Bamboo crushing device for paper making industry

A crushing equipment and papermaking technology, applied in papermaking, textiles and papermaking, fiber raw material processing, etc., can solve problems such as inability to crush bamboo evenly, affect paper quality, and reduce work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

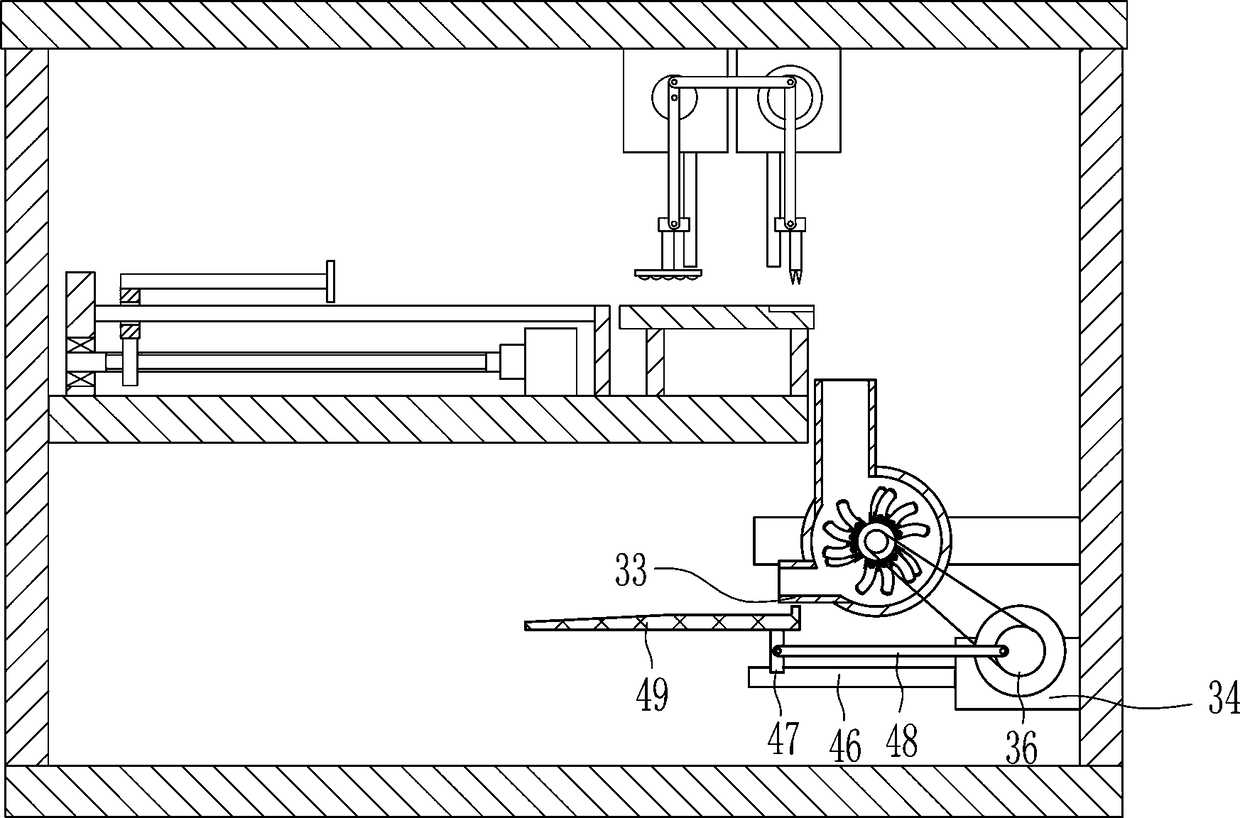

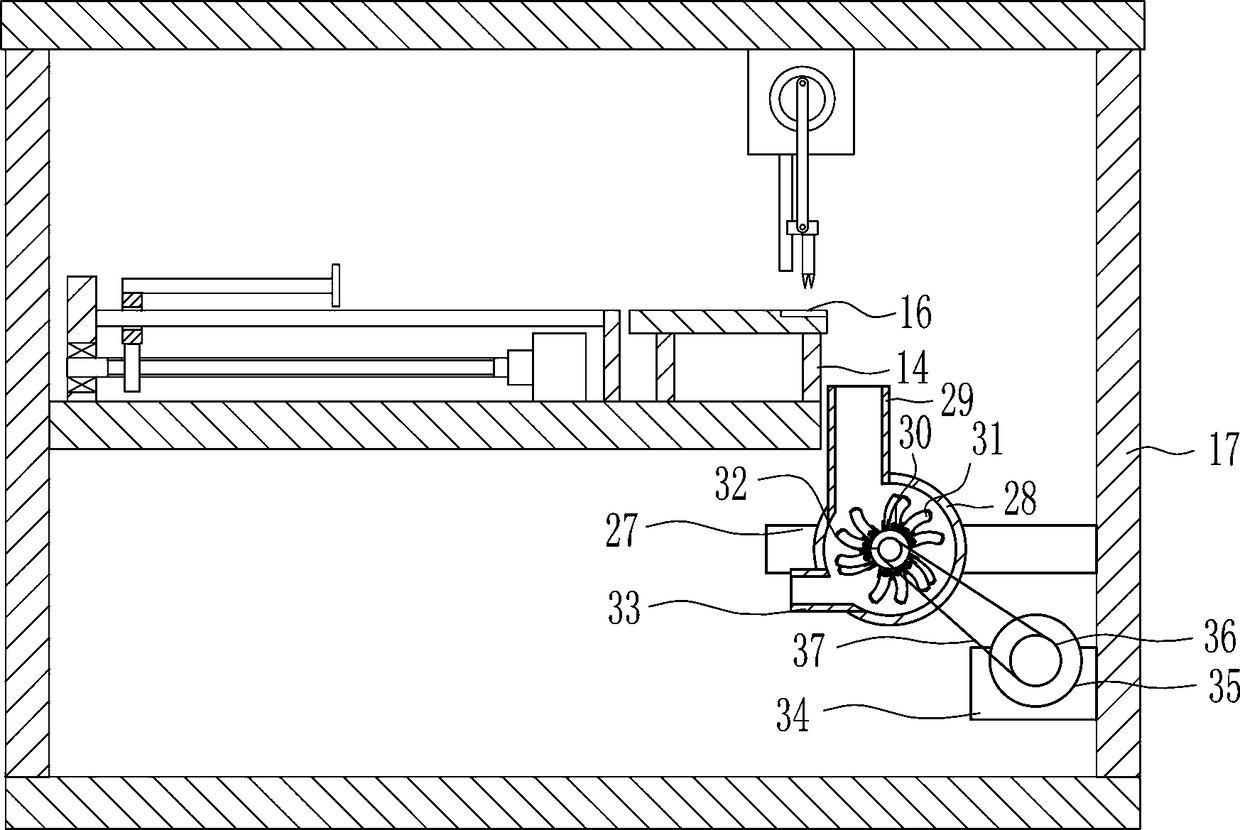

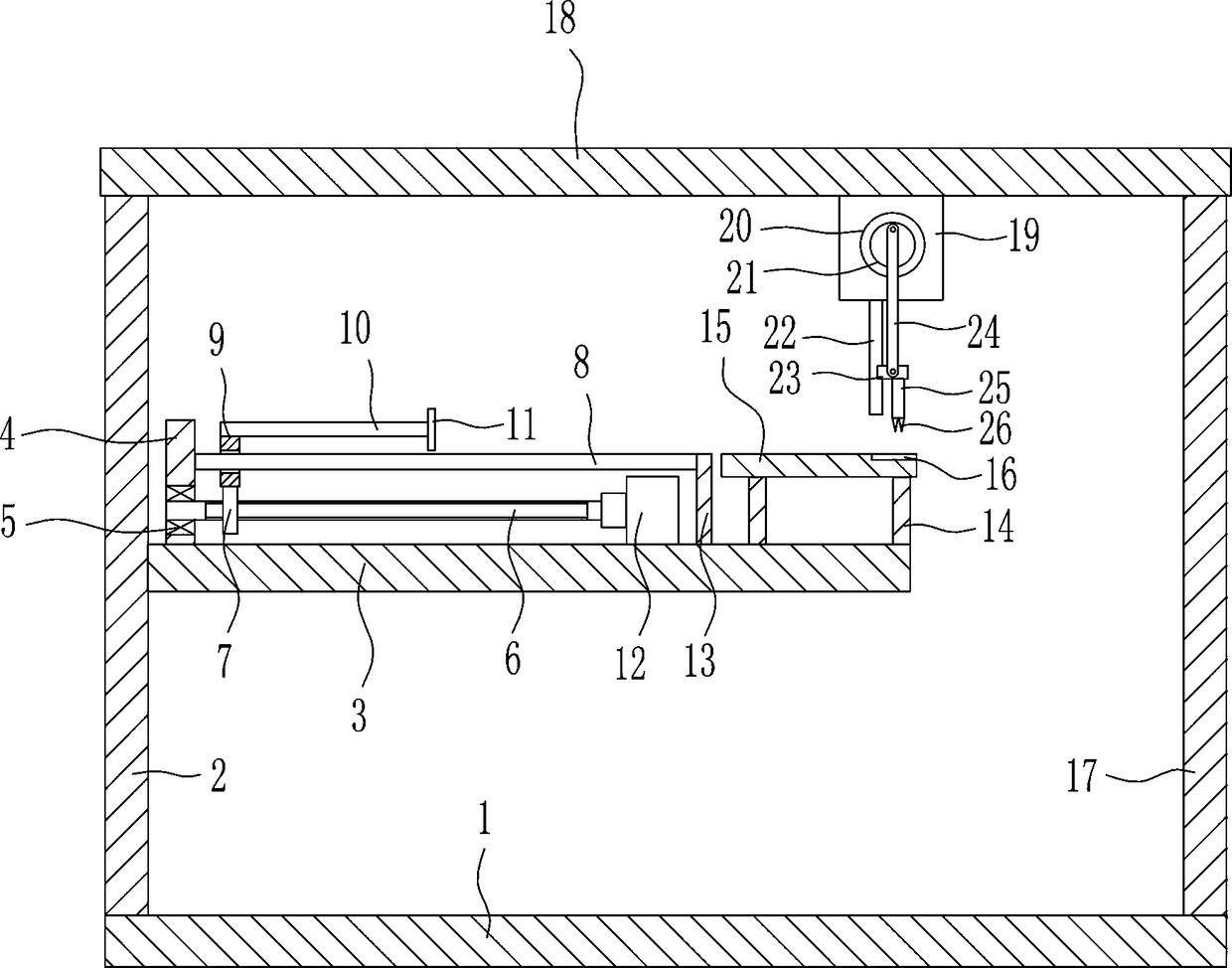

[0026] A kind of bamboo pulverizing equipment for papermaking industry, such as Figure 1-5 As shown, it includes a base 1, a first support 2, a second support 3, a first support rod 4, a bearing 5, a screw rod 6, a nut 7, a sliding rod 8, a sliding sleeve 9, a second support rod 10, and a push plate 11 , the first motor 12, the third pole 13, the third support 14, the first support plate 15, the fourth support 17, the fifth support 18, the first fixed plate 19, the second motor 20, the first turntable 21, the first A slide rail 22, the first slider 23, the first connecting rod 24, the fourth pole 25 and the slice 26 are fixedly connected with the first bracket 2 on the left side above the base 1, and