Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Realize the shredding function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

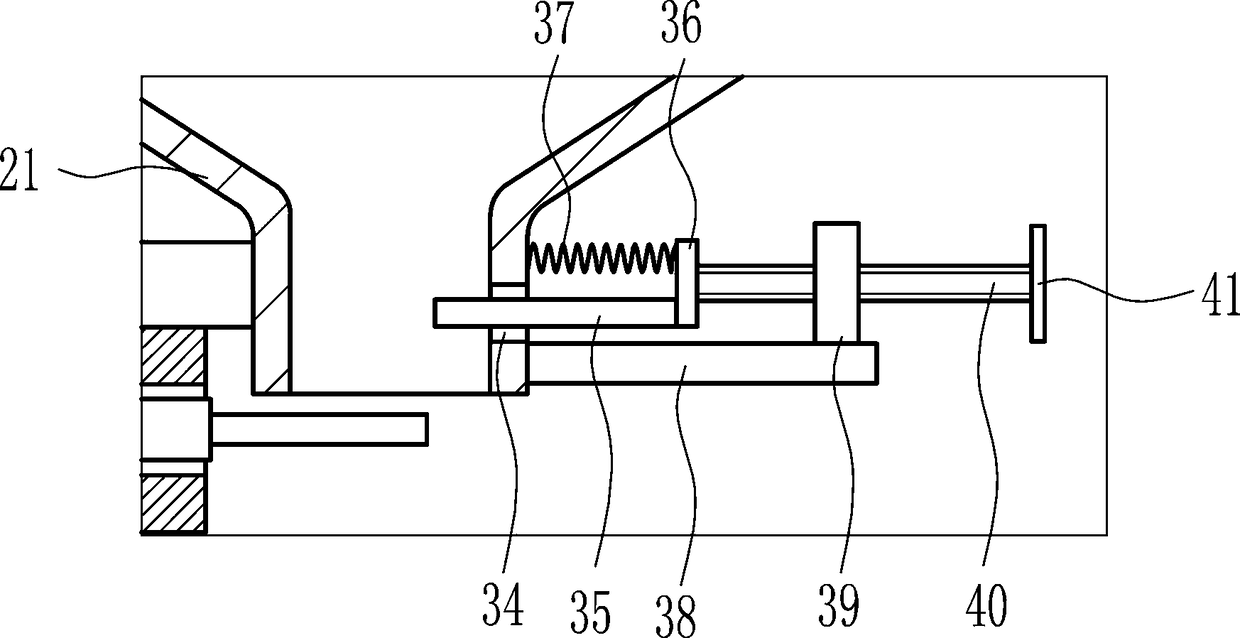

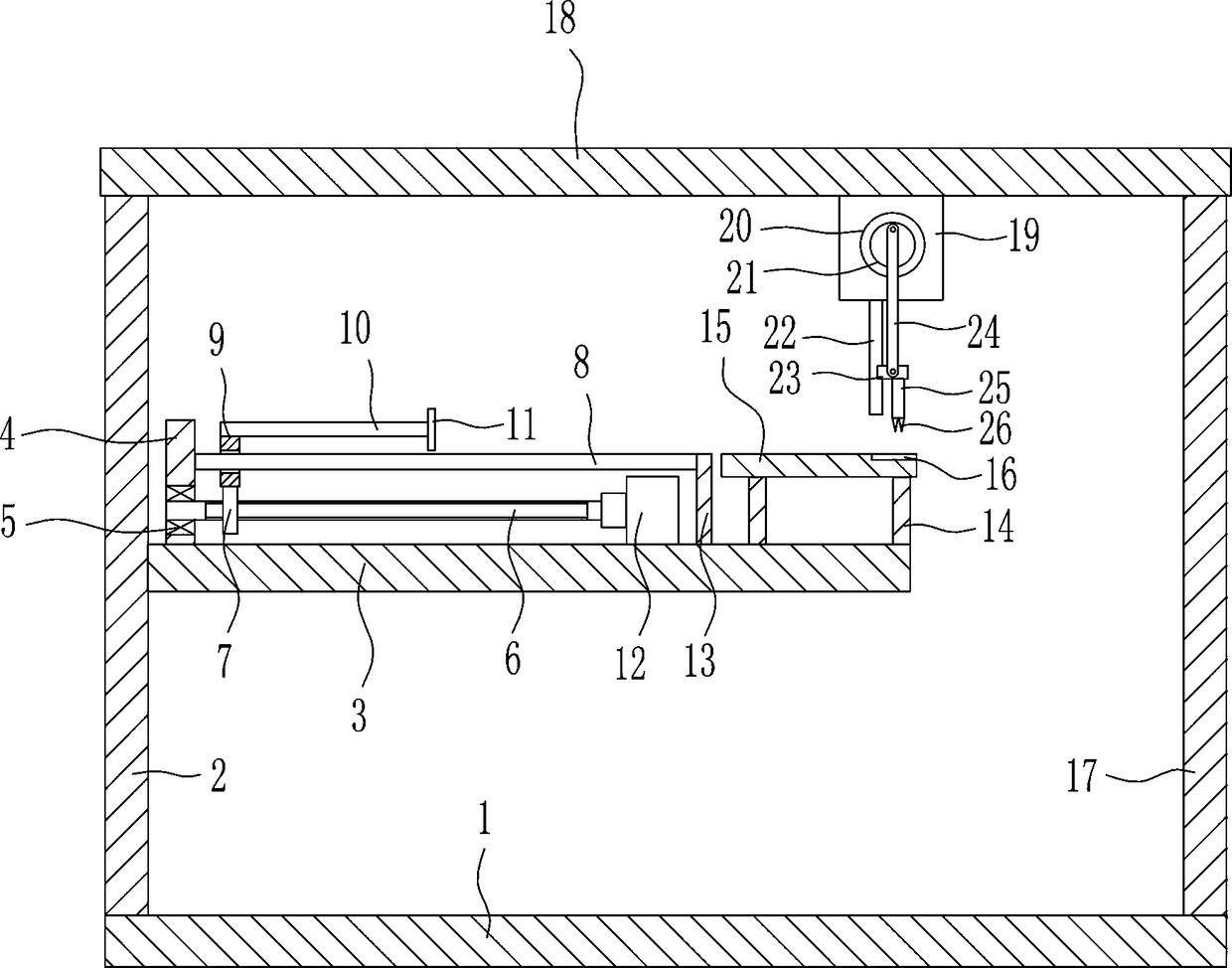

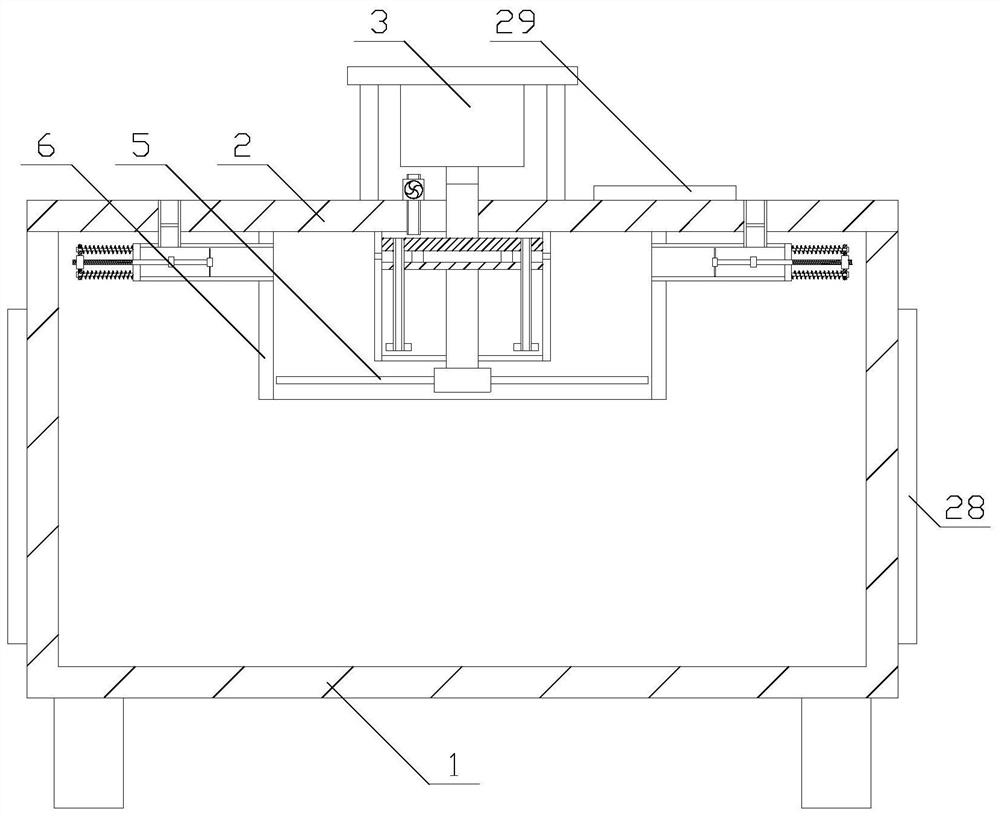

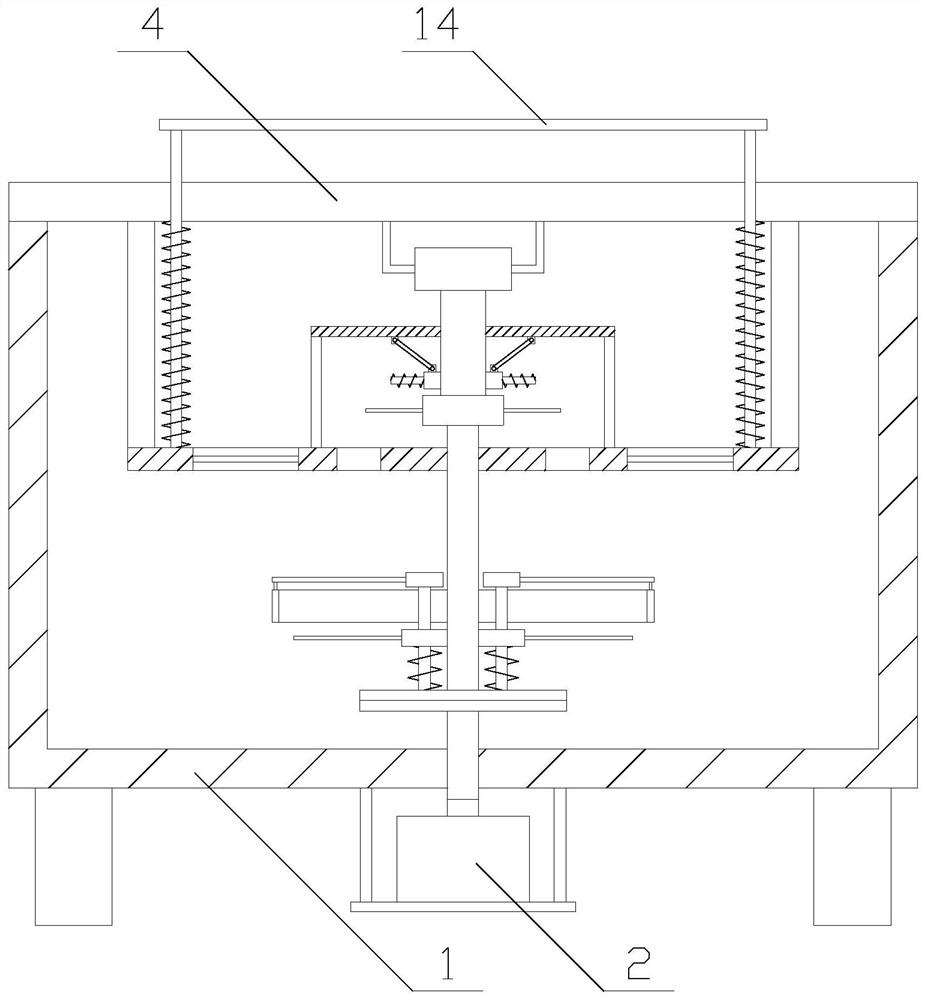

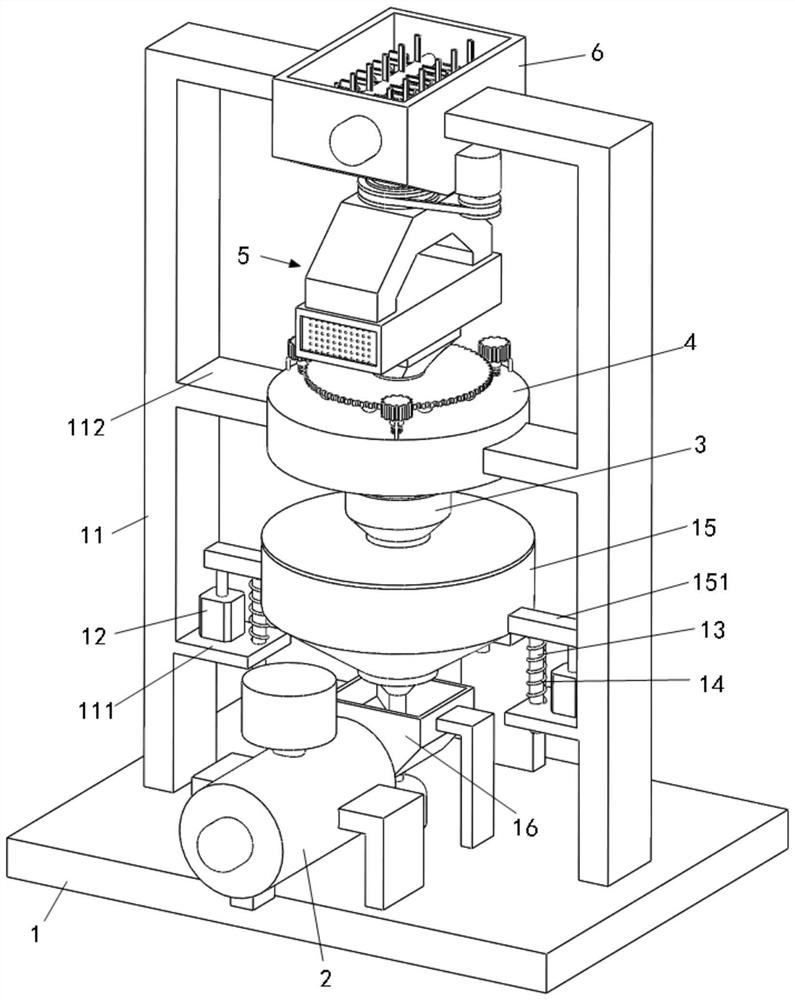

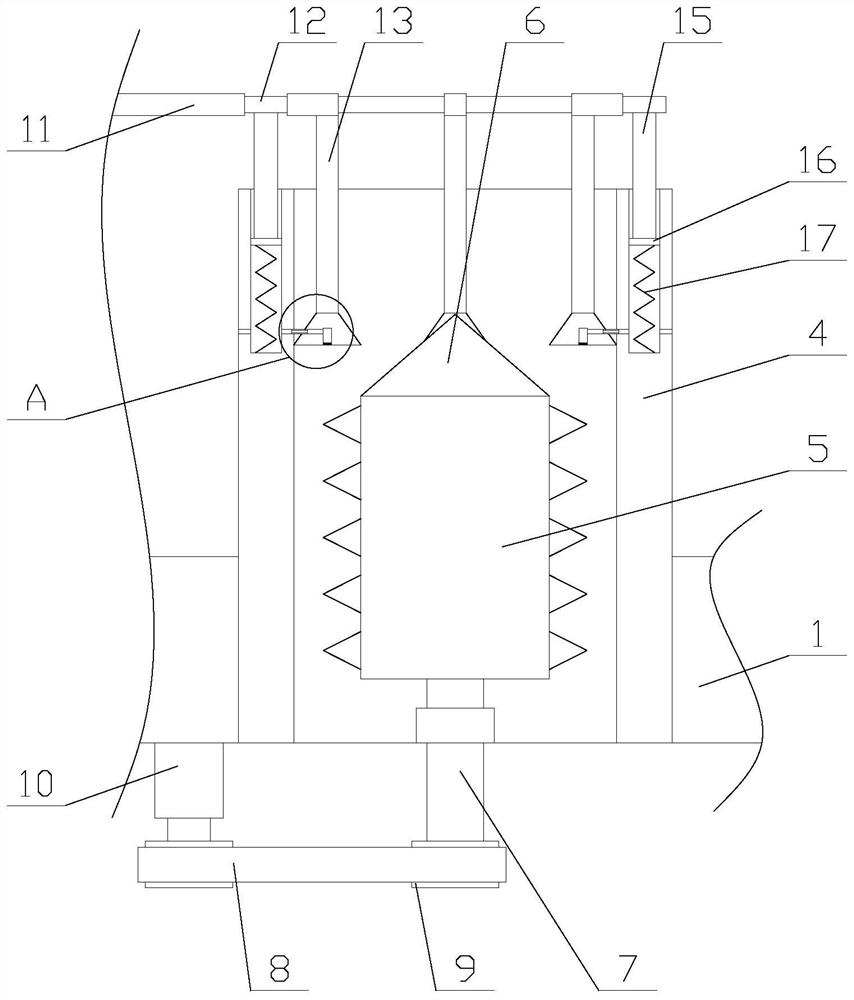

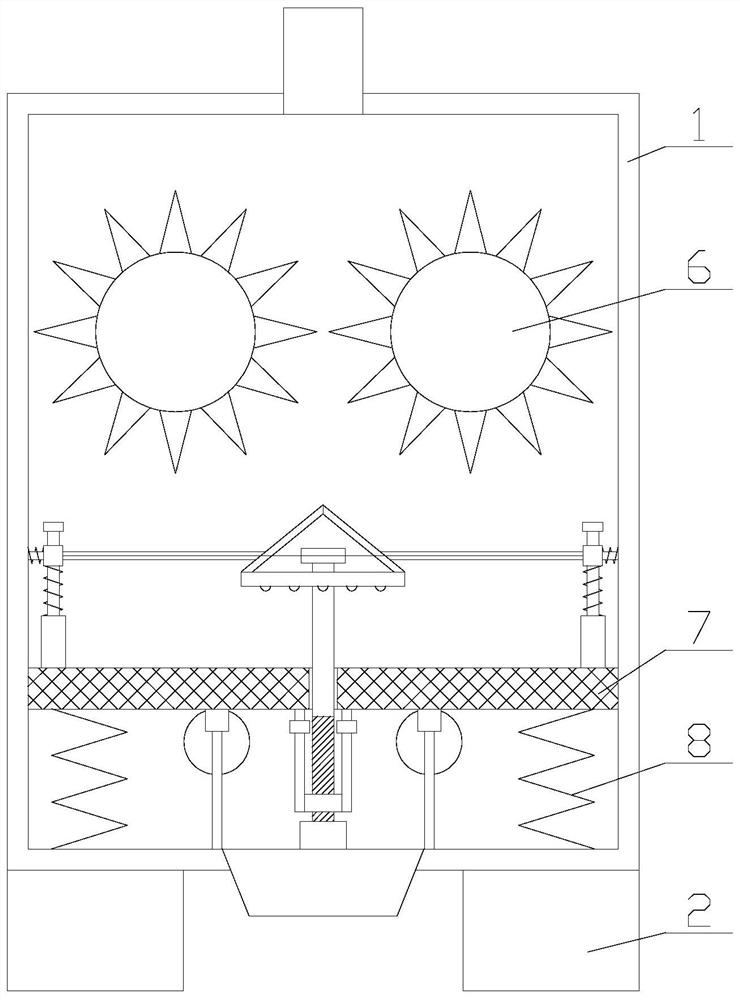

Gypsum crushing device for building

InactiveCN108295930ARealize the shredding functionRealize the function of controlling the blankingGrain treatmentsGypsumCivil engineering

