Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

167results about How to "Easy to palletize" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

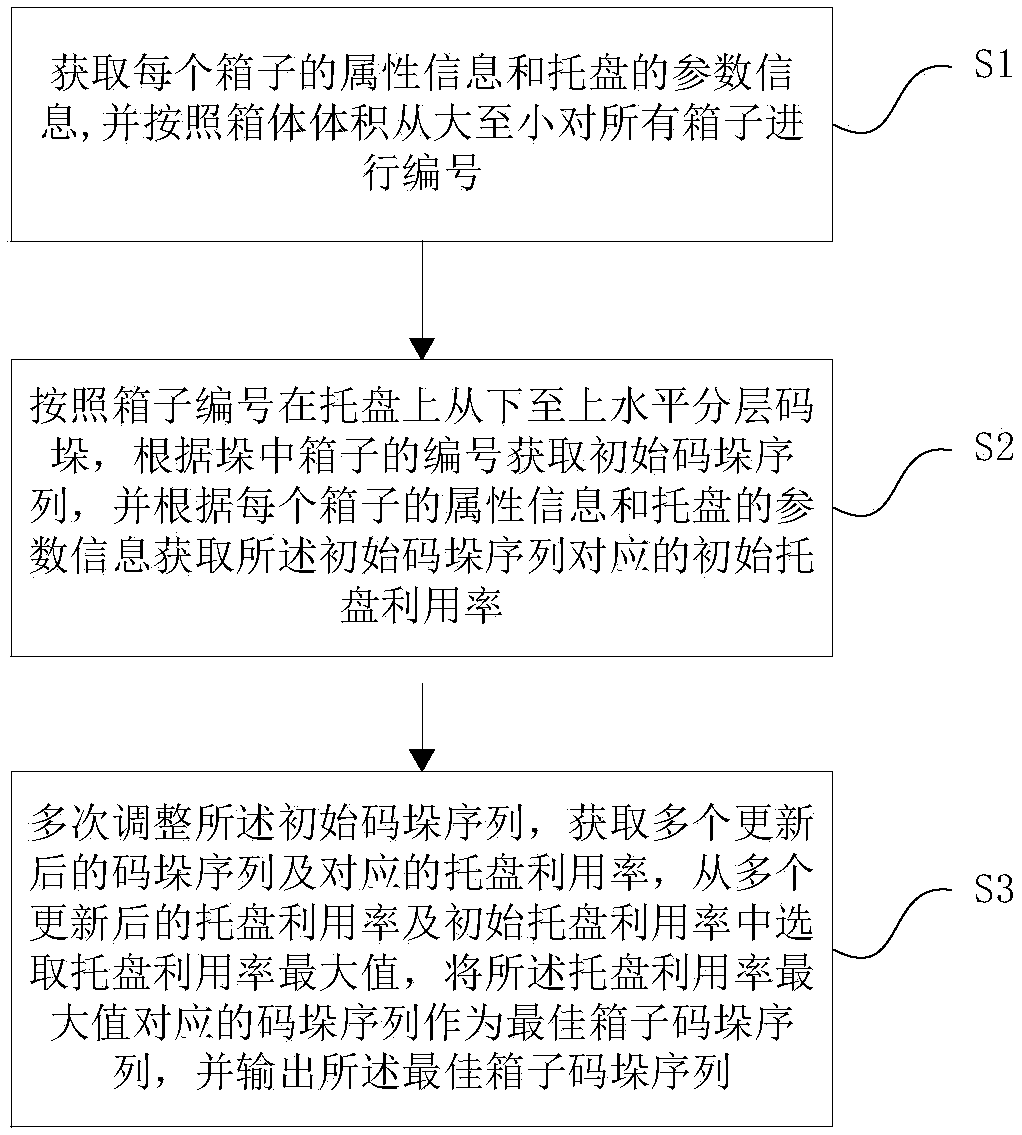

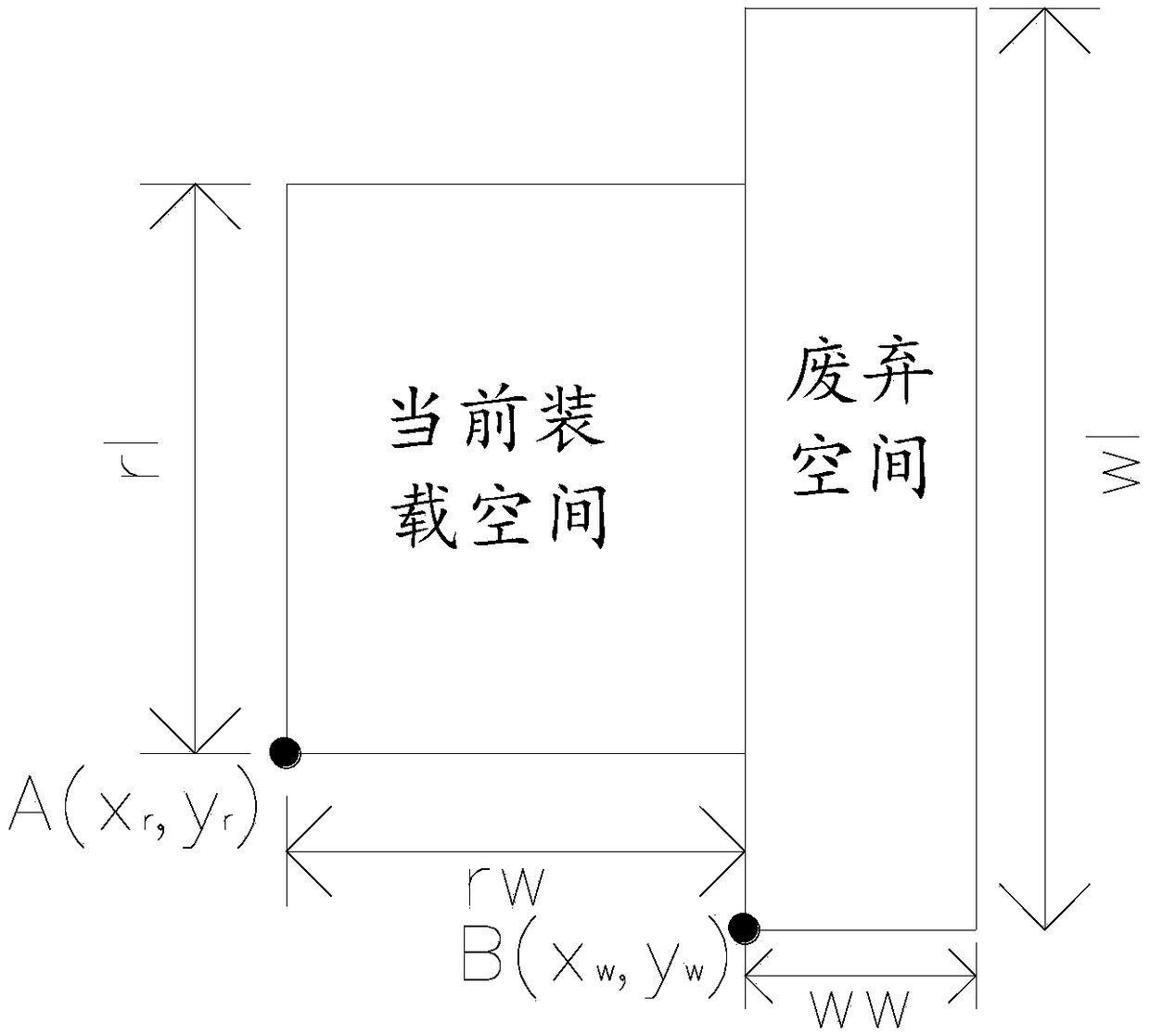

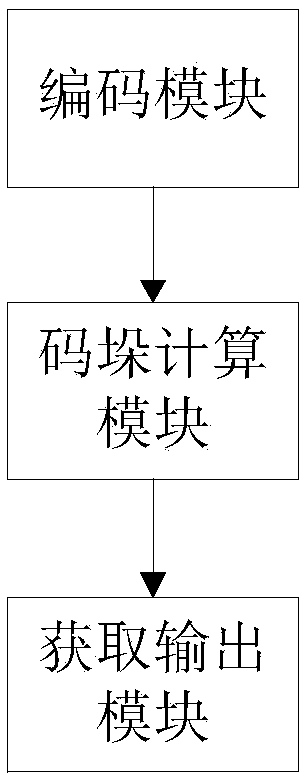

Offline hybrid stacking method and system

ActiveCN108750685AEnsure stack stabilityRealize horizontal layered palletizingConveyorsStacking articlesEngineeringUtilization rate

The invention relates to an offline hybrid stacking method and system. The method comprises the steps of acquiring the attribute information of each box and the parameter information of a tray, and numbering all boxes according to the volumes of the boxes from big to small; stacking the boxes on the tray from bottom to top according to the number of the boxes in a layered manner, and acquiring aninitial stacking sequence and the utilization rate of a corresponding initial tray; regulating the initial stacking sequence for many times, and acquiring the maximum value of the tray utilization rate; and taking the stacking sequence corresponding to the maximum value of the tray utilization rate as the optimal stacking sequence of the boxes, and output the optimal stacking sequence. According to the offline hybrid stacking method, cuboid boxes of different sizes can be stacked in a hybrid manner, and the stacking stability can be ensured; the horizontal layered stacking is achieved, and theoffline hybrid stacking method has the advantages that the stacking stability is high, and the stacking by a robot is facilitated; the utilization rate of the tray is high, etc., and the automation and intelligence of the hybrid stacking process are achieved.

Owner:哈尔滨库柏特科技有限公司

Preparation method of porous slurry green body

The invention relates to a preparation method of a porous slurry green body, belonging to the technical field of ceramic and refractory materials. The method comprises five steps of: foam preparation, slurry blending, foam and slurry mixing, green body pouring and green body maintenance. The invention specifically comprises the following steps of: prefabricating bubbles in advance under the action of compressed air through a foaming device by adopting a physical foaming agent so as to provide fine, uniform and stable bubbles; and mixing high-alumina cement, Suzhou clay, pyrophyllite, lime and calcium carbonate according to a required proportion and then adding water to prepare a prefabricated slurry, wherein in the slurry, the high-alumina cement is used as one of ingredients to provide aluminum oxide and calcium oxide, and meanwhile, the characteristics of fast-solidification and fast-hardening of the high-alumina cement are adopted to accelerate the solidification and the hardening of pouring a green pouring body so as to ensure that on one hand, the bubbles are fixed as soon as possible to reduce bubble loss, and on the other hand, the green body is enhanced to reduce the deformation of the green body. The invention can easily prepare a green body with a drying density of 0.34-0.45kg / m<3>, and the compression strength of a corresponding drying green body is 0.15-0.50MPa.

