Ship diesel engine gas exhaust denitration catalyst preparation method

A technology of denitrification catalyst and marine diesel engine, which is applied in the field of denitrification catalyst, can solve the problems of inability to adapt to various working conditions, low denitrification efficiency, and short service life of denitrification catalyst, so as to improve system integration, improve denitrification efficiency, and reduce treatment costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

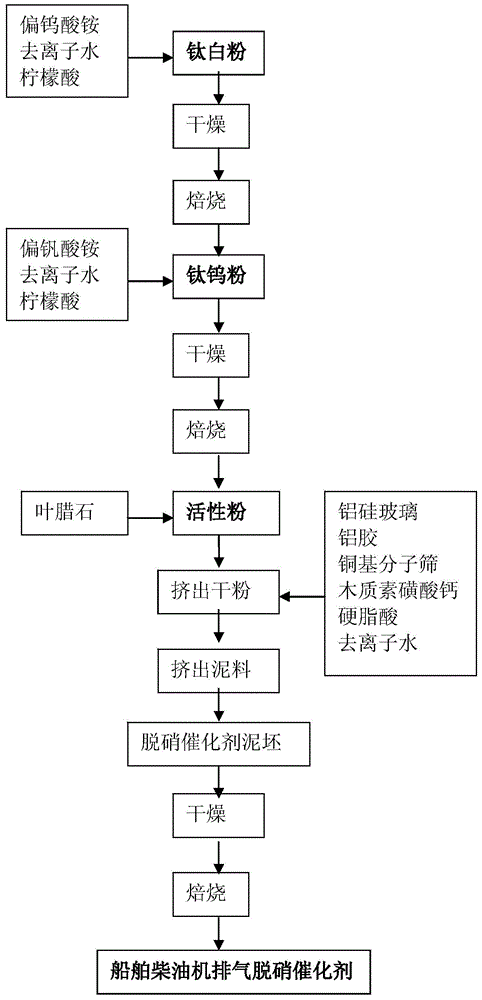

[0056] The preparation process of ship denitrification catalyst is as follows: figure 1 As shown, it mainly includes: modifying titanium dioxide with 5% ammonium metatungstate and 0.41% ammonium metavanadate by mass to obtain active powder; adding pyrophyllite as a plasticizer to the active powder to obtain extruded dry powder ;Use extruded dry powder, aluminosilicate glass, aluminum glue, copper-based molecular sieve, calcium lignosulfonate, stearic acid and an appropriate amount of deionized water to prepare mud through the shearing action of the mixer; use mud to add vacuum extrusion The honeycomb denitration catalyst body is obtained by extruding from the machine; the honeycomb denitration catalyst body is placed in a steam drying furnace for drying along the direction of the honeycomb denitration catalyst channel; the dried product is placed in an electric furnace for roasting and activation, etc. step.

[0057] The active ingredient of the catalyst V 2 o 5 、WO 3 The ...

Embodiment 1

[0076] Preparation of active powder:

[0077] Step A: primary modification to prepare titanium tungsten powder, including the following sequential steps:

[0078] Take ammonium metatungstate and titanium dioxide with a mass ratio of 8:92;

[0079] Add ammonium metatungstate as a primary modifier to deionized water to prepare ammonium metatungstate solution with a concentration of 5% by mass;

[0080] Add citric acid as a solubilizing dispersant to the ammonium metatungstate solution, wherein the amount of citric acid added is 1% of the mass of the ammonium metatungstate aqueous solution to obtain a mixed solution;

[0081] Add titanium dioxide into the mixed solution, and after stirring, prepare the first suspension, wherein the stirring speed is 100r / min;

[0082] Then the first suspension is dried and roasted to obtain titanium tungsten powder, wherein the drying temperature is 90°C, the drying time is 15h, the roasting temperature is 600°C, and the roasting time is 16h; ...

Embodiment 2

[0107] Preparation of active powder:

[0108] Step A: primary modification to prepare titanium tungsten powder, including the following sequential steps:

[0109] Take ammonium metatungstate and titanium dioxide with a mass ratio of 10:90;

[0110] Add ammonium metatungstate as a primary modifier to deionized water to prepare ammonium metatungstate solution with a concentration of 3% by mass;

[0111] Add citric acid as a solubilizing dispersant to the ammonium metatungstate solution, wherein the amount of citric acid added is 0.6% of the mass of the ammonium metatungstate aqueous solution to obtain a mixed solution;

[0112] Add titanium dioxide into the mixed solution, and after stirring, prepare the first suspension, wherein the stirring speed is 70r / min;

[0113] Then the first suspension is dried and roasted to obtain titanium tungsten powder, wherein the drying temperature is 80°C, the drying time is 13h, the roasting temperature is 580°C, and the roasting time is 14h;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com