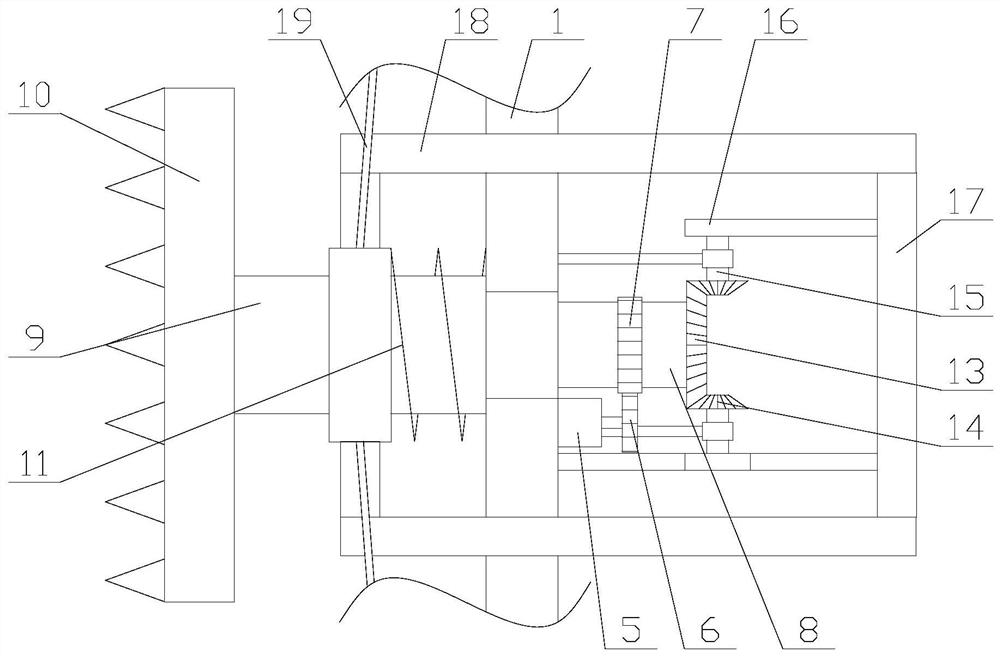

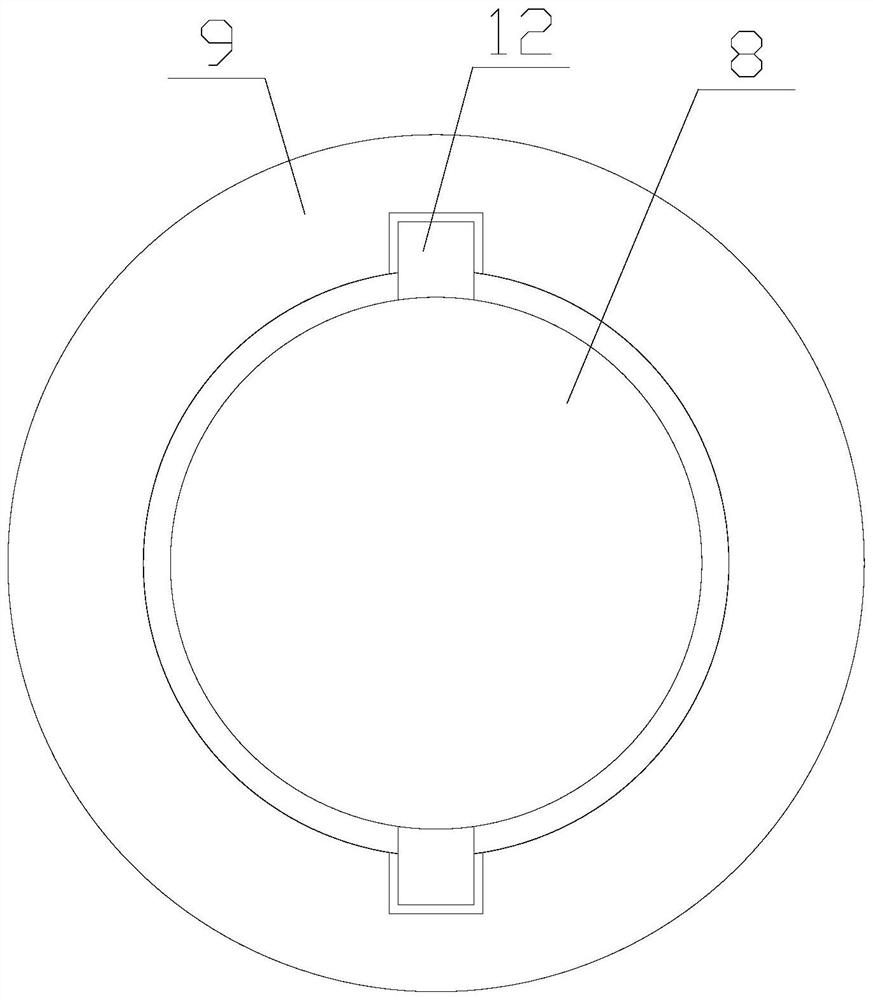

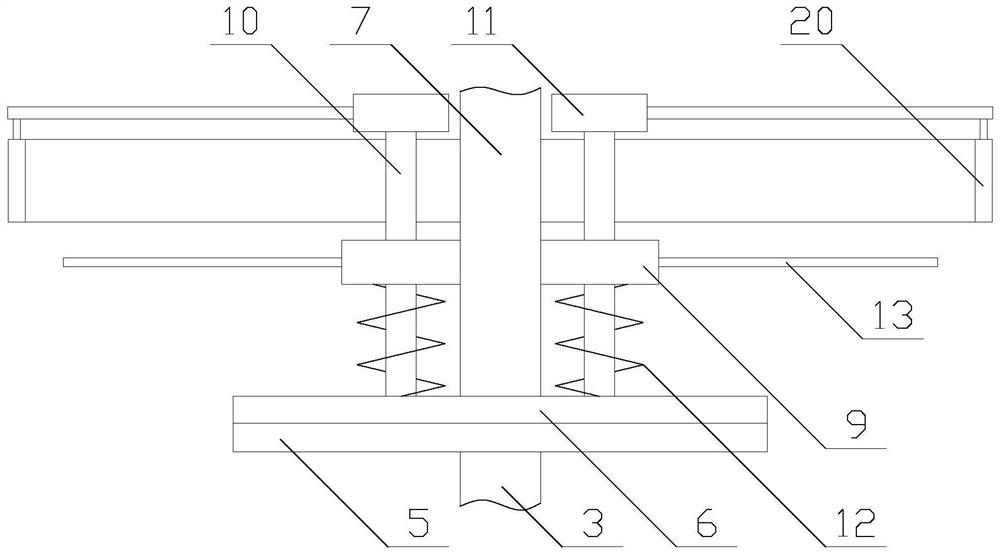

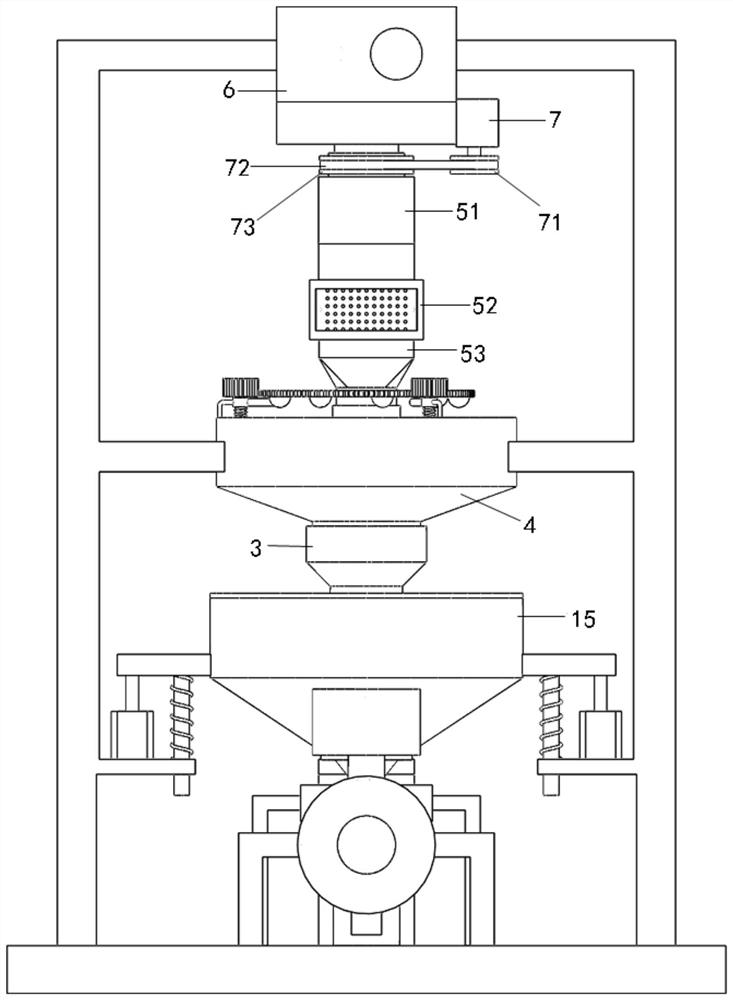

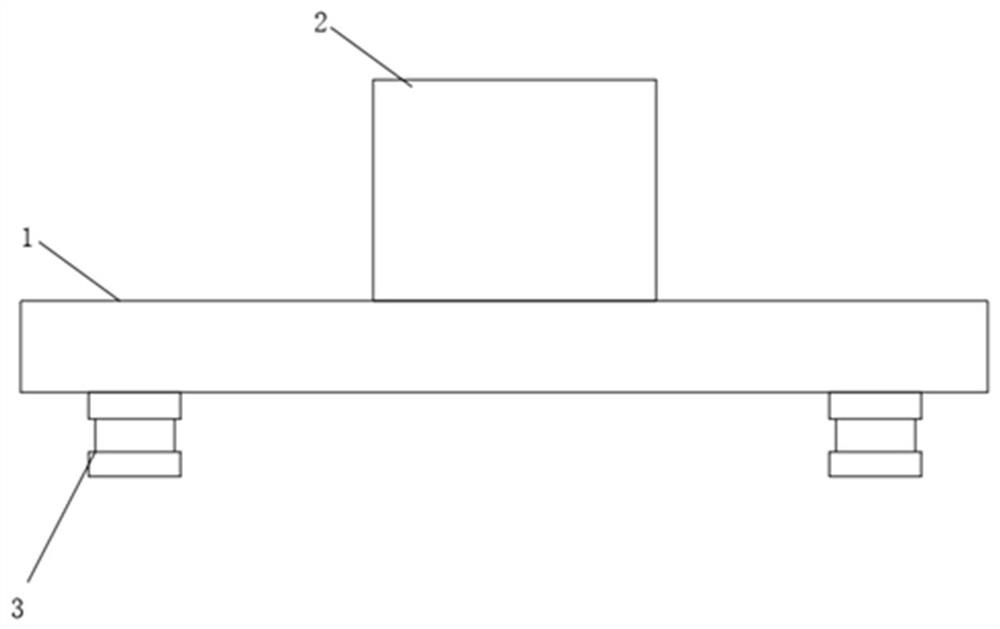

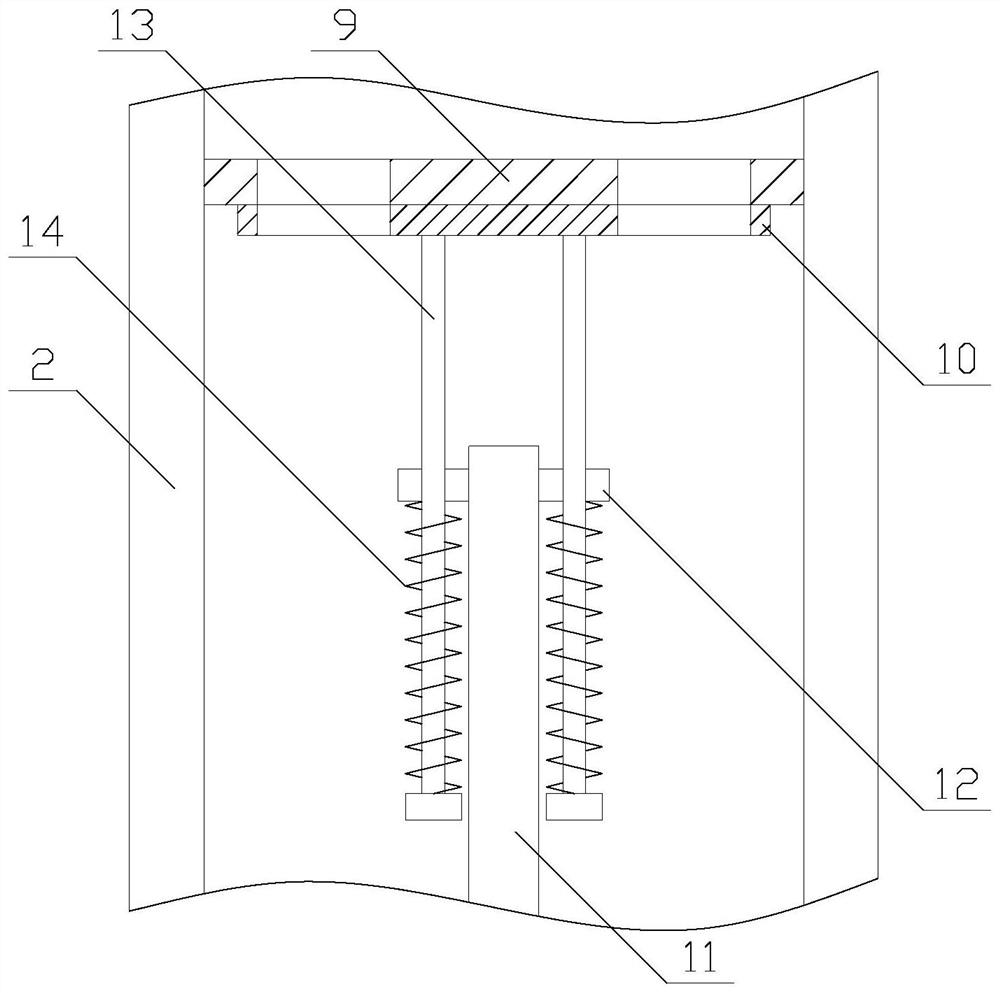

The invention relates to a crushing device, in particular to a gypsum crushing device for a building. The invention aims to provide the gypsum crushing device for the building which is time-saving andlabor-saving and is uniform in crushing. In order to solve the technical problem, the invention provides the gypsum crushing device for the building. The device comprises a base, a first support, a second support, a first nut, a first screw rod, a first rotary table, a sliding rail, a sliding block, a first supporting rod, a first crushing plate, a second supporting rod and the like, wherein thefirst support is fixedly connected to the right side of the upper part of the base, a second support is fixedly connected to the top end of the first support, the first nut is fixedly connected to theright side of the upper portion of the second support, and the first screw rod is matched in the first nut. According to the gypsum crushing device for building, the function of crushing the gypsum for the building is realized, not only the function of rapidly crushing gypsum is realized, but also the function of controlling discharging of a funnel is achieved.

Owner:罗九莲

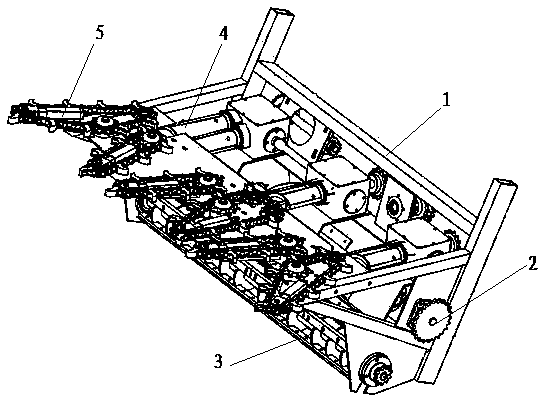

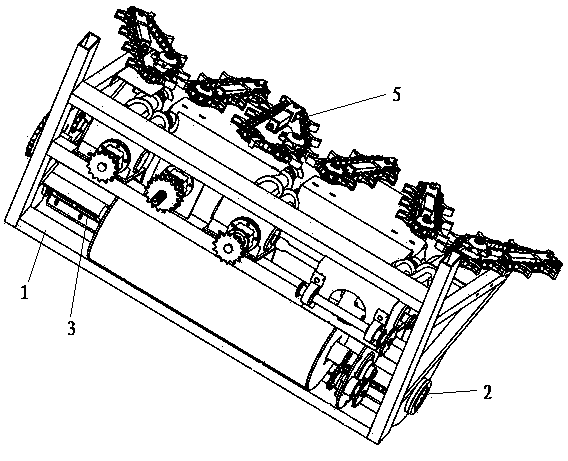

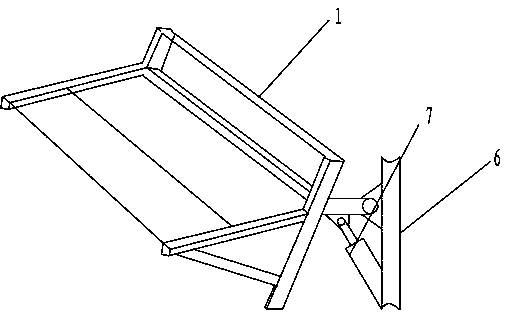

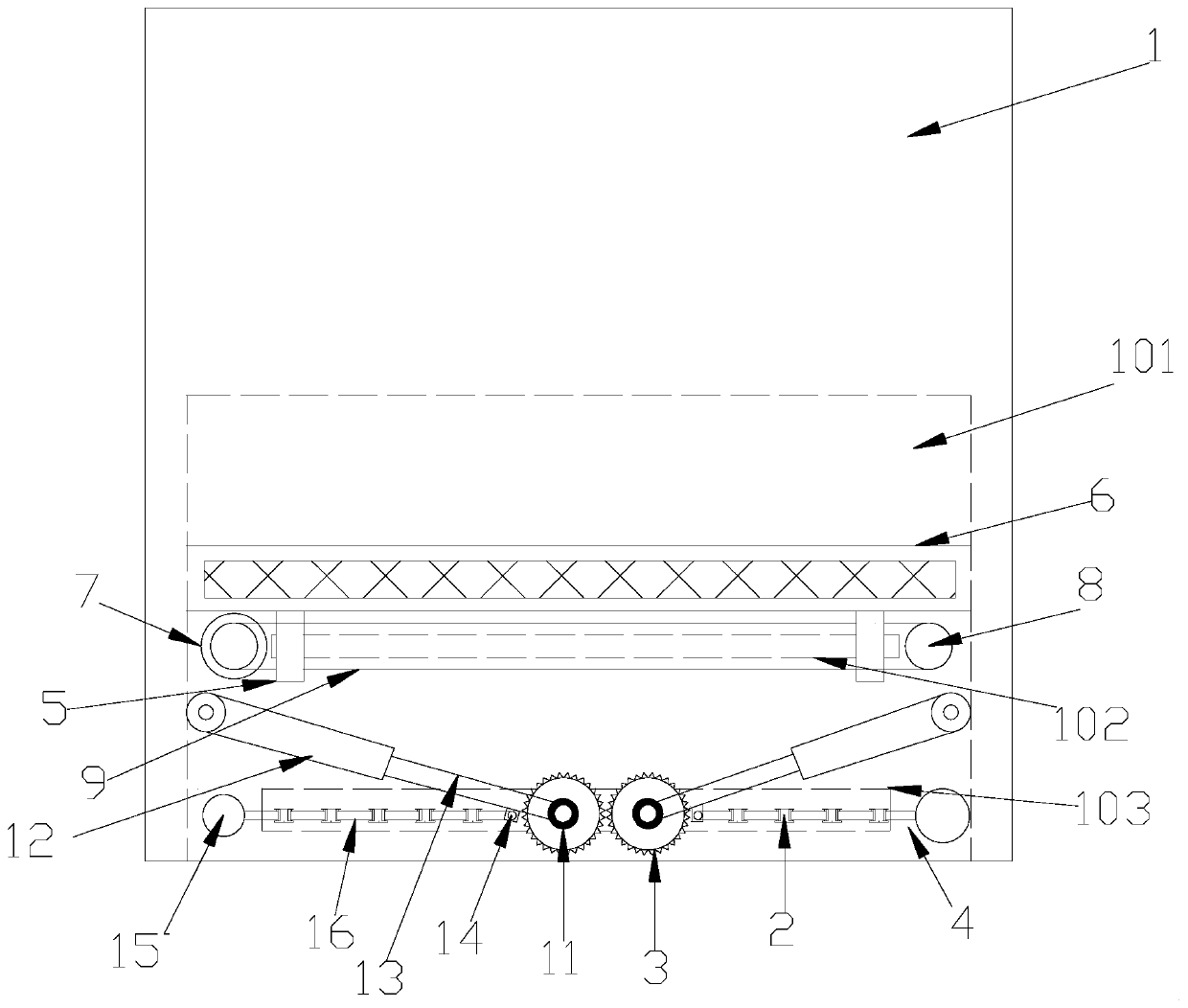

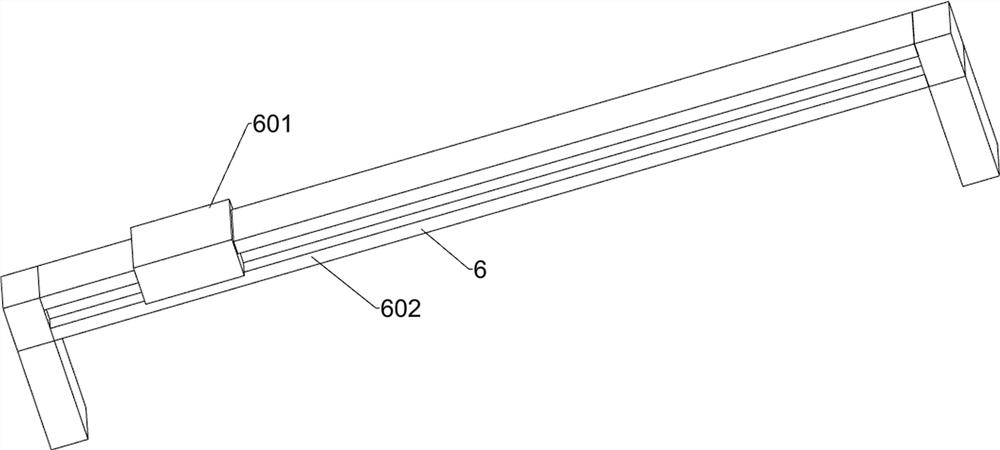

Corn harvester header

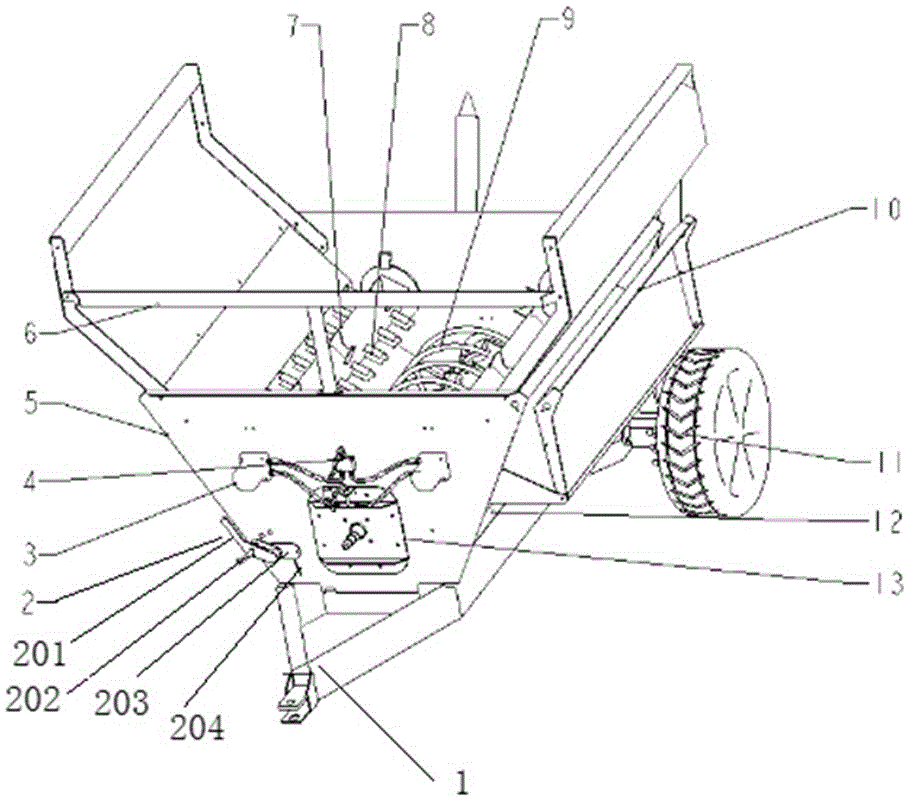

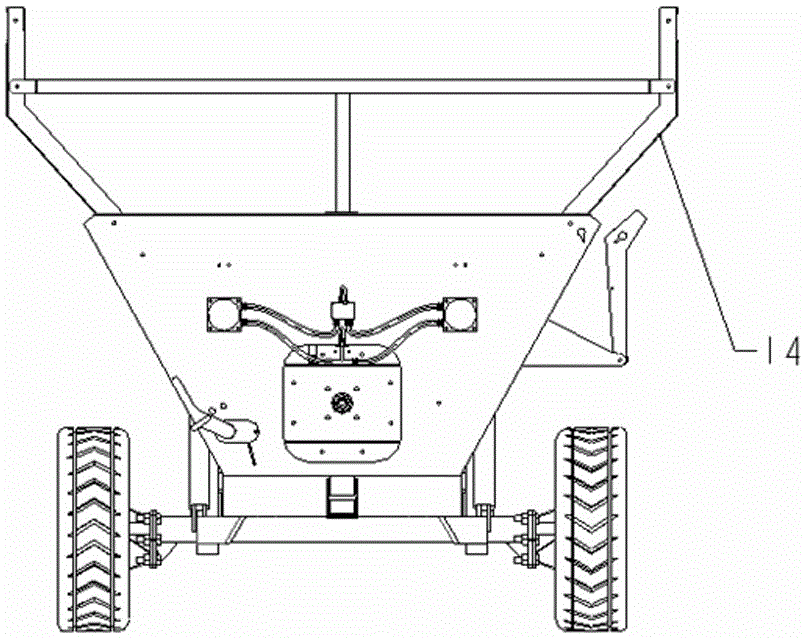

The invention discloses a corn harvester header, and relates to the technical field of corn combine harvesters. The corn harvester header comprises a header frame, more than two groups of ear picking devices are equidistantly arranged on a main plane of the header frame, the head of each ear picking device is connected with a feeding device through a spline, the ear picking devices are connected through a universal coupling with a spider, and a suspension cutting device is arranged below the front of the ear picking devices. The corn harvester header can realize feeding, ear picking and crushing functions and is simple in structure, reasonable in arrangement, small in overall size, convenient and fast in harvesting, fine in effect and wide in application range, and various portions are compact.

Owner:赵县金利机械有限公司

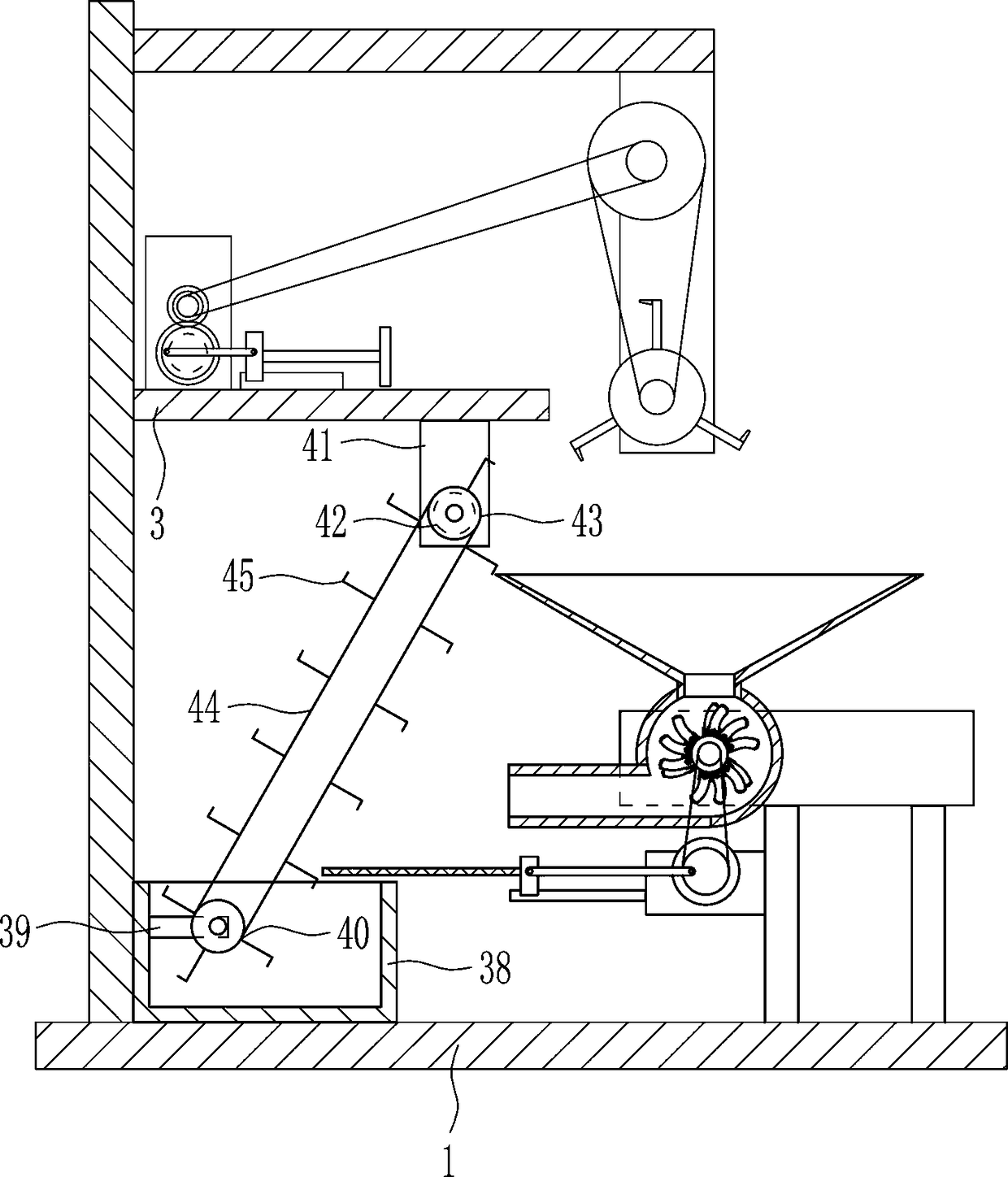

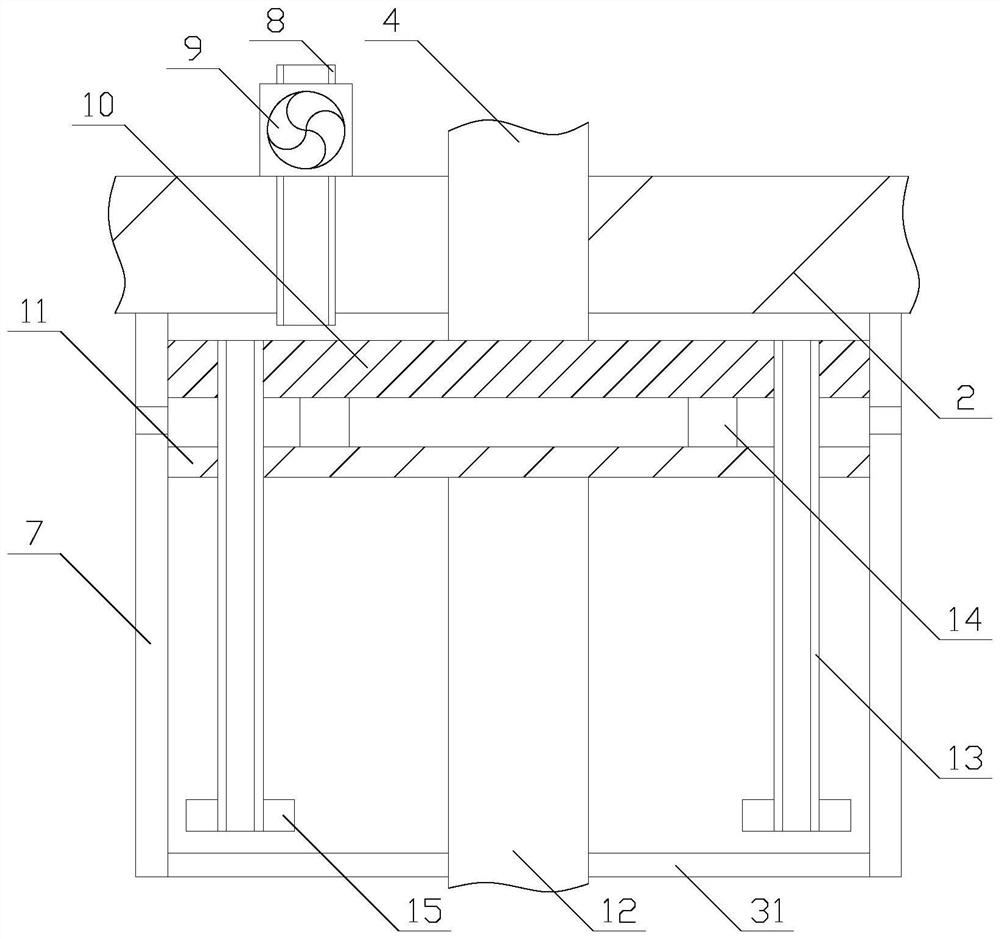

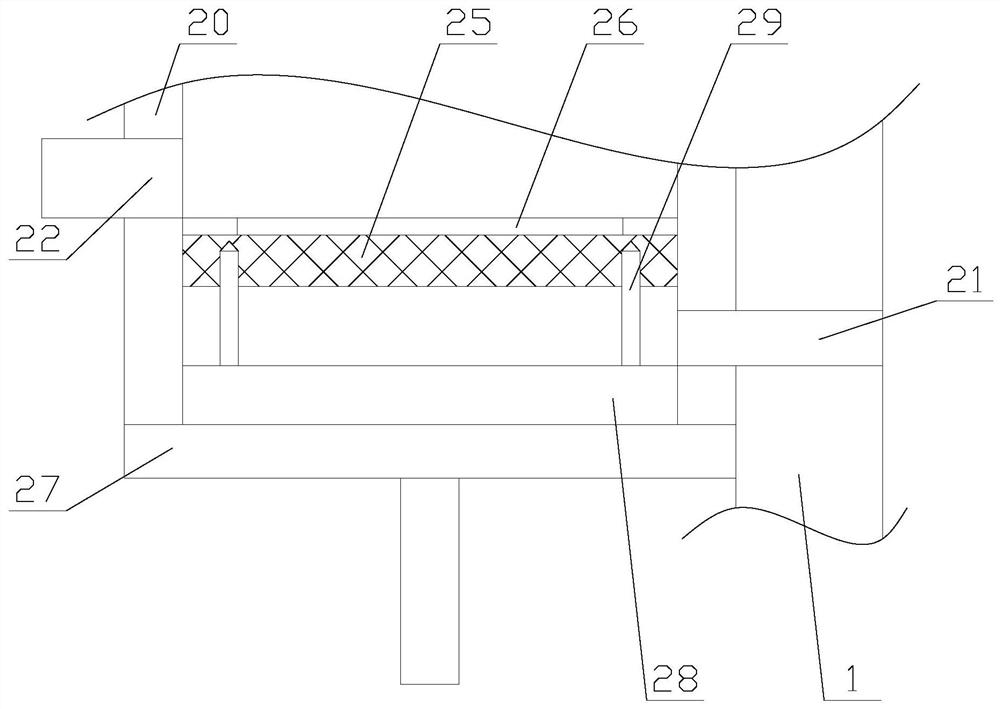

Bamboo crushing device for paper making industry

InactiveCN108360278AEasy to cutReach the filter functionRaw material divisionPulp and paper industry

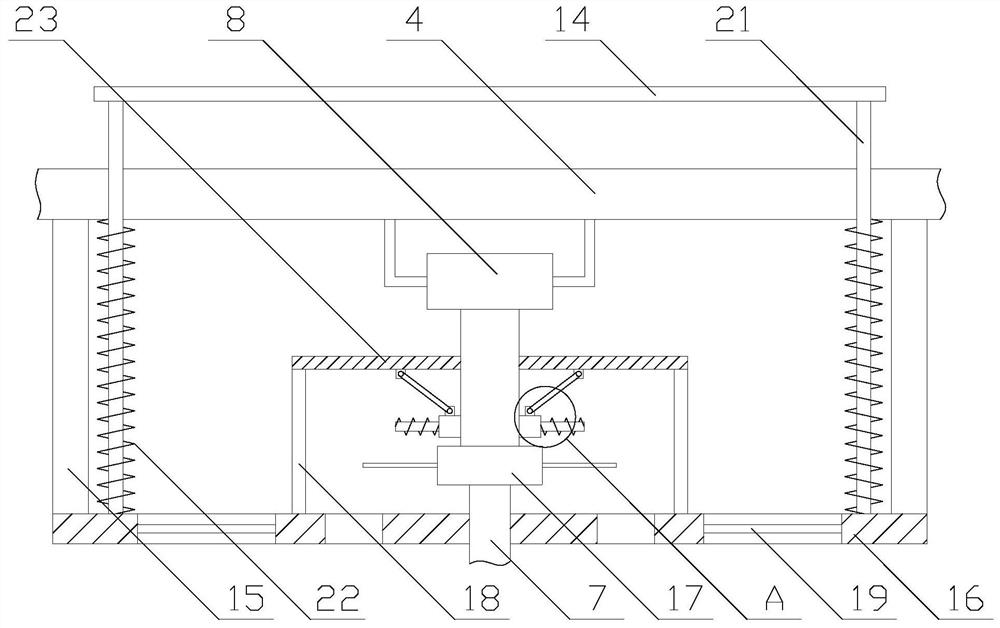

The invention relates to a crushing device, and particularly relates to a bamboo crushing device for paper making industry. The technical problem to be solved by the invention is to provide a bamboo crushing device with high working efficiency and uniform crushing for paper making industry. In order to solve the technical problem, the invention provides the bamboo crushing device for papermaking industry. The bamboo crushing device comprises a base, a first support frame, a second support frame, a first support rod, a bearing, a screw rod, a nut, a sliding rod, a sliding sleeve, a second support rod, a push plate, a first motor, a third support rod and the like; the first support frame is fixedly connected to the left side of the upper part of the base; a second support frame is fixedly connected to the right side of the first support frame; a first support rod is fixedly connected to the left side of the upper part of the second support frame; the bearing is embedded in the first support rod; and the screw rod is in interference connection with the inner part of the bearing. According to the bamboo crushing device provided by invention, the function of cutting bamboos is realized,the function of rapidly cutting the bamboos is realized, and the function of crushing the bamboos is also realized.

