Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Convenience for subsequent transportation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

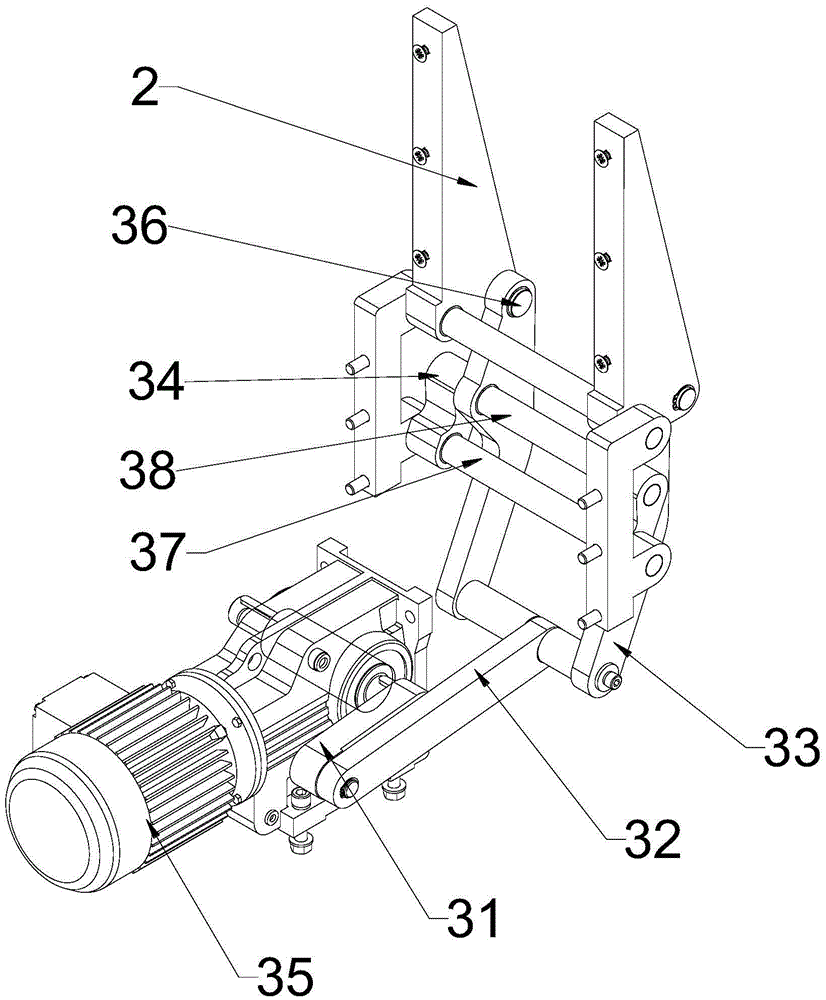

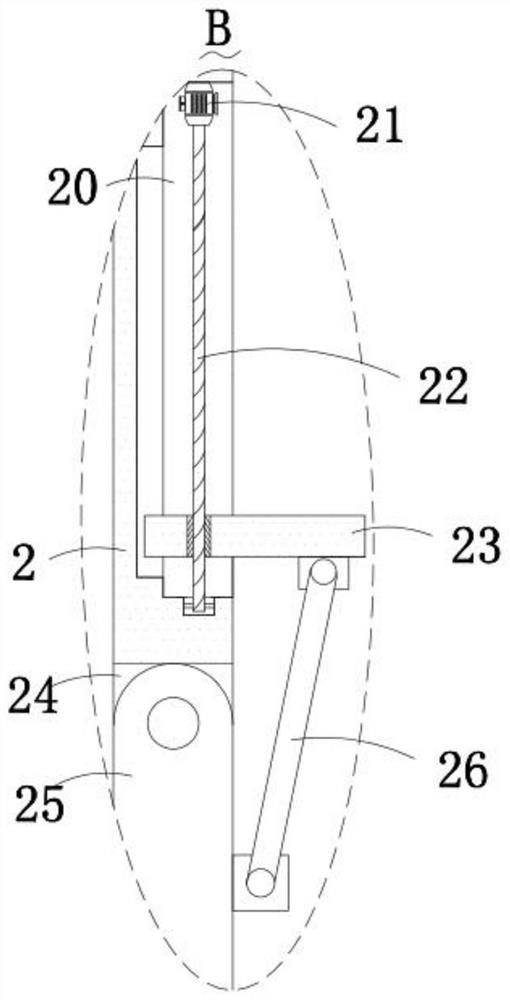

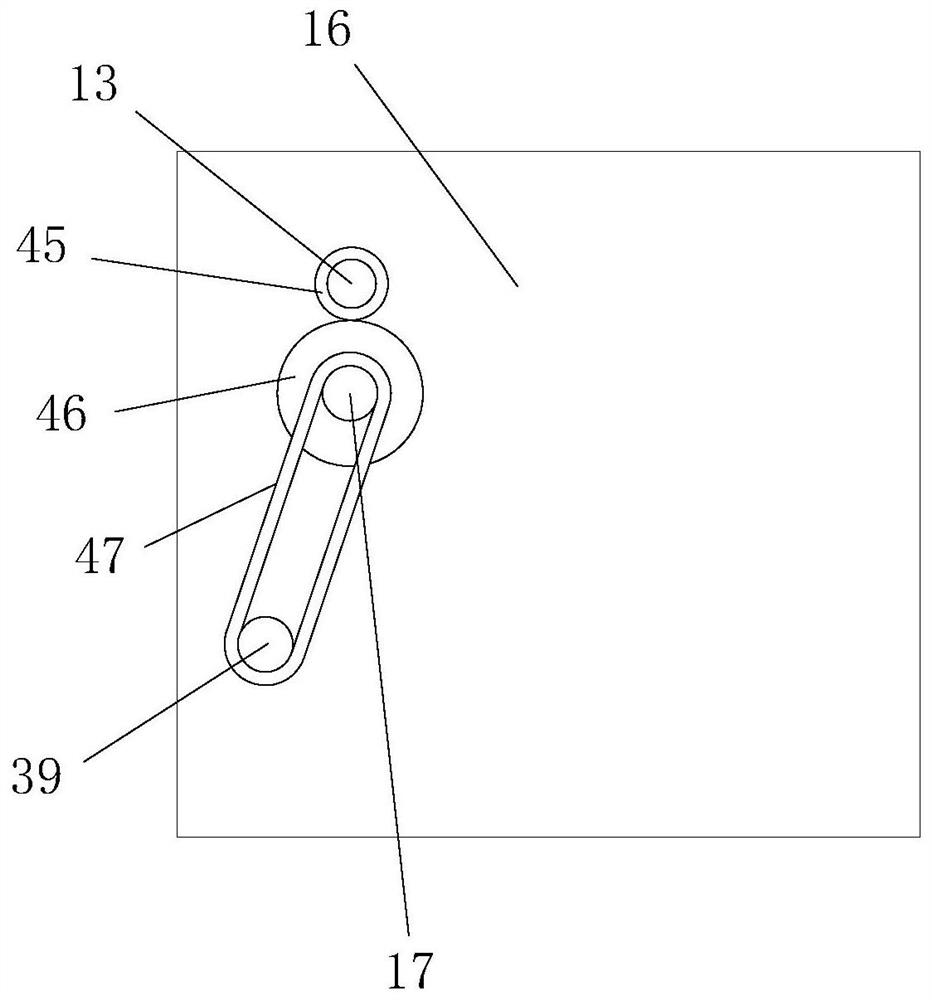

Baffle turnover mechanism

PendingCN105460593ANo tipping overPlay a blocking roleConveyor partsEngineeringElectrical and Electronics engineering

The invention discloses a baffle turnover mechanism. The baffle turnover mechanism comprises a machine frame, a stop part connected to the machine frame in a pivoted mode and a drive mechanism; the drive mechanism is used for driving the stop part to rotate between a first position and a second position, wherein the first position and the second position protrude out of a work-piece placement surface; when the stop part is located at the second position, the upper surface of the stop part is flush with the work-piece placement surface; the drive mechanism comprises a crank, a connection rod, a linkage part, a swing part and a power part; the linkage part comprises a first end, a second end and a connection part arranged between the first end and the second end; the other end of the connection rod is connected to the first end of the linkage part in a pivoted mode, and the second end of the linkage part is connected to the stop part in a pivoted mode through a first pivot; one end of the swing part is connected to the machine frame in a pivoted mode through a second pivot, and the other end of the swing part is connected to the connection part of the linkage part in a pivoted mode through a third pivot. According to the invention, participation by operation staff can be reduced, the work efficiency can be improved, and self-locking can be formed.

Owner:HGHY PULP MOLDING PACK

Environment-friendly dredging device

ActiveCN109853656AWork effectively for a long timeGuarantee dredging efficiencyMechanical machines/dredgersSludgeSpiral blade

