Combined stacking system based on machine vision for irregular tobacco packets

A machine vision, combined code technology, applied in the stacking of objects, de-stacking of objects, instruments, etc., can solve problems such as process errors and cigarette pack information deviation, to ensure reliability, reduce stacking errors, and eliminate errors. The effect of matching point pairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions in the embodiments of the present invention will be described clearly and in detail below with reference to the drawings in the embodiments of the present invention. The described embodiments are only some of the embodiments of the invention.

[0024] The technical scheme that the present invention solves the problems of the technologies described above is:

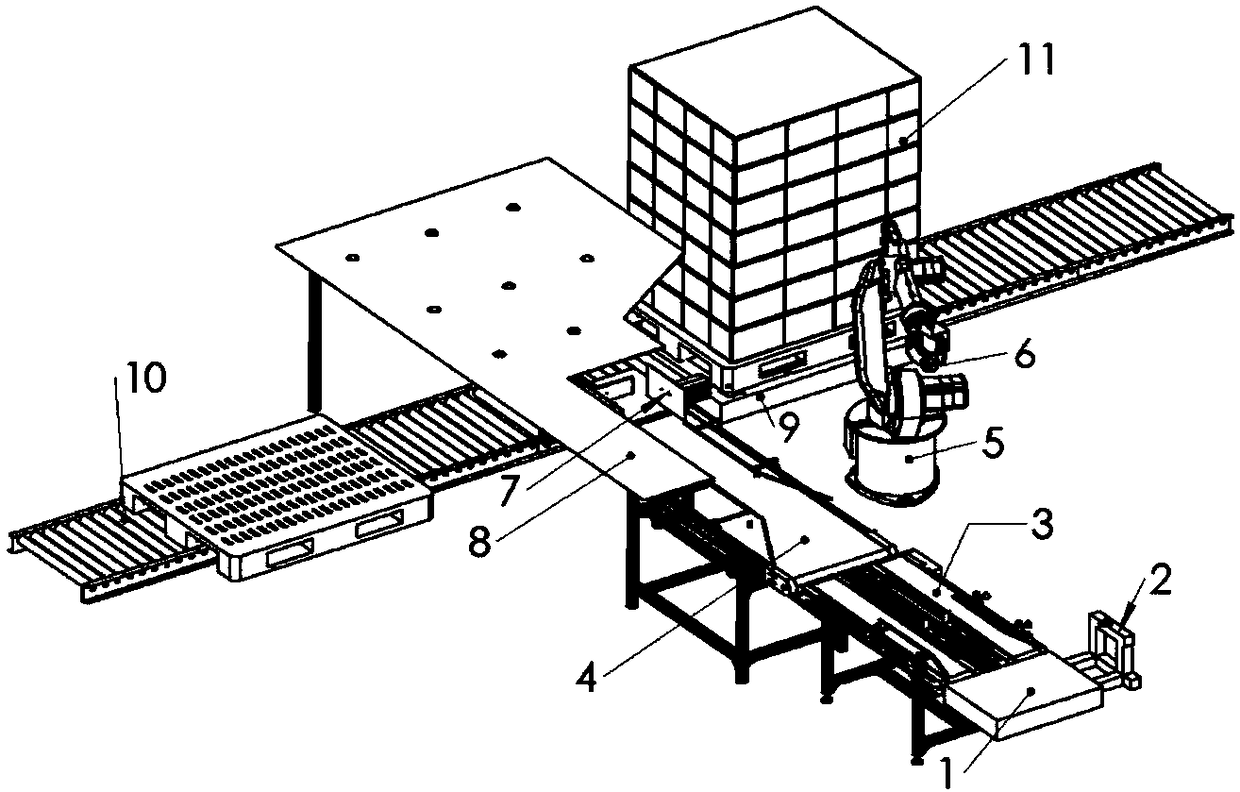

[0025] The present invention aims to solve the above problems, and proposes a new machine vision-based checking and stacking system for irregular cigarette packs. The correct identification rate of irregular cigarette packs is 100%, and the proofreading and combined palletizing of irregular cigarette packs can be completed efficiently and quickly, which can meet the requirements of safe palletizing while ensuring the reliability of palletizing. A new automatic stacking mode of cigarette packs has been created, which has prompted the tobacco logistics industry to take a solid step towards in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com