Owner:NANJING TECH UNIV

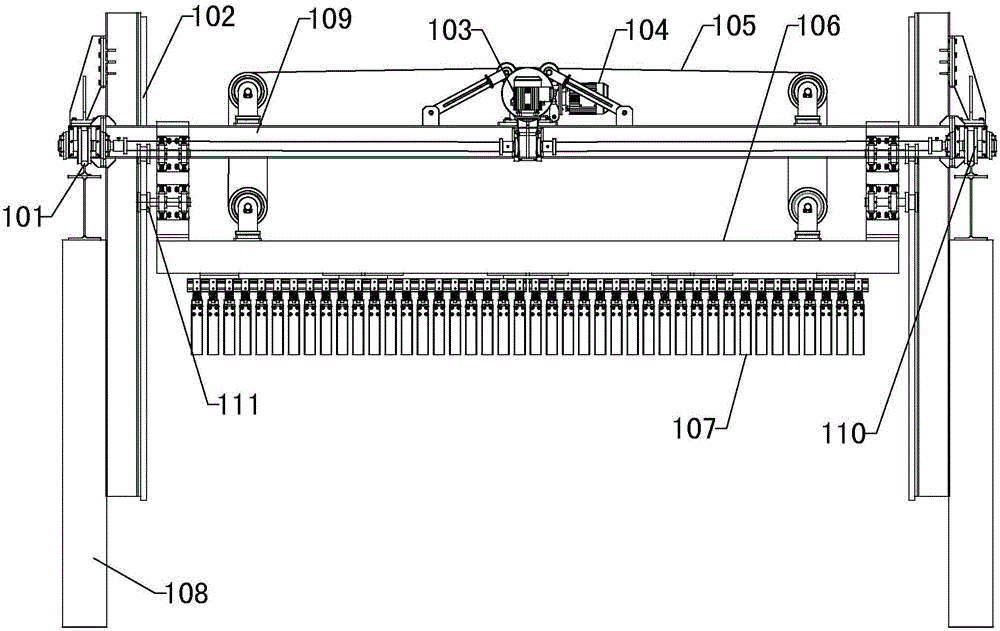

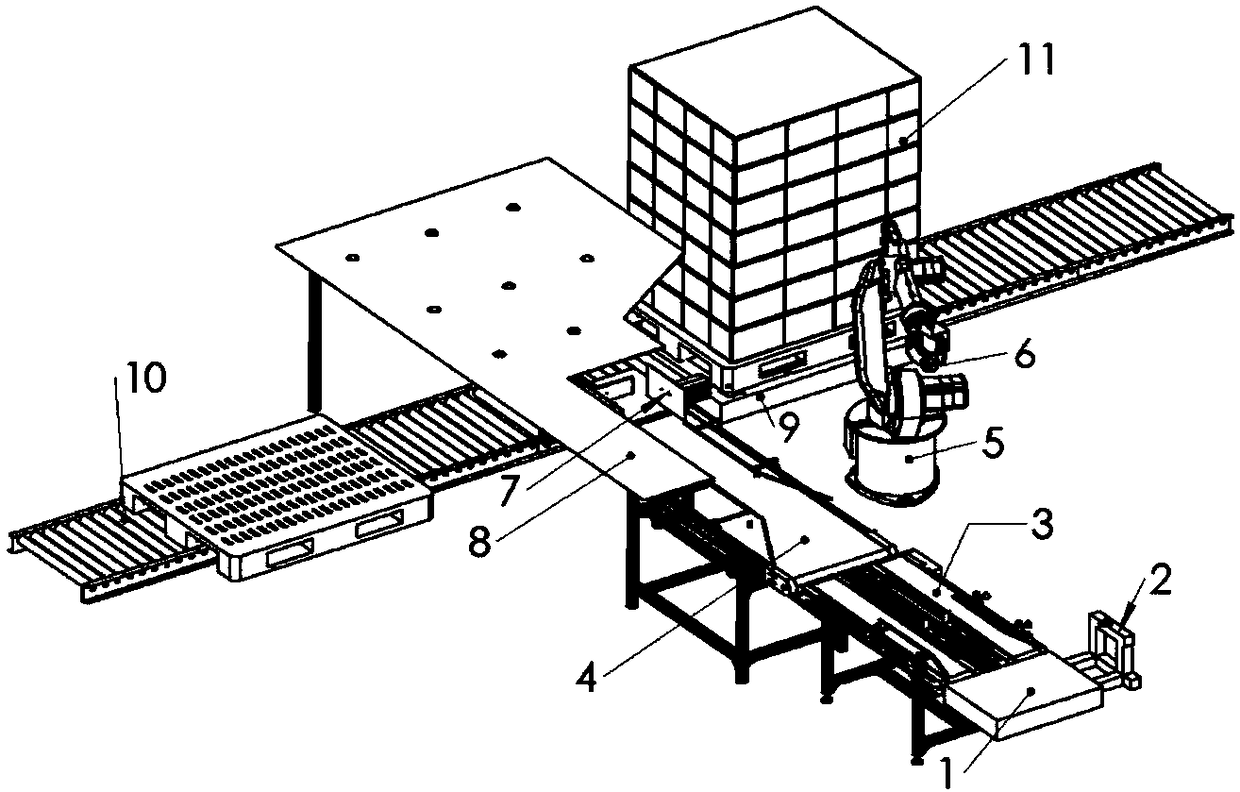

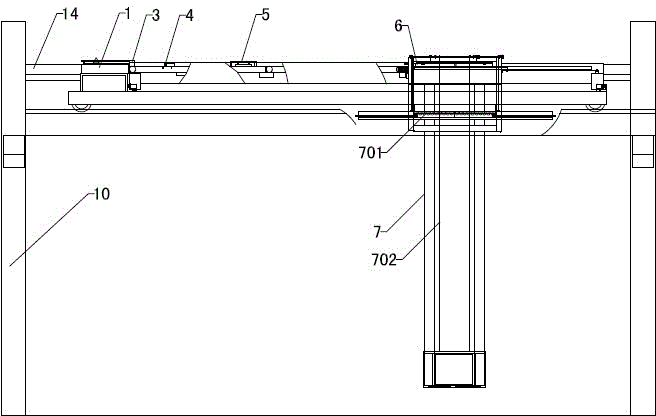

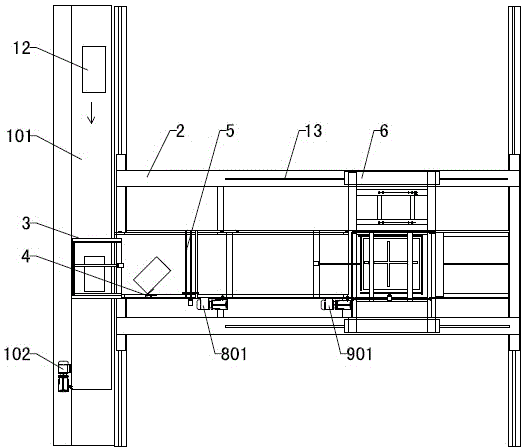

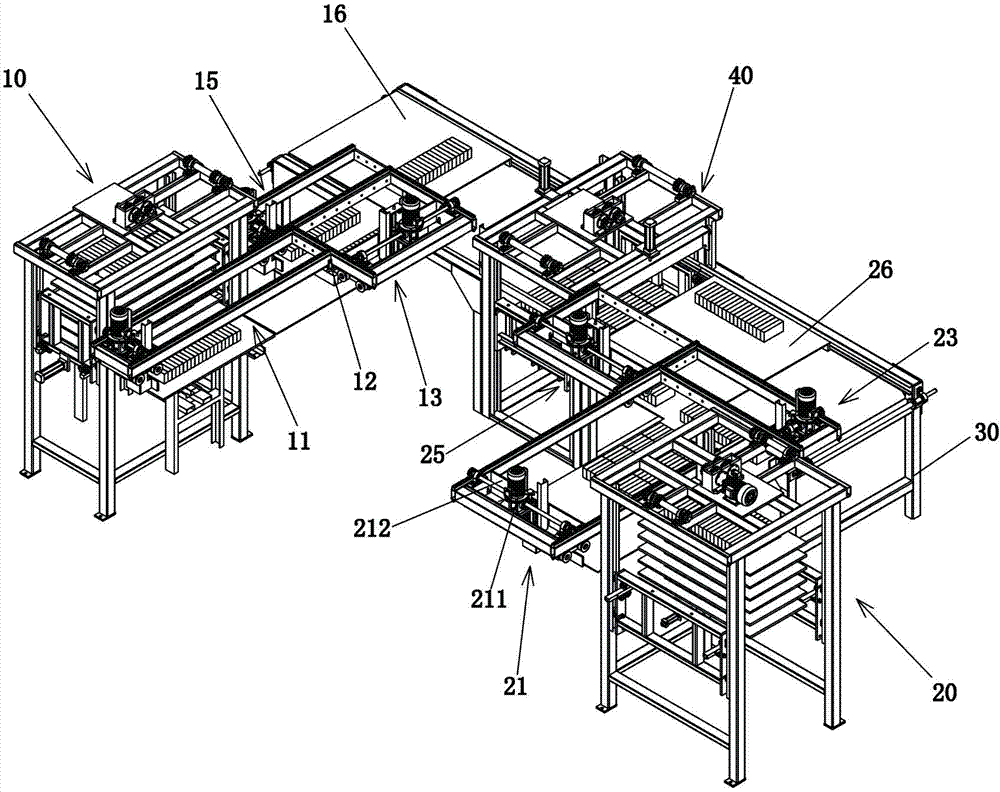

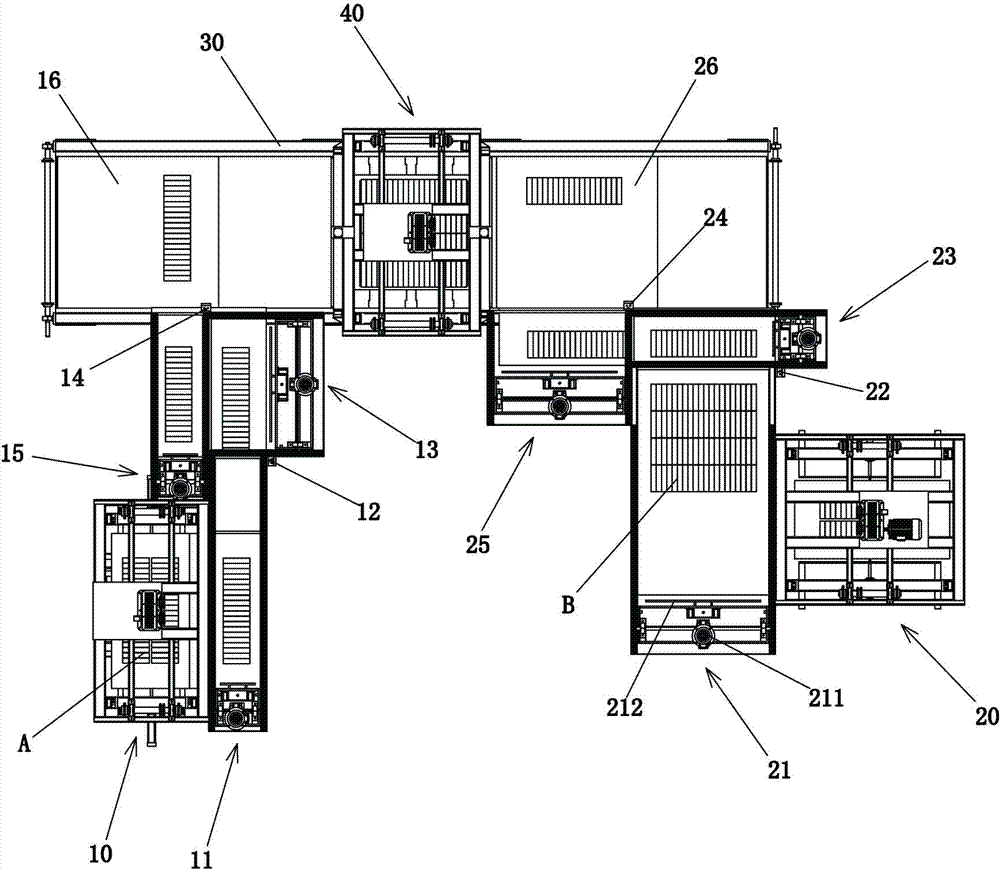

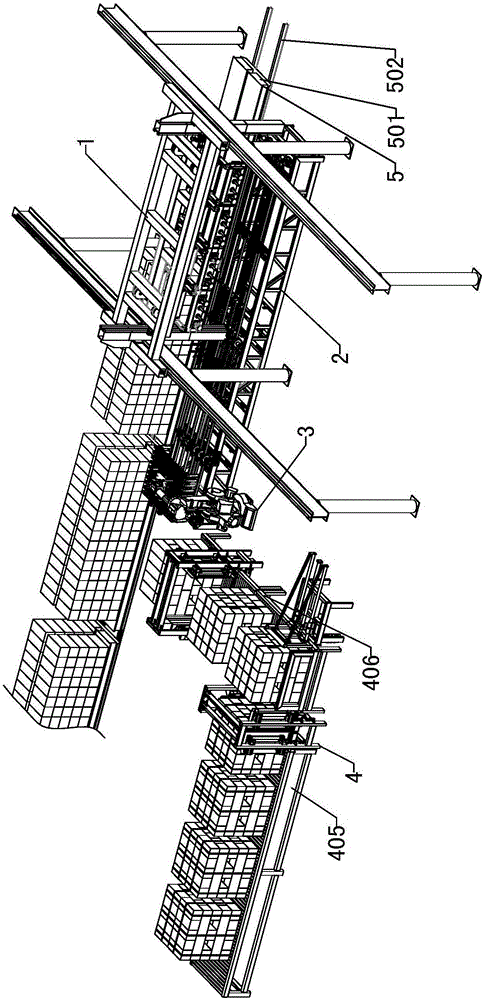

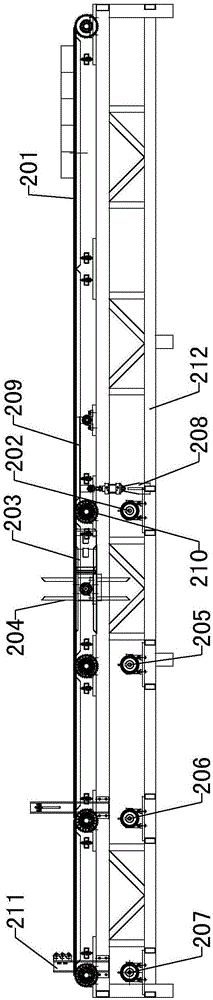

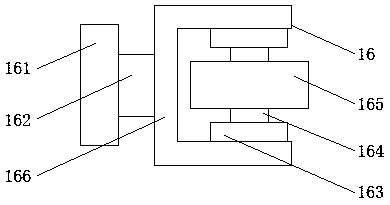

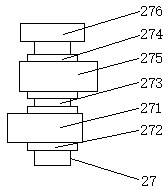

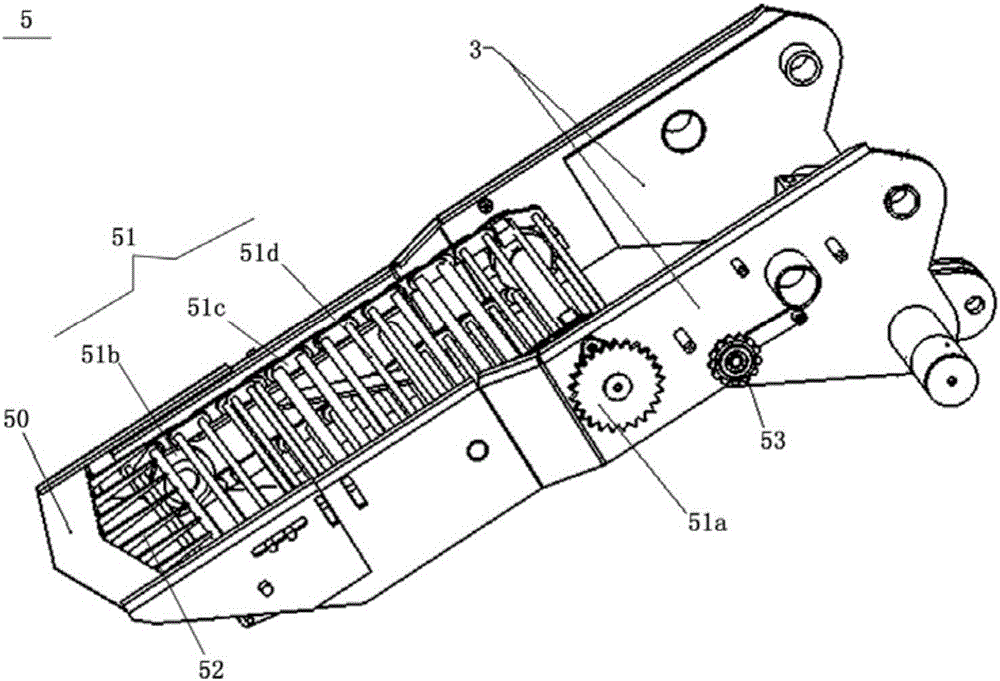

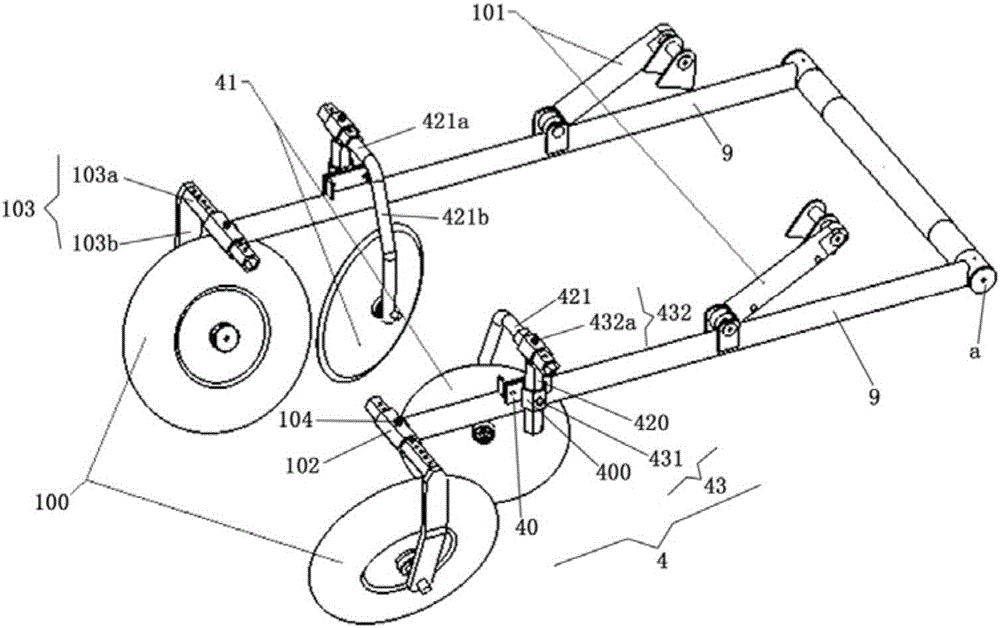

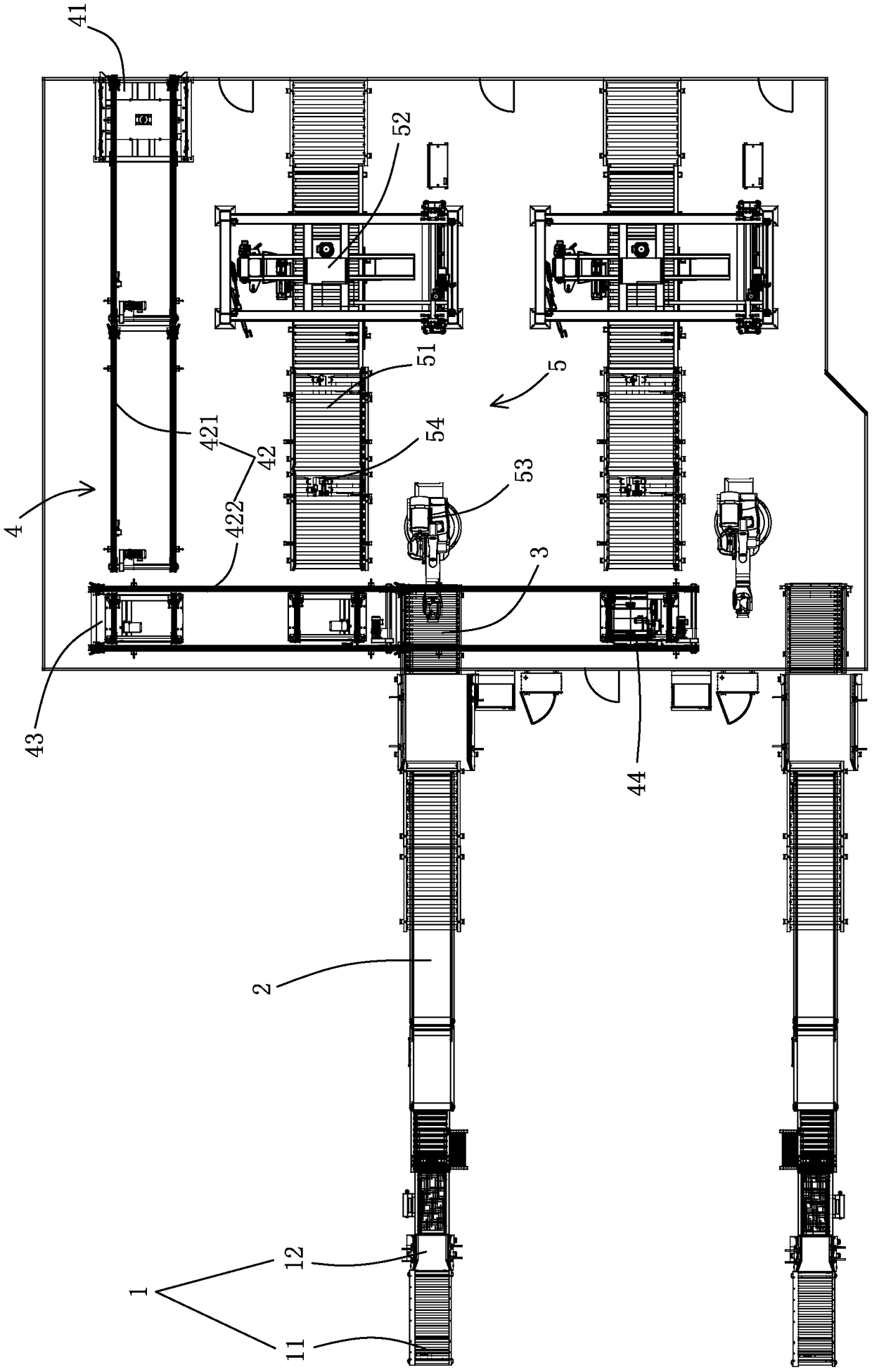

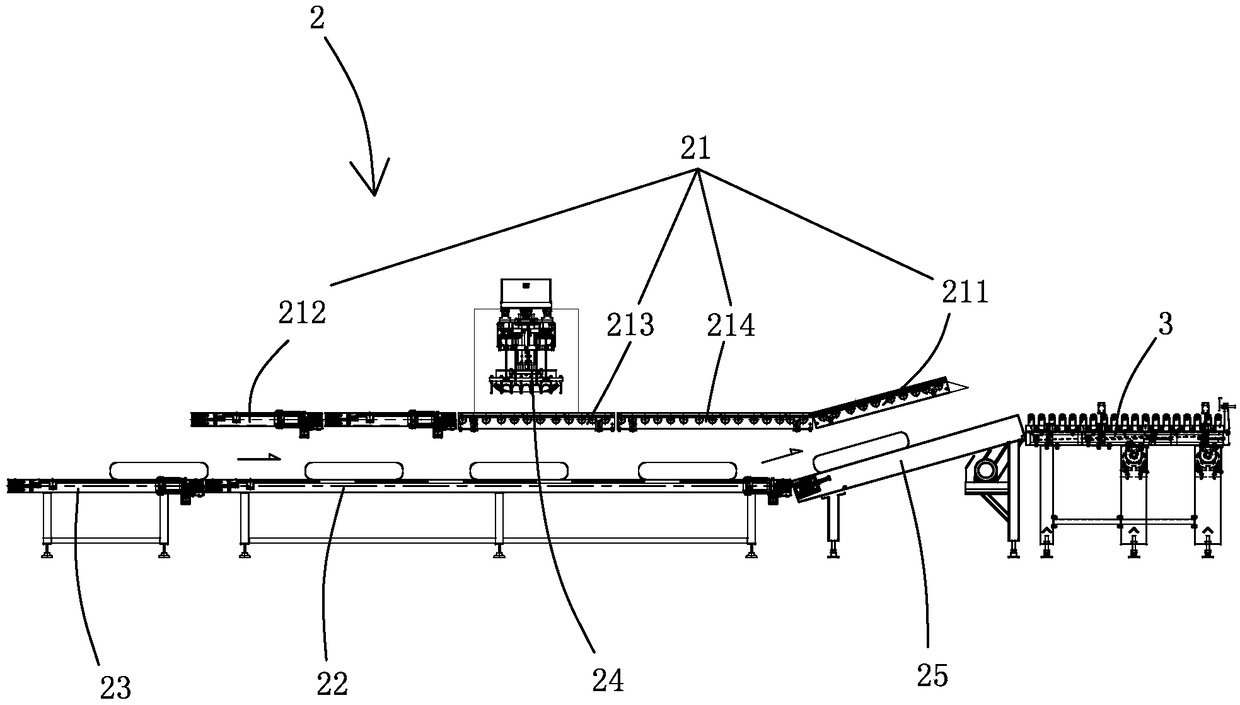

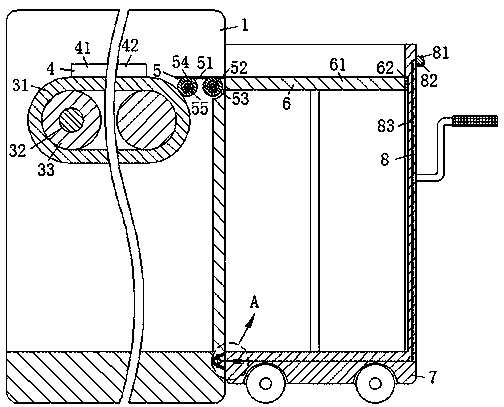

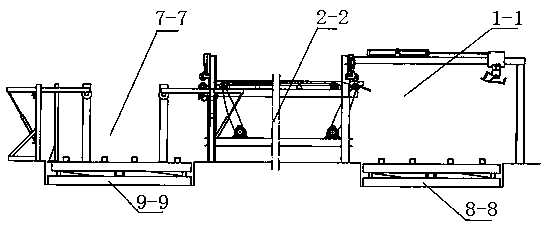

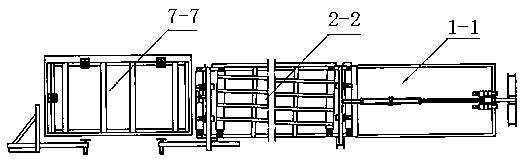

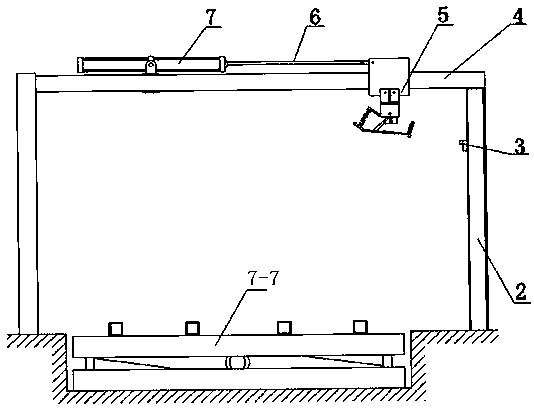

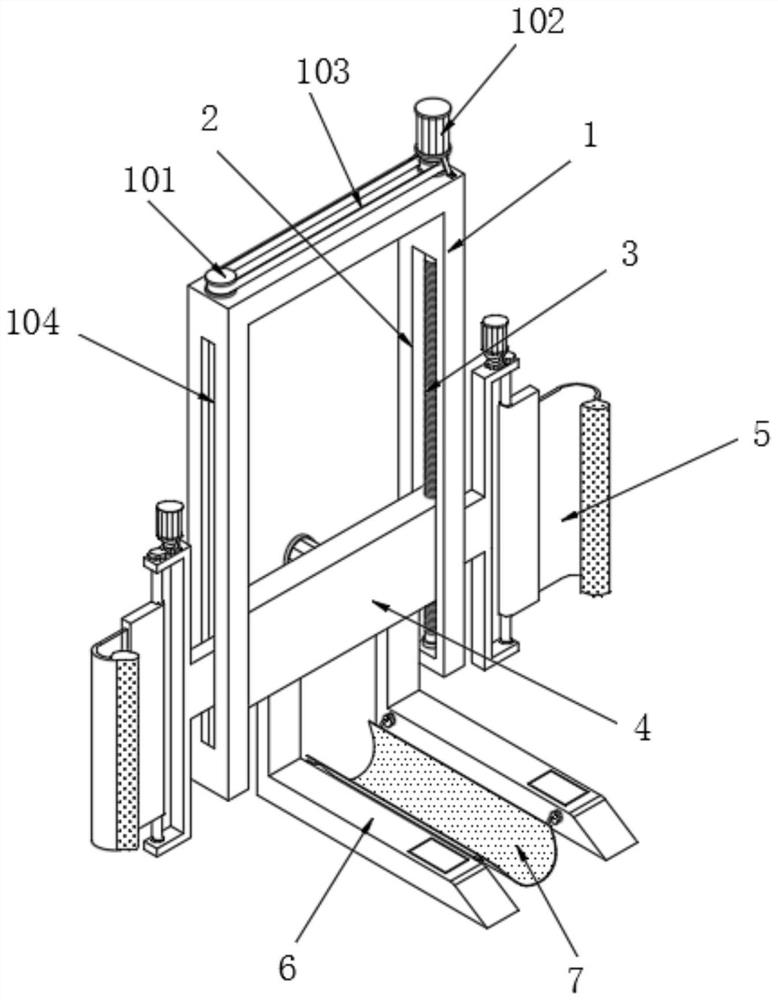

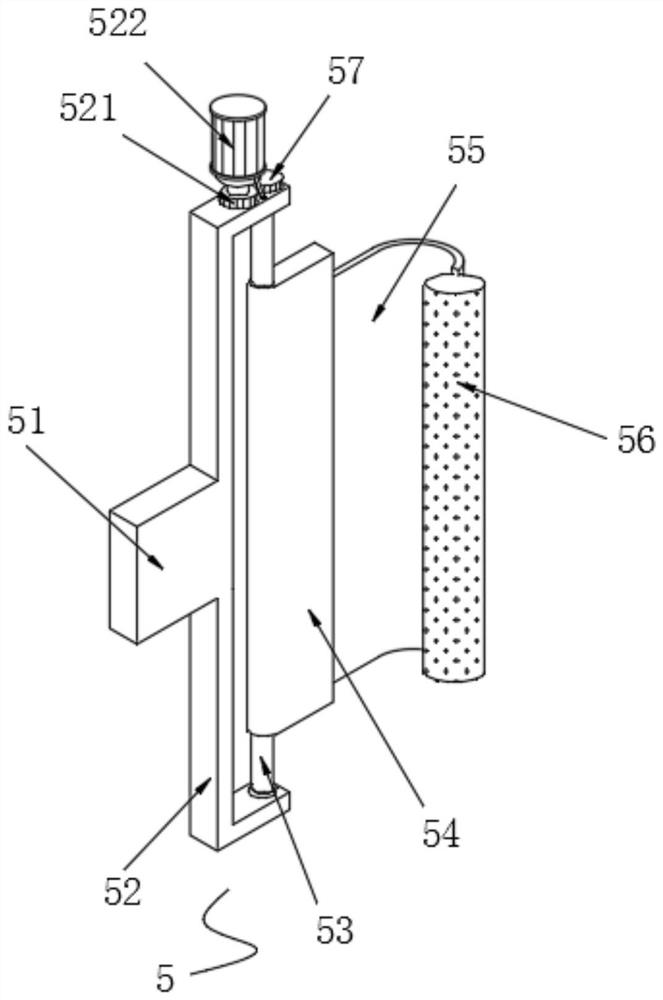

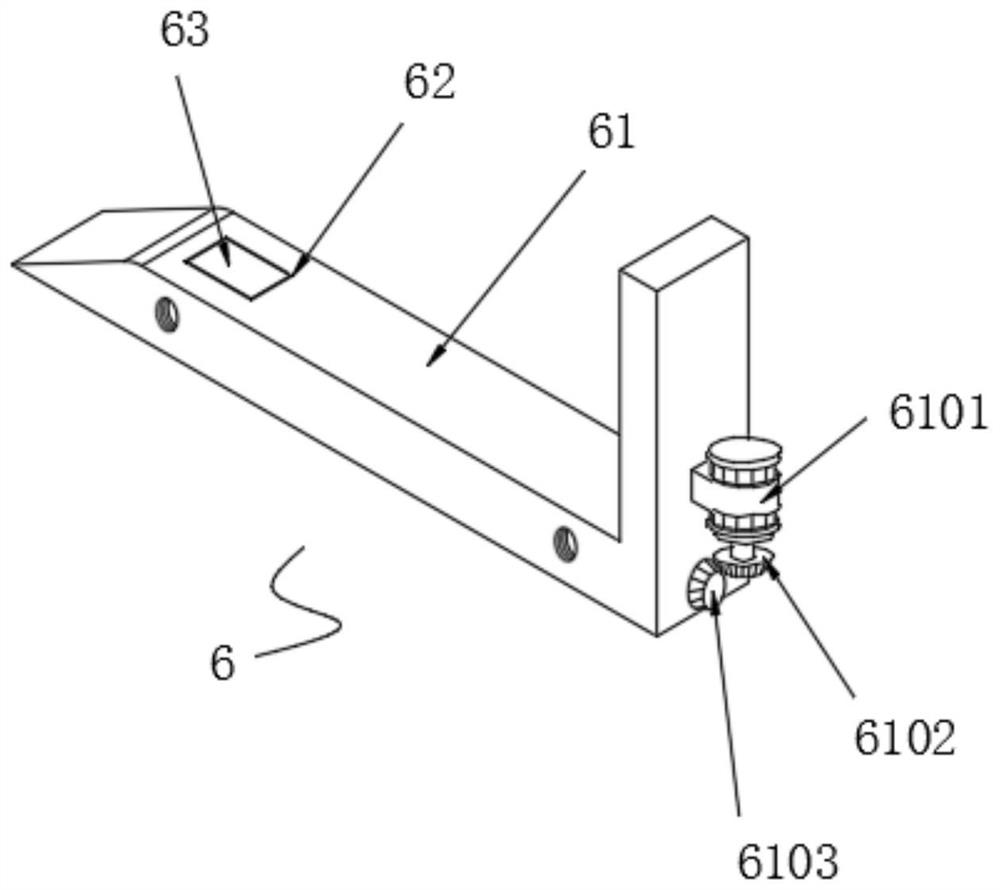

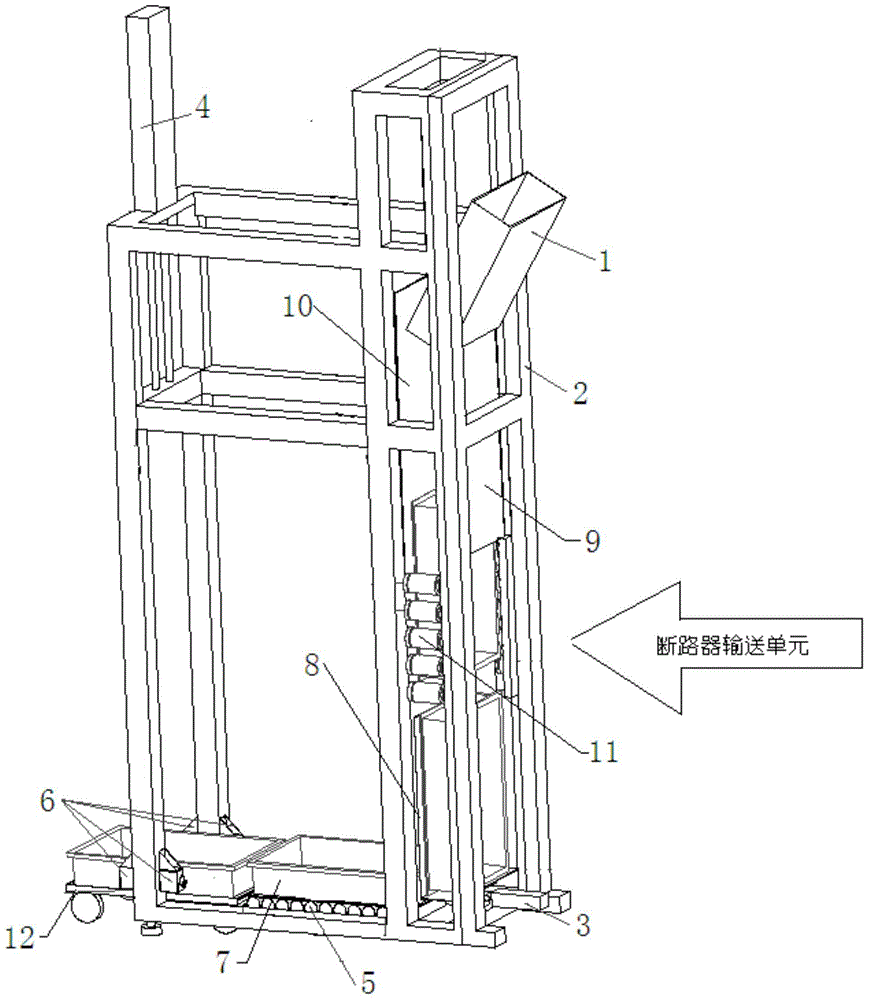

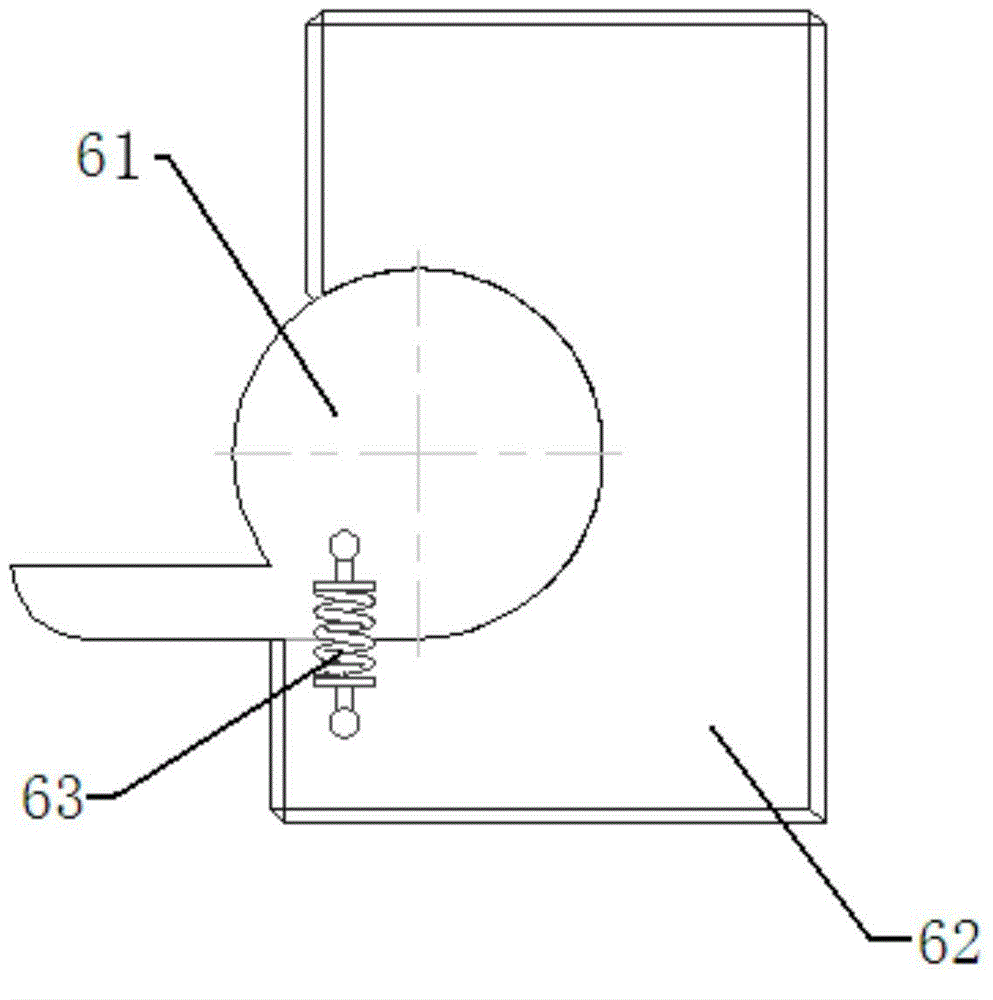

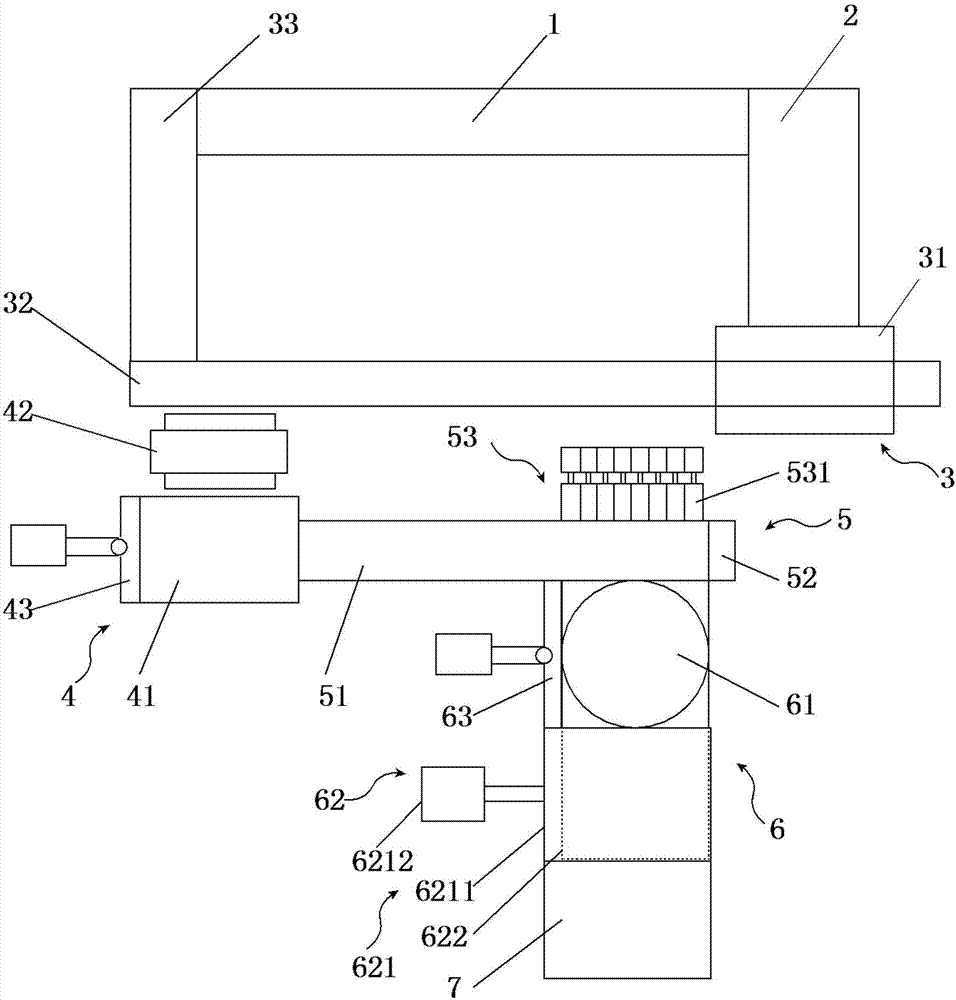

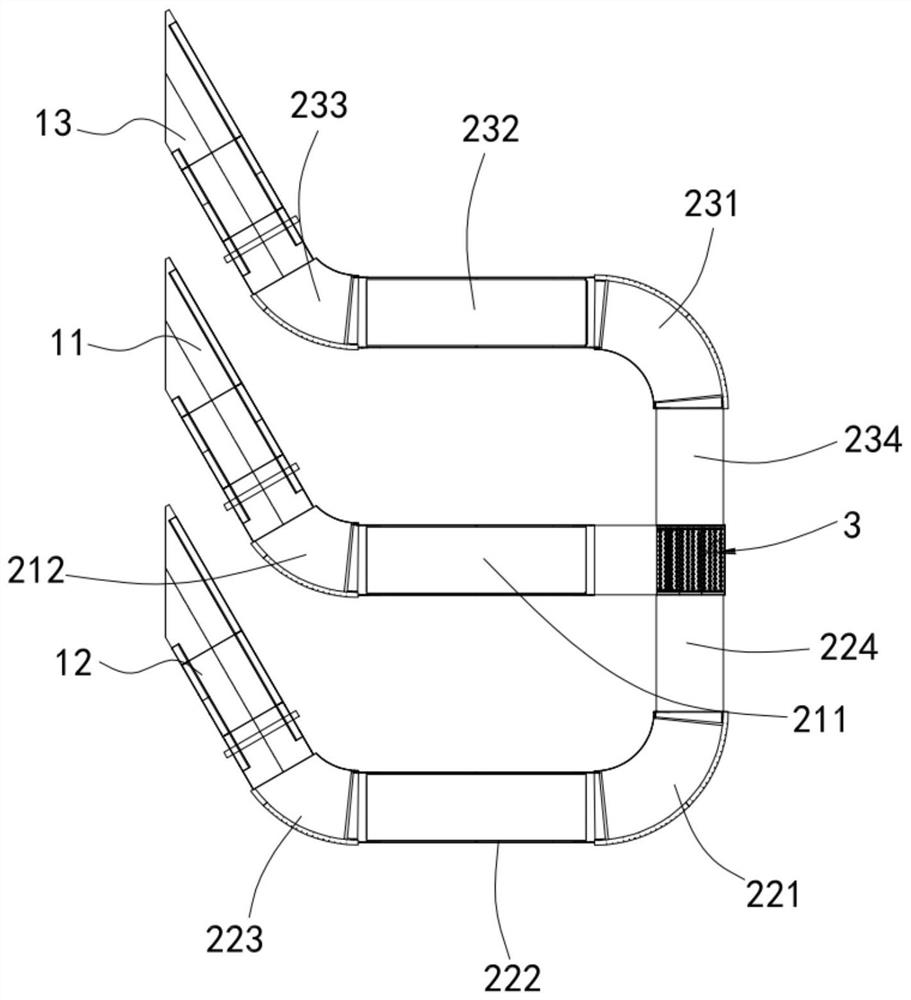

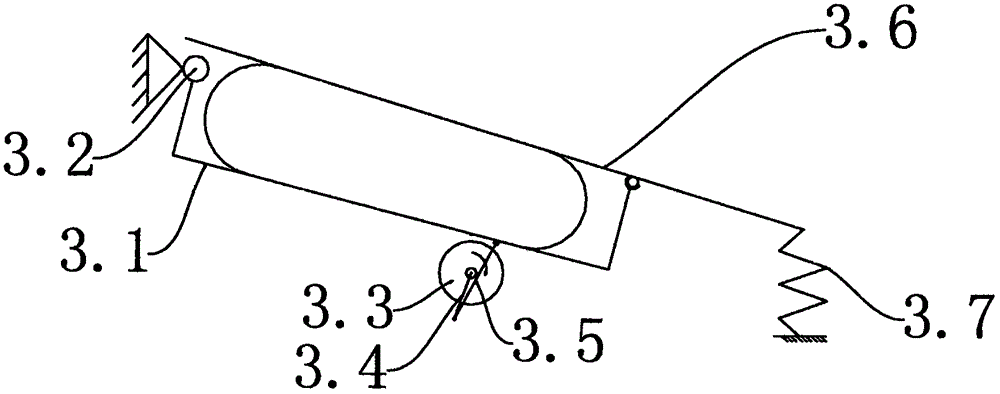

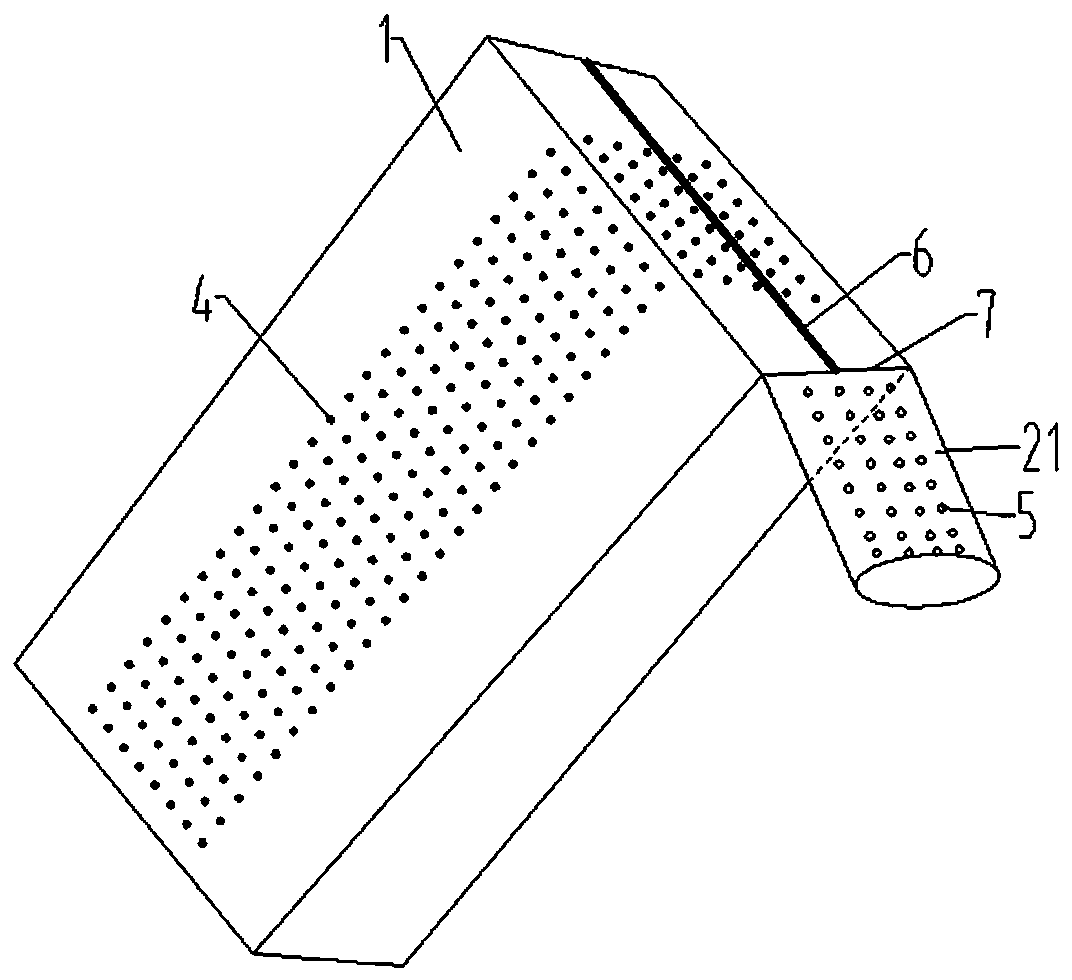

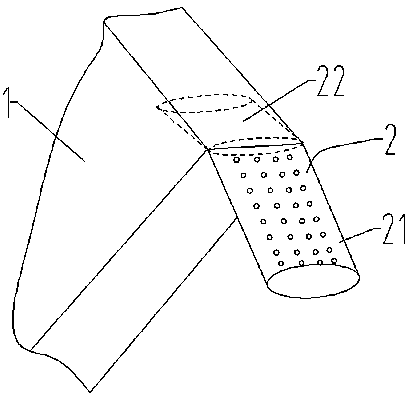

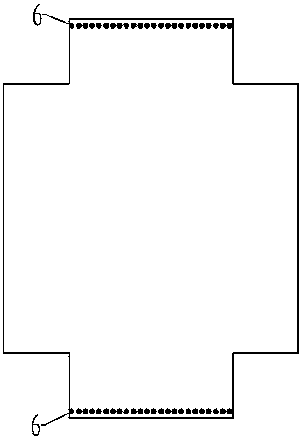

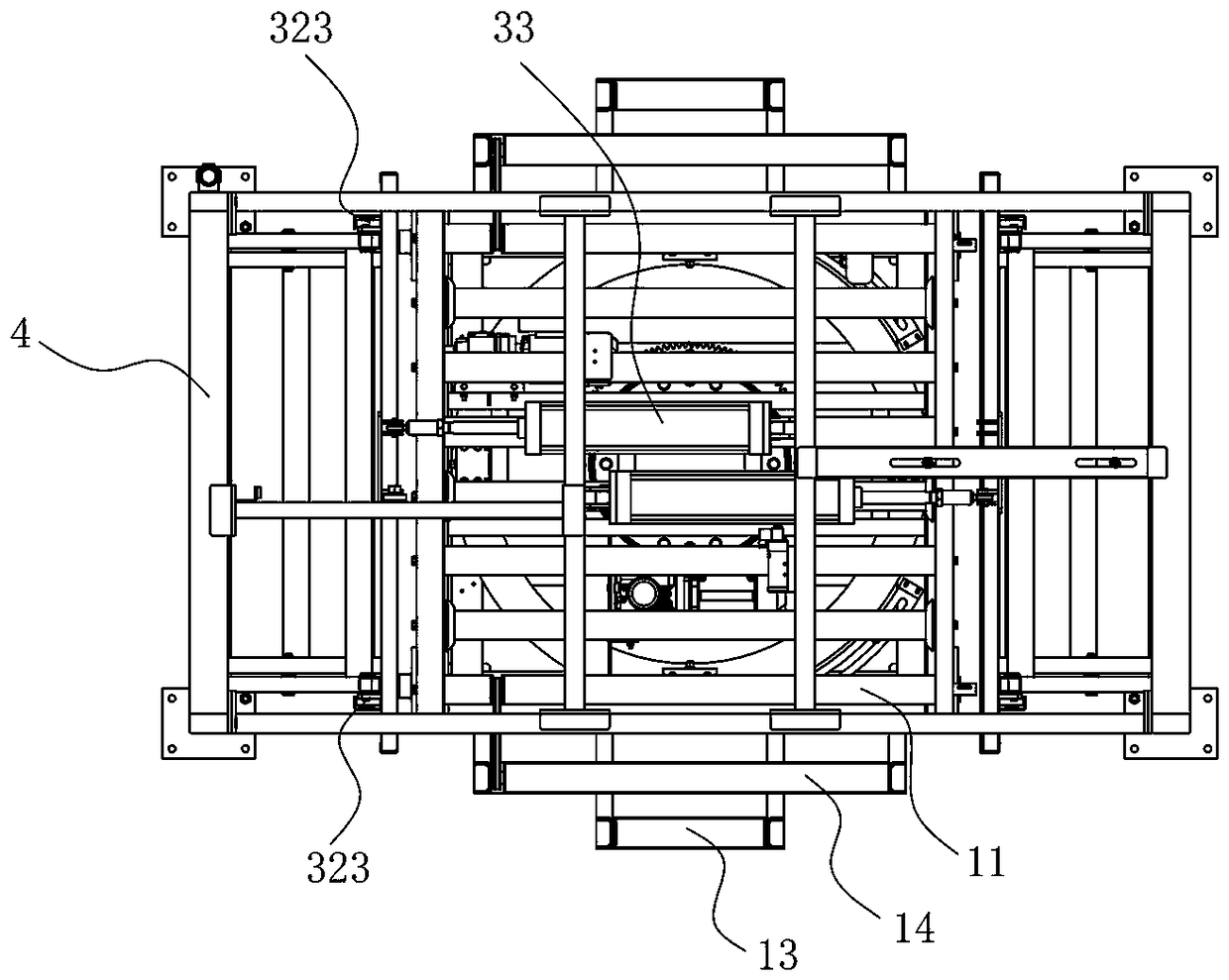

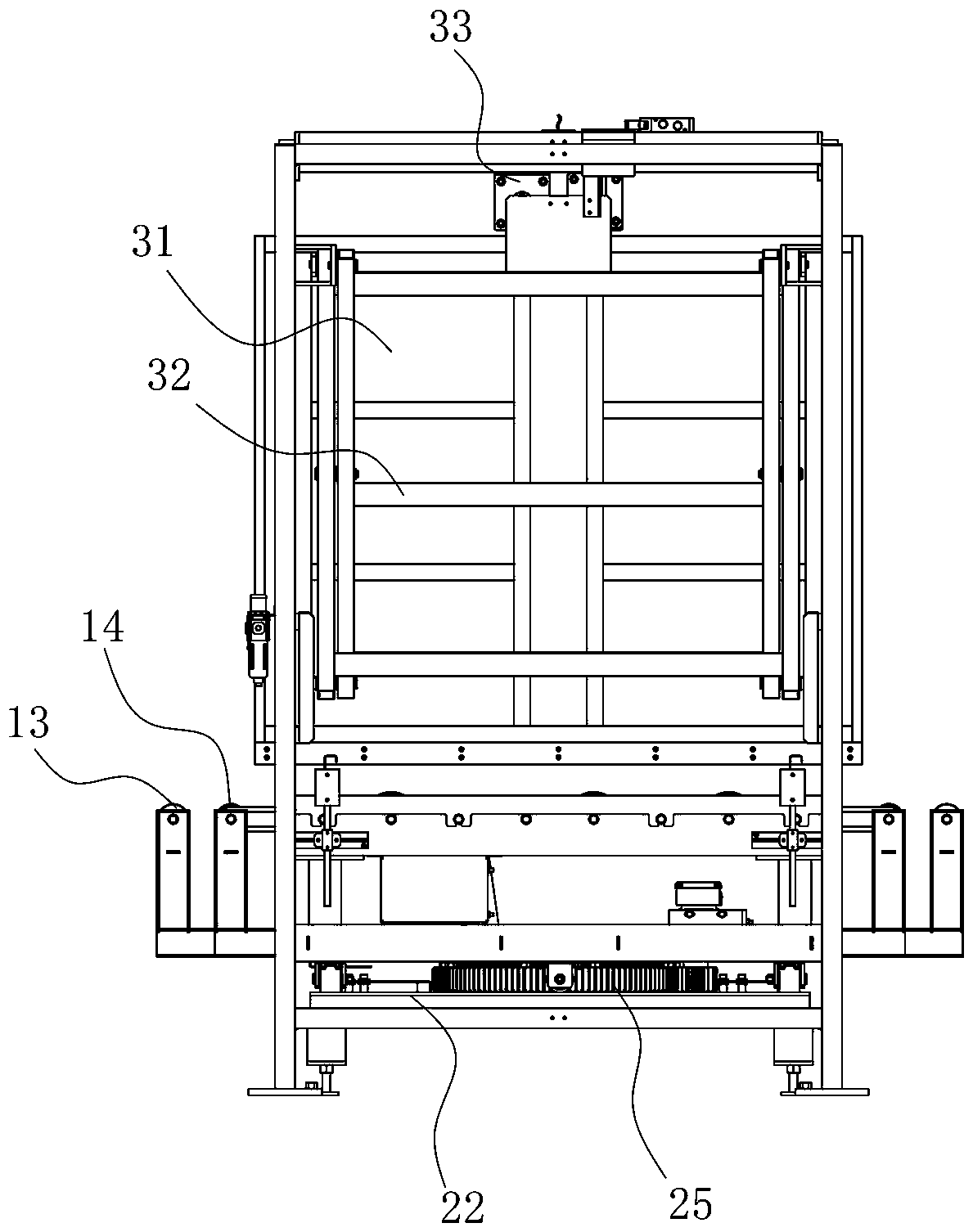

Full-automatic packaging system of autoclaved aerated concrete blocks

ActiveCN106218948AEasy to palletizeStable flowBuilding material packagingEngineeringMechanical engineering

The invention discloses a full-automatic packaging system of autoclaved aerated concrete blocks, and belongs to the field of packaging devices of the concrete blocks. The system is characterized in that one end of a block conveying mechanism (5) is connected with an autoclave, the other end of the block conveying mechanism (5) is a stack outlet output end, a stack unloading mechanism (1) reciprocates and transversely moves between the stack outlet output end and the input end of a blank turning mechanism (2) through a transverse moving sliding mechanism, and vertically ascends and descends on the input end of the blank turning mechanism (2), the output end of the blank turning mechanism (2) is connected with a double-way packaging mechanism (4), and a mechanical arm stacking mechanism (3) is arranged between the output end of the blank turning mechanism (2) and the double-way packaging mechanism (4). In the whole conveying process, trays do not need to be used, a large number of trays are removed, in stacking work, several stacking clamps at the designated positions can be selectively selected for carrying out the clamping action, cavities or through holes are formed in a whole block stack, carrying through a forklift can be directly carried out, the trays do not need, the trays are thoroughly removed, and a large amount of production cost is saved.