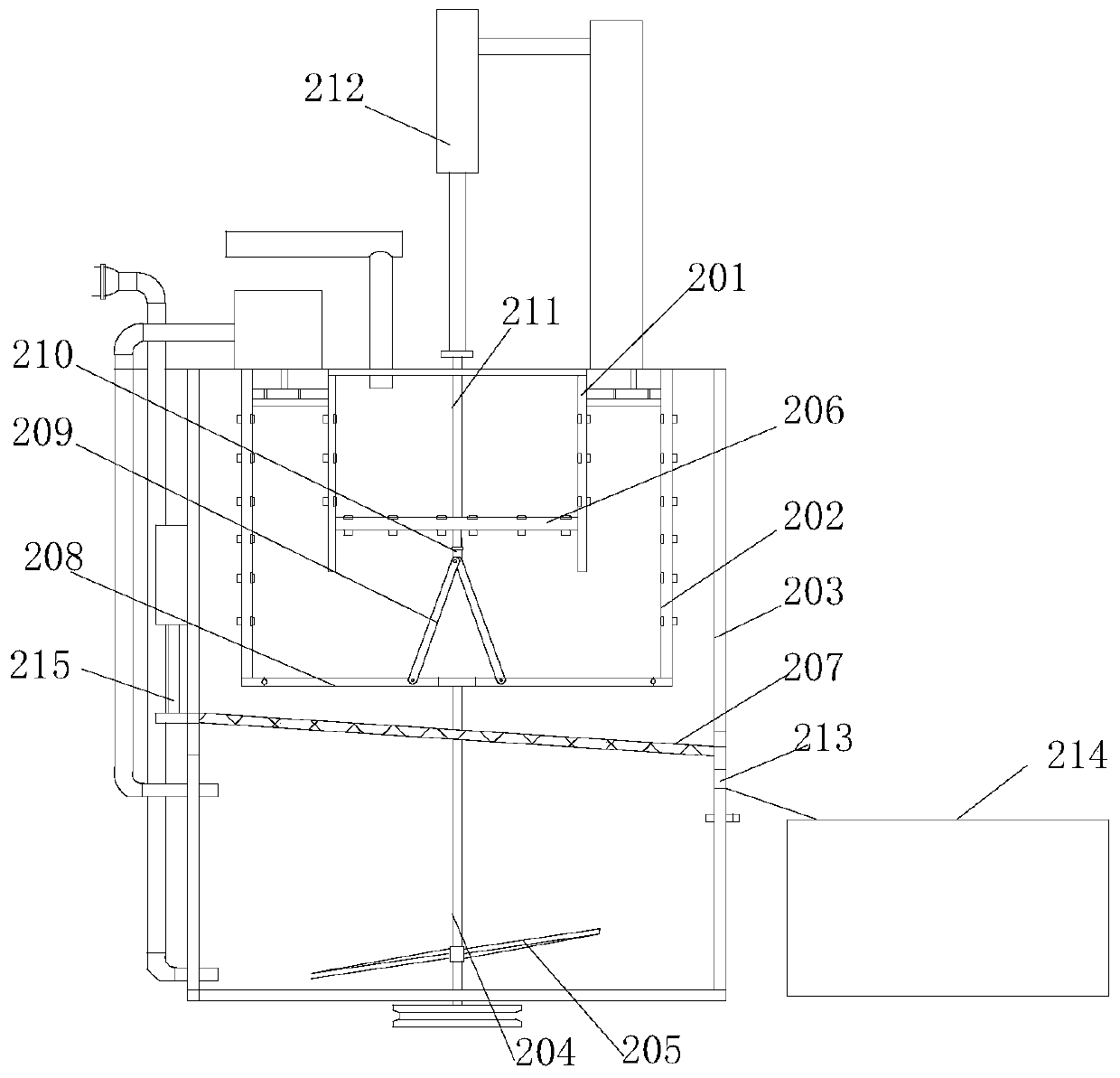

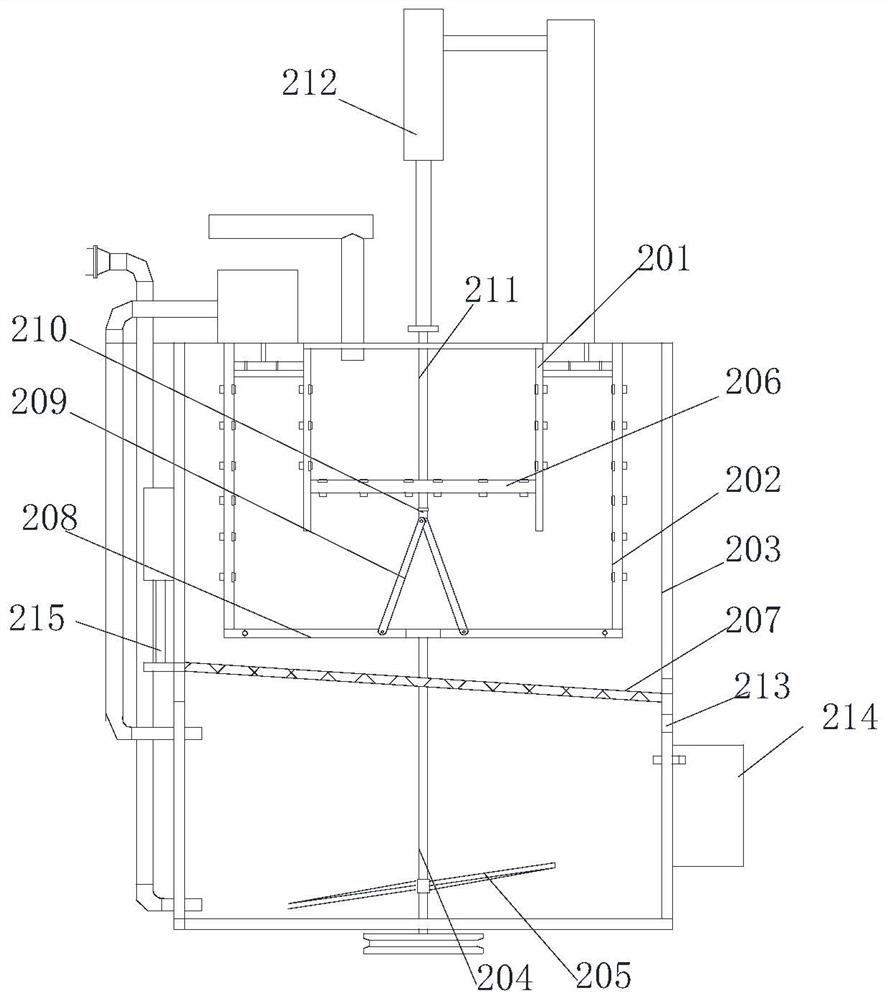

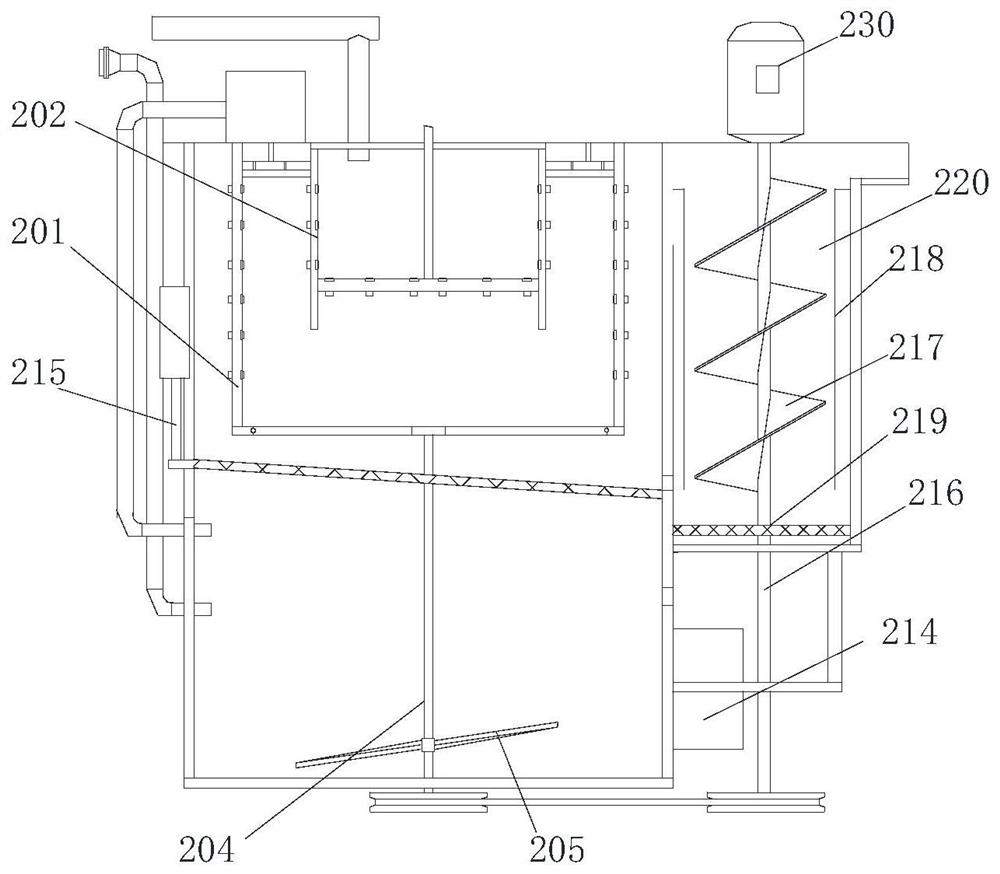

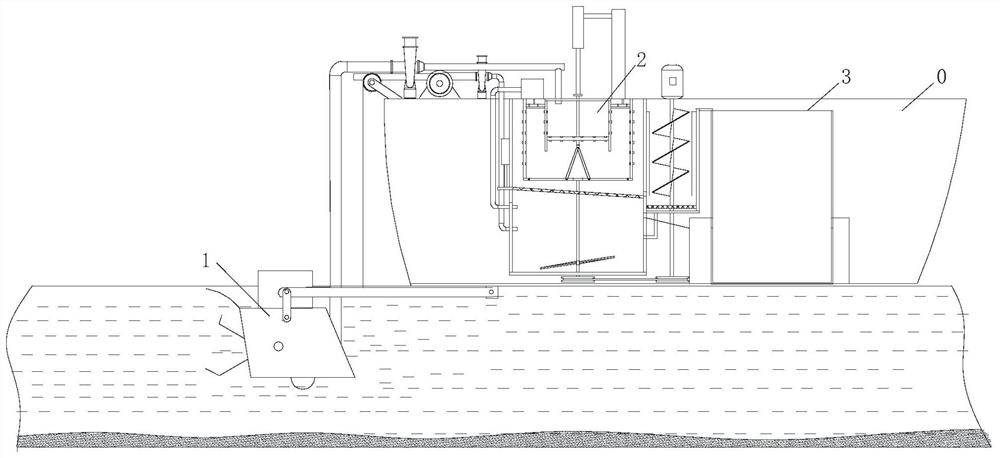

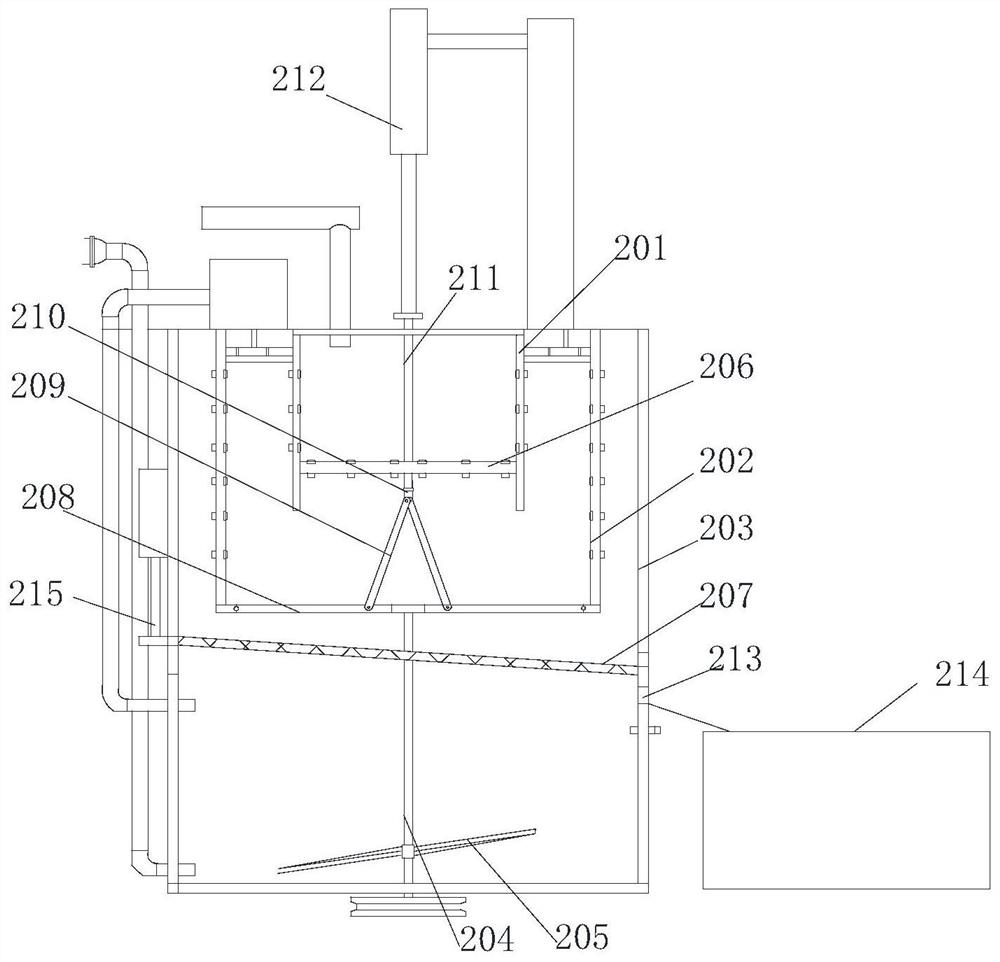

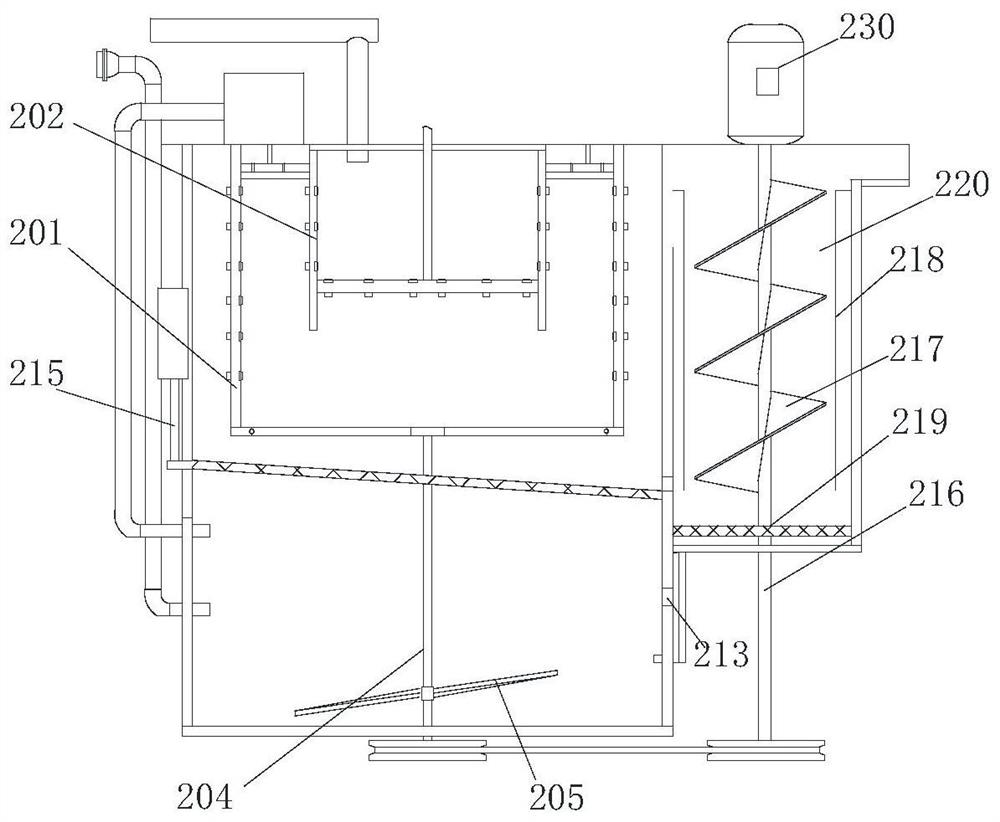

The invention relates to an environment-friendly dredging device. A dredging unit comprises a silt loosening mechanism and a silt pump; a sludge separation unit comprises an outer box body, a first inner box body and a second inner box body which are arranged on a ship body; the sludge separation unit further comprises a dewatering box, and spiral blades are arranged in the dewatering box; the ship body is also provided with a water pump and a chemical tank, and a water inlet of the water pump extends into the bottom of the outer box body through a water pipe; deodorizing liquid is contained in the chemical tank, and a liquid outlet of the chemical tank extends into the bottom of the outer box body through a liquid outlet pipe; and the first inner box body, the second inner box body, a stirring paddle and the spiral blades are all driven to rotate through a transmission mechanism. The environment-friendly dredging device is capable of automatically removing silt at the river bottom orthe lake bottom, is also capable of filtering and dewatering the silt, and has the technical effects of simple operation, high working efficiency, energy conservation and environmental friendliness.

Owner:天津市雷升科技有限公司

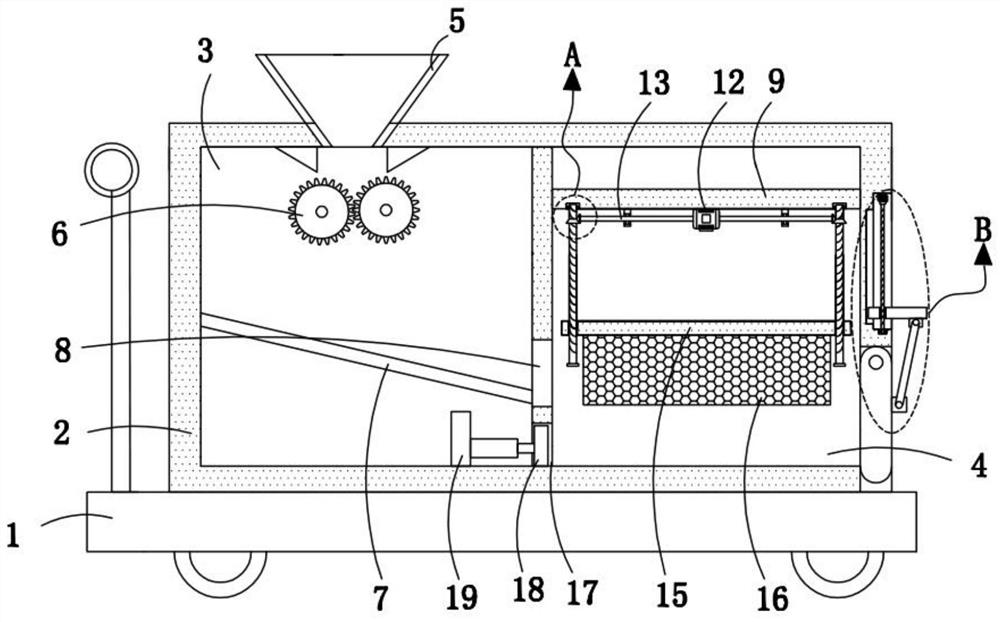

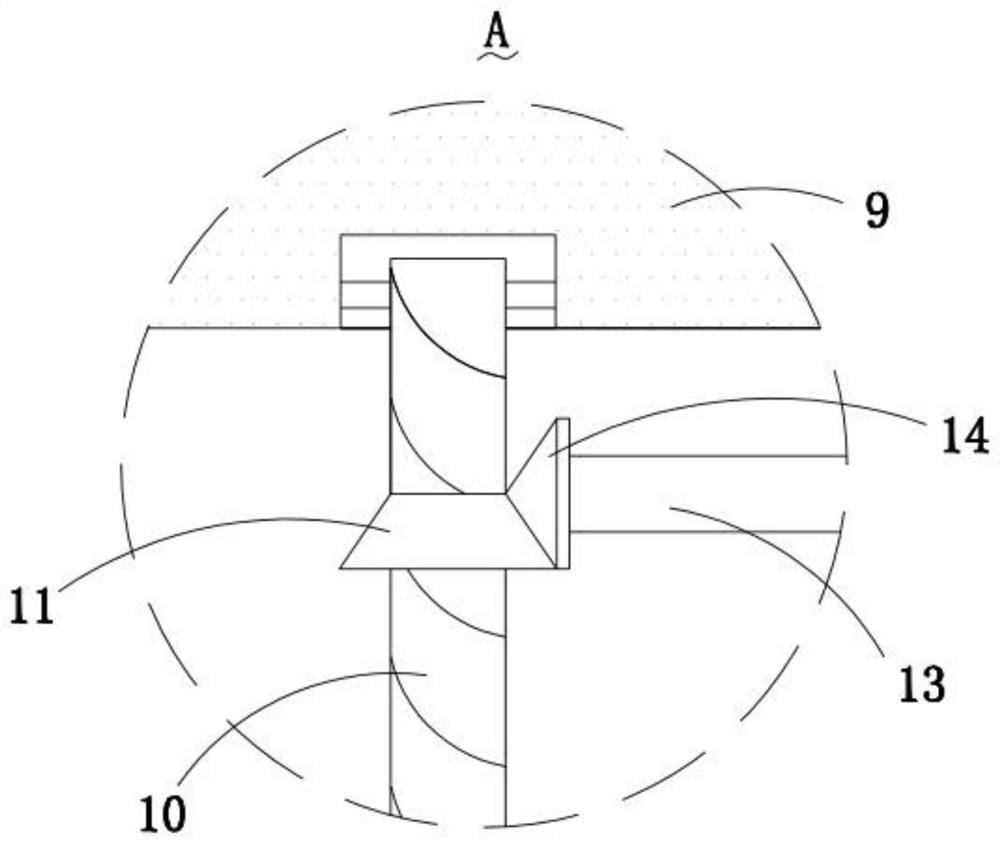

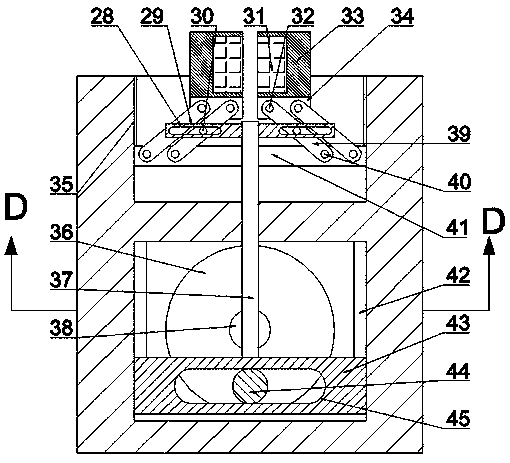

Pretreatment device used before solid garbage transportation

ActiveCN108855340AImprove the extrusion effectImprove crushing effectSievingScreeningSpiral bladeEngineering

The invention discloses a pretreatment device used before solid garbage transportation. The pretreatment device comprises a pulverizing barrel, a crushing hopper and a water removal barrel. The upperend of the right side of the pulverizing barrel communicates with the crushing hopper, and the upper portion of the crushing hopper communicates with a charging hopper. Front-back-symmetry extrusion rollers are arranged in the crushing hopper. The lower end of the pulverizing barrel communicates with the water removal barrel through a discharging roller. A horizontal shaft is arranged in the waterremoval barrel and fixedly connected with an extrusion spiral blade. The left end of the water removal barrel communicates with a liquid discharging pipe. The right side of the water removal barrel communicates with a horizontal pipe. The horizontal pipe communicates with a discharging pipe. Through the extrusion rollers and a pulverizing cutter, the solid garbage is subjected to extrusion crushing and then is pulverized, and the pulverizing effect and efficiency are improved. Through the arrangement of the pulverizing cutter with the blade distance gradually reduced from top to bottom, the garbage is subjected to step-by-step pulverizing, and the pulverizing effect is improved. Through the arrangement of the extrusion spiral blade and a movable block connected with spring telescopic rods, the garbage particle extrusion effect is improved, the water removal effect is improved, and later transportation is convenient.

Owner:山东国晟环境科技有限公司

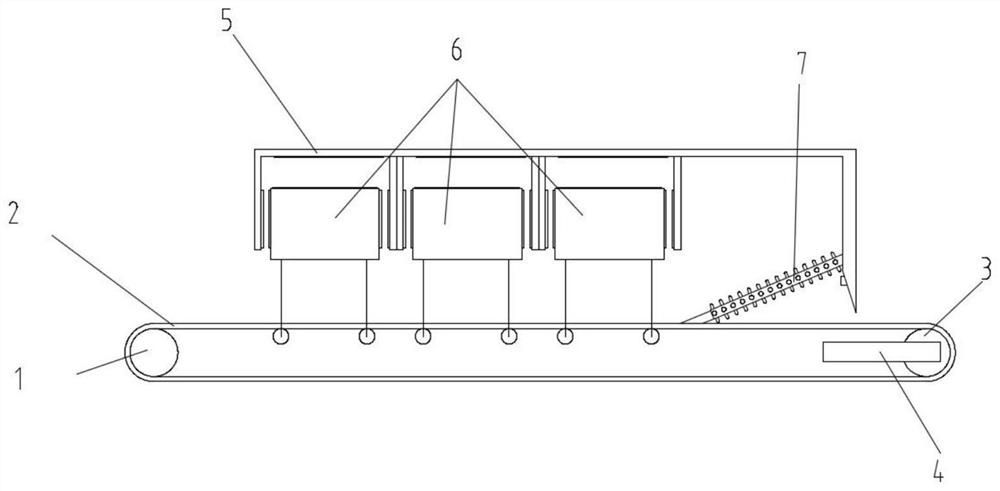

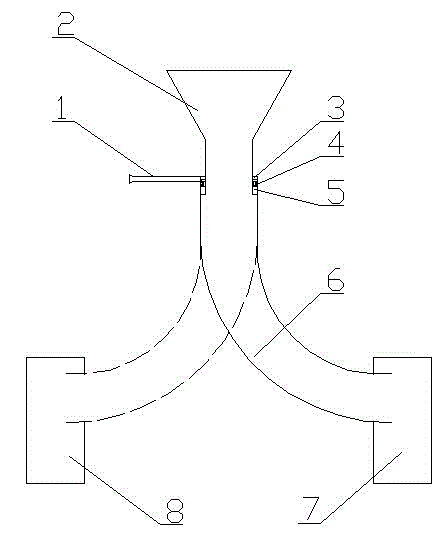

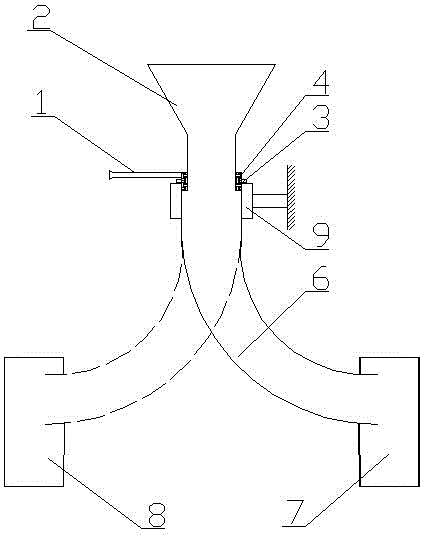

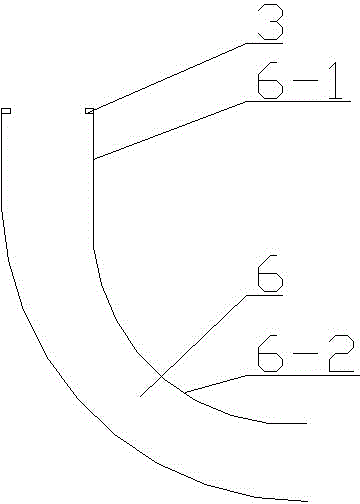

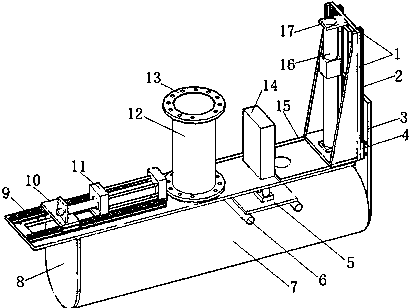

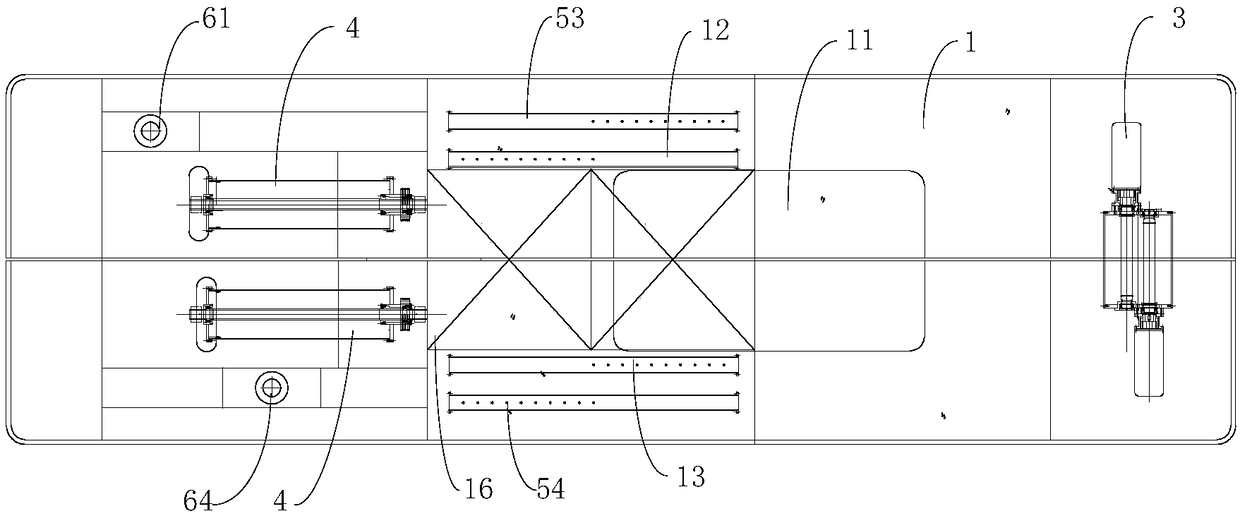

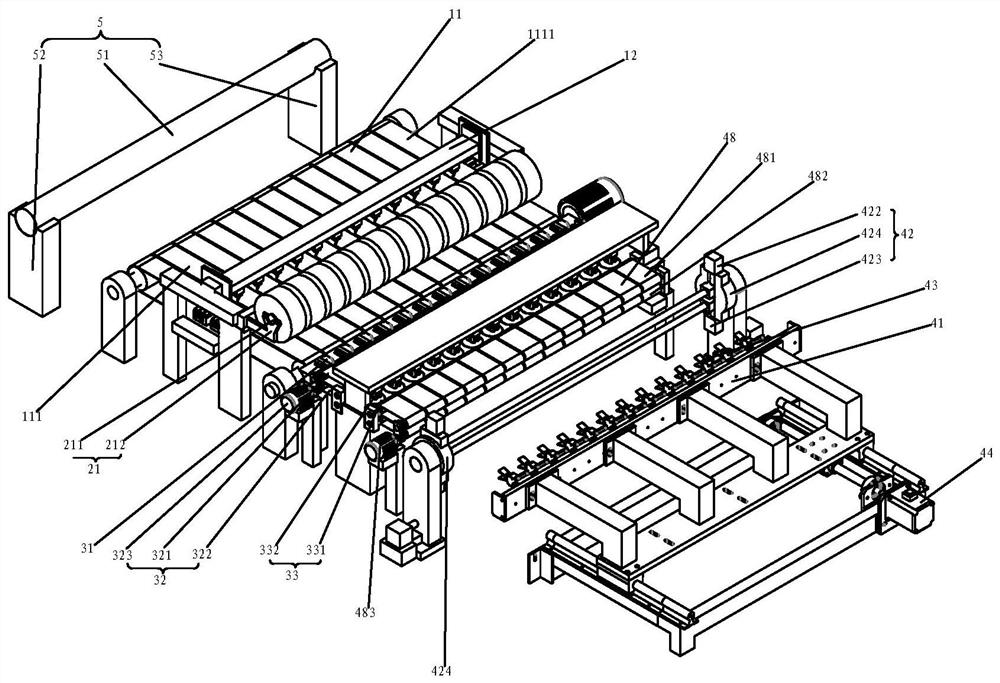

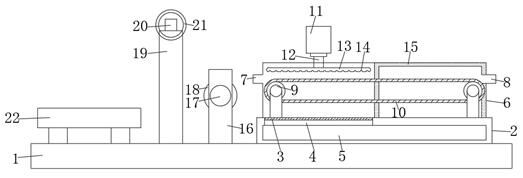

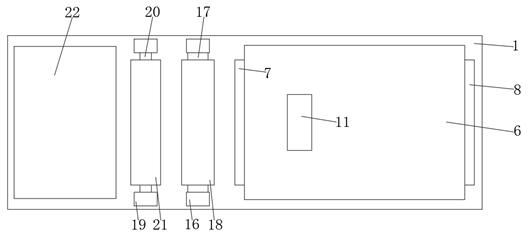

Automatic efficient shape correcting machine

PendingCN108545429AEffective regulationConvenience for subsequent transportationConveyor partsRoller-waysMechanical engineeringEngineering

The invention provides an automatic efficient shape correcting machine. The automatic efficient shape correcting machine comprises a rack. The rack is provided with a conveying mechanism. A rotation mechanism driving the conveying mechanism to rotate on the horizontal plane is arranged at the lower end of the conveying mechanism, and shape correcting mechanisms for conducting extruding and shape correcting on cargo are oppositely arranged on the two sides of a conveying track. The device can efficiently avoid the situations that parcels are loosened, the side surfaces are inclined and are notaligned, and the appearance is poor, and subsequent transporting and stacking are convenient.