Owner:台州市黄岩赵兴工艺品有限公司

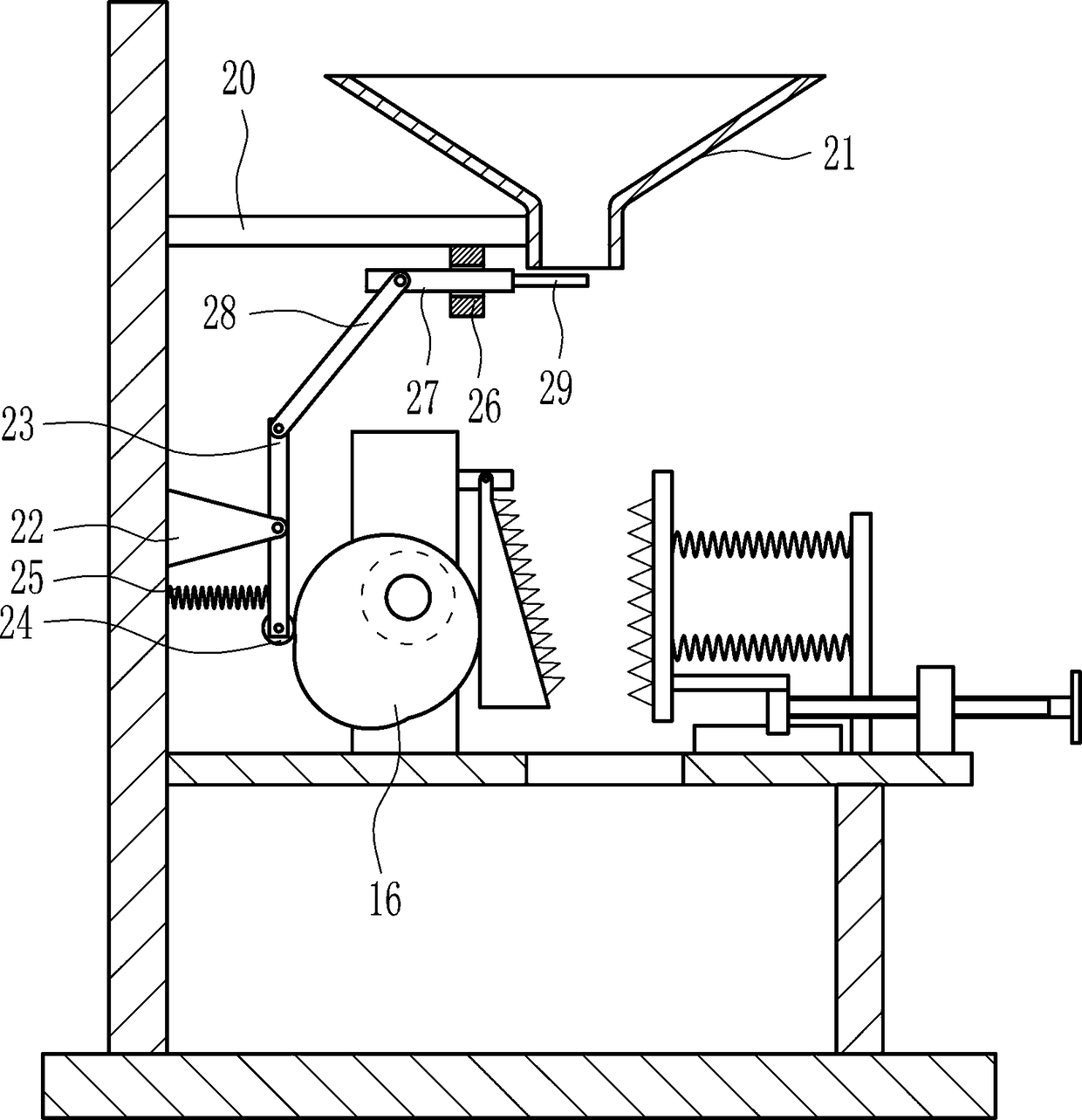

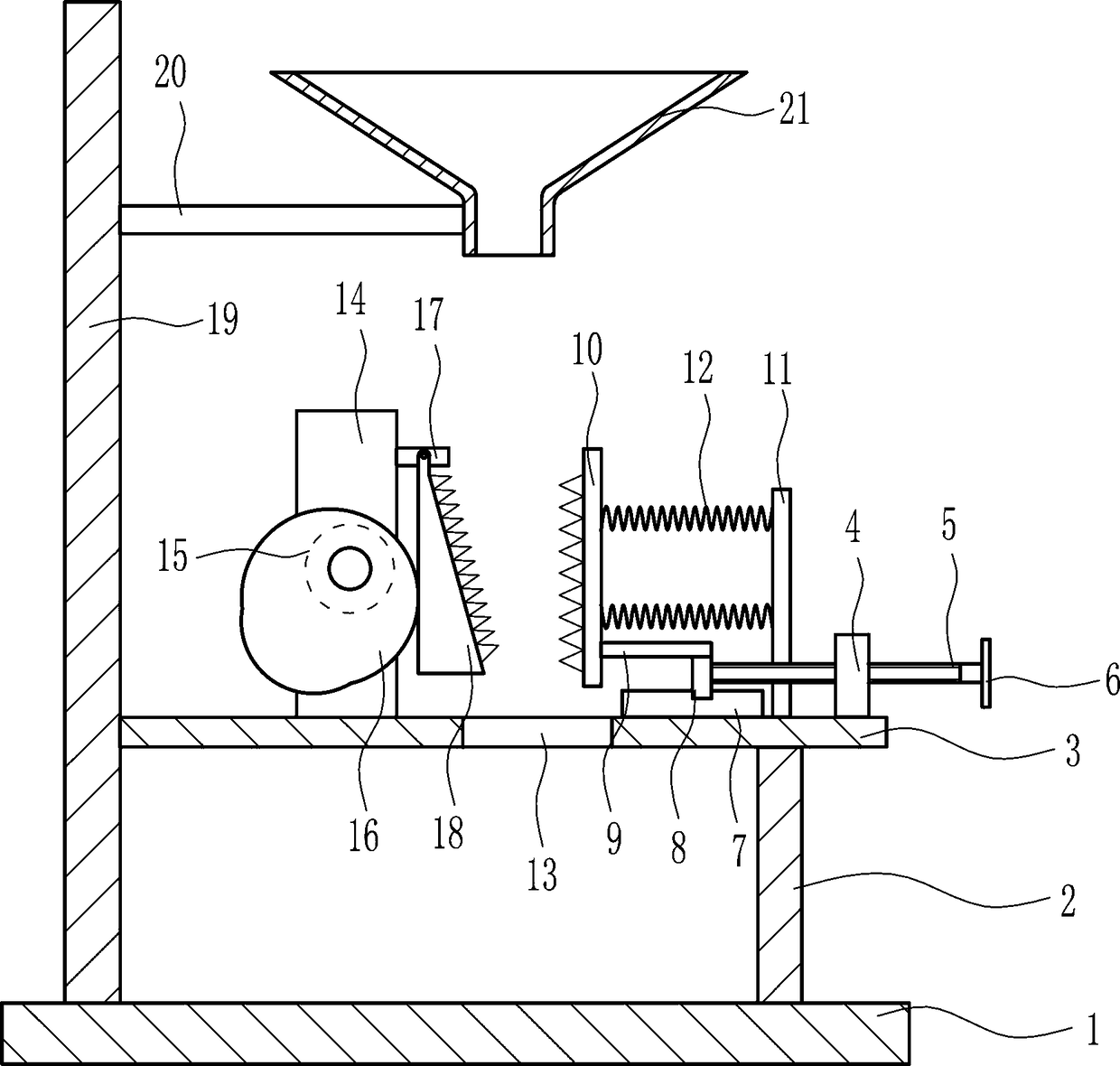

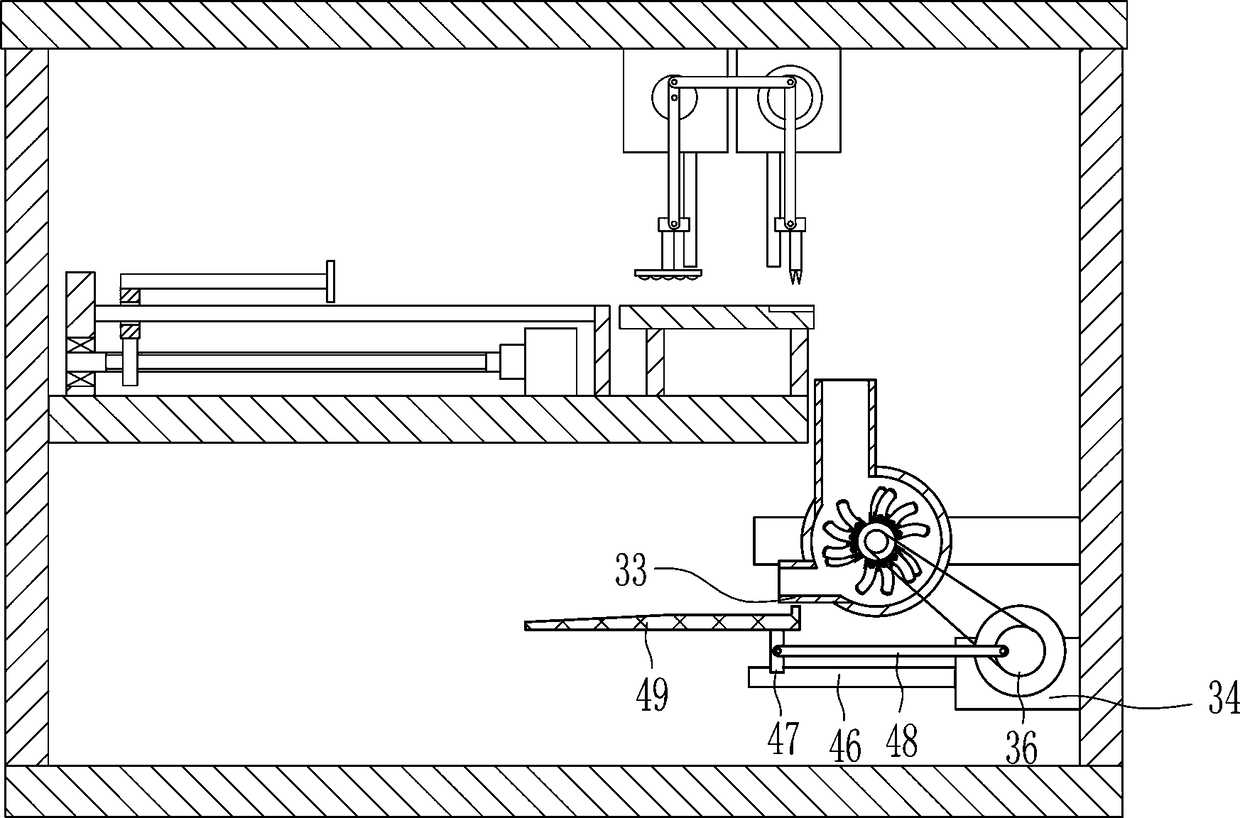

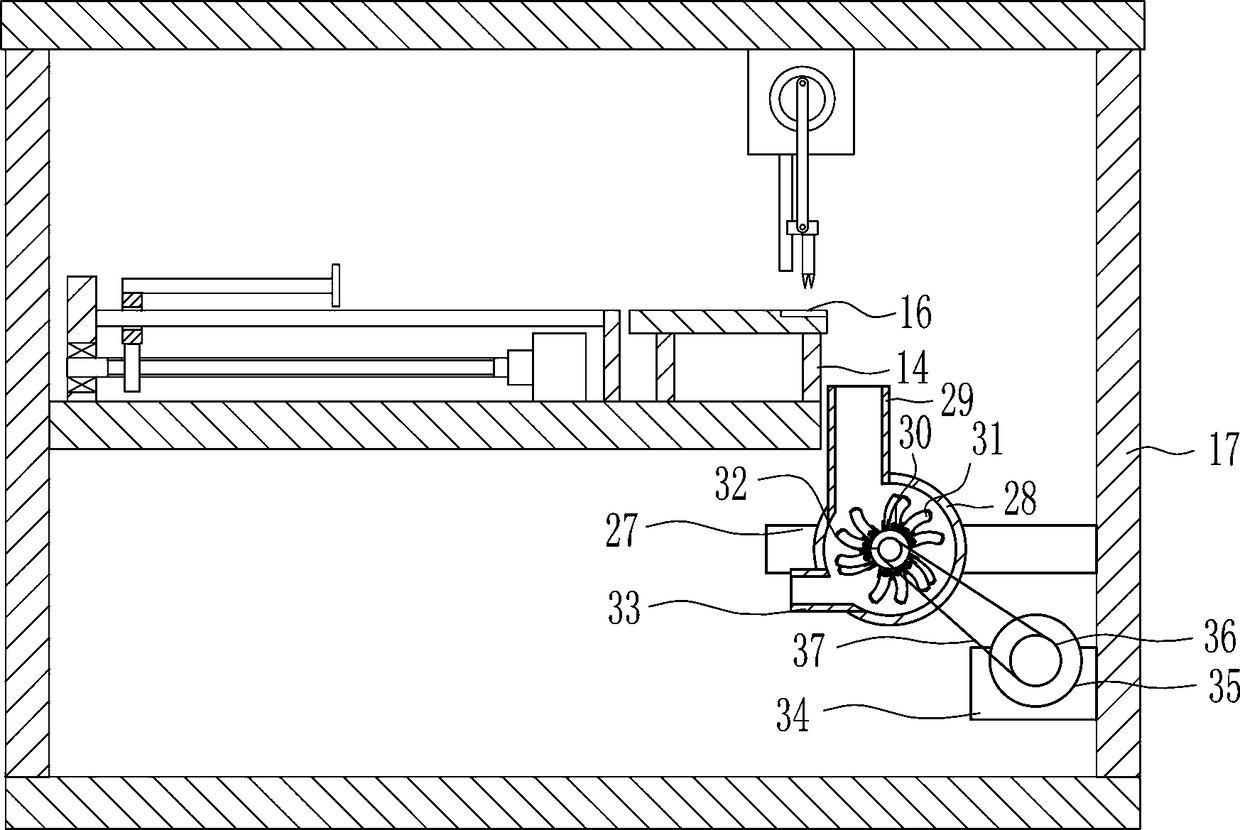

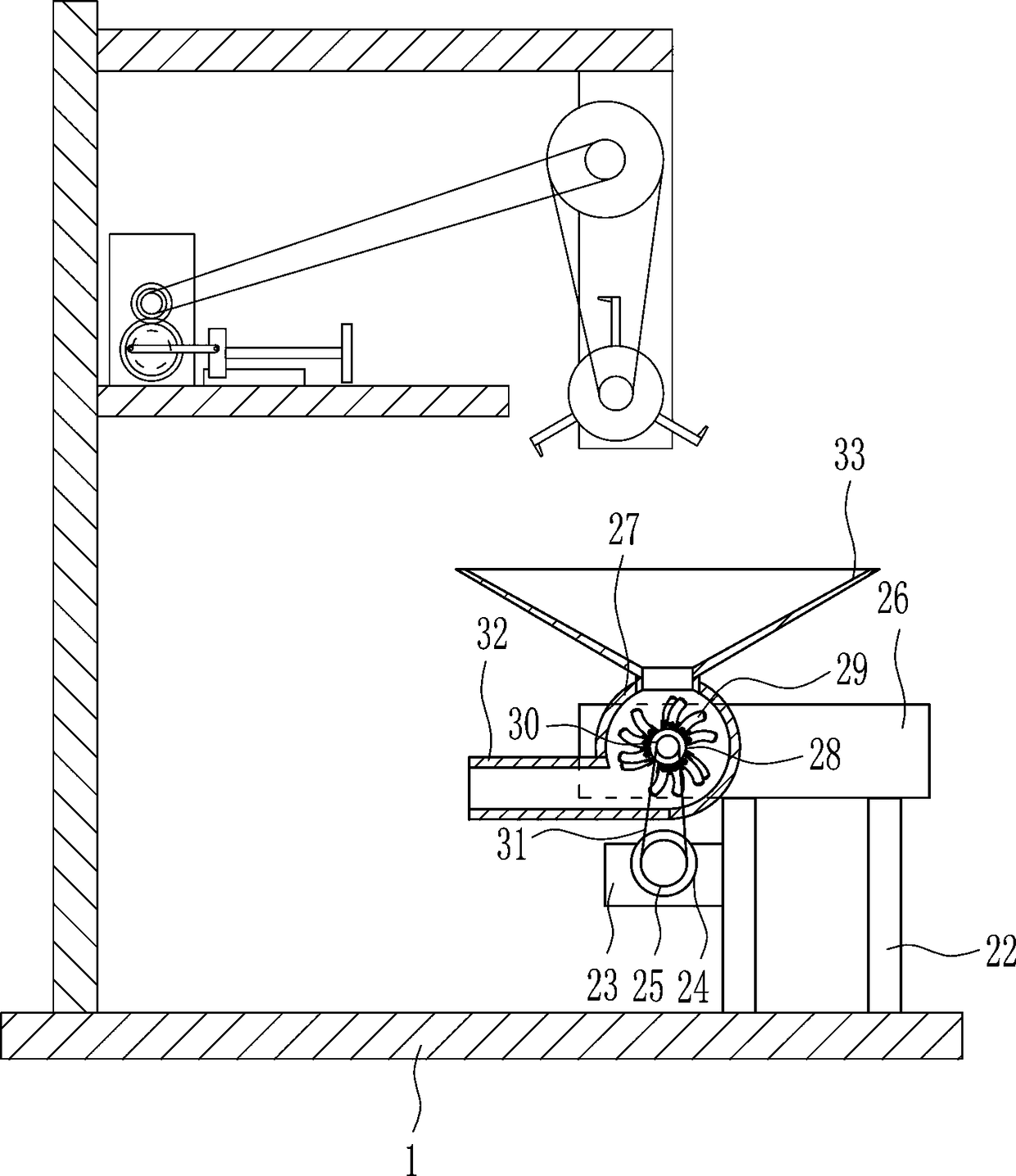

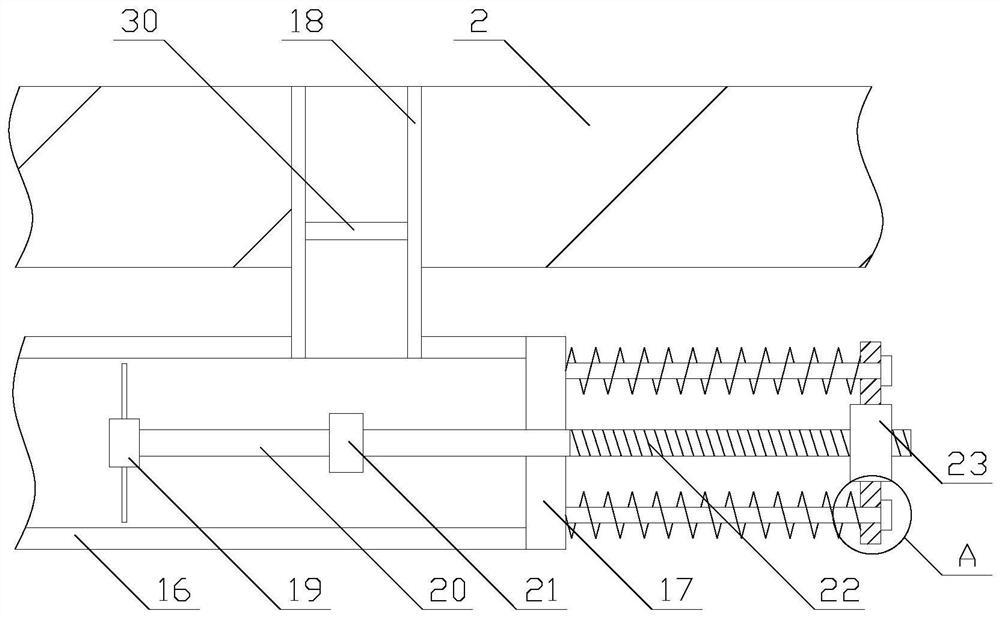

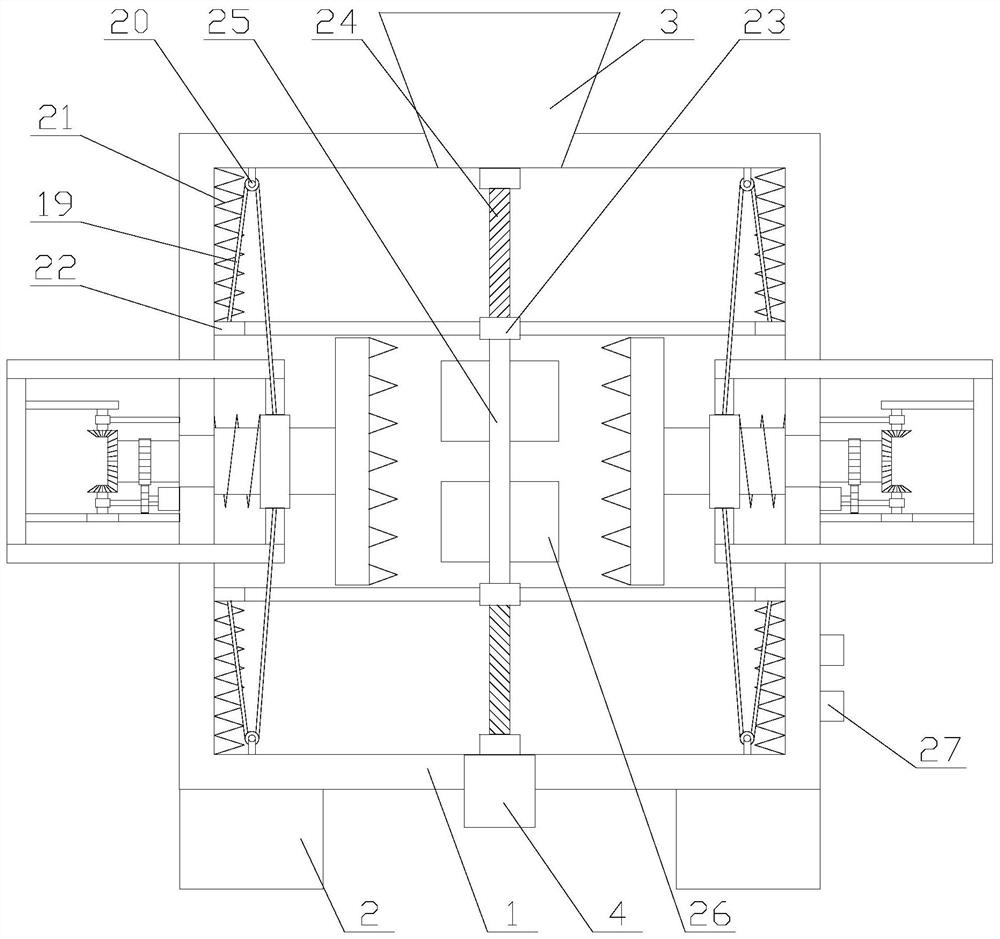

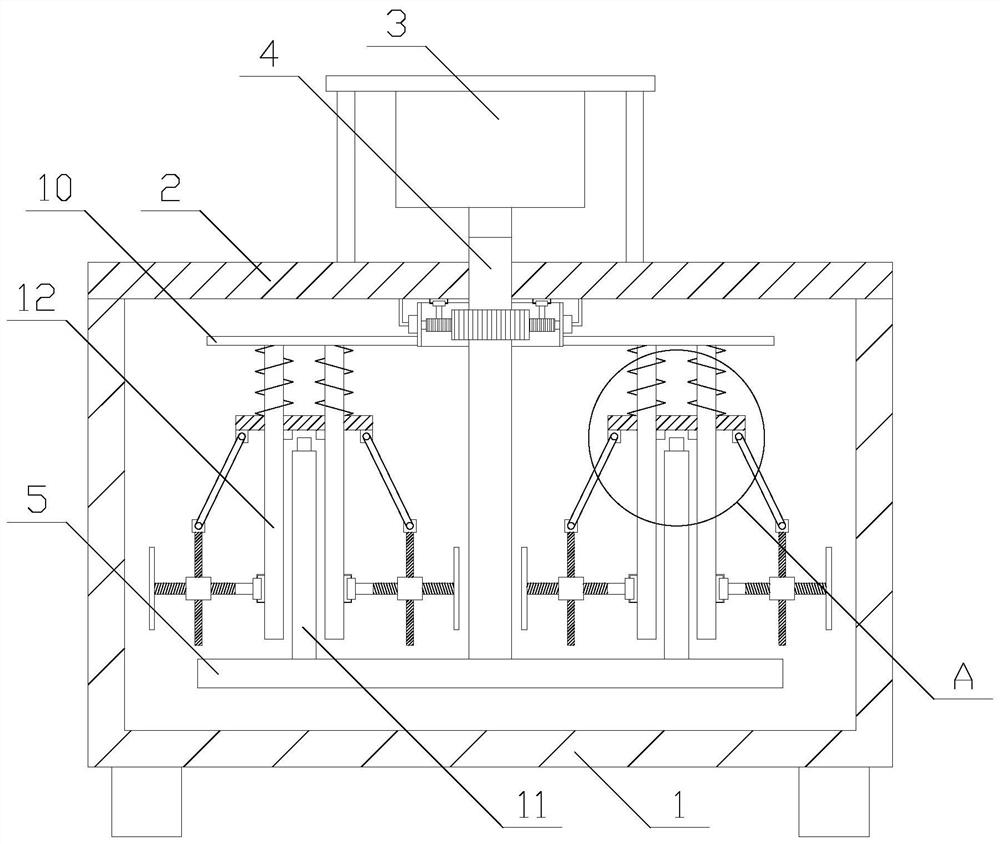

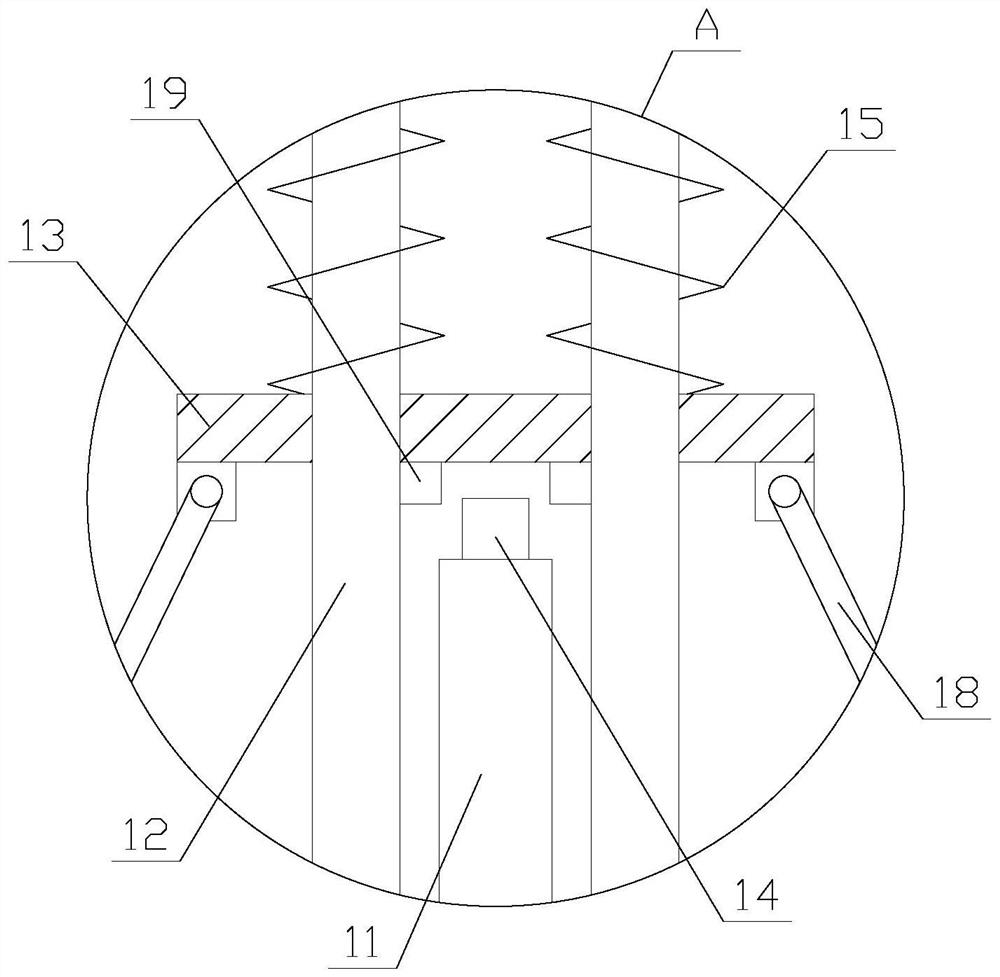

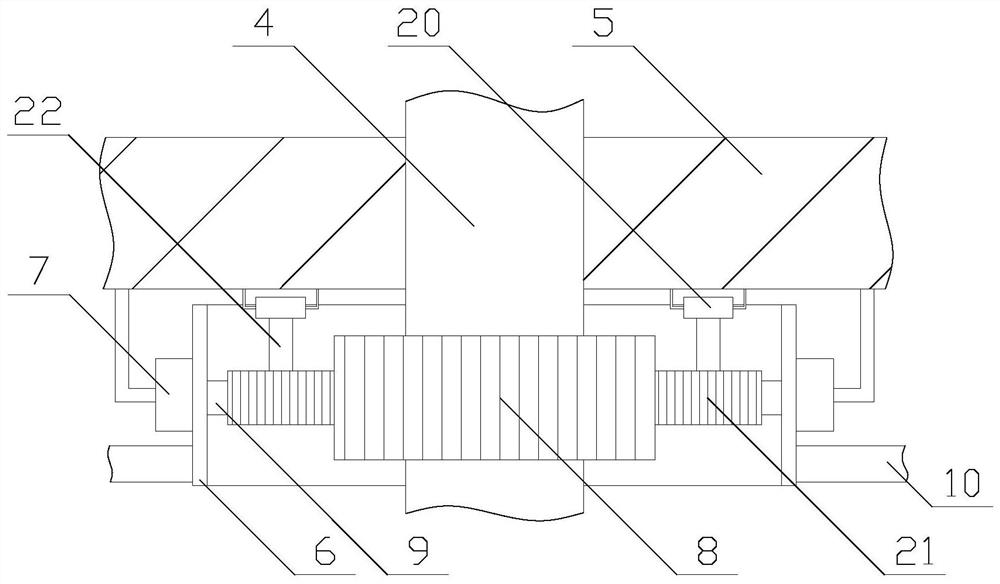

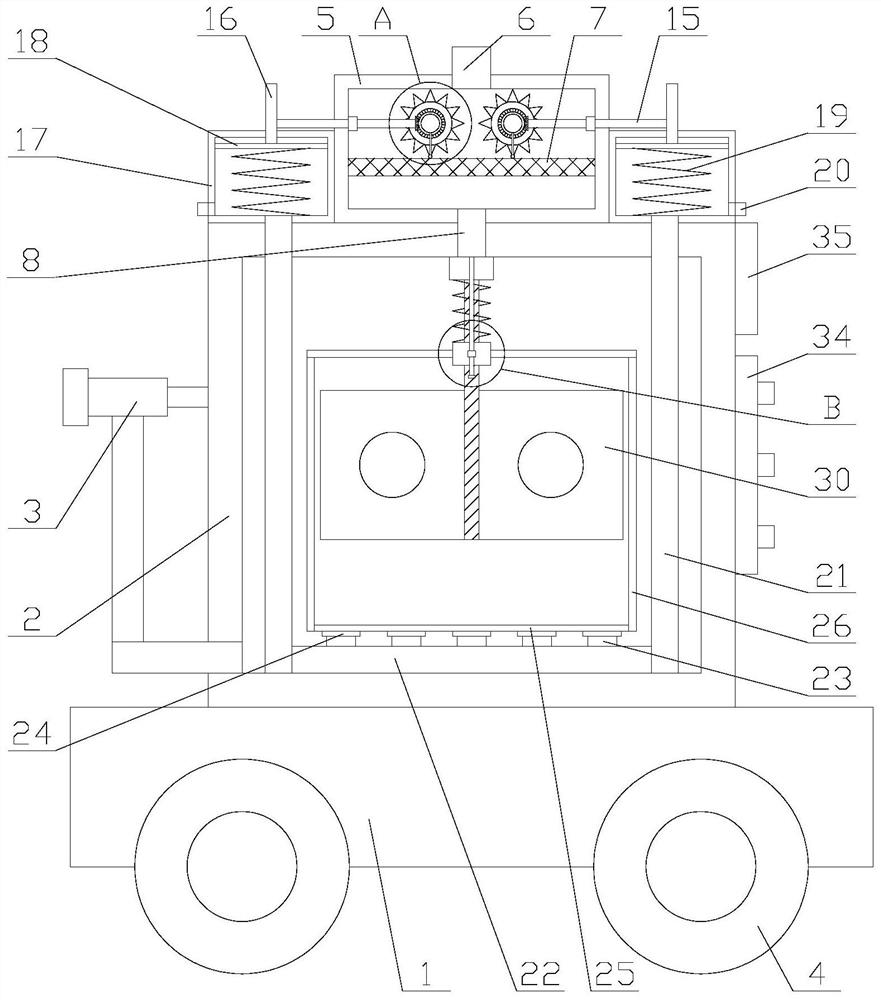

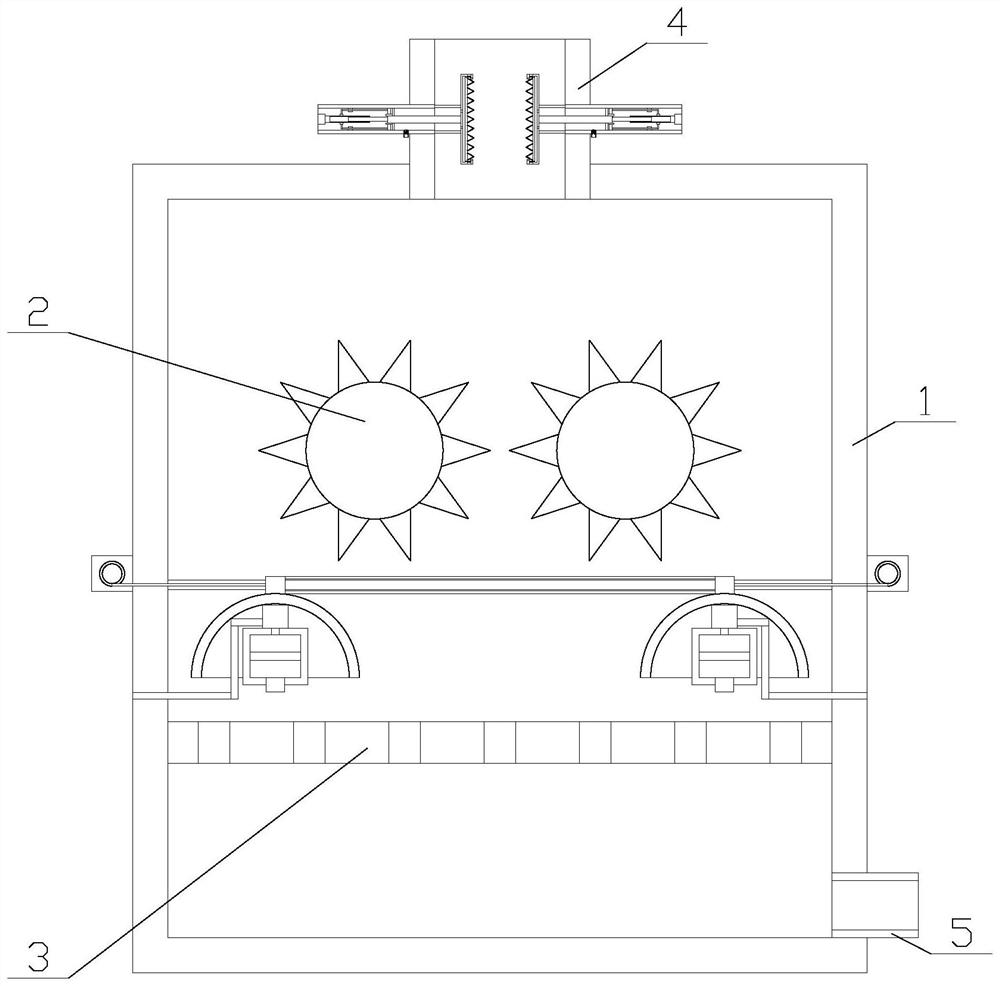