are fixed on the right side of the first bracket 2 A second support 3 is connected, and a first support rod 4 is fixedly connected to the upper left side of the second support 3, and a bearing 5 is embedded on the first support rod 4, and a screw rod 6 is interferingly connected ...

Embodiment 2

[0028] A kind of bamboo pulverizing equipment for papermaking industry, such as Figure 1-5 As shown, it includes a base 1, a first support 2, a second support 3, a first support rod 4, a bearing 5, a screw rod 6, a nut 7, a sliding rod 8, a sliding sleeve 9, a second support rod 10, and a push plate 11 , the first motor 12, the third pole 13, the third support 14, the first support plate 15, the fourth support 17, the fifth support 18, the first fixed plate 19, the second motor 20, the first turntable 21, the first A slide rail 22, the first slider 23, the first connecting rod 24, the fourth pole 25 and the slice 26 are fixedly connected with the first bracket 2 on the left side above the base 1, and are fixed on the right side of the first bracket 2 A second support 3 is connected, and a first support rod 4 is fixedly connected to the upper left side of the second support 3, and a bearing 5 is embedded on the first support rod 4, and a screw rod 6 is interferingly connected ...

Embodiment 3

[0031] A kind of bamboo pulverizing equipment for papermaking industry, such as Figure 1-5 As shown, it includes a base 1, a first support 2, a second support 3, a first support rod 4, a bearing 5, a screw rod 6, a nut 7, a sliding rod 8, a sliding sleeve 9, a second support rod 10, and a push plate 11 , the first motor 12, the third pole 13, the third support 14, the first support plate 15, the fourth support 17, the fifth support 18, the first fixed plate 19, the second motor 20, the first turntable 21, the first A slide rail 22, the first slider 23, the first connecting rod 24, the fourth pole 25 and the slice 26 are fixedly connected with the first bracket 2 on the left side above the base 1, and are fixed on the right side of the first bracket 2 A second support 3 is connected, and a first support rod 4 is fixedly connected to the upper left side of the second support 3, and a bearing 5 is embedded on the first support rod 4, and a screw rod 6 is interferingly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com