Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

95 results about "Combinatorial synthesis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Combinatorial synthesis is a technique used by chemists to create a large number of related or similar chemical compounds for the purpose of comparing them. Pharmaceutical companies may use combinatorial synthesis to discover new drugs.

Support for high performance affinity chromatography and other uses

Multilayered particulate materials are formed by coating a particulate substrate with a metal and adsorbing an organic layer comprising a recognition moiety onto the metal film. The recognition moiety interacts with an analyte of interest allowing for its detection, purification, etc. Suitable recognition moieties can be selected from a range of species including, small molecules, polymers and biomolecules and the like. The novel particulate materials of the invention can be utilized in an array of methods including, ion-exchange, ion-selective ion-exchange, assays, affinity dialysis, size exclusion dialysis, as supports in solid phase synthesis, combinatorial synthesis and screening of compound libraries and the like.

Owner:RGT UNIV OF CALIFORNIA

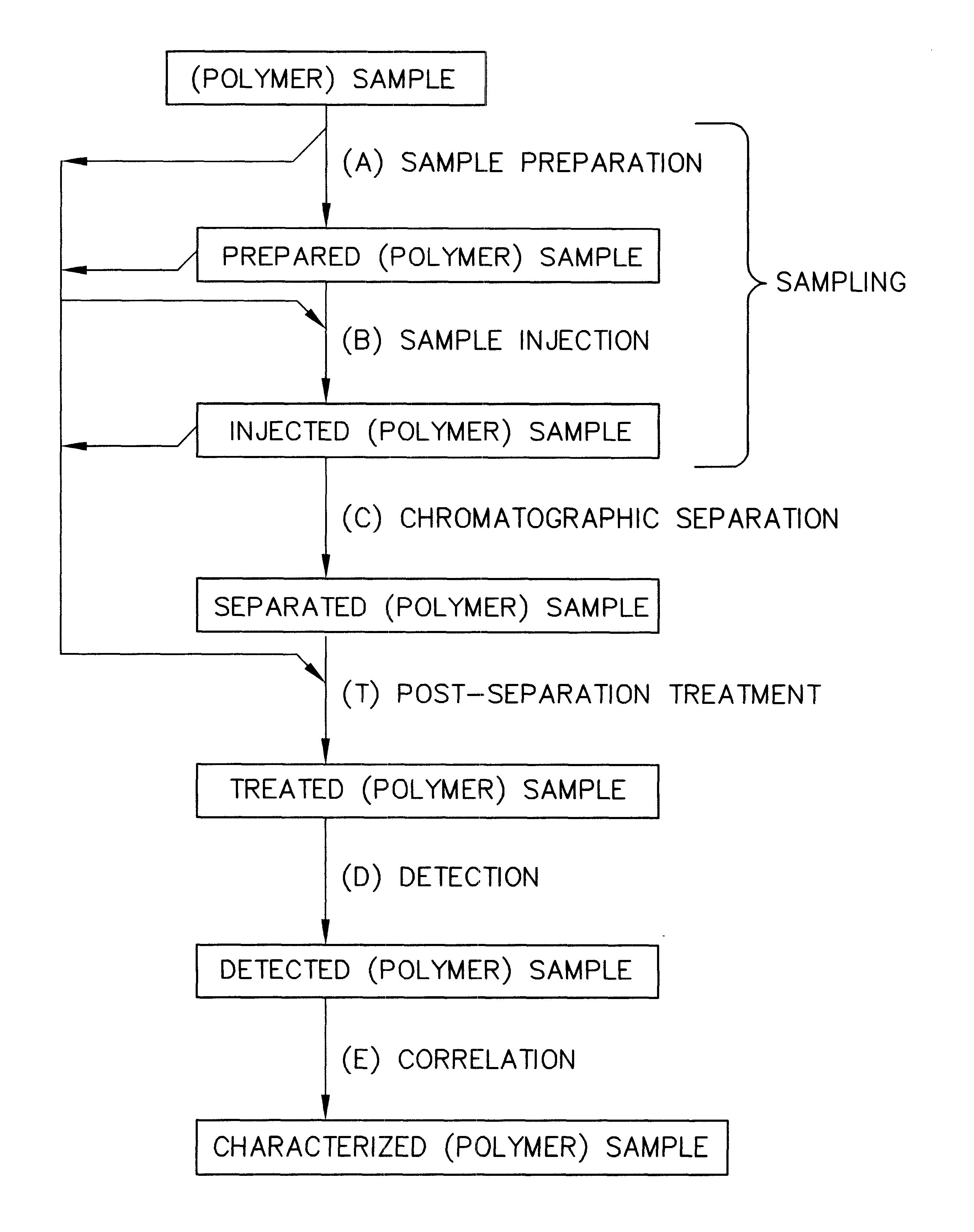

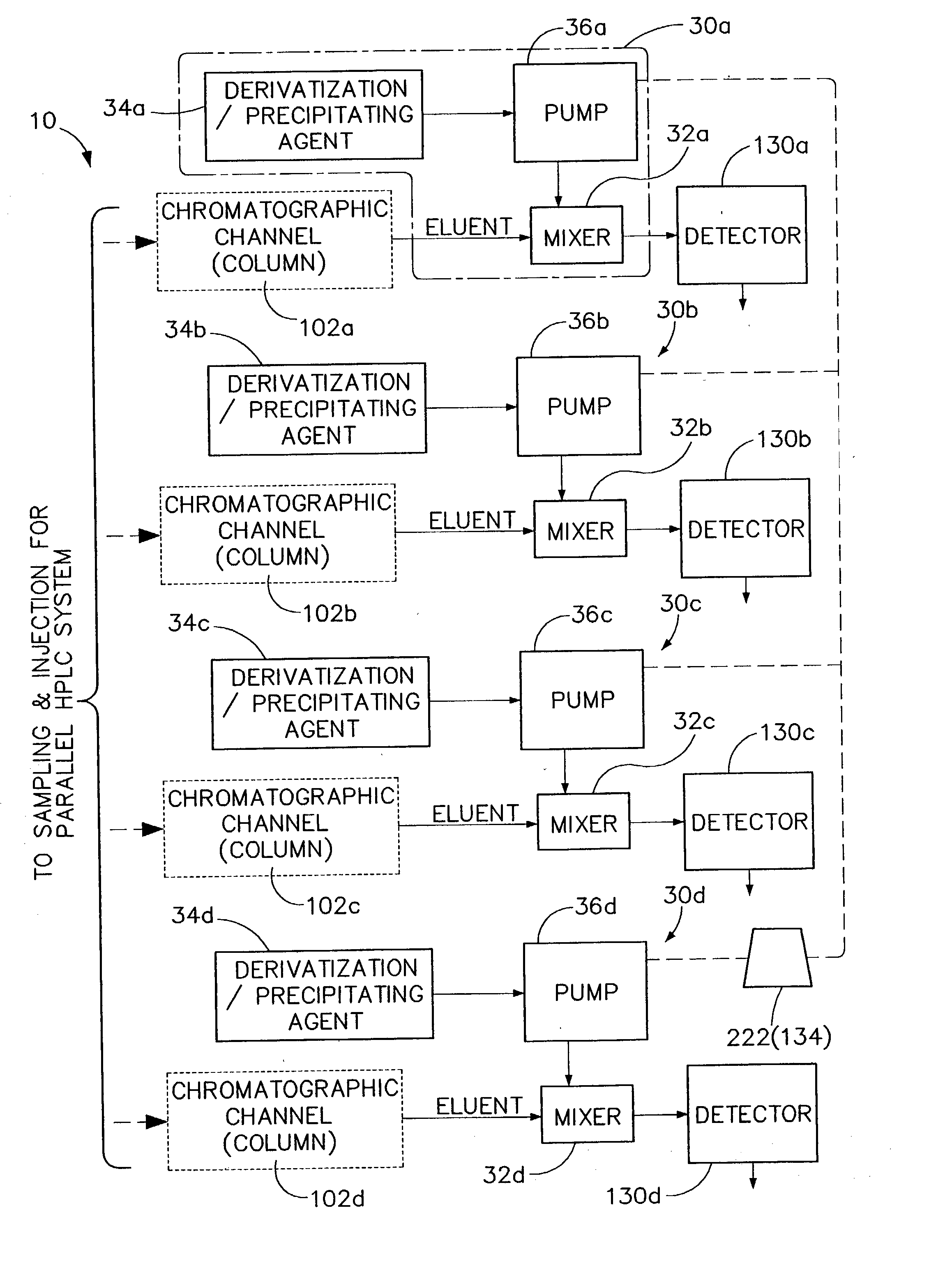

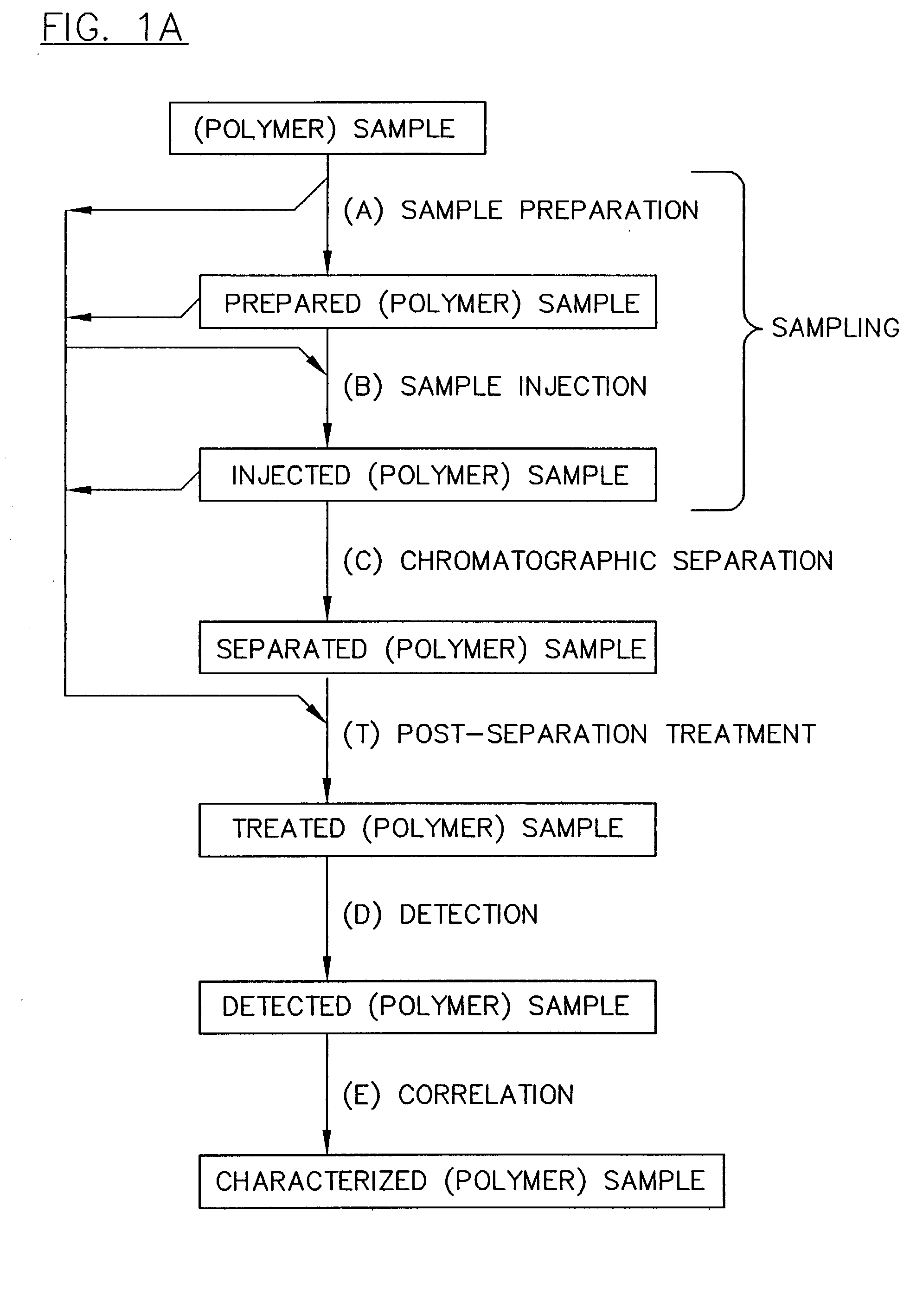

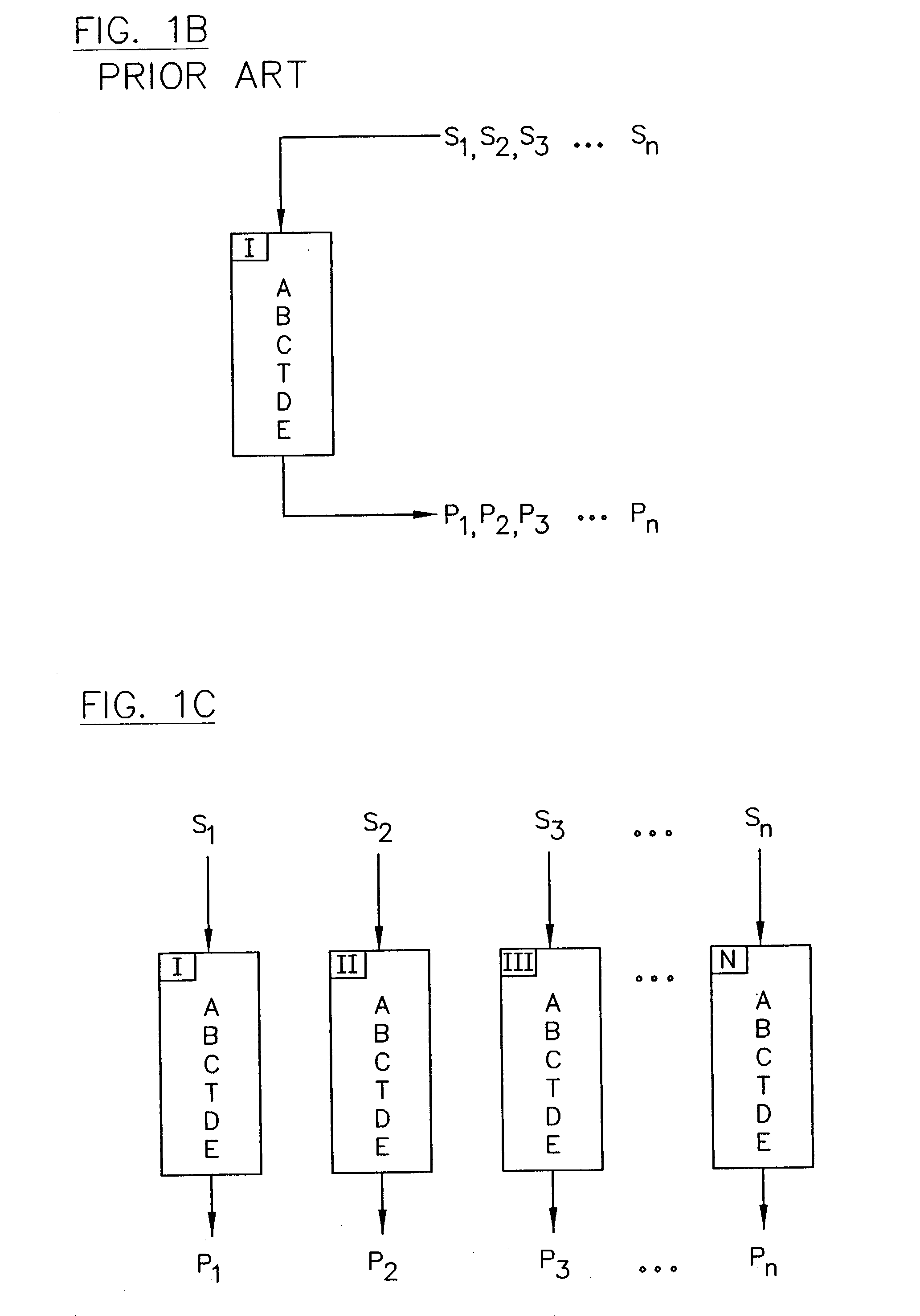

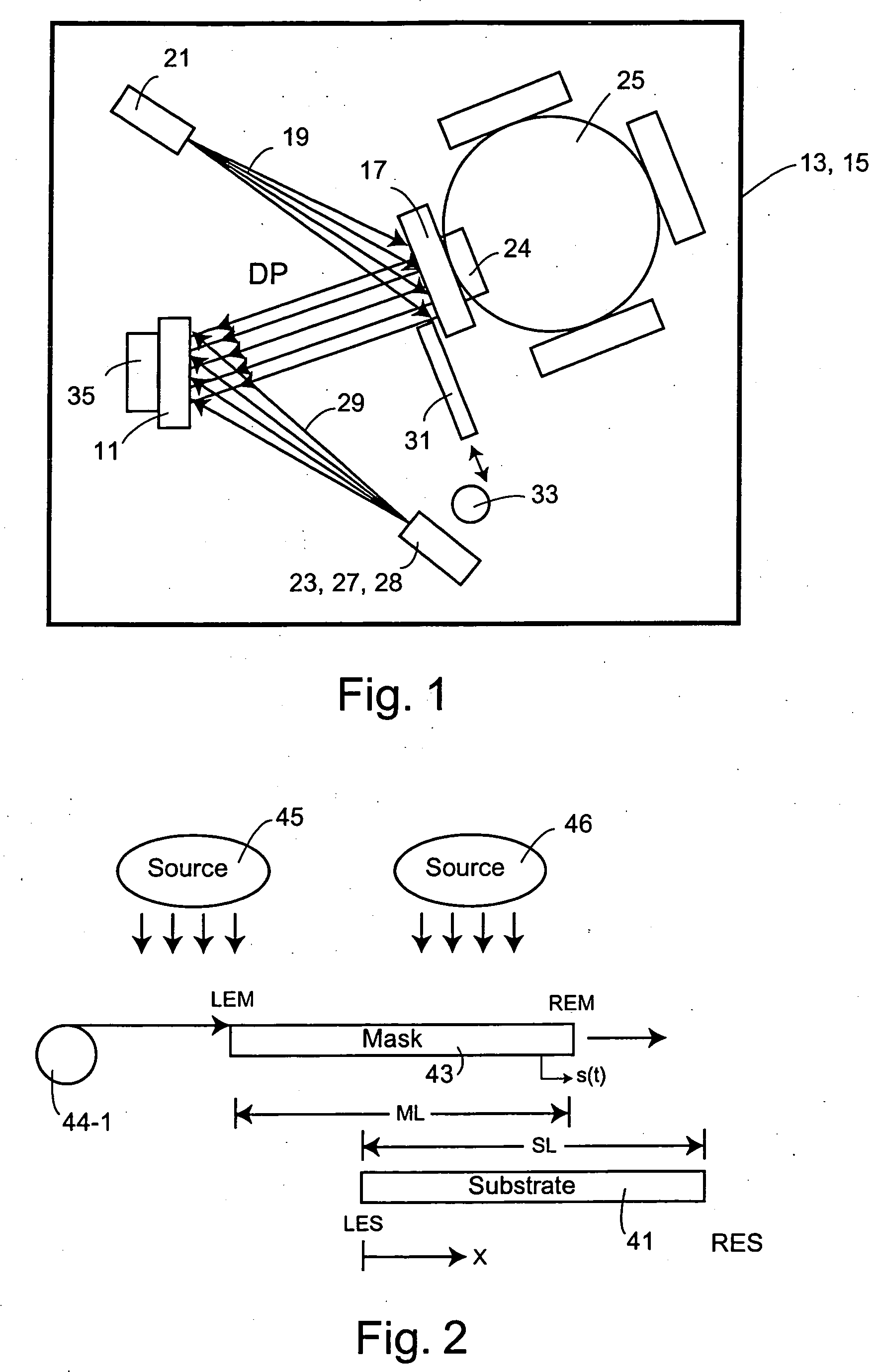

Parallel high-performance liquid chromatography with post-separation treatment

InactiveUS6436292B1High sample throughputEasy to findIon-exchange process apparatusSamplingChromatographic separationCombinatorial synthesis

