Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Good opacification effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anion easy-cleaning functional ceramic additive and preparation method thereof, ceramic prepared by using additive and preparation method thereof

The invention belongs to the technical field of ceramics, and particularly relates to an anion easy-cleaning functional ceramic additive and a preparation method thereof, a ceramic prepared by using the additive and a preparation method thereof. The additive is prepared from the following raw materials in percentage by mass: 10-16% of Chongguang stones with a particle size of 5-20 microns, 16-25% of tourmaline with a particle size of 5-15 microns, 5-15% of copper pectolite with a particle size of 5-20 microns, 8-12% of nano titanium dioxide, 6-8% of nano zinc oxide, 5-10% of lead-free frits, 7-20% of rare earth materials, 8-10% of superfine alumina, 8-15% of superfine quartz powder and 5-10% of sodium carbonate. The preparation method of the additive comprises the following steps of carrying out mixed ball-milling on the lead-free frits, the rare earth materials, the superfine alumina, the superfine quartz powder and the sodium carbonate firstly; and then, adding the Chongguang stones, the tourmaline, the copper pectolite, the nano titanium dioxide and the nano zinc oxide into the obtained product, and ball-milling the obtained mixture, so that the additive with a particle size of 1-10 microns is obtained. The additive disclosed by the invention has a self-polarizing performance, and has strong adsorption and decomposition functions, so that negative ions are produced; and after the additive is added into a ceramic, the ceramic is extremely easy to clean and not stained, and has no hidden dirt, therefore, the ceramic has a strong affinity to water.

Owner:ZIBO BAIKANG ECONOMIC & TRADE

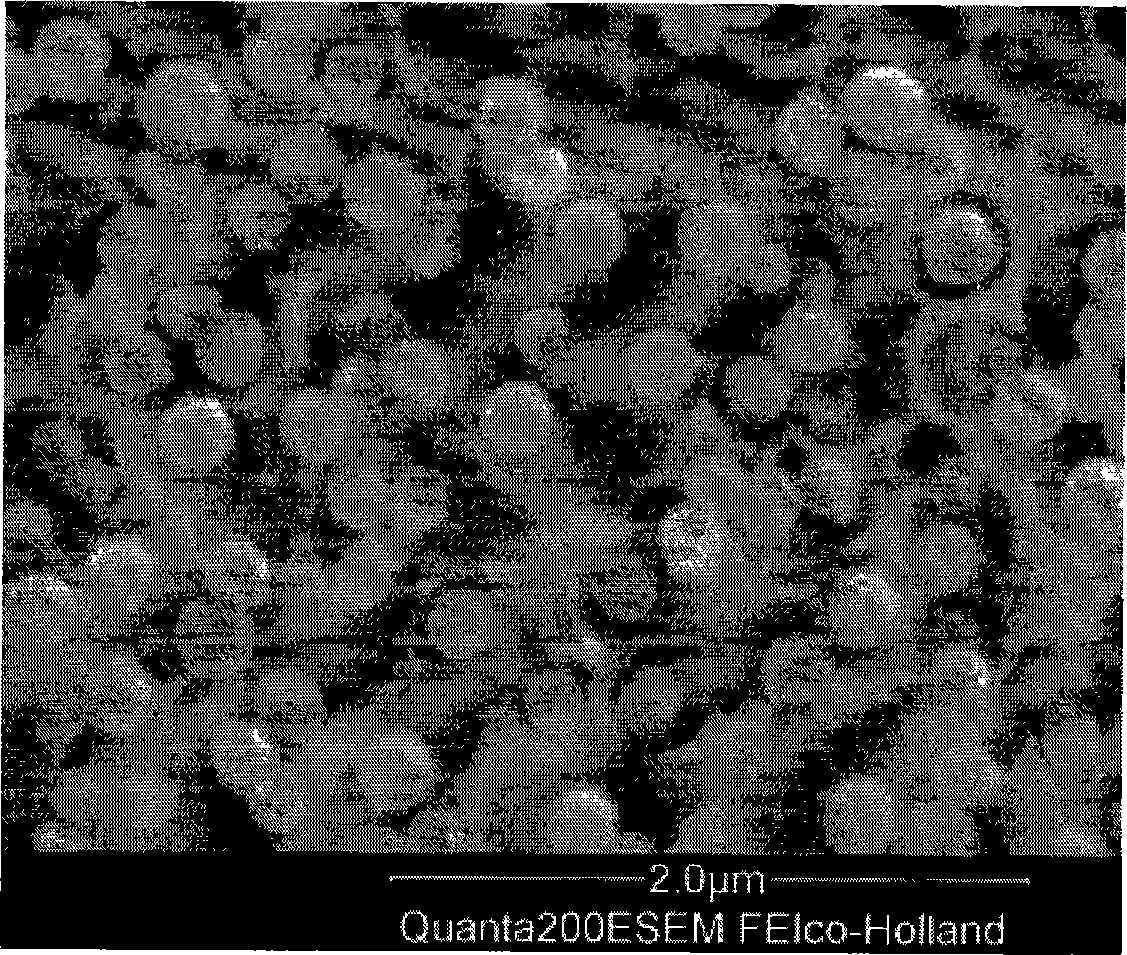

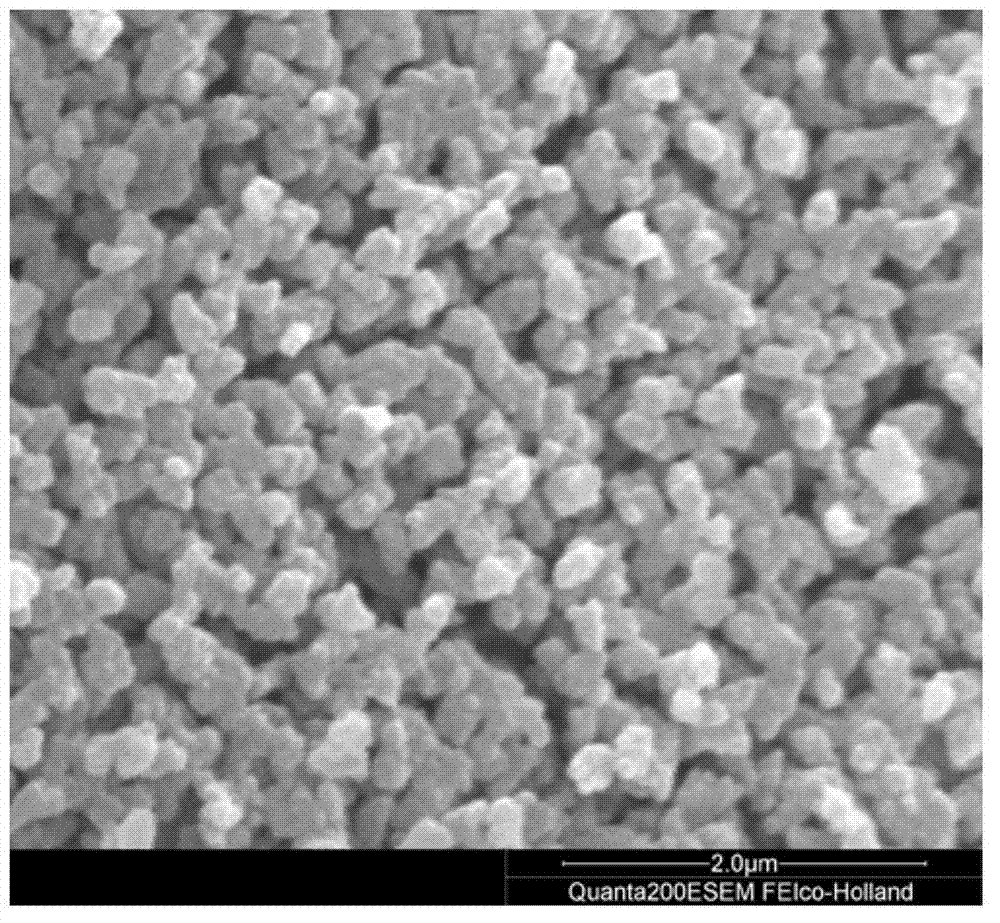

Non-fluorin environment protection opacifiedglass material and method for manufacturing same

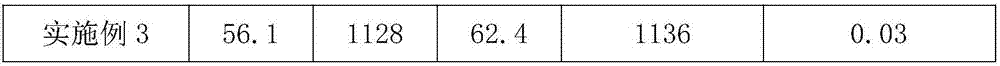

InactiveCN101244889AGood opacification effectHigh opacityGlass furnace apparatusGlass furnacePhosphate

The invention relates to a fluorine-free environmental opaque glass material and a preparation method thereof and belongs to the new material field of glass. Composition of the glass material is SiO2-Al2O3-B2O3P2O5-MgO-CaO-SrO-BaO-Li2O-Na2O-K2O. The preparation method comprises that raw materials are mixed to make an even batch, then the batch is put into a corundum crucible, and then the batch is casted and molded after being melted and insulated under 1500 DEG C to 1520 DEG C for 3 hours, and then the batch is insulated and annealed under 550 DEG C to 560 DEG C for 1 hour. The preparation of the invention replaces the fluoride with a small amount of phosphate to generate opaque effect, and no environmental pollution can be caused in the industrial production of the opaque glass, and the short service life of glass furnaces and safety problems caused by fluorine can be avoided, and a compact net structure reconstruction technology is adopted to adjust the relative contents of SiO2 and P2O5, meanwhile, alkali metals or alkaline earth metal oxides are introduced, and the glass produces significant opaque effect under the spontaneous phase separation in the process of cooling, and a small amount of B2O3 is introduced to enhance the opaque effect of the glass, meanwhile, a certain amount of Al2O3 is introduced to endow the glass with excellent chemical stability.

Owner:QILU UNIV OF TECH

Foam ceramic insulation material and preparation method thereof

InactiveCN106082962AImprove insulation effectIncrease productivityCeramic materials productionCeramicwareLithiumFoaming agent

The invention relates to a foam ceramic insulation material and a preparation method thereof. The foam ceramic insulation material comprises the following raw materials in weight content: 30-95% of industrial waste material by mixing one or more of waste slag, waste stone flour or kaolin mine tailing, 1-18% of lithium porcelain stone, 1-20% of light-burnt magnesia, 1-30% of clay, and 0.5-20% of a foaming agent. The preparation method comprises the following steps: A) performing ball-milling on the raw materials of the foam ceramic insulation material to prepare the granular powder; B) performing burden distribution on powder and sintering the powder at the temperature of 1000-1400 DEG C, insulating for 2-5 hours to obtain the foam ceramic insulation material; and C)cutting the foam ceramic insulation material and processing the foam ceramic insulation material. According to the invention, waste slag, waste stone flour or kaolin mine tailing are used for preparing the foam ceramic insulation material, the preparation has advantage of environmental protection, the foam ceramic insulation material has the advantages of uniform distribution of inner pores, low heat conduction coefficient, high intensity and light weight, and can be used as building fireproof, insulation and energy-saving material and other insulation energy saving industries.