Owner:淄博捷达机械有限公司

Combined stacking system based on machine vision for irregular tobacco packets

ActiveCN108529180AMeet speed requirementsHigh degree of intelligenceImage enhancementImage analysisMachine visionLogistics management

The invention provides a combined stacking system based on machine vision for irregular tobacco packets. The combined stacking system is characterized in that an irregular tobacco packet image is processed through a visual system so as to obtain a target binary image, then the angular point features of the tobacco packets are extracted so as to perform feature point matching, in addition, error matching point pairs are eliminated by using an improved RANSAC algorithm, so that recognition matching of the tobacco packets can be realized, and the recognition result is then proofread with the order tobacco packet information in an upper computer database; and after proofreading is completed, the tobacco packets enter the combined stacking system, adjusting and accurate positioning are carriedout according to pre-arrangement algorithm combined stacking of the upper computer, and finally the tobacco packets are grabbed the stacked by a stacking robot. The combined stacking system has the advantages that the correct recognition rate of the irregular tobacco packets reaches 100%, and proofreading and combined stacking of the irregular tobacco packets can be efficiently and rapidly completed; and a novel automatic tobacco packet stacking mode is created, and the tobacco logistics industry is promoted to make one essential step towards intelligentization.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

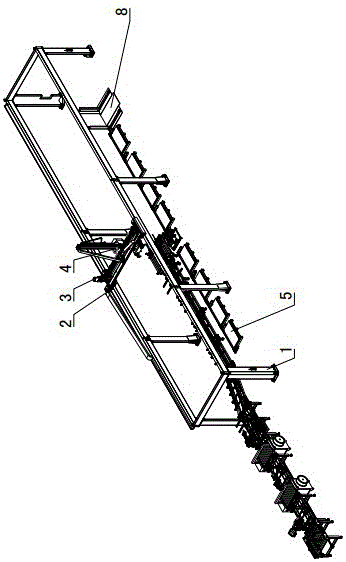

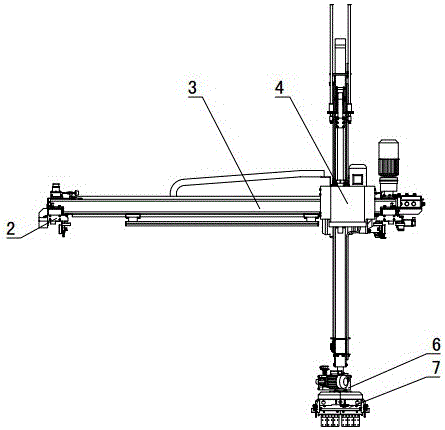

Automatic loading and stacking integrated machine of goods

ActiveCN103979321AFulfillment of loading requirementsRealize integrationLoading/unloadingBelt conveyorPush out

The invention provides an automatic loading and stacking integrated machine of goods and belongs to the field of automatic loading equipment of the goods. The automatic loading and stacking integrated machine is characterized in that one side of a vertical belt conveyor mechanism (1) is provided with a horizontal conveyor mechanism which is perpendicular to the vertical belt conveyor mechanism (1); the bilateral sides of the horizontal