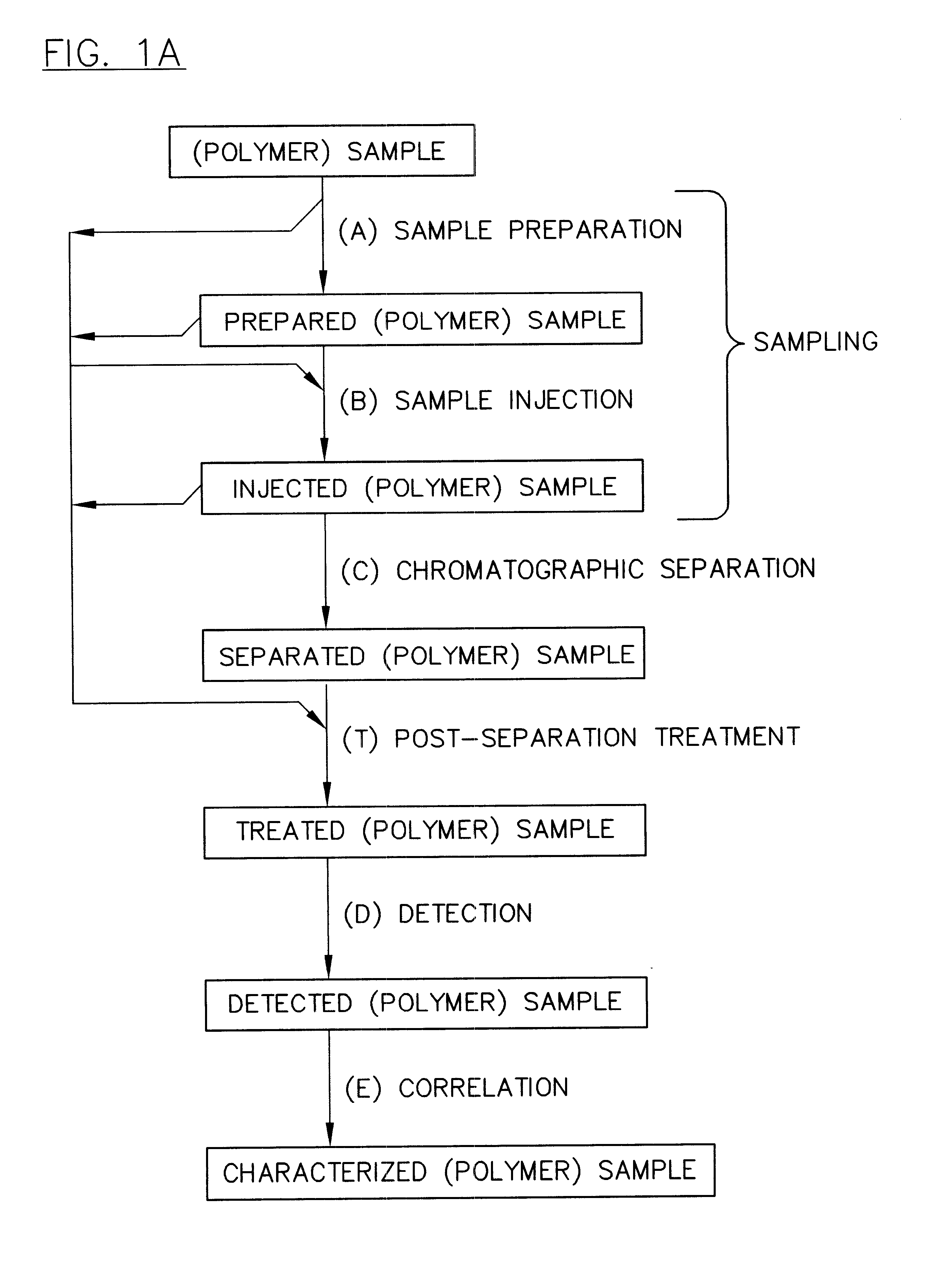

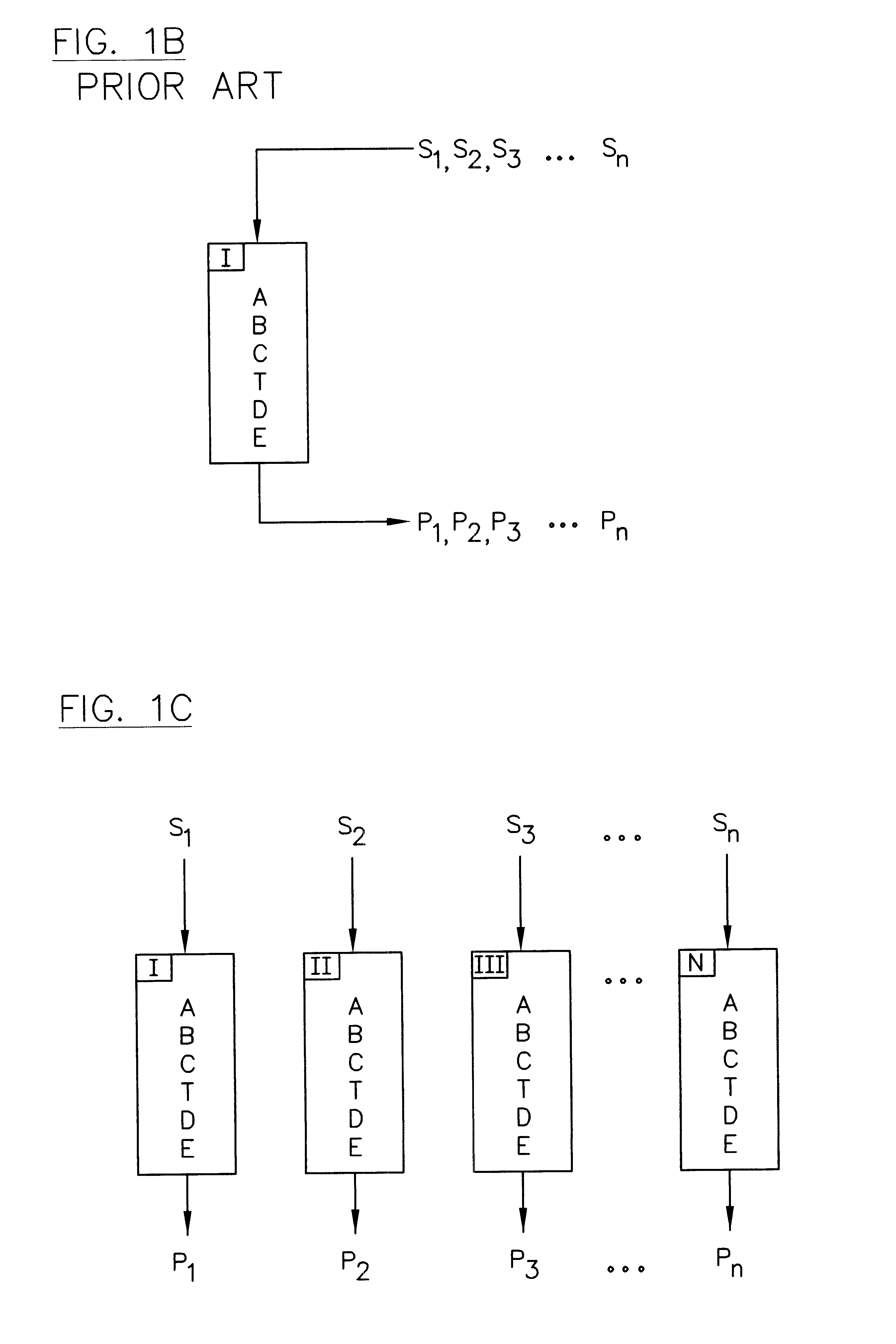

High-performance liquid chromatography (HPLC) methods and systems are disclosed that combine parallel chromatographic separation of a plurality of samples with a detection technique that involves post-separation treatment of the plurality of samples to enhance one or more properties of the sample or of a component thereof, followed by detection of the one or more enhanced properties. Selective, tunable detection schemes are achievable, and are particularly advantageous as applied in connection with combinatorial chemistry, combinatorial material science and more particularly, combinatorial synthesis and screening of polymeric materials.

