Large and square packed straw picking and bundling machine

A baler and straw technology, which is applied in the field of large square bales of straw picking and baling machines, can solve the problems of heavy dust removal workload, high cost, irregular straw bales, etc., and achieve the effect of reducing workload, reducing costs, and facilitating handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

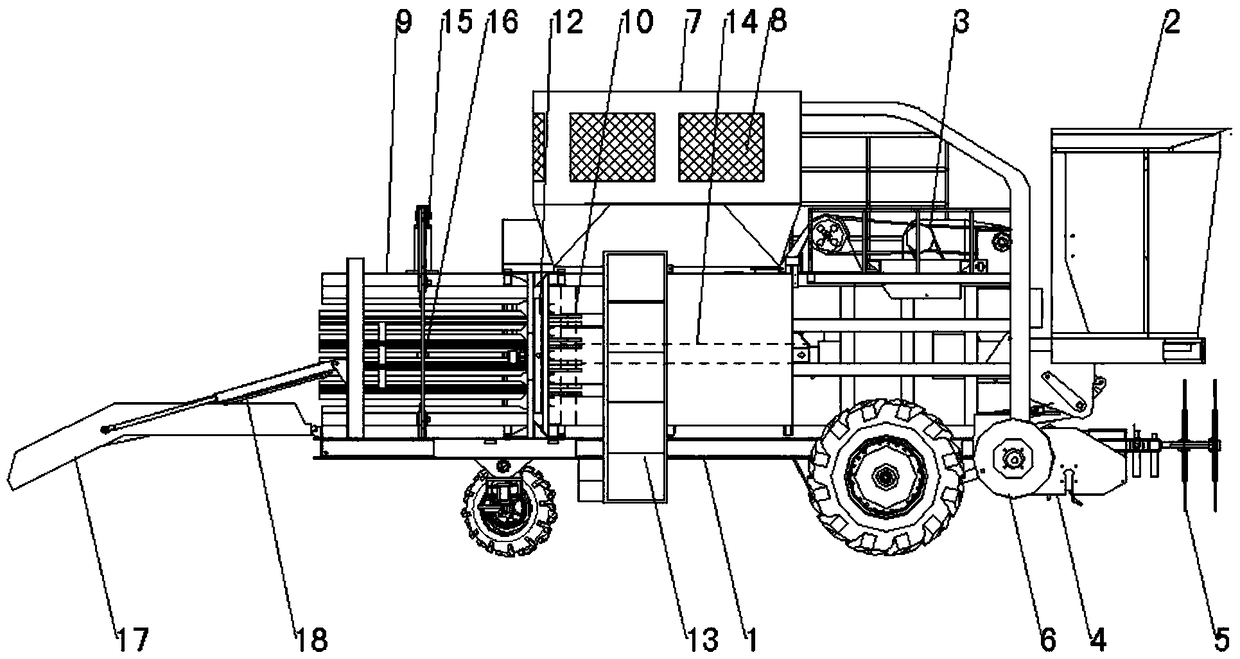

[0020] Such as Figure 1-Figure 3 As shown, the large square baler straw picking and bundling machine includes a car body 1, a control room 2 and a power assembly 3 arranged on the car body 1, and a picker 4 is arranged at the front end of the car body 1, and the picker 4 is formed by picking up Box 401, the pick-up roller 402 and the stirring cage 403 that are installed in the pick-up box 401 front and rear and connected with the powertrain 3 through the transmission mechanism, the movable blade 404 that is installed on the pick-up roller 402 in the circumferential direction, are installed on the inner wall of the pick-up box 401 and the movable blade The fixed blade 405 corresponding to 404 constitutes; the left and right rolling grass disc 5 connected with the power assembly 3 through the transmission mechanism is vertically arranged in front of the pickup 4, and the power assembly 3 is installed at the discharge end of the pick-up box 401 through the transmission mechanism....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com