Owner:江西嘉陶无机材料有限公司

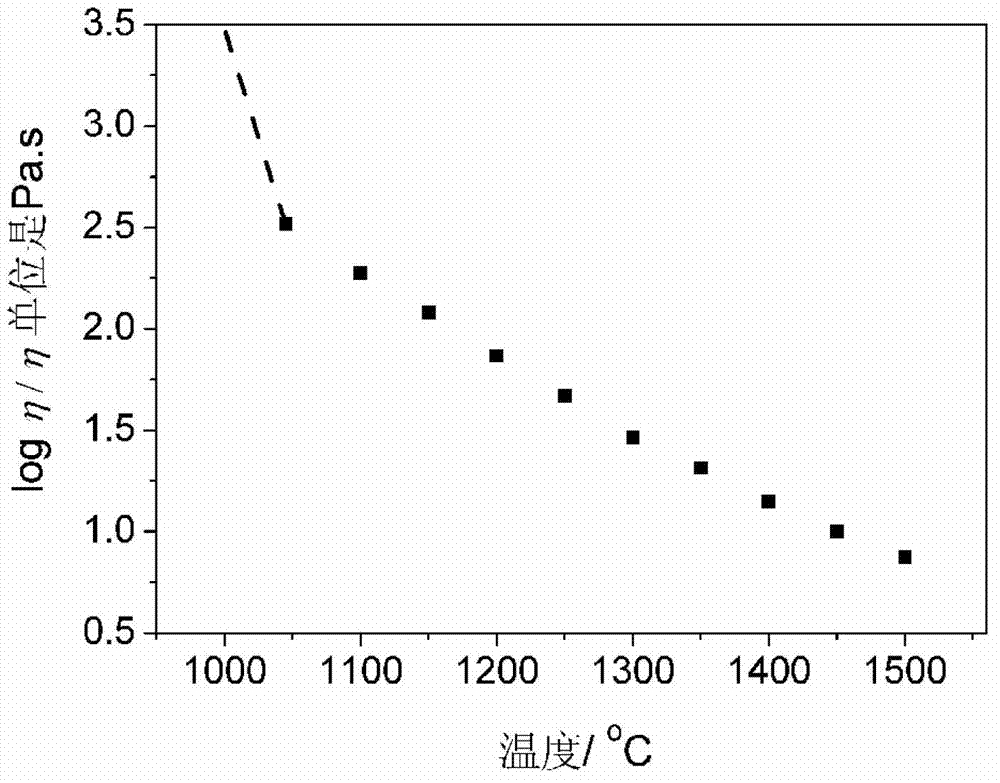

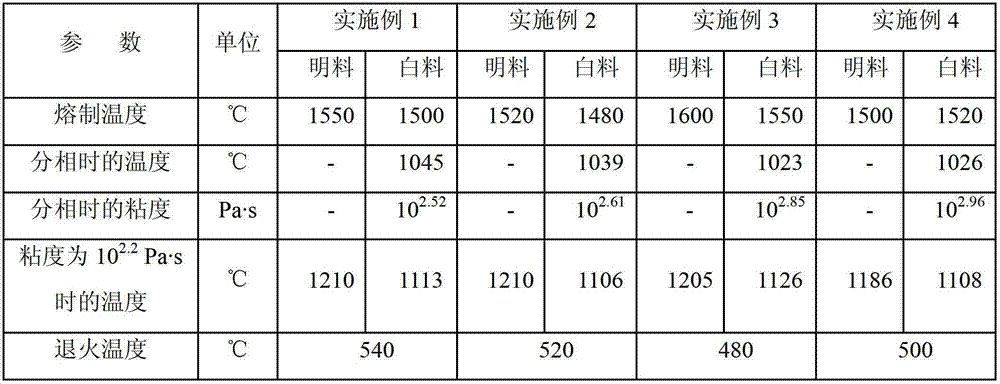

Manufacturing method for colored fluorine-free imitation ceramic glaze

ActiveCN102786202AReduce cooling rateSlow coolingGlass blowing apparatusDevitrificationPhase splitting

A manufacturing method for colored fluorine-free imitation ceramic glaze belongs to the field of advanced glass materials. According to the manufacturing method, a melt jacking blowing method is adopted, and the five-layer colored fluorine-free imitation ceramic glaze is prepared by dip blowing according to the sequence of bright material, white material, bright material, pigment and bright material. The manufacturing method overcomes the defect that the traditional imitation ceramic glass production greatly depends on the initial temperature of glass melt phase-splitting or devitrification and the cooling speed during forming; and meanwhile, the manufacturing method realizes very good opacifying effect under the condition of lower phosphorous content, and the common defects of uneven opacifying degree, stripe and the like are not liable to occur.

Owner:淄博市宝泉轻工制品有限公司

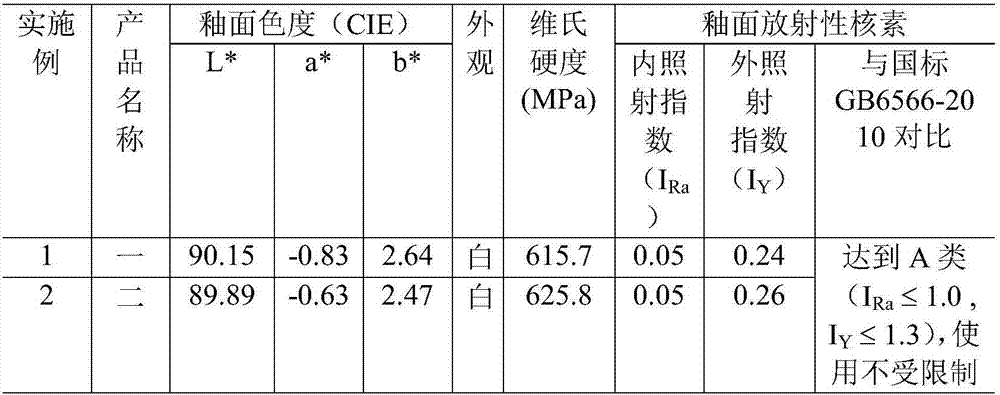

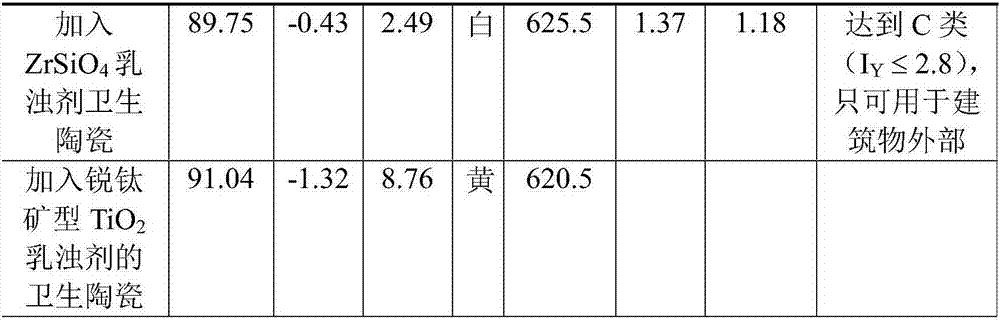

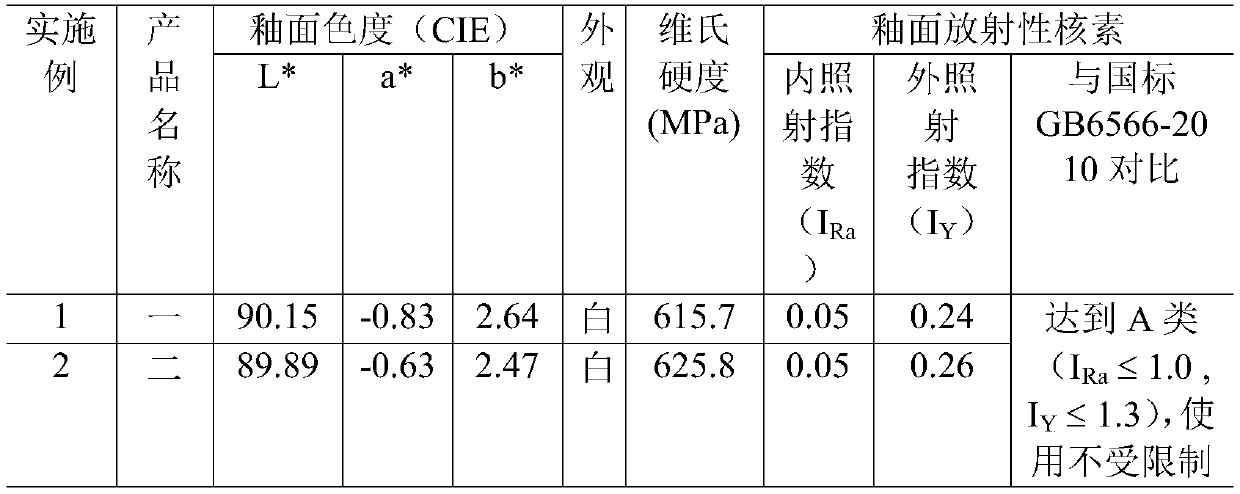

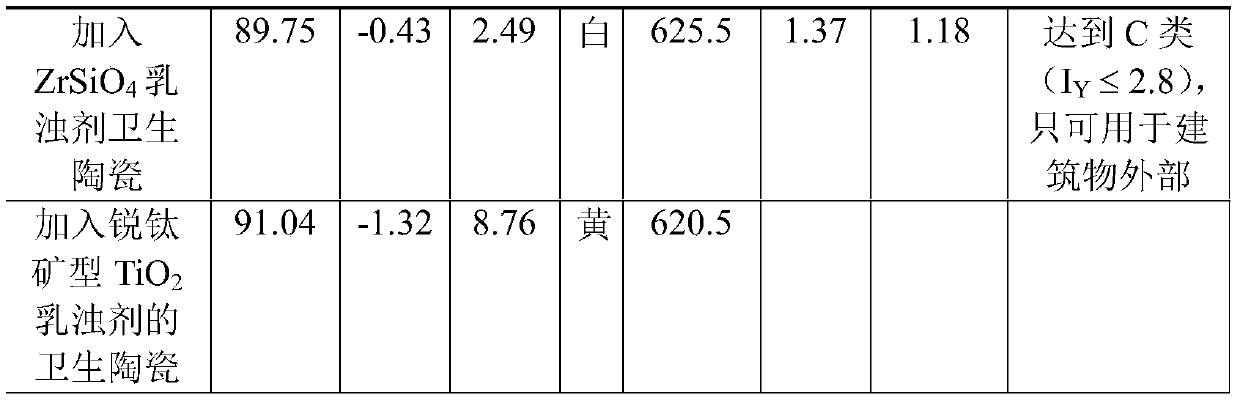

Technique of sanitary ceramic using composite titanium dioxide opacifier

The invention provides a technique of sanitary ceramic using a composite titanium dioxide opacifier in glaze slurry. The technique adopts the composite titanium dioxide opacifier, phosphate, potash feldspar, quartz, calcite, dolomite, zinc oxide, aluminum oxide, kaoline and a frit as raw materials for preparing opalescent glaze of the ceramic. The sanitary ceramic prepared by the technique has the advantages that: (1) a glaze layer of the prepared sanitary ceramic is tightly combined with a green body; a glaze surface has a good opacifying effect, and is high in whiteness, strong in luster sensation and delicate; (2) the composite titanium dioxide opacifier glaze and the glaze layer of the sanitary ceramic are free from radioactive substances and radioactive radiation and has effects of safety and protection of user health; and (3) the composite titanium dioxide opacifier is lower in cost and price; and phosphate is added into the glaze at the same time to further reduce the use amount of the composite titanium dioxide opacifier, so that the cost of the sanitary ceramic is lowered.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Ceramic glaze with water activating function, preparation method thereof, ceramic prepared by ceramic glaze and preparation method of ceramic

The invention belongs to the technical field of ceramic and particularly relates to ceramic glaze with a water activating function, a preparation method thereof, ceramic prepared by the ceramic glaze and a preparation method of the ceramic. The ceramic glaze is prepared by, by mass percentage, 60-80% of ceramic glaze base material, 5-20% of ceramic additives with the water activating function, 5-8% of nano-zirconia, 0.5-5% of phosphate, 1-5% of nano cesium oxide, 2-8% of yttrium oxide, 1-5% of nano titanium dioxide and 3-8% of tourmaline. The preparation method of the ceramic glaze includes: ball milling the ceramic glaze base material until all the ceramic glaze base material can pass a 250-mesh sieve, adding the rest of components, adding water and ceramic diluent to prepare slurry, ball milling, and discharging. The ceramic glaze has the advantages that the ceramic glaze can acts on water molecular cluster structures to allow the hydrogen bonds to be destroyed and chemical bonds to break, large molecular clusters become small molecular clusters only containing 5-6 water molecules, toxic gas dissolved in water is released at the same time, the water become slightly alkaline, and the activity of the water is increased.

Owner:ZIBO BAIKANG ECONOMIC & TRADE

Zinc-boron-silicon system heat-resisting environmental-friendly emulsion opal glass and preparation method thereof

InactiveCN102910818ASmall expansion coefficientImprove heat resistanceGlass shaping apparatusGlass productionThermal dilatationAlkali metal oxide

The invention relates to zinc-boron-silicon heat-resisting environmental-friendly emulsion opal glass and a preparation method thereof. The glass is characterized by consisting of the following components in percentage by mass: 68-78% of SiO2, 0-4% of Al2O3, 10-15% of B2o3, 5-8% of ZnO, 0.5-3% of CaO, 0-2% of MgO, 2.5-4.5% of alkali metal oxide and 1-5% of P2O5. The preparation method comprises the steps of: preparing the components into a glass batch and melting; then moulding by casting; and annealing to obtain the emulsion opal glass. The method is environmental-friendly and free of pollution and the glass does not contain fluorine, has less erosion to the refractory matters and is molded in one step; and compared with the conventional emulsion opal glass, the prepared zinc-boron-silicon heat-resisting environmental-friendly emulsion opal glass is low in thermal expansion coefficient, stable in opacification, less in environment pollution, less in corrosivity of refractory matters, high in opacity, less in phosphorus volatilization and good in glossiness.