Owner:HUZHOU RIGOR TECH

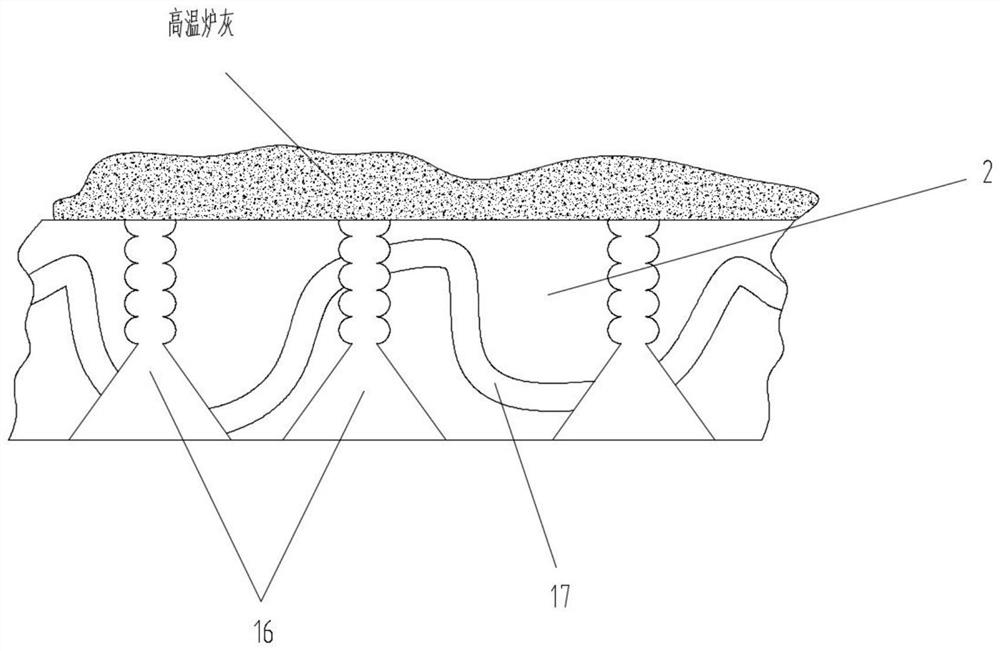

Conveying treatment device for air-cooled high-temperature furnace ash

ActiveCN112460614ACool down completelyImprove cooling efficiencyContainers for heating foodPackaging foodstuffsStructural engineeringConveyor belt

The invention discloses a conveying treatment device for air-cooled high-temperature furnace ash. The device comprises a fixed conveying shaft and a movable conveying shaft, wherein a conveyor belt ismounted on the surfaces of the fixed conveying shaft and the movable conveying shaft, the conveyor belt is made of a high-temperature-resistant material, a ventilation flow channel is formed in the middle of the conveyor belt, the bottom of the ventilation flow channel is conical, the top of the ventilation flow channel is spiral, fans are mounted on two sides of the conveyor belt, fans are alsomounted at the bottom of the conveyor belt, a support is mounted above the conveyor belt, heated lifting devices are evenly mounted below the support, and each heated lifting device comprises a lifting support. A first positive magnet is fixedly mounted on the inner wall of the lifting support, an internal liquid nitrogen flow channel is formed in the conveyor belt, and the internal liquid nitrogen flow channel communicates with all the ventilation flow channels, and the device has the beneficial effects that the practicability is high, and furnace ash can be packaged in a blocked mode.

Owner:应县方圆炉业制造有限责任公司

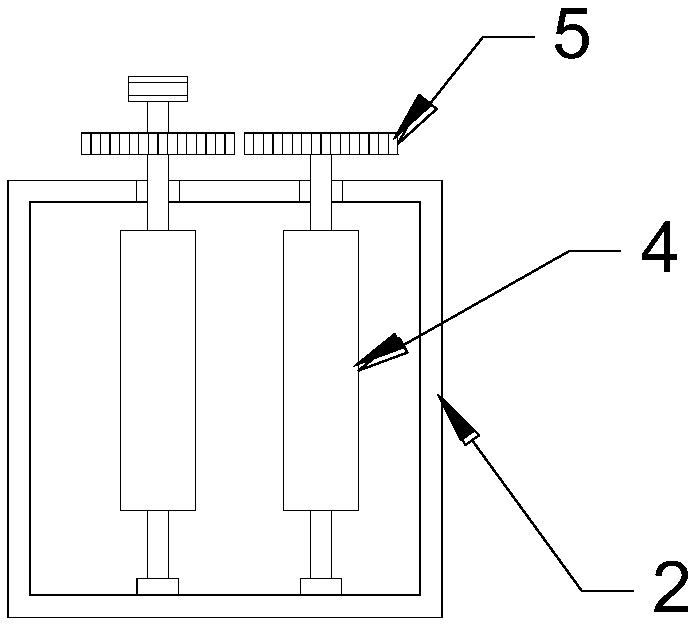

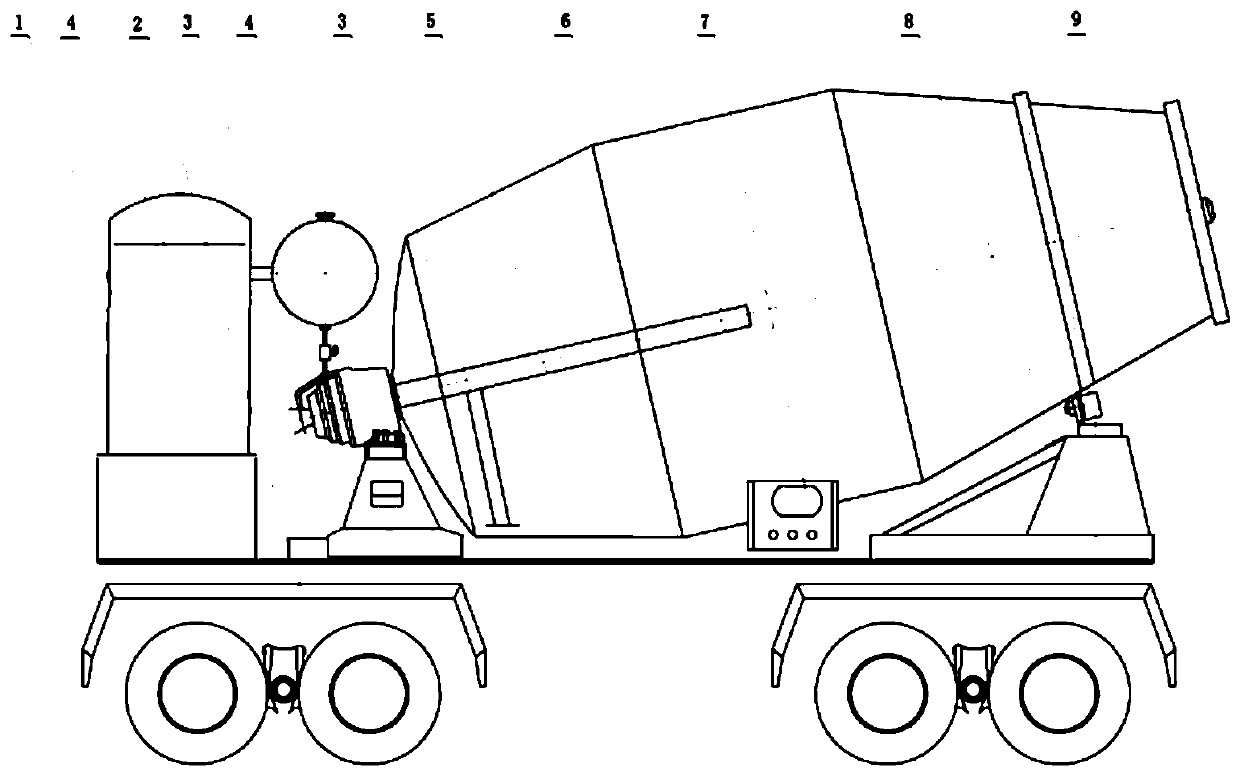

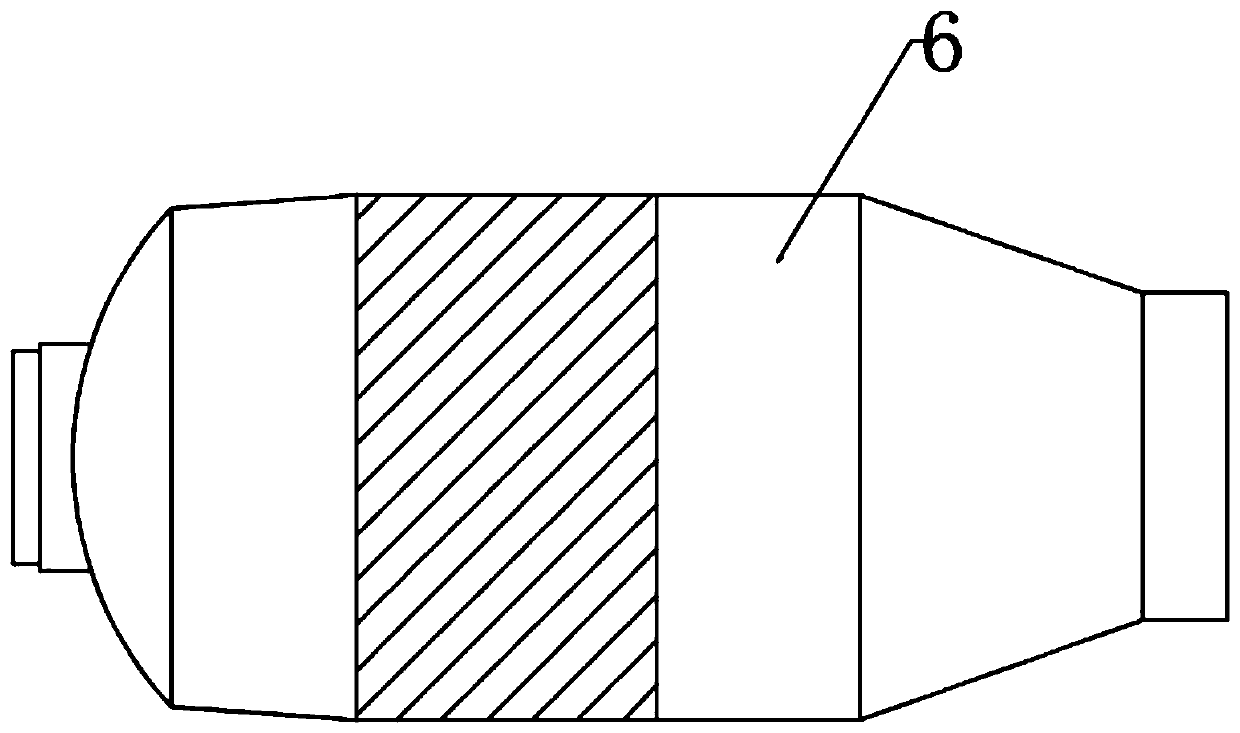

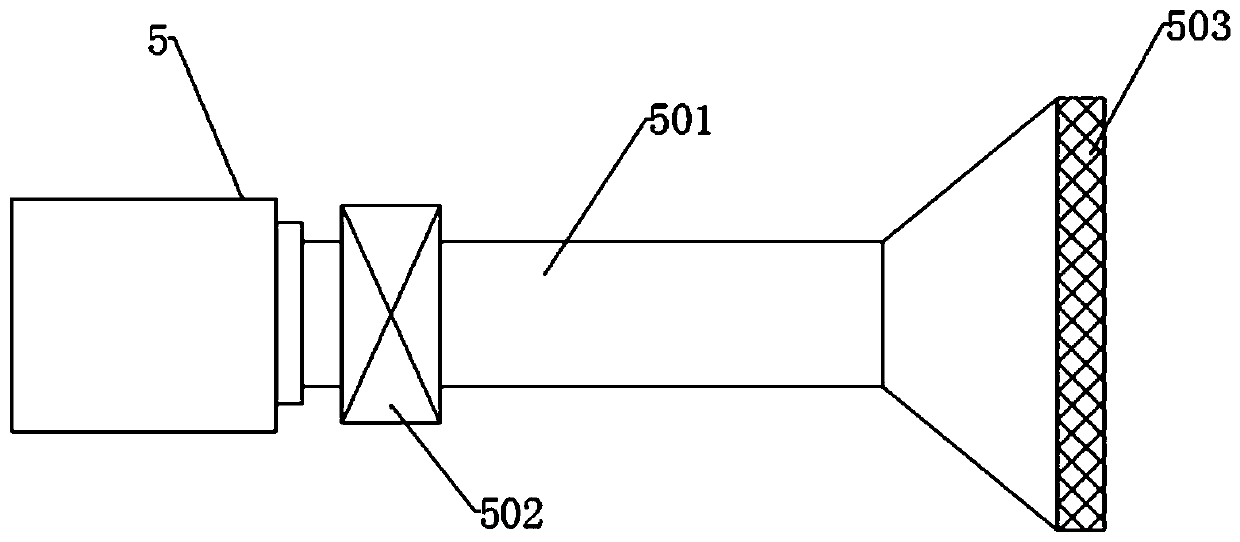

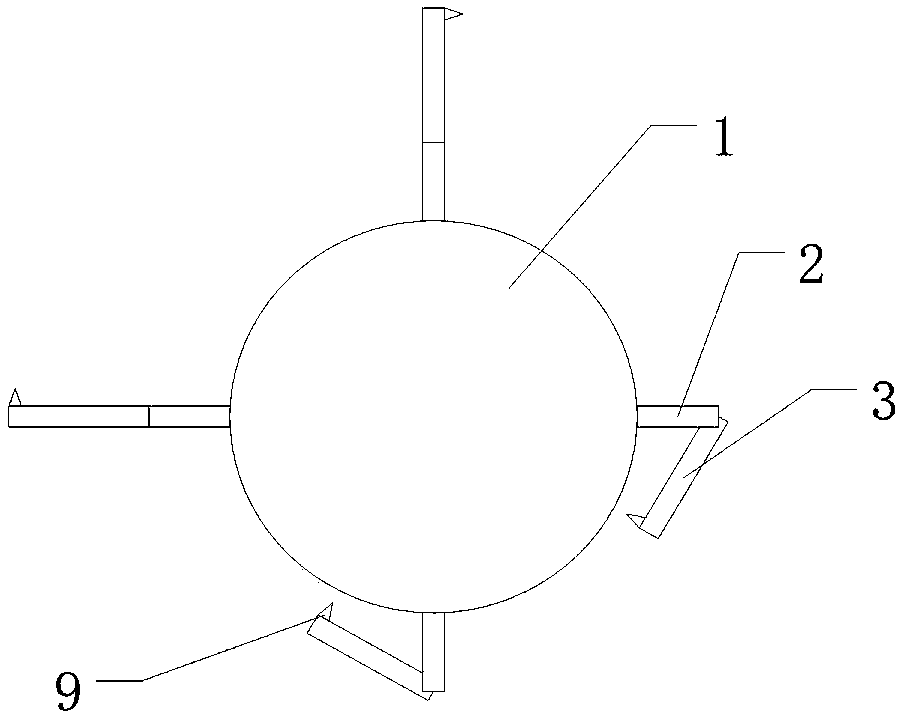

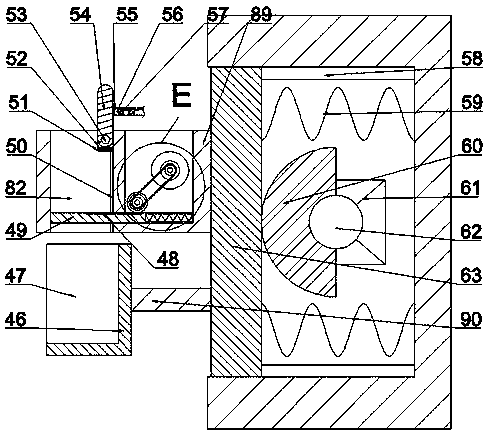

Movable device for quickly preparing modified material supported with micro-nano oxygen bubbles

ActiveCN110270274AEfficient preparationEasy to sprinkle on the spotWater/sewage treatment with mechanical oscillationsChemical/physical/physico-chemical moving reactorsMicro nanoEngineering

The invention discloses a movable device for quickly preparing a modified material supported with micro-nano oxygen bubbles. The movable device comprises a movable platform, a power system, a tank body, a vacuum system, a feeding and discharging system, an oxygen preparation system, a gear rotation system, a control system and the like. According to the device, the movable platform is used as a movement supporting platform, under the condition of negative pressure, by using a method for modifying a porous substrate material with a pure oxygen source, and controlling exhausting, feeding, oxygen addition, stirring and discharging, the modified material supported with the micro-nano oxygen bubbles can be quickly prepared. The device can significantly increase the micro-nano oxygen bubble supporting rate of the substrate material, the operation is convenient, the modified material supported with the micro-nano oxygen bubbles can be massively prepared on site, the transportation link is shortened, and the movable device is conveniently used in water ecological restoration engineering.

