Method for preparing high-strength gypsum by adopting atmospheric pressure solution method

A high-strength gypsum and solution method technology, applied in the direction of calcium/strontium/barium sulfate, etc., can solve the problems of large initial investment, lengthy process, and complicated equipment, and achieve the effect of simple equipment, convenient operation, and easy control of conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for preparing high-strength gypsum by atmospheric solution method, the steps are:

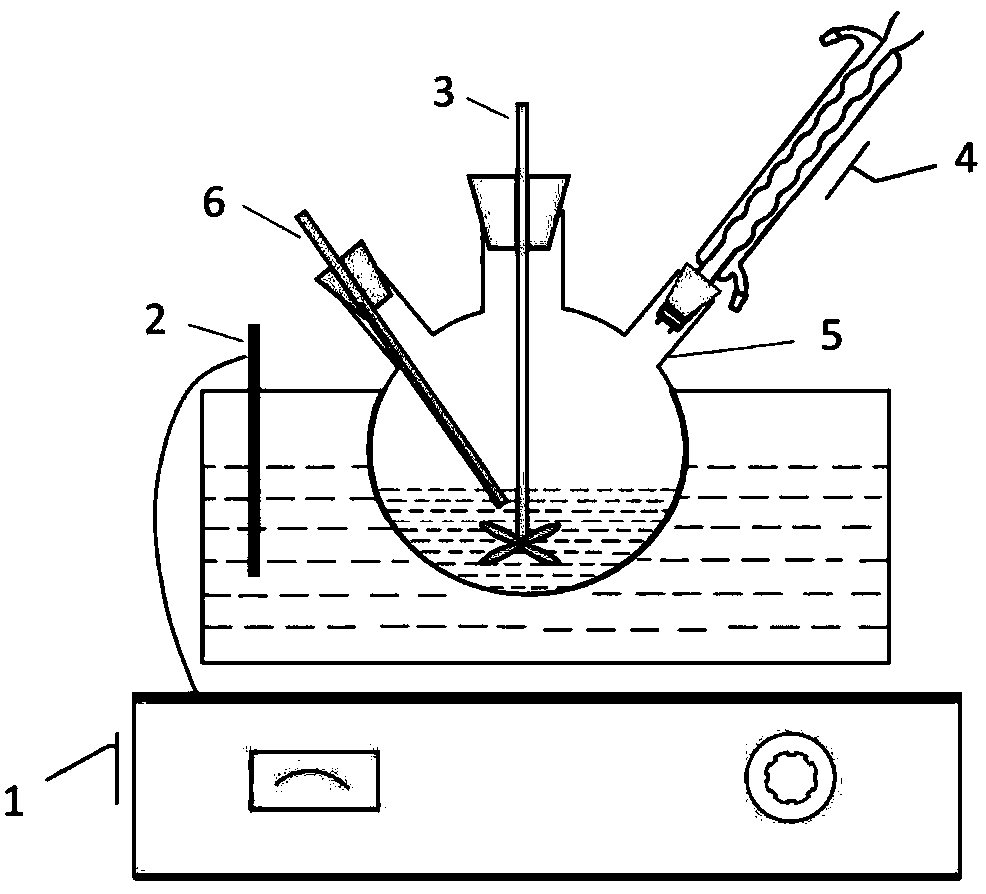

[0046] (1) Configure a compound chloride solution with a mass concentration of 5%, in which the mass ratio of the compound chloride salt is NaCl:LiCl=1:1, figure 1 Continue heating and stirring in the reactor shown. After the thermostatic heater is heated to 85°C, stabilize for 30 minutes, and use a mercury thermometer to help maintain a constant temperature;

[0047] (2) Under the condition of constant temperature and continuous stirring, slowly add flue gas desulfurization gypsum with a mass concentration of 5% and tartaric acid with a mass concentration of 0.1% to the composite chloride solution, and adjust the pH of the system with HCl and NaOH to make it Keep it in the range of 5-8, and the mixed slurry continues to react for 0.5h;

[0048] (3) The slurry in the reactor is quickly filtered in a sand core filter device, washed three times with near-boiling water (95℃-98℃), fixed b...

Embodiment 2

[0051] A method for preparing high-strength gypsum by atmospheric solution method, the steps are:

[0052] (1) Prepare a composite chloride solution with a mass concentration of 30%, in which the mass ratio of the composite chloride salt is MgCl 2 :CaCl 2 =1:1, in figure 1 Continuous heating and stirring in the reactor shown, after the constant temperature heater is heated to 96°C, stabilize for 30 minutes, and use a mercury thermometer to help maintain a constant temperature;

[0053] (2) Under the condition of constant temperature and continuous stirring, slowly add flue gas desulfurization gypsum with a mass concentration of 20%, sodium gluconate with a mass concentration of 0.2%, and 1% sodium alginate to the salt solution system, using HCl and NaOH Adjust the pH of the system to keep it in the range of 5-8, and the mixed slurry continues to react for 6 hours;

[0054] (3) The slurry in the reactor is quickly filtered in a sand core filter device, washed three times with near-bo...

Embodiment 3

[0057] A method for preparing high-strength gypsum by atmospheric solution method, the steps are:

[0058] (1) Prepare a composite chloride solution with a mass concentration of 30%, in which the mass ratio of the composite chloride salt is MgCl 2 :LiCl=4:1, in figure 1 Continue heating and stirring in the reactor shown. After the thermostatic heater is heated to 65°C, stabilize for 30 minutes, and use a mercury thermometer to help maintain a constant temperature;

[0059] (2) Under the condition of constant temperature and continuous stirring, slowly add 20% mass concentration of flue gas desulfurization gypsum and mass concentration of 0.1% tartaric acid, 0.05% sodium alginate to the salt solution system, and use HCl and NaOH to adjust the system Keep the pH in the range of 5-8, and the mixed slurry will continue to react for 2h;

[0060] (3) Quickly filter the slurry in the reactor, wash it with near-boiling water (95°C-98°C) for three times, add absolute ethanol to fix it, and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com