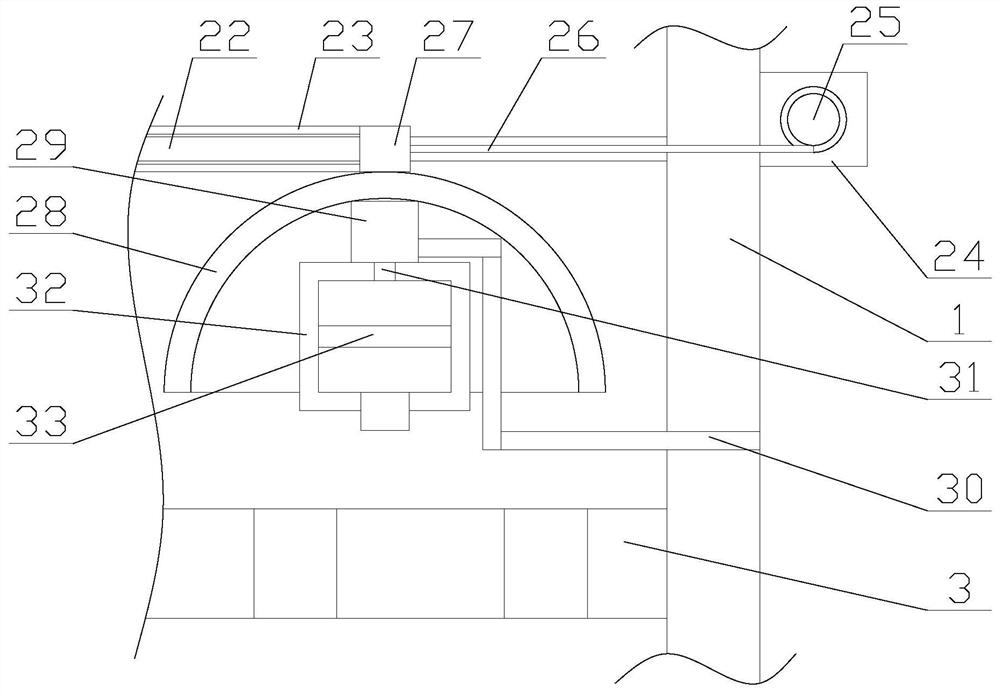

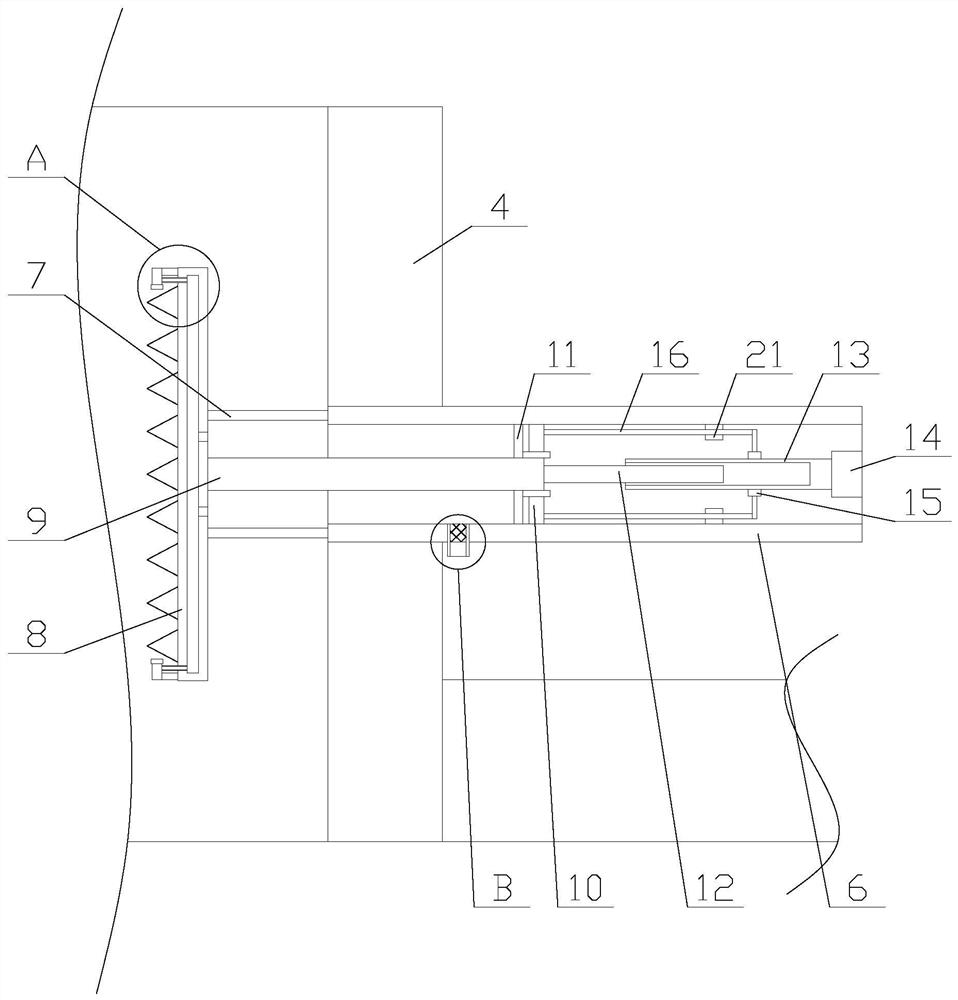

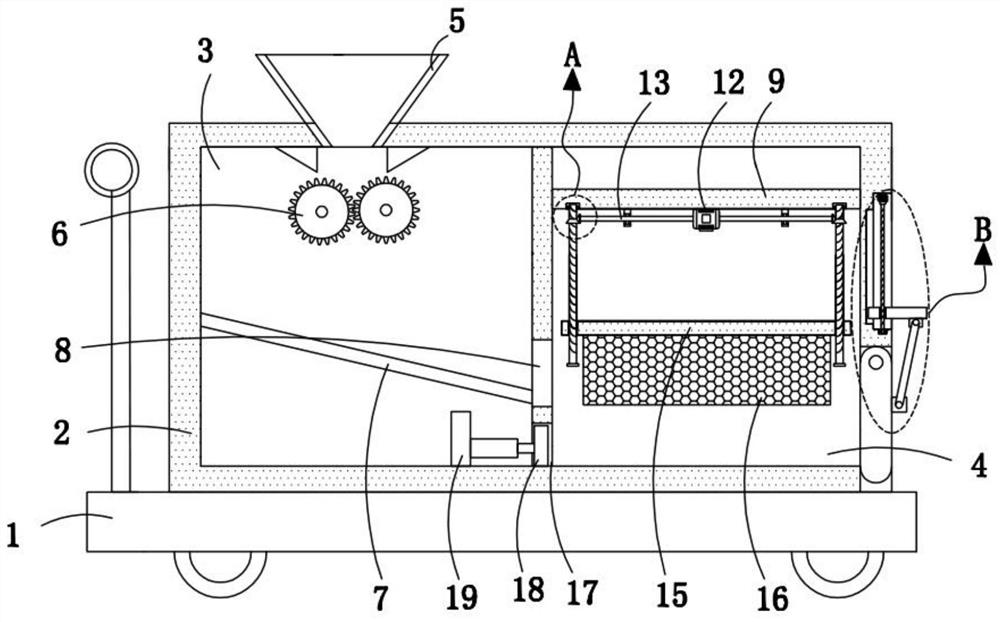

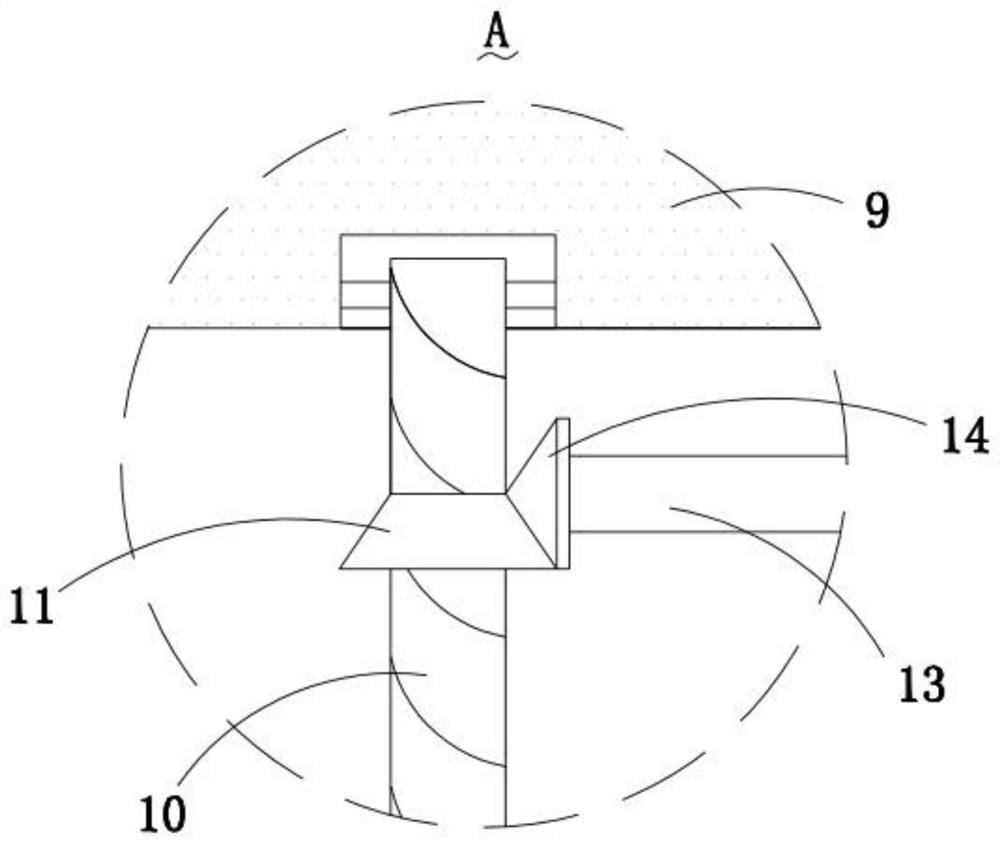

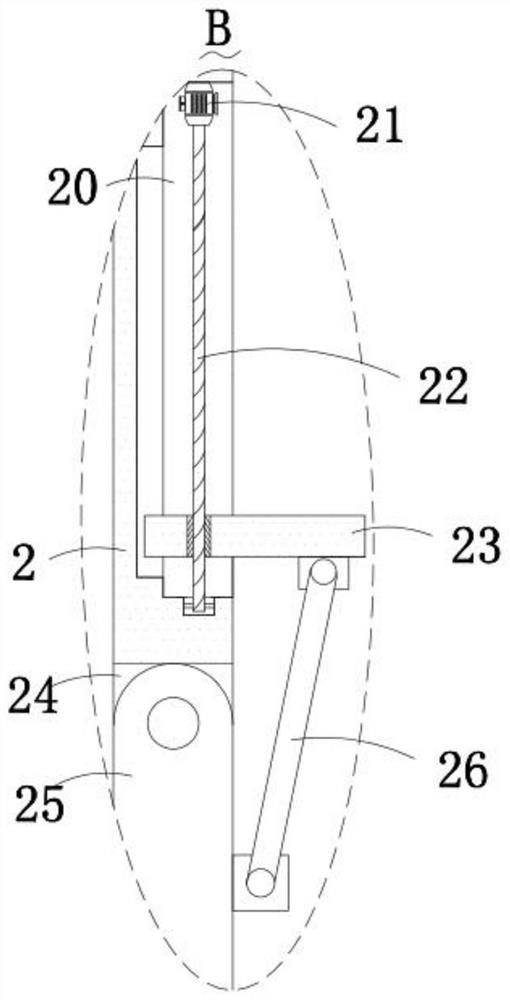

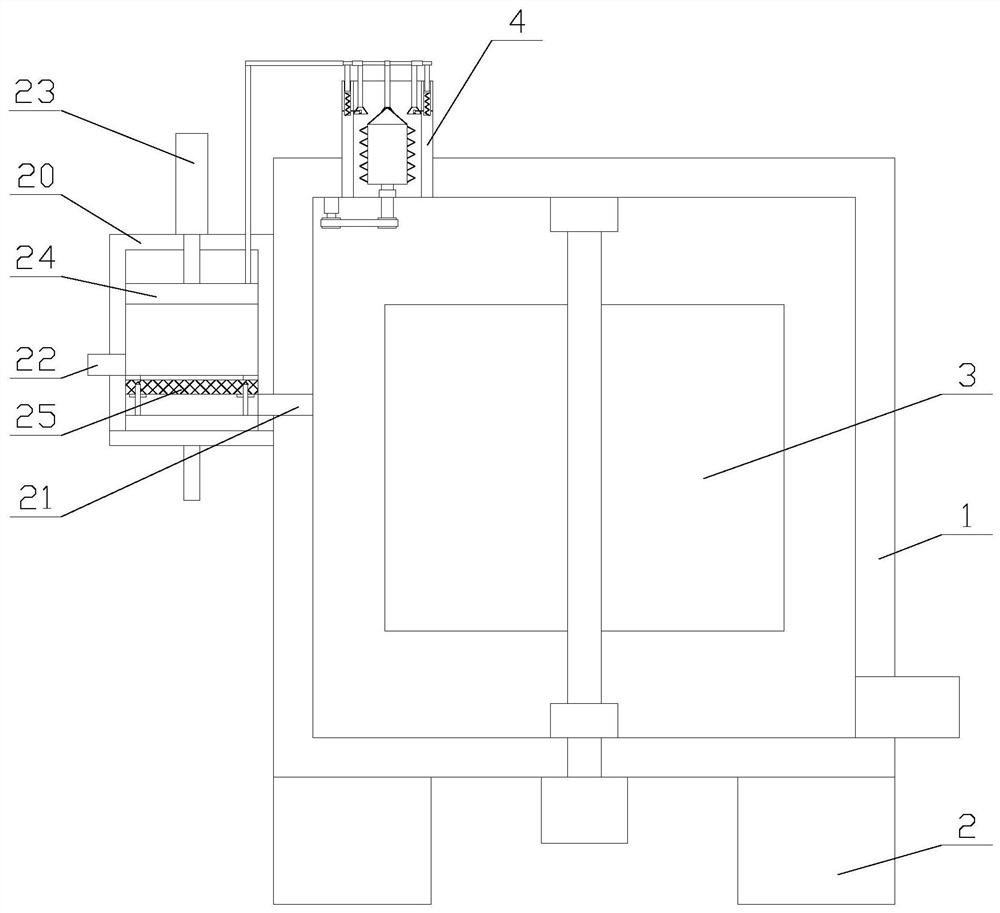

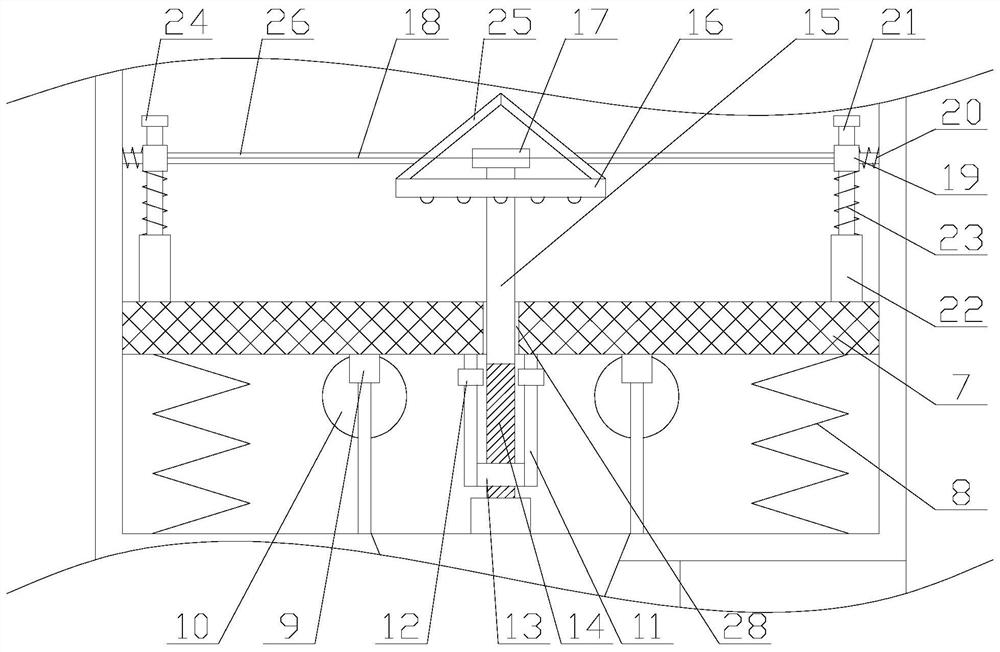

Construction waste asbestos tile crushing equipment

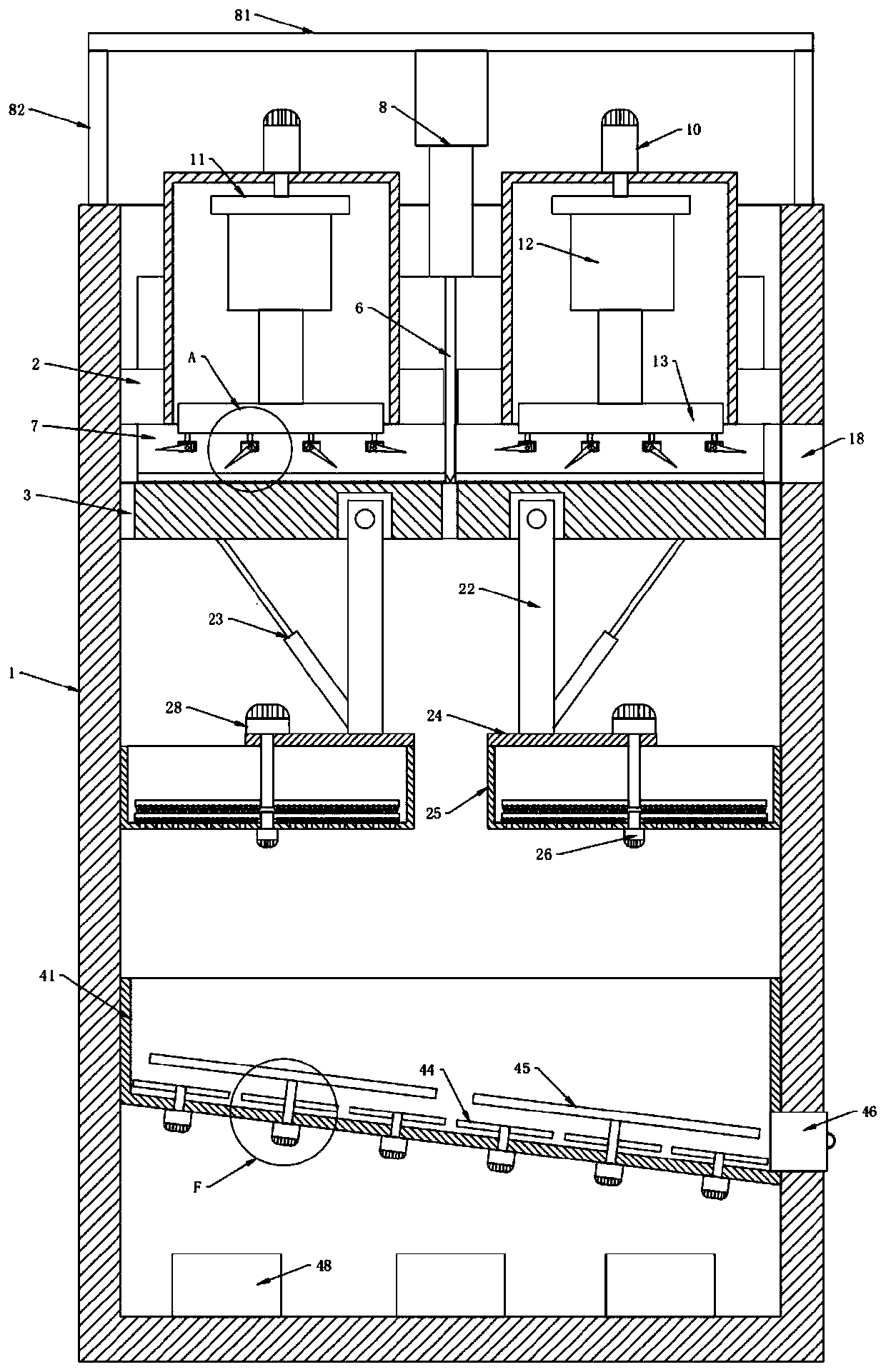

ActiveCN108295957AReach the function of secondary crushingRealize the shredding functionGrain treatmentsEngineeringConstruction waste

