite feldspar, and silicon carbide are evenly mixed together;

[0097] c. Forming: add appropriate amount of water to the mixed raw materials, and automaticall...

Embodiment 3

[0105] The preparation of lightweight ceramsite by using fly ash and gasification slag comprises the following steps:

[0106] a. Pretreatment: Dry the fly ash and gasification slag raw materials in a blast drying oven at 100°C, conduct appropriate ball milling on the dried fly ash and gasification slag raw materials, and then pass the fly ash and gasification slag raw materials through 100 Mesh sieve, the sieve residue is less than 5%, packaged for use;

[0107] B. Mixing of ingredients: composition according to weight percentage: base material: fly ash 78%, gasification slag 10%, potassium feldspar 8%, albite 4%, additive: silicon carbide 0.5% (additional, silicon carbide quality account for 0.5% of the base material), semi-coke 1% (additional, the semi-coke quality accounts for 1% of the base material), the total mass of the base material is 50g, weigh the material, and fly ash, gasification slag, potassium feldspar, Sodium feldspar and silicon carbide are evenly mixed tog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com