conveyor mechanism can move horizontally along one side of the vertical belt conveyor mechanism (1) through a horizontal sliding device; the horizontal conveyor mechanism can be driven by the vertical belt conveyor mechanism (1) to move horizontally on a machine travelling mechanism (14) simultaneously through a travelling sliding device which is arranged at the bottom of the vertical belt conveyor mechanism (1); a connection position of the machine travelling mechanism (14) and the vertical belt conveyor mechanism (1) is provided with an adjustment baffle plate (11) which is used for adjusting the movement direction of the goods; a horizontal push-out mechanism (3) is arranged above a connection position of the vertical belt conveyor mechanism (1) and the horizontal conveyor mechanism. According to the automatic loading and stacking integrated machine of the goods, manual operation is not required in the integral loading process, integration of loading and stacking is automatically achieved, and accordingly the loading efficiency is greatly improved, the installation space is saved, and the goods loading and conveying requirements of any position in a warehouse is achieved through match of the vertical conveyor mechanism and the horizontal conveyor mechanism.

Owner:山东长江粮油仓储机械有限公司 +1

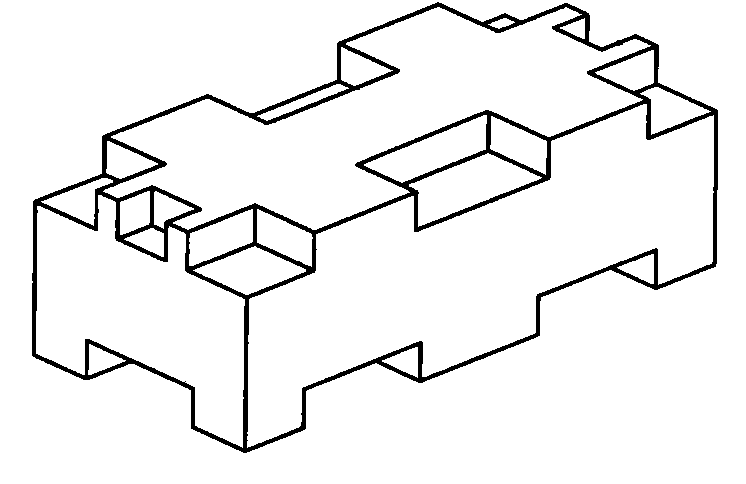

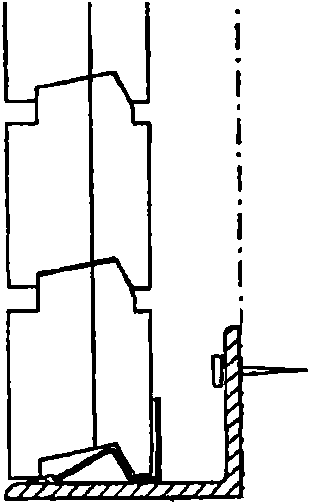

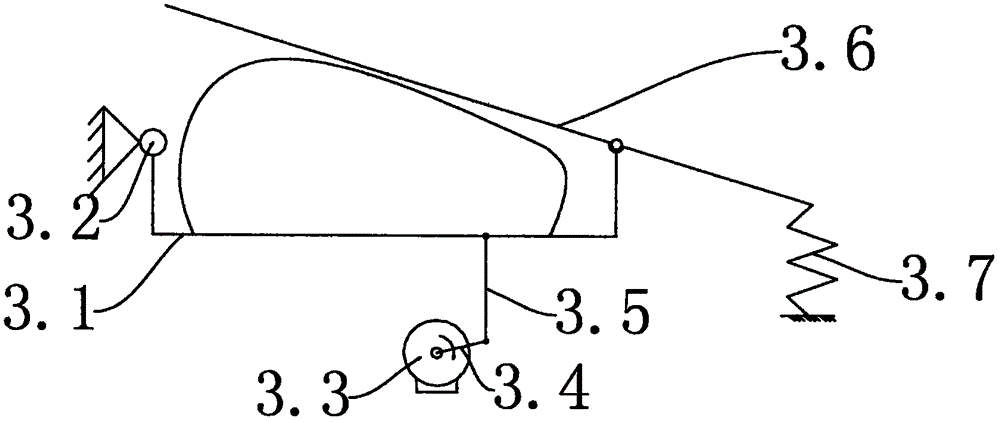

Preset-clearance stacking arrangement mechanism

ActiveCN104495395AControl pass numberGuaranteed reliabilityConveyorsStacking articlesBrickControl system

The invention discloses a preset-clearance stacking arrangement mechanism and relates to the field of brickmaking. The mechanism comprises a rack and a control system, at least one slidable carrier plate is arranged on the rack, and each carrier plate is provided with at least one push mechanism; along the brick conveying direction, each push mechanism sequentially comprises a first pusher, a second pusher with the pushing direction perpendicular to the first pusher, a third pusher with the pushing direction parallel to the first pusher and detectors arranged between the pushers and used for detecting the number of bricks. The stacking arrangement mechanism has the advantages that the bricks can be arranged, the bricks can form different types of brick layers on the carrier plates and particularly form the brick layers and mixed brick layers with preset clearances, and the brick layers can be stacked to form different-sized brick stacks and particularly brick stacks and mixed brick stacks with insertion holes.