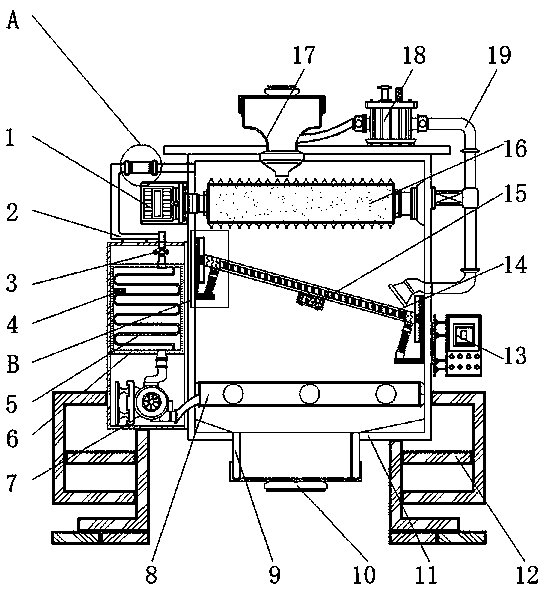

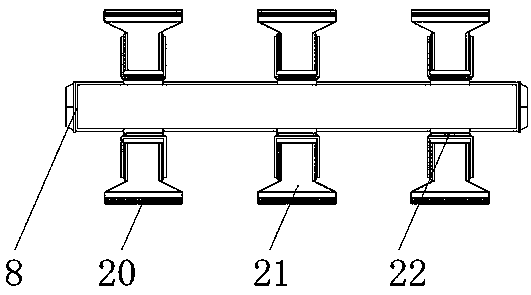

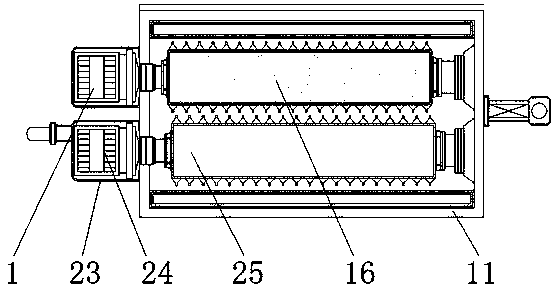

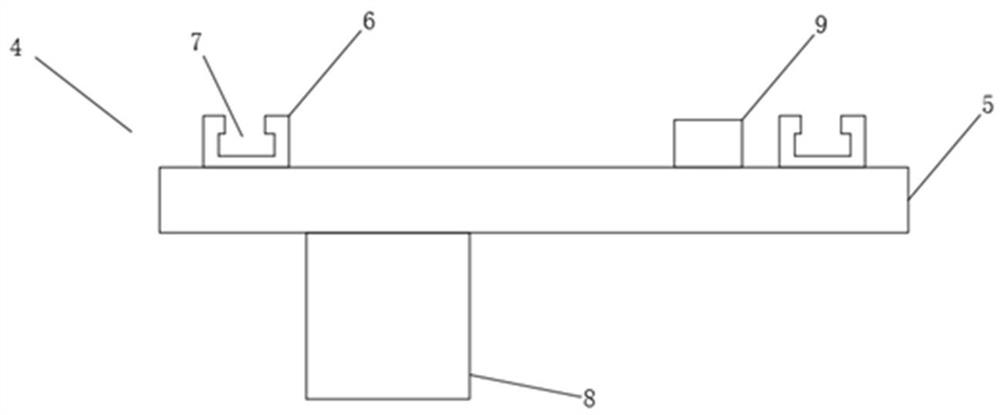

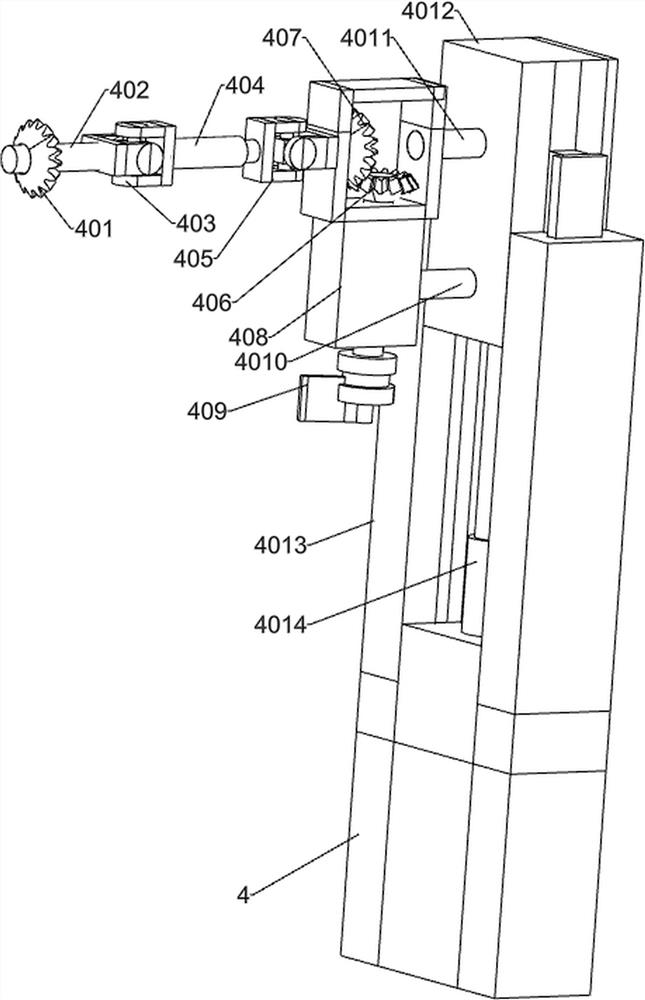

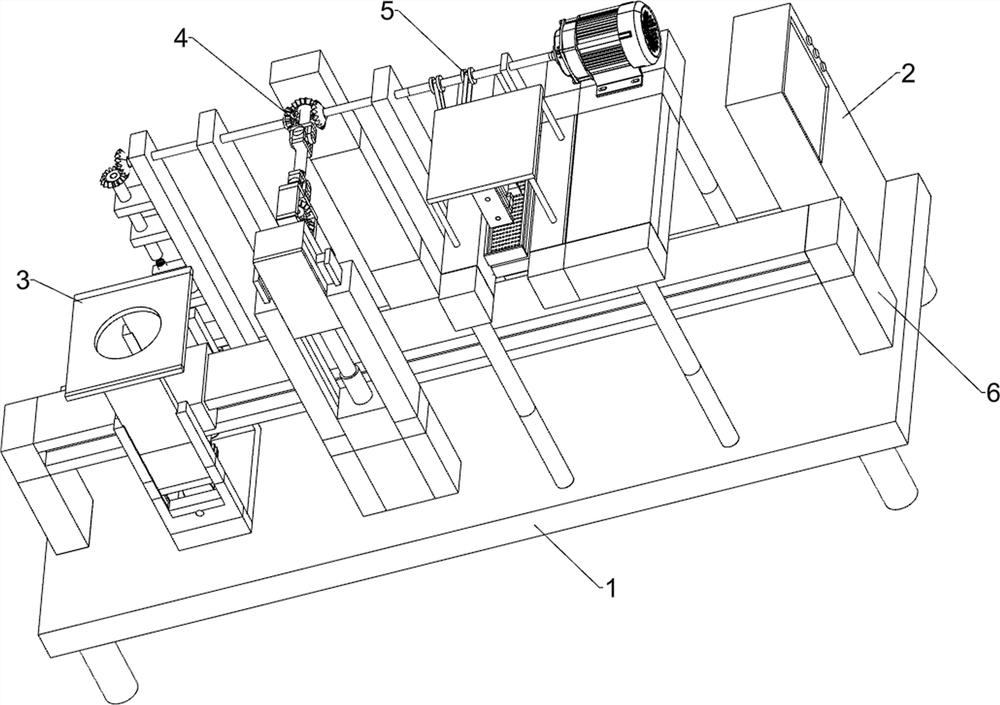

The invention relates to crushing equipment, in particular to construction waste asbestos tile crushing equipment. The construction waste asbestos tile crushing equipment is high in crushing speed anduniform in crushing. The equipment comprises a base, a first support, a second support, a first fixing plate, a first motor, a first gear and a second gear, a first belt wheel, a first connecting rod, a first sliding rail and the like; and the first support is fixedly connected to the left side of the upper part of the base, the second support is fixedly connected to the right side of the first support, and the first fixing plate is fixedly connected to the left side of the upper portion of the second support. According to the equipment, the function of crushing the abandoned asbestos tiles is achieved, the function of rapidly crushing the asbestos tiles is achieved, and the function of carrying out secondary crushing on the asbestos tiles is further achieved.

Owner:徐州创正新能源科技发展有限公司

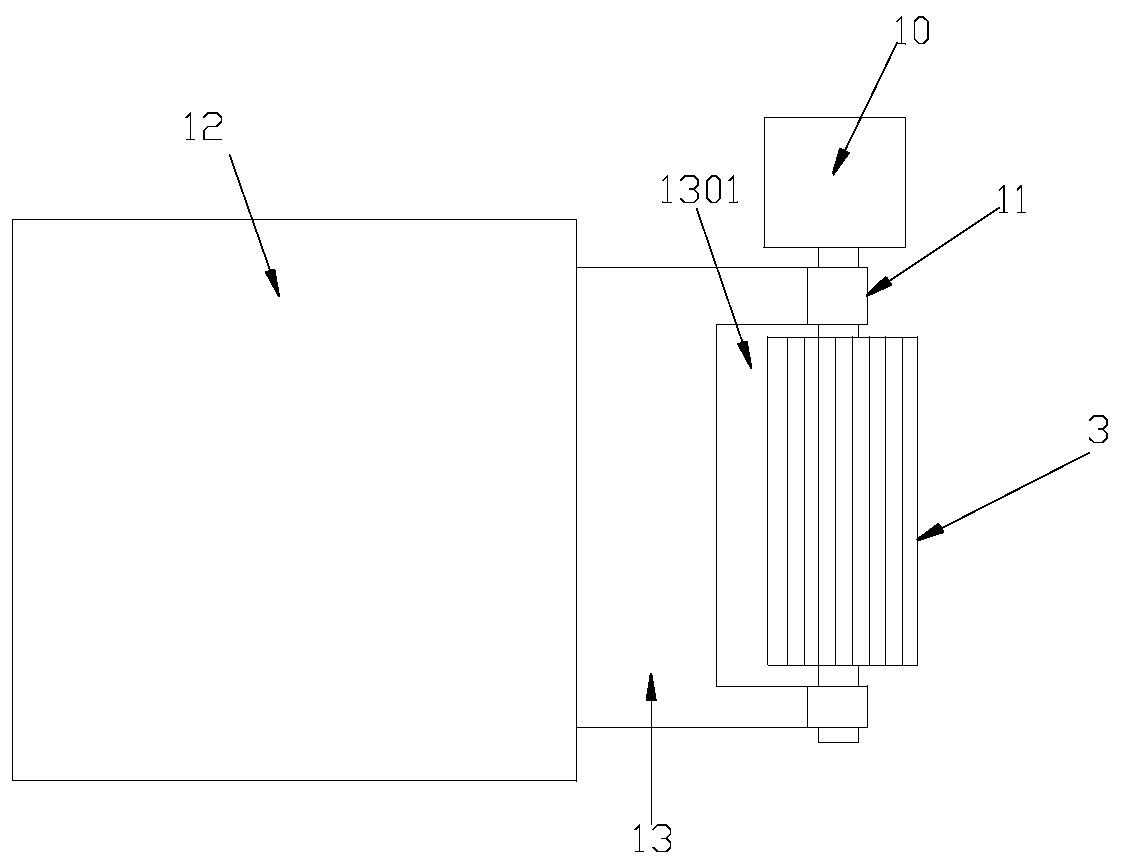

Rhizoma atractylodis processing device capable of achieving pulverizing and drying

InactiveCN110756267AReduce heat lossEasy disassembly and cleaningSievingScreeningHot blastElectric machinery

The invention discloses a rhizoma atractylodis processing device capable of achieving pulverizing and drying. A first drive motor, a temperature sensor, a body and a bearing frame are included. Through installation of a silencing cover, a PLC, a heating wire, a temperature sensor, an air guiding main pipe, a body, an air guiding branch pipe and filter cloth, the device can heat gas through the heating wire, the temperature sensor is used for monitoring the gas temperature situation in a hot air cavity constantly, the monitored data are sent to the PLC, once the temperature reaches the preset value, the PLC can control the heating wire to power off and stop heating, and a good temperature control heating function is achieved. By utilization of the functions of the air guiding main pipe andthe air guiding branch pipe, hot airflow can be evenly guided into the body, and uniformity during drying is improved; and through the arrangement of the filter cloth, the situation that dust scraps in the body enter the air guiding main pipe and the air guiding branch pipe, and blockage is caused can be avoided, and accordingly the practicability of the device is enhanced.

Owner:湖北宏图中药材科技有限公司

Rotary-type meat stuffing mashing device with uniform pickling function

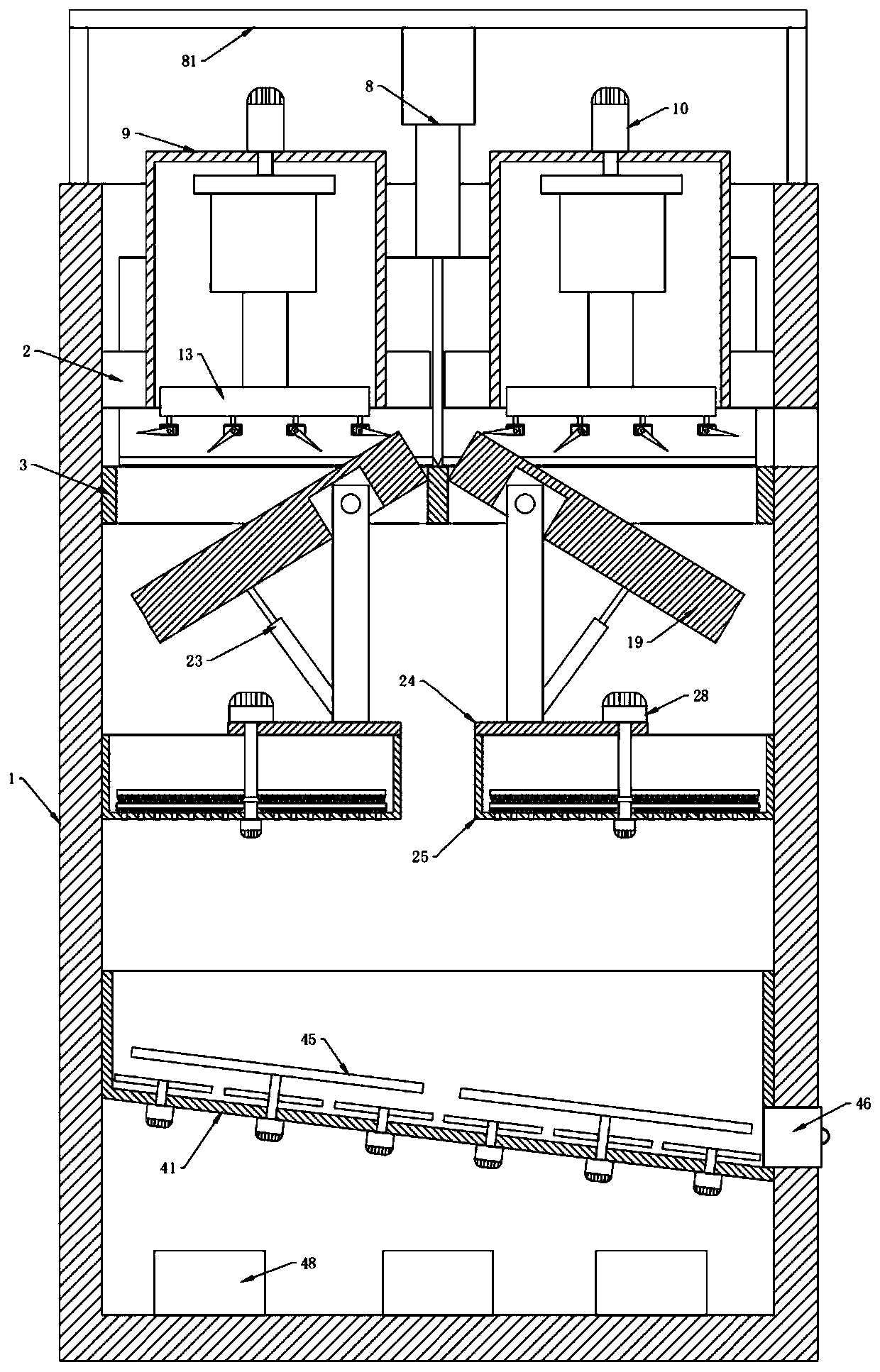

InactiveCN109820020ARealize the shredding functionRealize blankingMeat processing devicesEngineeringMashing

The invention discloses a rotary-type meat stuffing mashing device with a uniform pickling function. The rotary-type meat stuffing mashing device comprises a casing box, an upper-layer plate and a lower-layer plate are fixed to the inner side wall of the casing box from top to bottom in sequence, a vertical cutter port is formed in the upper-layer plate, transverse cutter ports are connected to the two sides of the vertical cutter port, a vertical cutter and transverse cutters are perpendicularly and fixedly connected, and a lower cutting push rod is fixedly connected to the upper end of the vertical cutter; several upper rotary rods are connected to upper device shafts, several lower rotary rods are connected to lower device shafts, meat stuffing holes are formed in the bottom walls of stirring grooves, and inclined grooves are fixedly connected to the portions, below the stirring grooves, of the inner side wall of the casing box. By means of the rotary-type meat stuffing mashing device, large pieces of whole meat can be directly mashed, and the working efficiency can be greatly improved; meanwhile, through multiple meat mashing devices which are arranged up and down, the meat blocks are mashed, so that the effect of mashing the meat stuffing is better, edible salt can be better added for uniform pickling, and the rotary-type meat stuffing mashing device is very high in practicability and very worthy of popularization.

Owner:BENGBU COLLEGE

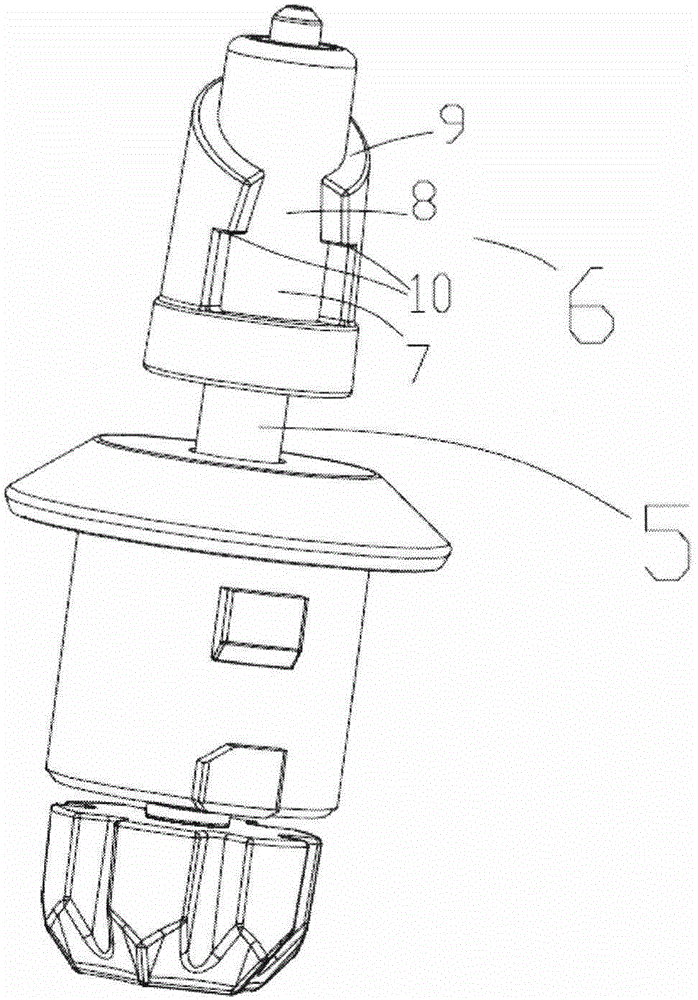

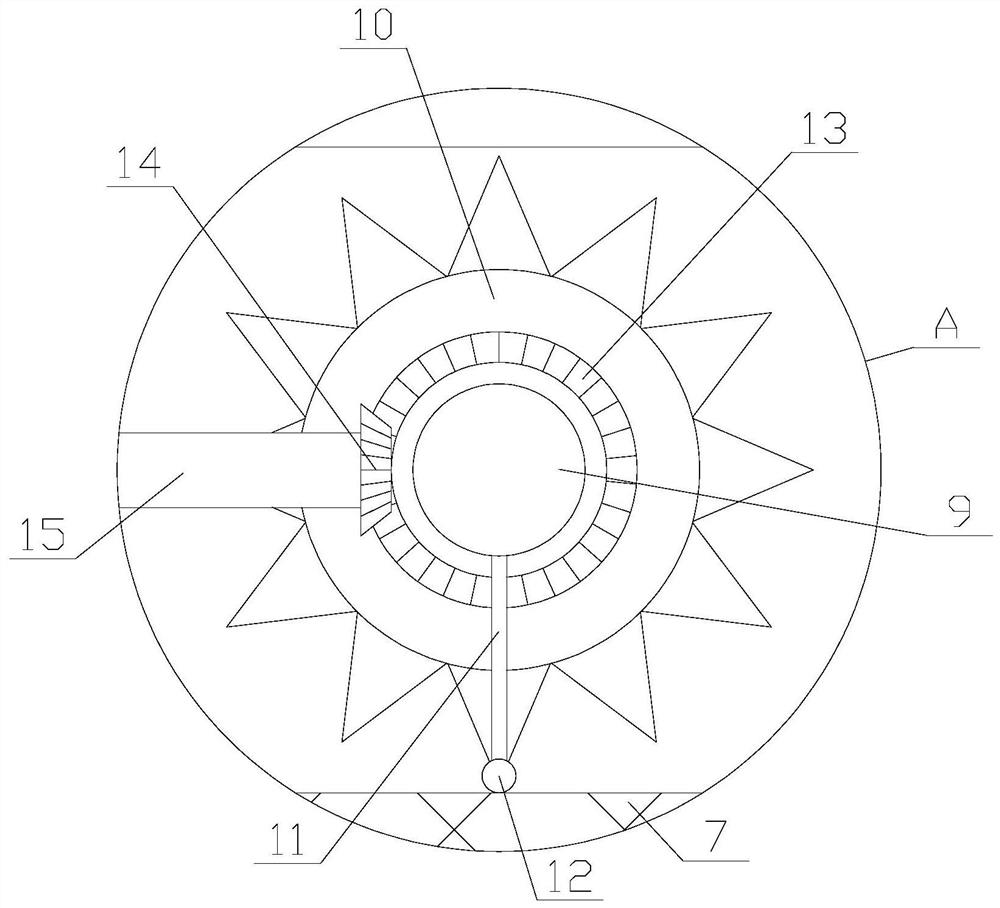

Pipeline dredger of rotary crushing reverse jet propulsion

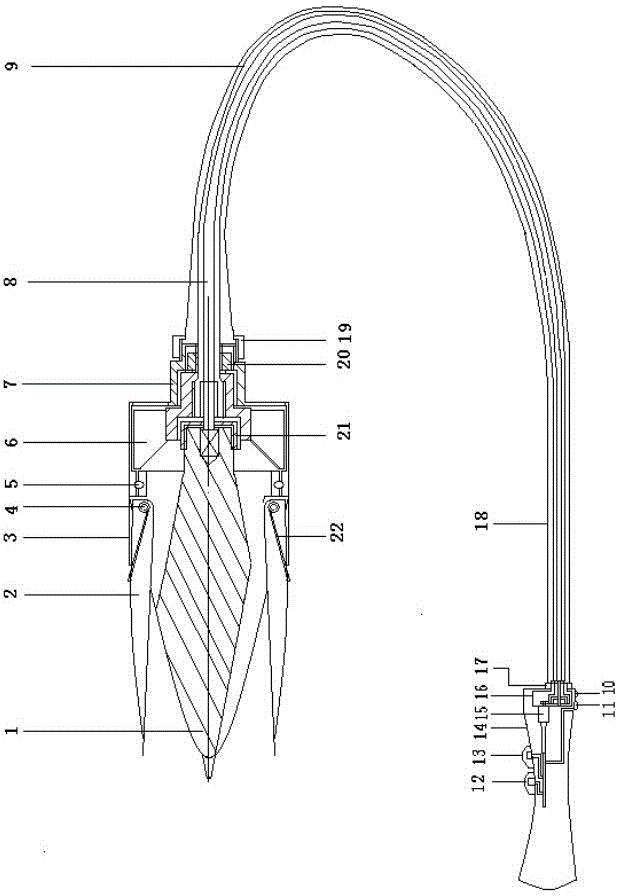

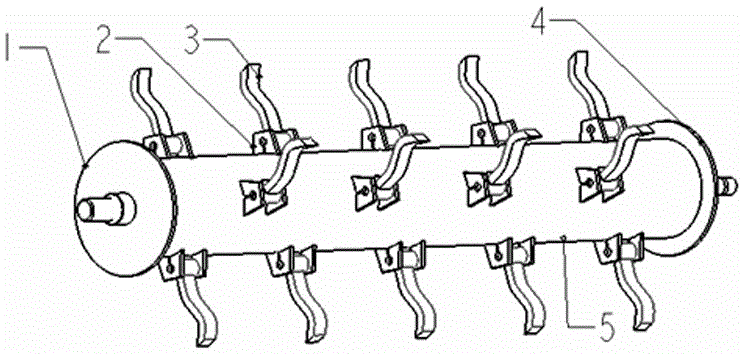

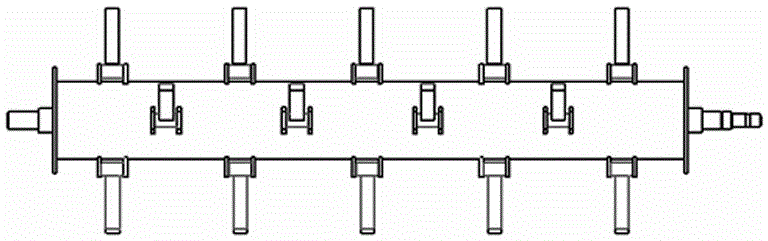

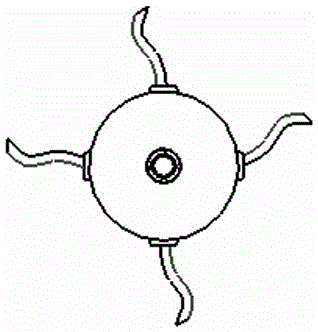

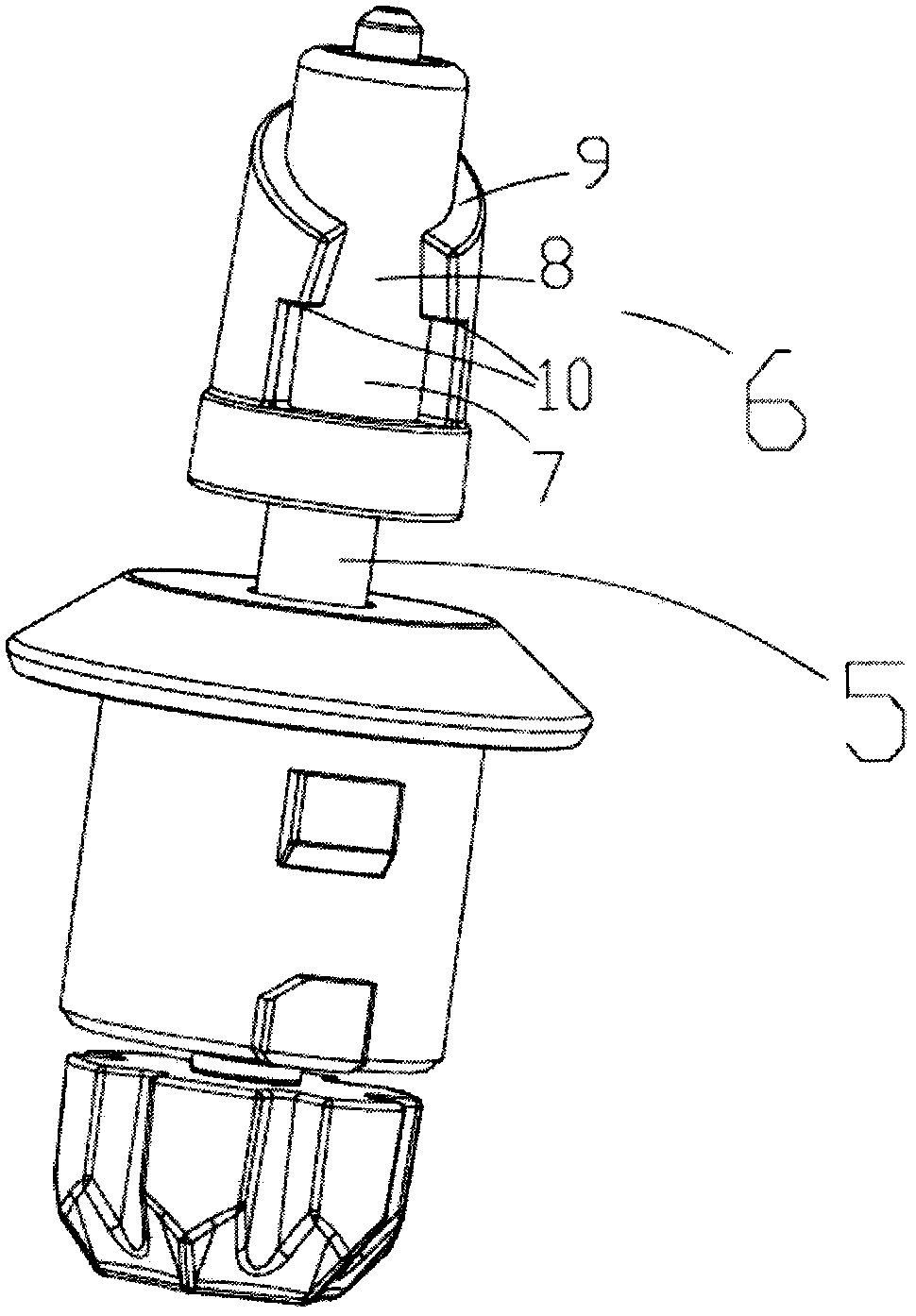

InactiveCN106807697AImplement the rotation functionRealize the shredding functionSewer cleaningHollow article cleaningImpellerJet propulsion