Owner:FREESLATE

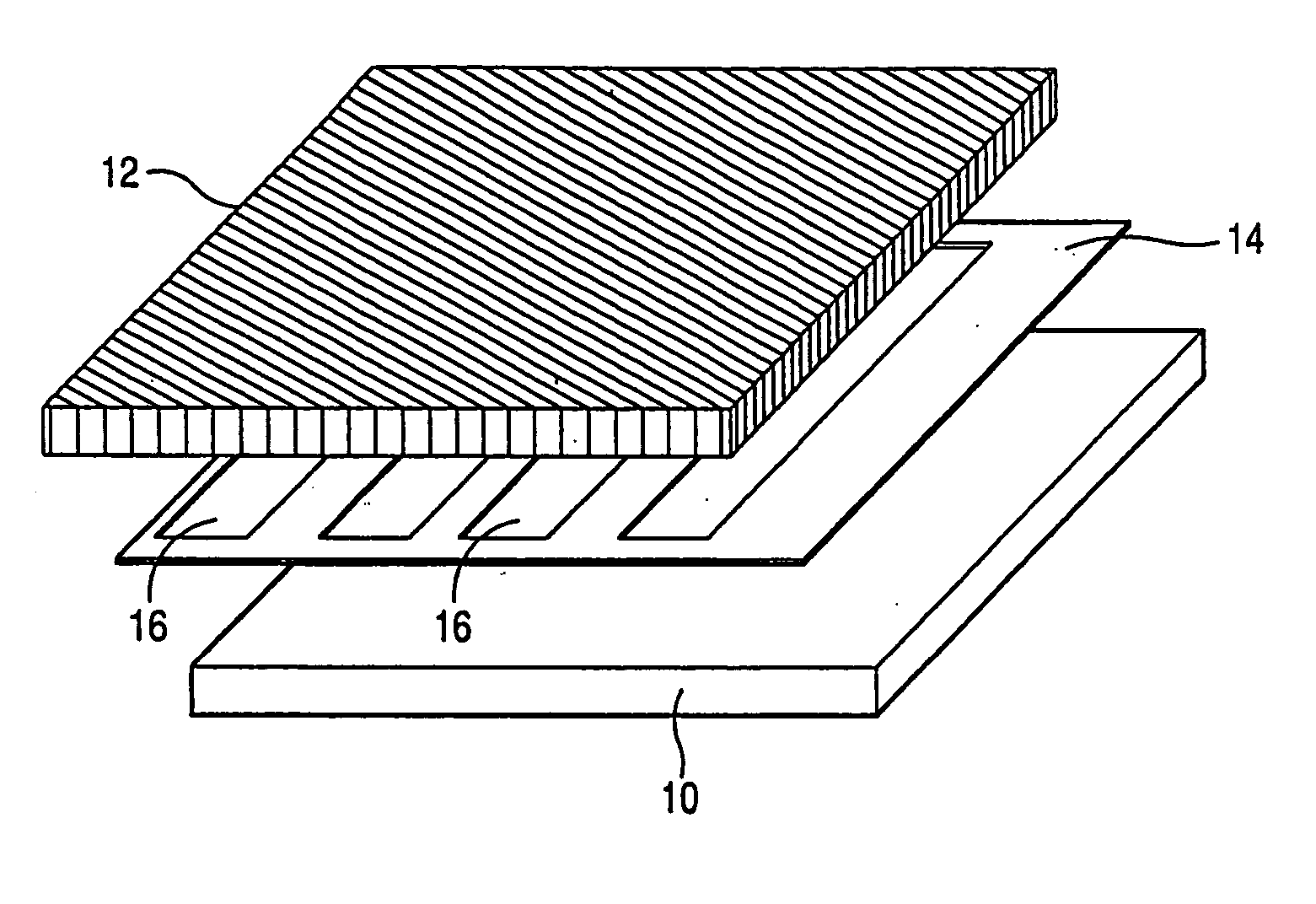

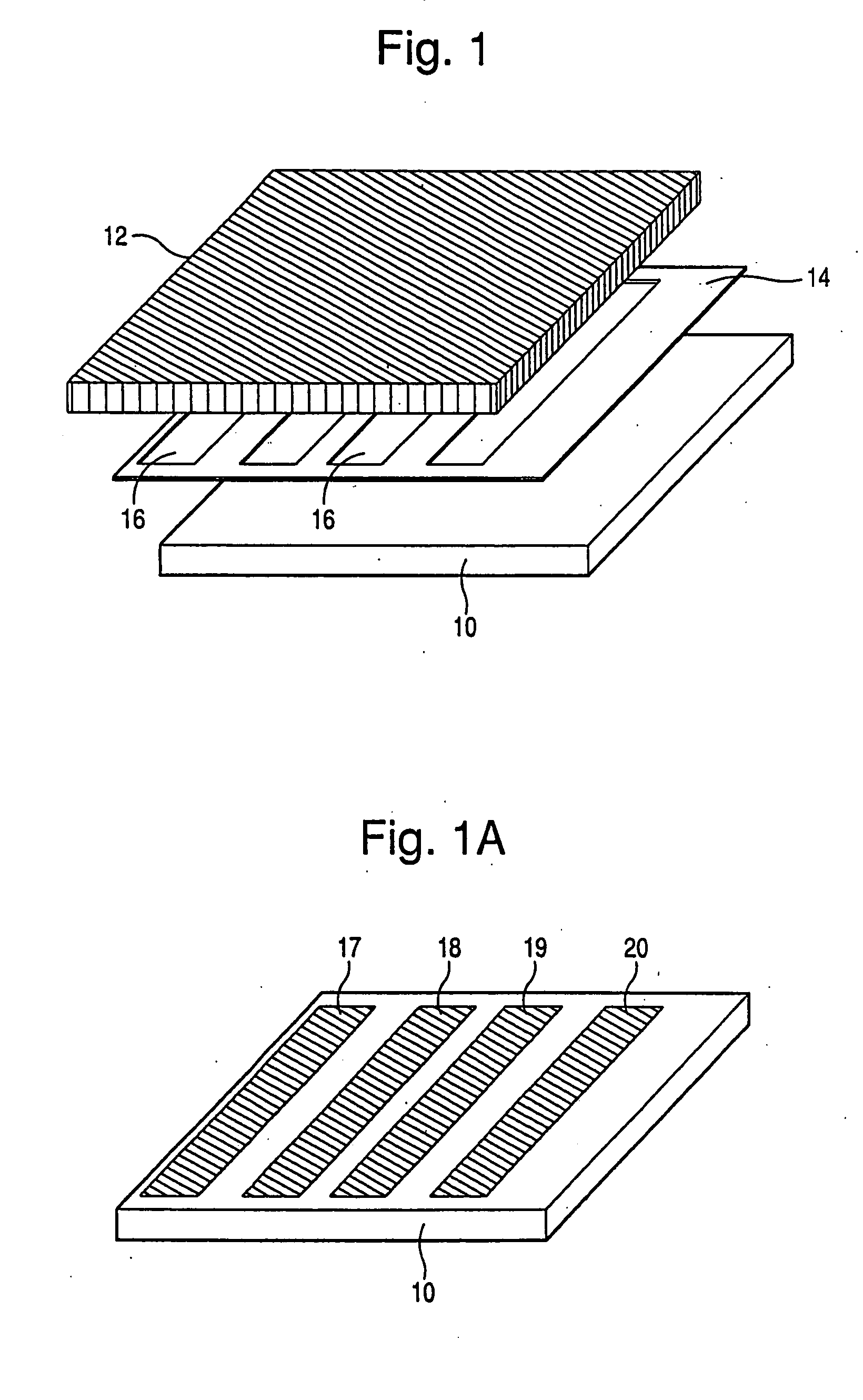

Combinatorial synthesis system

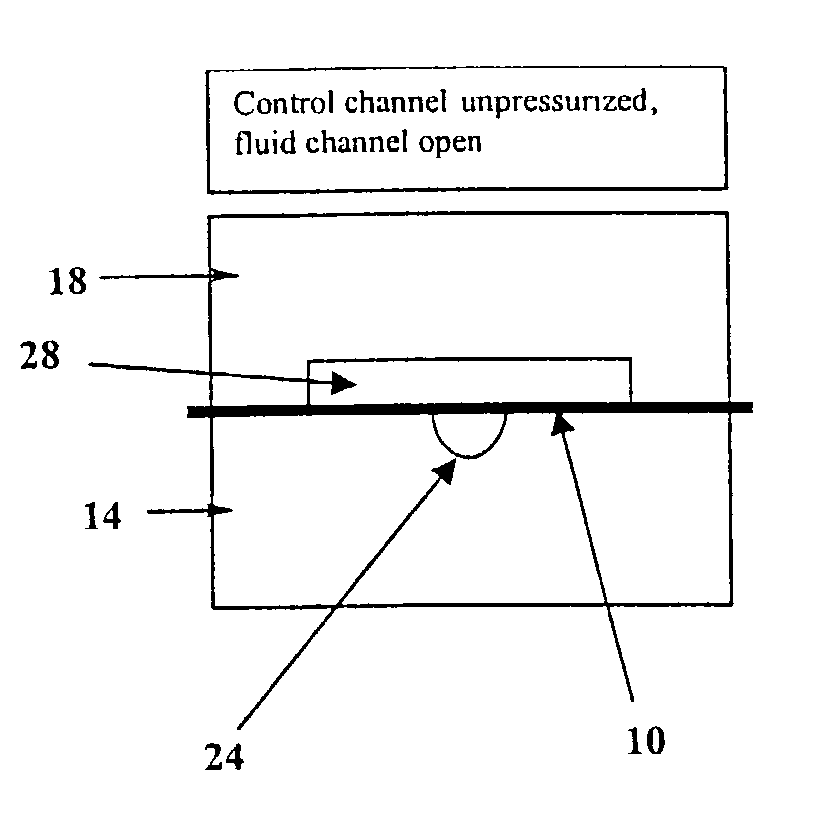

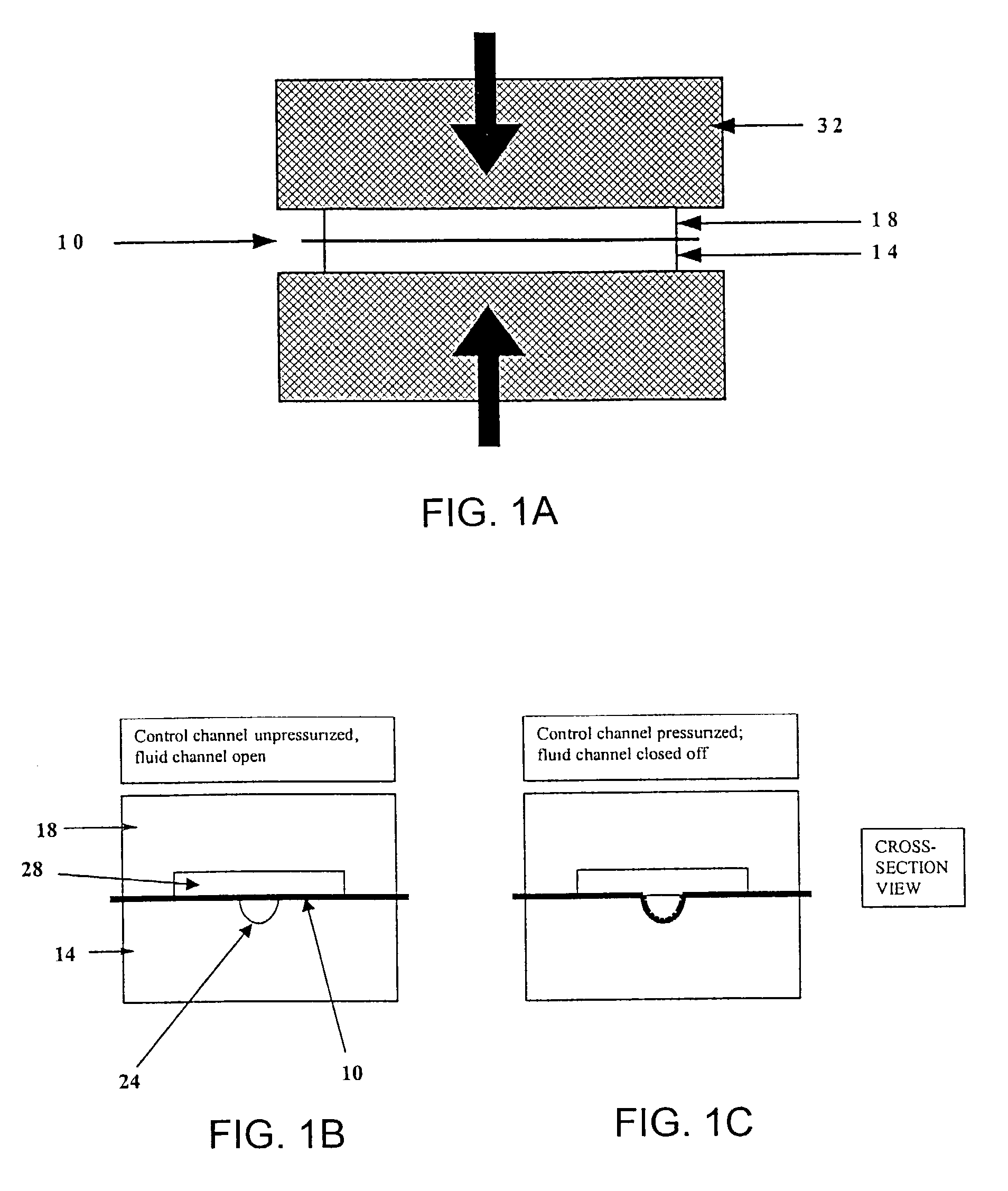

InactiveUS7097809B2Material nanotechnologySequential/parallel process reactionsControl channelEngineering

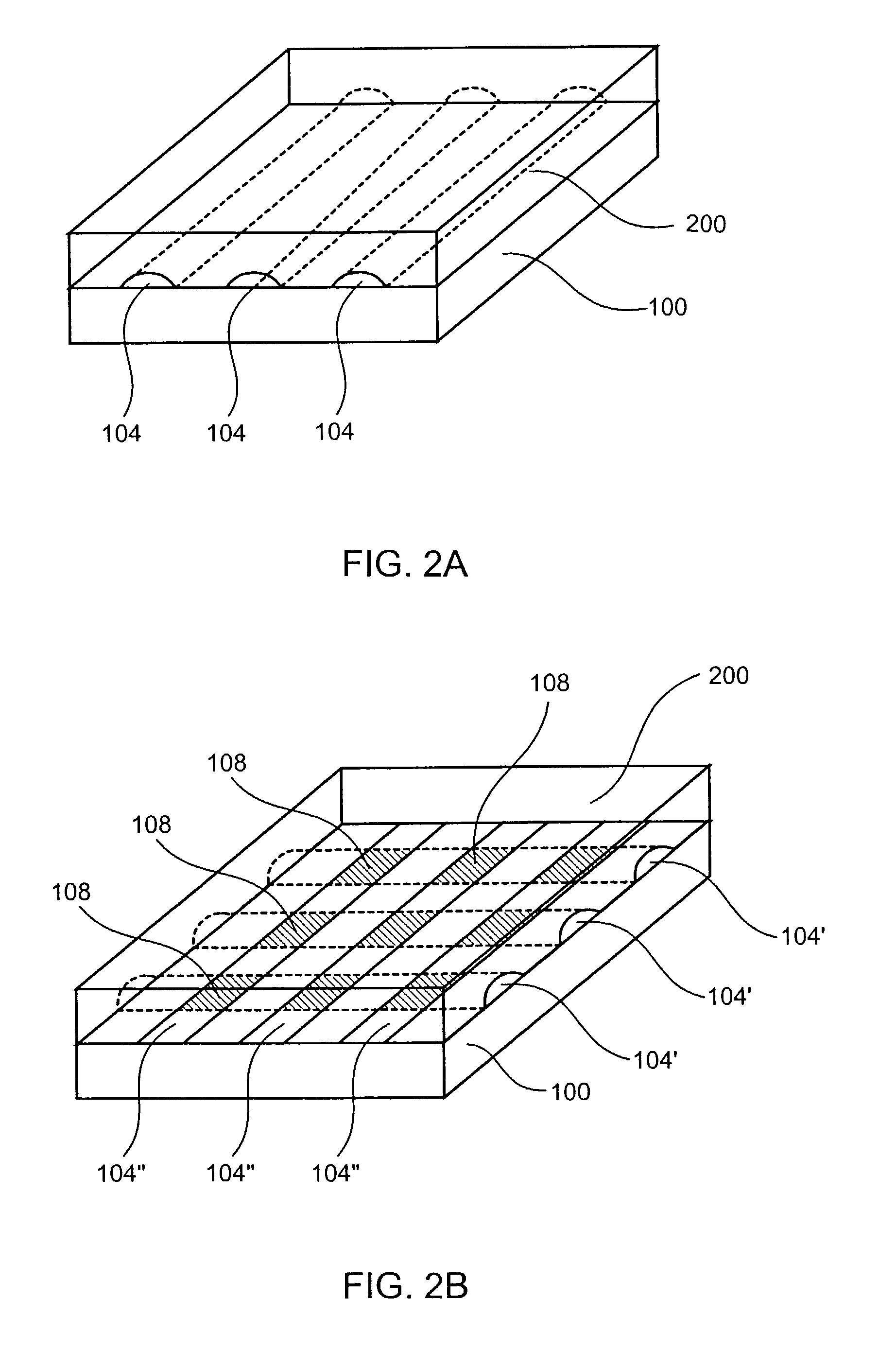

The present invention provides a microfluidic device for synthesizing an array of compounds and methods for using the same. In particular, the microfluidic device of the present invention comprises a solid support base, an elastomeric layer attached to the solid support, and a plurality of flow channels located within the interface between the solid support and the elastomeric layer. In addition, the solid support comprises a functional group for forming a bond with a reactive reagent. In some embodiments, the microfluidic device further comprises a second plurality of flow channels that intersect the first plurality of flow channels. A plurality of control channels are also present in the microfluidic devices of the present invention. The control channels can be actuated to regulate flow of fluids within the flow channel(s).

Owner:CALIFORNIA INST OF TECH

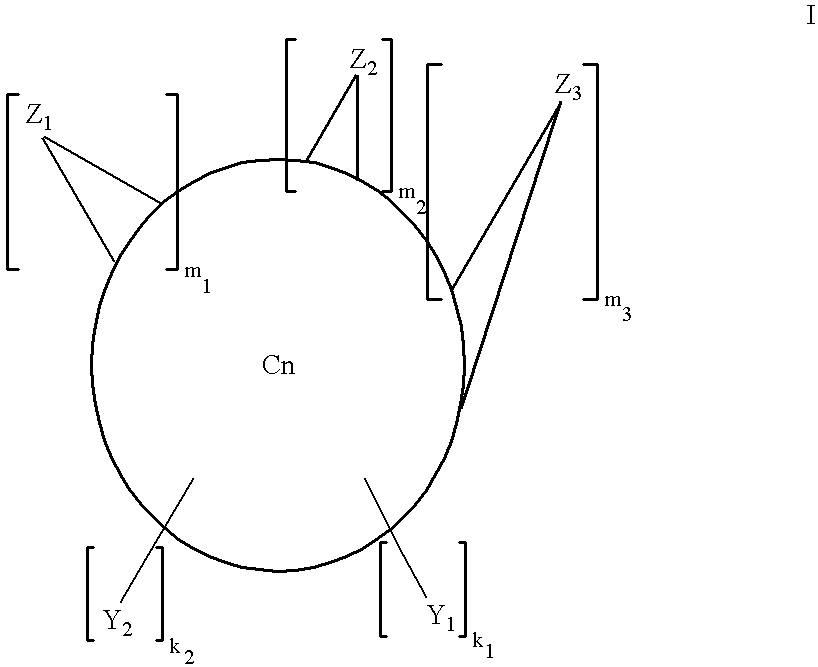

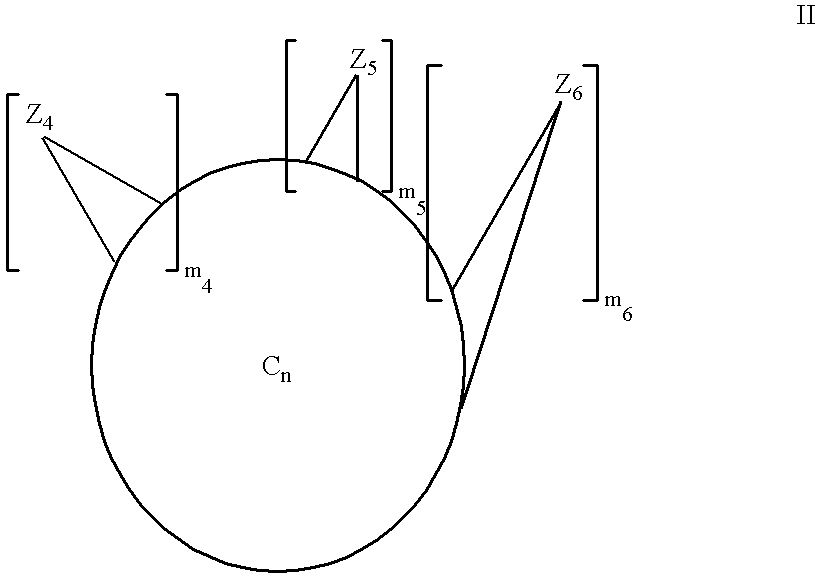

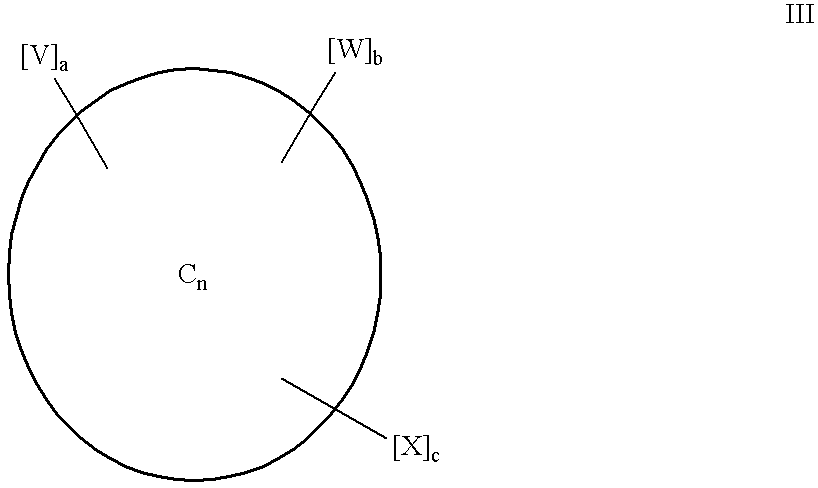

Multi-substituted fullerenes and methods for their preparation and characterization

InactiveUS6162926AGenerate efficientlyLow costSilicon organic compoundsOrganic compound preparationNMR - Nuclear magnetic resonanceCombinatorial synthesis