Owner:泉州盛科智能装备制造有限公司

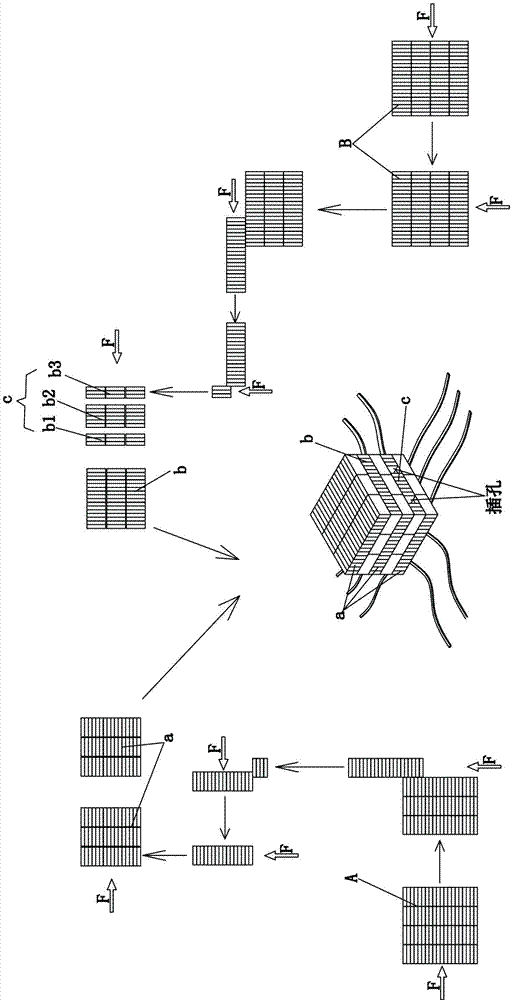

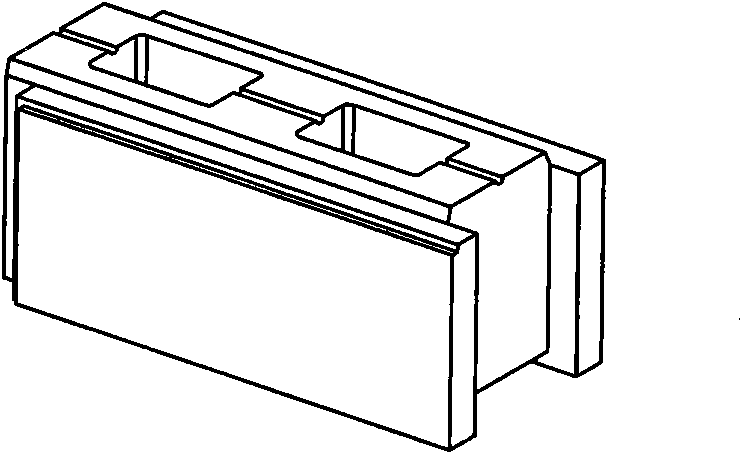

Tray-free stacking process for autoclaved lightweight concrete building blocks

The invention discloses a tray-free stacking process for autoclaved lightweight concrete building blocks, and belongs to the field of concrete building block packaging processes. The tray-free stacking process is characterized by being implemented by a full-automatic packaging system, and each stacking clamp (302) is independently controlled to be opened and closed through a line; the tray-free stacking process comprises the following stacking steps: (1) setting the arrangement direction and the quantity of the building blocks on each layer in building block stack, and sizes of loading and unloading holes; (2) performing green brick rolling over: continuously rolling over a plurality of rows of building blocks row by row; (3) performing grounding: grouping the building blocks row by row until the quantity of building blocks for each layer is met; (4) performing layer-by-layer stacking: stacking the subsequent building blocks on the lower layer of the building block stack in sequence through a mechanical arm stacking mechanism (3); (5) reserving and setting loading and unloading holes; and (6) performing packaging. According to the tray-free stacking process for the autoclaved lightweight concrete building blocks, no tray is used in the whole conveying process, so that a large number of trays are saved; the building blocks can be directly carried by a forklift truck without the tray, so that the effect of the tray is thoroughly eliminated; and therefore, a lot of production cost is saved.

Owner:淄博捷达机械有限公司

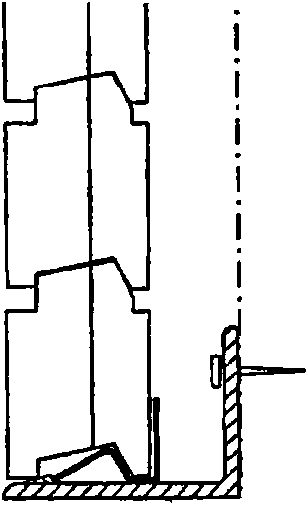

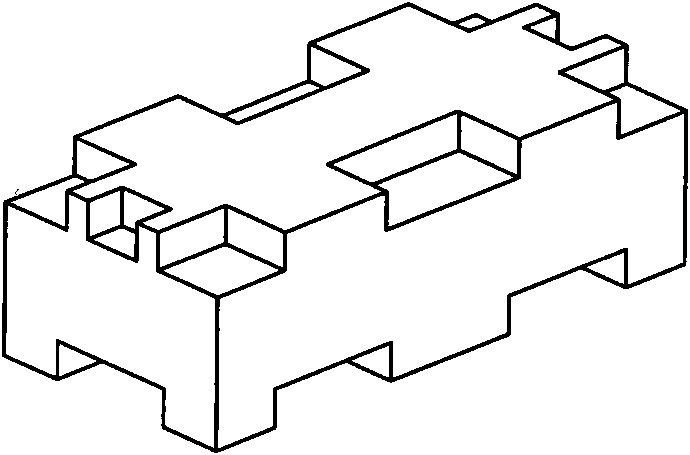

Wall body structure formed by building block

InactiveCN101775858AIncrease lateral forceGood lateral seismic performanceWallsBuilding insulationsWater leakageEngineering

The invention relates to a wall body structure formed by building blocks. A wall body comprises wall layers formed by the building blocks in a longitudinally connecting way. The wall layers are overlaid layer by layer. The building blocks of adjacent wall layers are arranged in a staggering way. Each building block is a longitudinal section and comprises a top surface, a bottom surface and two end surfaces. As a whole, the cross section of the building block is of downward horn mouth shape. A middle ridge is arranged at the top surface, the two sides are lower and a left supporting slope and a right supporting slope are formed. The top surface and the bottom surface are formed in a way that when a building block is overlaid with a lower similar building block to form a wall body, the left supporting slope and the right supporting slope of the top surface of the lower building block are in contact with the bottom surface of the building block, so the two building blocks are locked and the relative transverse movement is stopped. Since the building block has the shape and the dimension, when three similar building blocks are overlaid from top to bottom, the ridge of the lowest building block is higher than the bottom toe part of the top building block. Any surface of the wall body can prevent water leakage, the permeable soil keeping effect is good, the seismic stability is high and the wall body is suitable for a plurality of kinds of buildings and all kinds of construction methods.