Owner:中国科学院北京综合研究中心

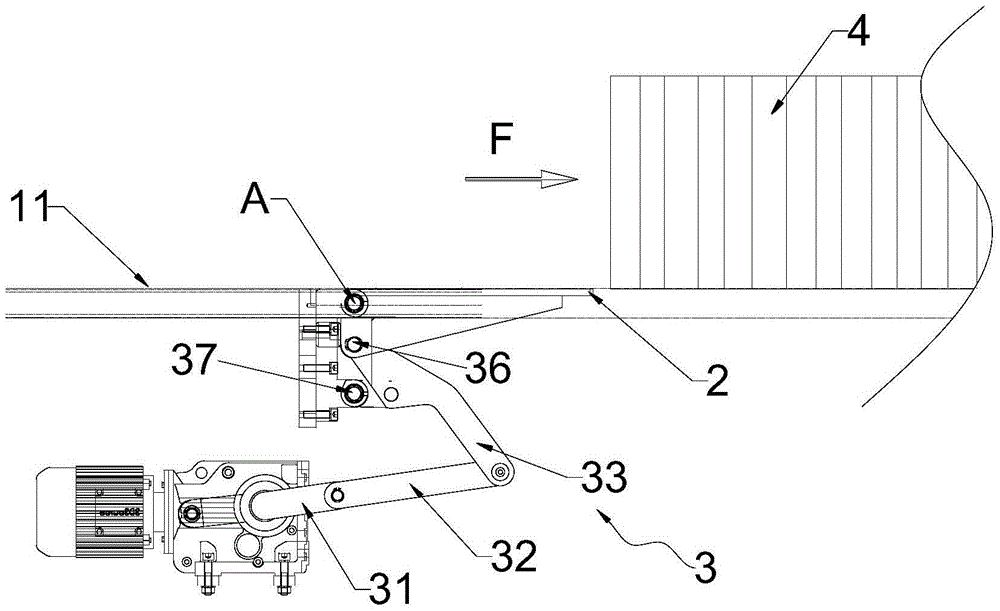

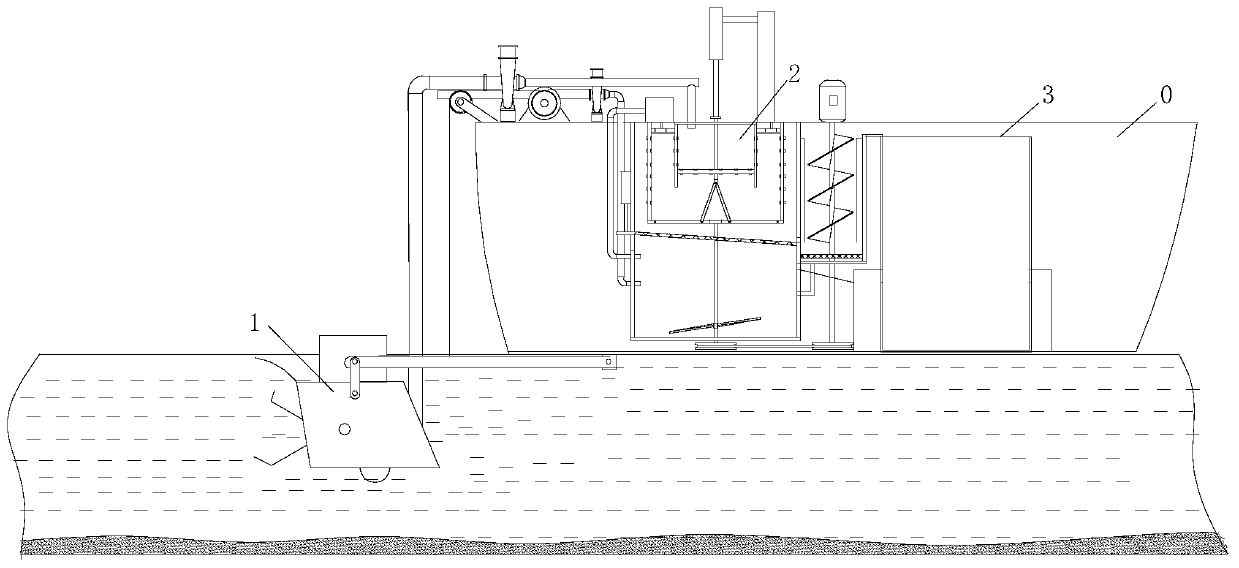

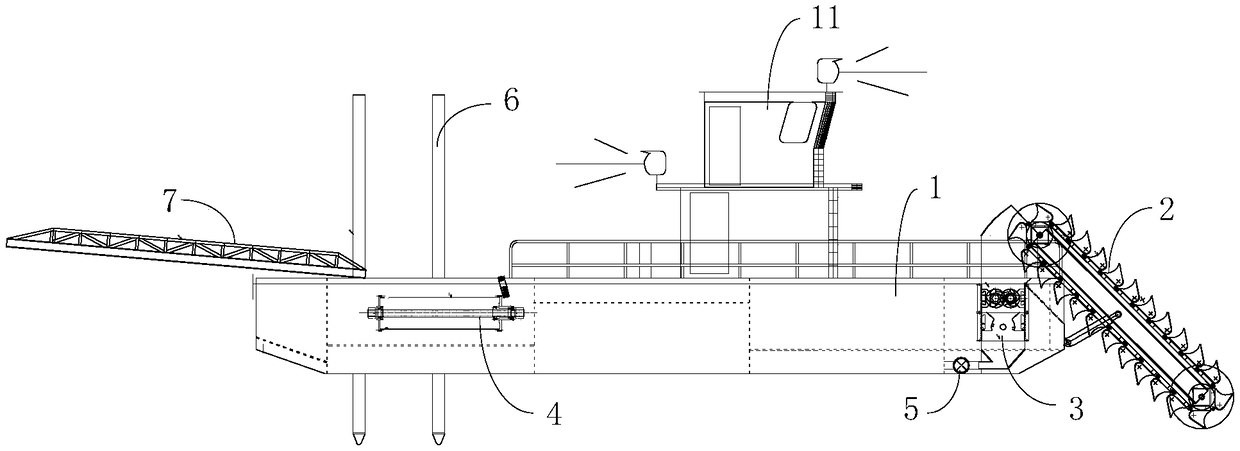

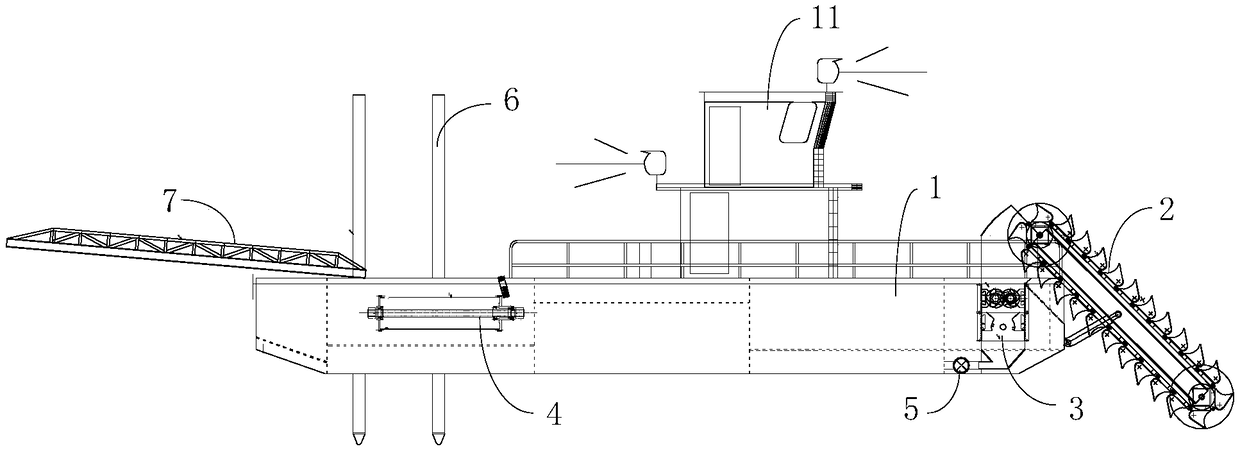

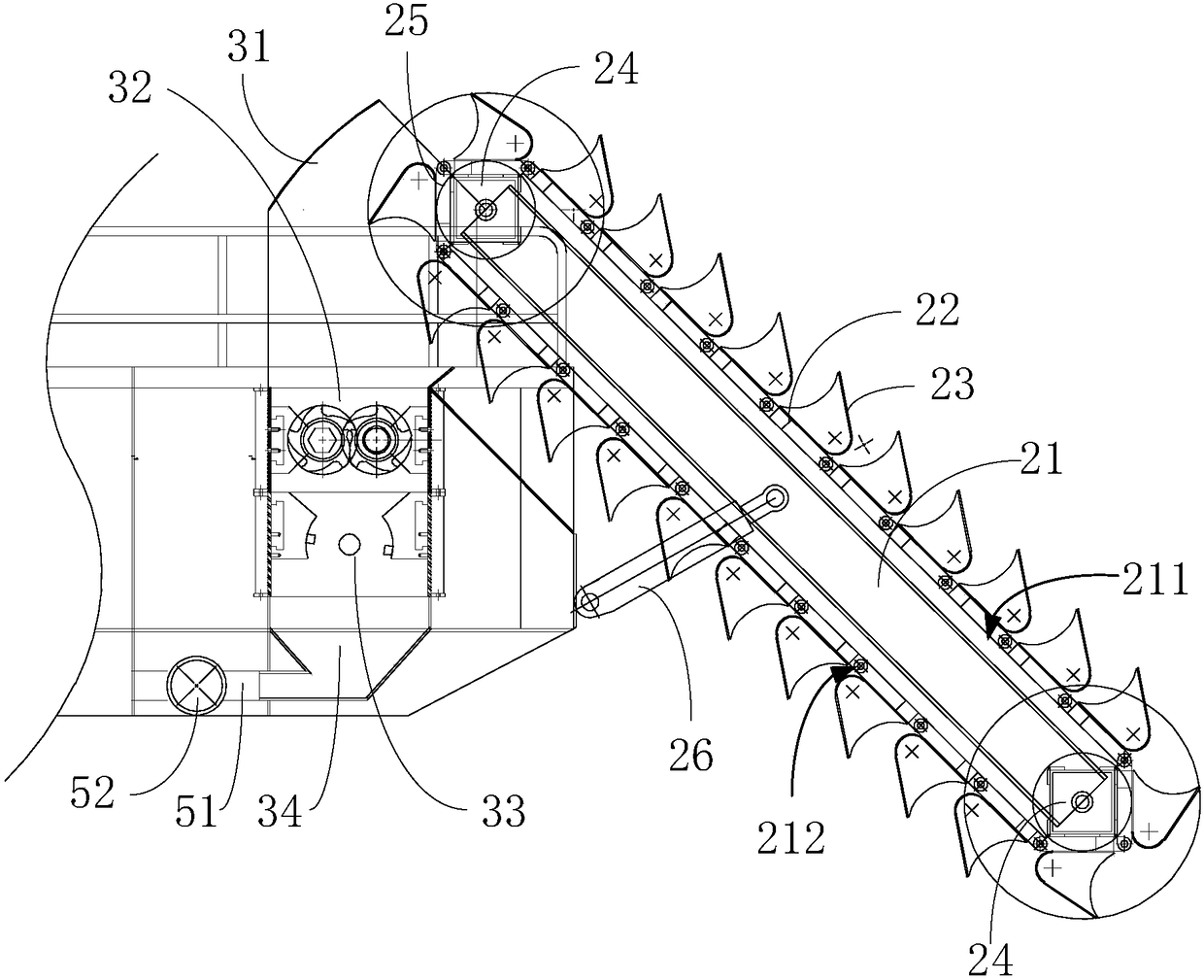

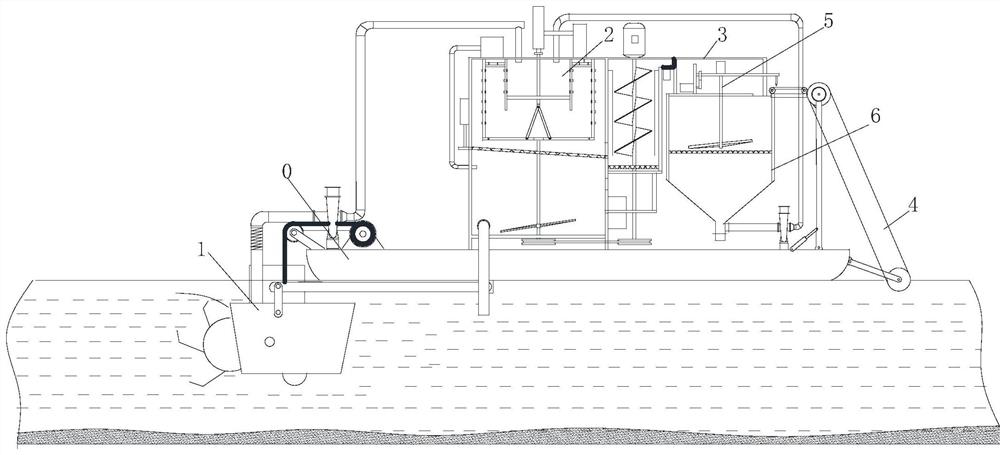

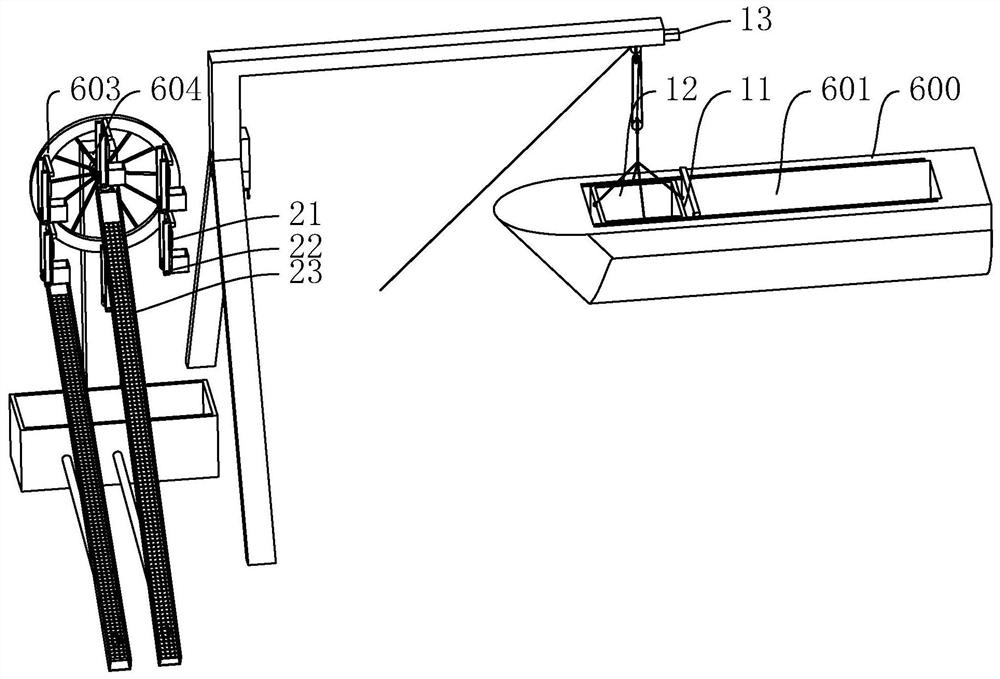

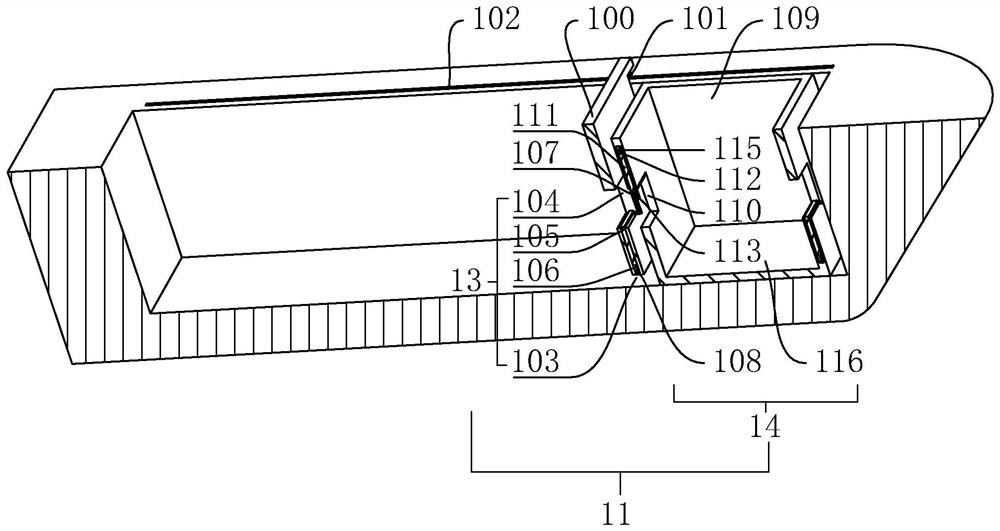

Dredging and sludge drying ship

The invention relates to a dredging and sludge drying ship. The dredging and mud drying ship comprises a ship body, a sludge collecting device, a smashing device, a dewatering device and a sludge conveying channel. The smashing device, the dewatering device and the sludge conveying channel are all arranged on the ship body, and the sludge collecting device is connected with the ship body. The sludge collecting device, the smashing device and the dewatering device are sequentially connected through the sludge conveying channel. The sludge collecting device is used for collecting sludge on the ship body, and the smashing device is used for smashing the sludge. The dewatering device is used for dewatering the sludge. The dredging and sludge drying ship is provided with the dewatering device,the sludge can be dewatered, the weight and size of the sludge are greatly reduced, subsequent transportation of the sludge is convenient, and the dredging efficiency is improved.

Owner:GUANGZHOU HAOLI TOOLS CO LTD

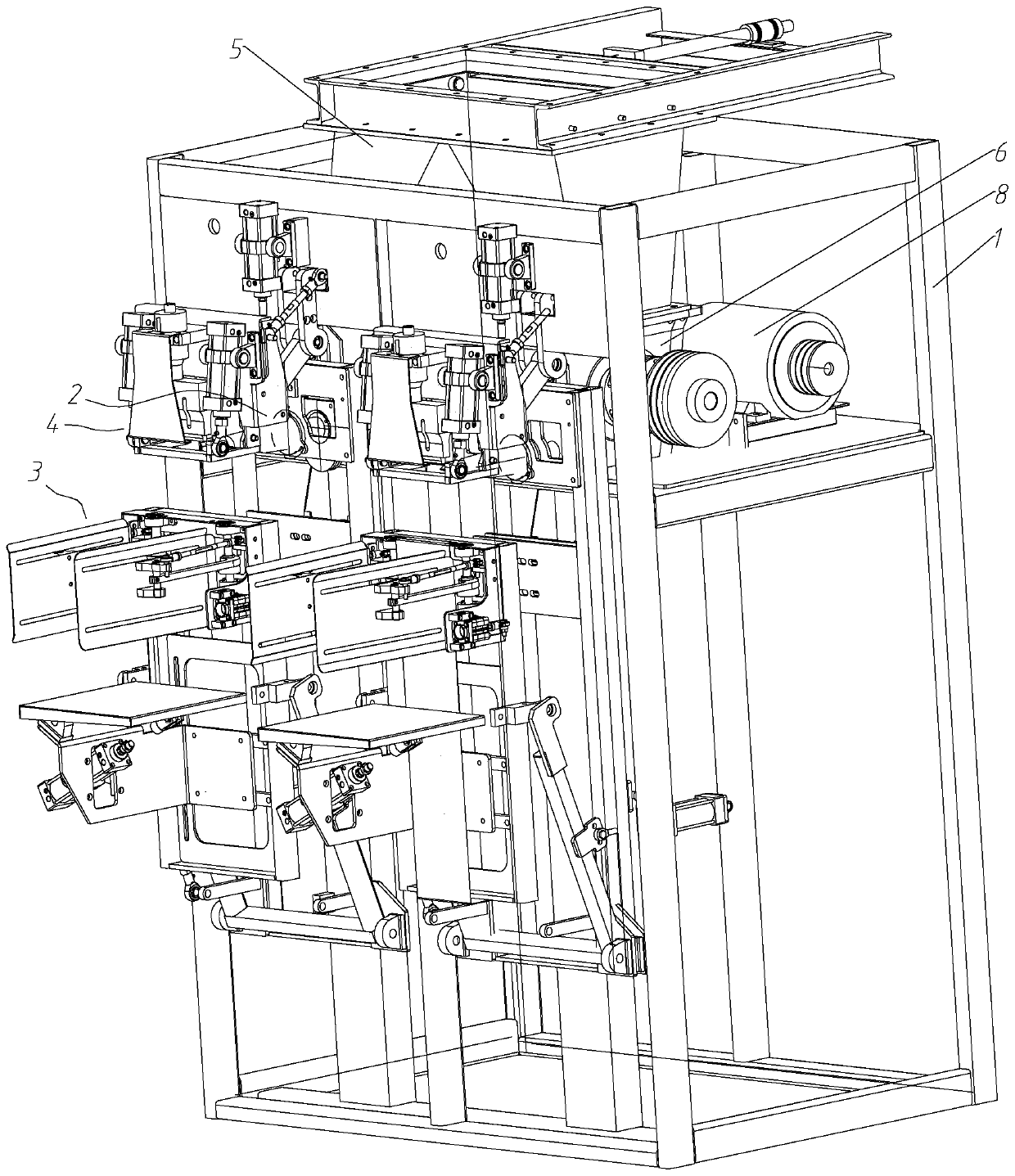

Heat seal packaging machine

InactiveCN110901969AUniform shapeMake sure the connection is firmWrapper twisting/gatheringSolid materialEngineeringPhysics

The invention belongs to the technical field of powder packaging equipment and provides a heat seal packaging machine. The heat seal packaging machine comprises a main rack, a filling nozzle and a bagsupporting mechanism; the filling nozzle is arranged on the main rack; the bag supporting mechanism is arranged on the main rack and located below the filling nozzle; the bag supporting mechanism comprises a bag pushing rack, a bag supporting bottom plate and bag blocking side plates; the bag pushing rack is arranged on the main rack; the bag supporting bottom plate is arranged on the bag pushingrack; and the two bag blocking side plates are arranged on the bag pushing rack; and the bag supporting bottom plate and the two bag blocking side plates form a material supporting space. By means ofthe above technical schemes, the problem that a material bag deforms and leaks materials in a powder packaging process in the prior art is solved.