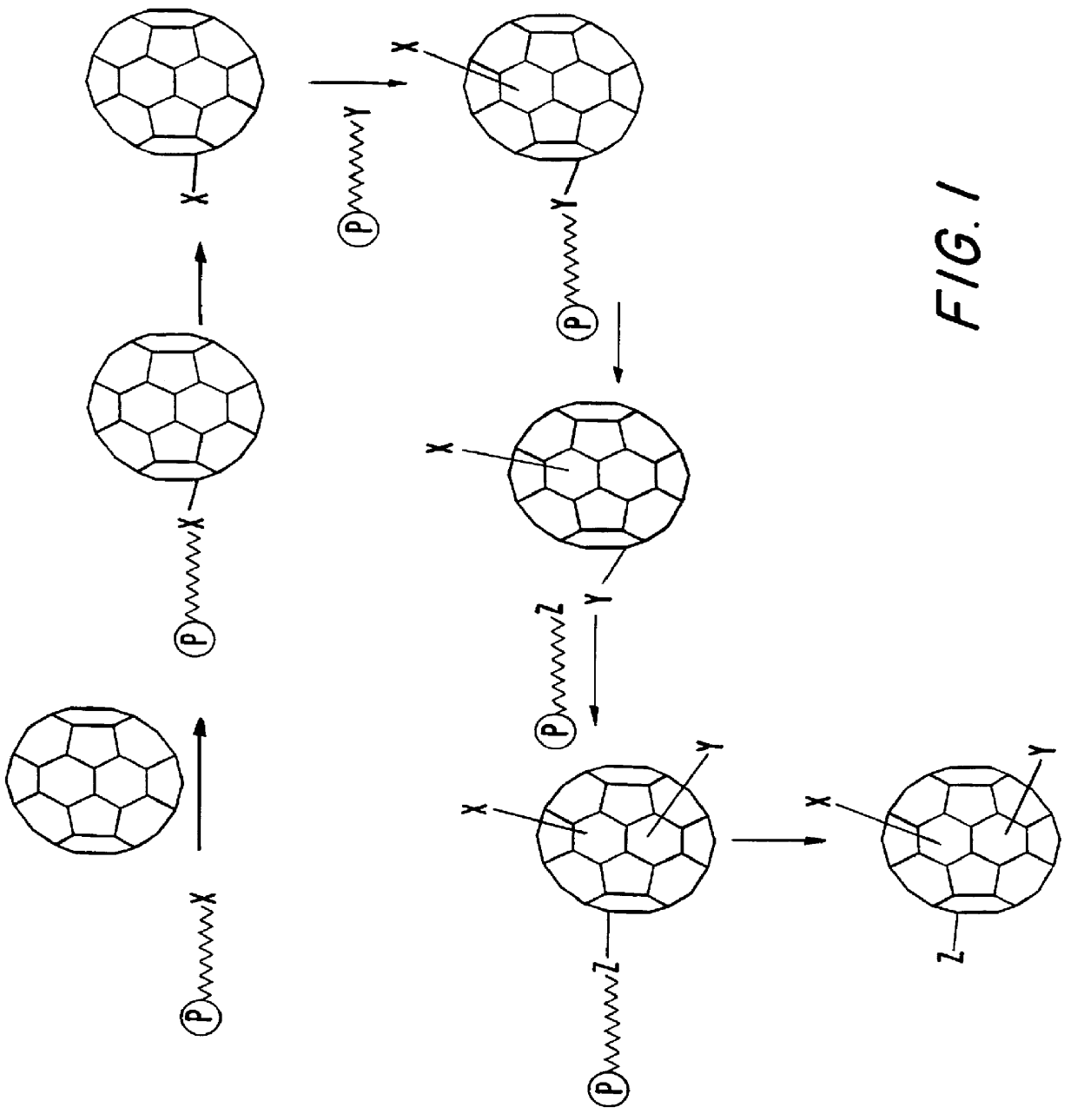

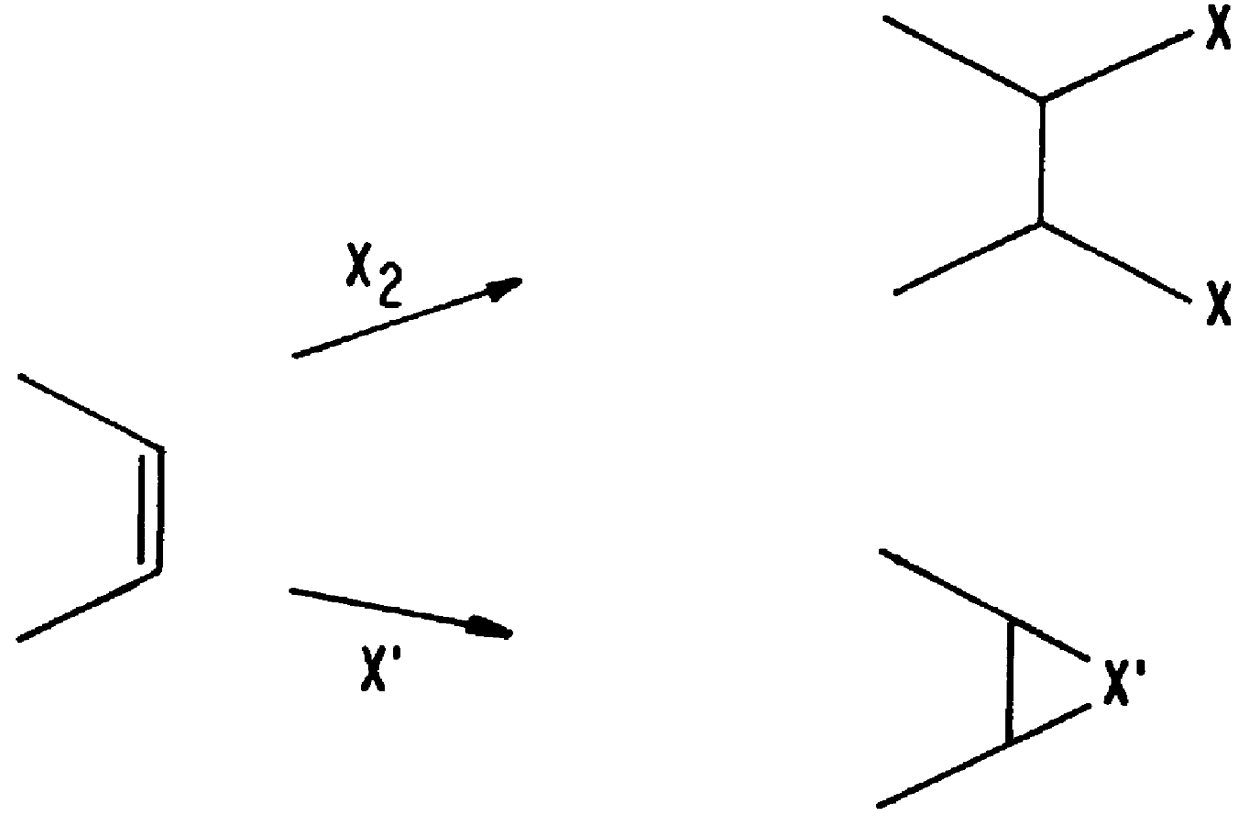

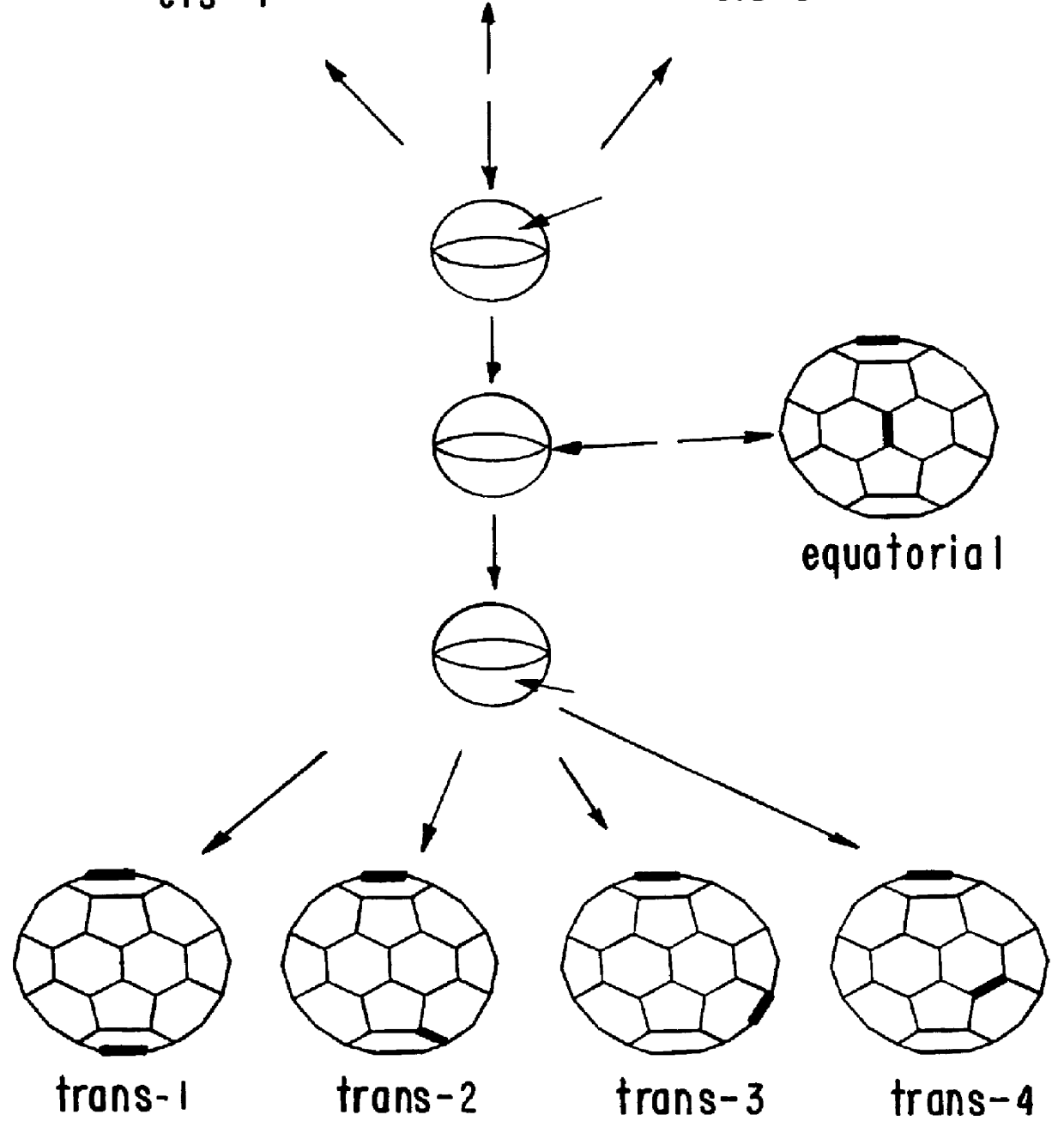

The invention is directed to multiply-substituted fullerene derivatives of novel configurations, and methods for their preparation and use. The methods involve the combinatorial synthesis of a library of fullerene derivatives and comprises the steps of forming a mixture of fullerene derivatives by reacting the Cn fullerene with two or more reactive precursor compounds, and removing the unreacted compounds to yield the fullerene derivatives having the desired activity. Methods for the identification and screening of a combinatorial library of fullerenes by 3He-nuclear magnetic resonance and electrospray mass spectrometry to define members with the optimal desired activity are also provided.

Owner:LUNA INNOVATIONS

Multiply-substituted fullerenes

InactiveUS6399785B1Generate efficientlyLow costSilicon organic compoundsOrganic compound preparationNMR - Nuclear magnetic resonanceCombinatorial synthesis

The invention is directed to multiply-substituted fullerene derivatives of novel configurations, and methods for their preparation and use. The methods involve the combinatorial synthesis of a library of fullerene derivatives and comprises the steps of forming a mixture of fullerene derivatives by reacting the Cn fullerene with two or more reactive precursor compounds, and removing the unreacted compounds to yield the fullerene derivatives having the desired activity. Methods for the identification and screening of a combinatorial library of fullerenes by 3He-nuclear magnetic resonance and electrospray mass spectrometry to define members with the optimal desired activity are also provided.

Owner:LUNA INNOVATIONS

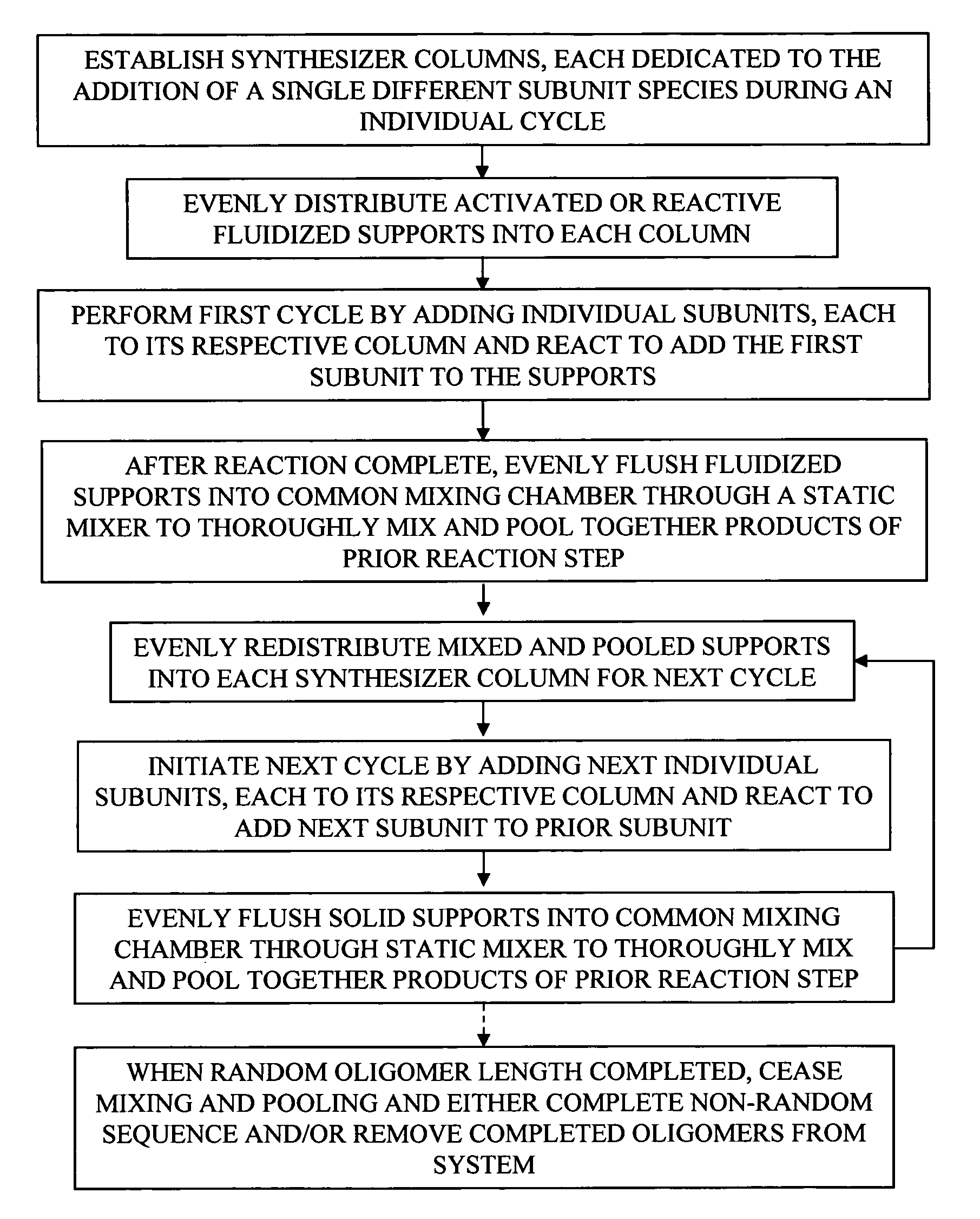

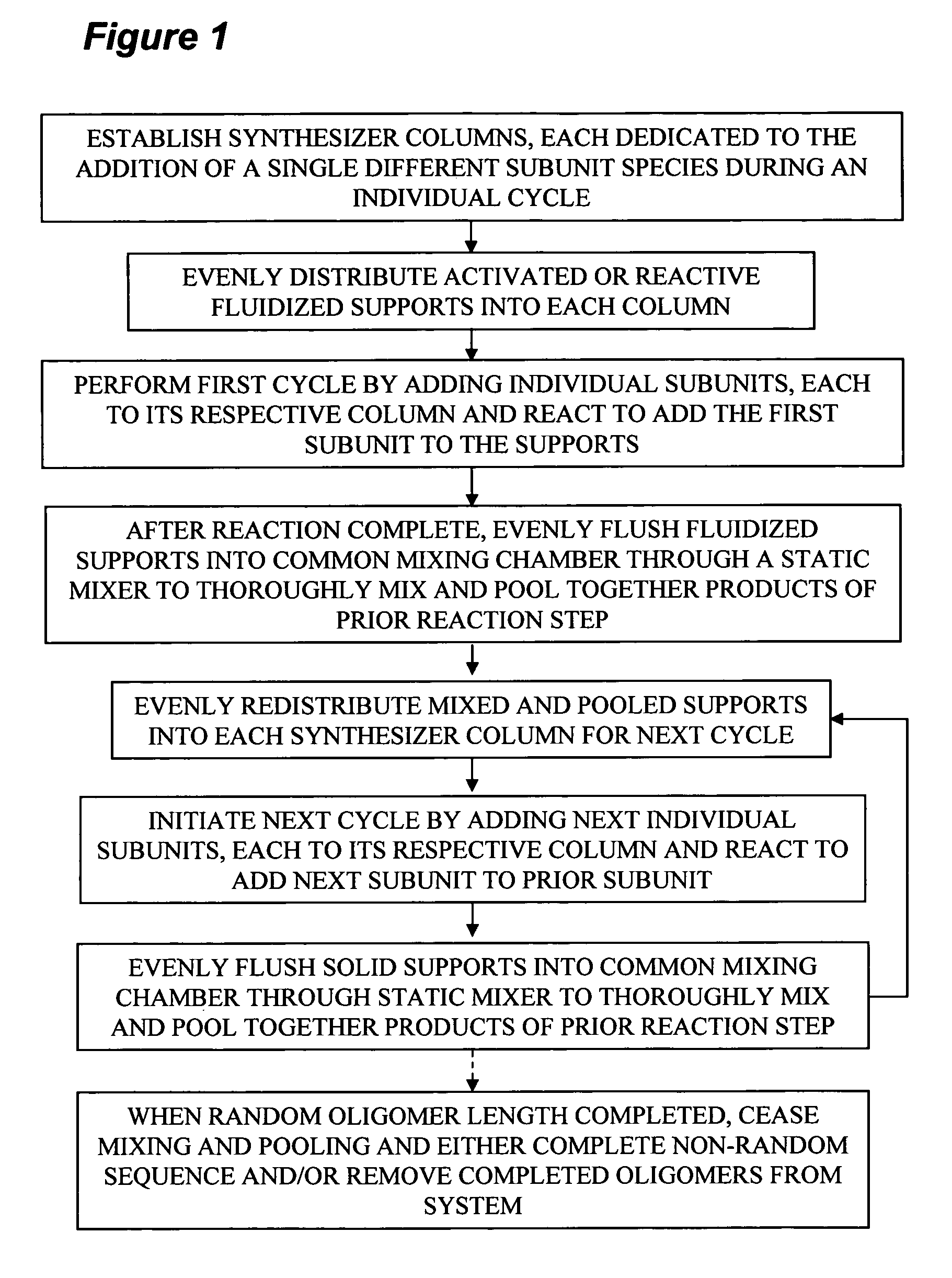

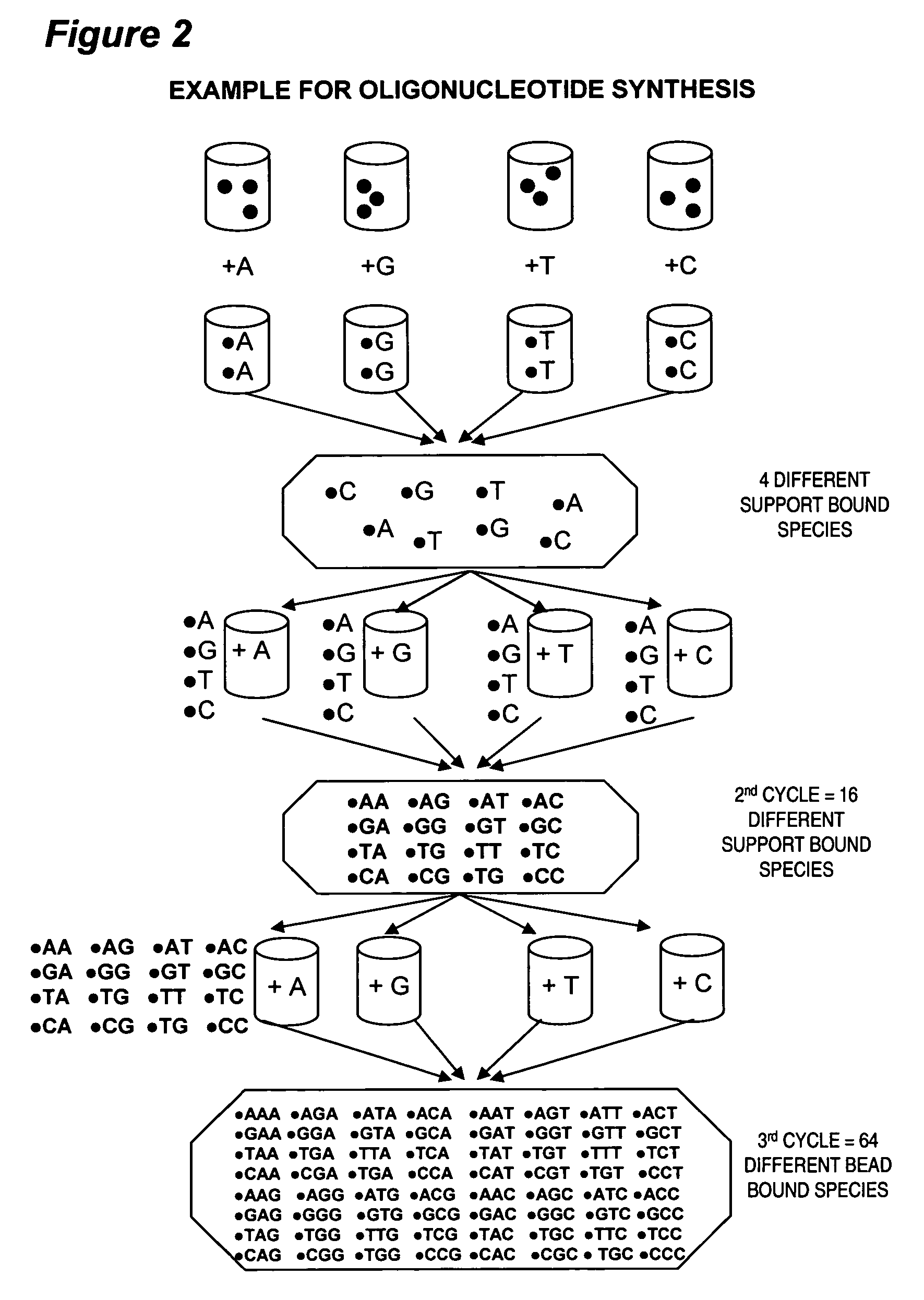

Process and apparatus for combinatorial synthesis

InactiveUS7576037B2Generate efficientlyBioreactor/fermenter combinationsSequential/parallel process reactionsCombinatorial synthesis

Apparatus and methods are described for split synthesis combinatorial chemistry that provides candidate libraries where an even distribution of theoretical products is obtainable through even mixing during the pooling step, followed by controlled redistribution of the mixed pooled products from the prior addition step into separate synthesis columns, one for each different specie of subunit to be added.