Owner:汪荣勋

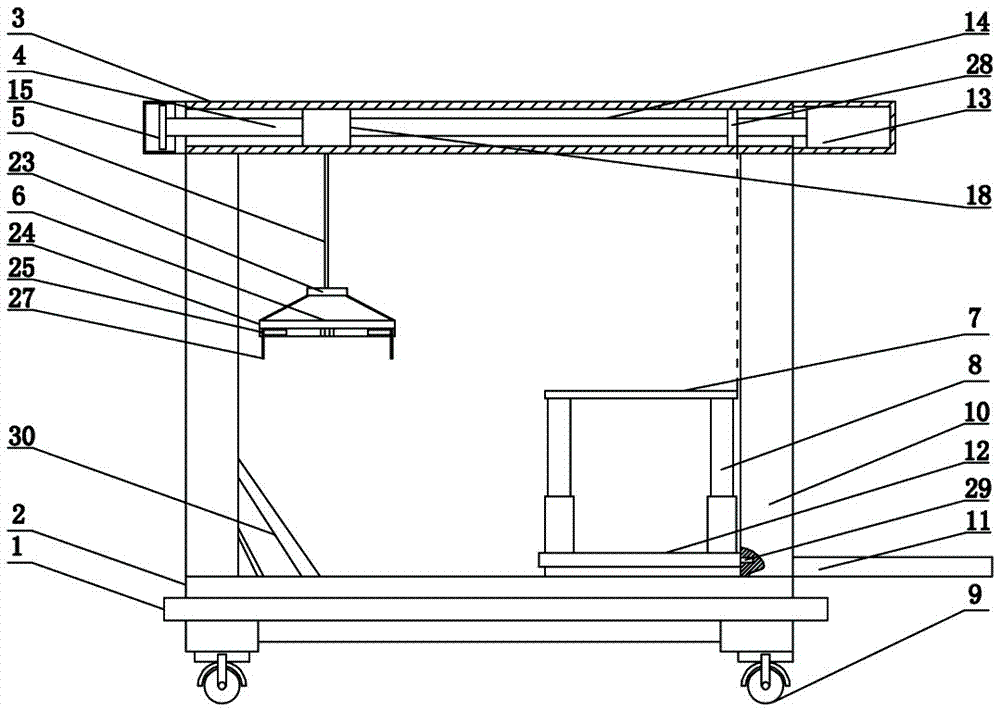

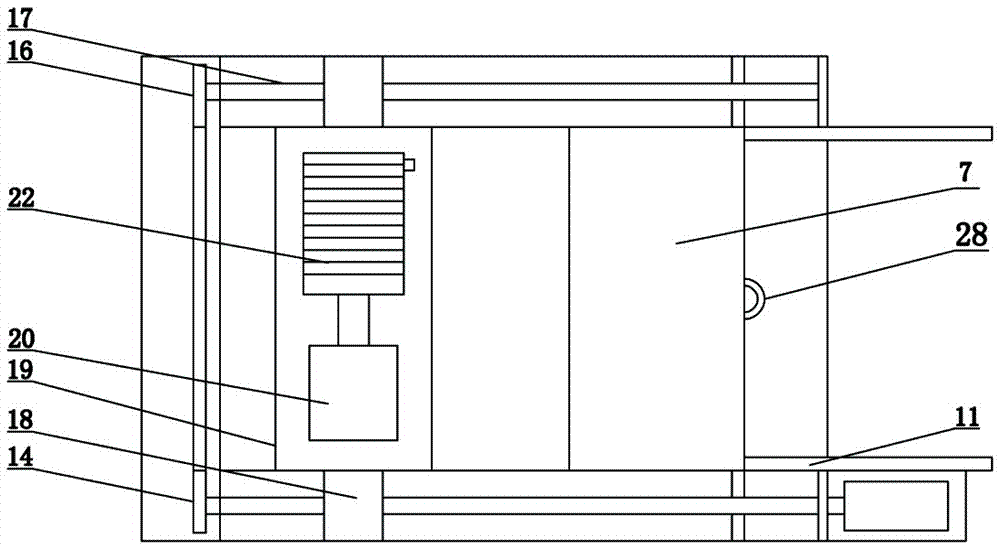

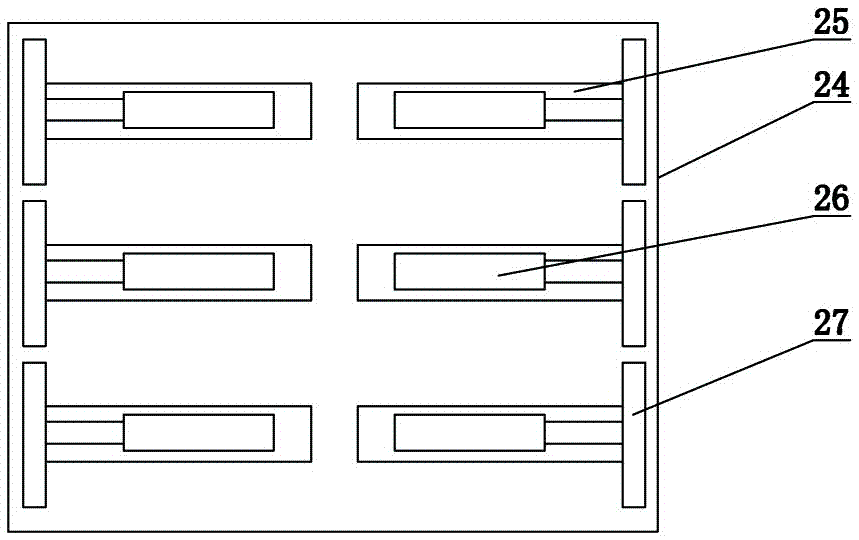

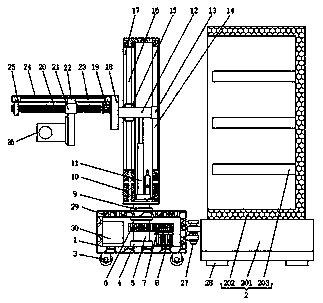

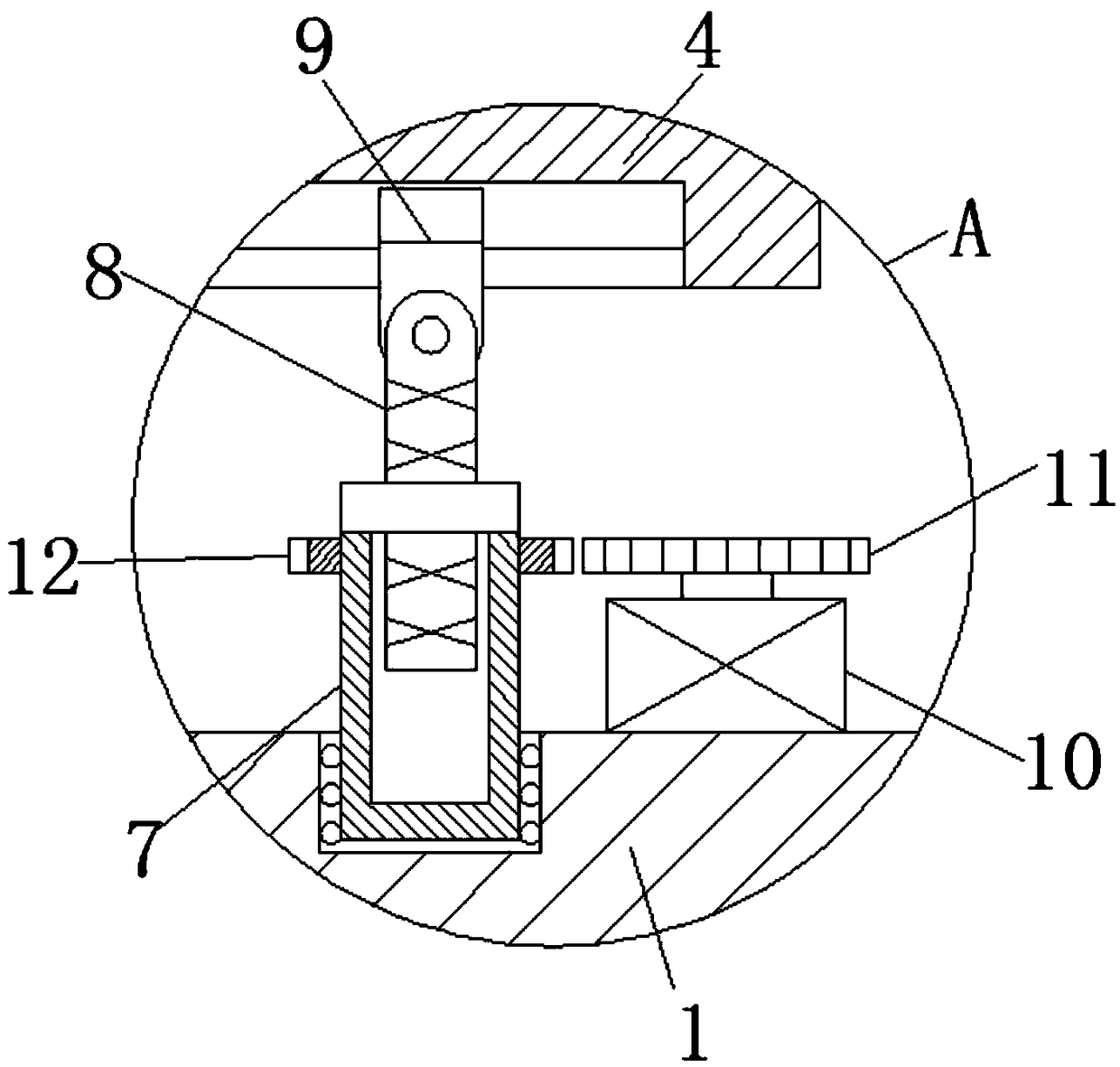

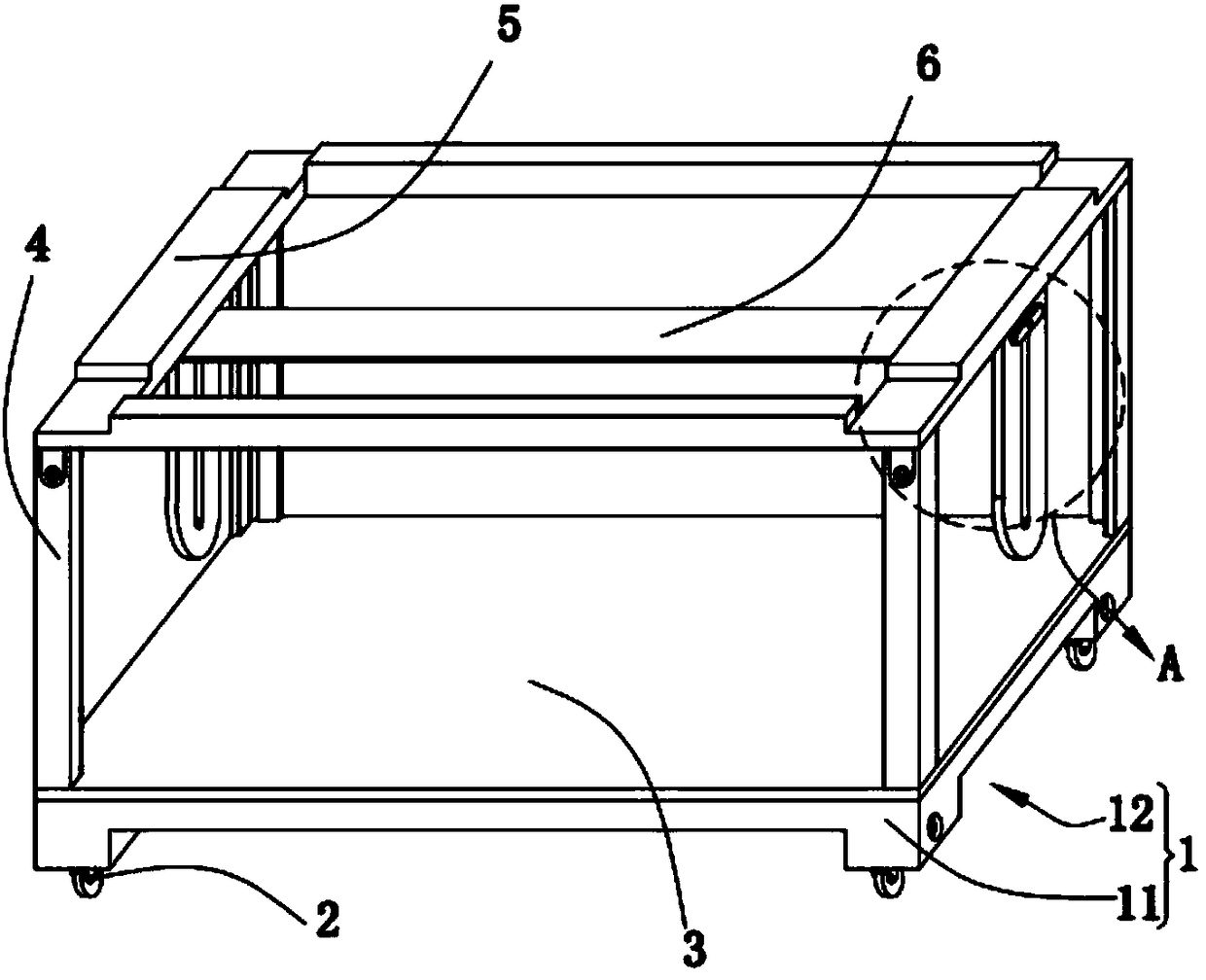

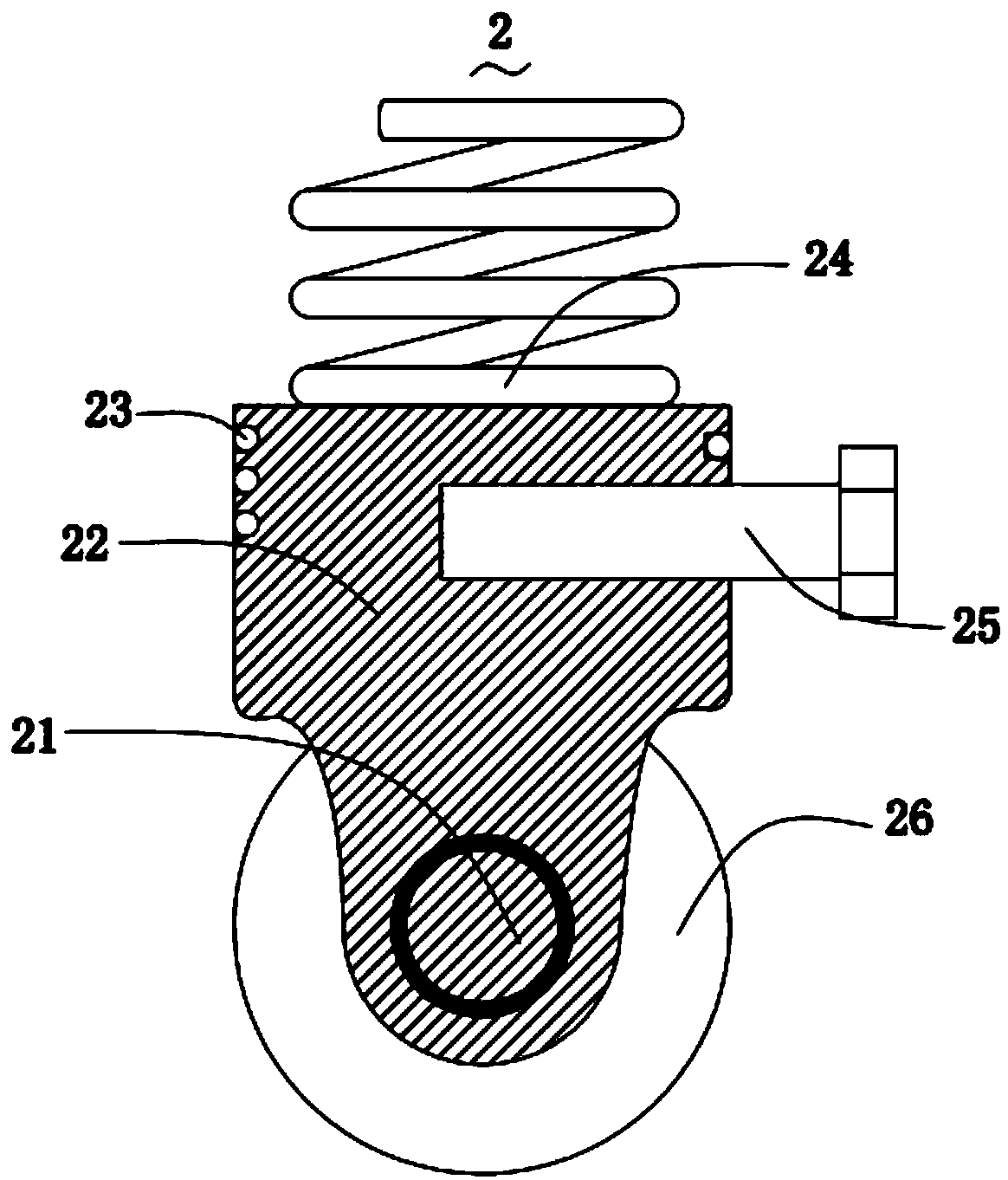

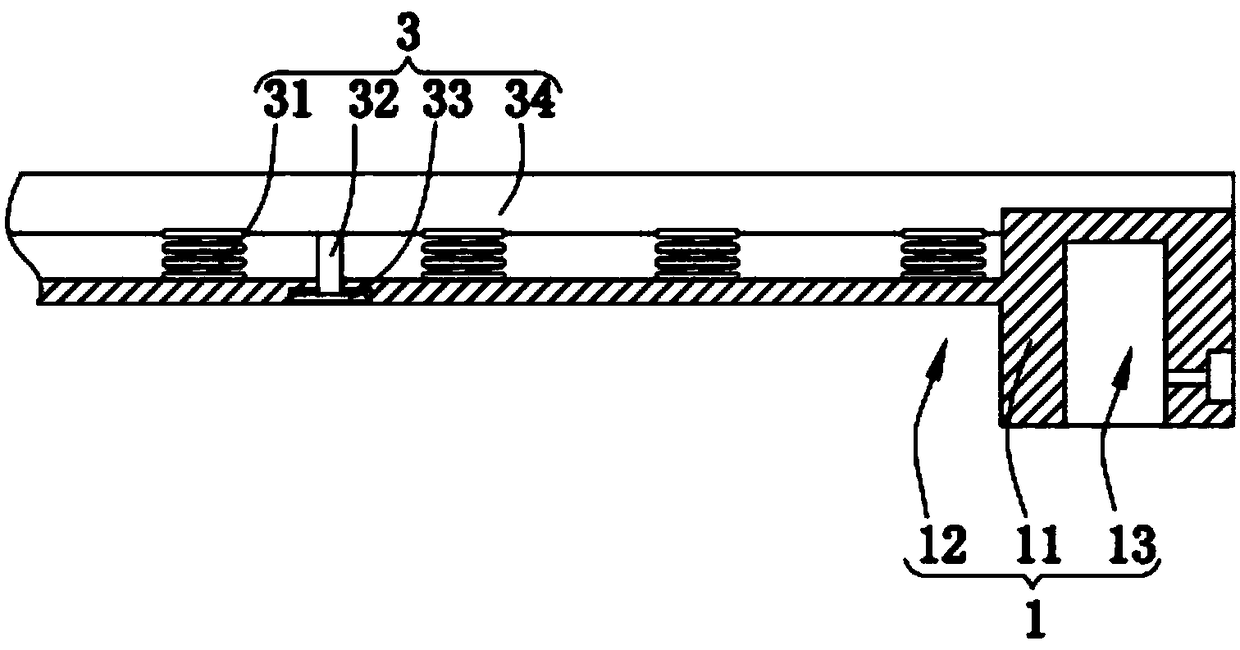

Movable building block brick stacking machine

InactiveCN108002042AEasy to palletizeReduce workloadStacking articlesDe-stacking articlesBrickStack machine

The invention relates to a movable building block brick stacking machine. comprises a mounting frame; two sets of mounting sliding grooves are formed in the mounting frame; movable frames are arrangedin the mounting sliding grooves; movable universal wheels are arranged on the movable frames; four sets of mounting stand columns are arranged on the mounting frame; every two sets of mounting standcolumns are fixedly connected to one set of mounting cross beams; transverse moving devices are arranged in the mounting cross beams; stacking clamping lifting devices are arranged on the moving devices and are connected to stacking clamping devices; two sets of movable optical rails are further arranged on the mounting frame; a movable platform is arranged on the movable optical rails; stacking platform lifting devices are arranged on the movable platform; and a stacking platform is arranged on the stacking platform lifting devices. The movable building block brick stacking machine has the advantages that the movable frames are arranged on the mounting frame, the universal wheels are arranged on the movable frames, a stacking machine body can be conveniently moved to the position close toa pile of bricks, a stacking machine can be mechanically clamped and moved to the stacking platform, and therefore the manual workload can be reduced, and the safety of stacking workers can be guaranteed.

Owner:王晓燕

Intelligent manufacturing device based on industrial robot

InactiveCN108748171AReduce wearExtended service lifeGripping headsStacking articlesRough surfaceEngineering

The invention discloses an intelligent manufacturing device based on an industrial robot. The intelligent manufacturing device comprises a first box and a stacking frame. Four universal wheels are fixedly connected to the lower surface of the first box and are located on the four corners of the lower surface of the first box correspondingly, and a first bearing is clamped to the lower surface of the inner wall of the first box. A first rotary shaft is sleeved with the first bearing. According to the intelligent manufacturing device based on the industrial robot, a clamping device is arranged and comprises a first fixed plate, a buffer pad, a second fixed plate, a second electric push rod, a first extrusion plate, a third fixed plate, an elastic device and a second extrusion plate. Comparedwith use of a vacuum sucker, the clamping device can reduce abrasion between the clamping device and goods, thus the service life can be longer, various goods of different sizes can be fixedly clamped through the clamping device, and the goods fixing effect can be better when goods with rough surfaces are clamped.

Owner:杨光平

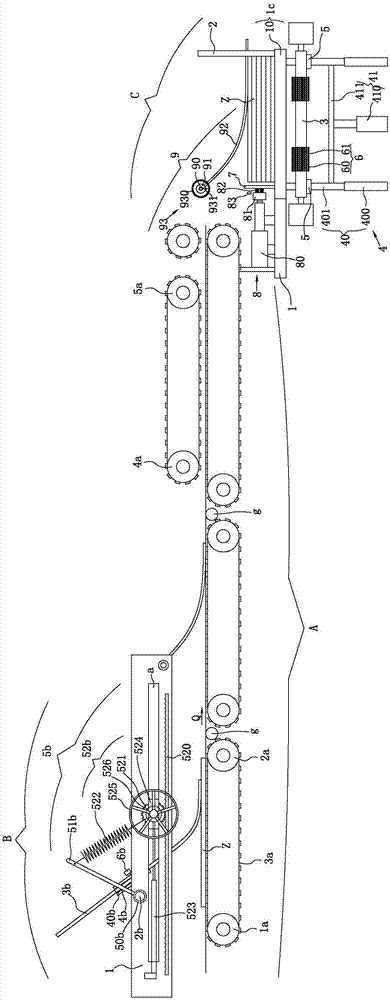

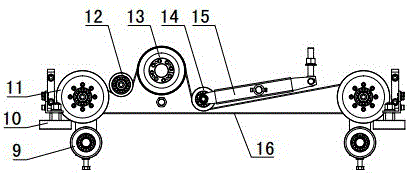

Method for harvesting green Chinese onion

The invention discloses a method for harvesting green Chinese onion. The method comprises the following steps: 1) while shoveling soil, forming two cutting slots by a soil-separating device; 2) backwardly moving the shoveled green Chinese onion, primarily removing the soil on the roots of the green Chinese onion by using a comb-shaped joint part and then leading a longitudinal conveying device; 3) vertically clamping the green Chinese onion in the longitudinal conveying device, using a soil-shaking device for shaking off the soil on the roots of the green Chinese onion in the conveying process, thereby realizing the secondary removing of the soil on the roots of the green Chinese onion; 4) after the soil is removed, moving the green Chinese onion from the longitudinal conveying device to the horizontal conveying device, and rotating the green Chinese onion through an inclined channel and gradually backward conveying; and 5) when the green Chinese onion is conveyed to the discharging end, correcting to the horizontal state by the guiding mechanism, thereby completing the secondary rotation, and then conveying to a stacking area and completing the packing. According to the method provided by the invention, the shoveling soil volume can be reduced, and meanwhile, the secondary removal for the soil on the roots of the green Chinese onion and the secondary rotation for the green Chinese onion are adopted, so that the stacking and packing operations can be conveniently performed.