Owner:DONGHUA UNIV

Wear-resistant domestic ceramic product and preparation method thereof

InactiveCN110117184AHigh strengthHigh hardnessCeramic materials productionClaywaresWear resistantMullite

The invention provides a wear-resistant domestic ceramic product and belongs to the technical field of ceramics. The ceramic product comprises a matrix and glaze. The matrix is prepared from, by weight, 35-40 parts of kaolin, 4-8 parts of quartz, 23-28 parts of potash feldspar, 18-22 parts of clay, 2-5 parts of zircon sand, 10-15 parts of waste ceramic powder and 15-20 parts of alumina. The glazeis prepared from, by weight, 10-15 parts of kaolin, 10-15 parts of orthoclase, 10-15 parts of mullite, 18-25 parts of alumina, 12-18 parts of zinc oxide, 1-3 parts of talc, 6-10 parts of zircon sand,5-10 parts of dolomite, 3-6 parts of ferric oxide and 3-6 parts of copper oxide. A preparation method of the wear-resistant domestic ceramic product includes the following steps that matrix slurry isprepared, glaze slip is prepared, and green bodies are immersed in the glaze slip, then subjected to bisque firing and finally sintered at 1280-1380 DEG C. The domestic ceramic product obtained by theprovided raw materials and the process through sintering has the advantages of good wear resistance and high shock resistance.

Owner:福建省德化县合和陶瓷技术开发有限公司

High-strength whitening glaze slurry for ceramic and preparation method of high-strength whitening glaze slurry

The invention discloses high-strength whitening glaze slurry for ceramic and a preparation method of the high-strength whitening glaze slurry. The glaze slurry is prepared from raw materials and water through mixing and ball milling; the raw materials comprise, in parts by weight, 16-22 parts of potash feldspar, 15-19 parts of calcite, 16-20 parts of quartz, 10-14 parts of frit, 1-5 parts of sodium carbonate, 10-14 parts of calcium carbonate, 0.5-2.5 parts of dolomite, 4-6 parts of a whitening agent and 0.5-2.5 parts of a reinforcing agent, wherein the whitening agent is prepared from 50-70 parts of kaoline, 50-70 parts of titanium dioxide, 1-2 parts of calcium stearate and 2-4 parts of gamma-chloropropyltrimethoxysilane; the reinforcing agent is prepared from, in parts by weight, 10-14 parts of hydroxyapatite, 10-20 parts of calcined talc and 0.2-0.4 parts of an aluminum zirconium coupling agent. The high-strength whitening glaze slurry for the ceramic adopts reasonable materials, a preparation method is simple, the production cost is low, the performance is good, and the high-strength whitening glaze slurry is worth popularization and application.

Owner:JIAXIAN HONGDA PORCELAIN CO LTD

Opacified glaze and preparation method thereof

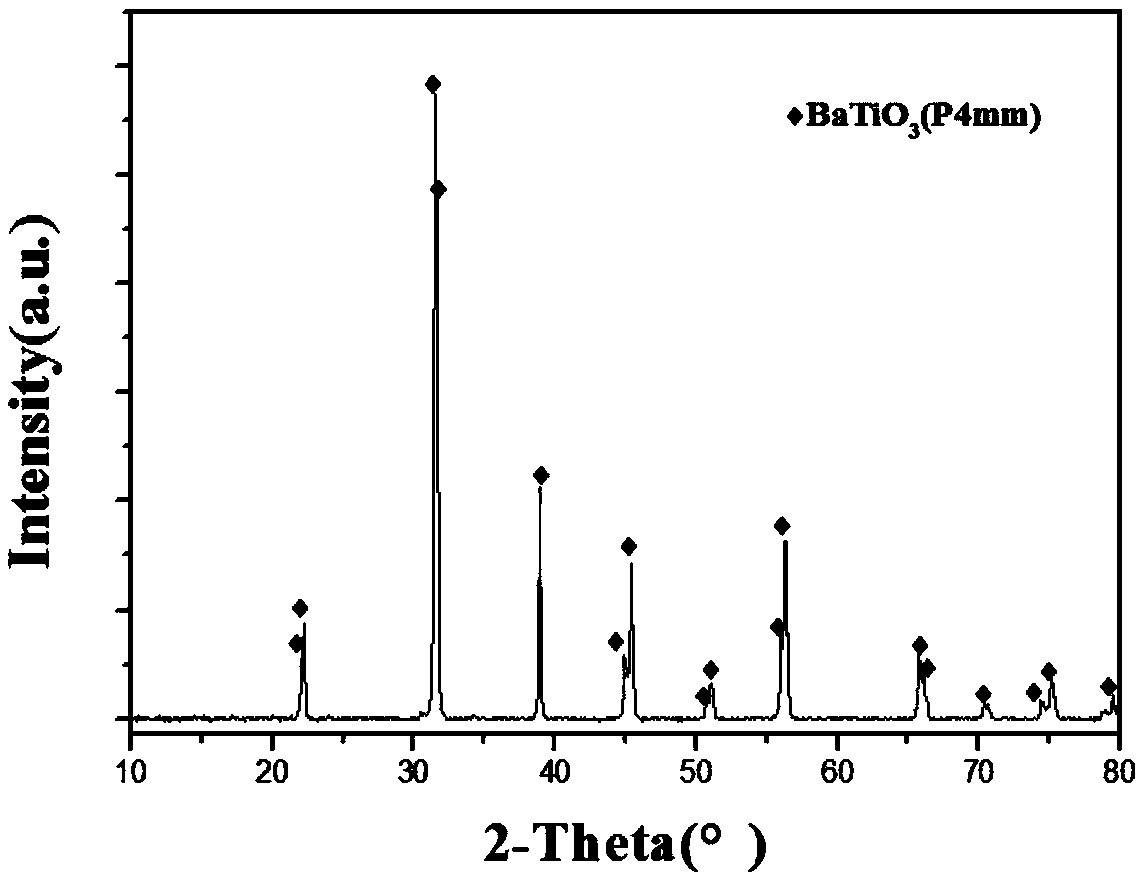

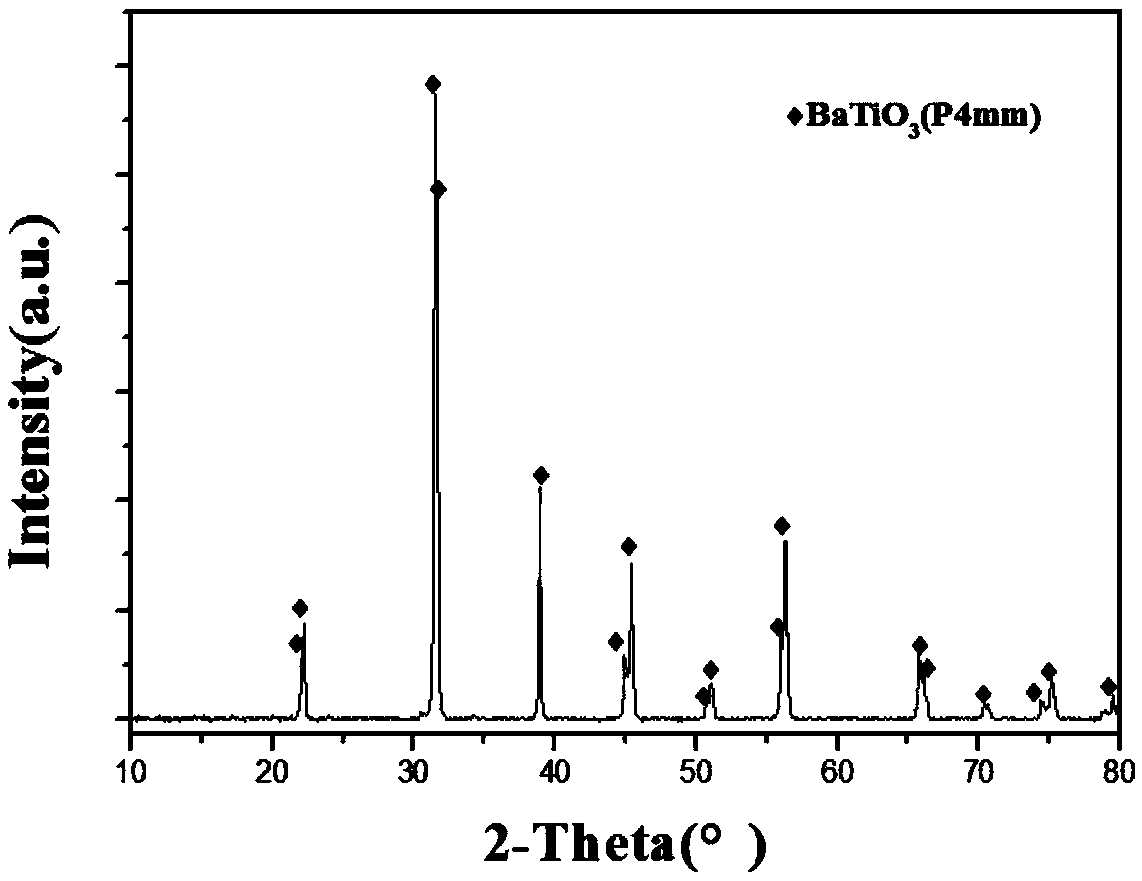

ActiveCN106698949AGlazed effect is goodWell mixedAlkaline earth titanatesTetragonal crystal systemBarium titanate

The invention relates to opacified glaze and a preparation method thereof. The opacified glaze is prepared by using barium titanate power of a tetragonal system as an opacifier, wherein the particle size of the barium titanate power is 400-800 nm. The preparation method comprises the following steps that 1, glaze powder is prepared, wherein raw materials for preparing the glaze powder are weighed in proportion and then are mixed evenly to obtain the glaze powder; 2, the opacified glaze is prepared, wherein the glaze powder obtained in the step 1, water and ballstone are arranged in a rapid mill to be milled till screen residues after screening of a 250-mesh screen are 0.1% or below by weight, the obtained glaze slip is the opacified glaze. The high-temperature stable barium titanate power of the tetragonal system is used as the opacifier to prepare the opacified glaze good in opacifying effect and high in whiteness after firing, and the used raw materials are environmentally friendly. Compared with the prior art, the opacified glaze further has the advantage of low cost. In addition, the preparation method of the opacified glaze is simple in process and easy to operate and facilitates large-scale production.

Owner:WUHAN UNIV OF TECH

High-strength and crash-resistant sky blue glaze ceramic product and preparation method thereof

