Automatic efficient shape correcting machine

A shaping machine and high-efficiency technology, applied in the direction of conveyor objects, transportation and packaging, roller tables, etc., can solve the problems of loose goods, out-of-tolerance appearance, low efficiency, etc., and achieve the effect of wide application range and high-efficiency adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The invention will be further described below in conjunction with the embodiments in the accompanying drawings.

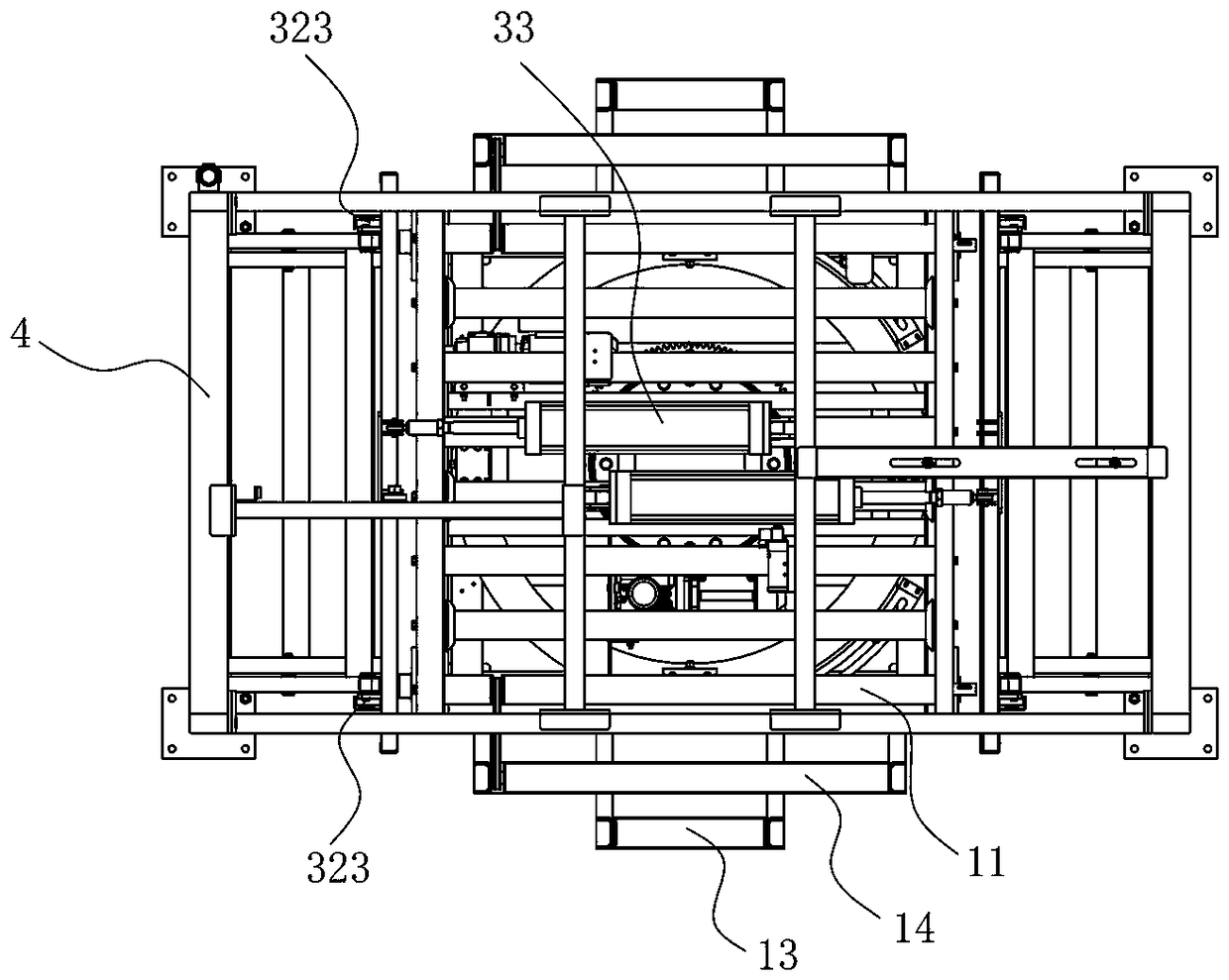

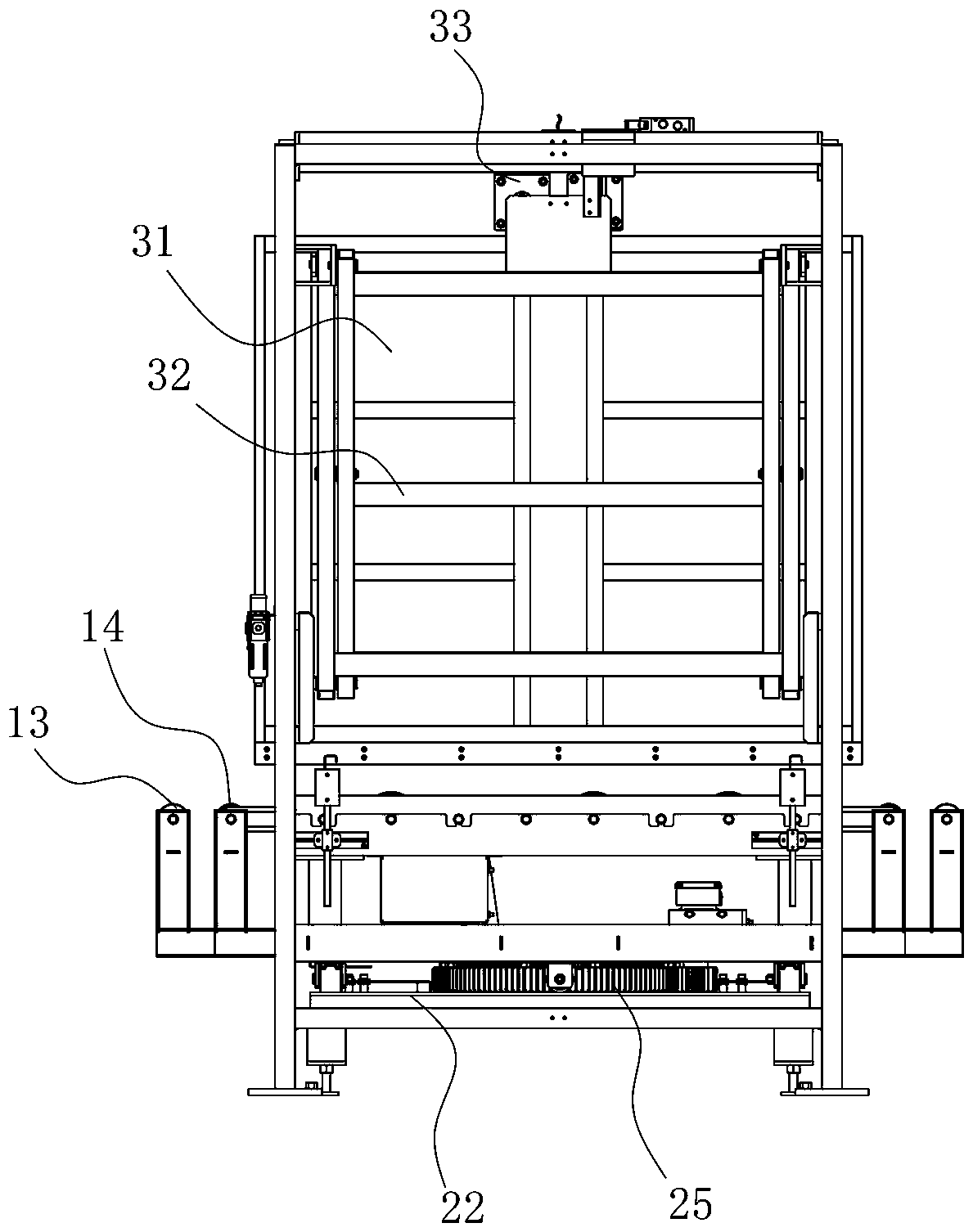

[0020] like Figure 1 to Figure 3 The shown automatic high-efficiency shaping machine includes a frame 4. A conveying mechanism 1 is arranged on the frame 4. The lower end of the conveying mechanism 1 is provided with a rotary mechanism 2 that drives the conveying mechanism 1 to rotate in a horizontal plane. The two sides of the conveying track are oppositely provided with Shaping mechanism for extruding and shaping goods 3. The conveying mechanism 1 transports the parcels to a suitable position, and the shaping mechanism 3 squeezes and shapes the parcels, which can efficiently adjust the loose parcels, unaligned side surfaces, and poor shapes, which is convenient for subsequent transportation and palletizing; the rotary mechanism 2 drives The wrapping rotation can realize the shaping of different angles of wrapping in different shapes, and has a wide range...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com