Owner:山东沃华农业科技股份有限公司

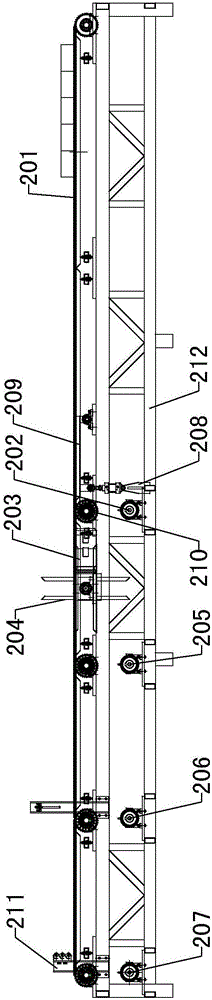

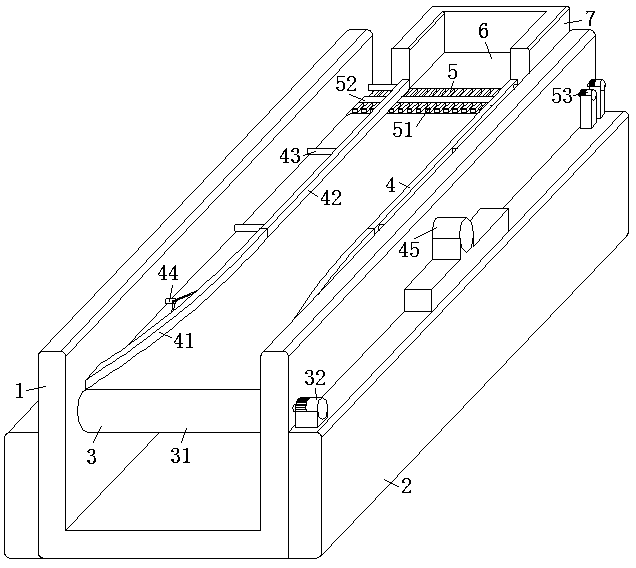

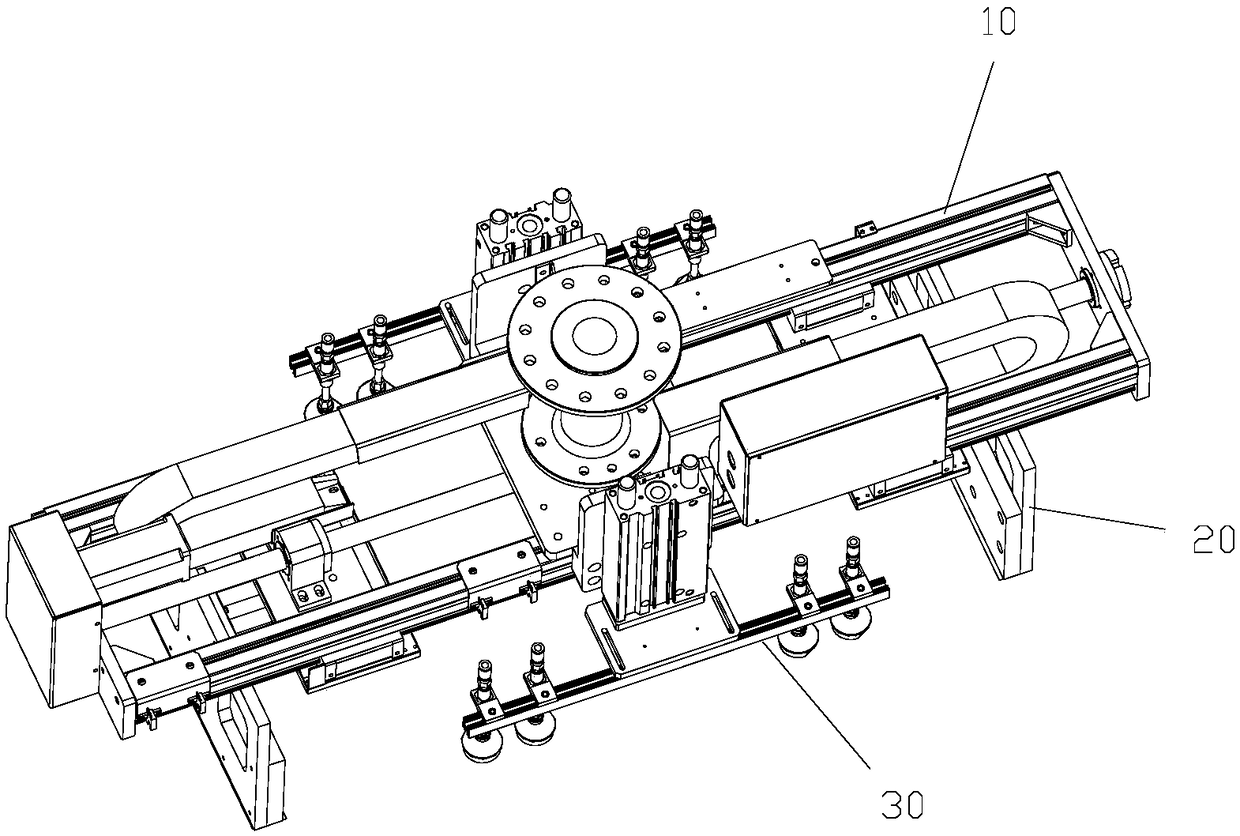

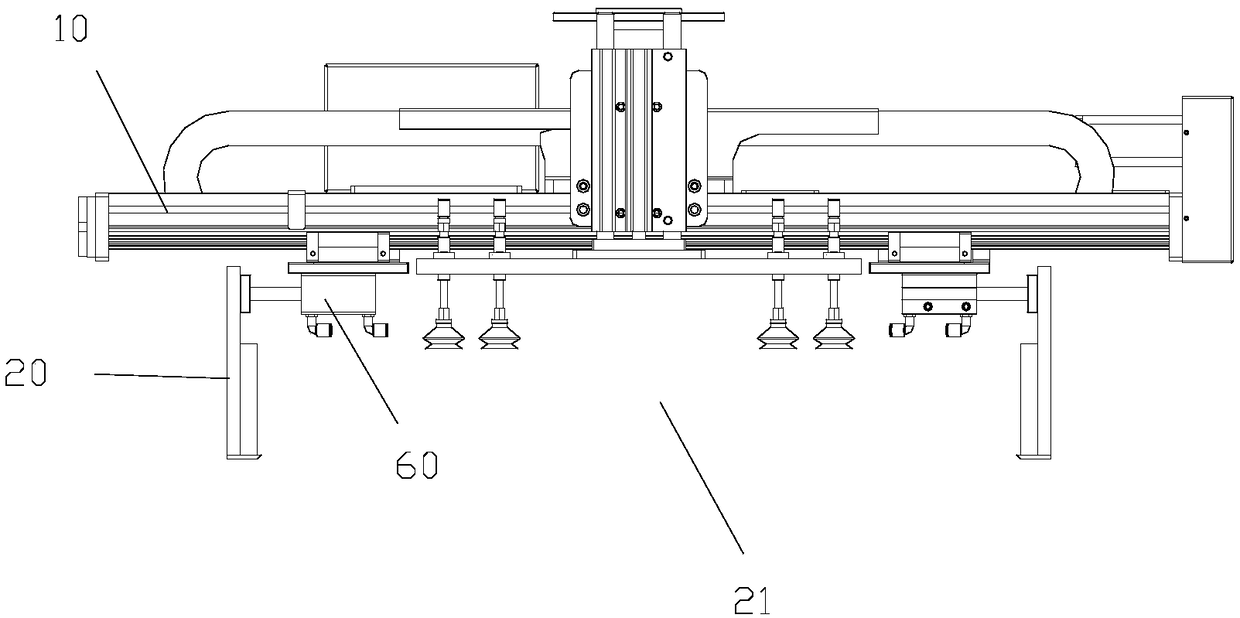

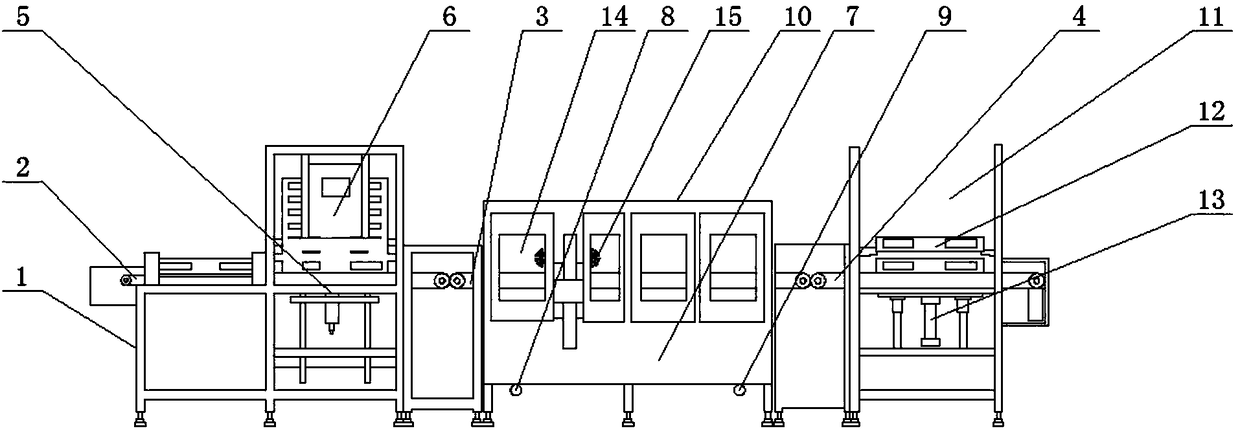

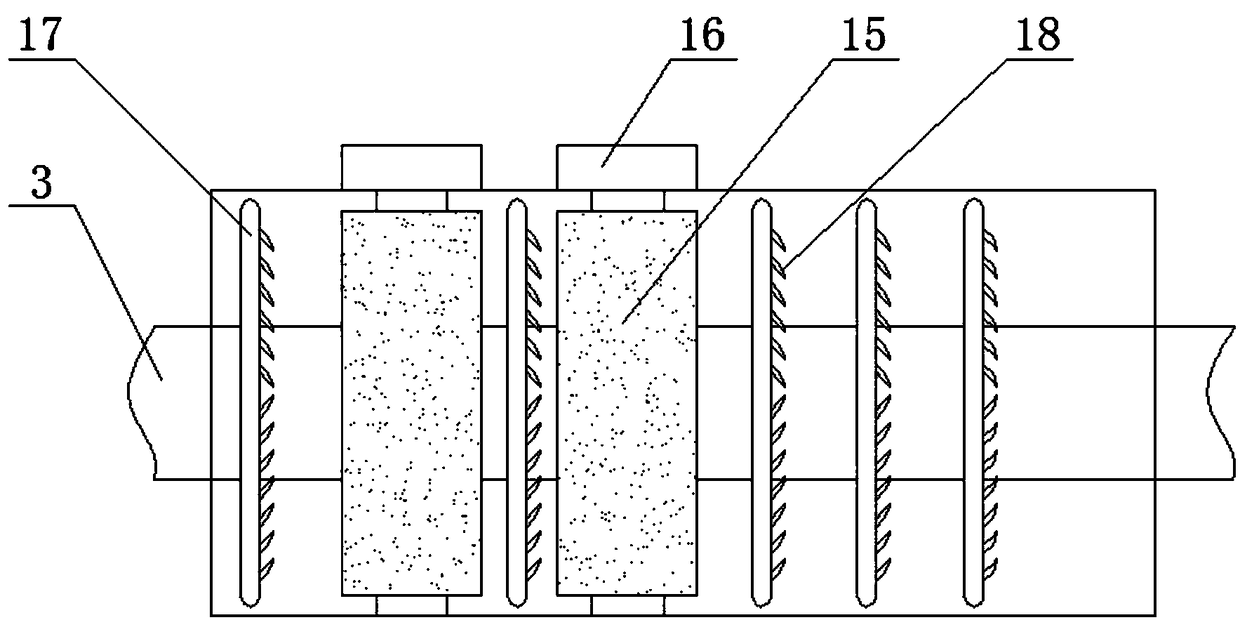

Bagged material stacking line

ActiveCN109230395AEasy to palletizePalletizing is stableConveyorsStacking articlesManipulatorEngineering

The invention provides a bagged material stacking line. The bagged material stacking line comprises a leveling and conveying station, a stacking platform, a tray conveying station and a stacking station; the leveling and conveying station comprises a first conveying line and a pressing and shaping conveyor, the first conveying line conveys bagged materials to the pressing and shaping conveyor, thepressing and shaping conveyor squeezes and levels the bagged materials and outputs the bagged materials, the stacking platform receives the bagged materials which are squeezed and leveled, and the tray conveying station comprises a tray storehouse used for storing trays and a tray conveying line used for conveying the trays; the stacking station comprises a stacking conveying line, a winding device and a carrying manipulator, the tray conveying line conveys the trays to the stacking conveying line, the carrying manipulator carries the bagged materials on the stacking platform onto the trays of the stacking conveying line, and the stacking conveying line conveys the trays loaded with the materials to the winding device, so that the winding device winds and packages the bagged materials. According to the bagged material stacking line, through the leveling and conveying station, the bagged materials are squeezed and leveled, so that the bagged materials are conveniently and steadily stacked, and the phenomenon that the materials topple over is prevented.

Owner:中山市毛毛虫机器人科技有限公司

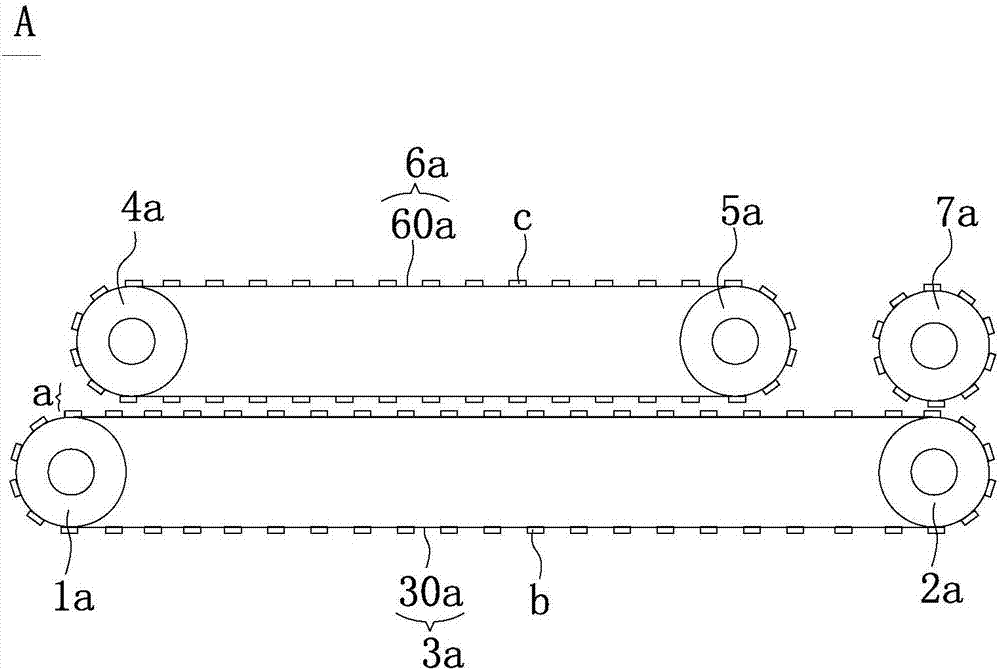

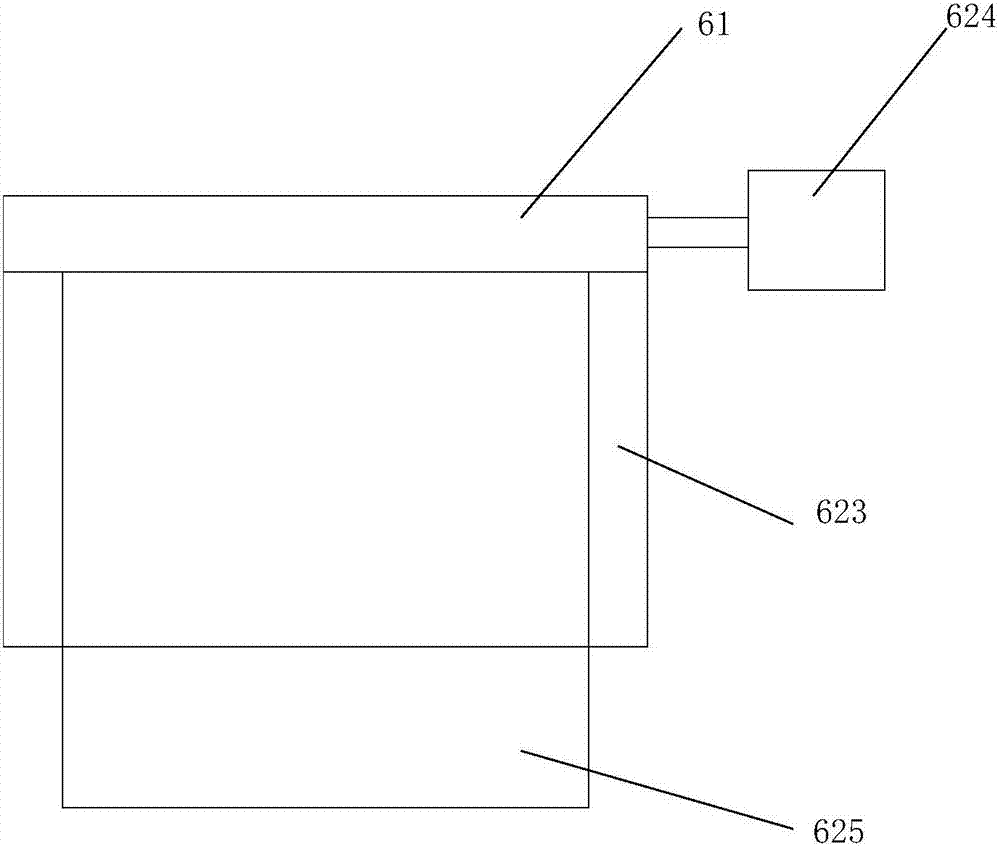

Paperboard collecting machine

ActiveCN106956956AAdjust frictionPrevent slippingPile receiversArticle deliveryPaperboardEngineering

The invention relates to a paperboard collecting machine. The paperboard collecting machine comprises first driving roller, second driving rollers and annular driving belts, wherein each first driving roller and each second driving roller horizontally extend in the direction perpendicular to the paperboard conveyance direction of the corresponding annular driving belt, each annular driving belt comprises multiple first annular partitioned belts arranged in the length direction of the corresponding first driving roller and the corresponding second driving roller at intervals. A conveying device further comprises a first compression roller, a second compression roller and an annular pressing belt, wherein the first compression roller and the second compression roller are arranged between the corresponding first driving roller and the corresponding second driving roller and located above the corresponding first driving roller and the corresponding second driving roller, and the corresponding first driving roller and the first compression roller rotate oppositely so that paperboards can move in the conveyance direction. The annular pressing belt comprises multiple second annular partitioned belts which are arranged in the length direction of the first compression roller and the second compression roller at intervals, wherein the first annular partitioned belts and the second annular partitioned belts are mutually parallel, a conveyance channel is formed, and the height of the conveyance channel can be adjusted. According to the paperboard collecting machine, the multiple vertically-corresponding annular partitioned belts clamp the top and bottom of the sequentially-stacked paperboards, so that the paperboards move relatively stable, cost is low, and the conveyance efficiency is high.

Owner:苏州庆丰包装材料有限公司

Plate cutting stacking robot

InactiveCN110844611AEasy to palletizeEasy to navigateStacking articlesDe-stacking articlesPalletizerStructural engineering

The invention relates to the field of stacking robots, in particular to a plate cutting stacking robot. The plate cutting stacking robot comprises a fixed seat, a supporting seat, a conveying mechanism, a guiding mechanism, a cleaning mechanism, a stacking mechanism, a small trolley and a clamping mechanism, wherein the guiding mechanism is mounted on the fixed seat, and plates are guided throughthe guiding mechanism, so that the plates can conveniently parallel to the side wall of the fixed seat, guide of the plates is facilitated, and the guiding mechanism can be adjusted to facilitate transmission and guide of the plates with different widths; the cleaning mechanism is installed on the fixed base, and debris on the bottom end of a conveying belt and the plates is cleaned through the cleaning mechanism, so that the cleanliness of the conveying belt is facilitated, the bottom surfaces of the plates conveniently make contact with the conveying belt, and the stability of the plates inthe conveying process is kept; the clamping mechanism is installed on the small trolley, the clamping mechanism is clamped to the fixed seat, the small trolley and the fixed seat are fixed through theclamping mechanism, and the position of the small trolley is shifted due to the impulsive force of the plates when the plates enter the small trolley.

Owner:江西清研扬天科技有限公司

Board pushing, conveying and stacking system on high-density fiber boards

ActiveCN107758366AAvoid rescatteringIncrease contact areaStacking articlesDe-stacking articlesFiberHigh density

The invention discloses a board pushing, conveying and stacking system on high-density fiber boards. A lifting platform and a stacking platform are arranged at the head end and the tail end of the system, and extend downwards to be arranged with the basic planes of a board pushing system and a stacking system with reference; one end of the board pushing system is a free end; the other end of the board pushing system is welded to a gantry support on a downstream conveying system; the tail end of the conveying system is a free end; and the stacking system is arranged tightly close to the tail end of the conveying system. Due to the technical scheme, at least five high-density fiber boards can be conveyed at a time, the contact area between a push plate and the high-density fiber boards is large, grabbing hook conveying is stable, the production efficiency is improved by 5 times or above, time and energy are saved, and meanwhile the production cost is reduced.

Owner:河南鑫饰板业有限公司

Fixture

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Forklift lifting device capable of improving safety performance

ActiveCN112520651AImprove securityPlay a stabilizing roleLifting devicesGear wheelIndustrial engineering

The invention discloses a forklift lifting device capable of improving the safety performance. The device comprises a concave frame, wherein grooves are formed in the two side faces of the interior ofthe concave frame, lead screws are perpendicularly and rotationally connected into the two grooves, a cavity plate is arranged between the two lead screws in a sleeving mode, and clamping mechanismsare installed on the two side faces of the concave frame in an embedded and sliding mode. Two pallet fork parts are symmetrically embedded into the lower surface of the cavity plate in a sliding mode,and an anti-falling part is arranged between the two pallet fork parts. The invention relates to the technical field of forklifts. According to the forklift lifting device capable of improving the safety performance, through the arrangement of the clamping mechanisms, under meshing connection of driving gears and driven gears, along with rotation of fourth servo motors, the driven gears can drivelimiting plates on rotating shafts to move, and then rubber columns on hook plates are driven to rotate; and the rubber columns clamp the two sides of stacked cargoes, so that the cargoes are stabilized, and the situation that people are injured due to the fact that the too high cargoes topple over is avoided.

Owner:安徽宇锋智能科技有限公司

Novel casing device

ActiveCN105015811AEasy to handleWill not cause quality problems such as scratchesIndividual articlesEngineeringMechanical engineering

Owner:TIANJIN DONGMING ELECTRONICS IND

Building block for forming wall structure

InactiveCN101775867ASolve the double-sided leak-proof problemSolve the problem of permeable soilBuilding insulationsShock proofingWater leakageArchitectural engineering

The invention relates to a building block for forming a wall structure. A plurality of similar building blocks are alternately superposed continuously in the wall. The building block is a longitudinal section material and comprises a top surface, a bottom surface and two end surfaces; the cross section of the building block is integrally in a downward horn mouth shape; the middle part of the top surface has a ridge, and two sides of the top surface are low, thereby forming a left supporting slope and a right supporting slope; the building block has the shape and the size, thus when three similar building blocks are superposed from top to bottom, the ridge of the undermost building block is higher than the base part of the topmost building block; the lower part of each supporting slope is provided with a shoulder table which comprises an upper table surface, a table bottom surface and a transverse lateral surface; the upper table surface, the upper slope and the middle ridge form the top surface; and when the building block is superposed with the upper similar building blocks to form the wall, protrusions formed by slopes at two sides are bonded with horn notches on the bottom surfaces of the upper similar building blocks. The invention can prevent water leakage of any surface of the formed wall, simultaneously enables the wall to have stable shock resistance, and is suitable for various buildings and various construction methods.

Owner:汪荣勋

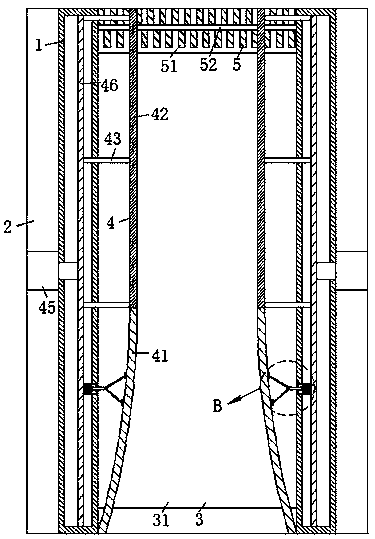

Automatic supporting-plate-free cement brick stacking device and method and packing production line

InactiveCN106865246ARealize transportationAutomate operationStacking articlesDe-stacking articlesProduction lineBrick

The invention belongs to the technical field of machine manufacturing and provides an automatic supporting-plate-free cement brick stacking device comprising a conveying and brick-pushing device and a space-reserving stacking device. The conveying and brick-pushing device comprises a conveyer and a brick pusher. The brick pusher comprises a plurality of brick pushing mechanical arms arranged side by side. The space-reserving stacking device comprises a rotating disk and a stacking device body. The invention provides an automatic stacking method adopting the automatic supporting-plate-free cement brick stacking device. Bricks are automatically stacked into a brick stack provided with space-reserved structures through the conveying and brick pushing device and the space-reserving stacking device. The invention further provides an automatic packing production line adopting the automatic supporting-plate-free cement brick stacking device. The automatic packing production line comprises a cement brick forming device, a cement brick maintaining device, a spreading conveying device, a brick and plate separating device, the conveying and brick pushing device, a space-reserving stacking device and a packing device. According to the automatic supporting-plate-free cement brick stacking device, the automatic stacking method adopting the automatic supporting-plate-free cement brick stacking device and the automatic packing production line adopting the automatic supporting-plate-free cement brick stacking device, the concept is ingenious, the structure is reasonable, the building block production requirement is met, and the technical problems that in the prior art, in the process of stacking and packing the brick stacks provided with the space-reserved structures, the work efficiency is low, and manpower resources are wasted are solved.

