Zircon-free anorthite-based opaque glaze and preparation method thereof

An opaque glaze and anorthite technology, applied in the field of ceramic glaze, can solve problems such as excessive radioactivity of products, damage to consumers' health, easy yellowing of the glaze surface, low cost, favorable promotion and application, and scope of application. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

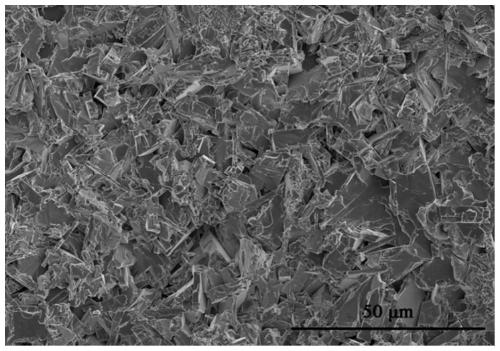

Image

Examples

Embodiment 1

[0022] 1. A zirconium-free anorthite-based opacified glaze in this embodiment. The raw material composition is: clay 8wt%, potash feldspar 10wt%, albite 20wt%, quartz 15wt%, calcite 15wt%, wollastonite 5wt% %, alumina 8wt%, zinc oxide 3wt%, burnt talc 5wt%, glass powder 10wt%, nucleating agent 1wt% (TiO 2 0.5 wt%+B 2 O 3 0.5wt%). Among them, the raw material composition of glass powder is SiO 2 65 wt%, Al 2 O 3 4 wt%, CaO 8wt%, MgO 3wt%, K 2 O 5wt%, Na 2 O 15wt%.

[0023] 2. The method for preparing the above-mentioned zirconium-free anorthite-based opacified glaze in this embodiment includes the following steps:

[0024] (1) According to the raw material composition of the opal glaze, add water and wet ball milling (according to the mass ratio of materials: ball stone: water = 1:2:0.5) for 8 hours to obtain a glaze slurry with a particle size D90 of 8.3 μm;

[0025] (2) Add water to adjust the specific gravity of the glaze slurry to 1.75g / cm 3 , The flow rate is 25s / 100mL, and the ...

Embodiment 2

[0028] 1. In this embodiment, a zirconium-free anorthite-based opacified glaze, the raw material composition is: clay 8wt%, albite 30wt%, quartz 15wt%, calcite 20wt%, alumina 8.5wt%, zinc oxide 3wt% , Burned talc 6wt%, glass powder 9wt%, nucleating agent P 2 O 5 0.5 wt%. Among them, the raw material composition of glass powder is SiO 2 70 wt%, Al 2 O 3 3wt%, CaO 8wt%, MgO2wt%, K 2 O 4wt%, Na 2 O 13wt%.

[0029] 2. The method for preparing the above-mentioned zirconium-free anorthite-based opacified glaze in this embodiment includes the following steps:

[0030] (1) According to the raw material composition of the opal glaze, add water and wet ball milling (according to the mass ratio of materials: ball stone: water = 1:2:0.5) for 6 hours to obtain a glaze slurry with a particle size D90 of 9.5 μm;

[0031] (2) Add water to adjust the specific gravity of the glaze slurry to 1.50g / cm 3 , The flow rate is 20s / 100mL, and the glaze slurry is applied to the surface of the body by spraying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface gloss | aaaaa | aaaaa |

| Surface gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com