Low-fluorine milk glass product and preparation method thereof

A technology of opalescent glass and products, which is applied in the field of low-fluorine opalescent glass products and its preparation, can solve problems such as health concerns, damage to human health, and usage restrictions of fluorine-containing opalescent glass products, so as to promote immiscibility and promote Effects of energy saving and emission reduction, improvement of glass strength and thermal shock performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A low-fluorine opalescent glass product, the following raw materials are weighed: SiO 2 80kg, Al 2 o 3 15kg, B 2 o 3 10kg, CaO 10kg, BaO 9kg, Na 2 O 3kg, ZnO 4kg, K 2 O 3kg, CeO 2 5kg, MgO 2kg, Cu 2 O 2kg, SnO 1kg, Sb 2 o 3 1kg, CaF1kg and modified diatom powder 5kg;

[0026] The modified diatom powder is made of the following raw materials in parts by weight: 30 kg of diatomite, 8 kg of titanium dioxide, 4 kg of lithopone, 3 kg of lignin, 10 kg of expanded perlite, 6 kg of ferric chloride, n-butyraldehyde-aniline Condensate 3kg, praseodymium oxide 3kg, beeswax 6kg, 10,10'-oxobisphenoxarsenic 3kg, 2,2'-thiobis(4-tert-octylphenoxy)nickel 3kg; its preparation method is Soak diatomaceous earth in 8% hydrochloric acid solution for 40 minutes, filter and dry the obtained material, then mix it with expanded perlite, perform high-temperature calcination at 680°C for 1 hour, take it out and cool it to room temperature, and then mix it with beeswax , Grind into 120-me...

Embodiment 2

[0033] A low-fluorine opalescent glass product, the following raw materials are weighed: SiO 2 90kg, Al 2 o 3 20kg, B 2 o 3 15kg, CaO 15kg, BaO 13kg, Na 2 O 4kg, ZnO 6kg, K 2 O 4kg, CeO 2 6kg, MgO 4kg, Cu 2O 3kg, SnO 2kg, Sb 2 o 3 2kg, CaF2kg and modified diatom powder 10kg;

[0034] The modified diatom powder is made of the following raw materials in parts by weight: 30 kg of diatomite, 8 kg of titanium dioxide, 4 kg of lithopone, 3 kg of lignin, 10 kg of expanded perlite, 6 kg of ferric chloride, n-butyraldehyde-aniline Condensate 3kg, praseodymium oxide 3kg, beeswax 6kg, 10,10'-oxobisphenoxarsenic 3kg, 2,2'-thiobis(4-tert-octylphenoxy)nickel 3kg; its preparation method is Soak the diatomite in 10% hydrochloric acid solution for 50 minutes, filter the obtained material and dry it, then mix it with expanded perlite, perform high-temperature calcination at 700°C for 1.5 hours, take it out and cool it to room temperature, and mix it with beeswax Mix and grind into 14...

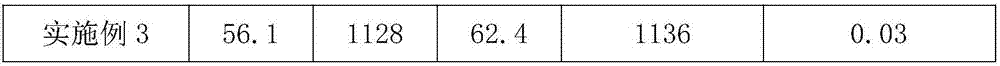

Embodiment 3

[0041] A low-fluorine opalescent glass product, the following raw materials are weighed: SiO 2 100kg, Al 2 o 3 25kg, B 2 o 3 20kg, CaO20kg, BaO17kg, Na 2 O 5kg, ZnO 8kg, K 2 O 5kg, CeO 2 7kg, MgO 6kg, Cu 2 O 4kg, SnO 3kg, Sb 2 o 3 3kg, CaF 3kg and modified diatom powder 15kg;

[0042] The modified diatom powder is made of the following raw materials in parts by weight: 30 kg of diatomite, 8 kg of titanium dioxide, 4 kg of lithopone, 3 kg of lignin, 10 kg of expanded perlite, 6 kg of ferric chloride, n-butyraldehyde-aniline Condensate 3kg, praseodymium oxide 3kg, beeswax 6kg, 10,10'-oxobisphenoxarsenic 3kg, 2,2'-thiobis(4-tert-octylphenoxy)nickel 3kg; its preparation method is Soak diatomite in 12% hydrochloric acid solution for 60 minutes, filter the obtained material and dry it, then mix it with expanded perlite, perform high-temperature calcination at 720°C for 2 hours, take it out and cool it to room temperature, and then mix it with beeswax , Grind into 160-mesh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com