Owner:唐山鑫宏达机械设备有限公司

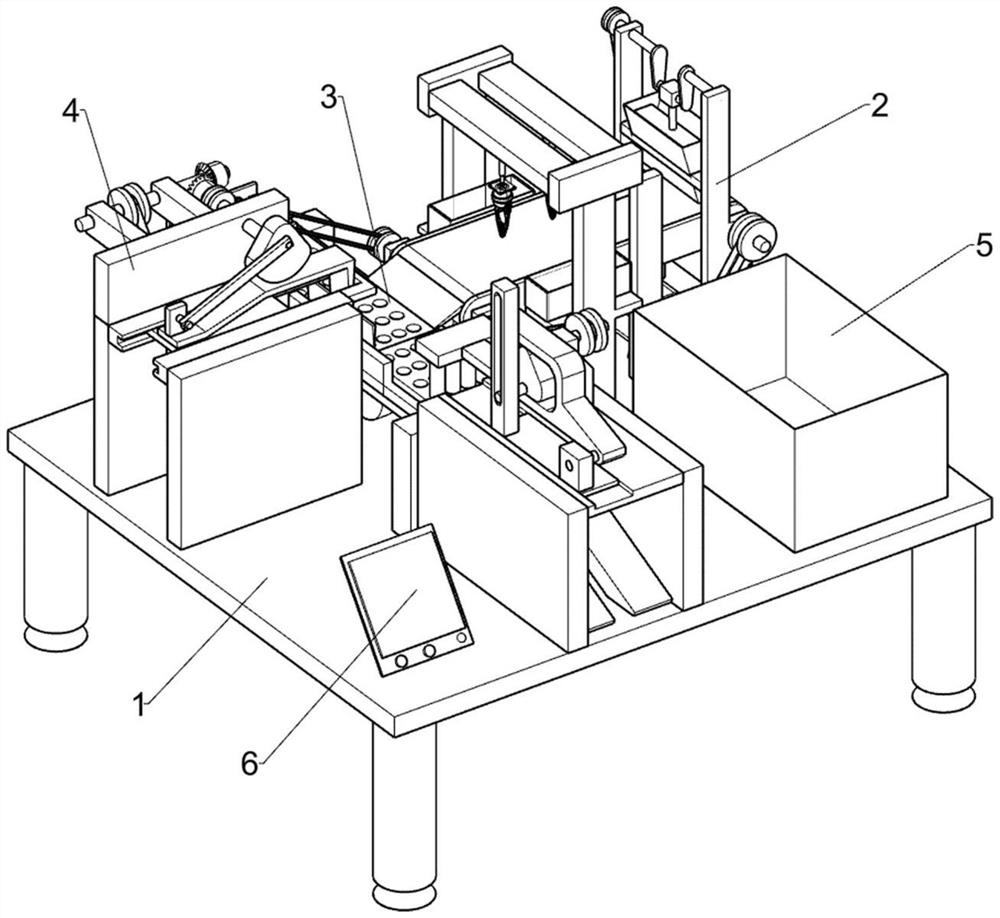

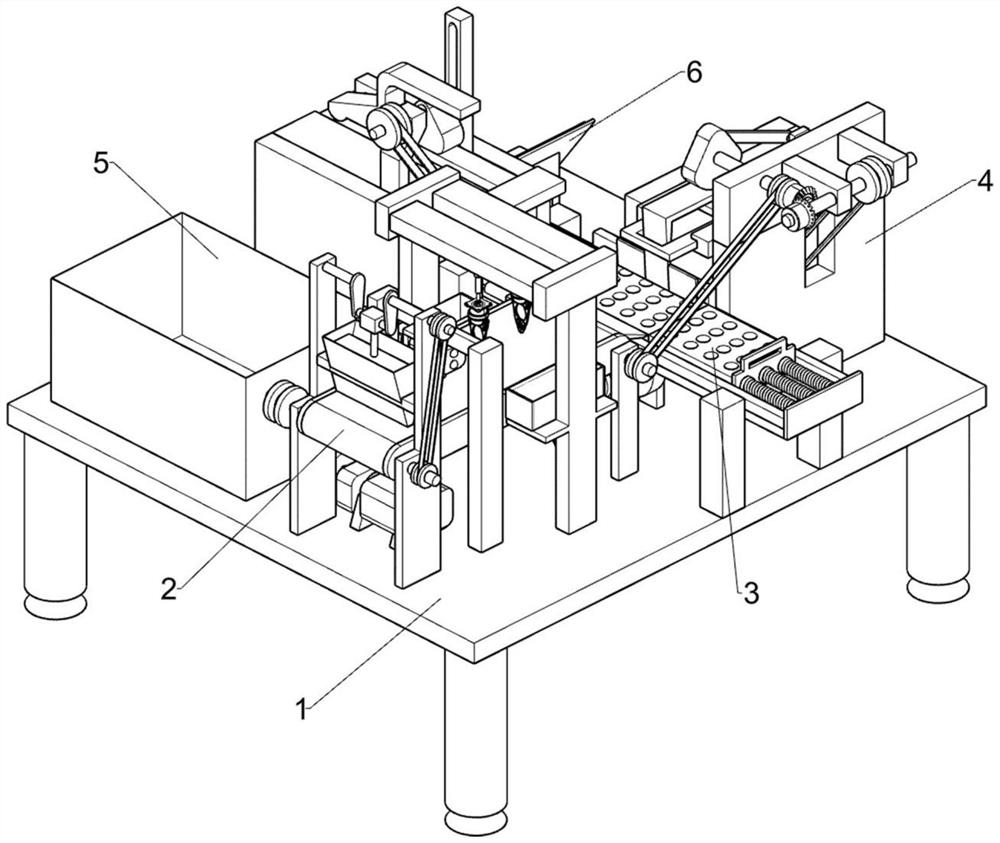

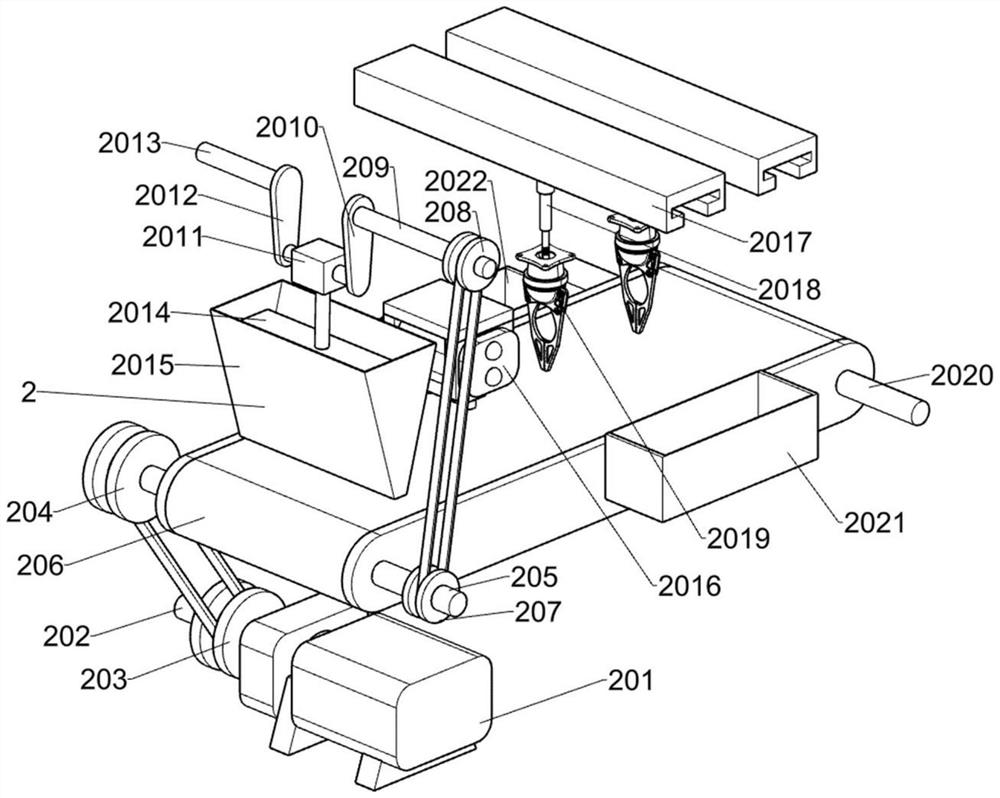

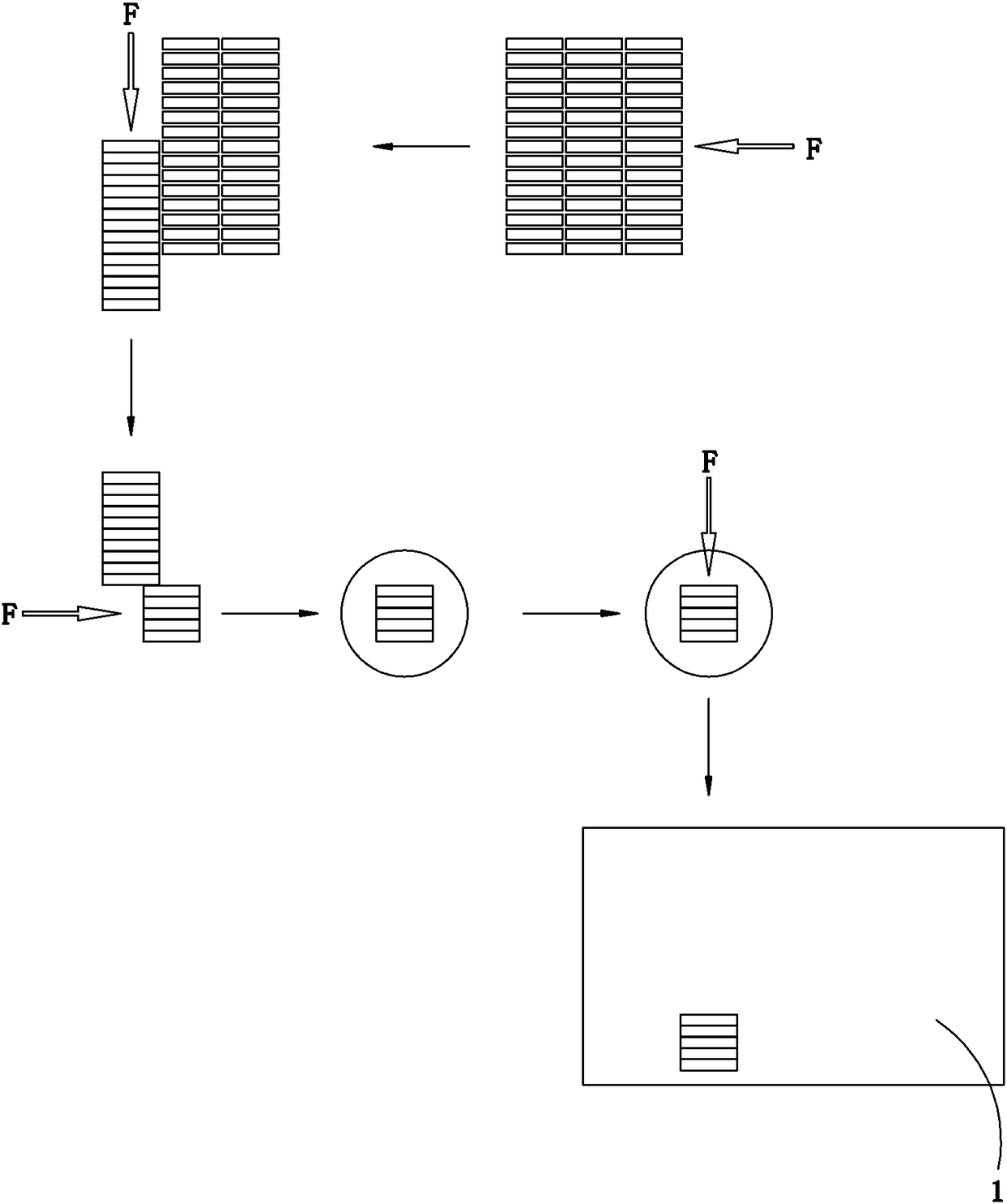

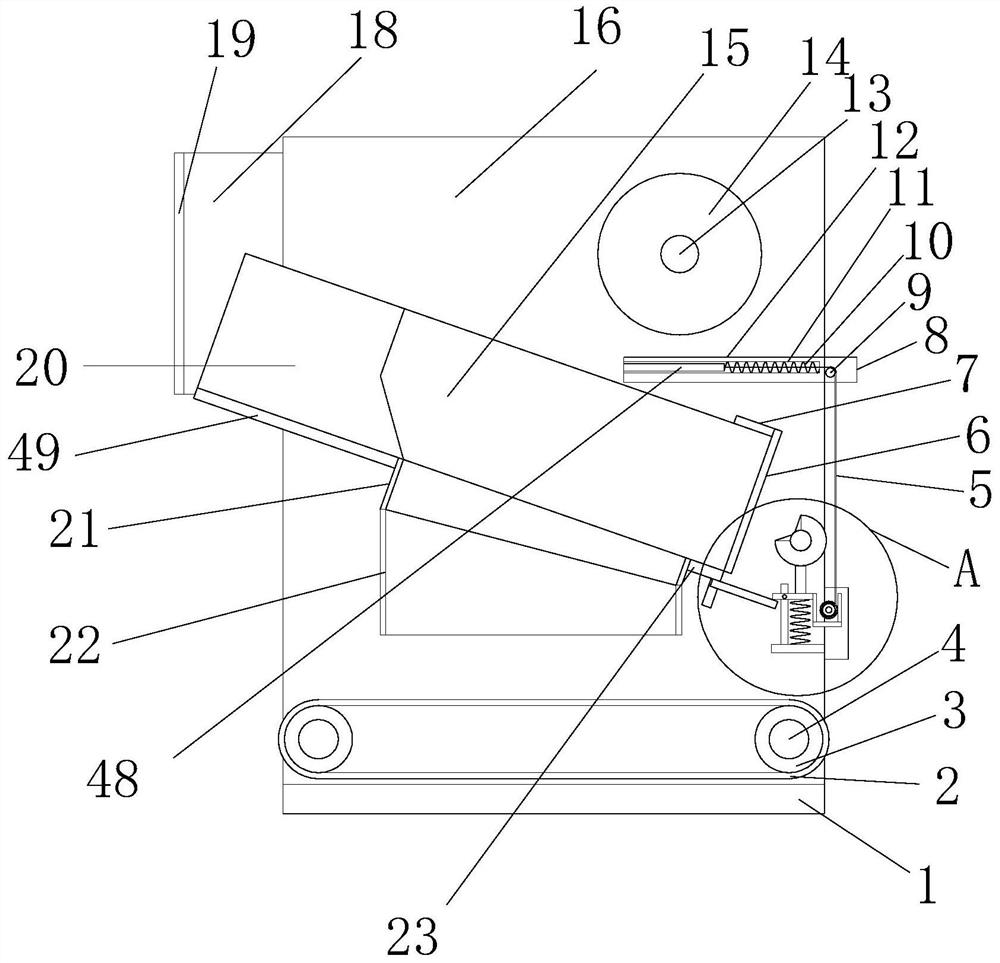

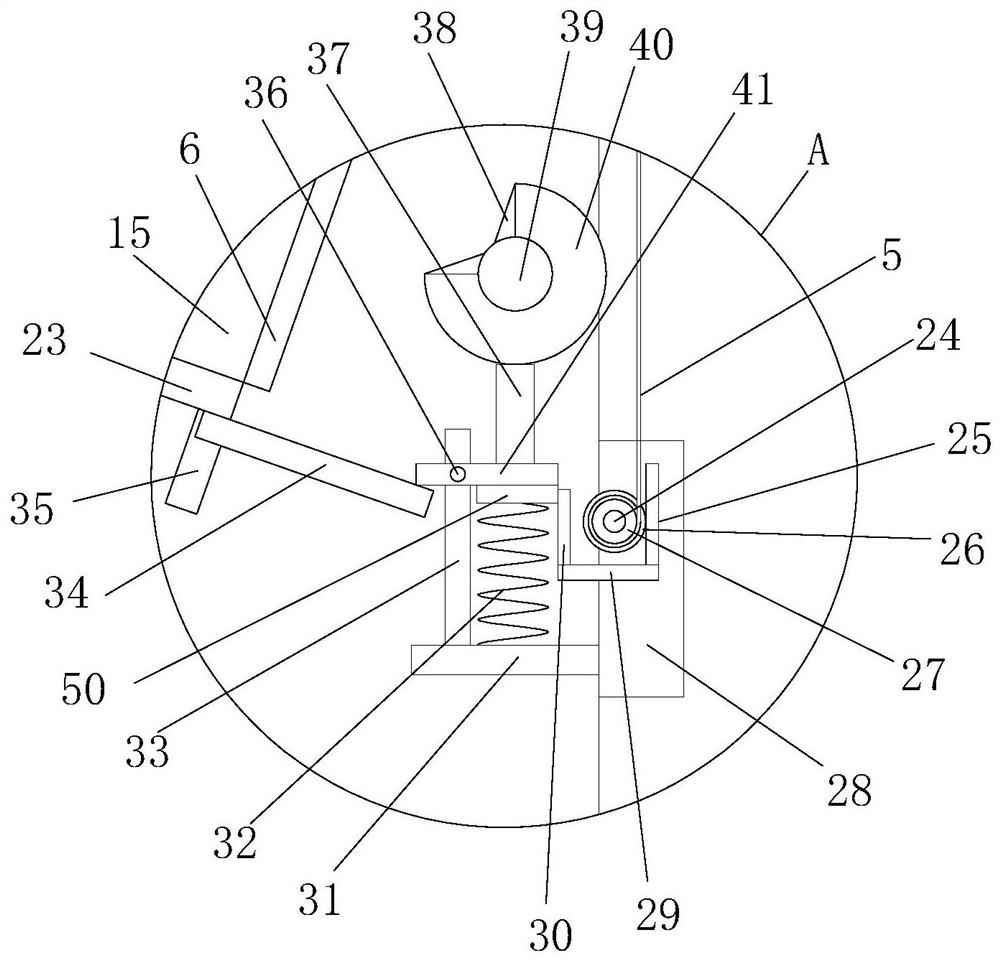

Treatment device of raw materials for dog food

InactiveCN112137144AConvenience for subsequent transportationFeeding-stuffSortingProcess engineeringCompanion animal

The present invention relates to the field of pets and particularly to a treatment device of raw materials for dog food. A technical problem to be solved is to provide the treatment device of the rawmaterials for the dog food. A technical scheme is as follows: the treatment device of the raw materials for the dog food comprises a bottom frame, a screening mechanism, a distributing mechanism, a compacting mechanism, a storage box and a control screen; the bottom frame is connected with the screening mechanism; the bottom frame is connected with the distributing mechanism; the bottom frame is connected with the compacting mechanism; the bottom frame is connected with the storage box; the bottom frame is connected with the control screen; the screening mechanism is connected with the distributing mechanism; and the distributing mechanism is connected with the compacting mechanism. The treatment device realizes picking and screening of mildewed bagasse, the mildewed bagasse is selected out, then non-mildewed bagasse is distributed and compacted, fluffy bagasse is changed into compact bagasse, and transportation is convenient.

Owner:田立勇

Blanking device for centrifuge

The invention discloses a blanking device for a centrifuge. The blanking device comprises a receiving hopper, a blanking pipe, a blanking pipe fixing mechanism, a positioning handle, a sealing ring and discharging barrels, wherein the upper end of the blanking pipe is movably connected with the lower end of the receiving hopper through the blanking pipe fixing mechanism; the sealing ring is arranged at a joint of the blanking pipe and the receiving hopper; the positioning handle for rotating the blanking pipe is fixedly connected to the upper end of the blanking pipe; the blanking pipe consists of a circular steel pipe and an arc-shaped hose; the tail end of the arc-shaped hose is positioned in one discharging barrel, so that materials in the arc-shaped hose tangentially enter the discharging barrel; nicks for placing the arc-shaped hose are formed in the sidewalls of the discharging barrels. According to the blanking device for the centrifuge, the blanking position and range can be conveniently, rapidly and flexibly switched, the discharging impact is reduced, and the uniform distribution of the materials is facilitated.

Owner:HUNAN XIANGHENG SALT CHEM

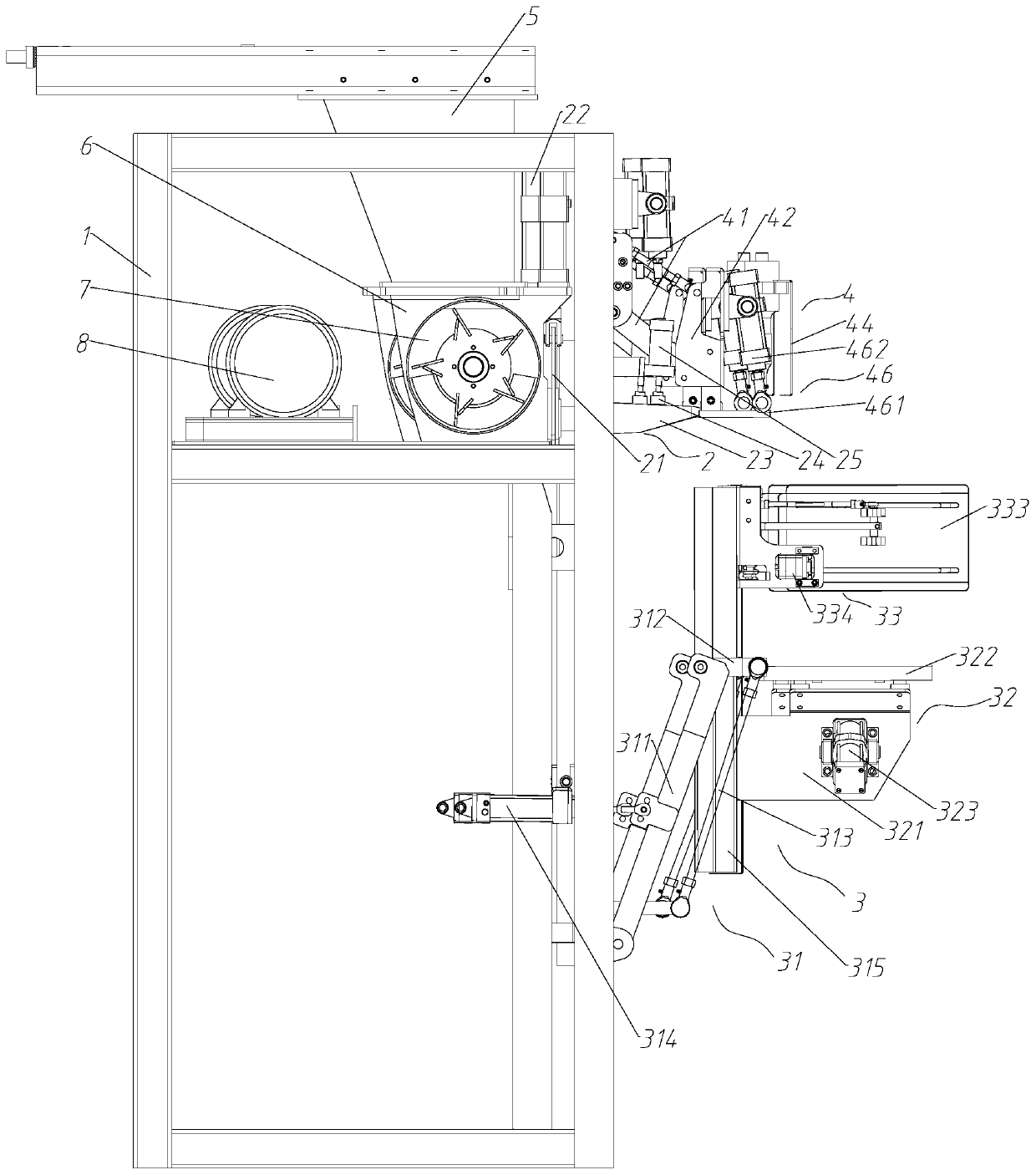

Coiled material stacking manipulator device

PendingCN111302080AConvenience for subsequent transportationGuaranteed not to dropStacking articlesDe-stacking articlesEngineeringRobot hand

The invention discloses a coiled material stacking manipulator device, and relates to the technical field of stacking equipment. The coiled material stacking manipulator device comprises a bottom frame, wherein a first clamping device is arranged at one end of the bottom frame in the Z-axis direction, the first clamping device is provided with a first clamping plate, and the first clamping plate moves up and down in the Z-axis direction; a second clamping device is arranged at the other end of the bottom frame in the X-axis direction, the second clamping device is provided with a second clamping plate, the second clamping plate moves in the X-axis direction, and the first clamping plate and the second clamping plate abut against and clamp the two ends of a coiled material; anti-skid structures are arranged on the contact surface of the first clamping plate and the coiled material and the contact surface of the second clamping plate and the coiled material, a third connecting seat is further arranged on the bottom frame, and the third connecting seat is connected with an external robot arm; and a pushing-out device is further arranged on the bottom frame, and the pushing-out deviceis perpendicular to the axis of the coiled material. According to the coiled material stacking manipulator device, the structure is simple, the coiled material is prevented from falling off in the clamping process, the arc surface of the coiled material cannot be damaged, and the coiled material is tightly attached to other placed coiled materials without gaps.

Owner:河北万向智能科技有限公司

An anode carbon block carbon bowl cleaning unit convenient for subsequent transportation and its use method

The invention provides an anode carbon block carbon bowl cleaning unit convenient for subsequent transportation and an application method thereof. The anode carbon block carbon bowl cleaning unit comprises anode carbon blocks, an inlet conveying device, a carbon bowl cleaning groove, a fully-enclosed dustproof cover, carbon bowl cleaning devices and a control system; the inlet conveying device starts on the ground, and is upwardly connected with the carbon bowl cleaning groove; the fully-enclosed dustproof cover is arranged over the carbon bowl cleaning groove, corresponds to the carbon bowl cleaning groove and is connected with a liquid nitrogen tank; the carbon bowl cleaning devices are arranged in the carbon bowl cleaning groove; the carbon bowl cleaning devices comprise ultrasonic position detection devices, cleaning drills, cleaning brushes and rotating plates; the ultrasonic detection position devices, the cleaning drills and the cleaning brushes are arranged on the rotating plates uniformly with an angle of 120 degrees reserved; the bottom of the carbon bowl cleaning groove is connected with a dust collecting device; and the back of the carbon bowl cleaning groove is connected with a carrying conveying belt. The anode carbon block carbon bowl cleaning unit has the advantages of being high in automation degree, good in dustproof and noise-reducing effects, capable of realizing automatic stacking, and convenient for batch cleaning and processing of the anode carbon block carbon bowl.

Owner:东兴市家家鸿红木家具有限公司

Cutting platform waste collecting device for indoor decoration

InactiveCN112827564AImplement the collection functionRealize the shredding functionGrain treatmentsPressesEnvironmental engineeringWaste material

The invention provides a cutting platform waste collecting device for indoor decoration. The cutting platform waste collecting device for indoor decoration comprises a bottom plate, a box body fixedly mounted at the top of the bottom plate, a crushing chamber formed in the box body, a compression chamber formed in the box body, a feeding hopper which is fixedly mounted at the top of the box body and communicates with the crushing chamber, a crushing mechanism which is fixedly mounted in the crushing chamber and is located under the feeding hopper, and an inclined plate fixedly mounted in the crushing chamber. The cutting platform waste collecting device for indoor decoration has the advantages that operation is easy, waste is automatically compressed and collected, and collision is prevented.