Owner:MEI TECH +1

Combinatorial synthesis

InactiveUS20050271795A1Liquid surface applicatorsSequential/parallel process reactionsConcentration gradientComposite sample

Methods are disclosed for providing a library of composite compositions on a support. The method involves depositing one or more components onto the support on either discrete spaced regions of the support or as a continuous concentration gradients on the surface of the support. The composite samples can be removed from the support by drilling out portions of the coated support so as to yield individual composite tablets containing the support with one or more component layers thereon. By using this method, a vast number of composites can be made and tested simultaneously.

Owner:MOINI AHMAD +2

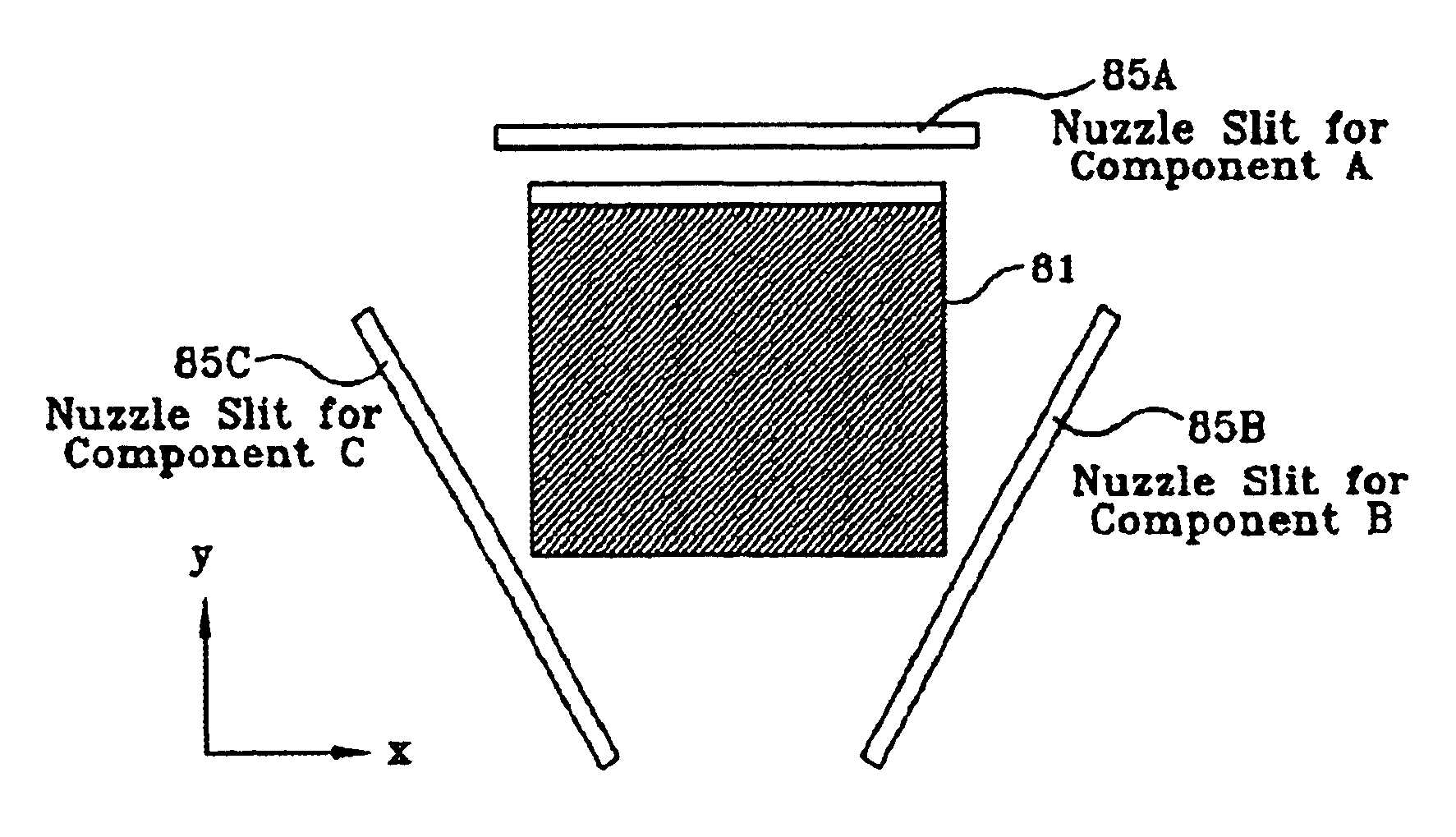

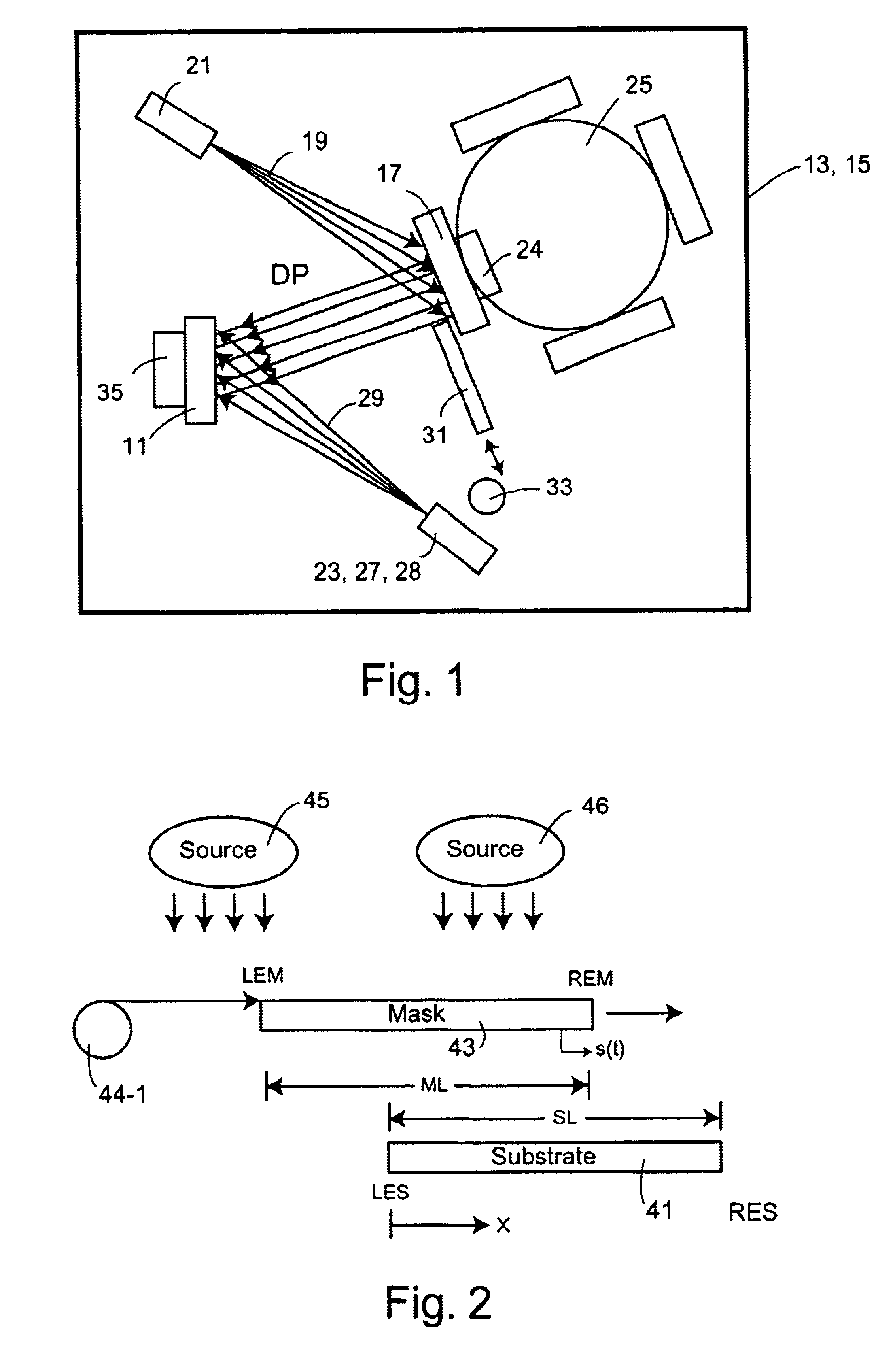

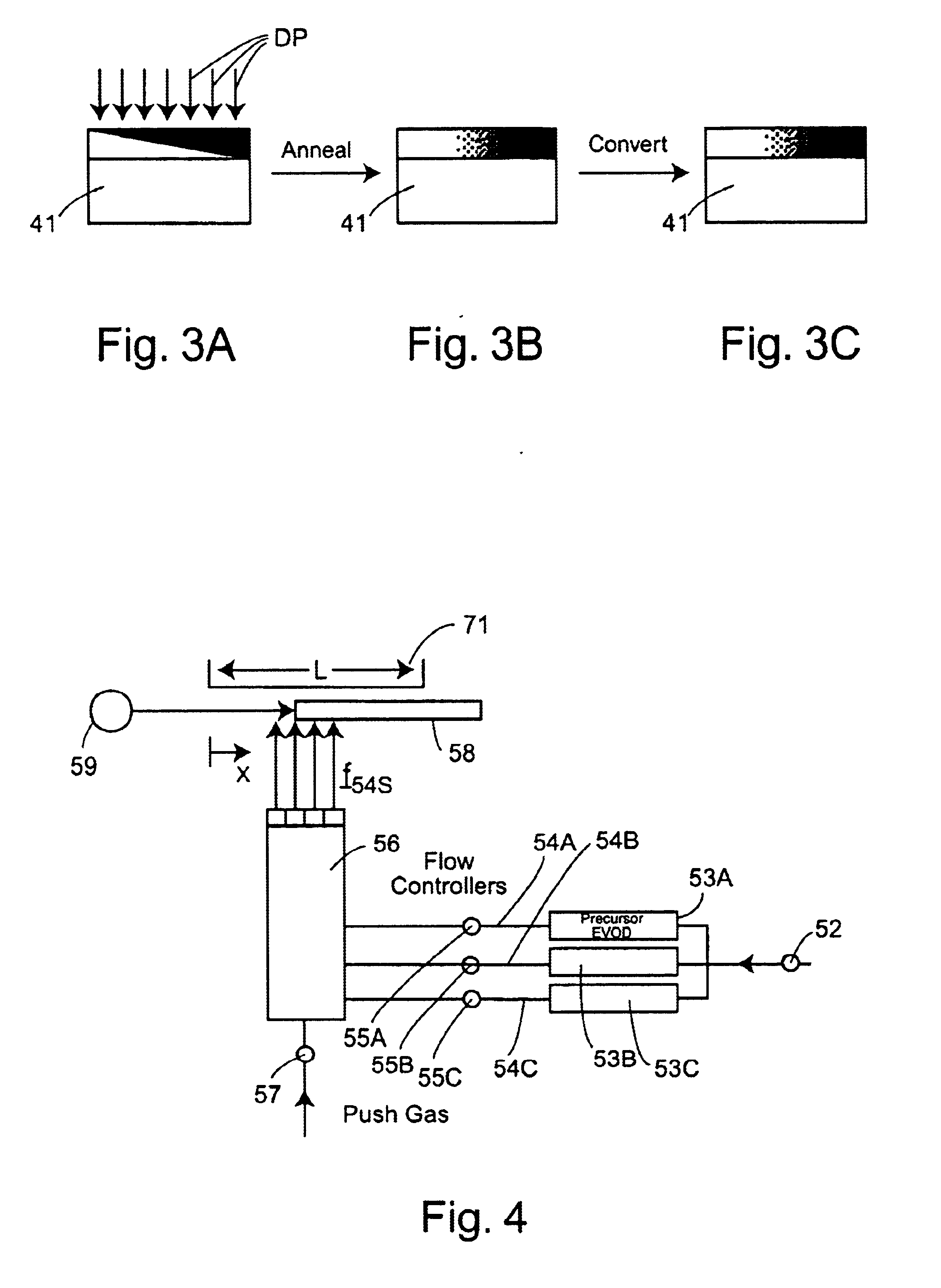

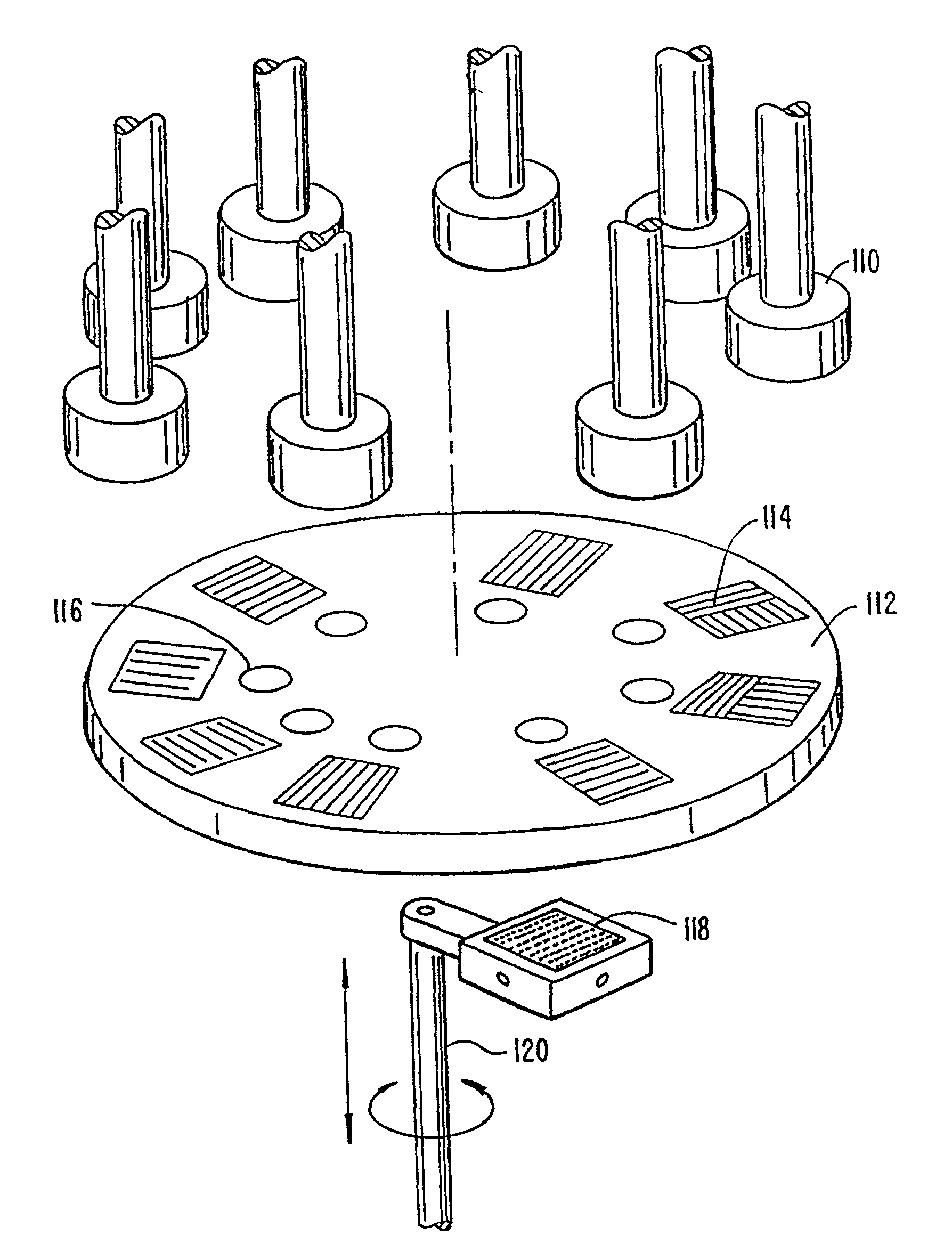

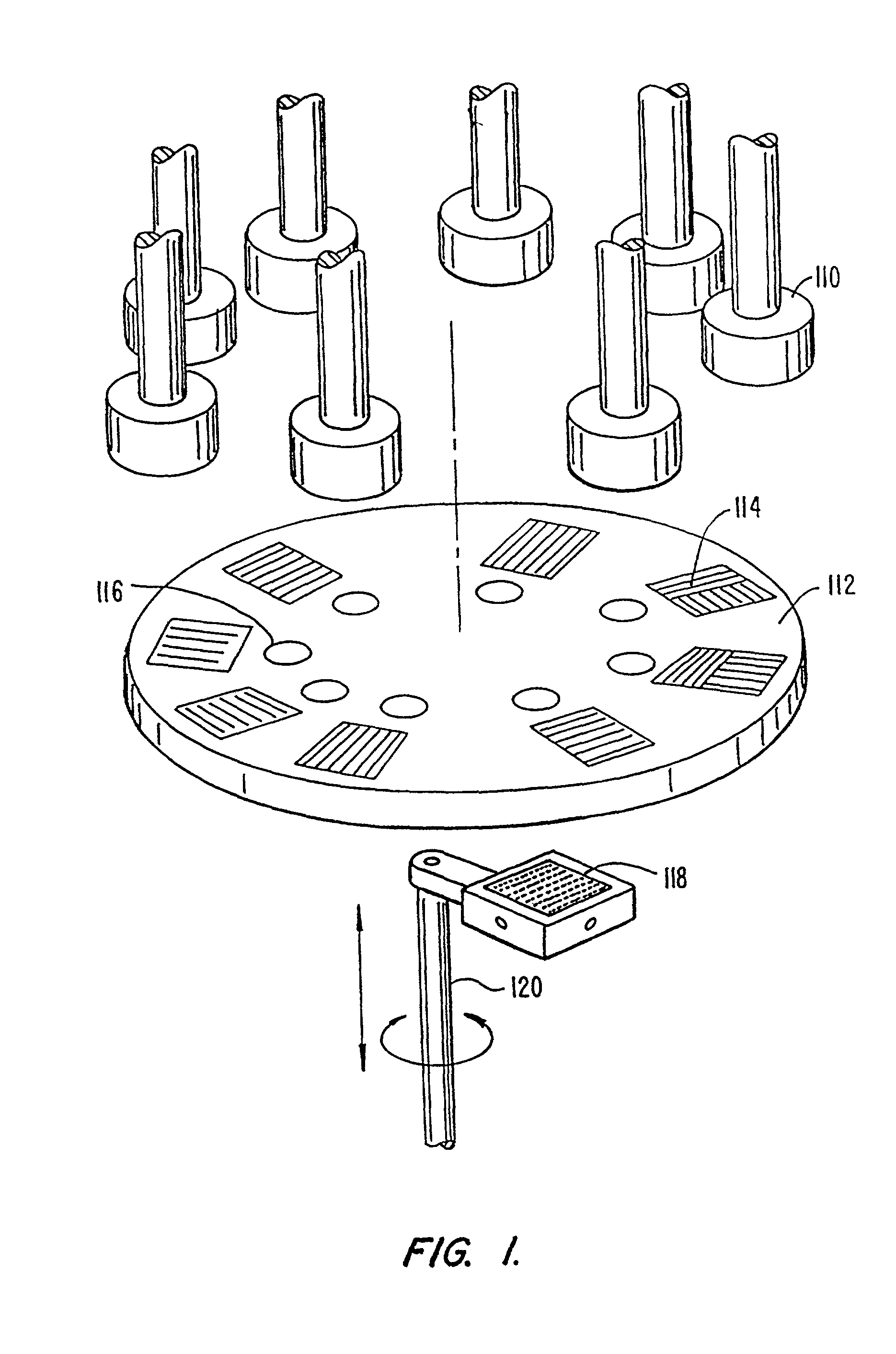

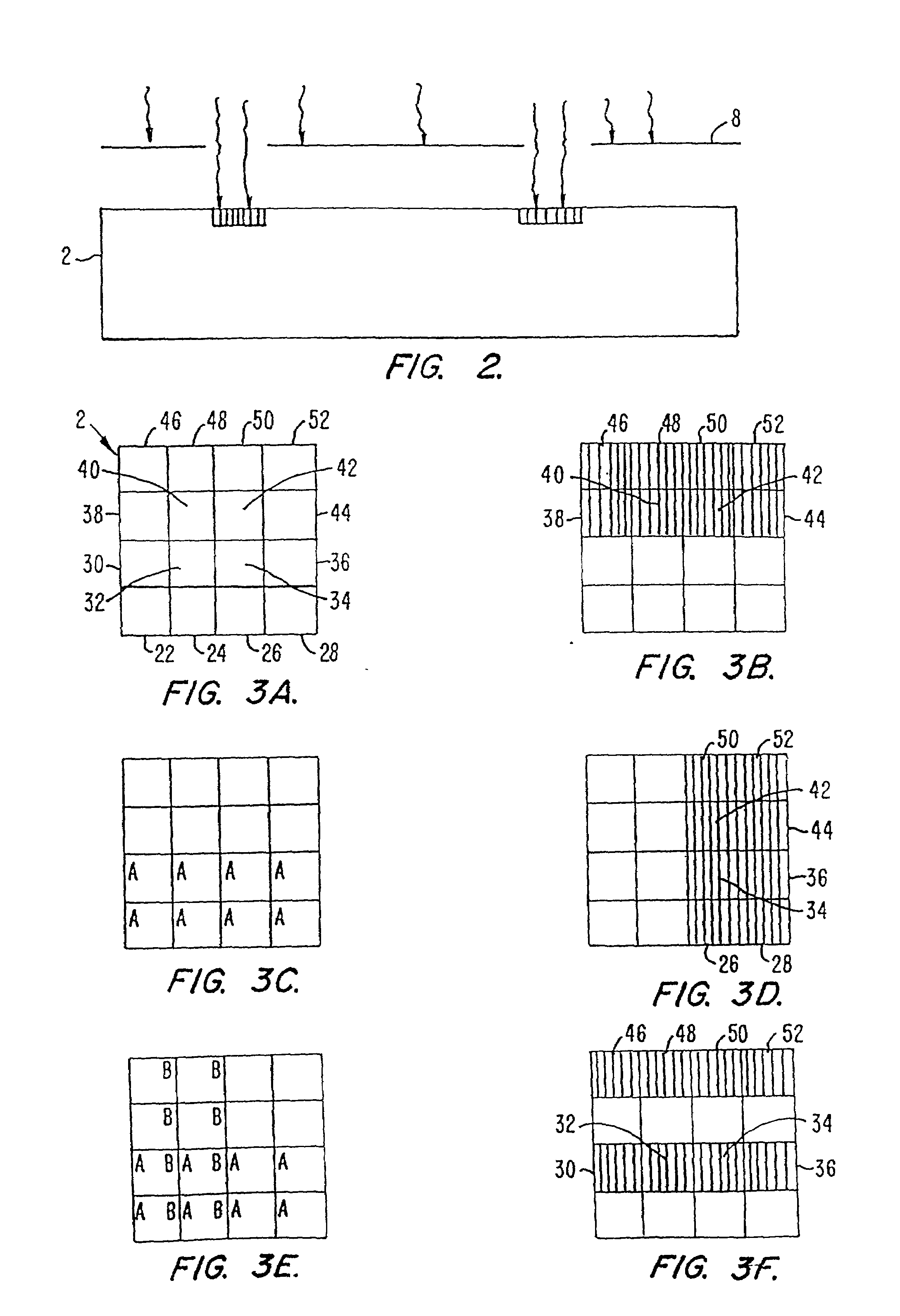

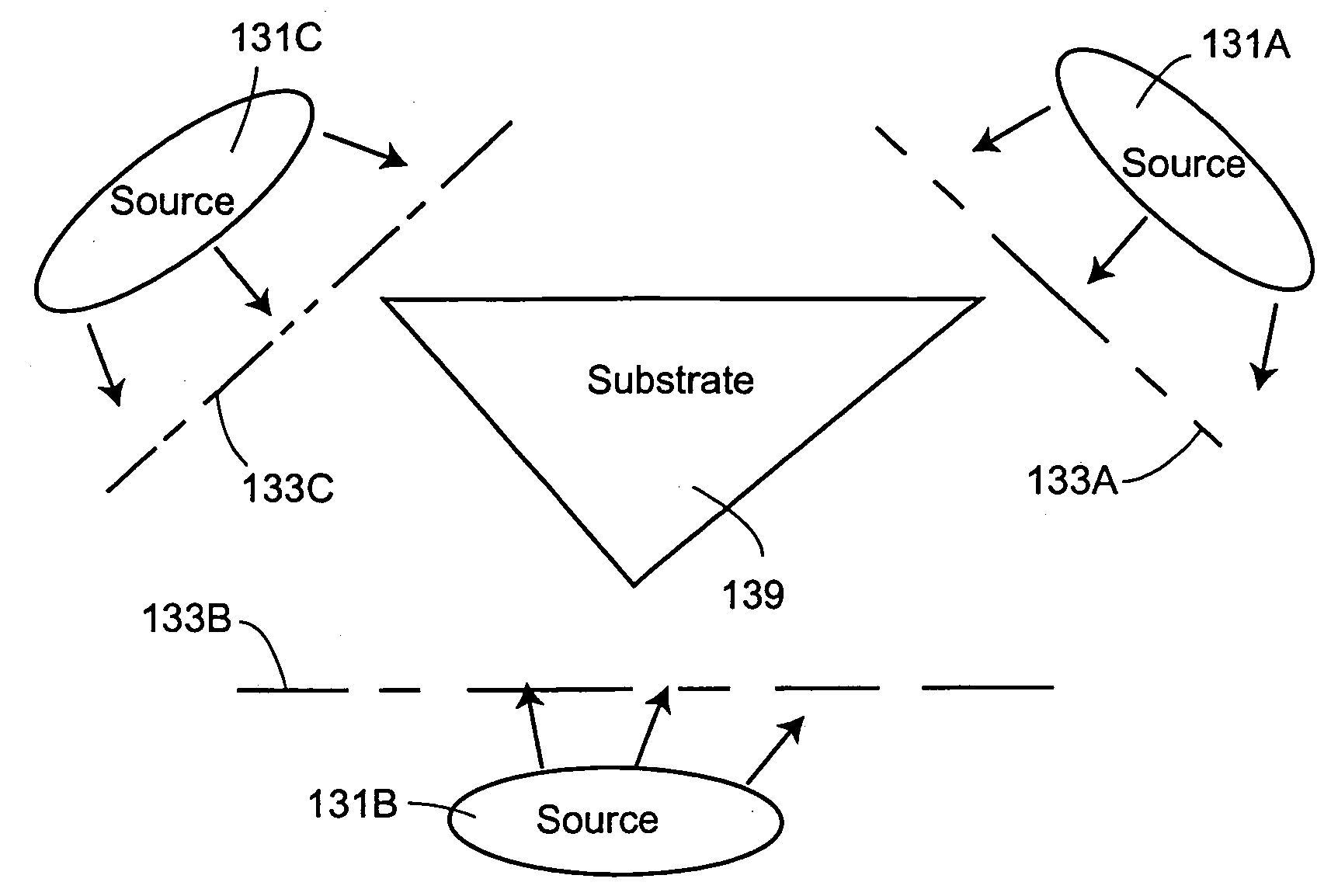

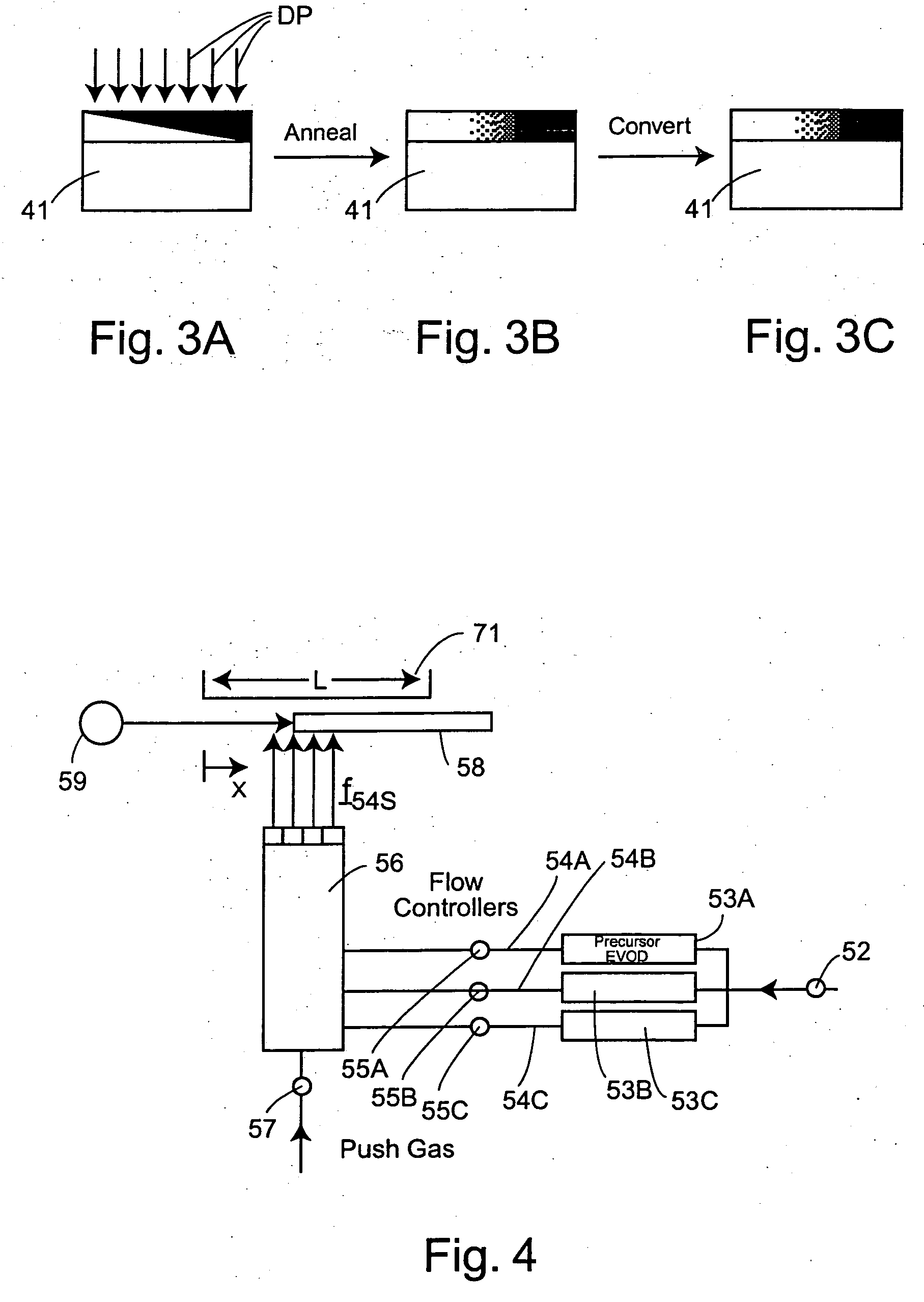

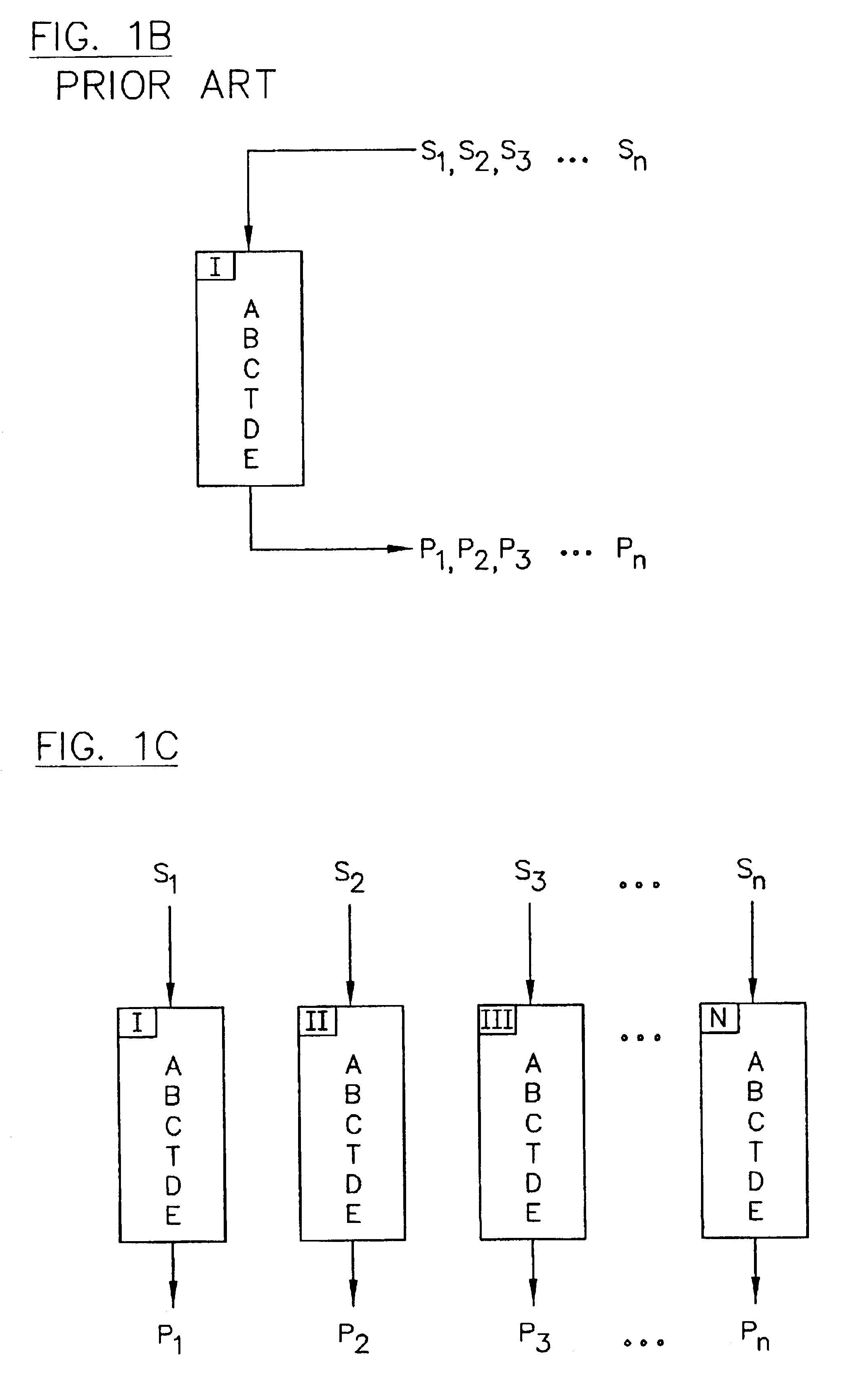

Combinatorial synthesis of material chips

InactiveUS6911129B1Promote exchangeReduce the temperatureCellsSequential/parallel process reactionsEngineeringCombinatorial synthesis

Systems and methods for providing in situ, controllably variable concentrations of one, two or more chemical components on a substrate to produce an integrated materials chip. The component concentrations can vary linearly, quadratically or according to any other reasonable power law with one or two location coordinates. In one embodiment, a source and a mask with fixed or varying aperture widths and fixed or varying aperture spacings are used to produce the desired concentration envelope. In another embodiment, a mask with one or more movable apertures or openings provides a chemical component flux that varies with location on the substrate, in one or two dimensions. In another embodiment, flow of the chemical components through nuzzle slits provides the desired concentrations. An ion beam source, a sputtering source, a laser ablation source, a molecular beam source, a chemical vapor deposition source and / or an evaporative source can provide the chemical component(s) to be deposited on the substrate. Carbides, nitrides, oxides halides and other elements and compounds can be added to and reacted with the deposits on the substrate.