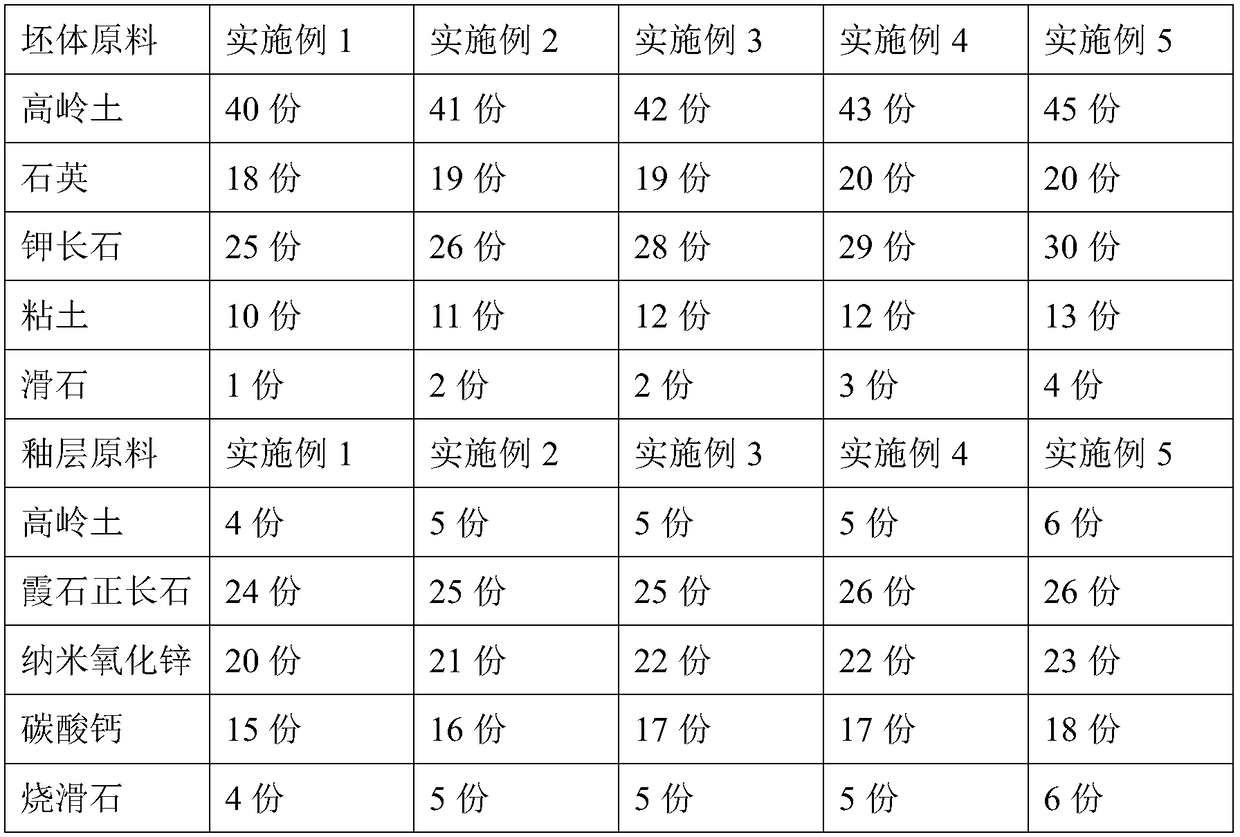

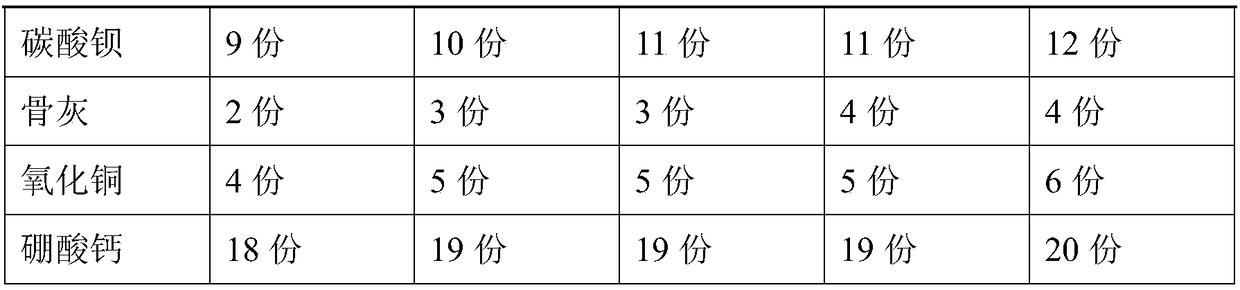

The invention provides a high-strength and crash-resistant sky blue glaze ceramic product which is prepared from an embryo material and a glaze material, wherein the embryo material is prepared from the following raw materials in parts by weight: 40-45 parts of kaolin, 18-20 parts of quartz, 25-30 parts of potassium feldspar, 10-13 parts of clay and 1-4 parts of talcum; the glaze material is prepared from the following raw materials in parts by weight: 24-26 parts of nepheline orthoclase, 20-23 parts of nano-zinc oxide, 15-18 parts of calcium carbonate, 4-6 parts of sintered talc, 4-6 parts ofkaolin, 9-12 parts of barium carbonate, 2-4 parts of bone ash, 4-6 parts of copper oxide and 18-20 parts of calcium borate. The preparation method of the high-strength and crash-resistant sky blue glaze ceramic product comprises the following steps: performing ball milling to obtain embryo material slurry and glaze slurry; making a green body from the embryo material slurry and performing biscuitfiring; glazing; and firing. The ceramic product prepared from the raw materials and by the technology provided by the invention shows a jade-like opalescent semi-transparent sky blue form and has asimple and elegant color as well as excellent crash resistance.

Owner:福建省德化业美陶瓷有限公司

Sanitary shale ceramic and preparation method thereof

The invention discloses a sanitary shale ceramic and a preparation method thereof. The blank of the sanitary shale ceramic comprises the following raw materials: 10-20wt% of Boai clay, 5-15wt% of bauxite, 5-15wt% of white gangue, 5-15wt% of ash waste rock, 1-5wt% of Yuan'an clay, 5-15wt% of black mud, 5-40wt% of shale, 10-20wt% of quartz and 5-25wt% of feldspar. As shale is adopted as a main raw material, the sanitary ceramic with excellent properties are made, the material cost is effectively reduced, meanwhile the product quality is ensured, the sintering temperature is low in the preparation process, energy consumption is effectively reduced, and the production cost is reduced.

Owner:四川金辉卫浴洁具有限公司

Low-fluorine milk glass product and preparation method thereof

The invention discloses a low-fluorine milk glass product and a preparation method thereof. The low-fluorine milk glass product comprises the following raw materials: SiO2, Al2O3, B2O3, CaO, BaO, Na2O, ZnO, K2O, CeO2, MgO, Cu2O, SnO, Sb2O3, CaF and modified algae powder. The preparation method comprises the following steps: melting raw materials so as to prepare glass melt; performing casting molding on the glass melt; annealing the molded glass product; finally, removing the annealed glass product out of an annealing furnace, and performing air cooling to a room temperature, thereby obtaining the low-fluorine milk glass product. The glass product is high in refractive index and excellent in opaque effect, and is relatively high in thermal stability, chemical stability and mechanical strength, simple to prepare, low in energy consumption, less in pollution and wide in market prospects.

Owner:合肥钢骨玻璃制品有限公司

Composite zirconium silicate opacifier, preparation method thereof and application

The invention discloses composite zirconium silicate opacifier, a preparation method thereof and an application. The composite zirconium silicate opacifier is prepared from the following materials in weight percentage, 65%-84% of zircon sand, 1%-15% of calcined alumina and 15%-30% of low-temperature frit. The low-temperature frit is prepared from the following raw materials in weight percentage, 25%-35% of potassium feldspar powder, 10%-20% of apatite powder, 2%-8% of fluorite powder, 10%-15% of calcium carbonate, 15%-18% of sodium borate, 1%-8% of zinc oxide and 2%-8% of quartz powder. The glazing L value of the composite zirconium silicate opacifier is basically higher than 91, opacifying effects are ideal, production cost is reduced, and the radioactivity of a product can be effectively controlled.

Owner:MATRIX GUANGZHOU CHEM CORP

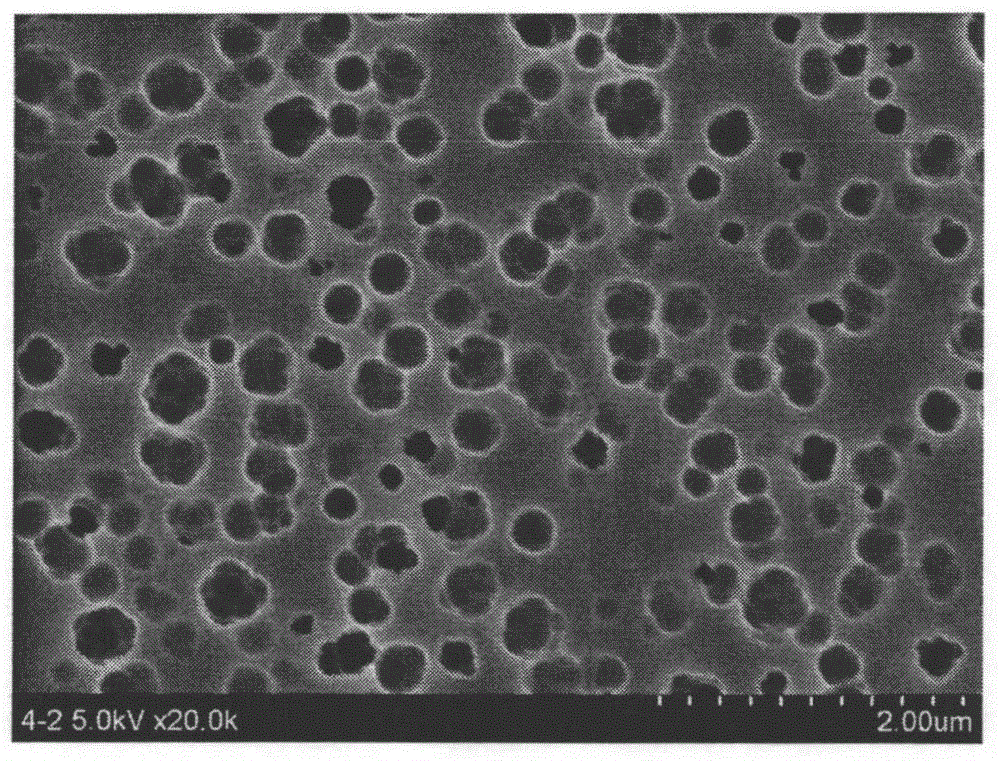

Semitransparent high haze opal glass for LED and preparation method thereof

The invention provides semitransparent high haze opal glass for an LED and a preparation method thereof. The semitransparent opal glass for the LED provided by the invention is characterized by comprising the following components by weight percent: 60-68% of SiO2, 0-4% of Al2O3, 6-10% of B2O3, 1-5% of ZnO, 0-3% of CaO, 0-2% of MgO, 6-13% of alkali metal oxide, 2-5% of fluoride and 1-5% of P2O5. The preparation method comprises the following steps: mixing all the components according to the proportion to prepare glass batch; fusing at 1450-1550 DEG C; casting for formation or drawing for formation; naturally cooling or naturally cooling after annealing, so as to obtain the semitransparent opal glass for the LED. According to the semitransparent opal glass series prepared through the preparation method, the light transmittance is guaranteed, and the problems that the LED light is dazzling and blue ray overflows are avoided; for a glass sheet with the thickness of 3 mm, the light transmittance is 2-10%, the haze value is 30-95, and the brightness is 60-80.

Owner:DONGHUA UNIV

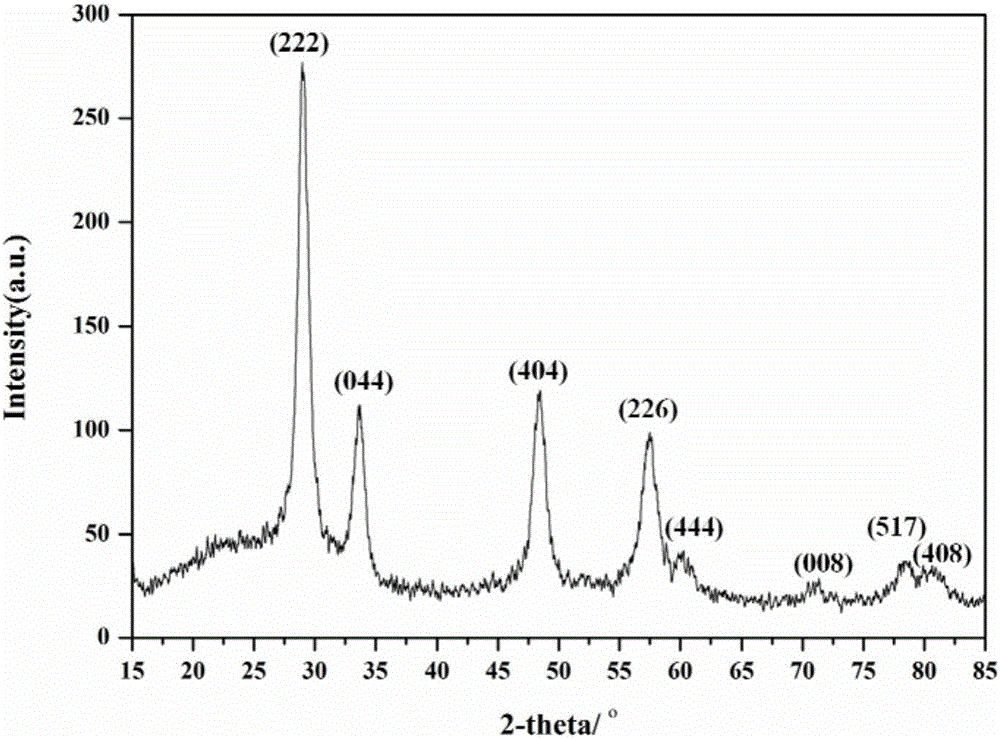

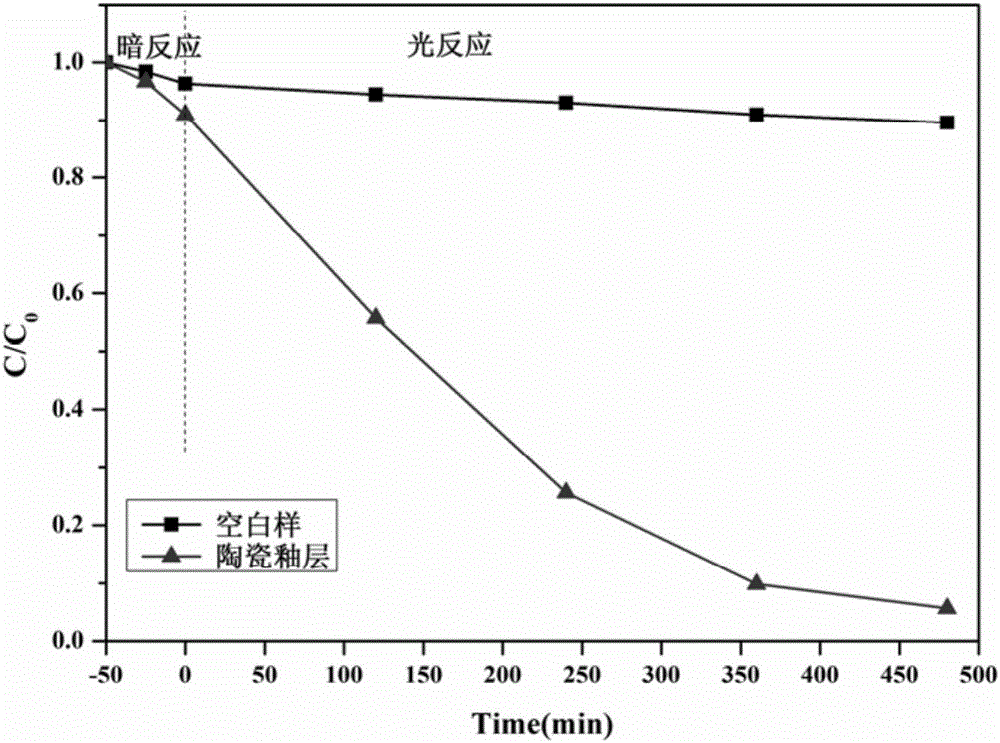

Preparation method of bismuth zirconate microcrystal ceramic glaze with photocatalytic function