Owner:新鸿天装饰工程有限公司

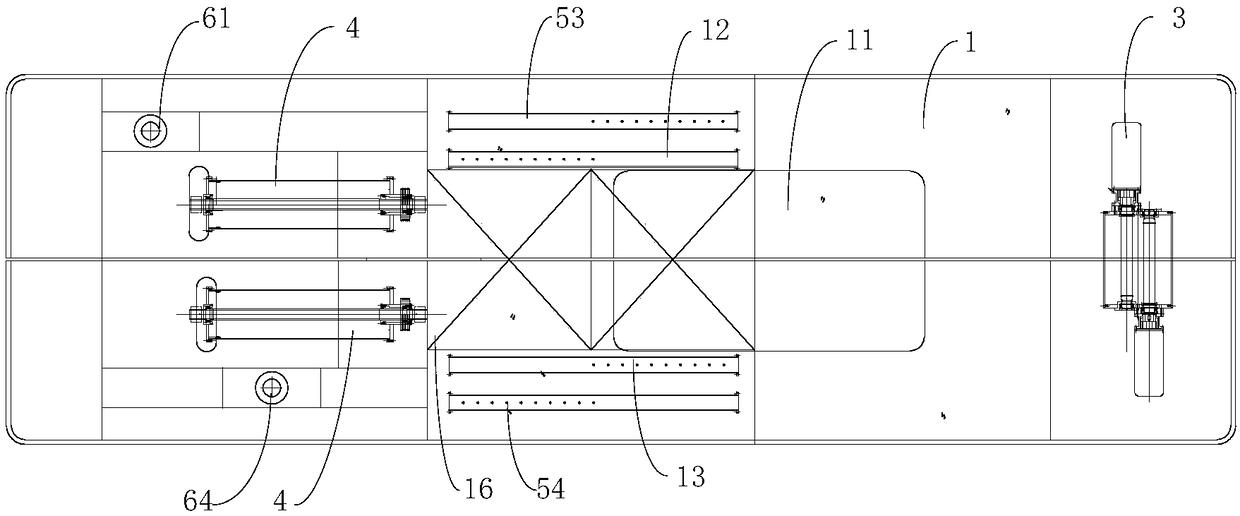

Silt dehydration device and desilting and silt drying ship provided with same

PendingCN108176521AReduce weightReduce volumeMechanical machines/dredgersRotary centrifugesEngineeringCentrifugal force

The invention relates to a silt dehydration device and a desilting and silt drying ship provided with the same. The silt dehydration device comprises a centrifugal screen, a centrifugal screen rotaryshaft, a filter screen, a spiral material pushing plate and a dehydration motor. The silt dehydration device is provided with a charging inlet and a discharging outlet. The centrifugal screen is connected with the centrifugal screen rotary shaft. The filter screen is in a barrel type and is fixedly connected with the centrifugal screen and matched with the centrifugal screen in a nested mode. Thespiral material pushing plate is arranged in the filter screen and extends in the axial direction of the filter screen. The spiral material pushing plate is located between the charging inlet and thedischarging outlet. The dehydration motor is connected with the centrifugal screen rotary shaft and drives the centrifugal screen rotary shaft to rotate. The centrifugal screen, the filter screen andthe spiral material pushing plate rotate relatively. According to the silt dehydration device disclosed by the embodiment of the invention, by rotating the centrifugal screen with the filter screen, water in silt can be thrown out of the centrifugal screen under the action of centrifugal force, silt can be discharged out of the discharging outlet, thus, the weight and size of silt are greatly reduced, subsequent silt conveying is facilitated, and the desilting efficiency is improved.

Owner:GUANGZHOU HAOLI TOOLS CO LTD

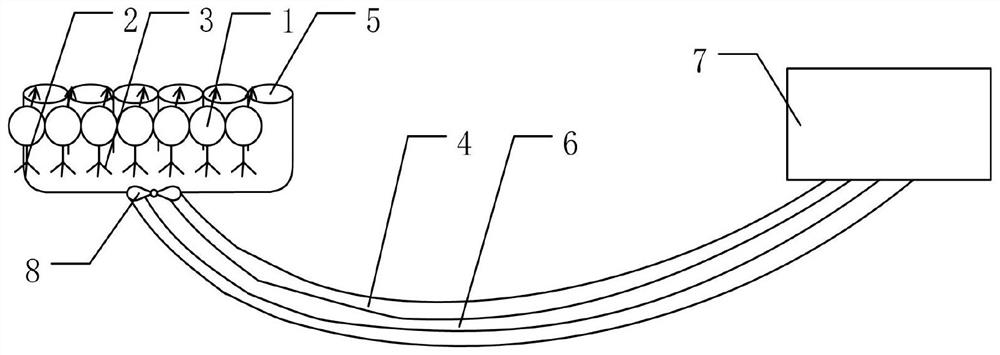

Automatic enteromorpha fishing and dehydrating system and monitoring method based on big data analyzing and monitoring

ActiveCN109673252AAvoid gatheringTo achieve the effect of automatic processingHarvestersFood treatmentControl systemEngineering

The invention discloses an automatic enteromorpha fishing and dehydrating system and a monitoring method based on big data analyzing and monitoring. The system comprises an enteromorpha intercepting line, a fishing mechanism, a transmission mechanism, a collecting mechanism and a control system. The enteromorpha intercepting line is an intercepting line, composed of a plurality of floating balls,floating on a seawater; 3-4 through holes are uniformly formed in each floating ball; the fishing mechanism comprises a rotating shaft, a paddle and a rotating motor; a rotating motor is arranged in each floating ball; the first end of the rotating shaft is connected to the output shaft of the rotating motor and the second end stretches out of each floating ball through each through hole and is connected to the paddle; the transmission mechanism comprises a main pipeline, a branch pipeline and a conveyor belt; the branch pipeline is arranged corresponding to the floating ball; the opening in the bottom end of the branch pipeline is connected to the main pipeline; the conveyor belt is arranged in the main pipeline; the collecting mechanism communicates to the main pipeline; and the controlsystem controls the rotating motor to rotate and the conveyor belt to transmit. The system fishes and collects enteromorpha automatically, so that the manpower is saved. Meanwhile, the enteromorpha treatment efficiency is improved and the sea environment is protected.

Owner:TIANJIN RES INST FOR WATER TRANSPORT ENG M O T

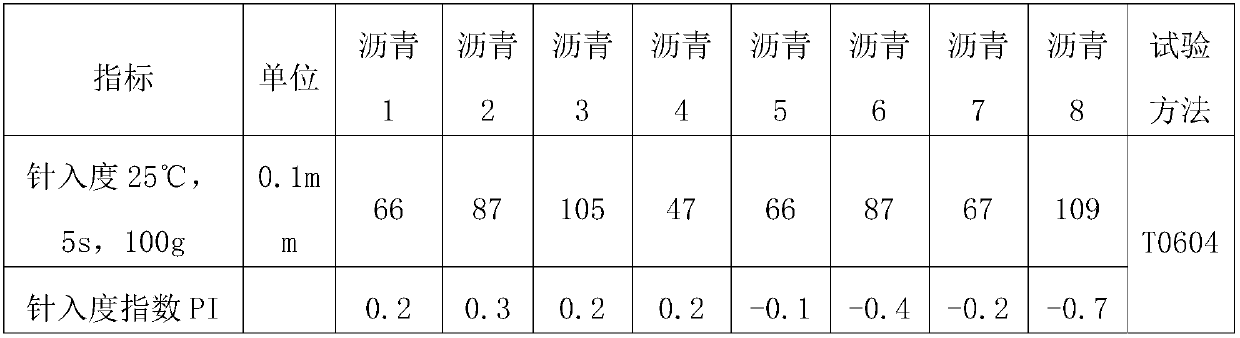

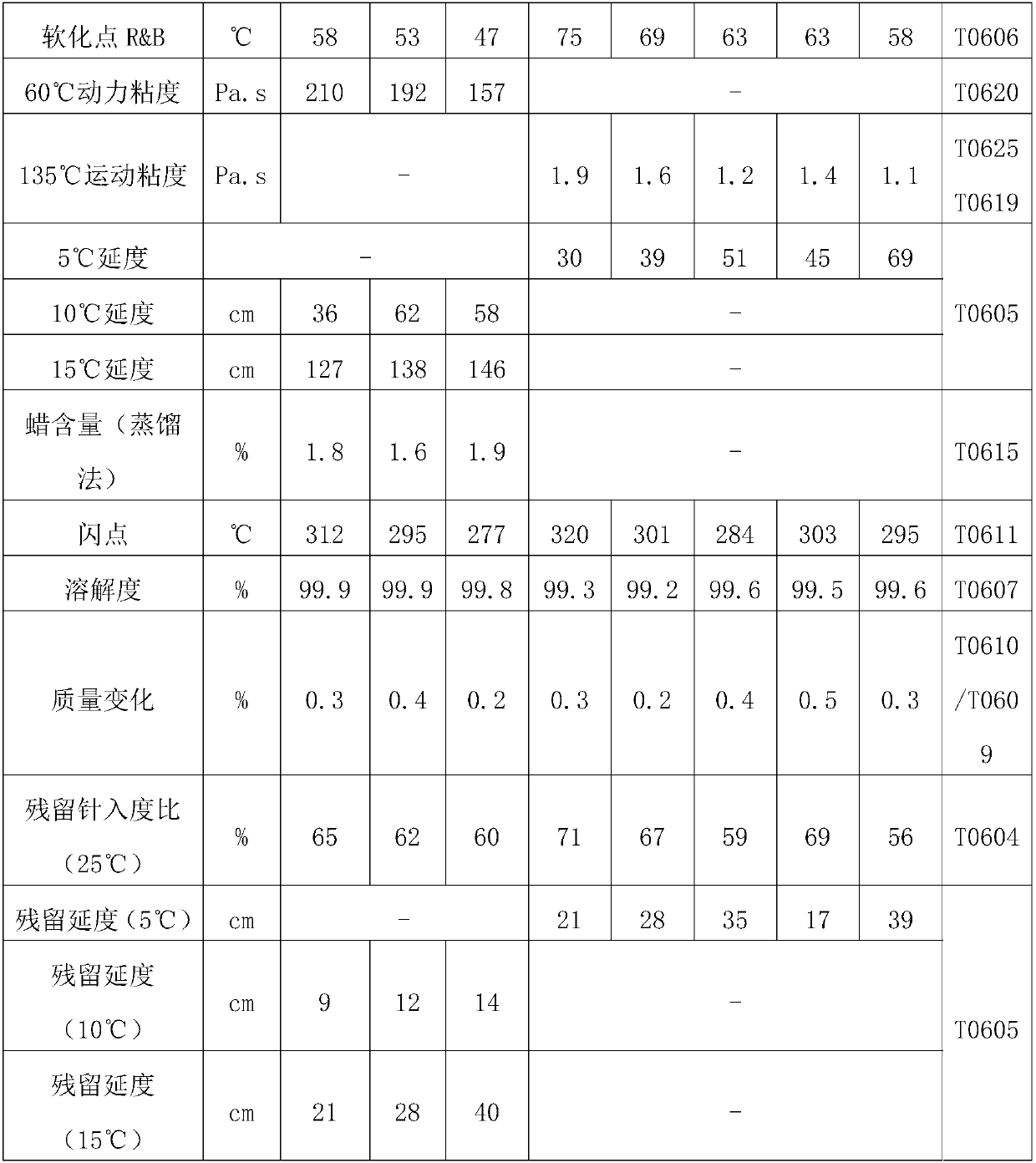

Pouring type granulated asphalt and preparing method thereof

PendingCN109627796AAvoid prone to bondingRich granulation manufacturing technologyBuilding insulationsPrillAdhesive

The embodiment of the invention discloses pouring type granulated asphalt and a preparing method thereof. The asphalt comprises an outer shell material, an inner core material, an accelerant, a delaying agent, a plasticizer and an adhesive. The pouring type granulated asphalt can be directly added into a mixing vat, asphalt granules are smashed and molten through high shearing force and heat of collected materials, an asphalt mixture is mixed, and the defect that liquid asphalt needs to be transported by heat insulation vehicles and needs to be stored at a high temperature after reaching the site is avoided; the liquid asphalt can be stored and transported at a normal temperature, energy is saved, the circular economy is developed, and the environment harmonious development is protected.

Owner:北京紫瑞天成科技有限公司

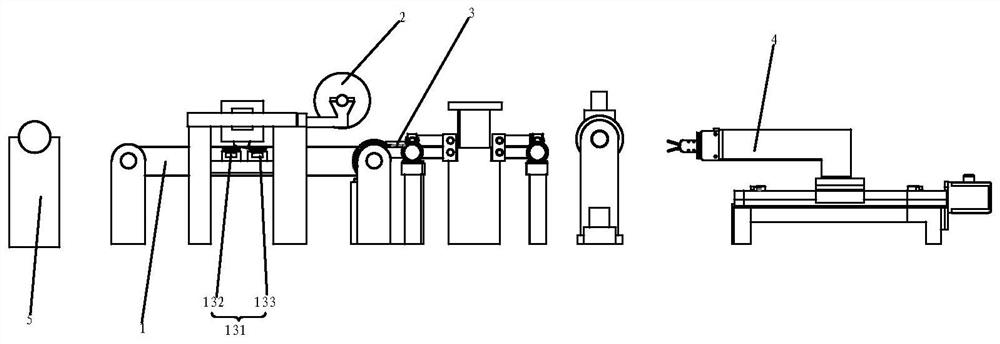

Efficient and intelligent cloth edge pressing assembly line

PendingCN112810158AConvenience for subsequent transportationBeautiful edge positionSevering textilesAssembly lineManufacturing line

The invention provides an efficient and intelligent cloth edge pressing assembly line. The efficient and intelligent cloth edge pressing assembly line comprises a first cloth cutting device for cutting first cloth into a plurality of first single bodies, a second cloth supply mechanism for supplying second cloth, a first forming device for connecting the first single bodies and the second cloth together according to a preset shape to form a cloth connecting body, and a first collecting mechanism used for collecting the cloth connecting bodies; the first collecting mechanism comprises a first grabbing mechanism for grabbing the cloth connecting body and a first winding mechanism for winding the cloth connecting body; and the first grabbing mechanism comprises a plurality of first grabbing devices which are in one-to-one correspondence with the cloth connecting bodies. The production line for continuously carrying out edge pressing treatment on the cloth is formed by means of automatic production of the assembly line, and the production efficiency is improved; and the cloth connecting body is connected with the edge of the processed umbrella cover which is not subjected to edge pressing, so that the edge position of the umbrella cover is more attractive, shapes formed by different colors or different edge pressing effects are presented, and the umbrella cover has rich diversity.

Owner:海峡(晋江)伞业科技创新中心有限公司

Peeling machine capable of machining hydraulic pipes with different pipe diameters

InactiveCN114434518AEasy to crushReduce volume rangeGrain treatmentsMetal working apparatusTool bitGear wheel

The invention discloses a peeling machine capable of processing hydraulic pipes with different pipe diameters, which comprises a base, one side of the bottom in the base is connected with a vertical plate through a moving mechanism, one end of a sleeve rod is provided with a nut, the top of the base is connected with a clamping plate through a second fastener, and the inner side of the clamping plate is connected with a second circular ring through a sliding rod. The inner side of the second circular ring is connected with a tool bit through a third electric telescopic rod, and the outer side of the second circular ring is engaged with a gear through a rack. According to the peeling machine capable of machining the hydraulic pipes with the different pipe diameters, a gear can be driven to rotate by starting a motor, a tool bit on the inner side of a second circular ring can be driven to rotate through meshing connection of the gear and a rack, peeling operation on the outer surfaces of the hydraulic pipes can be completed conveniently, and compared with cutting peeling conducted through extrusion of two tool bits, the peeling efficiency is improved; according to the peeling machine, the inner side part of the hydraulic pipe cannot be damaged, and the third electric telescopic rod drives the cutter head to move, so that peeling operation can be conveniently performed on hydraulic pipes with different pipe diameters.

Owner:徐州恒和机械科技有限公司

Recrystallization method of long-chain dicarboxylic acid

ActiveCN112742062AImprove solubilityReduce solubilitySolution crystallizationCarboxylic compound separation/purificationSolubilityAlcohol

The invention relates to a recrystallization method of long-chain dibasic acid, which comprises the following steps: by taking a mixed solution of ethers and at least one selected from water and low-carbon alcohol as a solvent of the long-chain dibasic acid and a to-be-treated material with the concentration of the long-chain dibasic acid in the to-be-treated material being 15-50g / 100g solvent, putting the to-be-treated material in a crystallizer, preserving heat at the temperature of 80-95 DEG C, reducing the pressure, keeping the vacuum degree, extracting part of the solvent to reduce the volume of the to-be-treated material by 0.5-10%, then increasing the pressure to maintain positive pressure, and cooling to crystallize and separate out the long-chain dibasic acid, thereby completing the recrystallization of the long-chain dibasic acid. According to the invention, seed crystals do not need to be added, the solubility of the dibasic acid can be greatly improved by adding the low-carbon alcohols, then the dibasic acid is discharged through pressure reduction, so that the solubility of the dibasic acid is greatly reduced, crystals are separated out, the dibasic acid explodes in a solvent to spontaneously nucleate in the subsequent cooling crystallization process, and compared with seed crystals added in an original process, the method has the advantages that the number of crystal nucleuses is larger, and the crystal tends to grow on a crystal nucleus rather than being separated out along a wall, so that the problem of cold wall separation is avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

Alloy steel manufacturing, conveying and heat treatment device

InactiveCN112342343AEffect of heat treatmentAvoid debrisFurnace typesMagnetic separationMechanical engineeringHeat treating

The invention discloses an alloy steel manufacturing, conveying and heat treatment device. The alloy steel manufacturing, conveying and heat treatment device comprises a bottom plate, wherein a supporting base is arranged on one side of the upper end of the bottom plate; a baffle is arranged at the top end in the supporting base; a pipeline is arranged at the lower end of the baffle; a material receiving box is arranged at the end, away from the baffle, of the pipeline; an operation box is arranged at the upper end of the supporting base; a feeding port is formed in one side of the outer surface wall of the operation box; and a discharging port is formed in the other side of the outer surface wall of the operation box. According to the alloy steel manufacturing, conveying and heat treatment device, a heat treatment box body, a water outlet pipeline, a water outlet pipe and a leaking opening are additionally arranged, and the heat treatment box body and the water outlet pipeline can achieve the heat treatment effect on alloy steel, so that the workload of workers is reduced; and in addition, chippings carried by the alloy steel can be adsorbed through magnets, so that the chippingsare prevented from appearing in the later period of the alloy steel, and the sales volume of the alloy steel is not influenced.