The invention discloses a pipe dredger for rotary pulverization and anti-jet propulsion, which belongs to the pipeline dredger. The invention aims to solve the problems that the propulsion process is easily blocked and that it is difficult to break when encountering severe blockage. The technical solution is as follows: including the handle, the flexible transmission shaft, the motor, the shaft head, the chopping blade, the diameter reducer of the chopping knife, the reverse spray impeller and the bracket, the transmission flexible shaft is connected with the handle, the motor is arranged on the handle, The transmission flexible shaft is mainly composed of transmission flexible shaft a, transmission flexible shaft b and transmission flexible shaft protection tube set from the inside to the outside. The motor can drive the transmission flexible shaft a and transmission flexible shaft b to rotate; the shaft head is fixed on the transmission flexible shaft a The end of the anti-spray impeller is fixed at the end of the transmission flexible shaft b, and the bracket is fixed at the end of the transmission flexible shaft protection tube; multiple chopping blades are installed on the outer periphery of the shaft head, and multiple chopping knife reducers are set on the bracket. The chopping blades are in one-to-one correspondence with the chopping knife diameter reducer; a spring is connected between each chopping blade and its corresponding chopping knife diameter reducer.

Owner:李诚智

Rice crushing equipment for production of rice flour

InactiveCN107088455ANovel structureGuaranteed uptimeGas current separationCocoaAgricultural engineeringTeeth grinding

The invention discloses rice crushing equipment for production of rice flour. The rice crushing equipment comprises a frame; a feed hopper is installed at the upper end of the frame and is arranged at the upper end of a feed channel; the lower end of the feed hopper is provided with a groove-shaped discharging hole; a dust removing fan box is installed at one side of the feed channel; an air discharging hood is installed on the feed channel which faces to the dust removing fan box; the air discharging hood is connected with an air discharging pipe; the lower end of the feed channel communicates with a crushing box body; the crushing box body is connected with a fixed fluted disc through a flange plate; a movable fluted disc is installed on the fixed fluted disc; movable crushing teeth are installed on the movable fluted disc; the movable fluted disc is connected with a gearbox through a rotating shaft; and a vibrating sieve device is installed at the lower end of the crushing box body. The rice crushing equipment disclosed by the invention is novel in structure, stable in operation, high in efficiency, clean, sanitary and capable of realizing the rice crushing function for production of the rice flour, realizing the dust removal function and meeting the present operation requirements.

Owner:江西省恒鸿食品有限责任公司

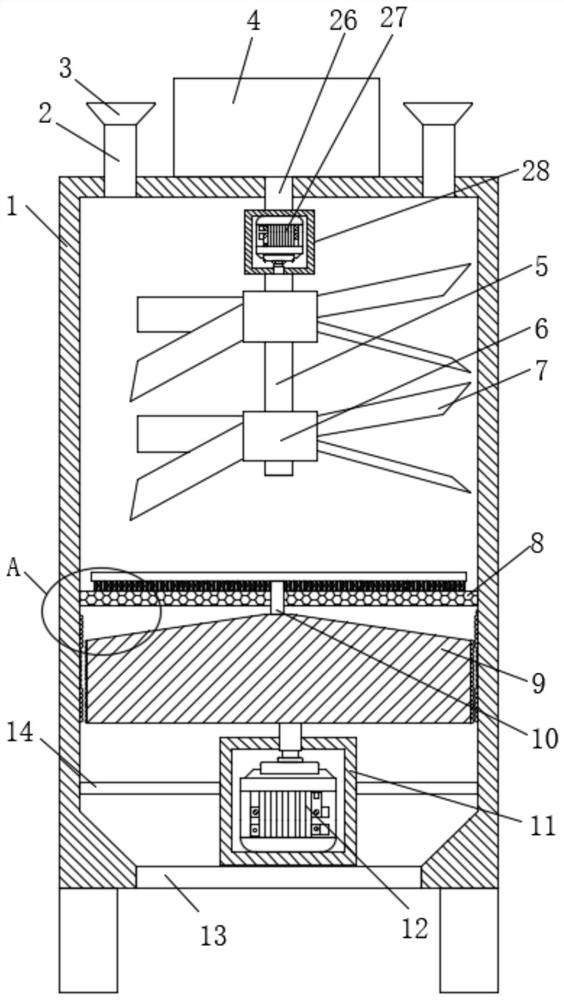

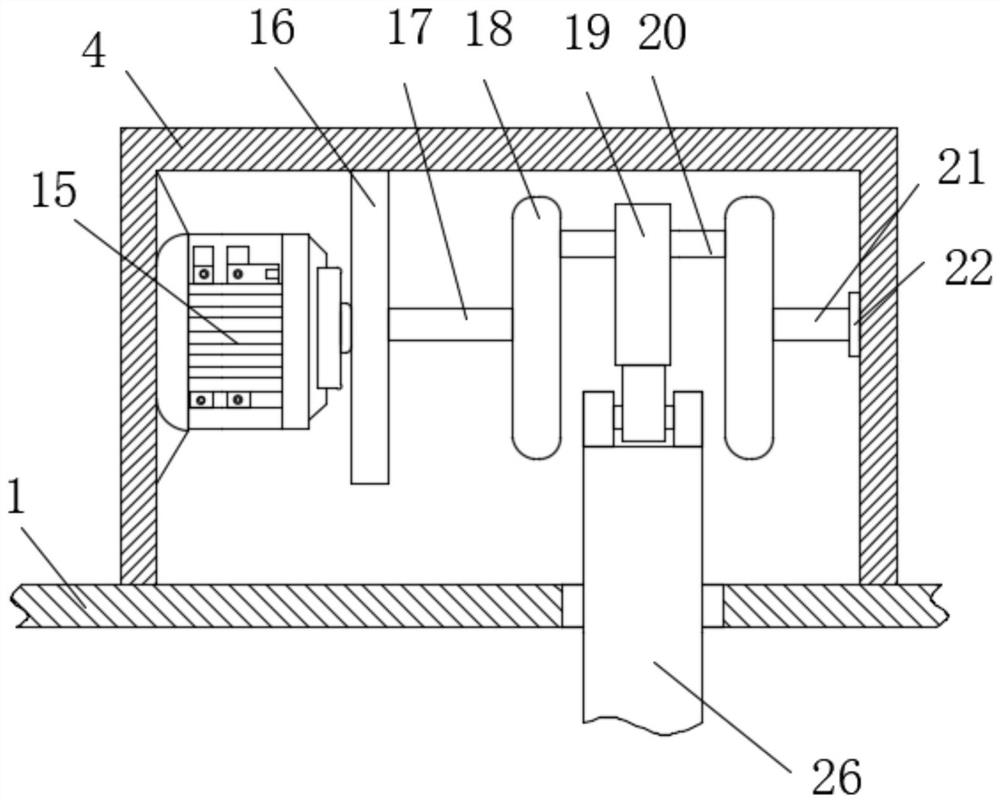

Food waste crushing equipment with drying function

InactiveCN112495530ARealize the drying functionEasy to separateDrying gas arrangementsCleaning using gasesDrive shaftElectric machinery

The invention relates to food waste crushing equipment with a drying function. The food waste crushing equipment with the drying function comprises a crushing barrel and a sealing cover; the crushingbarrel is cylindrical and is vertically arranged; an opening is arranged at the top of the crushing barrel; the sealing cover horizontally covers the top of the crushing barrel and is connected to thecrushing barrel in a sealed mode; a crushing mechanism and an auxiliary mechanism are arranged on the sealing cover; the crushing mechanism comprises a driving motor, a transmission shaft, a blade, afixing pipe, a connecting pipe, a suction assembly and a crushing assembly; the suction assembly comprises an air pipe, a suction pump and an air hole; the crushing assembly comprises a driving disc,a driven disc, a connecting shaft and two crushing units; and each crushing unit comprises a guide pipe, a first magnet block, a first connecting hole, a second connecting hole, a third connecting hole and two stop blocks. The food waste crushing equipment with the drying function achieves the crushing function through the crushing mechanism; and in addition, the function of drying the blade is achieved through the auxiliary mechanism.

Owner:江苏直播时代科技有限公司

Anti-caking piezoelectric ceramic production equipment

InactiveCN111957230AAvoid clumpingRestrict direction of movementRotary stirring mixersTransportation and packagingPipeMixing effect

The invention relates to anti-caking piezoelectric ceramic production equipment which comprises a main body, a feeding pipe, a discharging pipe and two supporting columns; and further comprises a cleaning mechanism and two crushing mechanisms; each crushing mechanism comprises a crushing plate, a driving assembly, a rotating shaft, a first bearing, a second bearing, a sleeve, a connecting assembly, a first spring, a power assembly, a moving plate and two moving rods; the cleaning mechanism comprises two stirring assemblies and two cleaning assemblies; each cleaning assembly comprises a scraping plate, two connecting ropes, two fixed pulleys and two second springs; the stirring assembly comprises a connecting shaft, two rotating units and a plurality of stirring blades; according to the anti-caking piezoelectric ceramic production equipment, the crushing function is achieved through the crushing mechanisms, the phenomenon that materials are caked during mixing is avoided, the mixing quality is improved, the cleaning function is achieved through the cleaning mechanism, and the situation that the mixing effect is affected due to the fact that the materials adhere to the inner wall isavoided.

Owner:南京宜泽新材料科技有限公司

Sewage pump with self-cleaning function

ActiveCN110566518AWith self-cleaning functionImprove self-cleaning functionPump componentsPumpsSewageSelf cleaning

The invention discloses a sewage pump with the self-cleaning function. The pump comprises a pump body, a filter plate, smashing wheels and scraping plates, a buffer cavity is formed in a water inlet of the pump body, the filter plate is fixedly arranged at the position, close to the water inlet, in the buffer cavity, first moving grooves are formed in the positions, below the filter plate, of thefront inner wall and the back inner wall of the buffer cavity, the symmetric scraping plates are arranged in the moving grooves in a sliding manner, the scraping plates are tightly attached to the filter plate, a first motor and a synchronous wheel are fixed to the two sides of each first moving groove, the output ends of the first motors are fixedly provided with the synchronous wheels which areconnected through a synchronous belt, the scraping plates are fixedly connected with the upper and the lower of the synchronous belt, second moving grooves are formed in the positions, below the firstmoving grooves, of the front and rear inner walls of the buffer cavity, second motors are symmetrically arranged in the second moving grooves in a sliding manner, the output ends of the second motorsare fixedly provided with rotating shafts, the rotating shafts are fixedly provided with the smashing wheels, and shaft sleeves are arranged at the positions, on the two sides of the smashing wheels,of the rotating shafts.

Owner:ESKE PUMP

Grass smashing mechanism

The invention relates to a grass-cutting mechanism comprising a left-rotating half-shaft assembly, a knife seat, a cutter, a right-rotating half-shaft assembly and a main frame. The left-rotating half-shaft assembly is welded on the left side of the main frame. The above-mentioned right-rotating axle assembly is welded on the right side of the main frame, and several knife seats are uniformly welded on the periphery of the main frame, and a cutter is installed on every two knife seats by bolts. The invention has the advantages of convenient manufacture, simple and easy-to-operate mechanism, superior performance, high production efficiency, easy adjustment, safety and reliability, and can adapt to crushing of different kinds of round bales.

Owner:呼伦贝尔市蒙拓农机科技股份有限公司

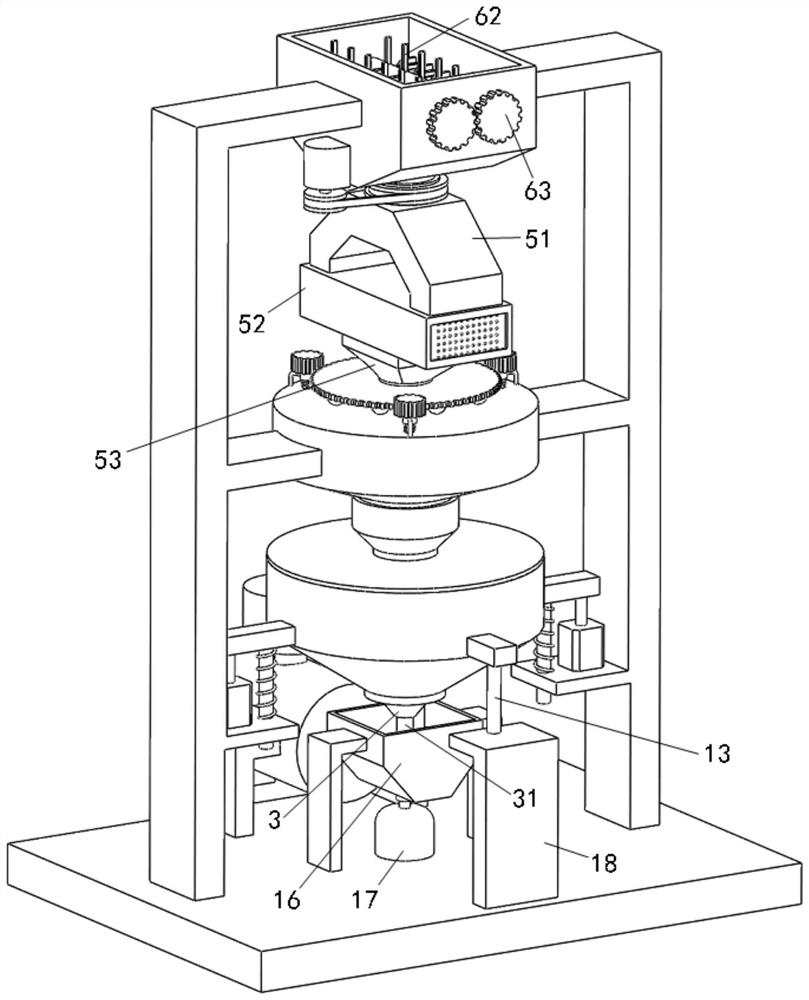

Refractory material production equipment with high mixing efficiency

PendingCN113649103ARealize the shredding functionPracticalShaking/oscillating/vibrating mixersRotary stirring mixersDrive shaftElectric machine

The invention relates to refractory material production equipment with high mixing efficiency. The refractory material production equipment comprises a shell, a sealing cover, a driving motor, a transmission shaft and a stirring rod, wherein the sealing cover covers the top of the shell, a mounting hole is formed in the sealing cover, the transmission shaft vertically penetrates through the mounting hole, the transmission shaft is in sliding and sealing connection with the inner wall of the mounting hole, the driving motor is in transmission connection with the top end of the transmission shaft, the driving motor is connected to the top of the sealing cover, the stirring rod is located in the shell, the axis of the stirring rod is perpendicular to and intersects with the axis of the transmission shaft, the middle end of the stirring rod is arranged at the bottom end of the transmission shaft, a smashing mechanism and an auxiliary mechanism are arranged in the shell, and the smashing mechanism comprises a rotating pipe, a first bearing, a driving gear, an inner gear, two rotating assemblies and two smashing assemblies. The refractory material production equipment with high mixing efficiency realizes a raw material smashing function through the smashing mechanism, and in addition, the raw material mixing effect is improved through the auxiliary mechanism.

Owner:广州级项建材有限公司

Efficient traditional Chinese medicine crushing equipment

The invention relates to efficient traditional Chinese medicine crushing equipment which comprises a shell, a driving motor, a transmission shaft and a sealing cover. A mounting hole is formed in the bottom of the shell, the transmission shaft vertically penetrates through the mounting hole, the driving motor is in transmission connection with the bottom end of the transmission shaft, the driving motor is connected with the bottom of the shell, and the sealing cover covers the top of the shell; and the sealing cover is connected with the shell in a sealing manner, an auxiliary mechanism is arranged on the sealing cover, a crushing mechanism is arranged on the transmission shaft, the crushing mechanism is arranged in the shell and located between the sealing cover and the transmission shaft, and the crushing mechanism comprises a driving disc, a driven disc, a rotating shaft, a bearing and at least two crushing assemblies. According to the efficient traditional Chinese medicine crushing equipment, the crushing function is achieved through the crushing mechanism, and in addition, the crushing efficiency is improved through the auxiliary mechanism.

Owner:广州云深生物科技有限公司

Soup cooker

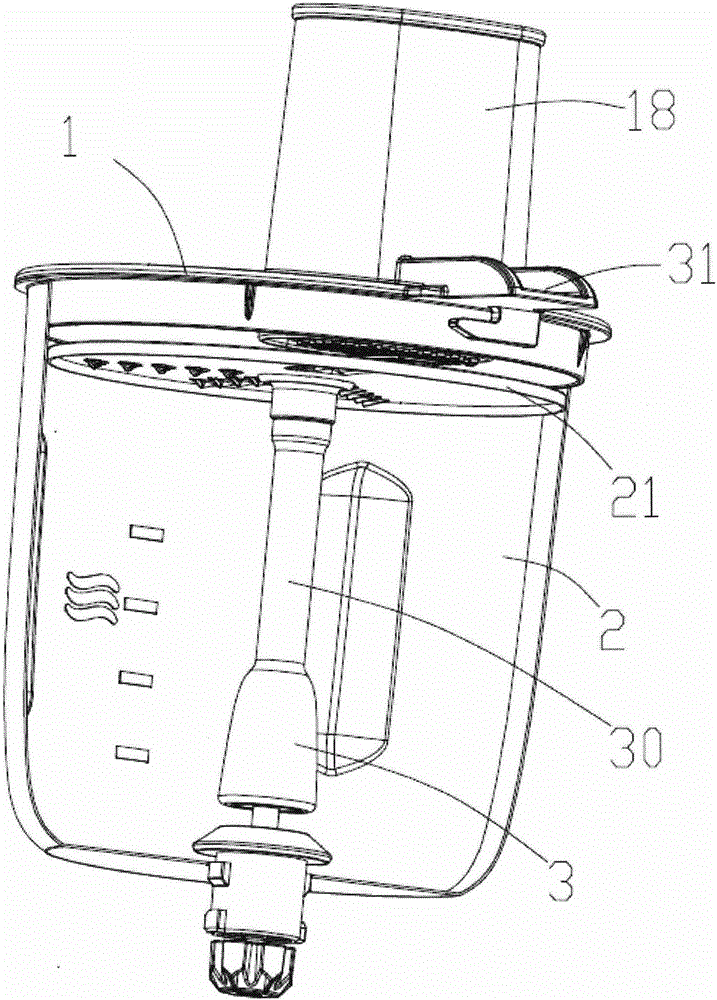

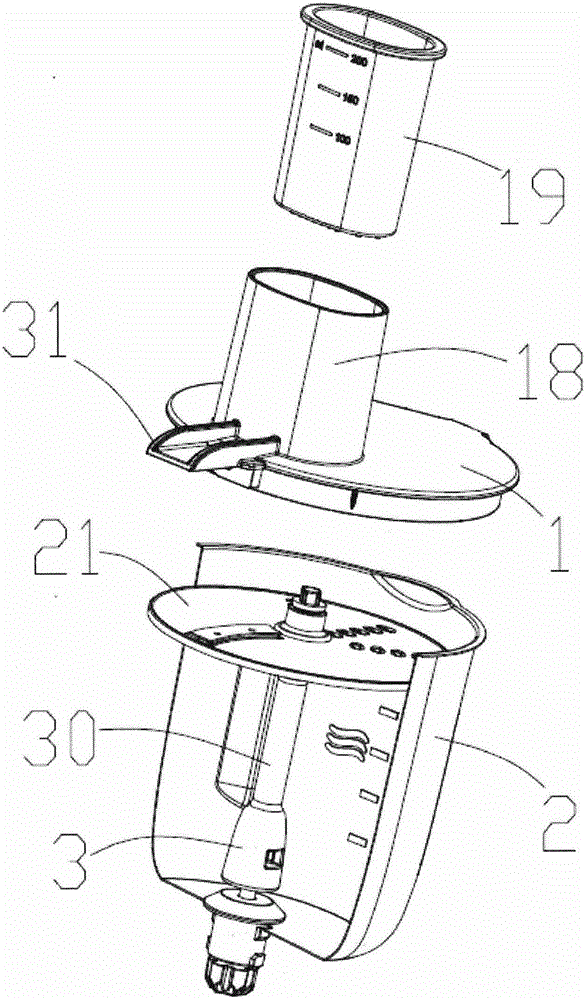

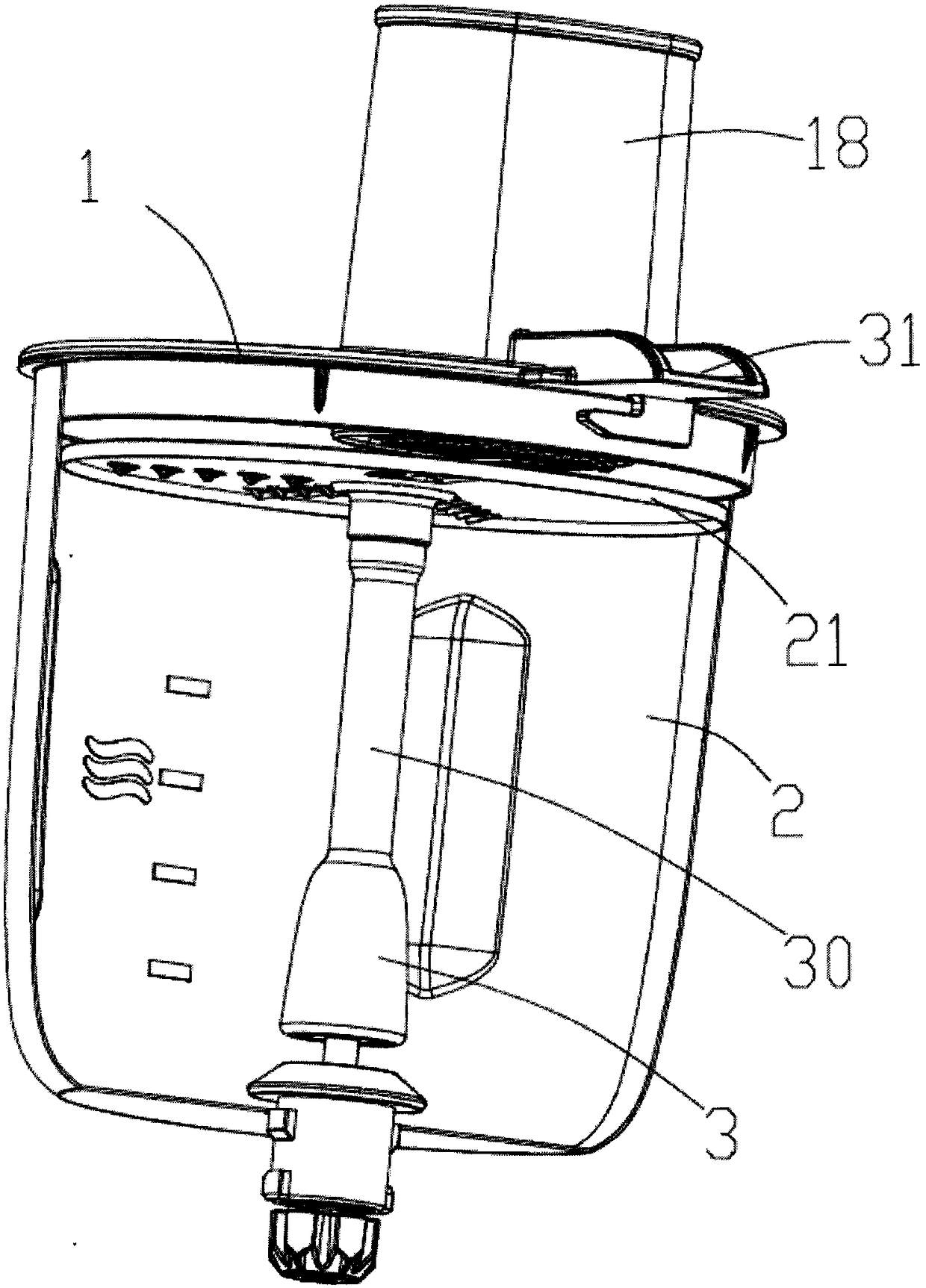

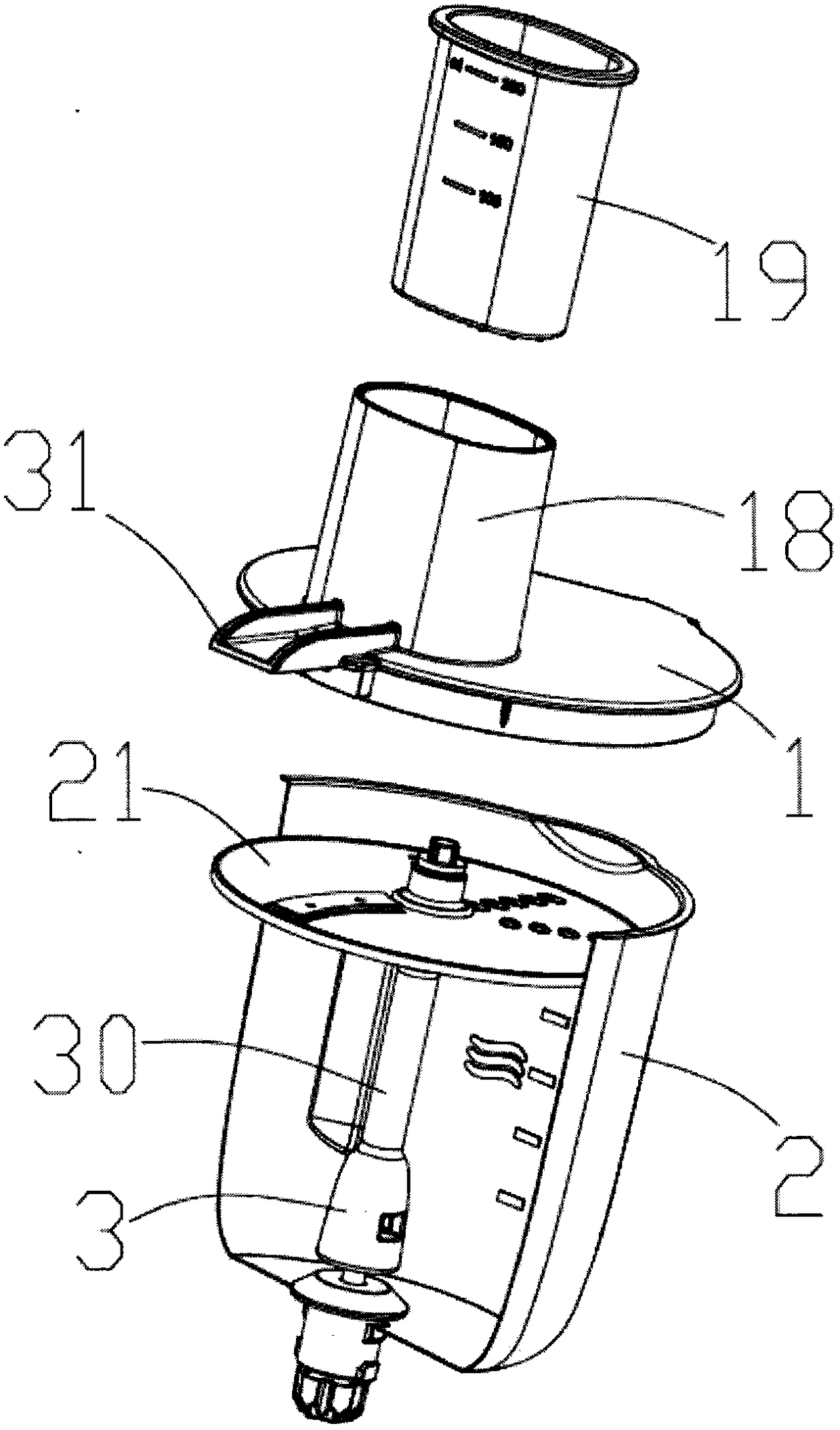

ActiveCN106108608AEasy to cleanRealize the shredding functionVessels with intergral heatingEngineeringCooker

The invention discloses a soup cooker which comprises a cup lid, a cup body, a tool rest arranged inside the cup body and a smashing tool arranged on the tool rest. The tool rest is of a cylindrical structure with an installation hole. A main shaft is sleeved with the tool rest. The main shaft is provided with a locking portion fixed to the installation hole. Due to close fit of the installation hole and the main shaft, the tool and the main shaft are detachably connected, the tool is disassembled to clean the tool bit, and cleaning is convenient.

