Low melting point valve port bag and manufacturing method thereof

A production method and technology of valve pockets, which are applied in the field of packaging bags, can solve problems such as unstable quality, poor physical strength, and insufficient heat-sealing strength, and achieve the effects of non-toxic raw materials, stable melting points, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

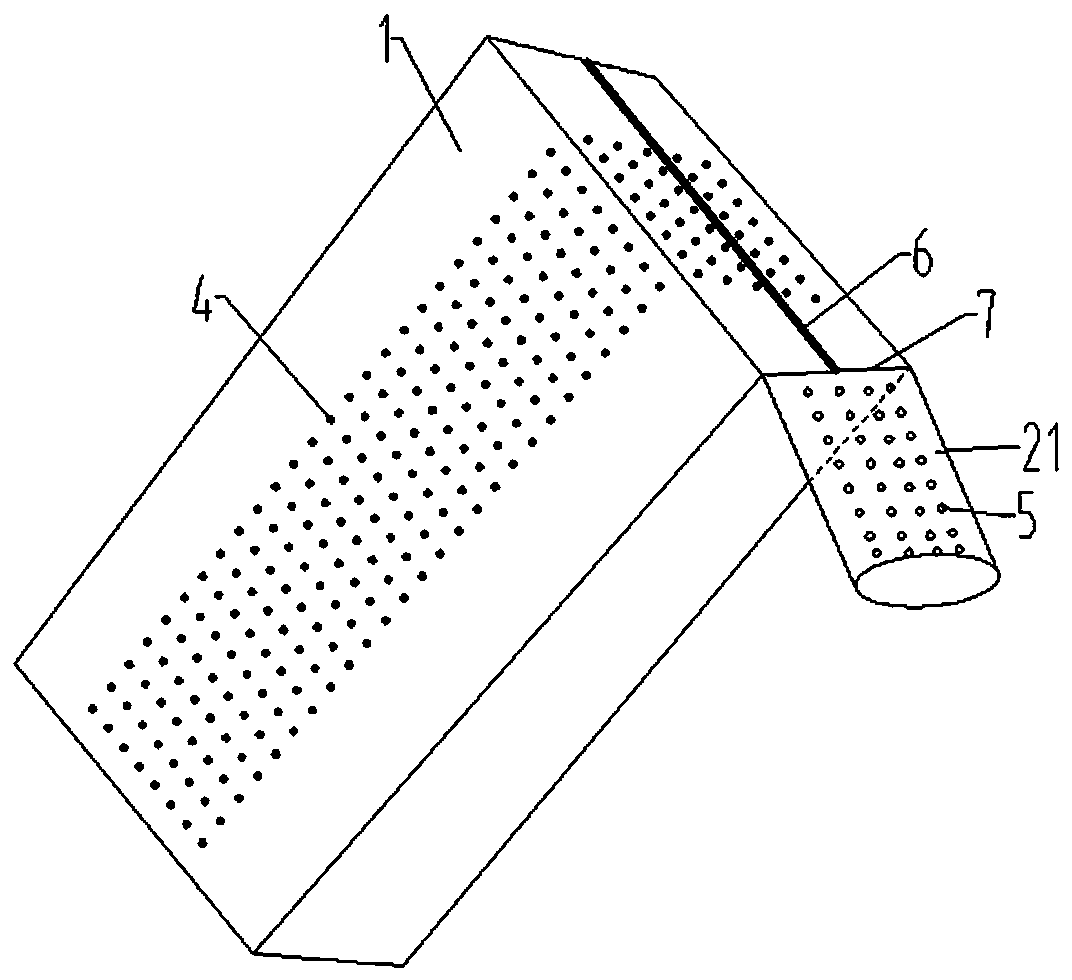

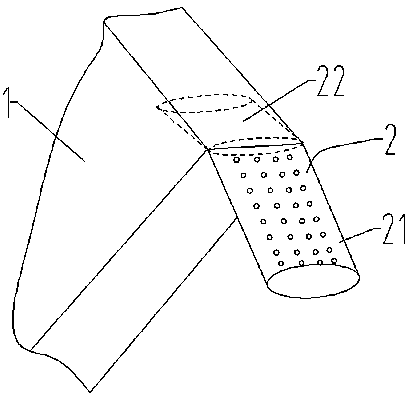

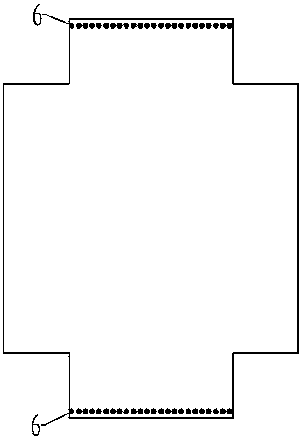

[0051] Example 1: See Figure 1~3 , a valve pocket with a low melting point, comprising a valve pocket body 1, the valve pocket body 1 is provided with a valve port 2, the valve port 2 includes an outer valve port 21 and an inner valve port 22, and the outer valve port 21 is arranged on the top right side of the valve bag body 1, and the inner valve port 22 is arranged at a position corresponding to the outer valve port 21 in the valve bag body 1, and the inner valve port 22 and the outer valve port 21 interconnected.

[0052] The carbon black material is poured into the valve pocket 1 through the valve port 2, and after the material is fully filled, the valve port 2 is folded toward the inner cavity of the valve body, and the carbon black material itself filled in the valve pocket 1 cavity is Self-sealing by gravity.

[0053]The cross section of the valve pocket body 1 can be in various shapes, such as circular, square or rectangular.

[0054] The overall length of the out...

Embodiment 2

[0087] Embodiment 2: The overall structure of the low melting point valve pocket in the present embodiment 2 is the same as that of Example 1, and the manufacturing method of the low melting point valve pocket specifically includes valve pocket body preparation and valve port preparation:

[0088] Wherein the valve pocket body preparation specifically comprises the following steps:

[0089] 1) Mixing: Take 87.5% ethylene-vinyl acetate copolymer and 12.5% linear low-density polyethylene by weight as raw materials for the bag body, and put them into a mixer for full stirring and mixing.

[0090] The stirring and mixing time of the mixer in the step 1) is 35 minutes, and the mixing temperature is normal temperature.

[0091] The VA content of the ethylene-vinyl acetate copolymer in the step 1) is 12%.

[0092] The linear low density polyethylene in the step 1) is a metallocene linear low density polyethylene produced with a metallocene catalyst.

[0093] 2) Film blowing: Pour...

Embodiment 3

[0108]Embodiment 3: The overall structure of the low melting point valve pocket in the present embodiment 3 is the same as that of Example 1, and the manufacturing method of the low melting point valve pocket specifically includes valve pocket body preparation and valve port preparation:

[0109] Wherein the valve pocket body preparation specifically comprises the following steps:

[0110] 1) Mixing: Take 90% ethylene-vinyl acetate copolymer and 10% linear low-density polyethylene by weight as raw materials for the bag body, and put them into a mixer for sufficient mixing.

[0111] The stirring and mixing time of the mixer in the step 1) is 40 minutes, and the mixing temperature is normal temperature.

[0112] The VA content of the ethylene-vinyl acetate copolymer in the step 1) is 10%.

[0113] The linear low density polyethylene in the step 1) is a metallocene linear low density polyethylene produced with a metallocene catalyst.

[0114] 2) Film blowing: Pour the mixed mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com