Owner:仪征市恒达钢结构有限公司如皋分公司

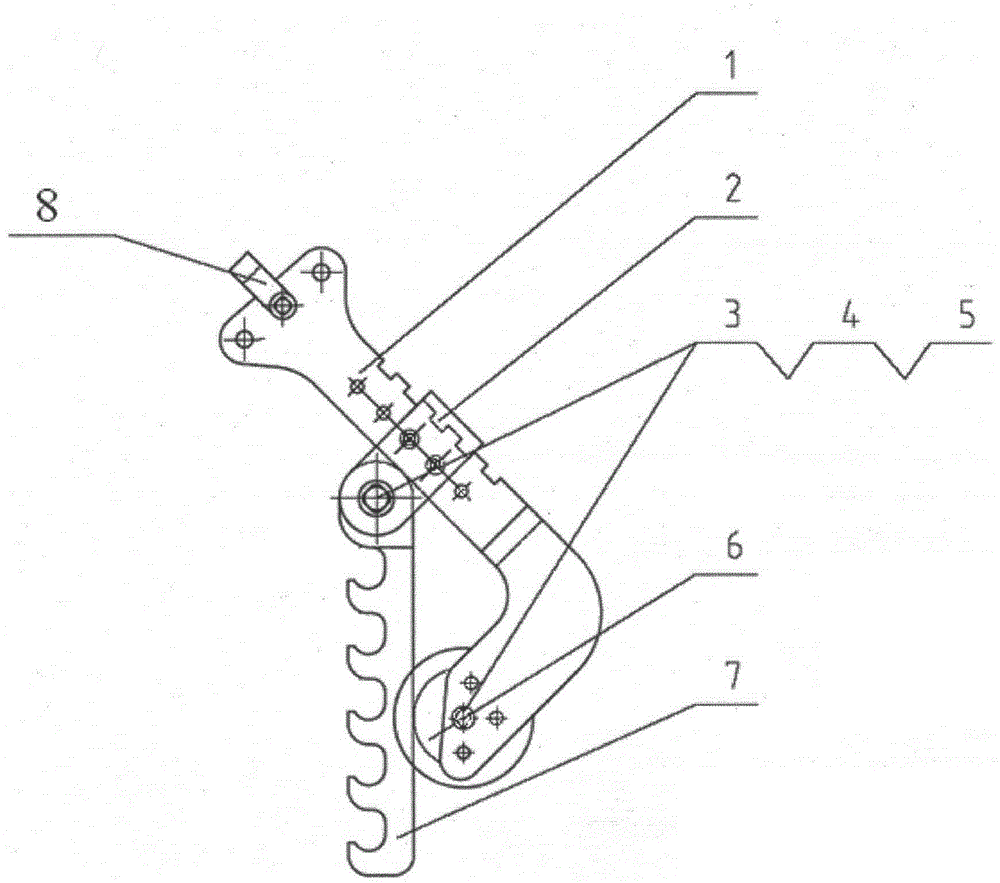

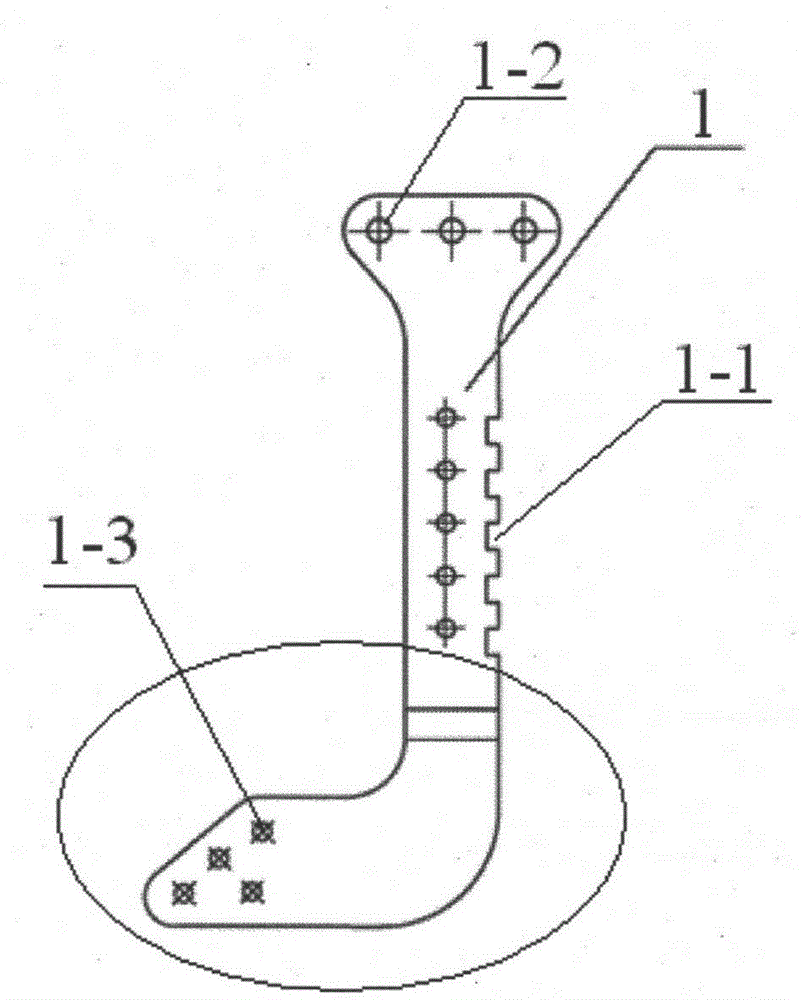

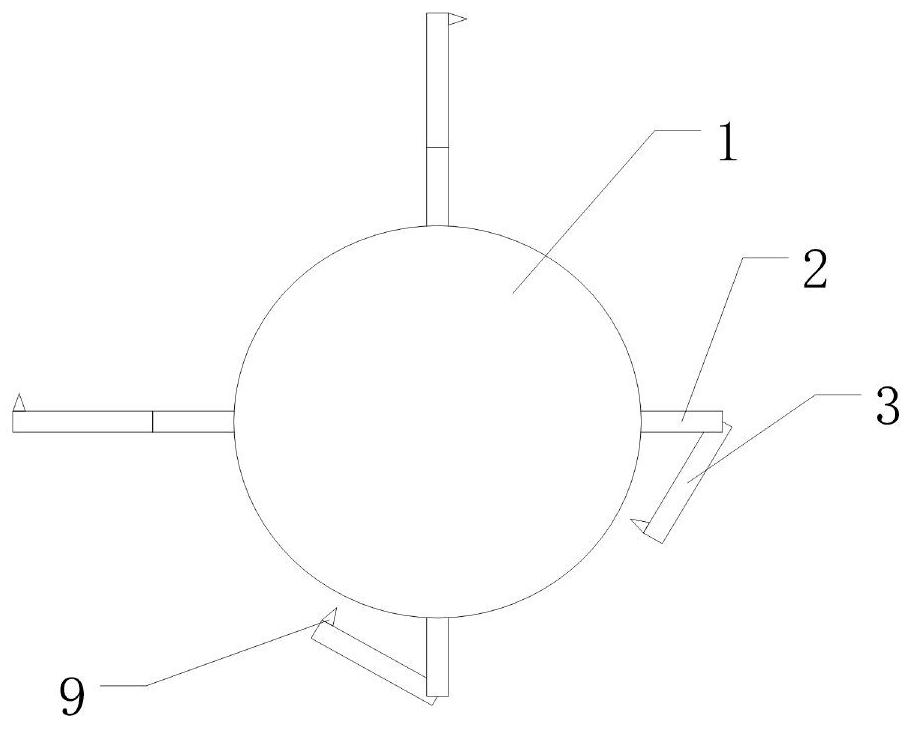

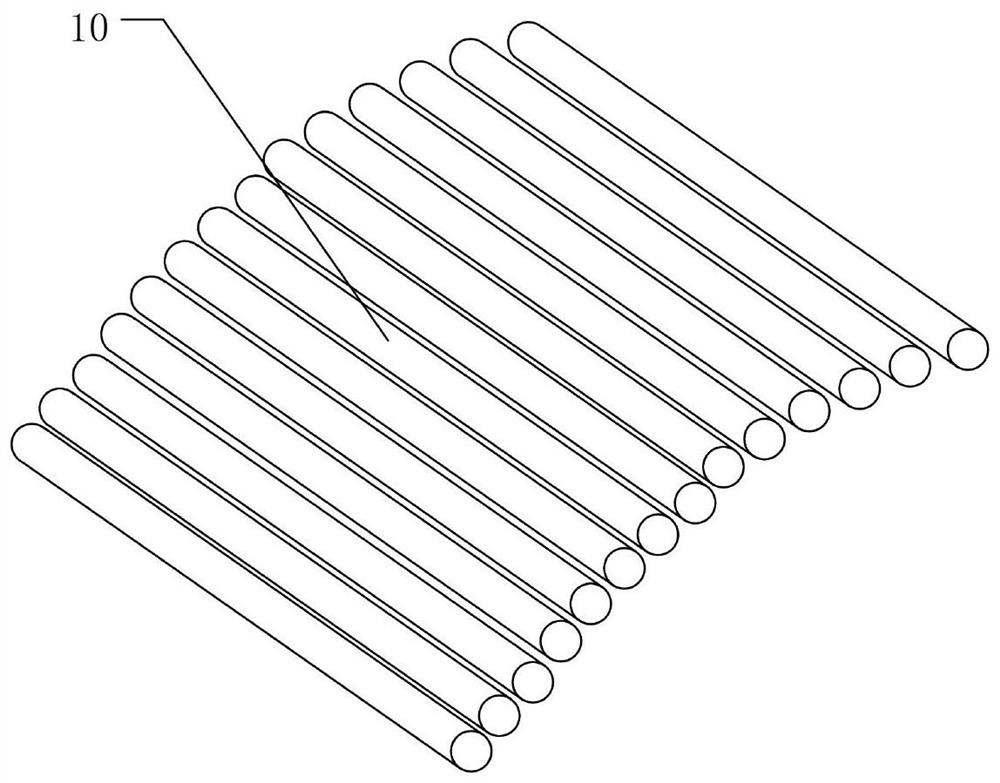

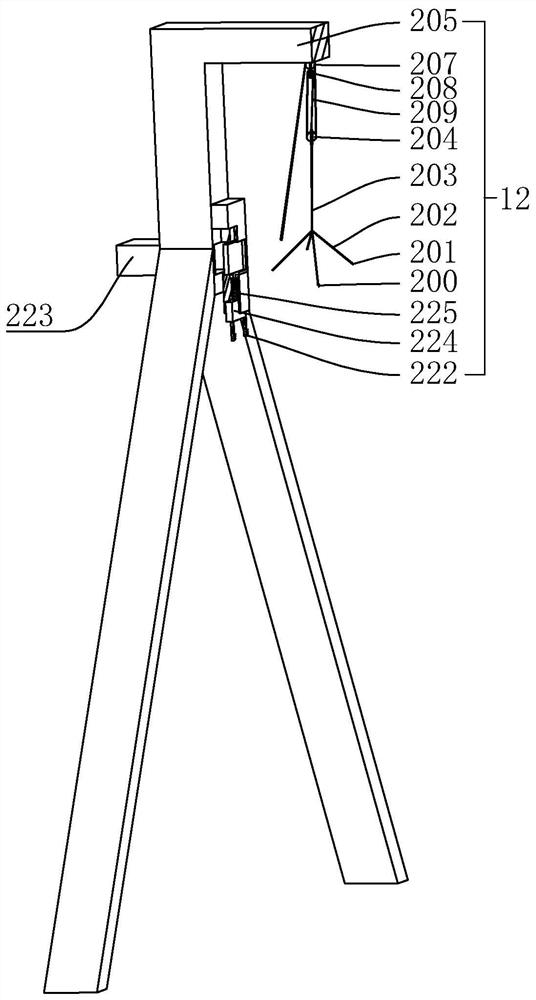

A multi-layer pipe row hook

ActiveCN103552909BGuaranteed accuracyEasy to useLoad-engaging elementsEngineeringMechanical engineering

The invention provides a multilayer tube row lifting hook which comprises a positioning hook, wherein a connection block is arranged on the positioning hook; a clamping wheel is arranged at the bottom of the positioning hook through a pin with a hole; a lifting hook is arranged on the connection block through the pin with the hole and is embedded into a groove in the end face of the clamping wheel. According to the device disclosed by the invention, the shortcomings in the prior art are overcome; a plurality of pipe rows can be simultaneously lifted and transported at a time, so that the pipe row lifting and transporting time is obviously shortened, and the production efficiency is improved; furthermore, the precision of placement positions between surfaces of the pipe rows can be guaranteed, and the subsequent transportation is facilitated; the multilayer tube row lifting hook can be matched with various specifications of clamping wheels. The multilayer tube row lifting hook has the advantages of high generality, small volume, low manufacturing cost and simplicity in loading and unloading and is favorable for large-scale use in a production workshop.

Owner:SHANGHAI BOILER WORKS

Flattening hot melting type snack packaging machine

InactiveCN111392101AQuick seal packagingLimited volumeWrapper twisting/gatheringPackaging foodstuffsSnack foodEngineering

The invention discloses a flattening hot melting type snack packaging machine. The machine comprises a machine body, a working cavity with a downward opening is formed in the machine body, packaging mechanisms are arranged in the working cavity, first sliding grooves are formed in the working cavity in a bilateral symmetry mode, first sliding blocks are arranged in the first sliding grooves in a sliding mode, second sliding grooves are formed in the first sliding blocks, second sliding blocks are arranged in the second sliding grooves in a sliding mode, pushing cavities are formed in the second sliding blocks, first rotating shafts are rotationally arranged in the pushing cavities, cams capable of abutting against the right end walls of the second sliding blocks are fixedly arranged on thefirst rotating shafts, and first connecting rods are fixedly arranged on the inner end faces of the second sliding blocks. According to the machine, the structure is simple, the operation is easy andconvenient, the machine can quickly seal and package snacks, and the size of a packaging bag can be limited during packaging of the machine, so that food is not deposited at the bottom after enteringthe packaging bag but becomes a regular rectangular block, and the subsequent transportation is facilitated; and all parts in the machine are perfectly cooperated, the manual intervention is not needed in the feeding and discharging process, the integration and automation degree is high, and the use is convenient.

