Composite fracturing and uniform permeability-improving method for tree-like boreholes in coal seams of underground coal mine

A composite fracturing and coal seam technology, applied in drilling equipment and methods, earthwork drilling, drilling equipment, etc., can solve the problems of high cost, poor effect, low efficiency, etc., and achieve large drilling size and good rock breaking effect. , the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

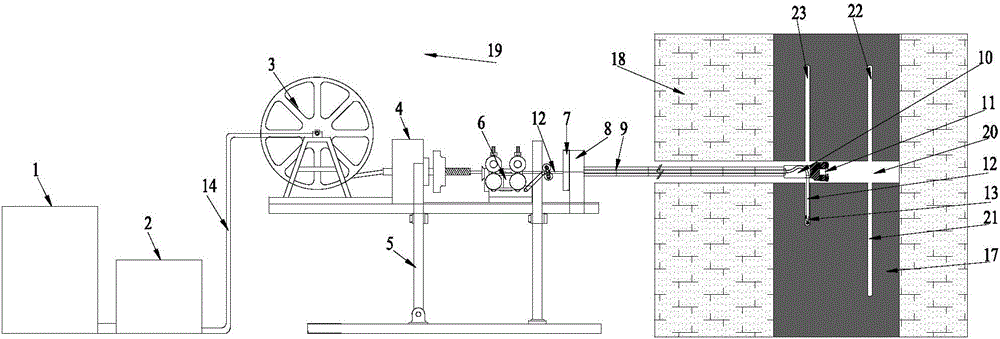

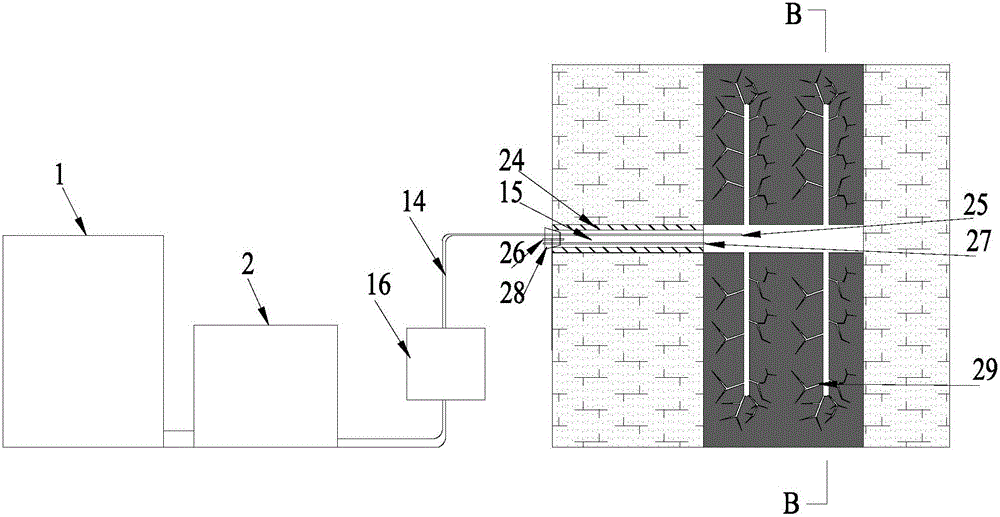

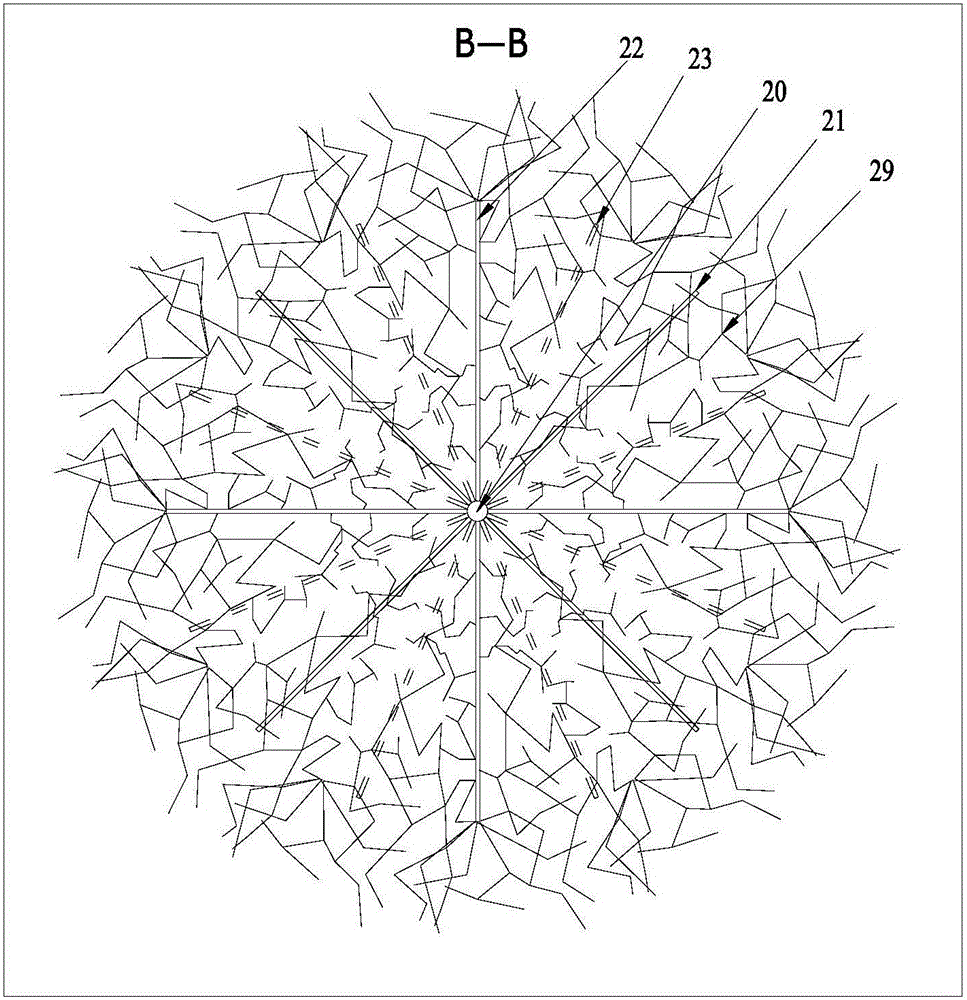

[0061] Embodiment 1: see figure 1 , figure 2 and image 3 In the following, taking drilling into a multi-layer sub-hole network as an example, the detailed process of the method for uniform anti-permeability enhancement of tree-shaped coal seam drilling and fracturing in underground coal mines of the present invention will be described in detail. The thickness of the coal seam is 5m, two layers of sub-hole networks are designed, the distance between the sub-hole networks is 2m, and the upper layer of sub-hole networks is 1.5m away from the roof; because the coal is hard and the buried depth is medium, the design drilling pressure is 32Mpa, and the angle between the sub-holes 45°, the sub-hole length is 18m, and the fracturing pressure is 30Mpa. The specific operation steps are as follows:

[0062] (1) Drill the pilot hole in advance to the coal seam (17) in the rock roadway (19) to form the mother hole (20) of tree-shaped drilling. Drilling needs to be drilled to the roof...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Turning radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com