ActiveCN106630621ATightly boundAffect aestheticsMetal/metal-oxides/metal-hydroxide catalystsZirconatePotassium

The invention relates to a preparation method of bismuth zirconate microcrystal ceramic glaze with a photocatalytic function. The preparation method includes: blending quartz, potassium feldspar, albite, borax, Bi2O3, Suzhou kaolin and lithium carbonate according to the mass ratio, performing heat preservation at 1270-1290 DEG C for 20-40 minutes, taking out, pouring into water for quenching, and grinding to obtain a material A; blending the material A, the Bi2O3, ZrO2 and the Suzhou kaolin according to the mass ratio to obtain a material B; adding the material B and a dispersing agent into water, and evenly stirring to prepare glaze slip; glazing the surface of ceramic with the glaze slip, and sintering to obtain the bismuth zirconate microcrystal ceramic glaze with the photocatalytic function. The preparation method has the advantages that the ceramic glaze is prepared by the sintering process, coating is not needed, the prepared functional glaze can be tightly combined with a ceramic matrix, the photocatalyst generated during the sintering of the Bi2O3 and the ZrO2 is evenly distributed in the glaze, and the 'rainbow effect' which affects glaze attractiveness is not generated.

Owner:SHAANXI UNIV OF SCI & TECH

Negative ion easy-cleaning functional ceramic additive

The invention belongs to the technical field of ceramics, and in particular relates to a negative ion easy-cleaning functional ceramic additive. The negative ion easy-cleaning functional ceramic additive is made of the following raw materials by mass: 10 to 16% of Chongguang stones with a particle size of 5-20 microns, 16 to 25% of tourmaline with a particle size of 5-15 microns, 5-15% of copper pectolite with a particle size of 5-20 microns, 8-12% of nano titanium dioxide, 6-8% of nano zinc oxide, 5-10% of lead-free frits, 7-20% of rare earth materials, 8-10% of superfine alumina, 8-15% of superfine quartz powder and 5-10% of sodium carbonate. The preparation method of the additive comprises the following steps of carrying out mixed ball-milling on the lead-free frits, the rare earth materials, the superfine alumina, the superfine quartz powder and the sodium carbonate firstly; and then, adding the Chongguang stones, the tourmaline, the copper pectolite, the nano titanium dioxide andthe nano zinc oxide into the obtained product, and ball-milling the obtained mixture, so that the additive with a particle size of 1-10 microns is obtained. The additive disclosed by the invention hasa self-polarizing performance, and has strong adsorption and decomposition functions, so that negative ions are produced; and after the additive is added into a ceramic, the ceramic is extremely easyto clean and not stained, and has no hidden dirt, and the negative ion easy-cleaning functional ceramic additive has a strong affinity to water.

Owner:JIANGSU TIANZIGE NEW MATERIAL TECH CO LTD

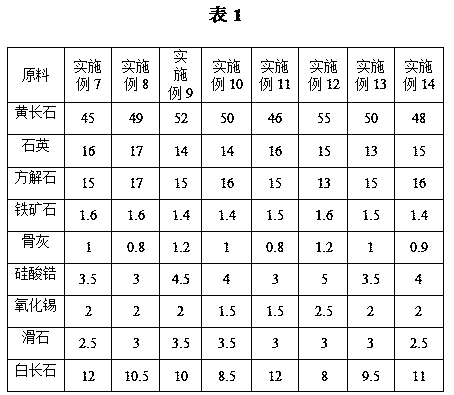

Jun and Ru light greenish-blue glaze

The invention discloses Jun and Ru light greenish-blue glaze. The Jun and Ru light greenish-blue glaze is prepared from raw materials including, by weight, 45-55 parts of melilite, 13-17 parts of quartz, 13-17 parts of calcite, 1.4-1.6 parts of iron ore, 0.8-1.2 parts of bone ash, 3-5 parts of zirconium silicate, 1.5-2.5 parts of tin oxide, 2.5-3.5 parts of talc and 8-12 parts of feldspar. The Junand Ru light greenish-blue glaze has the advantages that formulas and firing processes are optimized, accordingly the fired Jun and Ru light greenish-blue glaze is light greenish-blue and elegant, isbright and smooth just like jade, is free of cracking, is excellent in milky property just like Jun porcelain, and further has the characteristics similar to pure glaze surfaces and exquisite and soft glaze quality of Ru porcelain; the Jun and Ru light greenish-blue glaze is high in yield and suitable to be used for popularizing and applying practical porcelain, and the optimal yield of the Jun and Ru light greenish-blue glaze can reach 90% at least.

Owner:禹州市大龙山钧瓷文化有限公司

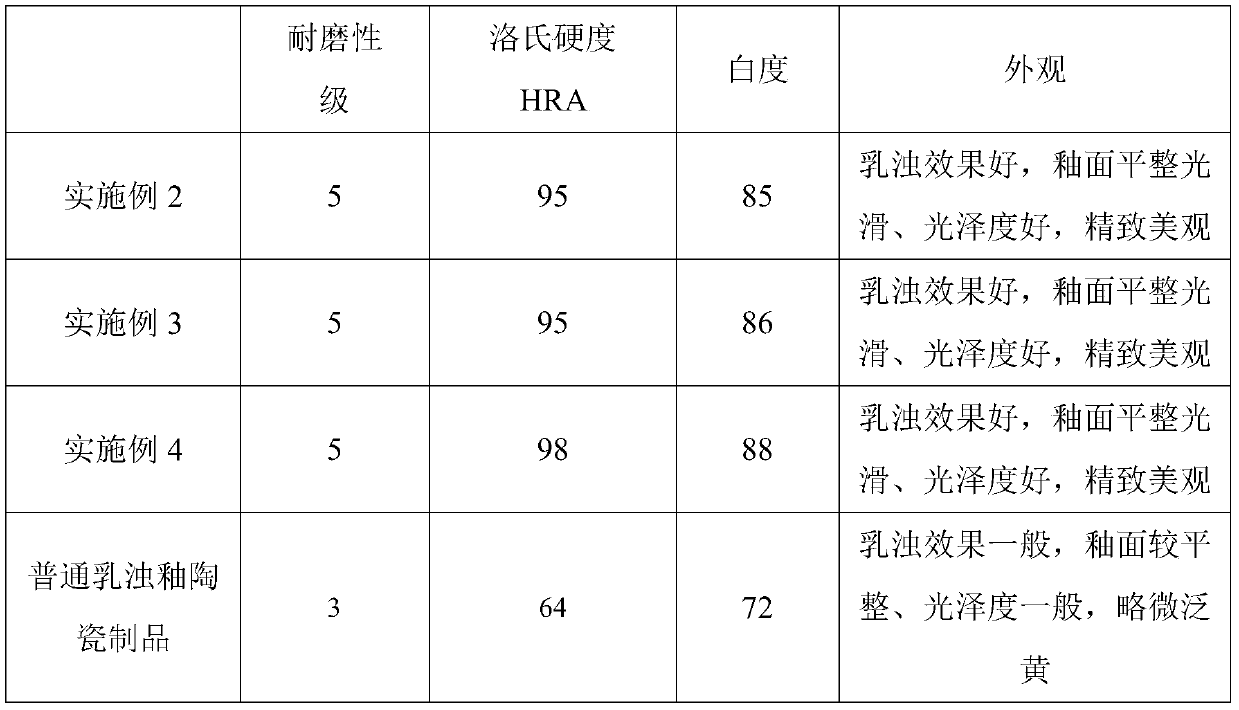

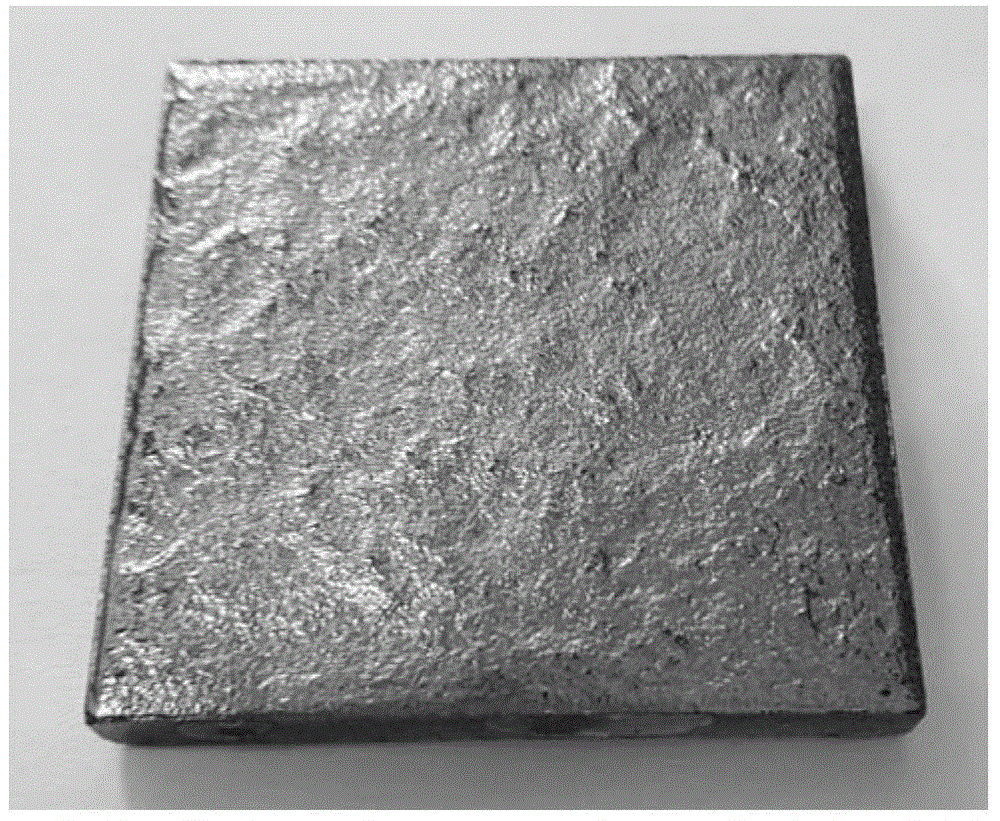

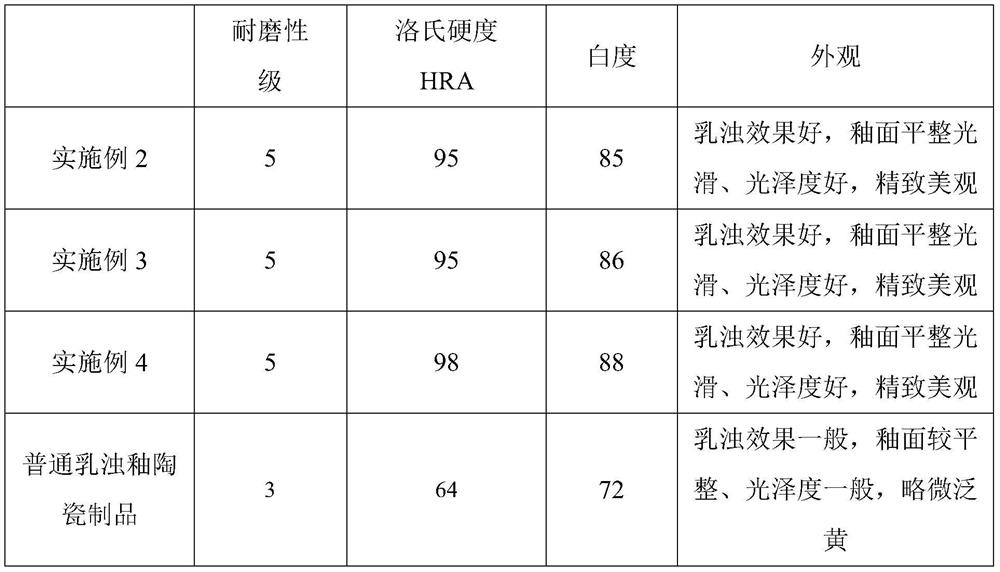

White opaque glaze, white opaque glaze ceramic product and preparation method thereof

The invention discloses white opaque glaze, a white opaque glaze ceramic product and a preparation method of the white opaque glaze ceramic product. The white opaque glaze is prepared from the following raw materials in parts by weight: 20-25 parts of potassium feldspar, 22-27 parts of albite, 8-12 parts of calcite, 16-20 parts of quartz, 10-14 parts of talcum powder, 4.5-5.5 parts of bentonite, 6-8 parts of strontium oxide, 5-7 parts of barium oxide, 6-9 parts of magnesium oxide, 5-6 parts of titanium oxide, 2.5-3.5 parts of barium zirconate titanate, 15-20 parts of zirconium silicate and 4-6parts of yttrium oxide. According to the prepared white opaque glaze ceramic product, the glaze surface (opaque glaze) has the advantages of being good in opaque effect, flat and smooth, good in glossiness, exquisite, attractive and the like, the whiteness is high, and the glaze surface is good in abrasion resistance and high in hardness.

