An environment-friendly cleaning system

An environmental protection and dredging device technology, applied in construction, mechanically driven excavators/dredgers, earth movers/shovels, etc., can solve the problems of long processing cycle, waste of water resources, heavy material weight, etc. The effect of convenient operation, high work efficiency and high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

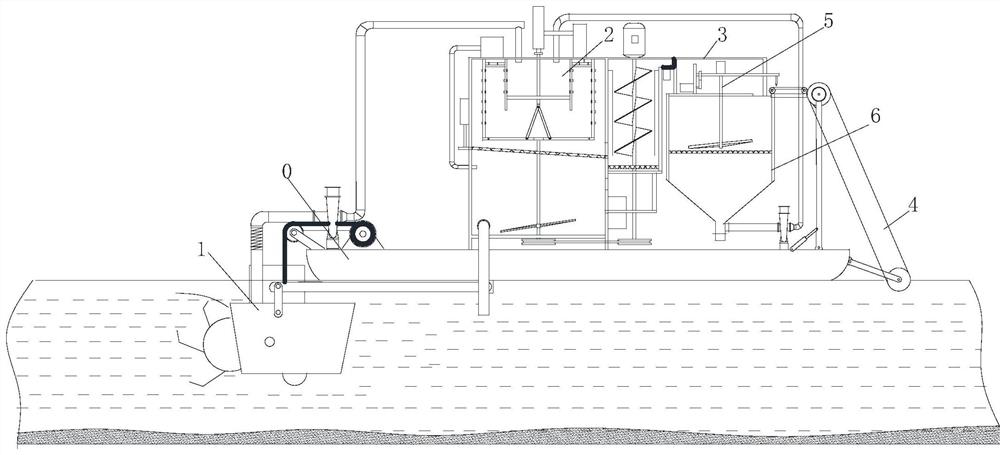

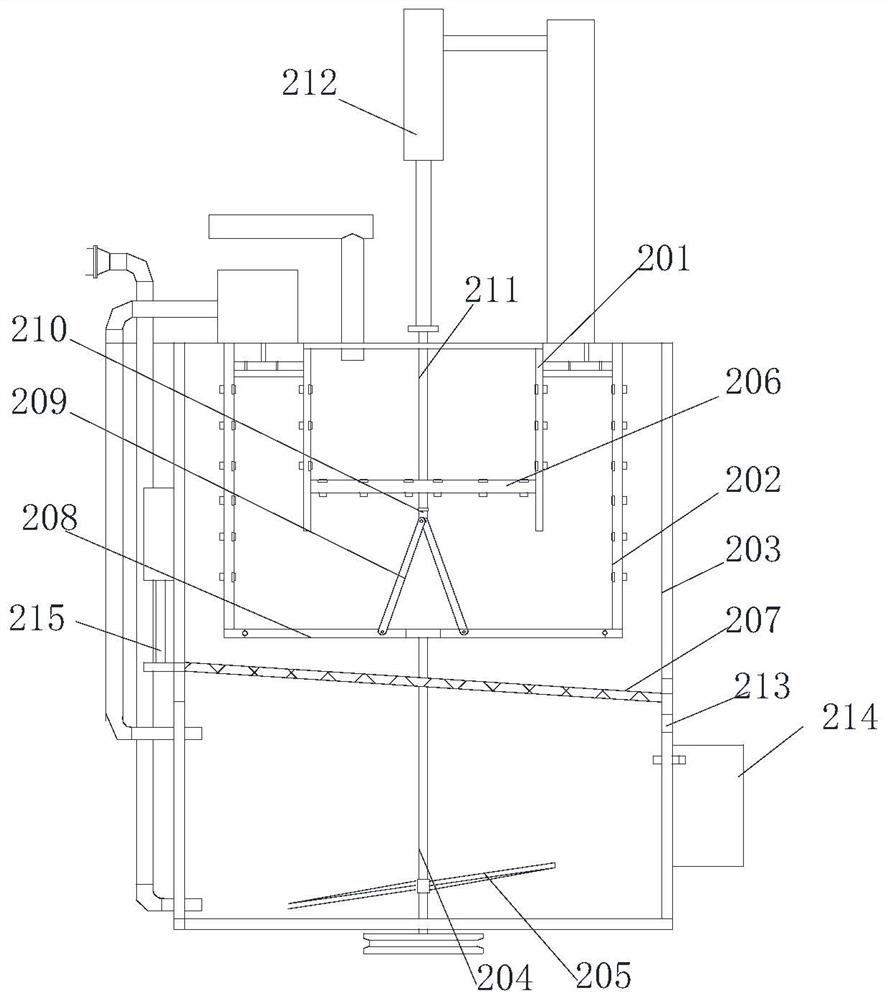

[0042] refer to figure 1 , a garbage disposal device proposed by the present invention, comprising a hull 0, a dredging unit 1, a silt separation unit 2 and a silt collection box 3 which are sequentially arranged on the hull 0 according to the process flow sequence; the dredging unit 1 is used for grabbing The sludge is taken and fed into the sludge separation unit 2; the sludge separation unit 2 is used for filtering and dehydrating the sludge; the silt collecting tank 3 is used for collecting the filtered and dehydrated sludge.