Owner:QINGYUAN TONGYE MACHINE MFG CO LTD

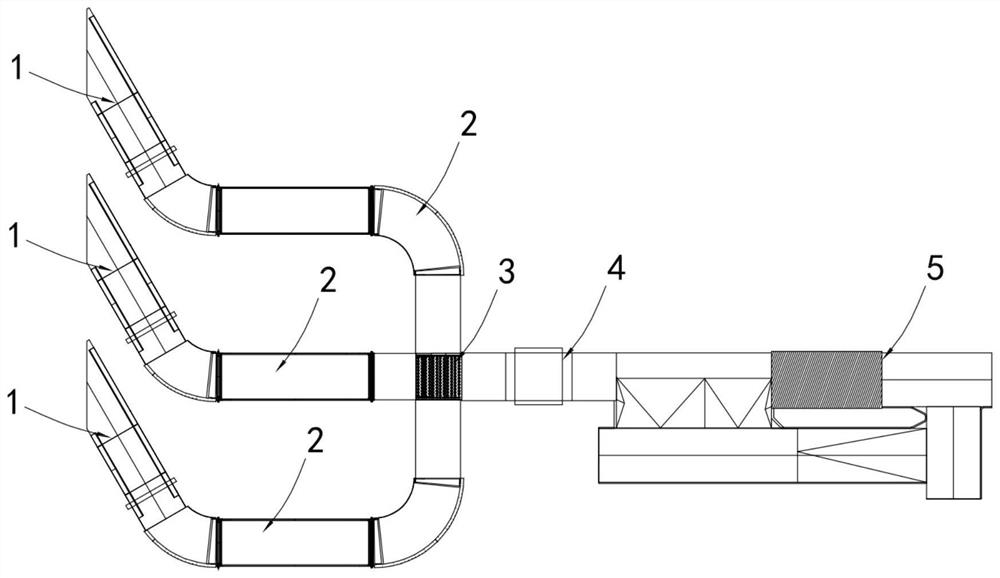

Parcel supply system, cross belt sorting system and parcel supply method

PendingCN112452812AOvercome uncertaintySmall amount of calculationConveyorsControl devices for conveyorsControl engineeringTransfer line

The invention discloses a parcel supply system, a cross belt sorting system and a parcel supply method. According to the parcel supply system, articles are automatically output one by one through a single-piece separation conveyor, so that the process of manually feeding parcels one by one can be omitted; meanwhile, the problem that the positions of bar codes on the articles conveyed by the single-piece separation conveyor are uncertain can be effectively solved through a six-face code scanning conveying line, so that manual-work-free automatic parcel supply can be achieved; furthermore, the articles are distributed to three parcel supply tables through a deflection wheel sorter, so that it is unnecessary to configure a six-face code scanning conveying line and a single-piece separation device for each parcel supply table, then the complexity of the equipment can be greatly reduced, the integration degree of the equipment is improved, and the utilization rate of the single-piece separation conveyor and the six-face code scanning conveying line can be increased; and meanwhile, compared with an arrangement mode with multiple code scanning devices and single-piece separation devices,the mode can effectively reduce the calculation amount of a control device and is beneficial to lowering the configuration requirement of the control device and improving the calculation efficiency.

Owner:SUZHOU JINFENG INTERNET OF THINGS TECH CO LTD

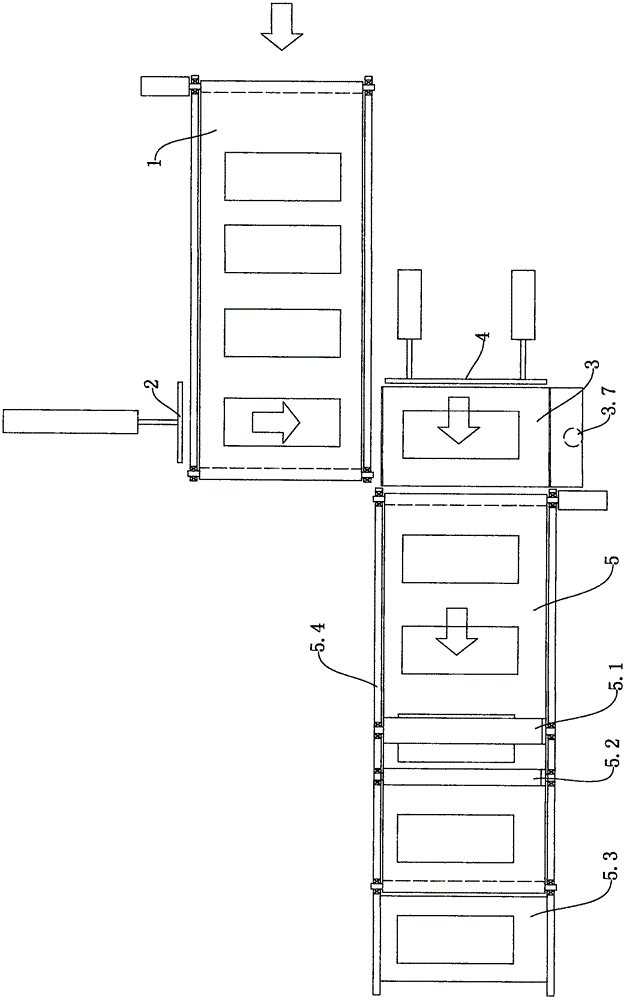

Stacking machine of feed production line and production method thereof

ActiveCN105858234AUniform longitudinal distributionUniform horizontal distributionStacking articlesProduction lineEconomic benefits

A stacking machine of a feed production line comprises a first conveyor belt, a first pusher, a levelling device, a second pusher and a second conveyor belt, wherein the first pusher is arranged at one side of the first conveyor belt and used for pushing a feed bag conveyed on the first conveyor belt to the levelling device at the other side of the first conveyor belt; the second pusher is arranged at one side of the levelling device and used for pushing the feed bag which is levelled in a tilting and pressing manner from the levelling device to the second conveyor belt at the other side of the levelling device. The stacking machine is high in production efficiency, low in working intensity of workers, and good in levelling and stacking effects; the production cost is greatly reduced, so that the economic benefit is greatly increased.

Owner:山东腾阳智能装备有限公司

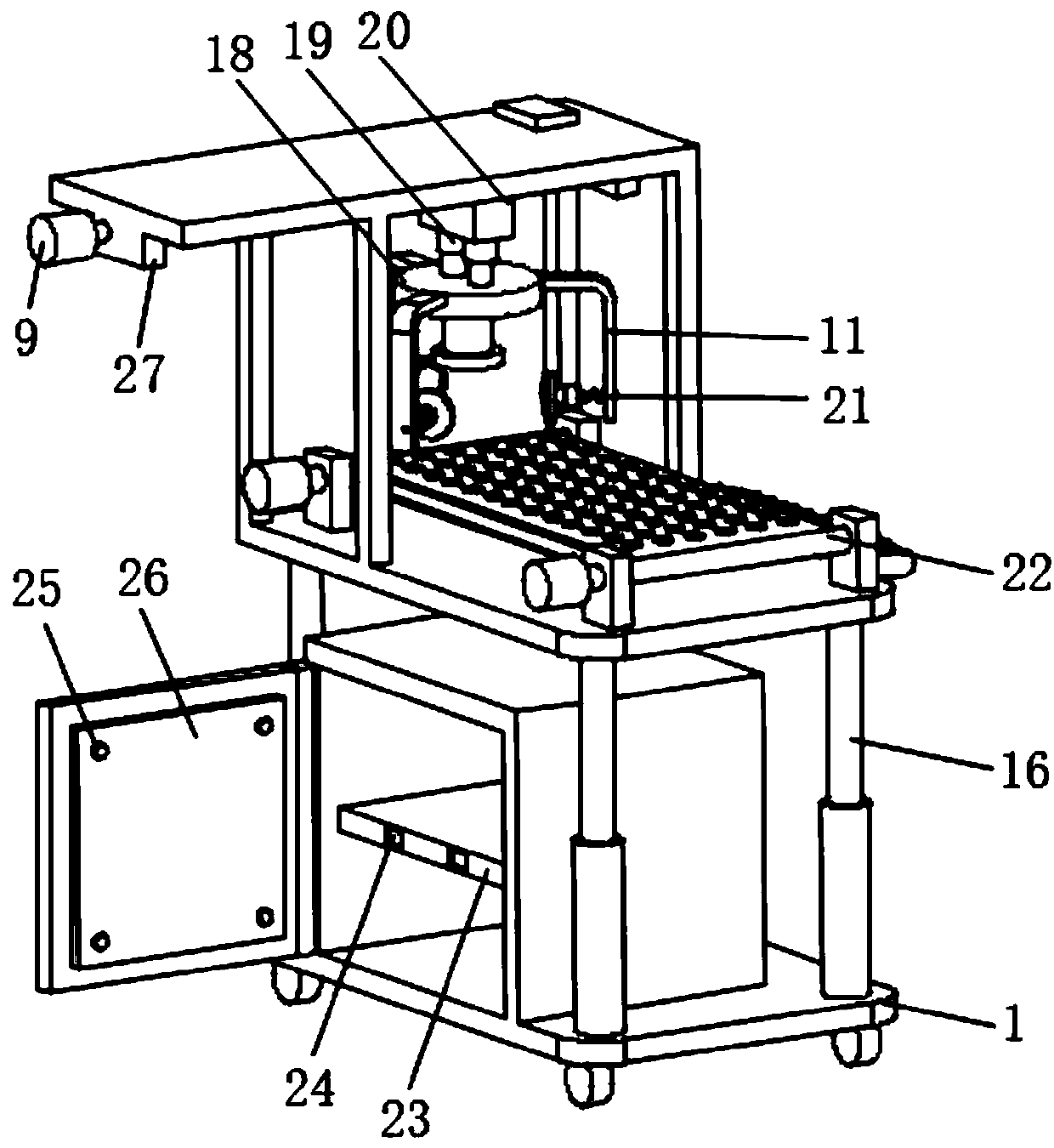

Tray cleaning machine

InactiveCN108067487AEasy to separateEasy to palletizeHollow article cleaningSynchronous motorInlet valve

The invention provides a tray cleaning machine, which comprises a support, a first conveyor belt, a second conveyor belt, a third conveyor belt, a tray separating mechanism, a touch control screen, awater tank, a water inlet valve, a water outlet valve, a cleaning chamber, a forklift discharging station, a tray, a tray lifting mechanism, an observation window, rolling brushes, a synchronous motor, water delivery pipes and water spray nozzles. The first conveyor belt is arranged above the left side of the support; and the tray separating mechanism is arranged under the right side end of the first conveyor belt. According to the tray cleaning machine provided by the invention, through arranging the two rolling brushes, trays to be cleaned can be favorably cleaned for two times; through arranging the water delivery pipes and the water spray nozzles, the trays can be sprayed with water so as to be cleaned cleanly before cleaning, during cleaning and after cleaning; through arranging the tray separating mechanism and the tray lifting mechanism, the trays can be favorably separated and stacked; and through arranging the observation window, the trays during cleaning can be favorably observed, so that the tray cleaning machine is convenient to operate, high in automation degree, and thorough in cleaning.

Owner:三佳泰克诺(天津)机械设备有限公司

Cardiogram paper stacking device

InactiveCN109051833AEasy to stackEasy to palletizeStacking articlesBlock matchMechanical engineering

Owner:TIANJIN GRAND PAPER IND

Production device for colored optical glass

InactiveCN108341268AEasy to carryEasy to fixNon-rotating vibration suppressionCharge manipulationOptical glassBiomedical engineering

The invention relates to the field of glass production equipment, in particular to a production device for colored optical glass. The production device for the colored optical glass comprises supporting structures, moving structures, a shock absorption structure, first limiting structures, fixing structures and a pressing structure; the moving structures for moving the device are arranged at the bottom ends of the supporting structures; the shock absorption structure for absorbing shock is arranged at the top ends of the supporting structures; the first limiting structures for limiting the glass are arranged at four corners of the end, away from the supporting structures, of the shock absorption structure; the fixing structures are arranged at the top ends of the first limiting structures;and the pressing structure is arranged at the bottom ends of the fixing structures and matched with the shock absorption structure to conduct abutting limiting on the glass. According to the production device for the colored optical glass, the moving structures and the supporting structures can slide, and the device can be carried conveniently through the moving structures; the shock absorption performance of the device is improved through cooperative use of the shock absorption structure and the supporting structures; difference pieces of glass can be limited conveniently through cooperativeuse of the fixing structures and the pressing structure; and meanwhile, portions of the glass are evenly stressed, and the fixing quality is improved.

Owner:夏美佳

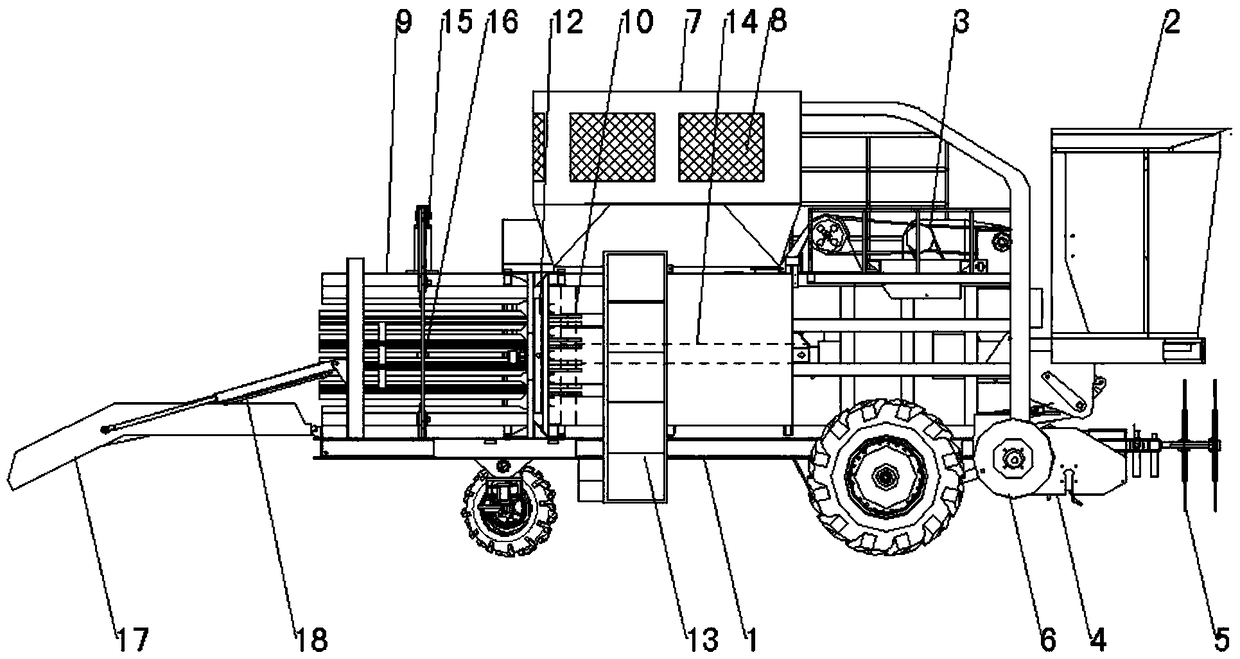

Large and square packed straw picking and bundling machine

The invention discloses a large and square packed straw picking and bundling machine which comprises a body, wherein a picker is arranged at the front end of the body, and is composed of a picking box, a picking roller, a stirring cage, moving blades and fixed blades; the picking roller and the stirring cage are arranged in the picking box; the moving blades are mounted on the picking roller; thefixed blades are arranged on the inner walls of the picking box; a wind hoist is arranged at the discharging end of the picking box; a storage silo with a filtering net on the side wall is arranged onthe top end of the body; a discharge hole of the hoist is tangentially inserted into a discharging bin; a bundling machine communicated with the bottom end of the discharging bin is arranged at the rear end of the body; the bundling machine comprises a bundling frame, an axial compression frame, a lateral compression frame, a stringing rod and a rope box; the axial compression frame is arranged in the bundling frame to move back and forth; the lateral compression frame is arranged on the left and right sides of the bundling frame; the stringing rod is perpendicular to one side of the bundlingframe and moves from side to side; and the rope box is arranged on one side of the bundling frame. The picked straws can be crushed, so that the molded straw packages are regular in structure, and the straw packages are convenient to transport and stack. Moreover, dust in the straws is removed, and the workload of later power generation or feed preparation is greatly decreased, and cost for laterpower generation or feed preparation can be lowered.

Owner:辽宁宁越农机装备有限公司

Low melting point valve port bag and manufacturing method thereof

ActiveCN111348317AWon't decomposeRaw materials are non-toxicBag making operationsPaper-makingThermal deformationUltimate tensile strength

The invention discloses a manufacturing method for a low melting point valve port bag. The low melting point valve port bag has the following indexes that the melting point is between 98 and 102 DEG C; the transverse tensile strength is between 23 and 25 MPa; the longitudinal tensile strength is between 24 and 27 MPa; the transverse elongation at break is between 750 and 820 percent; the longitudinal elongation at break is 730 to 760 percent; the upper and lower heat seal strength is between 38 and 45 N / 15mm; and the heat seal strength at four corners is between 38 to 45 N / 15mm. The packagingbag prepared by the technical scheme can be thrown into an internal mixer together with carbon black, cannot produce package garbage in use, and is an environment-friendly product; embossing processing is performed when a film is blown so as to facilitate opening; the overall anti-sliding effect of a bag body is good; the melting point of the low melting point valve port bag is between 98 and 102DEG C, and is stable; thermal deformation cannot occur after the carbon black is injected; and the port bag is automatically filled into a cuboid after being filled with materials, so that bags are stacked tidily. A valve port is perforated for exhausting, is breathable and does not leak material; and the valve port bag has good compatibility with rubber and can be quickly fused into the rubber without affecting the performance of the rubber.

Owner:仲铂新材料有限公司

Automatic efficient shape correcting machine

PendingCN108545429AEffective regulationConvenience for subsequent transportationConveyor partsRoller-waysMechanical engineeringEngineering

The invention provides an automatic efficient shape correcting machine. The automatic efficient shape correcting machine comprises a rack. The rack is provided with a conveying mechanism. A rotation mechanism driving the conveying mechanism to rotate on the horizontal plane is arranged at the lower end of the conveying mechanism, and shape correcting mechanisms for conducting extruding and shape correcting on cargo are oppositely arranged on the two sides of a conveying track. The device can efficiently avoid the situations that parcels are loosened, the side surfaces are inclined and are notaligned, and the appearance is poor, and subsequent transporting and stacking are convenient.

Owner:HUZHOU RIGOR TECH

Multi-station stacking device and stacking process thereof

ActiveCN106315241AConvenient storage and loadingImprove work efficiencyStacking articlesDe-stacking articlesCeramic tilesPallet

The invention discloses a multi-station stacking device and a stacking process thereof and belongs to the technical field of ceramic tileproduction equipment. The multi-station stacking device is characterized in that a palletstoreroom (8) and multiple ceramic tile storerooms (5) are arranged at the lower portion of a rack (1), the multiple ceramic tile storerooms (5) are arranged in the ceramic tile conveying direction, and a control device controls a walking mechanism and grabbing mechanism (7) to grab pallets in the palletstoreroom (8) and put the pallets in the ceramic tile storerooms (5). A ceramic tile detection unit is further arranged on the rack (1) and is used for detecting the categories of ceramic tiles and transmitting signals to the control device, the control device controls the walking mechanism and grabbing mechanism (7) toceramic tiles according to category signals of the ceramic tiles and respectively stack different categories of ceramic tiles in different ceramic tile storerooms (5). The multi-station stacking device improves the working efficiency and can also greatly reduce error probability. Manual ceramic tile sorting is avoided by adopting the stacking process of the multi-station stacking device, and the automation degree is greatly improved.

Owner:山东爱而生智能科技有限公司

Stacking machine capable of firmly grasping feed bags to avoid package breakage for feed production

InactiveCN109592419AAvoid affecting work efficiencyAvoid lossConveyorsStacking articlesStack machinePalletizer

The invention discloses a stacking machine capable of firmly grasping feed bags to avoid package breakage for feed production, comprising a bottom plate, wherein the upper surface of the bottom plateis provided with four equidistantly distributed electric telescopic rods II, the upper surfaces of the electric telescopic rods II are connected with an operation table, the upper surface of the operation table is provided with two connecting frames, rotating shafts are rotatably connected with the connecting frames, the end parts of the rotating shafts are rotatably connected with servo motors II, and a conveyor belt is rotatably connected between the two rotating shafts. The stacking machine can grasp a feed bag by utilizing a gripping plate, an electric telescopic rod I and a jacking plate,and can further suck the grasped feed bag by utilizing a sleeve, an electric telescopic rod IV, a piston and a suction cup, so as to prevent the feed bag from falling off in the transportation process, and affect the working efficiency; and springs and non-slip pads can prevent the situation that the jacking plate makes rigid contact with the feed bag, thereby causing the package bag to be brokenand causing economic losses to a user.

Owner:胡振宇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com