Owner:NINGBO HUABAO PLASTICS & RUBBER MOLD

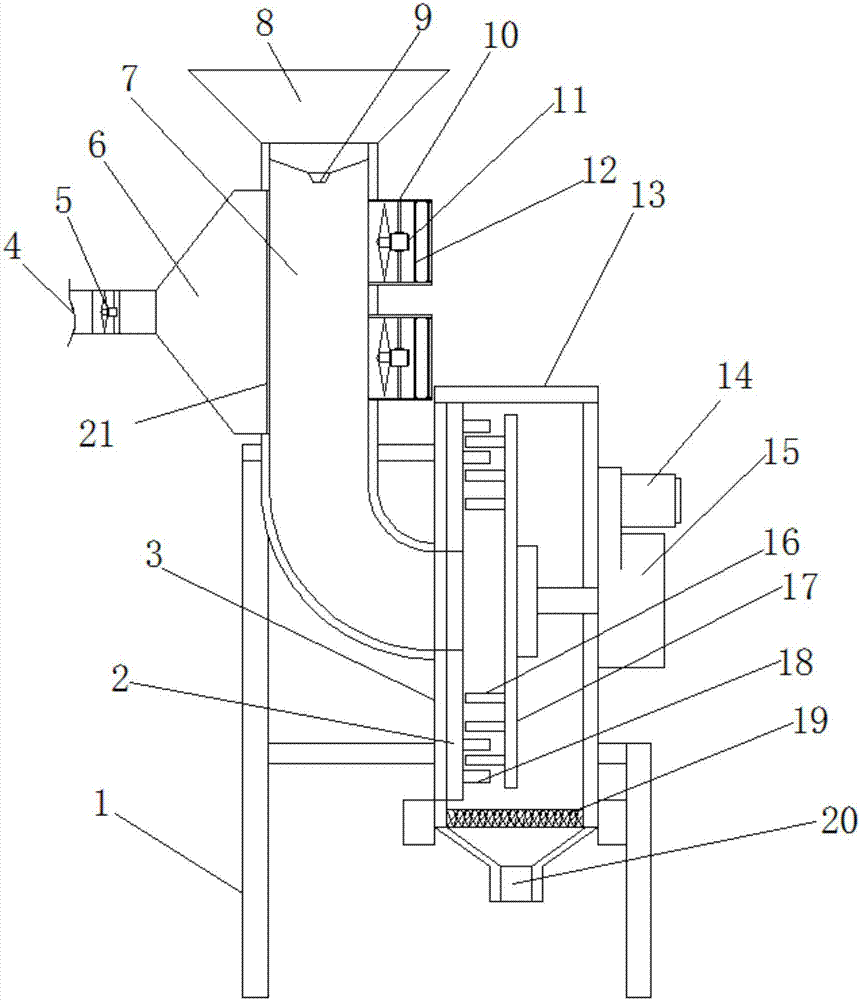

Full-automatic pulverizer for resin for rubber powder

InactiveCN106040400AFully automatedRealize the shredding functionVortex flow apparatusGrain treatmentsPulverizerEngineering

The invention relates to a full-automatic pulverizer for resin for rubber powder. The full-automatic pulverizer comprises a pulverizing case, a pulverizing motor, a raw material box and a separating system. Pulverizing blades are arranged in the pulverizing case and connected with the pulverizing motor. The pulverizing motor drives the pulverizing blades to rotate to pulverize the resin. A pulverizing hopper is arranged above the pulverizing case and connected with the raw material box through a feeding pipe. An outlet of the pulverizing case is connected with the separating system so that pulverized resin can be separated. The pulverizing case is of a jacket type structure. A jacket of the pulverizing case conveys circulating cooling liquid through a cooling pipe. Compared with the prior art, the pulverizer has a cooling function, and the problem of bonding of the pulverized resin is avoided. Meanwhile, the pulverizer is full-automatic equipment, integrates feeding, pulverizing, cooling, separating and outputting, and is high in safety performance while improving the efficiency.

Owner:明辉大秦(上海)环保科技股份有限公司

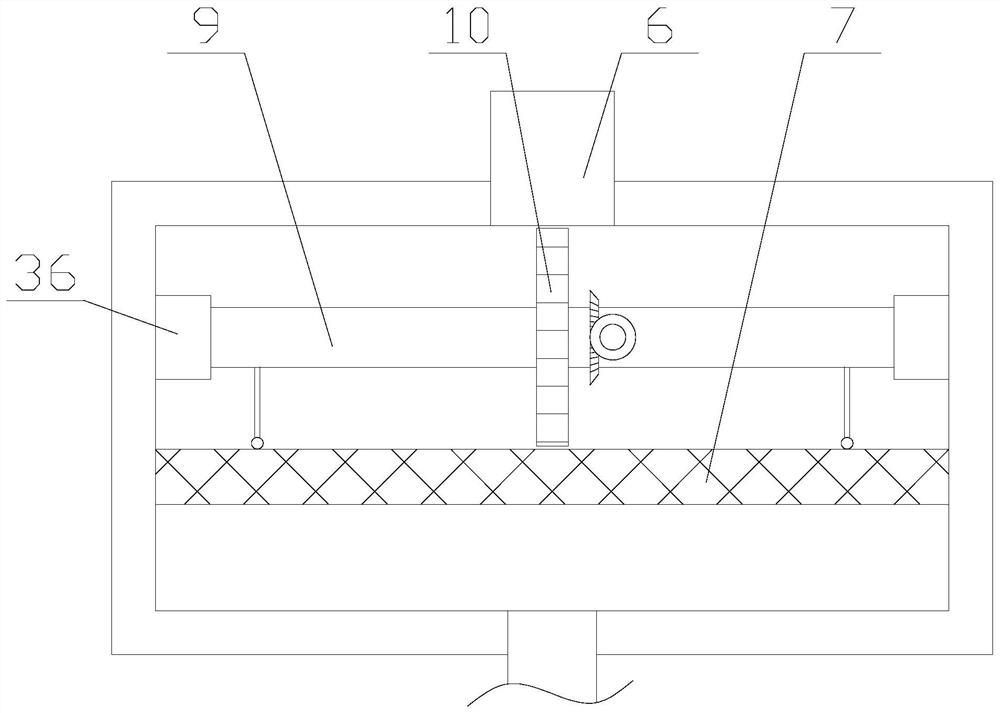

Anti-precipitation intelligent pesticide spraying equipment

InactiveCN112189642AReduce volumeIncrease contact areaSievingScreeningPesticideAgricultural engineering

The invention relates to anti-precipitation intelligent pesticide spraying equipment. The equipment comprises a vehicle body, a material box, a pesticide spraying device and four wheels and further comprises a smashing mechanism and a stirring mechanism, the smashing mechanism comprises a fixing box, a feeding pipe, a discharging pipe, a filter screen and two smashing assemblies, and the stirringmechanism comprises a connecting pipe, a stirring assembly and two inflation assemblies. Each inflation assembly comprises an inflator, a piston, a first spring, an eccentric wheel, a driving shaft, an air inlet pipe, an air outlet pipe, a second bearing and a transmission unit. According to the anti-precipitation intelligent insecticide spraying equipment, through the smashing mechanism, the function of smashing pesticide powder is achieved, the size of the pesticide powder is reduced, and therefore the contact area between the pesticide powder and pesticide liquid is increased, the pesticidepowder and the pesticide liquid can be evenly mixed, through the stirring mechanism, air flow stirring and mechanical stirring are achieved, the stirring effect is improved, the probability that thepesticide medicine is deposited is reduced, and the influence on pesticide spraying work is avoided.

Owner:深圳市伊乐农产品有限公司

Energy-saving and environment-friendly rapid and efficient rice crushing equipment for rice processing

PendingCN114260062ARealize lifting functionRealize the shredding functionSievingScreeningAgricultural scienceAgricultural engineering

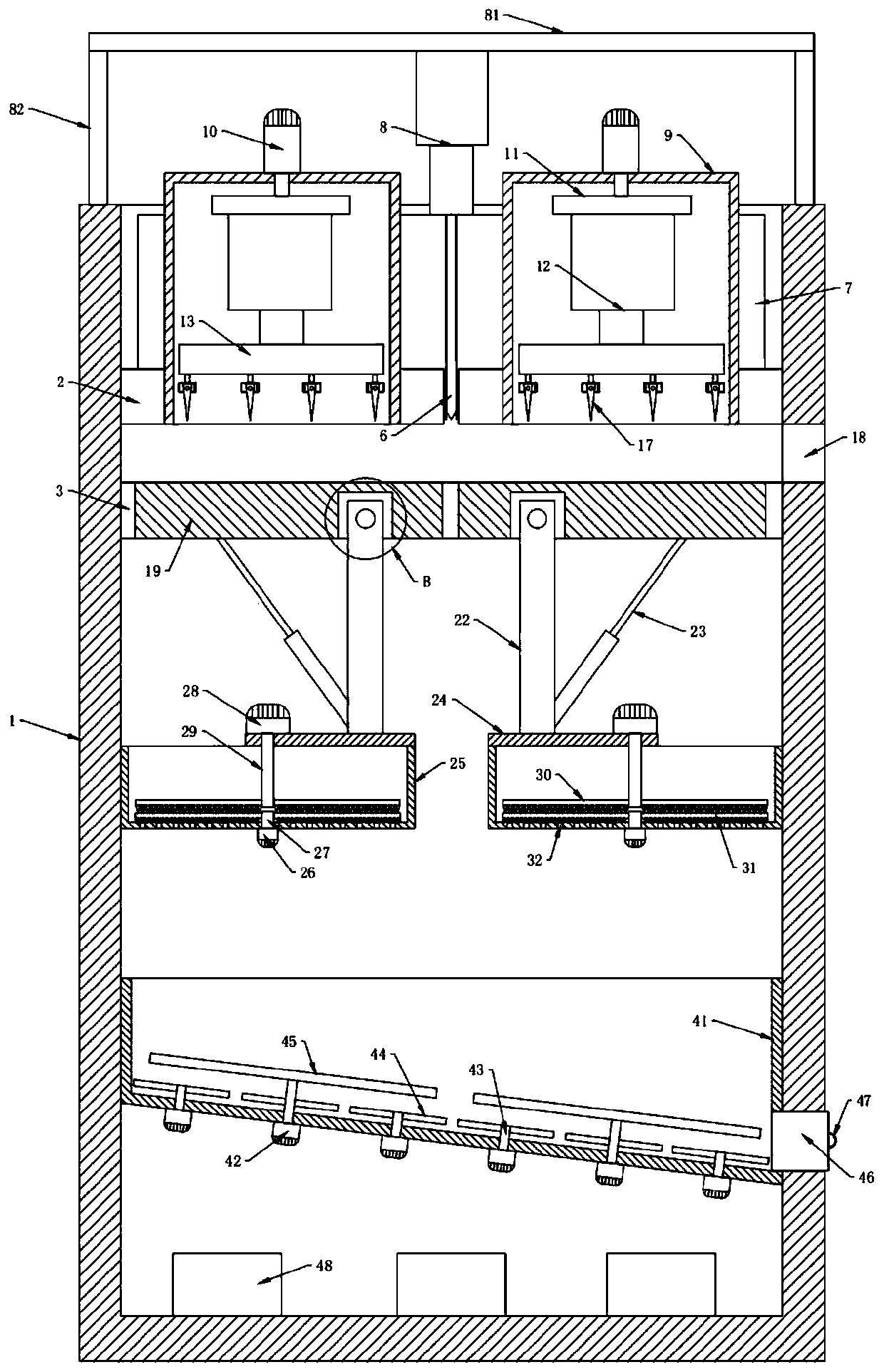

The invention belongs to the field of rice processing, particularly relates to energy-saving and environment-friendly rapid and efficient rice crushing equipment for rice processing, and aims to solve the problems that crushing blades of an existing rice crushing device only rotate at a horizontal position, crushing dead angles exist, crushing is not thorough enough, and subsequent processing quality and processing efficiency are affected. According to the technical scheme, the rice crushing device comprises a fixed box, the top of the fixed box is fixedly connected with two feeding pipes which are symmetrically arranged, and the bottoms of the feeding pipes penetrate through the fixed box and communicate with the interior of the fixed box. By means of the lifting assembly, the smashing blades of the smashing assembly can move in the vertical direction, the smashing range is enlarged, smashing is more thorough, smashed rice is ground through the grinding assembly and finally discharged through the discharging port, the structure is simple, and operation is convenient.

Owner:湖南四通食品科技有限责任公司

Medicine crusher capable of preventing blockage

InactiveCN112871420ARealize the shredding functionAffect the crushing efficiencySievingScreeningMedicinal herbsStructural engineering

The invention relates to a medicine crusher capable of preventing blockage. The medicine crusher comprises a main body, a screening board, a crushing device, a feeding tube and a discharge tube, and further comprises a drying mechanism and two anti-blocking mechanisms, wherein each anti-blocking mechanism comprises a fixed tube, a hose, a crushing plate, a moving assembly, a first bearing, a moving ring, a sealing ring, a support rod, a gas inlet tube and a plurality of dust-removal assemblies; and the drying mechanism comprises a guide rod, two elastic ropes and two drying mechanisms. The medicine crusher capable of preventing blockage disclosed by the invention realizes the function of crushing medicines blocked in the feeding tube, prevents greater medicines from blocking the feeding tube to affect unloading work to affect medicine crushing efficiency, improves reliability; and the medicine drying function is realized through the drying mechanism, so that the surfaces of the medicines are prevented from separating out water, and thus, the medicines are prevented from being adhered onto the screening plate, discharge work is prevented from being affected, medicine waste probability is reduced, and practicability is improved.

Owner:赵文勇

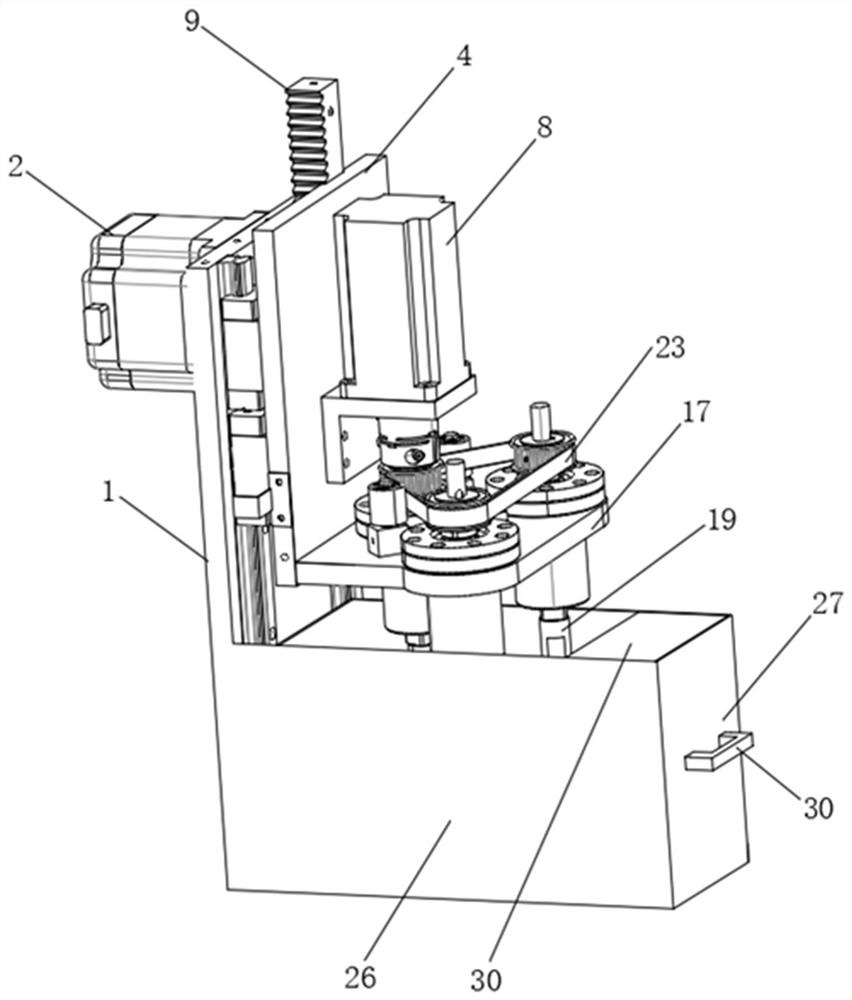

Quartz stone grinding system for quartz stone precision machining

ActiveCN114130468AAvoid lostRealize the shredding functionGrain treatmentsElectric machineryStructural engineering

The quartz stone grinding system comprises a first supporting frame, a second supporting frame and a grinding assembly, the top of the first supporting frame is fixedly provided with a smashing box, the smashing box is internally provided with a smashing assembly, the bottom of the smashing box is connected with a screening box in a penetrating mode, and the screening box is internally provided with a screening assembly; and one end of the screening assembly is in transmission connection with a first driving motor through a coupler, a transmission assembly is arranged between the screening assembly and the smashing assembly, a feeding pipe is connected to the bottom of the screening box in a penetrating mode, and a conveying assembly is arranged in the feeding pipe. According to the quartzite grinding system for quartzite precision machining, quartzite raw materials can be smashed and screened through the smashing assembly and the screening assembly, the grinding efficiency is improved, meanwhile, the dust falling effect can be effectively improved through the dust falling assembly, water mist flows into the water tank again after adsorbing dust through the filter box, and the dust falling effect is improved. Reutilization is achieved, and resources are saved.

Owner:中旗(湖北)新材料有限公司

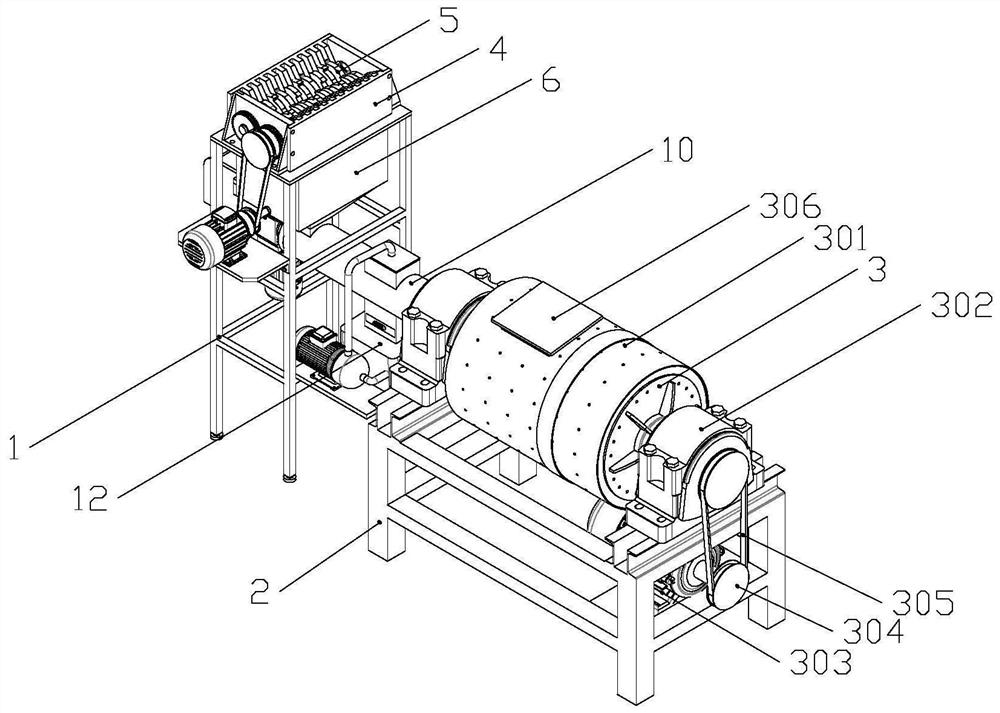

Plant-based biodegradable material manufacturing equipment and process

ActiveCN114798672ACompletely brokenAvoid cloggingSolid waste disposalDrying gas arrangementsEngineeringMaterials science

The invention discloses plant-based biodegradable material manufacturing equipment which comprises a bottom plate and a pair of stabilizing frames, a crushing box body, a crushing cylinder and a grinding cylinder shell are arranged between the two stabilizing frames, a moisture removal mechanism is rotatably arranged between the crushing box body and the crushing cylinder, a rotary grinding cylinder is rotatably arranged in the grinding cylinder shell, and the rotary grinding cylinder is rotatably arranged in the bottom plate. A material collecting box is arranged below the rotary grinding cylinder, and an internal mixing box body is connected to the front portion of the material collecting box. The device has the advantages that deadwood and rotten leaves pass through the crushing box body to obtain crushed materials, the crushed materials enter the crushing barrel body to be further crushed to obtain crushed materials, the crushed materials enter the rotary grinding barrel to be ground into thoroughly dried superfine powder by the grinding roller, and then the superfine powder enters the internal mixing box body to be stirred and mixed; all the mechanisms in the whole set of equipment are skillfully matched with one another from top to bottom, all procedures are closely and reasonably connected, the crushing mode is progressive layer by layer, and the process of changing deadwood and rotten leaves into superfine powder is simple and smooth.

Owner:浙江绿美景环保科技有限公司

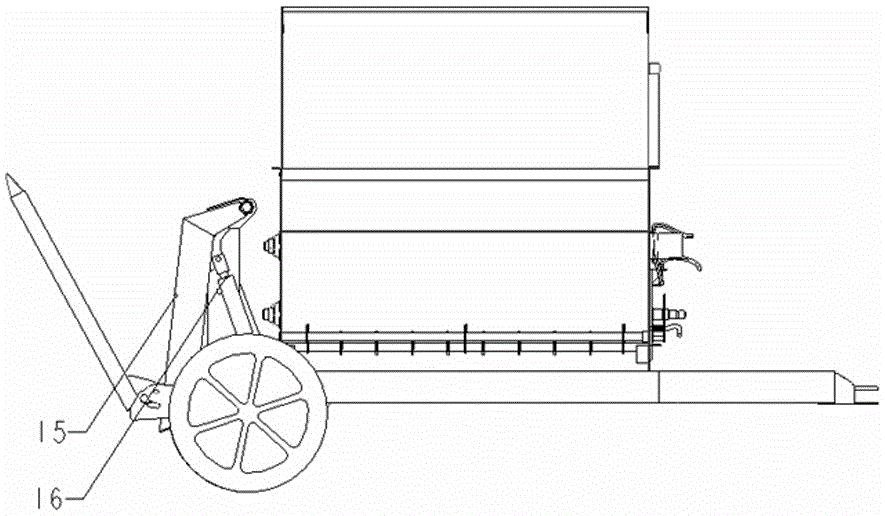

Round bale chopper

The invention relates to a round bale chopper which comprises a rack, a hopper, a walking mechanism, a grid, a hydraulic motor, a rotating cutter shaft, cutters, a stirring wheel shaft, stirring cutters, a hydraulic oil diverter, a picking mechanism and a forage ordering mechanism, wherein the walking mechanism is mounted at the bottom of the rack; the hopper is mounted at the upper part of the rack; the hydraulic motor and the hydraulic oil diverter are mounted at the front part of the hopper; the picking mechanism is mounted on the walking mechanism at the rear part of the hopper; the grid is mounted at the bottom of the rotating cutter shaft and is connected with a height adjusting mechanism mounted on the hopper; a discharge hole is formed in the hopper; the forage ordering mechanism is mounted at the discharge hole. The round bale chopper has the advantages of convenience in manufacturing, simplicity and easiness in mechanism operation, excellent performance, high production efficiency, easiness in adjustment, safety and reliability as well as solidness and durability.

