Non-fluorin environment protection opacifiedglass material and method for manufacturing same

A manufacturing method and technology of glass materials, applied in glass manufacturing equipment, manufacturing tools, glass furnace equipment, etc., can solve the problems of continuous production of unfavorable opacity glass, increase of glass production cost, etc., and avoid short furnace life and safety problems , enhance the opacification effect, reduce the effect of melting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

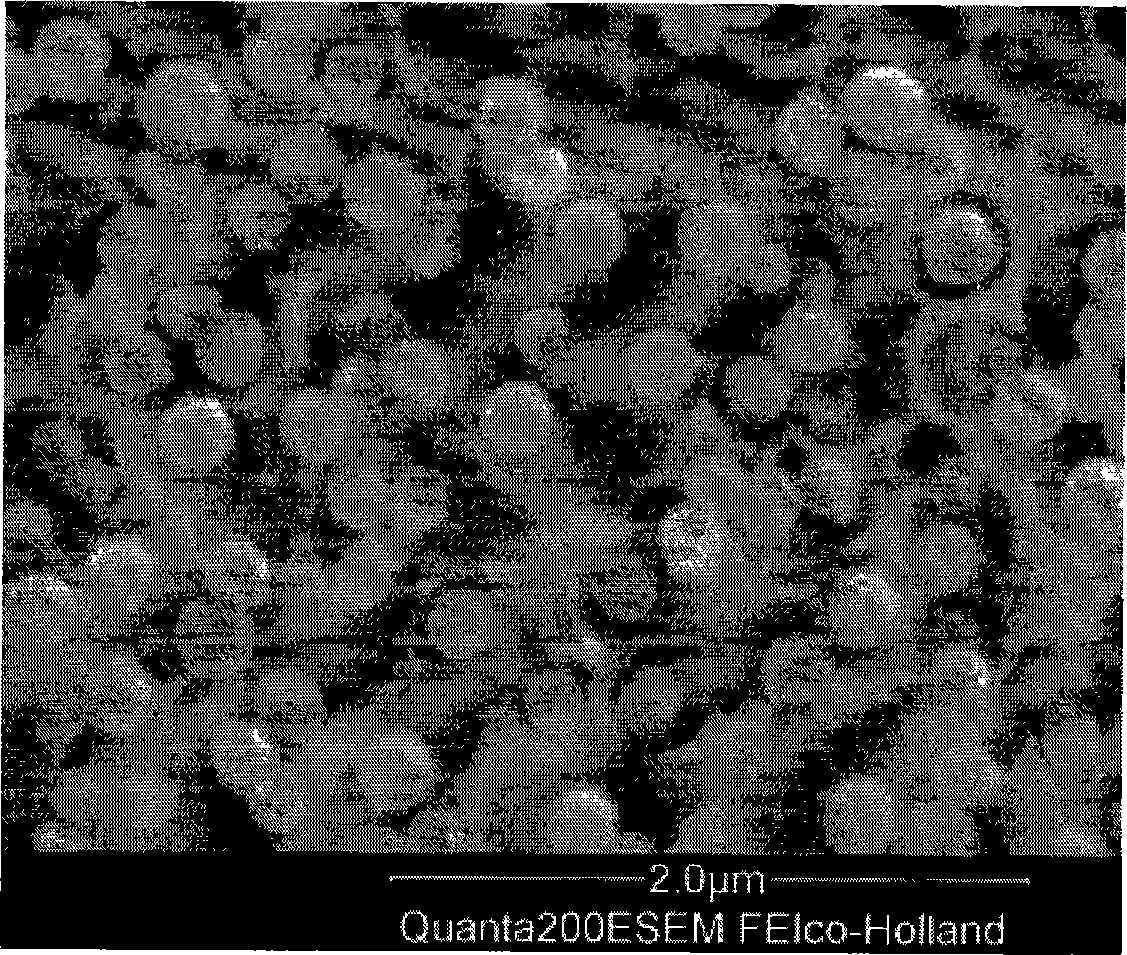

Image

Examples

Embodiment 1

[0013] Glass composition (wt%) is:

[0014] SiO 2 Al 2 o 3 B 2 o 3 P 2 o 5 MgO CaO BaO Na 2 o

[0015] SiO 2 Al 2 o 3 B 2 o 3 P 2 o 5 MgO CaO BaO Na 2 o

[0016] 61 4 4.2 7 2.1 1.2 8 12.5

[0017] Use silicon dioxide, aluminum oxide, boric acid, diammonium hydrogen phosphate, magnesium oxide, calcium carbonate, barium carbonate, and sodium carbonate as raw materials, weigh and mix them evenly according to the above components, and then keep warm in an electric furnace at 1520°C for 3 After 1 hour, the molten glass is rapidly cooled in a mold to form a block glass, which is sent to an annealing furnace at 560°C for annealing, kept for 1 hour, and then cooled to room temperature to form a fluorine-free silicate opaque glass material. Its coefficient of thermal expansion is 56.5×10 -7 ℃ -1 , the flexural strength is 96.2MPa, the whiteness is 84%, and other properties are shown in Table 1.

Embodiment 2

[0019] Glass composition (wt%) is:

[0020] SiO 2 Al 2 o 3 B 2 o 3 P 2 o 5 SrO BaO Na 2 OK 2 o

[0021] 60.5 4.2 3.3 7.2 6 5.6 11.2 2

[0022] Use silicon dioxide, aluminum oxide, boric acid, diammonium hydrogen phosphate, strontium carbonate, barium carbonate, sodium carbonate, and potassium carbonate as raw materials, weigh and mix them evenly according to the above components, and then keep warm in an electric furnace at 1520°C for 3 After 1 hour, the molten glass is rapidly cooled in a mold to form a block glass, which is sent to an annealing furnace at 560°C for annealing, kept for 1 hour, and then cooled to room temperature to form a fluorine-free silicate opaque glass material. Its coefficient of thermal expansion is 58.7×10 -7 ℃ -1 , the flexural strength is 90.3MPa, the whiteness is 86%, and other properties are shown in Table 1.

Embodiment 3

[0024] Glass composition (wt%) is:

[0025] SiO 2 Al2 o 3 B 2 o 3 P 2 o 5 MgO CaO BaO Li 2 O Na 2 o

[0026] 60 4.2 4 7.2 2.1 2.2 7.8 1.5 11

[0027] Use silicon dioxide, aluminum oxide, boric acid, diammonium hydrogen phosphate, magnesium oxide, calcium carbonate, barium carbonate, lithium carbonate, and sodium carbonate as raw materials, weigh and mix them uniformly according to the above components, and then heat them in an electric furnace at 1510°C Keep warm in medium for 3 hours, quickly cool the molten glass in the mold to form block glass, send it to an annealing furnace at 560°C for annealing, keep it warm for 1 hour, and then cool to room temperature to form fluorine-free silicate emulsion glass material. Its coefficient of thermal expansion is 61.3×10 -7 ℃ -1 , the flexural strength is 87.3MPa, the whiteness is 84%, and other properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| coefficient of linear thermal expansion | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com