[0043] refer to Figure 6 , the dredging unit 1 includes a mud loosening mechanism connected to the bottom of the hull O, and a silt pump 223 that feeds silt from the mud loosening mechanism into the sludge separation unit.

[0044] refer to Figure 5 , the mud loosening mechanism includes a feed box 11 with a mud flow passage, a rotating shaft connected in the mud flow passage, and a plurality of shifting plates 13 distributed along the axial dir...

Embodiment 2

[0072] The difference between this embodiment and Embodiment 1 is that this embodiment also discloses the following features:

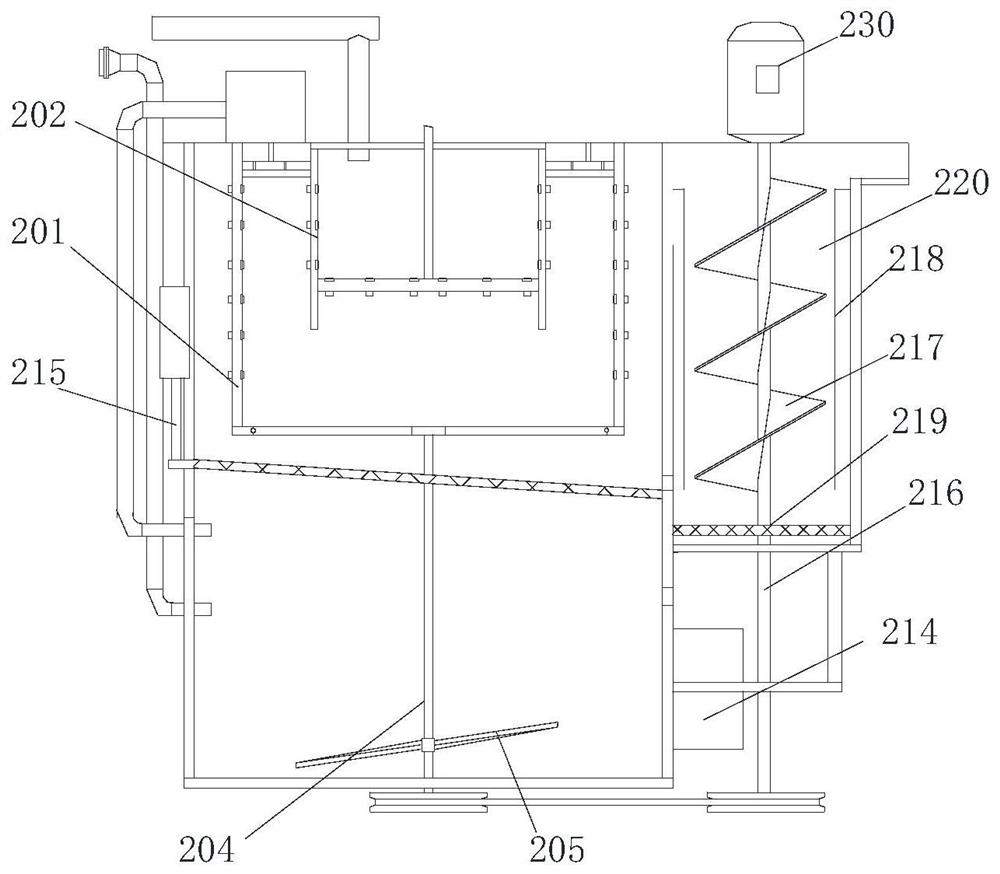

[0073] refer to Figure 7 , the guide screen 207 is movably connected to the outer box 203, and one side of the guide screen 207 is drivingly connected to the piston end of the blanking cylinder 215; the outer box 203 is also provided with The impurity outlet 213, the impurity outlet 213 is located directly below the sewage discharge hole, the guide screen 207 can be driven by the feeding cylinder 215 to the impurity outlet 213, the side of the impurity outlet 213 An impurity collection box 214 is provided.

[0074] It is mentioned in Embodiment 1 that when the impurities in the first inner box 201 need to be taken out, the cylinder 212 needs to be used to control the material baffle plate 206 to move upward. However, due to the deep depth of the first inner box 201 and the limited length of the suspender 209, it is found in actual operation that th...

Embodiment 3

[0079] The difference between this embodiment and the foregoing embodiments is that this embodiment also discloses the following features:

[0080] refer to Figure 10 , the dredging device is installed on the bow of the hull, the water weed removal device is installed on the stern of the hull, the water tank removal device includes a salvage unit 4, a cutting unit, a crushing unit and a grass box 6; the grass box 6 There are two material outlets, both of which are closed by control valves, and one of the material outlets extends into the first inner box 201 through a forage pipe, and a material pump 56 is installed on the forage pipe.

[0081] The salvage unit 4 is used to salvage aquatic plants on the river surface and send them into the grass collecting box 6 . In this process, the aquatic plants are cut by the cutting unit to reduce the size of the strip-shaped aquatic plants, and then the aquatic plants are crushed by the crushing unit to further reduce the size of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com