Owner:呼伦贝尔市蒙拓农机科技股份有限公司

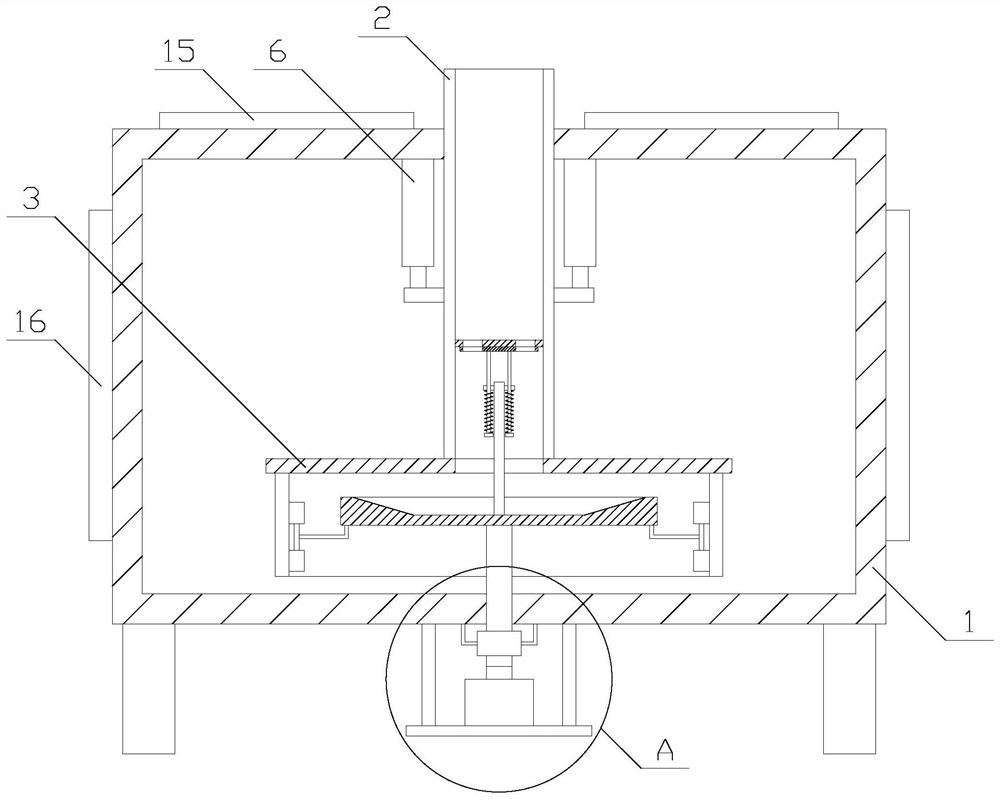

Cutting platform waste collecting device for indoor decoration

InactiveCN112827564AImplement the collection functionRealize the shredding functionGrain treatmentsPressesEnvironmental engineeringWaste material

The invention provides a cutting platform waste collecting device for indoor decoration. The cutting platform waste collecting device for indoor decoration comprises a bottom plate, a box body fixedly mounted at the top of the bottom plate, a crushing chamber formed in the box body, a compression chamber formed in the box body, a feeding hopper which is fixedly mounted at the top of the box body and communicates with the crushing chamber, a crushing mechanism which is fixedly mounted in the crushing chamber and is located under the feeding hopper, and an inclined plate fixedly mounted in the crushing chamber. The cutting platform waste collecting device for indoor decoration has the advantages that operation is easy, waste is automatically compressed and collected, and collision is prevented.

Owner:新鸿天装饰工程有限公司

A quick chili grinder

ActiveCN112138785BIncrease flexibilityAdjust the crushing strengthGrain treatmentsImpellerHot peppers

The present invention relates to the technical field of grinder, in particular to a quick grinder for chili peppers, which includes a support plate, a lifting assembly, a bottom platform and a crushing box, driven by a second motor to rotate a second rotating shaft, and the second rotating shaft drives The nut, the nut drives the screw, and the screw drives the rotating rod to rotate, so that the rotating rod drives the impeller to rotate at a high speed. By using the crawler belt, the third rotating shaft drives the other rotating wheels to rotate synchronously, so that several The impeller rotates at high speed at the same time, and the synchronous high-speed rotation of multiple impellers improves the efficiency of use. By using the nut and the screw, the screw can be quickly connected and separated from the nut, so that the mixer can quickly disassemble the impeller. By quickly disassembling the impeller, it provides convenience for later cleaning and maintenance, greatly improves the efficiency of later cleaning and replacement, and thus prolongs the service life of the crusher.

Owner:湖南佳森食品有限公司

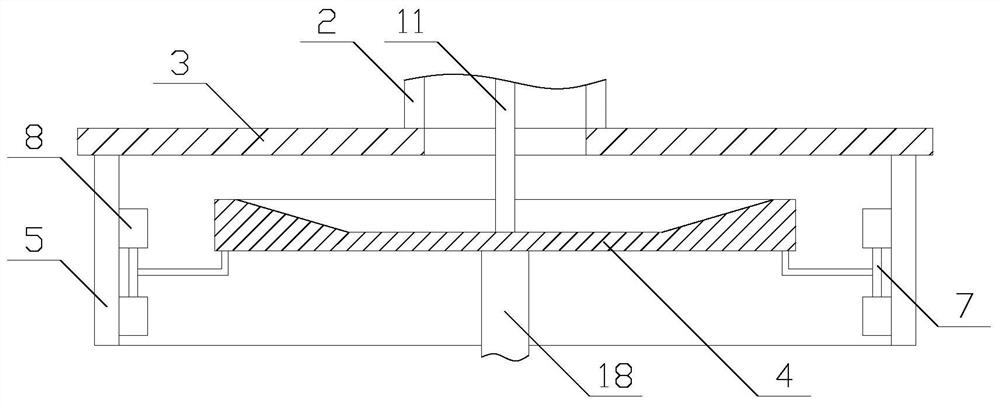

Polytetrafluoroethylene butterfly valve preprocessing device capable of saving raw materials

ActiveCN112440405ARealize the shredding functionRealize the function of scrapingGrain treatmentsPolytetrafluoroethyleneEngineering

The invention relates to the field of machining, in particular to a polytetrafluoroethylene butterfly valve pre-machining device capable of saving raw materials. In order to solve the technical problem, the invention provides the polytetrafluoroethylene butterfly valve preprocessing device capable of saving the raw materials. According to the technical scheme, the polytetrafluoroethylene butterflyvalve preprocessing device capable of saving the raw materials comprises a workbench, a control screen, a bearing assembly, a leveling assembly, a vibration assembly and a transportation assembly; the workbench is connected to the control screen; the workbench is connected to the bearing assembly; the workbench is connected to the leveling assembly; and the workbench is connected to the vibrationassembly. According to the polytetrafluoroethylene butterfly valve pre-machining device, the function of crushing caked polytetrafluoroethylene powder is achieved, the function of scraping the polytetrafluoroethylene powder to be flat is achieved, the subsequent collection function on the polytetrafluoroethylene powder is further achieved, resources are saved, and meanwhile, the product quality is guaranteed.

Owner:浙江亚发阀业有限公司

Mixing equipment for feed production

InactiveCN112934093AWell mixedReduce volumeFeeding-stuffRotary stirring mixersActivated carbonProcess engineering

The invention relates to mixing equipment for feed production, the mixing equipment comprises a main body, a stirring device, a feeding pipe, a discharging pipe and two supporting blocks, and further comprises a crushing mechanism and a deodorization mechanism, the crushing mechanism comprises a driving assembly, a first bearing, a rotating shaft, a rotating disc, a shunting block, a driving rod, a circular ring, a plurality of auxiliary assemblies and a plurality of limiting assemblies; the deodorization mechanism comprises a deodorization box, an air inlet pipe, an air outlet pipe, an activated carbon filter screen, a replacement assembly, a piston and an air cylinder. The mixing equipment for feed production can realize a crushing function through the crushing mechanism, so that the volume of raw materials is reduced, feed is uniformly mixed, and the mixing quality is improved; with application of the deodorization mechanism, the air purification function is achieved, the air quality of exhausted gas is improved, therefore, the situation that odor is scattered all around to pollute air can be avoided, and the environmental protection property of equipment is improved.

Owner:刘晓思

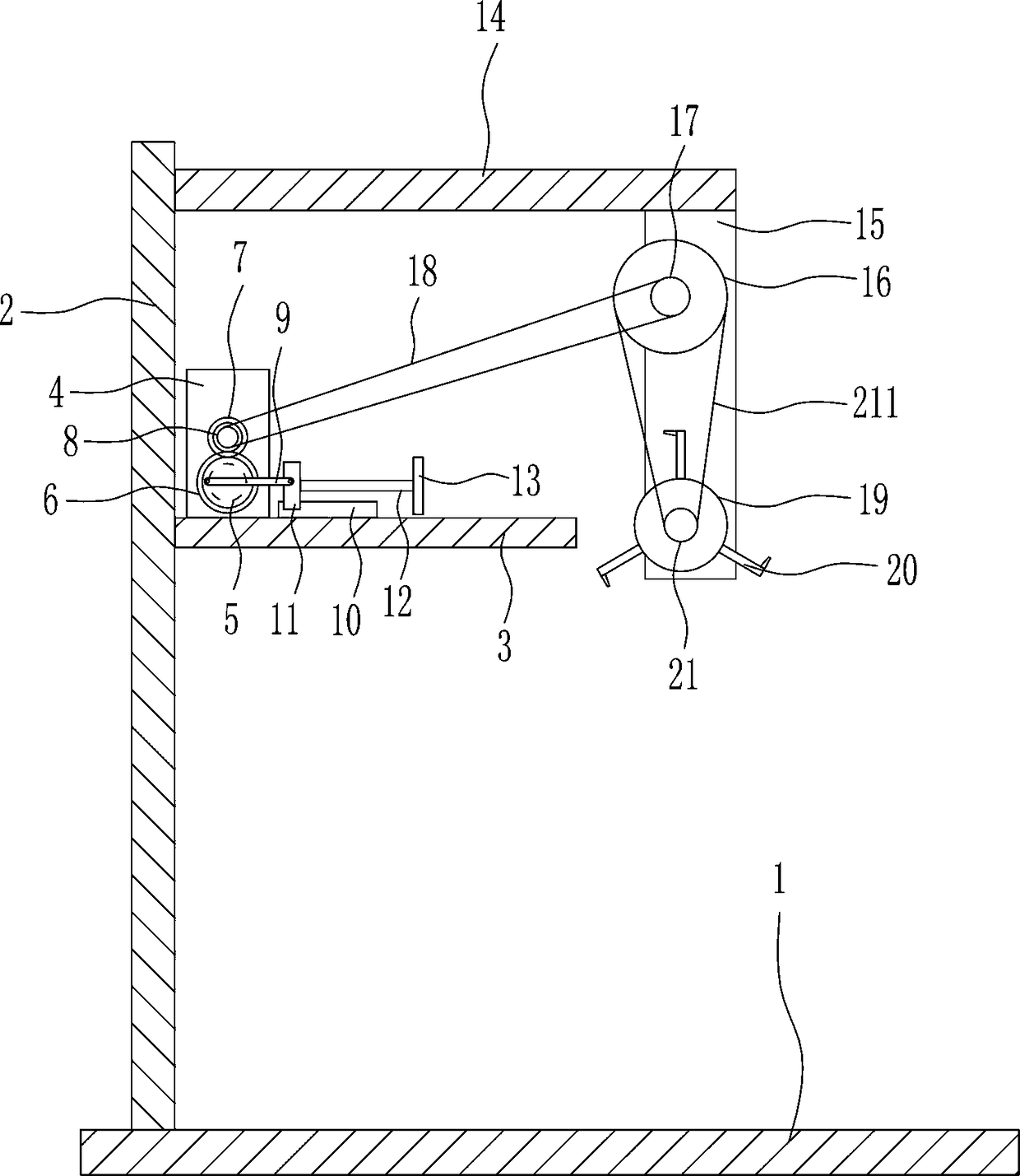

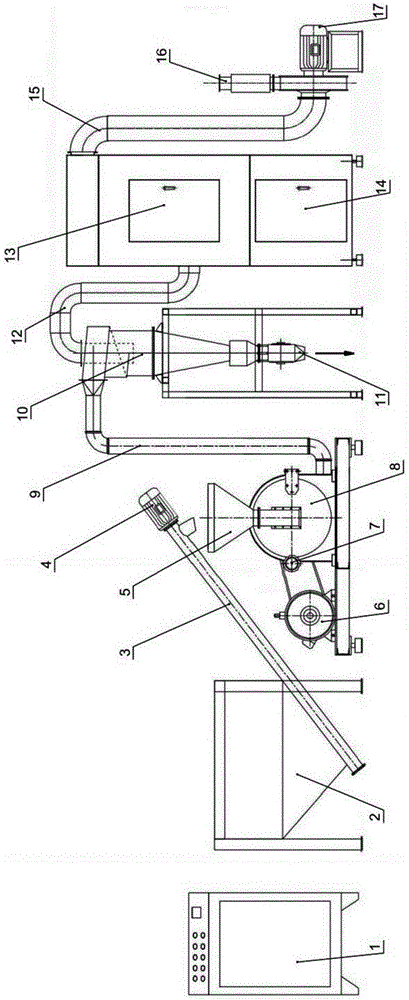

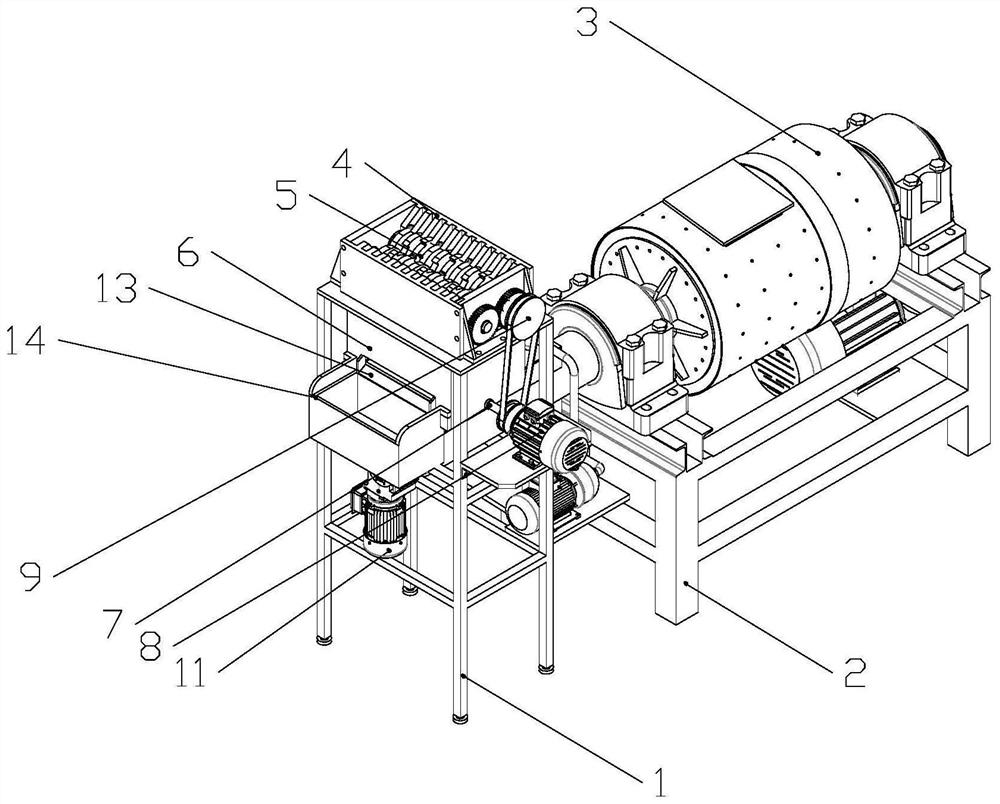

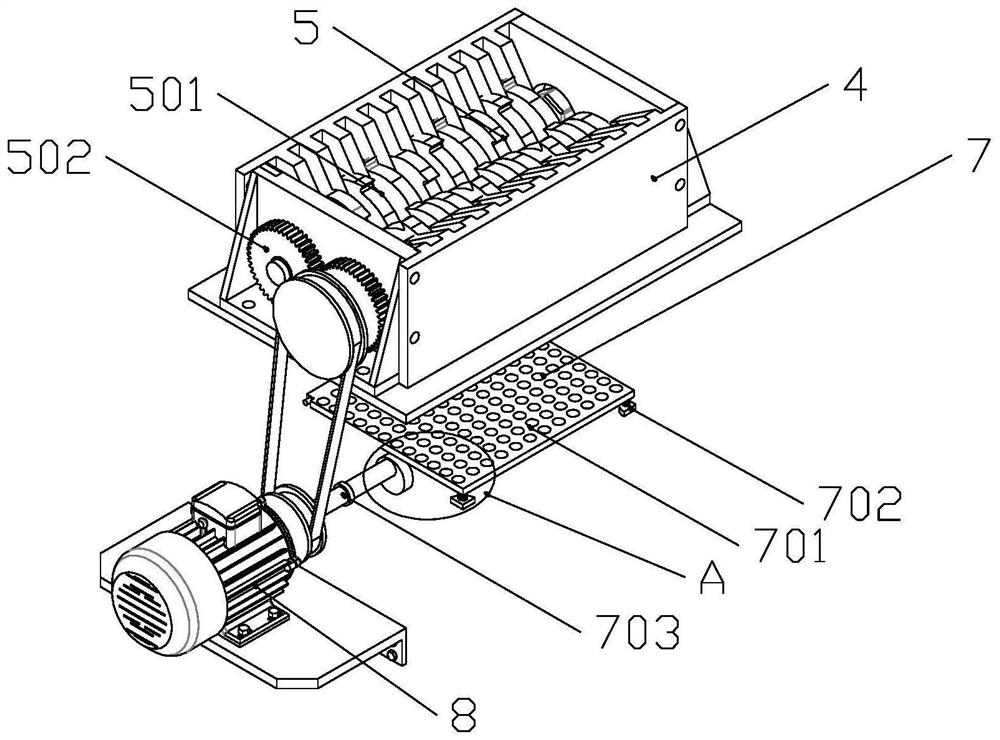

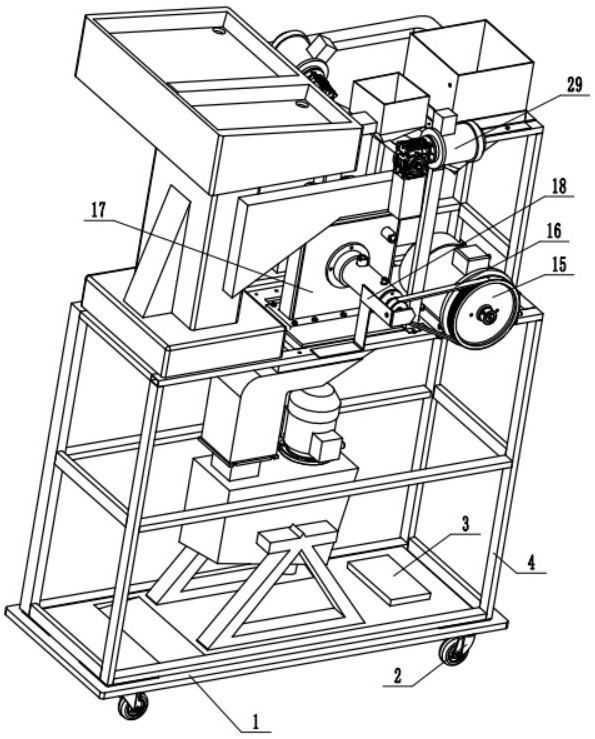

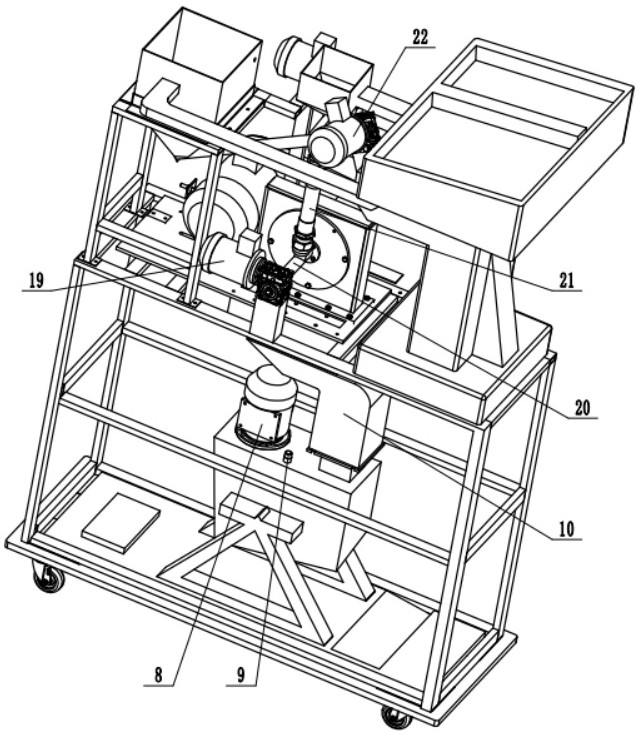

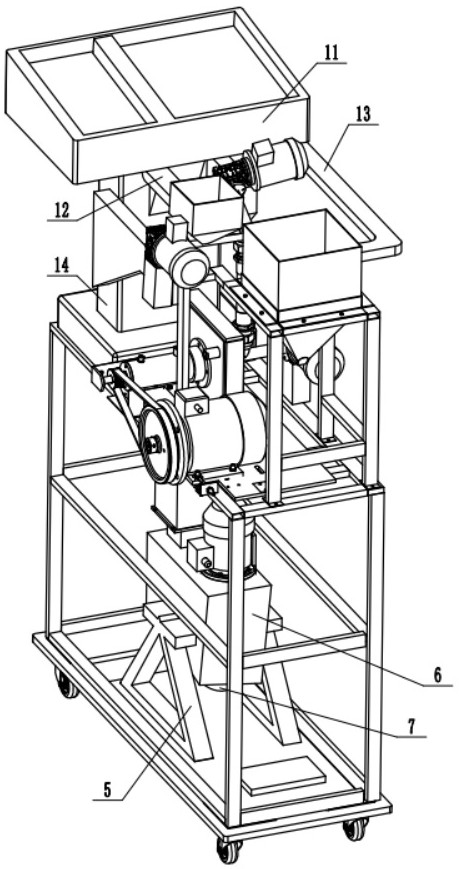

Automatic crushing and stirring equipment for livestock feed

InactiveCN112717810AAutomate transportationEasy to controlFeeding-stuffTransportation and packagingAnimal scienceAgricultural science

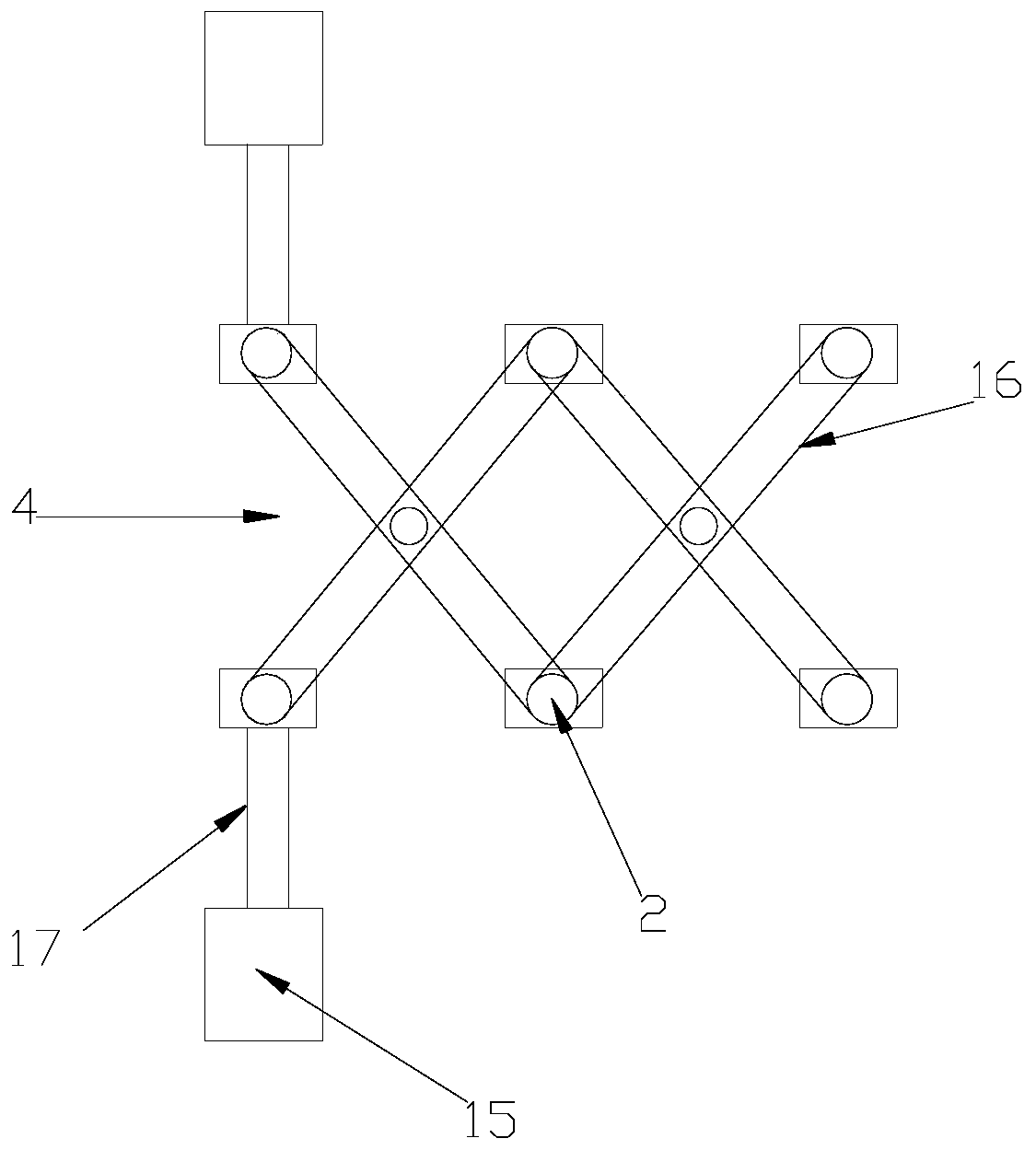

Automatic smashing and stirring equipment for livestock feed comprises a supporting mechanism, a feeding mechanism, a crushing mechanism and a stirring mechanism; the supporting mechanism comprises a bottom plate, universal wheels and a bearing frame; the feeding mechanism is fixedly mounted on the upper end surface of the bearing frame, collects and transmits grains to be stirred, and transmits the grains to the crushing mechanism for crushing; the crushing mechanism is fixedly mounted on the upper end surface of the bottom plate, and is used for crushing the grains; the stirring mechanism is fixedly mounted on the upper end surface of the bearing frame 4, and is used for stirring the crushed grains; A Y grain feeding motor drives a Y feeding shaft, an X grain feeding motor drives an X feeding shaft, and therefore automatic conveying of grains is achieved, control over the grains entering the smashing box can also be achieved, a smashing motor drives a driving belt wheel, and then a belt drives wheels on a driven belt wheel frame; therefore, the crushing device arranged in the crushing box is driven to move, and the crushing function is achieved.

Owner:王黑子

Anti-blockage powder mill

The invention relates to an anti-blockage powder mill. A body, an operation plate, a feeding pipe, a discharging pipe, a pulverizing device and two supporting feet are included. An anti-blockage mechanism and an auxiliary mechanism are further included. The anti-blockage mechanism comprises a screen, a transmission assembly, two first springs and two drive assemblies. Each drive assembly comprisesa motor, a fixing rod and a rotation disc. The transmission assembly comprises a first bearing, a lead screw, a ball screw bearing and two support rods. The auxiliary mechanism comprises a rotation shaft, a grinding disc, a connecting assembly and two pushing assemblies. Each pushing assembly comprises a connecting block, a connecting rod, a second spring, a third spring and a push plate. According to the anti-blockage powder mill, through the anti-blockage mechanism, the screen can vibrate, materials on the screen conveniently fall to the bottom in the body through the screen, the probability that the materials block the screen is reduced, screen circulation is not influenced, and practicability of equipment is improved. Through the auxiliary mechanism, materials not conforming to the specification on the screen can be subjected to secondary pulverizing, and accordingly the powder milling quality is improved.

Owner:深圳市伊乐农产品有限公司

Raw material crushing equipment for plastic film production

InactiveCN112606260AAvoid replacementRealize the shredding functionGrain treatmentsPlastic filmRotating disc

The invention relates to raw material crushing equipment for plastic film production. The raw material crushing equipment for plastic film production comprises a crushing box, wherein the crushing box is in a cylindrical shape and is vertically arranged; a discharge device is arranged at the bottom of the crushing box; a crushing mechanism and an auxiliary mechanism are arranged on the crushing box; the crushing mechanism comprises a power assembly and a crushing assembly; the power assembly is arranged at the bottom of the crushing box; the crushing assembly is arranged in the crushing box; the crushing assembly comprises a feeding pipe, a connecting disc, a rotating disc, a fixed pipe, two air cylinders and two crushing units; each crushing unit comprises a connecting shaft and two rollers; and the auxiliary mechanism comprises a fixed disc, an auxiliary disc, a transmission shaft and two transmission assemblies. According to the raw material crushing equipment for plastic film production, the crushing function is achieved through the crushing mechanism, and in addition, the overload prevention function is achieved through the auxiliary mechanism.

Owner:南京蒙腾新能源技术开发有限公司

a soup maker

ActiveCN106108608BEasy to cleanRealize the shredding functionVessels with intergral heatingTool bitEngineering

The invention discloses a soup cooker which comprises a cup lid, a cup body, a tool rest arranged inside the cup body and a smashing tool arranged on the tool rest. The tool rest is of a cylindrical structure with an installation hole. A main shaft is sleeved with the tool rest. The main shaft is provided with a locking portion fixed to the installation hole. Due to close fit of the installation hole and the main shaft, the tool and the main shaft are detachably connected, the tool is disassembled to clean the tool bit, and cleaning is convenient.

Owner:NINGBO HUABAO PLASTICS & RUBBER MOLD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com