Owner:FUQING MAOSHUN PACKING CO LTD

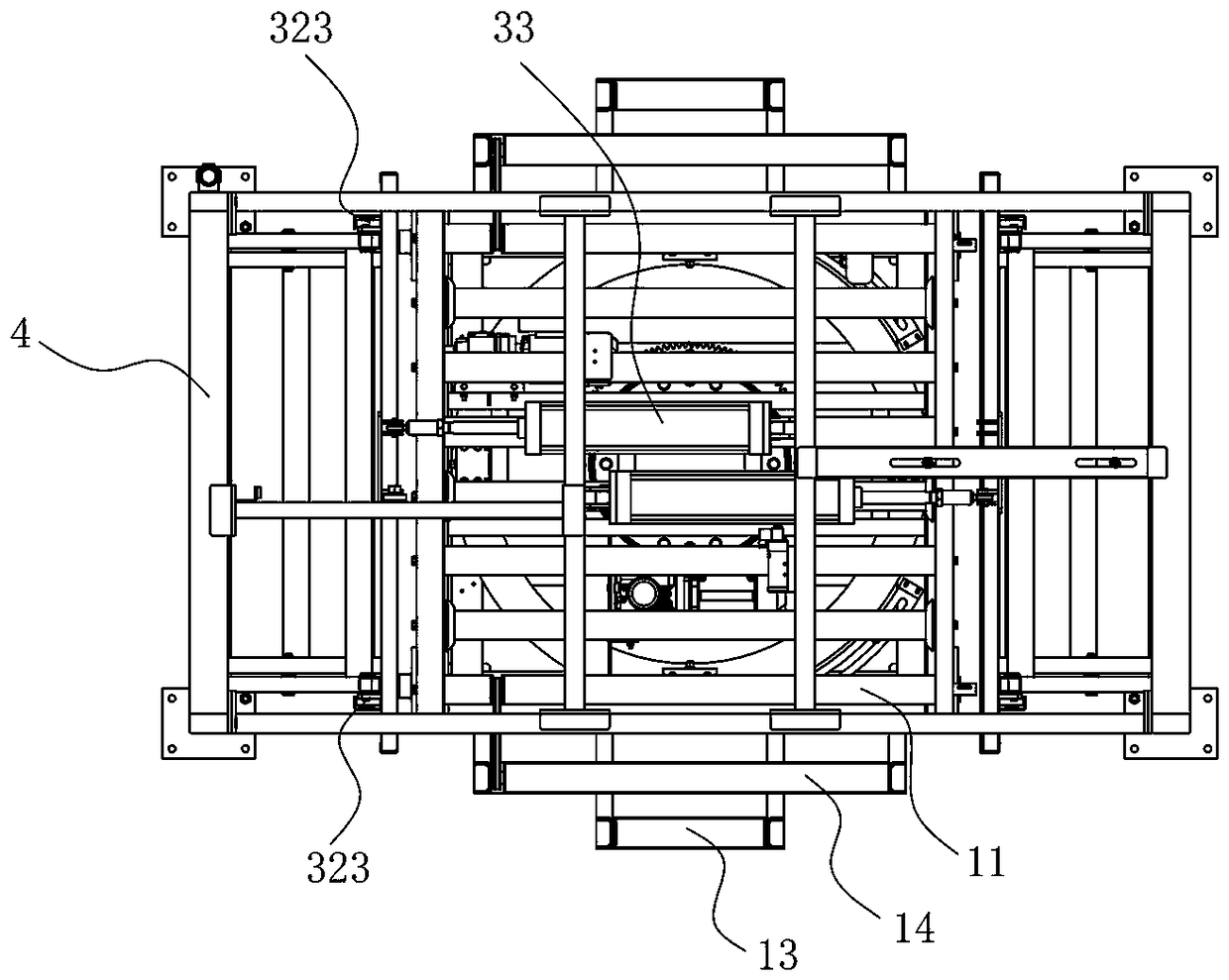

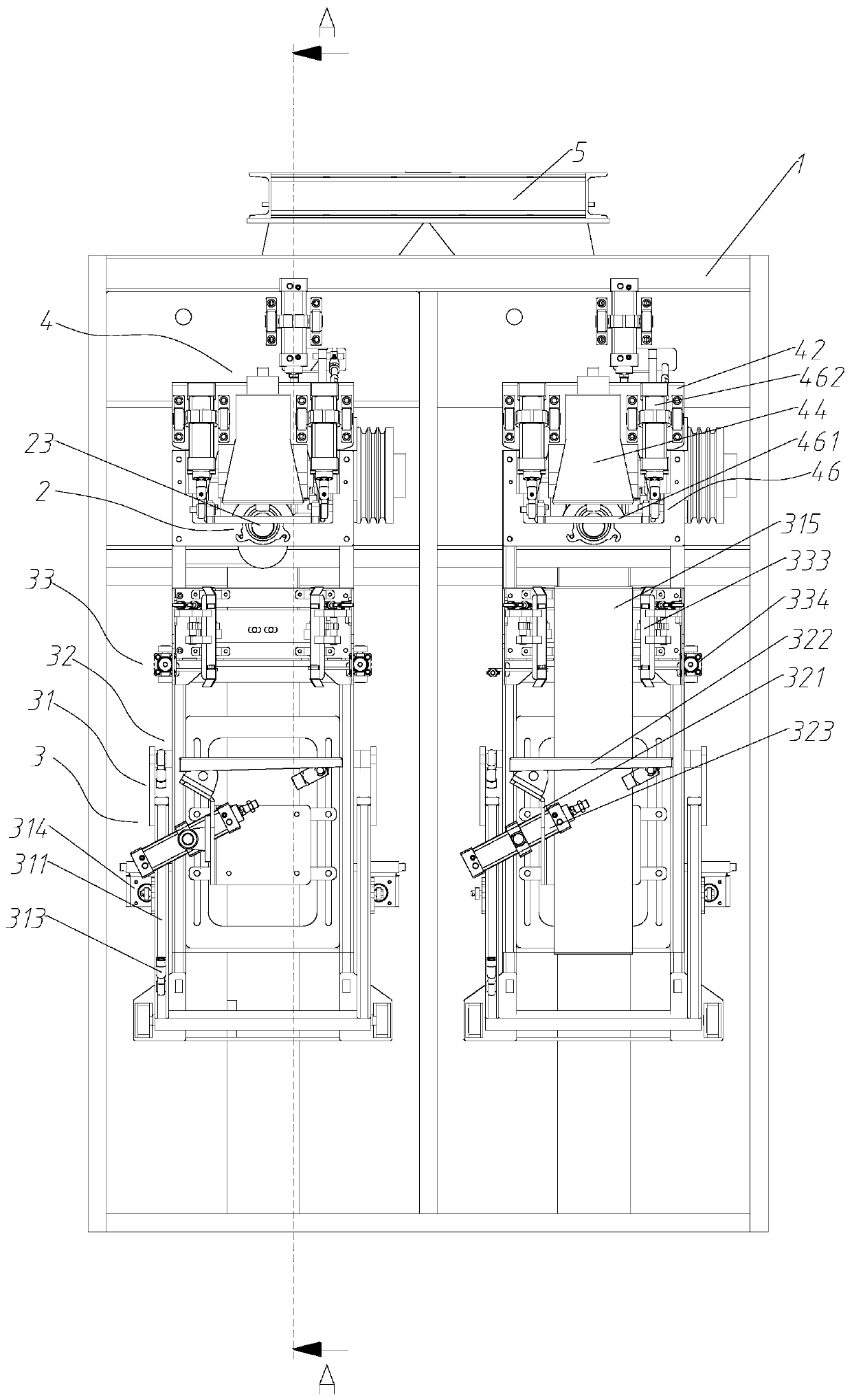

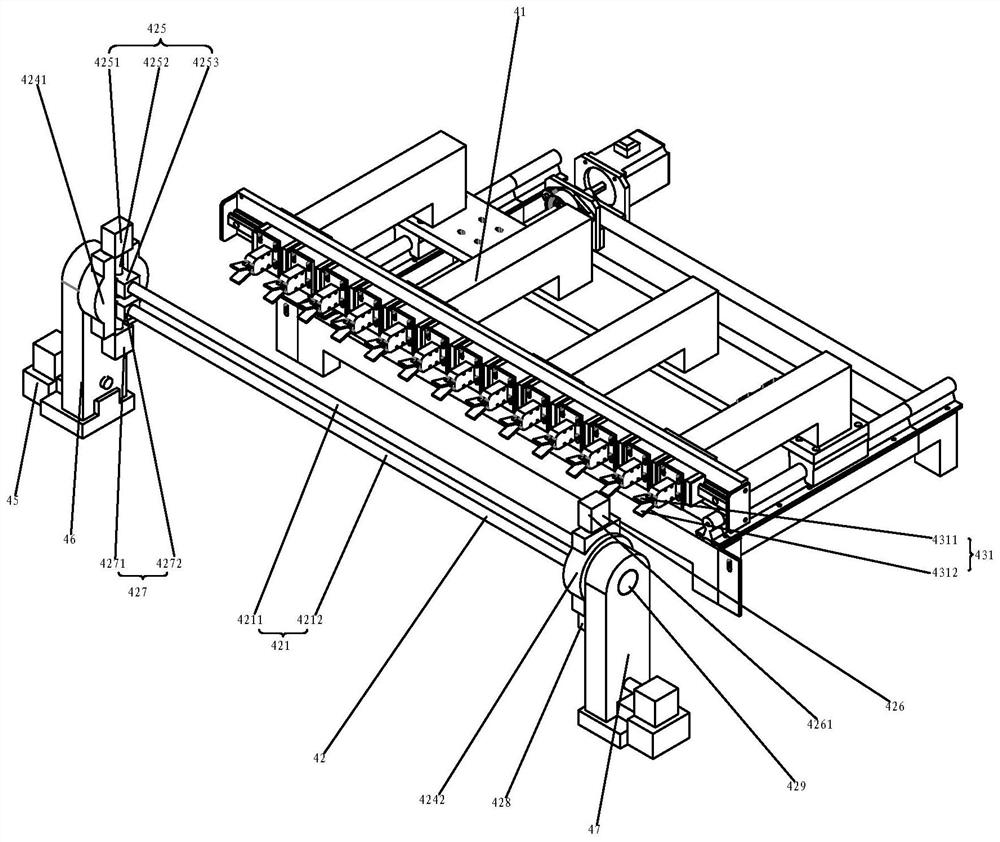

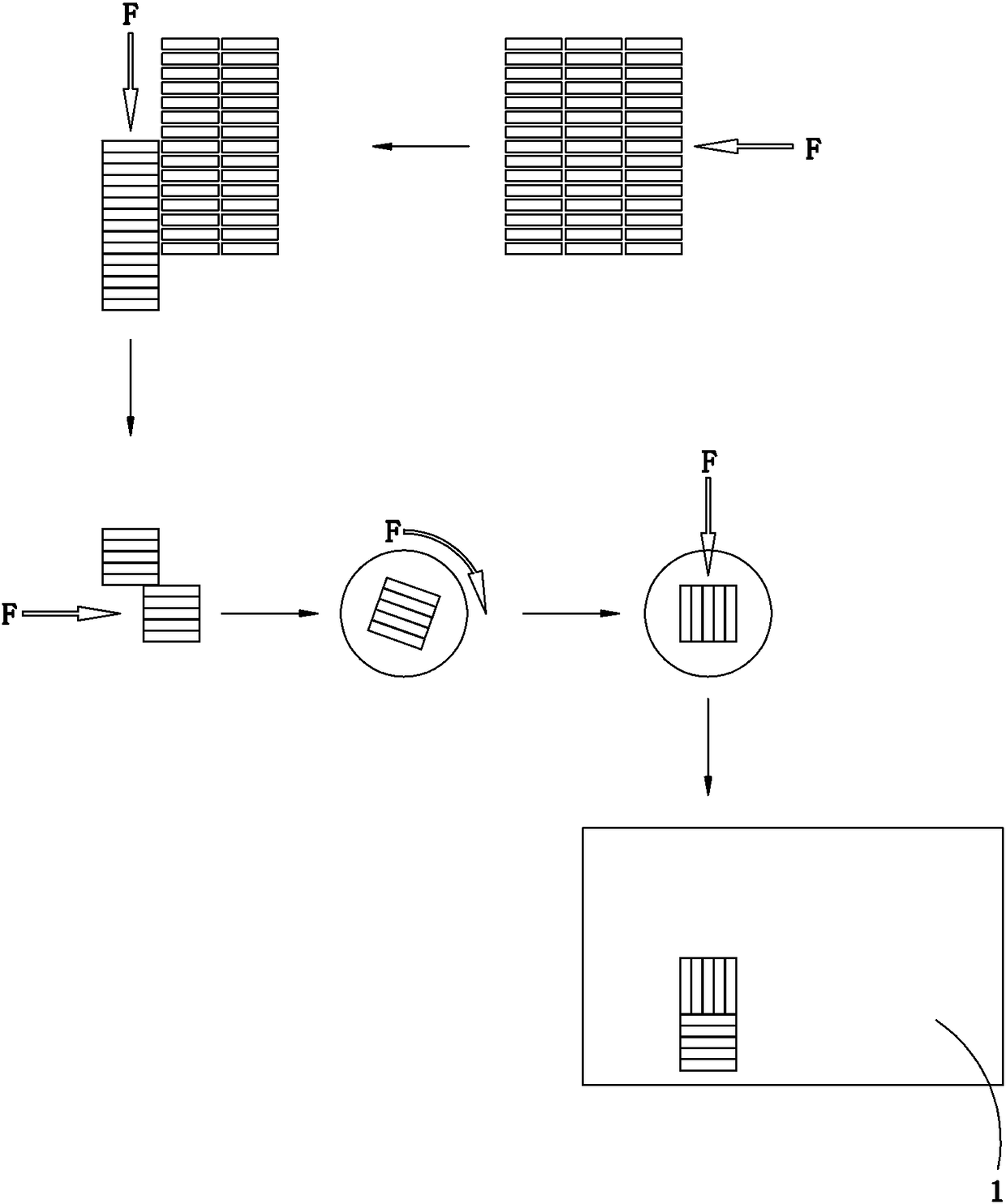

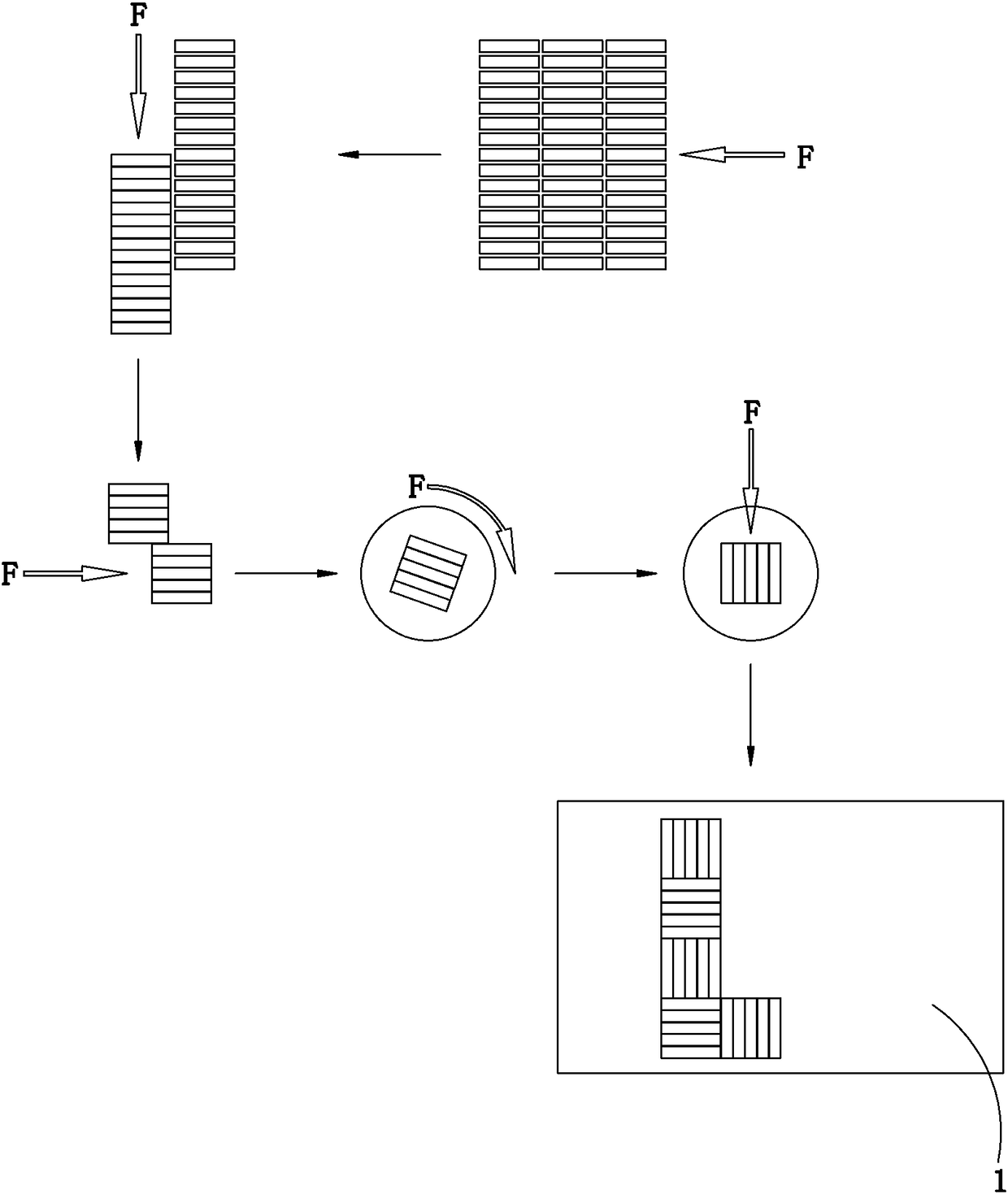

A method and device for intelligent partition palletizing arrangement

The invention discloses an intelligent partitioning and stacking arrangement method and device and relates to the field of brick making. By means of the method, brick blocks on each layer of stacked bricks can be arranged in a horizontal and longitudinal partitioning mode at will during stacking, more scientific and reasonable arrangement of the brick blocks is facilitated, and the firmness of the stacked bricks is improved. By means of the device, the brick blocks are transferred sequentially from a supporting plate to a first pushing device, a detection device, a horizontal pushing device, a rotary platform, a second pushing device and a carrying plate and finally form scientifically and reasonably arranged brick layers on the carrying plate, and the different brick layers are stacked to form the stacked bricks through a stacking device. The intelligent partitioning stacking arrangement device is compact in structure and small in occupied space, the structure of the finished stacked bricks is reasonable and firm, and the stacked bricks can be conveniently transferred, used and the like.

Owner:泉州盛科智能装备制造有限公司

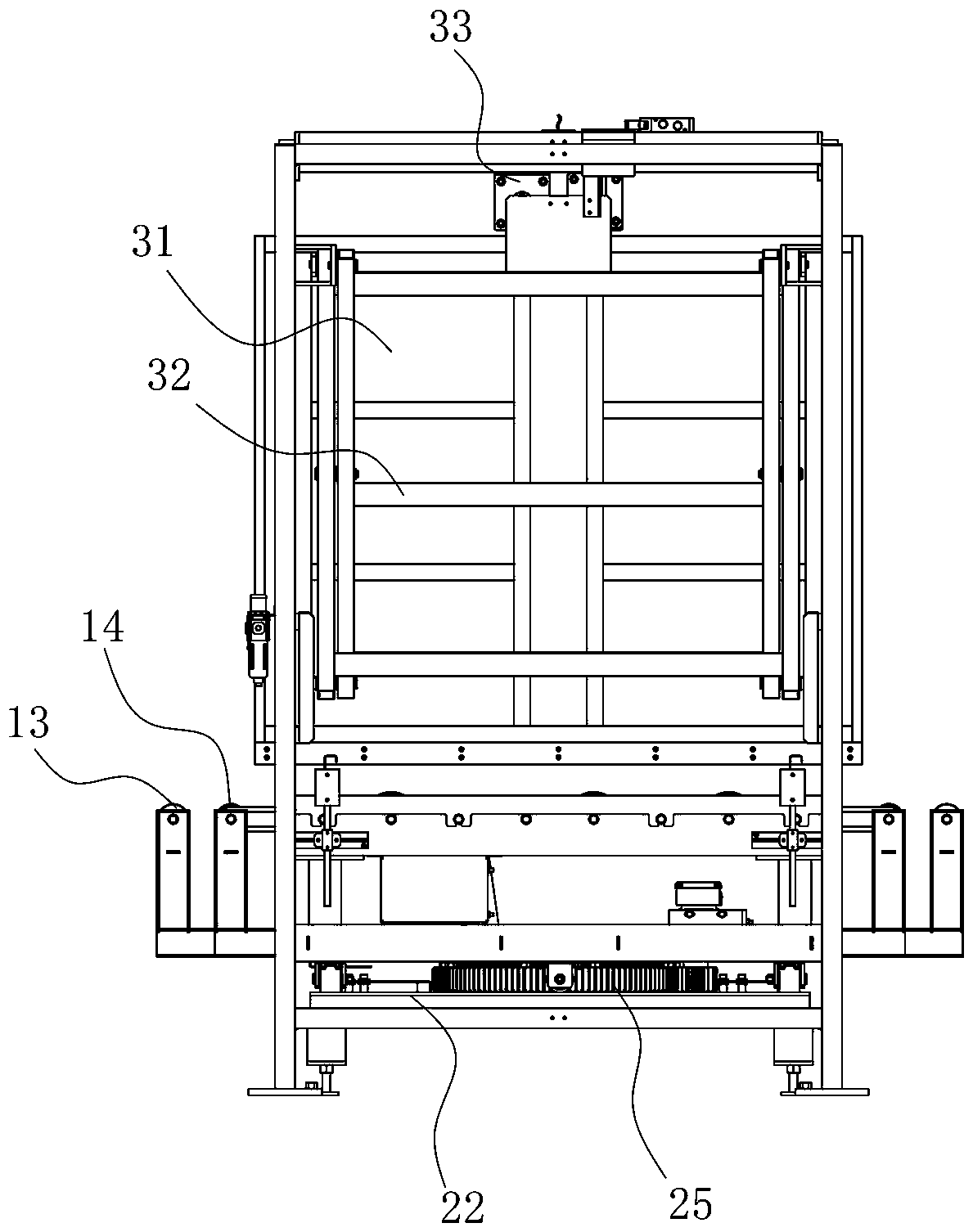

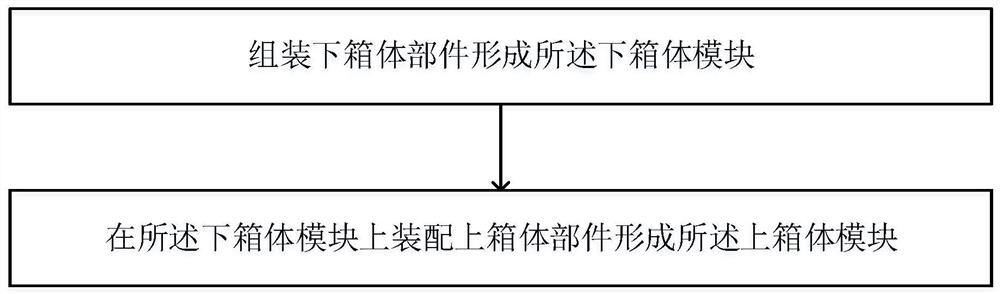

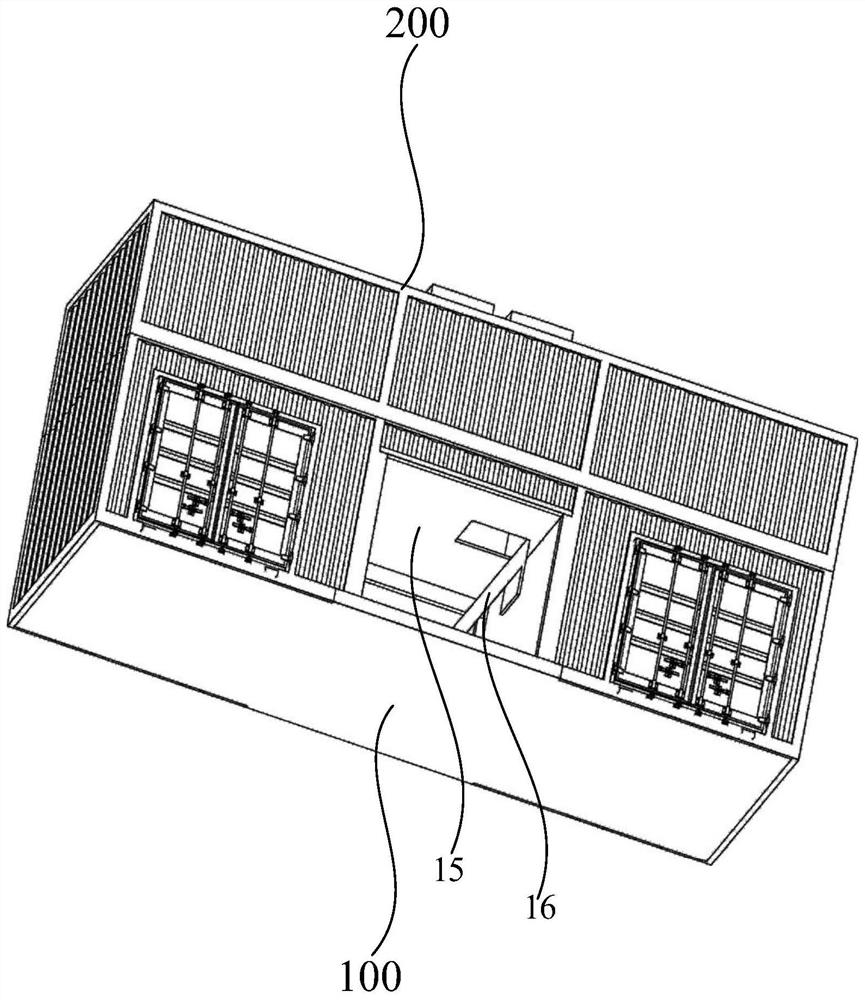

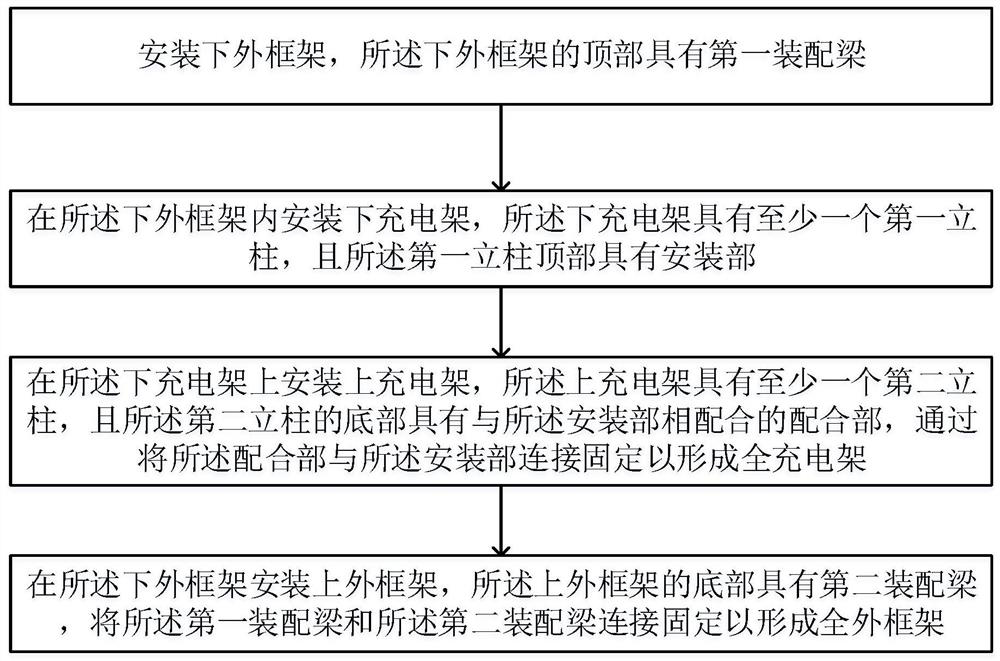

Battery replacement station assembling method

PendingCN114683917ARandom combinationStrong expandabilityCharging stationsVehicular energy storageProduction lineStructural engineering

The invention discloses a battery replacing station assembling method, a battery replacing station comprises an upper box body module and a lower box body module which are detachably connected, and the battery replacing station assembling method comprises the steps that lower box body parts are assembled to form the lower box body module; and assembling an upper box body part on the lower box body module to form the upper box body module. According to the assembling method of the battery replacing station, the lower box body module and the upper box body module are assembled on the production line, modularization of the lower box body module and the upper box body module is achieved, and subsequent transportation to a construction site and assembling on the construction site can be facilitated. Meanwhile, by adopting the assembling method, the battery replacing station has better expansibility, the vertical space is effectively utilized, and the construction cost is reduced.

Owner:AULTON NEW ENERGY AUTOMOTIVE TECHNOLOGY GROUP

Enteromorpha automatic salvage and dehydration system and monitoring method based on big data analysis and monitoring

ActiveCN109673252BAvoid gatheringTo achieve the effect of automatic processingHarvestersFood treatmentControl systemElectric machine

Owner:TIANJIN RES INST FOR WATER TRANSPORT ENG M O T

Corrugated paper production and processing equipment

ActiveCN112573152BLabor savingConvenience for subsequent transportationMechanical working/deformationConveyor partsPaperboardPaper production

Owner:日照环宇纸制品有限公司

An environment-friendly cleaning system

ActiveCN109944286BHigh degree of mechanizationImprove work efficiencyMechanical machines/dredgersSludgeAquatic weeds

The invention relates to an environment-friendly decontamination system. The desilting device includes a desilting unit, a silt separation unit and a silt collection box; the silt separation unit includes an outer box body, a first inner box body and a second inner box body; the aquatic weed removal device includes Salvage unit, cutting unit, crushing unit and grass collection box; the two outlets of the grass collection box are closed by control valves, one of the outlets extends into the first inner box through the grass pipe, and the grass pipe is installed There is a feed pump. This system integrates the functions of silt cleaning and aquatic weed removal. The two operations can be carried out at the same time. It can be applied to river channel management operations in various environments and has high operating efficiency. The aquatic weed removal device can make full use of the silt separation unit of the desilting device, so that the silt separation unit has the functions of separating silt and dehydrating aquatic plants. Since there is no need to additionally design a device for dehydrating aquatic plants, and no need to occupy the space of the hull, the technical effect of saving the manufacturing cost of the equipment and reducing the space requirement for the hull is achieved.

Owner:天津市雷升科技有限公司

An environment-friendly dredging device

ActiveCN109853656BWork effectively for a long timeGuarantee dredging efficiencyMechanical machines/dredgersSludgeHelical blade

The invention relates to an environment-friendly dredging device. The dredging unit includes a mud loosening mechanism and a dredging pump; the sludge separation unit includes an outer box body, a first inner box body and a second inner box body installed on the hull; the sludge separation unit It also includes a dehydration tank, which is provided with spiral blades; a water pump and a medicine tank are also installed on the hull, and the water inlet of the water pump extends to the bottom of the outer box through a water pipe; the medicine tank is filled with deodorizing liquid, medicine The liquid outlet of the tank extends to the bottom of the outer box through the liquid outlet pipe; the first inner box, the second inner box, the stirring paddle and the screw blade are all driven to rotate by the transmission mechanism. The invention can automatically clean the silt at the bottom of the river or lake, and can filter and dehydrate the silt, and has the technical effects of simple operation, high working efficiency, energy saving and environmental protection.

Owner:天津市雷升科技有限公司

Fresh food logistics transfer device

The invention discloses a fresh food logistics transfer device. The fresh food logistics transfer device comprises a supporting column, wherein a fish sorting table is arranged on the supporting column; a live fish weighing, screening and grading device is arranged on the fish sorting table; and the grading device comprises a fish containing hopper rotationally connected to the front side of the fish sorting table, a weighing mechanism for measuring the mass difference of water filled in the fish containing hopper and fishes and water mixing in the fish containing hopper through an elastic component to obtain the mass of live fishes, an output mechanism used for mixing and outputting the live fishes and the water through one-way opening of the bottom of the fish containing hopper, and a screening mechanism used for controlling graded opening of the output mechanism through longitudinal displacement of the fish containing hopper. The fresh food logistics transfer device has the technical effects that the live fish weighing speed is high, the fishes do not need to be fished in and out, and the live fishes are not prone to oxygen deficit and are high in transfer survival rate.

Owner:上海岳煜贸易有限公司

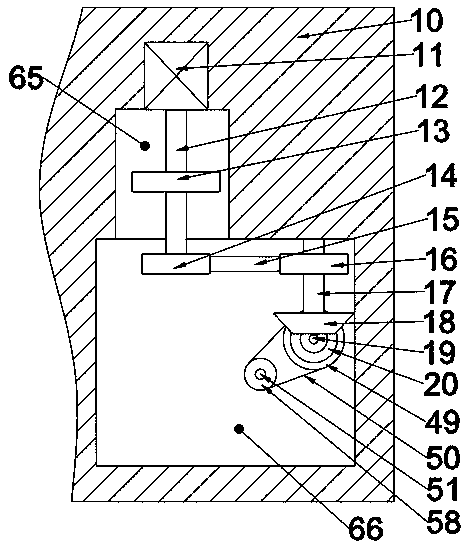

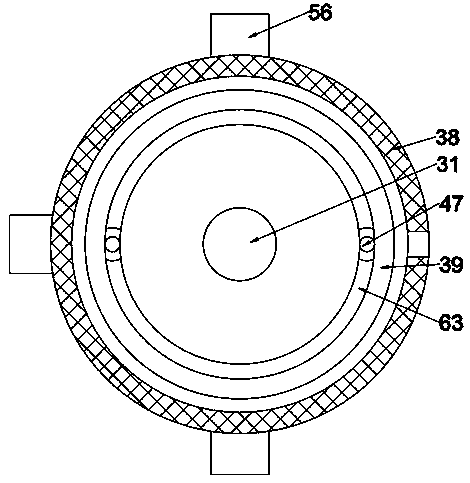

Earth surface ore excavating and collecting machine

InactiveCN110952606ASpeed up miningConvenience for subsequent transportationMechanical machines/dredgersMining engineeringEarth surface

The invention discloses an earth surface ore excavating and collecting machine. The earth surface ore excavating and collecting machine comprises a machine body, wherein a lifting cavity 67 is arranged in the machine body 10, a power cavity 65 communicating with the lifting cavity 67 is arranged on the right side of the lifting cavity 67, an excavating cavity 68 is arranged on the lower side of the lifting cavity 67, a conveying cavity 66 communicating with the excavating cavity 68 is arranged on the right side of the excavating cavity 68, and a lifting device 69 capable of lifting and excavating is arranged in the lifting cavity 67. The machine can automatically excavate minerals on the earth surface, and can complete the steps of crushing, screening and the like, thus accelerating the ore excavating speed and improving the efficiency.

Owner:YONGKANG YOUCHANG MINERAL MINING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com