Owner:INTEMATIX

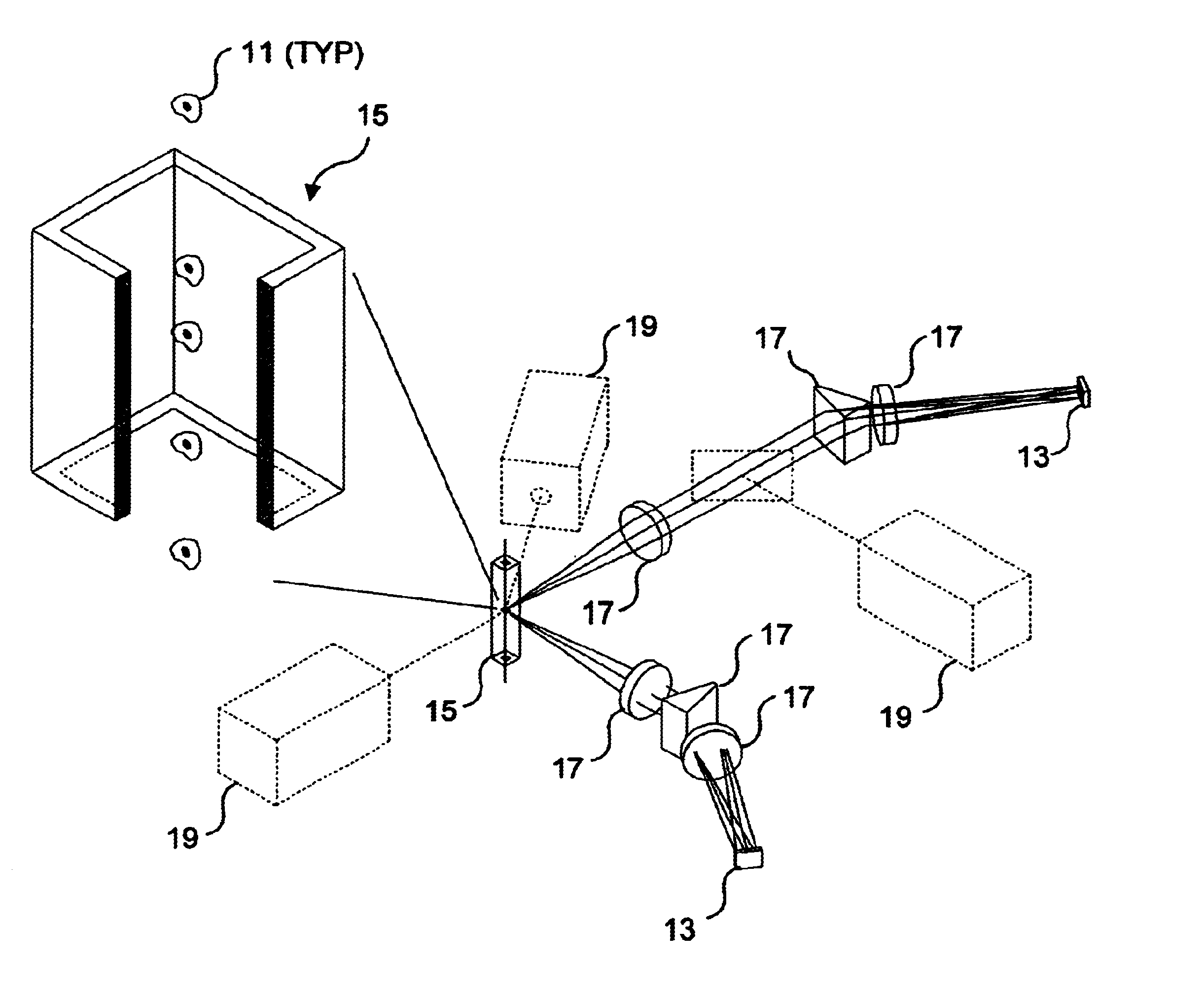

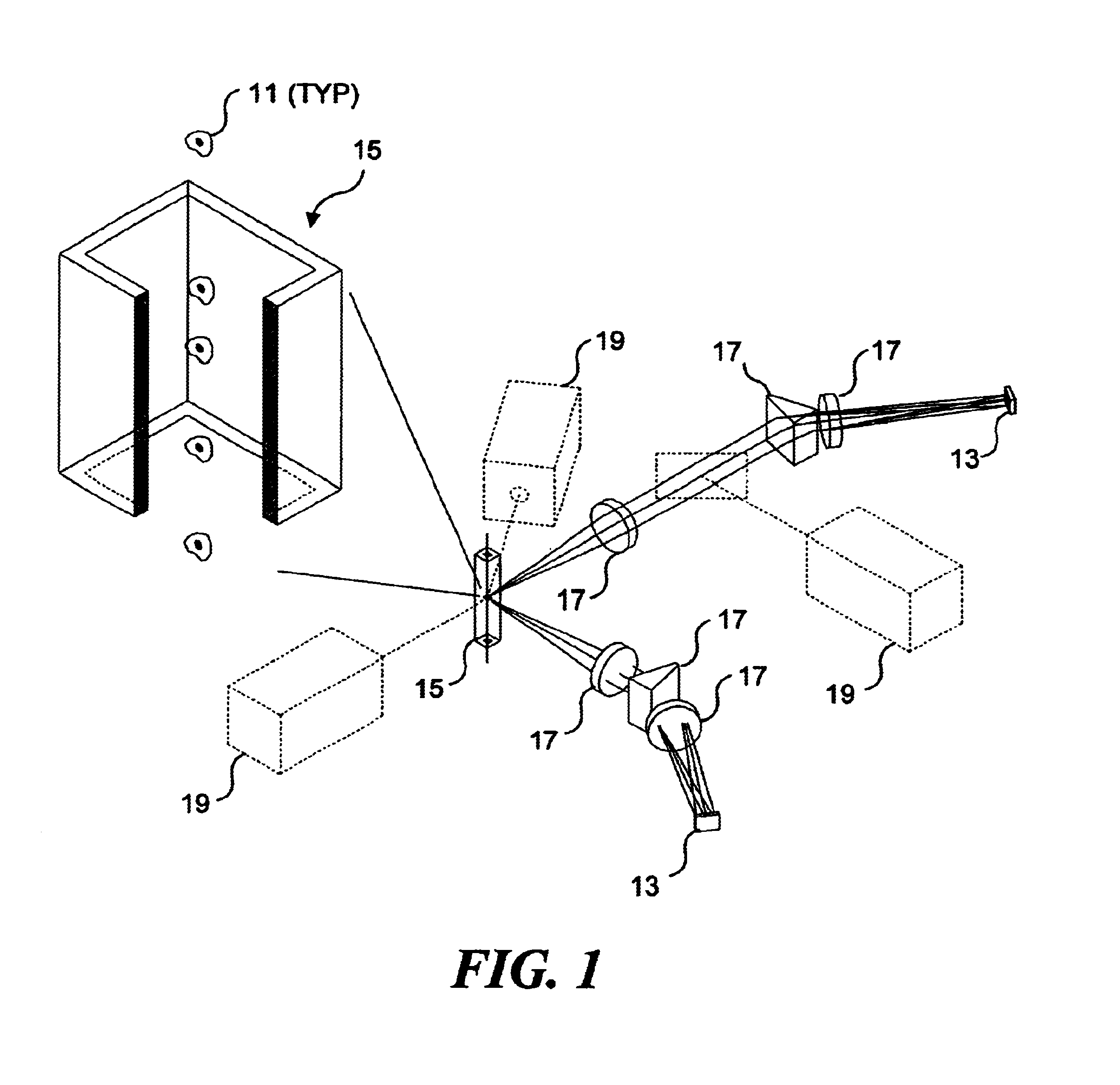

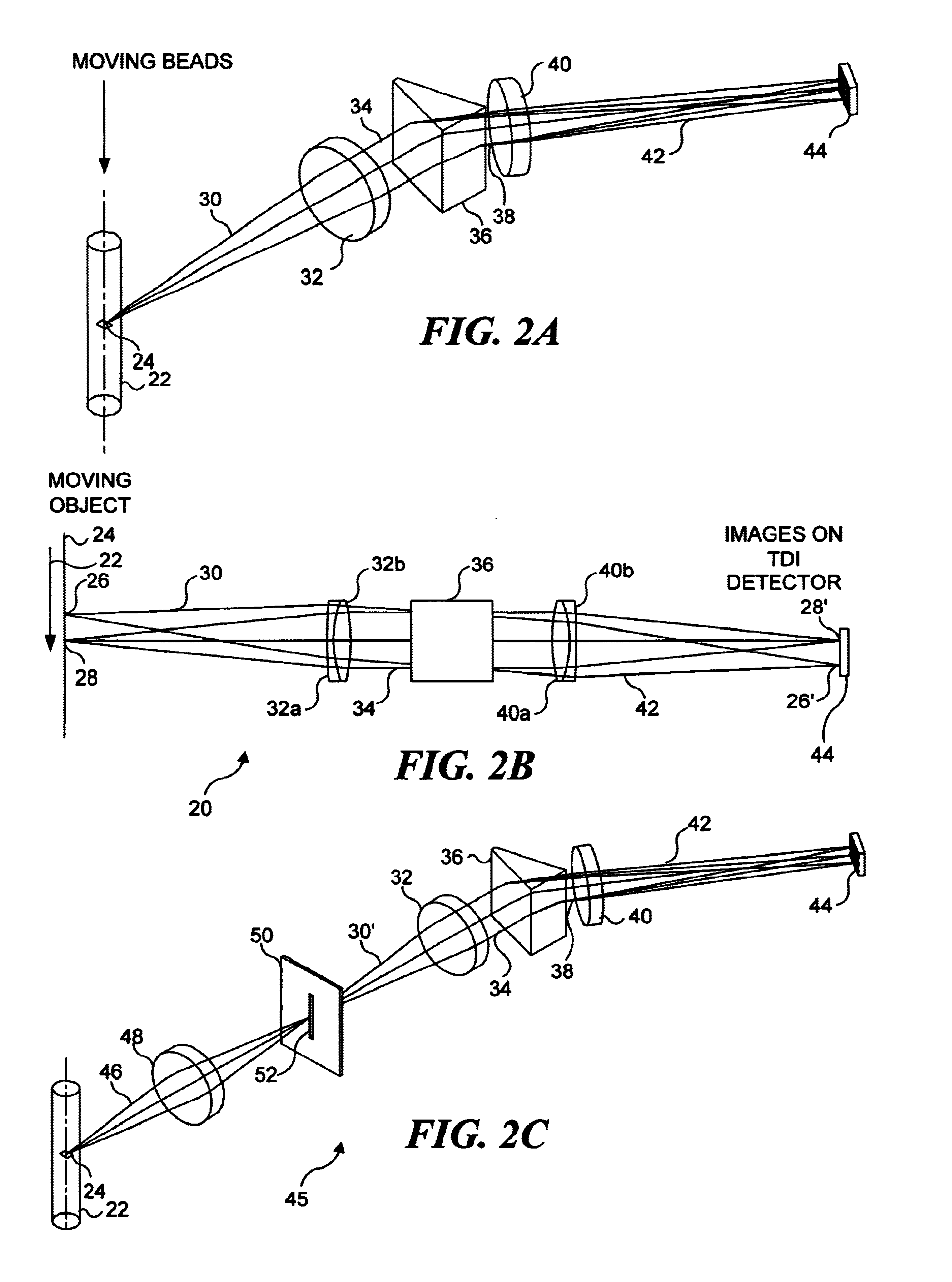

Method and apparatus for reading reporter labeled beads

Combinatorially-synthesized deoxyribonucleic acid (DNA) oligonucleotides attached to encoded beads that are hybridized to amplified and labeled genomic DNA or ribonucleic acid (RNA) are analyzed using a flow imaging system. Oligonucleotides and corresponding reporters are bound to the surfaces of a plurality of small beads such that different beads bear different oligo sequences. Each bead bears a unique optical signature comprising a predefined number of unique reporters, where each reporter comprises a predefined combination of different fluorochromes. The composite spectral signature in turn identifies the unique nucleotide sequence of its attached oligo chains. This optical signature is rapidly decoded using an imaging system to discriminate the different reporters attached to each bead in a flow in regard to color and spatial position on the bead.

Owner:AMNIS CORP

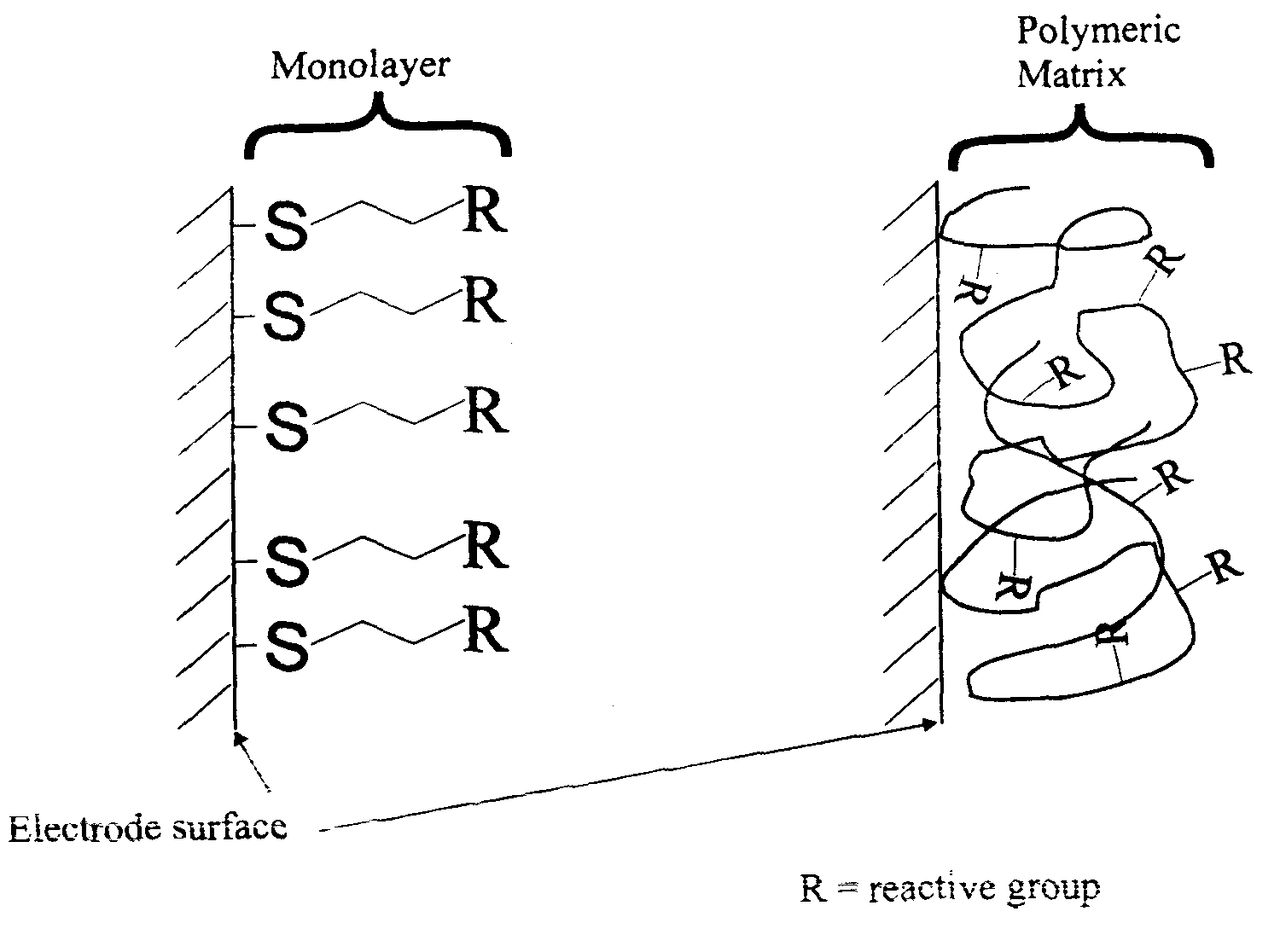

Combinatorial Electrochemical Synthesis

<heading lvl="0">Abstract of Disclosure< / heading> An array of selectively addressible microelectrodes for combinatorial synthesis of complex polymers or alloys.