Owner:福建省德化同鑫陶瓷有限公司

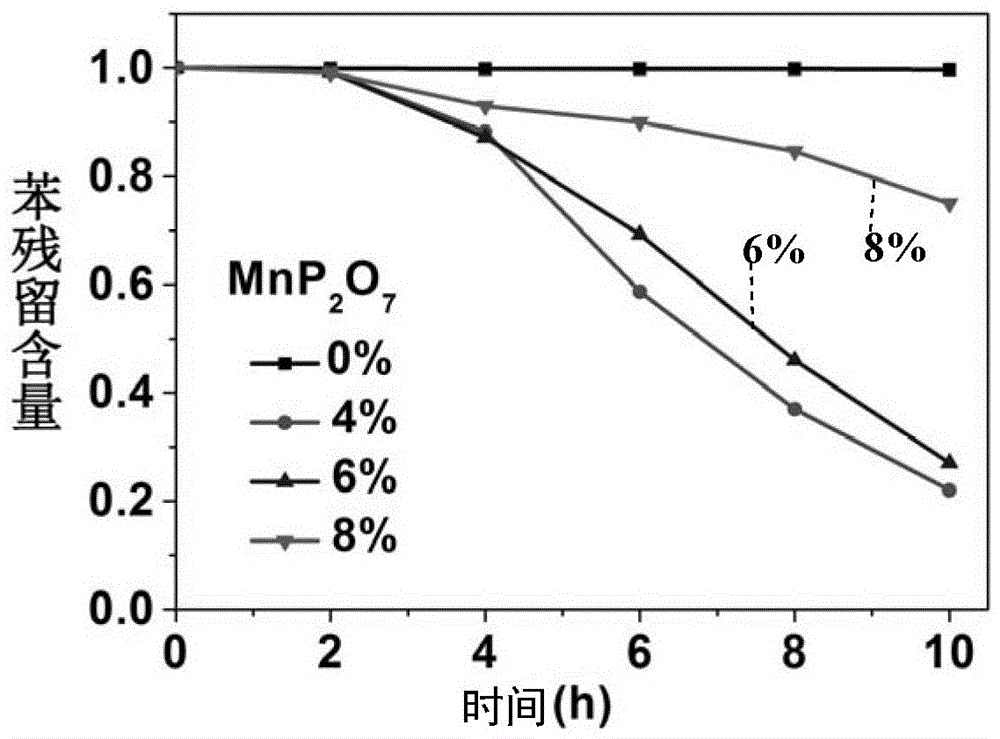

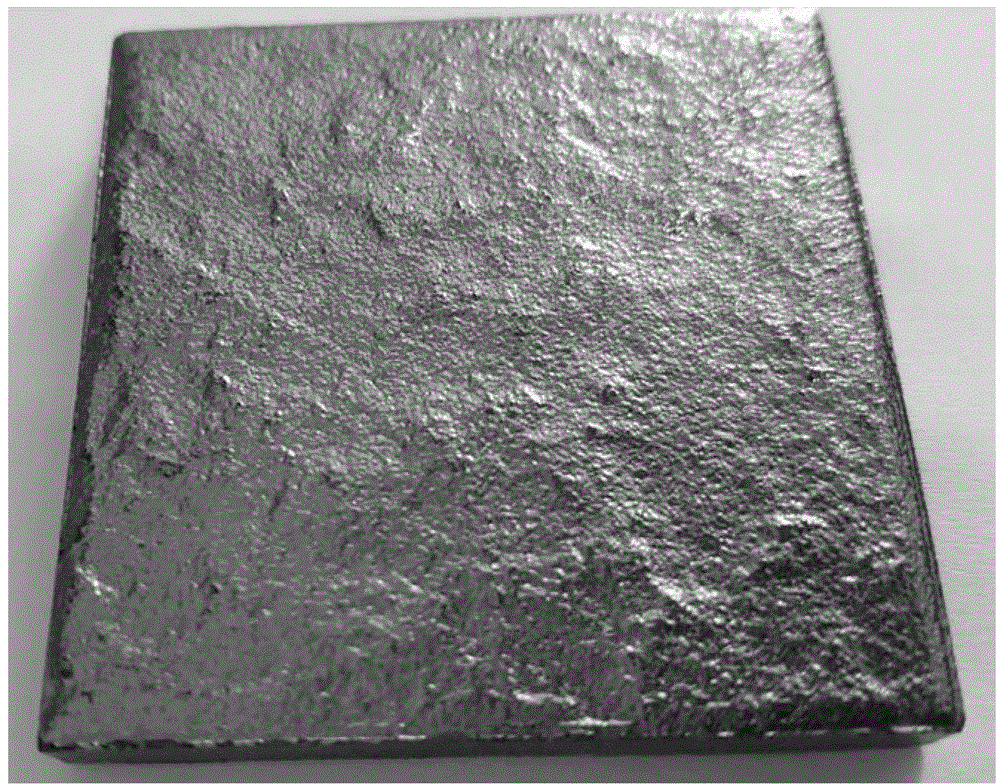

MnP2O7 microcrystalline opacified matt glaze material composition having photocatalysis function and preparation method thereof

The invention relates to a MnP2O7 microcrystalline opacified matt glaze material composition having photocatalysis function and a preparation method thereof. The MnP2O7 microcrystalline opacified matt glaze material composition comprises the following components by mass percentage: 88-92% of powder A, 4-6% of MnP2O7 and 4-6% of kaolin; wherein the powder A comprises the following components by weight: 12-14% of SiO2, 4-6% of Al2O3, 47-49% of P2O5, 1.5-2.5% of MnO, 12-14% of Li2O, 6-8% of Na2O, and 11-13% of K2O. According to the invention, MnP2O7 is firstly introduced in preparation of a glaze material, the surface crystallization and decorative effect of a glaze layer are good, and the toxic gas degradation through photocatalysis is excellent.

Owner:MONALISA GRP CO LTD

Composite zirconium silicate opacifier and its preparation method and application

The invention discloses a composite zirconium silicate opacifier and its preparation method and application. The composite zirconium silicate opacifier is prepared from materials comprising the following components in terms of mass percentage: zircon sand 65% ~84%, calcined alumina 1%~15%, low-temperature frit 15%-30%; the low-temperature frit is prepared from raw materials including the following components in terms of mass percentage: potassium feldspar powder 25%-35% %, apatite powder 10%-20%, fluorite powder 2%-8%, calcium carbonate 10%-15%, borax 15%-18%, zinc oxide 1%-8%, quartz powder 2%-8% . The glazing L value of the composite zirconium silicate opacifier of the invention is basically above 91, the opacifying effect is ideal, the production cost is reduced, and the radioactivity of the product can be effectively controlled.

Owner:MATRIX GUANGZHOU CHEM CORP

Treatment method of waste SCR denitration catalyst, composite opacifier for ceramic, ceramic glaze and ceramic product

The invention provides a treatment method of a waste SCR denitration catalyst, a composite opacifier for ceramic, ceramic glaze and a ceramic product, and relates to the technical field of treatment of waste SCR denitration catalysts. The treatment method comprises the following steps: mixing a pretreated waste SCR denitration catalyst, wollastonite, calcium carbonate and an optional dispersant, and crushing to obtain the composite opacifier for ceramic, wherein the waste SCR denitration catalyst is used as a raw material of the composite opacifier for the ceramic, so that the problem of reutilization of the waste SCR denitration catalyst is solved, the utilization value of the waste SCR denitration catalyst is greatly improved, and meanwhile, the production cost of the composite opacifierfor the ceramic is greatly reduced; and meanwhile, the obtained composite opacifier for the ceramic has good opacifying performance when in use. The invention also provides thecomposite opacifier forceramic. The composite opacifier is prepared by adopting the treatment method of the waste SCR denitration catalyst.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Cracked lavender grey glaze for jun porcelain and preparation method of cracked lavender grey glaze

The invention discloses cracked lavender grey glaze for jun porcelain. The cracked lavender grey glaze is prepared from raw materials in parts by weight as follows: 22-30 parts of melilite, 10-14 parts of benyao, 8-12 parts of glaze stone, 8-12 parts of monatomic silicon powder, 10-14 parts of quartz, 11-15 parts of calcite, 4-6 parts of talc, 0.5-0.7 parts of ferric oxide, 0.5-1.5 parts of tin oxide, 5-7 parts of wood ash and 3-5 parts of knar clay. A preparation method of the cracked lavender grey glaze for jun porcelain comprises steps as follows: (1), the raw materials are crushed and mixed, a mixture is put in a ball mill for ball milling, water is added, mass concentration of glaze is enabled to reach 56%-58%, wet milling is performed for 12-14 h, slurry obtained after wet milling isscreened by a sieve with 200-300 meshes, and glaze slip is obtained; (2), glaze is applied with the thickness being 1.2 mm-1.5 mm; (3), sintering is performed at the temperature of 1300-1320 DEG C.

Owner:禹州市大龙山钧瓷文化有限公司

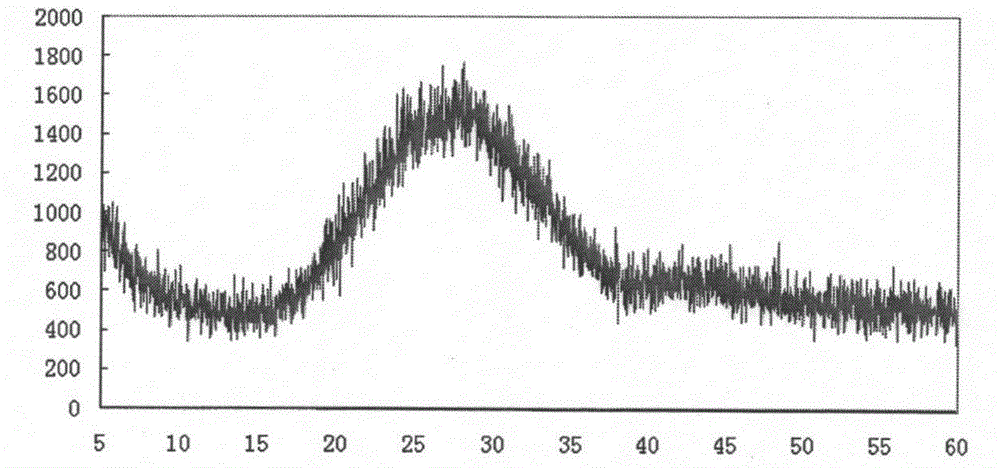

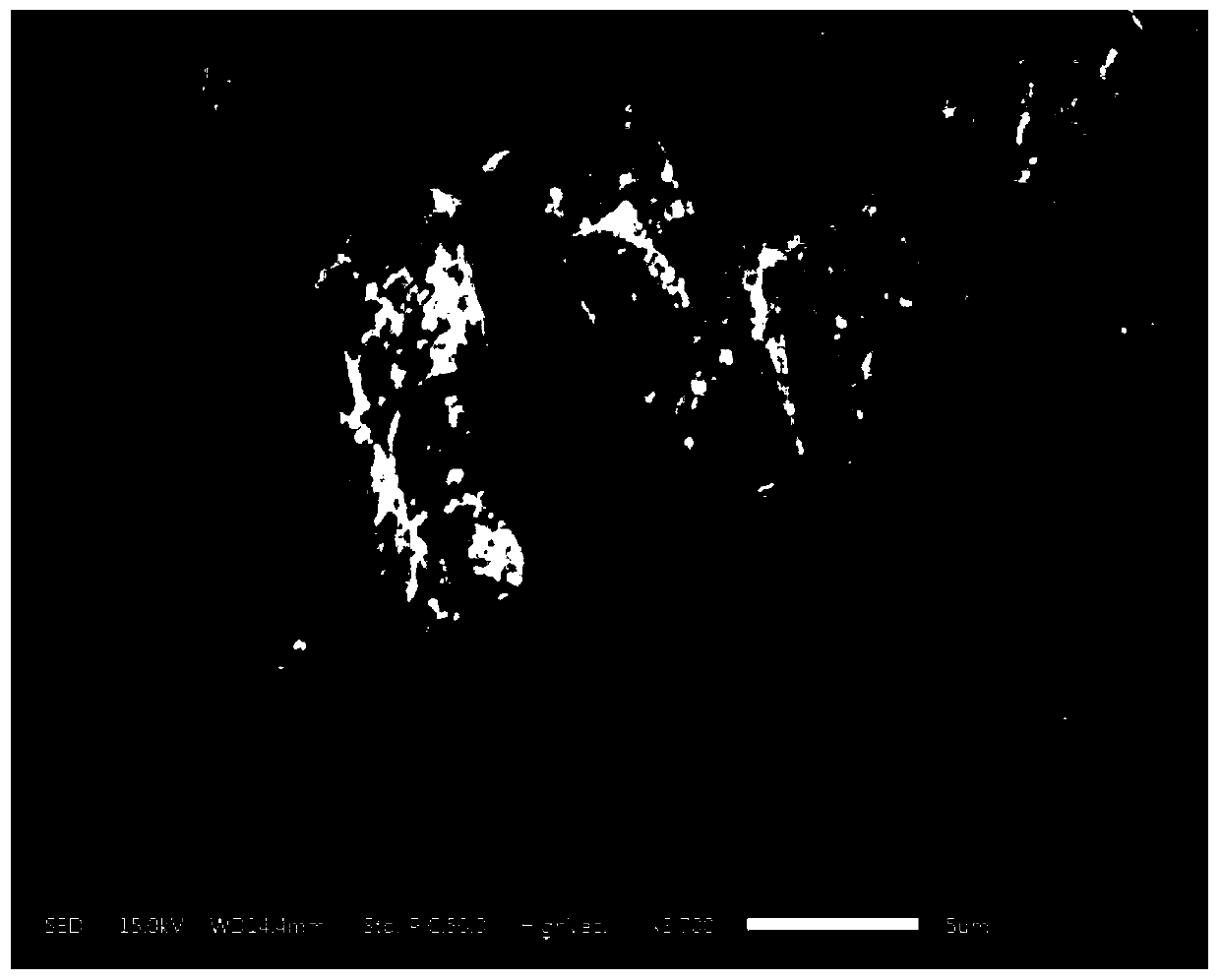

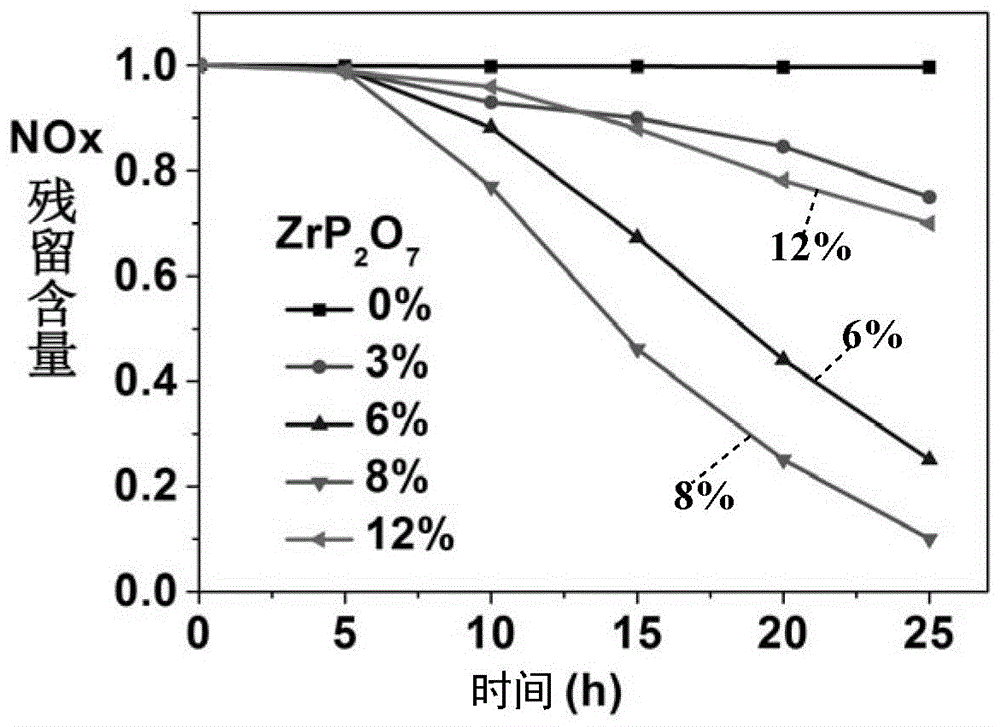

Photocatalytic function ZrP2O7 microcrystalline opaque glaze composition and preparation method thereof

ActiveCN106517794AGood opacity decorative effectImprove performancePhotocatalytic degradationMaterials science

The invention relates to a photocatalytic function ZrP2O7 microcrystalline opaque glaze composition and a preparation method thereof. The microcrystalline opaque glaze composition includes the following components by mass percentage: 86-90% of powder A, 6-8% of ZrP2O7 and 4-6% of kaolin. Specifically, the powder A comprises, by weight, 12-16% of SiO2, 2-4% of Al2O3, 51-55% of P2O5, 2-4% of MgO, 8-10% of Li2O, 8-10% of Na2O and 8-10% of K2O. According to the invention, ZrP2O7 is introduced into the preparation of glaze for the first time, the obtained glaze layer has good opacifying decorative effect, but also has excellent performance of photocatalytic degradation of toxic gas.

Owner:MONALISA GRP CO LTD

White opacity glaze, white opacity glaze ceramic product and preparation method thereof

The invention discloses a white milky glaze, white milky glaze ceramic products and a preparation method thereof. The white milky glaze comprises the following raw materials in parts by weight: 20-25 parts of potassium feldspar, 22-27 parts of albite , 8-12 parts of calcite, 16-20 parts of quartz, 10-14 parts of talc, 4.5-5.5 parts of bentonite, 6-8 parts of strontium oxide, 5-7 parts of barium oxide, 6-9 parts of magnesium oxide, and 5 parts of titanium oxide ~6 parts, barium zirconate titanate 2.5~3.5 parts, zirconium silicate 15~20 parts, yttrium oxide 4~6 parts. The white opacity glaze ceramic product prepared by the present invention has the advantages of good opacification effect on the glaze surface (opacity glaze), smooth and smooth glaze surface, good gloss, exquisite appearance, etc., and has high whiteness and wear resistance of the glaze surface. Good and firm.

Owner:福建省德化同鑫陶瓷有限公司

Composite opacifier and its preparation method and ceramic glaze and ceramics and application

The invention provides a composite opacifying agent, a preparation method of the composite opacifying agent, ceramic glaze, ceramic and application, and relates to the technical field of ceramics. Thecomposite opacifying agent comprises core shell structure microspheres with a core and a coating film, wherein the core comprises phosphorite; the coating film comprises titanium pigment; the mass ratio of the phosphorite to the titanium pigment is (40 to 50):(50 to 60). The composite opacifying agent provided by the invention has the advantages that the core shell structure microspheres are formed by using the phosphorite as the core and using the titanium pigment as the coating film; the raw materials can be easily obtained; the environmental-friendly effect is achieved; the cost is low; the composite opacifying agent is used as an additive to be added into a ceramic formula; the use is convenient and flexible; in the high-temperature firing process of the ceramic glaze, the double effects of phase-separated opacification and crystallization opacification are achieved; the opacification effect is obvious; the enamel layer whiteness is high; the covering power is high; the texture isexquisite and soft.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

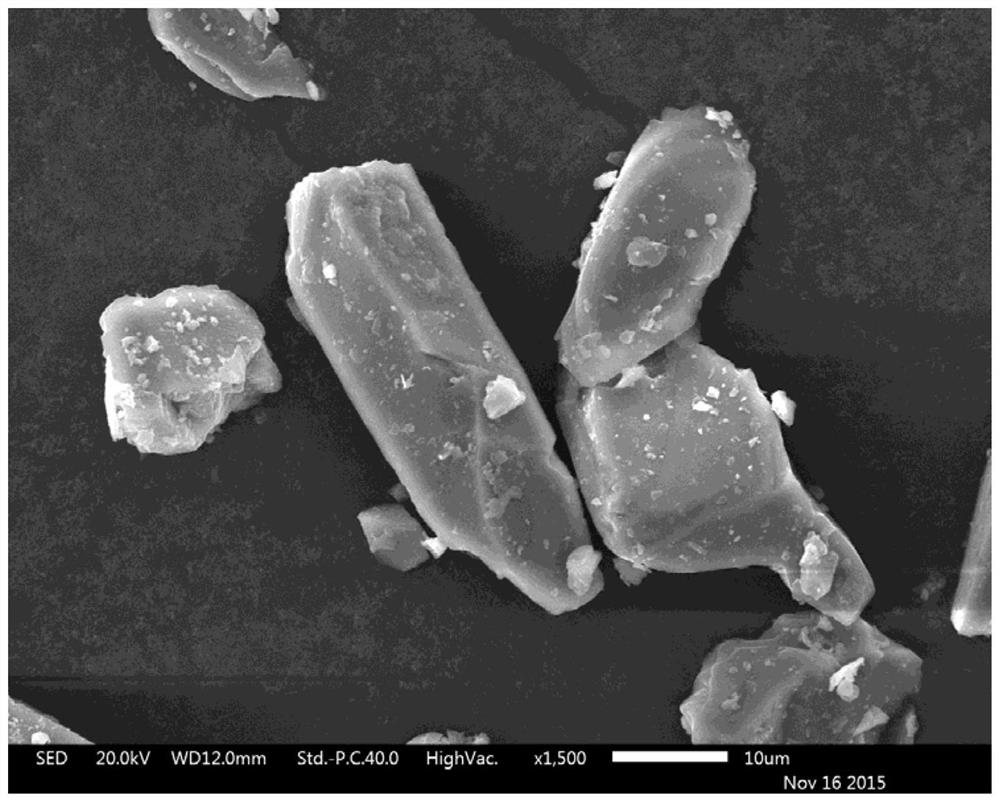

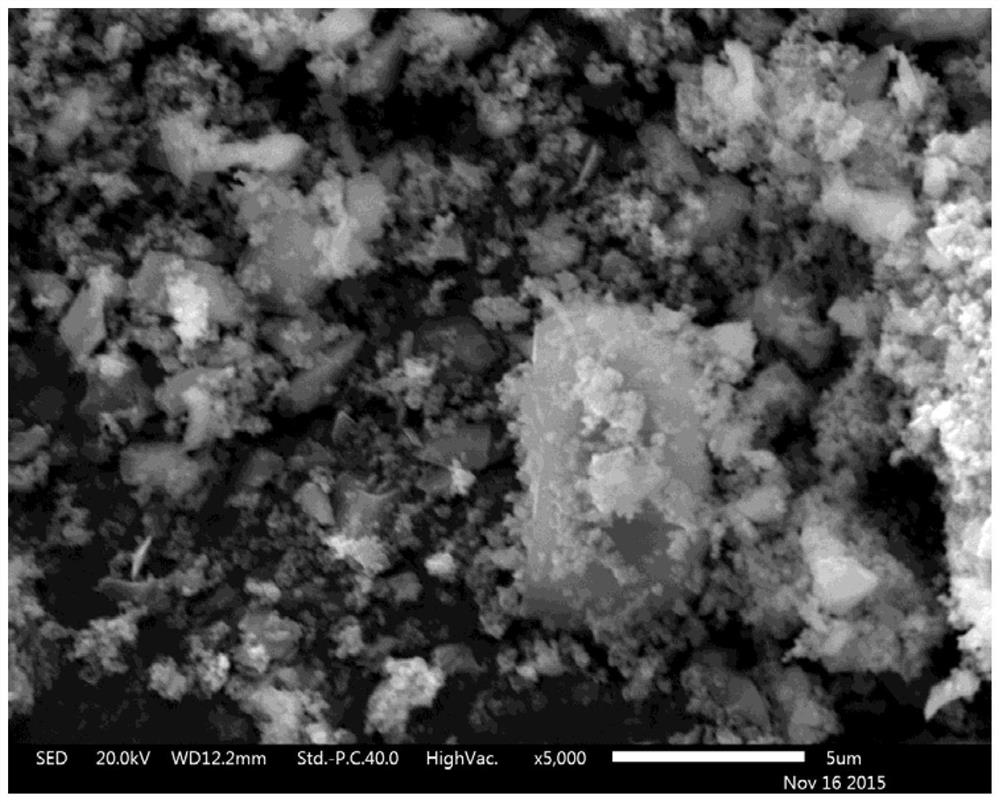

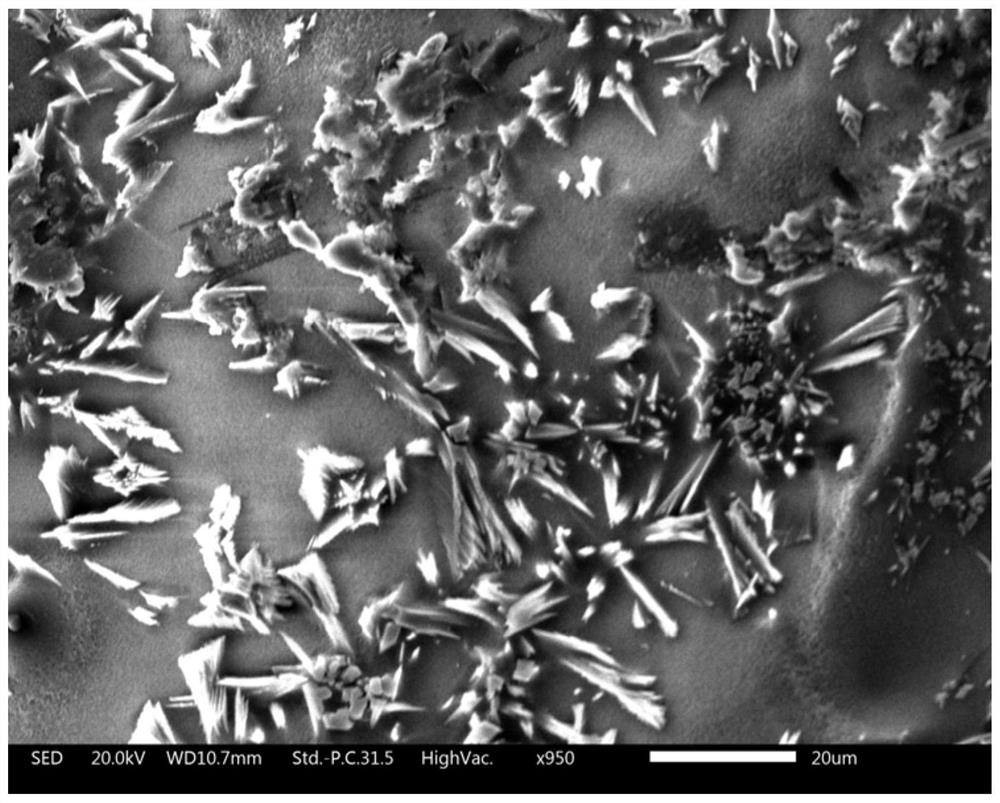

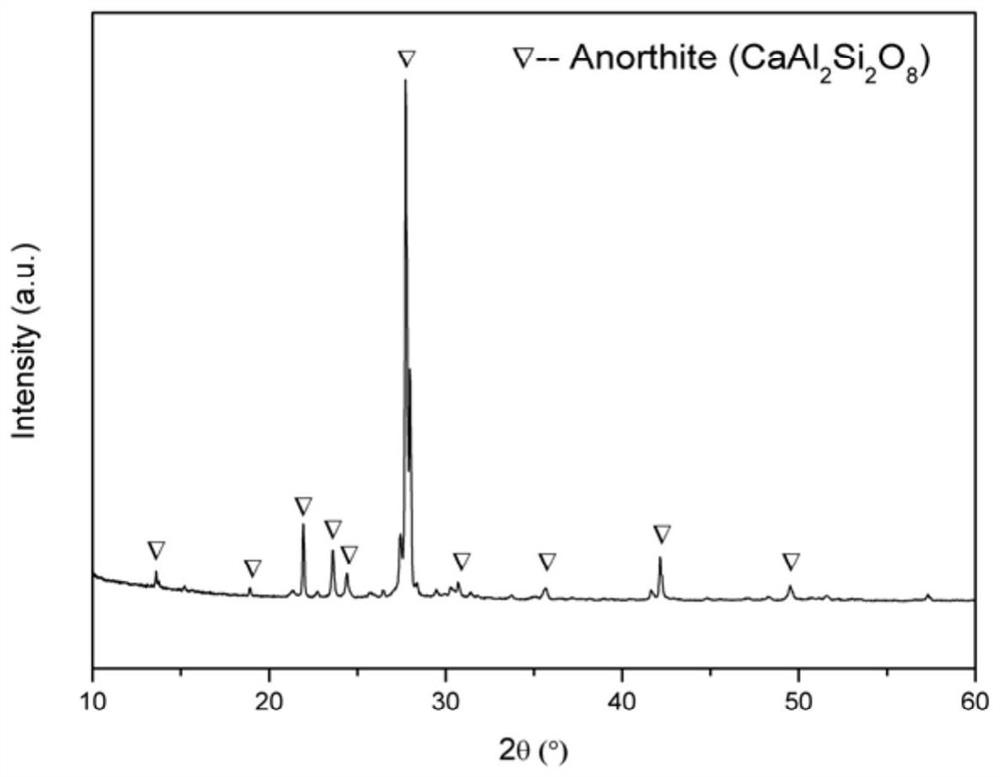

A zirconium-free anorthite-based opacified glaze and preparation method thereof

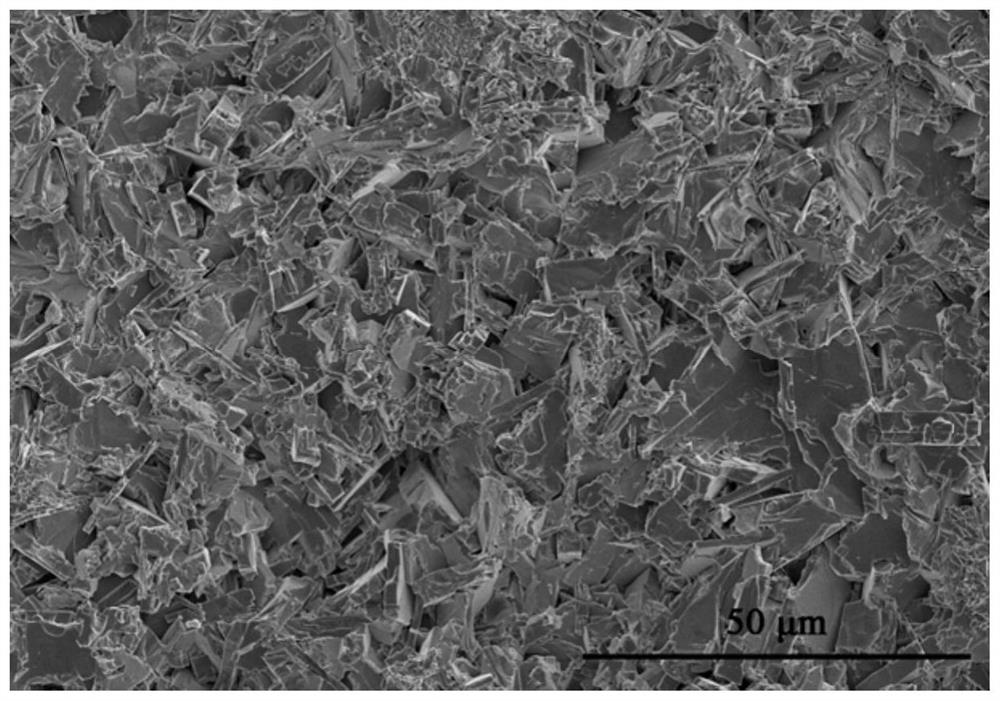

The invention discloses a zirconium-free anorthite-based opacified glaze, which is composed of raw materials: clay 5-10wt%, potassium feldspar 0-10wt%, albite 20-40wt%, quartz 5-20wt%, calcite 10-25wt%, wollastonite 0-10wt%, aluminum oxide 8-15wt%, zinc oxide 1-10wt%, calcined talc 3-8wt%, glass powder 1-15wt%, nucleating agent 0.5-1.5wt%. In addition, a preparation method of the above-mentioned zirconium-free anorthite-based opaque glaze is also disclosed. In the present invention, by using low-cost raw materials and optimizing the formula system, flaky or massive anorthite crystals are precipitated inside the glaze layer, and combined with three-dimensional crystallization, thereby achieving a good glaze opacity effect and improving the glaze. The whiteness and hardness of the surface can effectively improve the product performance. The raw material of the invention does not contain radioactive elements and is harmless to the environment and the human body; and the opacity glaze has a wide application range and is favorable for popularization and application.

Owner:JINGDEZHEN CERAMIC UNIV

White opacified glaze for jun porcelain

InactiveCN109095773AEnhance opacification effectGlaze opacification effect is goodSolventCeramic glaze

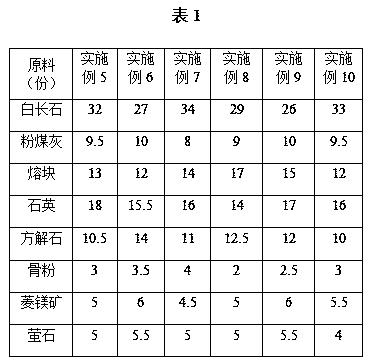

White opacified glaze for jun porcelain is prepared from raw materials in parts by weight as follows: 26-34 parts of white feldspar, 8-10 parts of fly ash, 12-18 parts of frit, 14-18 parts of quartz,10-14 parts of calcite, 2-4 parts of bone powder, 4-6 parts of magnesite and 4-6 parts of fluorite. The fly ash replaces part of feldspar to be used as a main solvent, then, magnesite and fluorite areadded to relieve yellowish-brown influence caused by fly ash and adverse firing influence caused by high impurities and high loss on ignition, the opacifying effect caused by micro bubbles easily produced by the fly ash can be enhanced, the fly ash can be successfully used for firing of the white opacified glaze, the glaze is slight yellow ivory white, the glaze surface has a good opacifying effect, and the white opacified glaze has higher ornamental value.

Owner:周彩云

A kind of technological method of sanitary ceramics using composite titanium dioxide opacifying agent

The invention provides a technique of sanitary ceramic using a composite titanium dioxide opacifier in glaze slurry. The technique adopts the composite titanium dioxide opacifier, phosphate, potash feldspar, quartz, calcite, dolomite, zinc oxide, aluminum oxide, kaoline and a frit as raw materials for preparing opalescent glaze of the ceramic. The sanitary ceramic prepared by the technique has the advantages that: (1) a glaze layer of the prepared sanitary ceramic is tightly combined with a green body; a glaze surface has a good opacifying effect, and is high in whiteness, strong in luster sensation and delicate; (2) the composite titanium dioxide opacifier glaze and the glaze layer of the sanitary ceramic are free from radioactive substances and radioactive radiation and has effects of safety and protection of user health; and (3) the composite titanium dioxide opacifier is lower in cost and price; and phosphate is added into the glaze at the same time to further reduce the use amount of the composite titanium dioxide opacifier, so that the cost of the sanitary ceramic is lowered.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Preparation method of harmless yellow ceramic glaze

The invention discloses a preparation method of harmless yellow ceramic glaze. The harmless yellow ceramic glaze is prepared from potassium feldspar, dolomite, aluminum oxide, asbestos tailing slag, kaolin, zirconium oxychloride octahydrate, ethyl orthosilicate, lithium fluoride, dibutyl phthalate and the like. The potassium feldspar, the dolomite, the asbestos tailing slag and the like are blended and smelted to prepare glaze base materials, yellow dye powder is prepared from the ethyl orthosilicate, praseodymium oxide and like, auto-combustion powder is prepared from the dibutyl phthalate and the like, the lithium fluoride is added in preparation of the yellow dye powder, a reaction place is provided for precipitation of zirconium silicate crystals, temperature needed by reaction of thepraseodymium oxide is reduced, interface bonding of the yellow dye powder and the glaze base materials is optimized, environmental pollution is greatly reduced by a preparation process of the ceramicglaze, process conditions are mild, the obtained glaze is fine, smooth and bright in color, the requirements of consumers can be met, and the preparation method has excellent generalization performance and practicability.

Owner:天长市天意玻璃制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com