Owner:THERASENSE

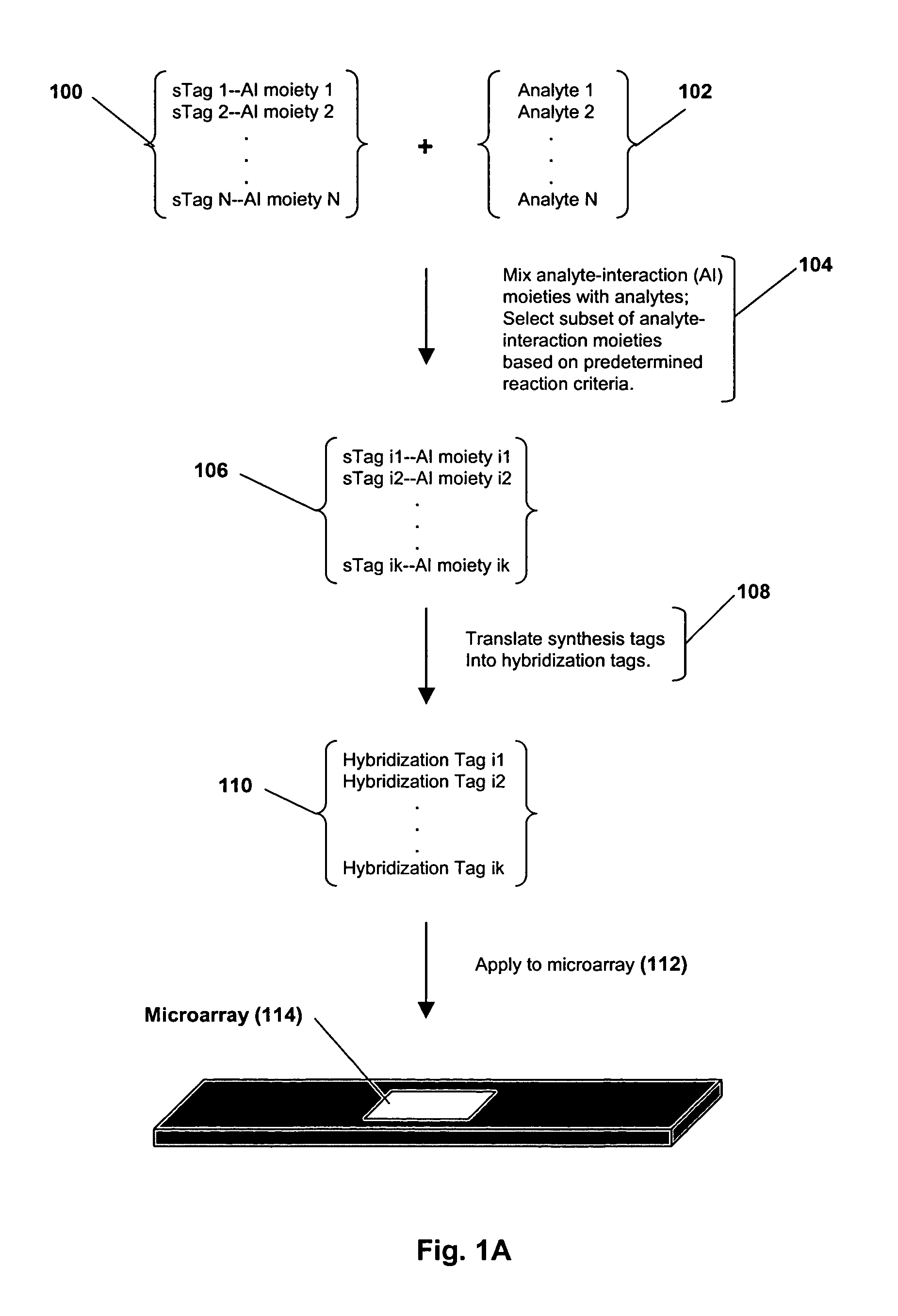

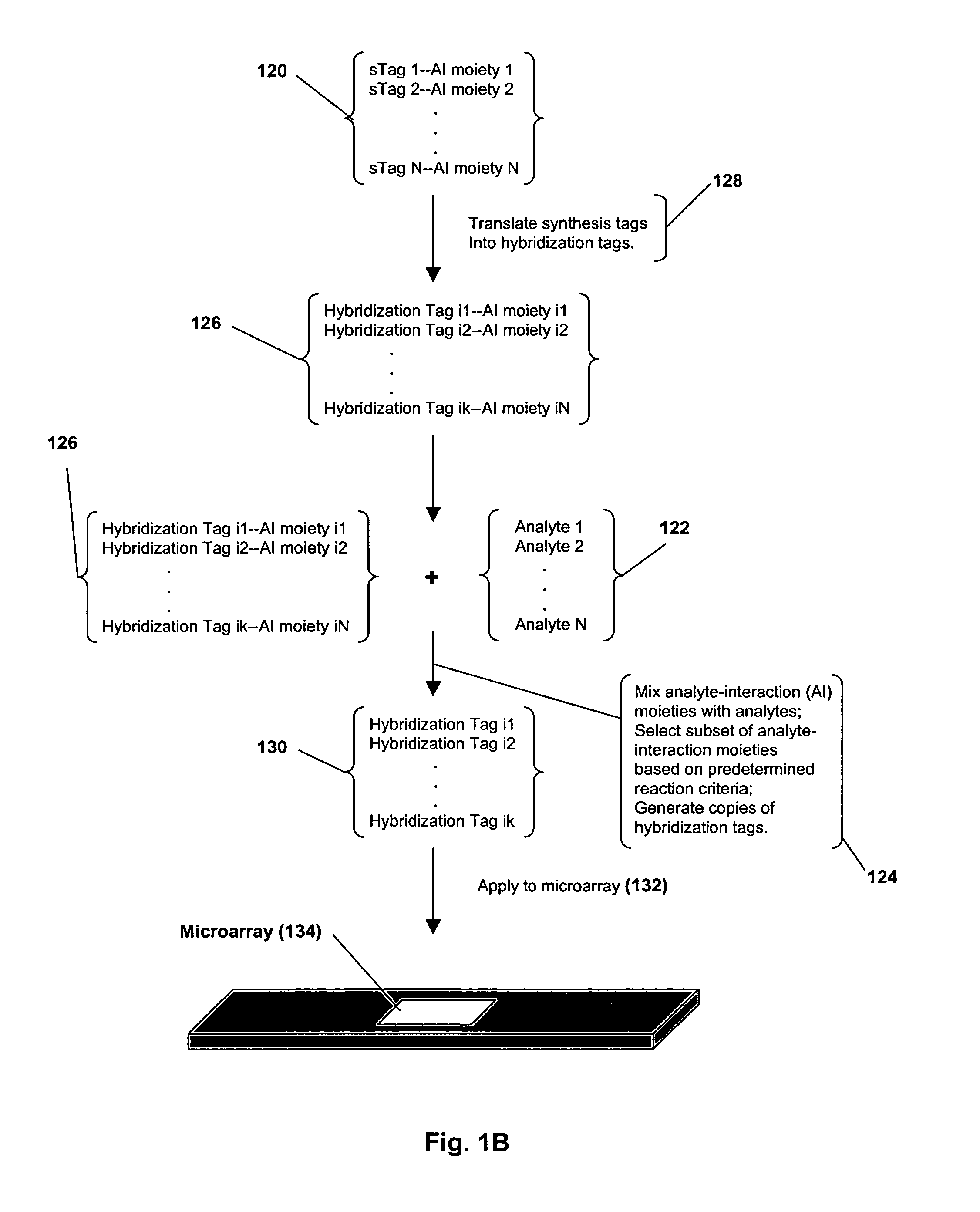

Multiplexed analytical platform

ActiveUS7365179B2Efficient productionMinimize occurrenceBioreactor/fermenter combinationsBiological substance pretreatmentsAnalyteNucleotide

The invention provides a system and reagents for carrying out multiplexed analytical measurements using the hybridization of oligonucleotide tags to addressable solid phase supports to obtain simultaneous readouts from hundreds to tens of thousands of reactions. In one aspect of the invention, analyte interaction moieties, such as oligonucleotide probes, are produced that are each labeled with a unique synthesis tag constructed from a set of two-nucleotide “words.” During or after an assay, the synthesis tags are converted to hybridization tags that are used in the readout step. Hybridization tags are constructed to maximize discrimination in the readout. Hybridization tags of the invention are preferably constructed from oligonucleotide “words” selected from a minimally cross-hybridizing set using combinatorial synthesis techniques. In a further aspect, discrimination in the readout is enhanced by employing hybridization tags that are constructed with words having the “comma-less” property and by minimizing or eliminating extraneous nucleic acids associated with the hybridization tag during a readout step.

Owner:AGENCY FOR SCI TECH & RES

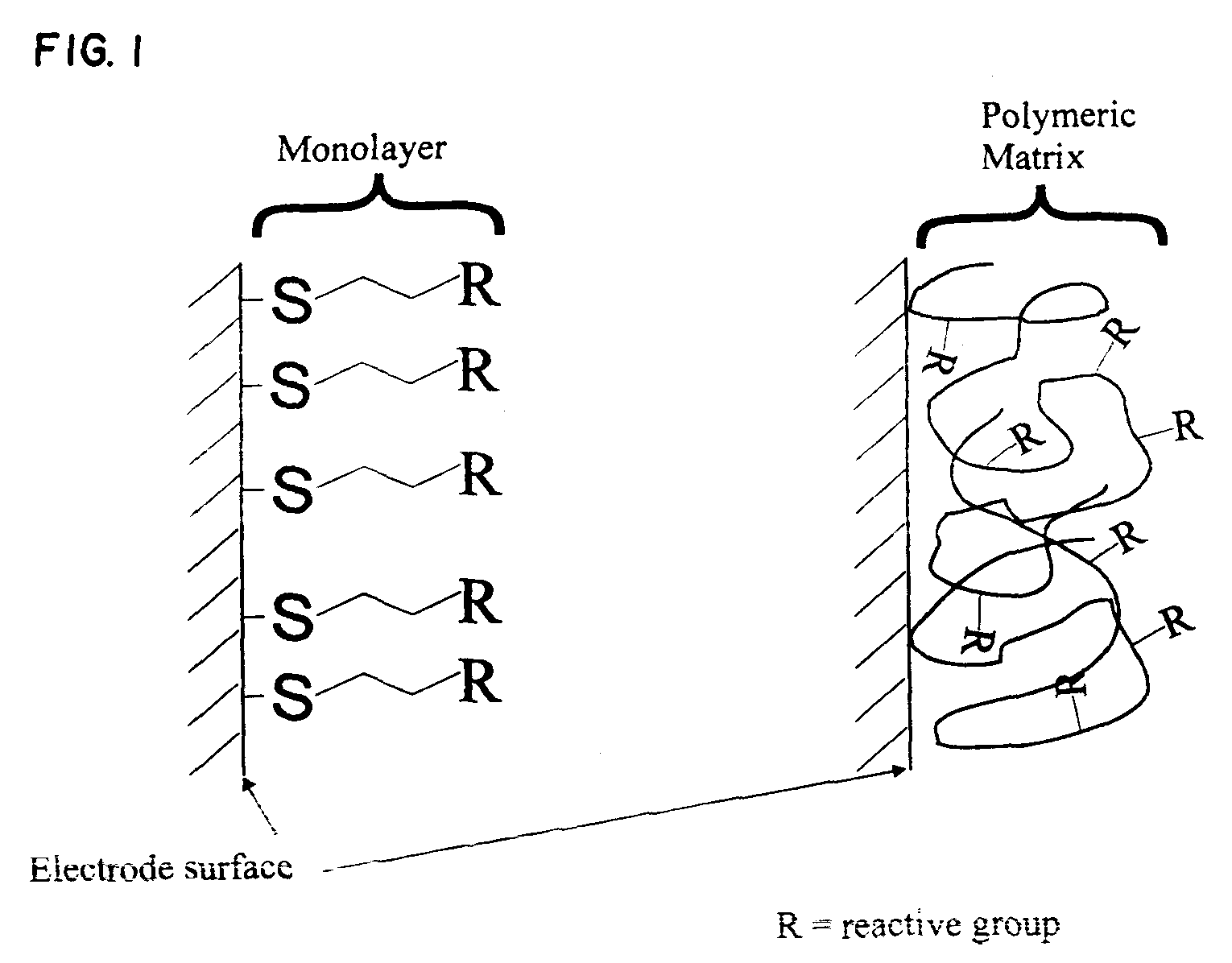

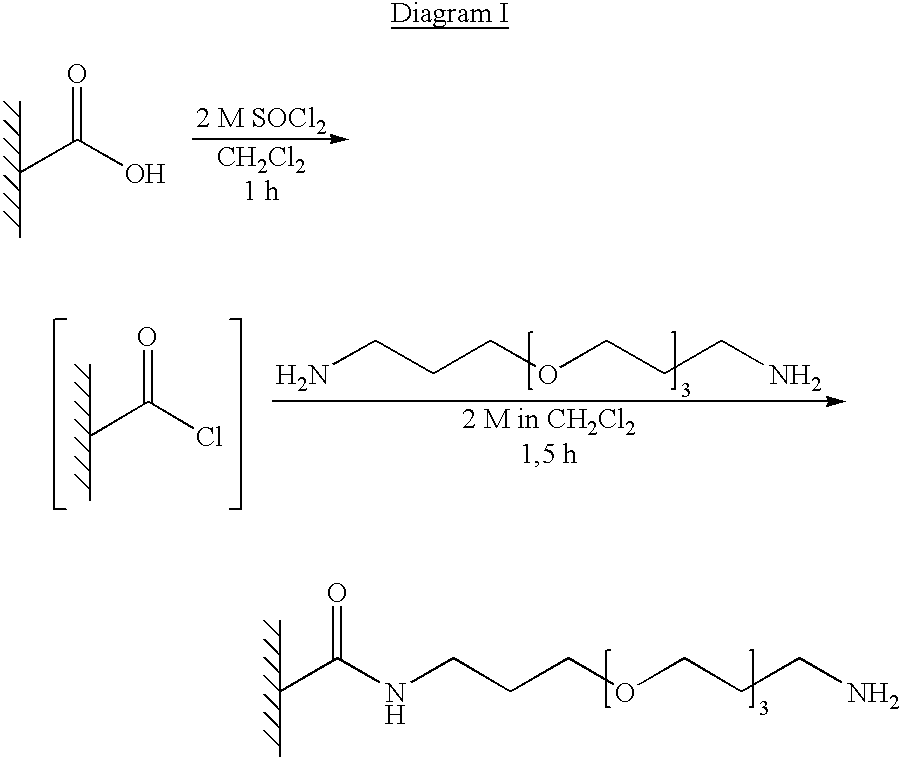

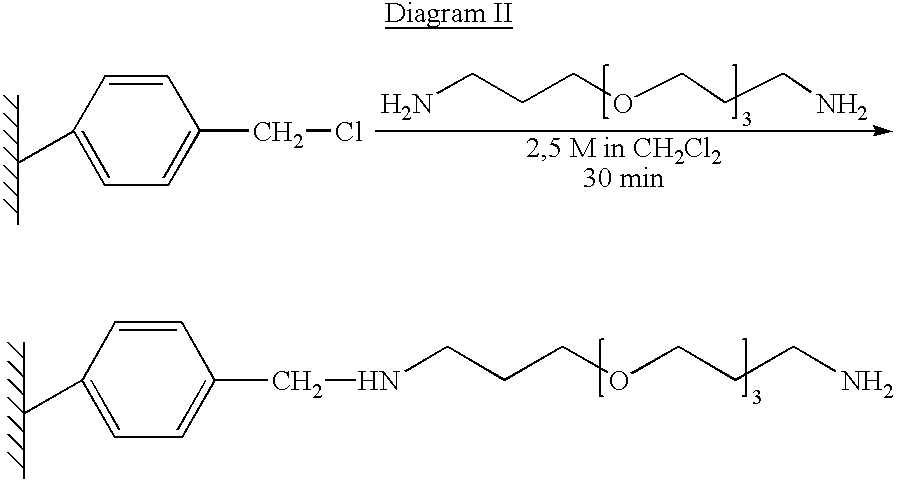

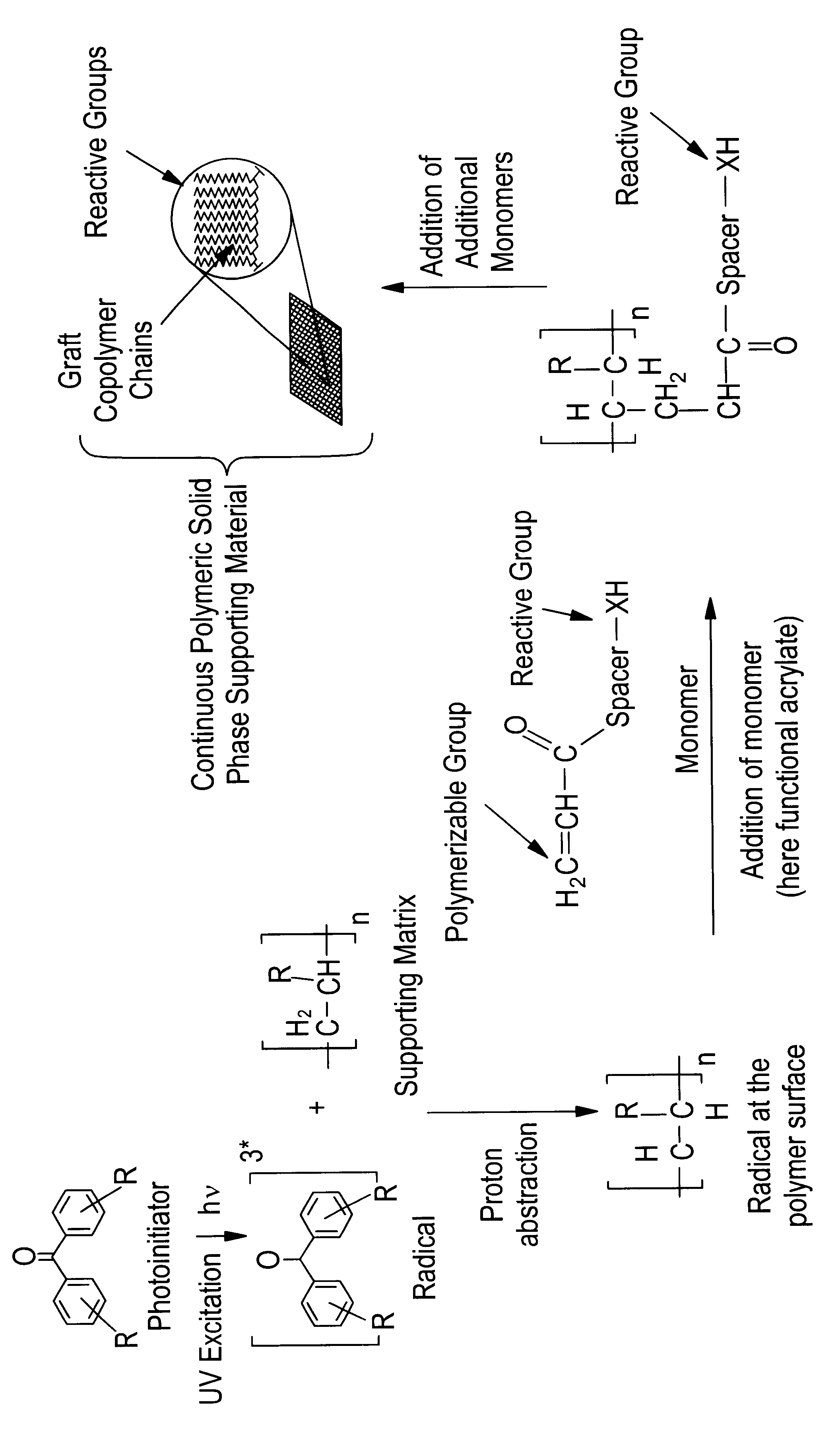

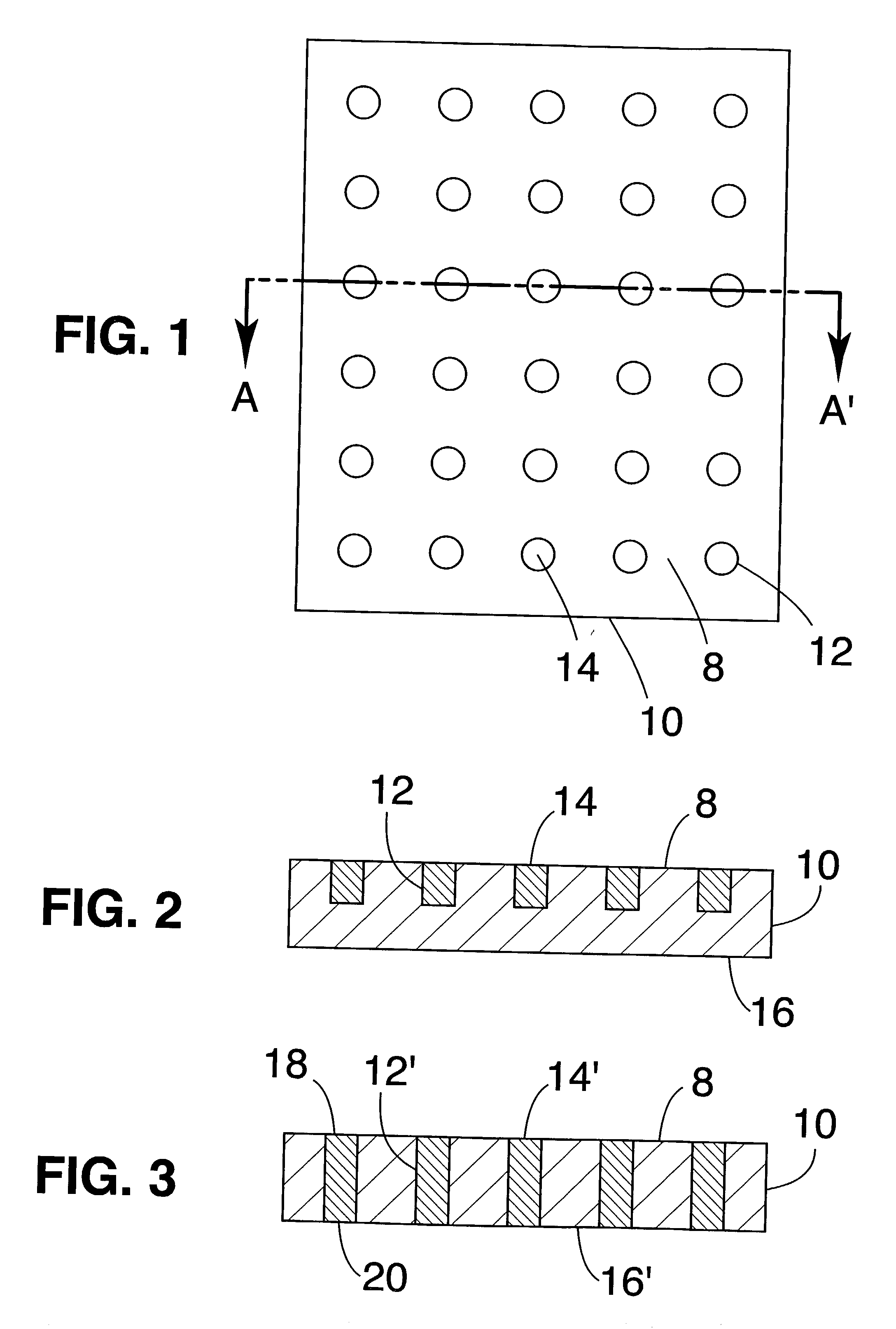

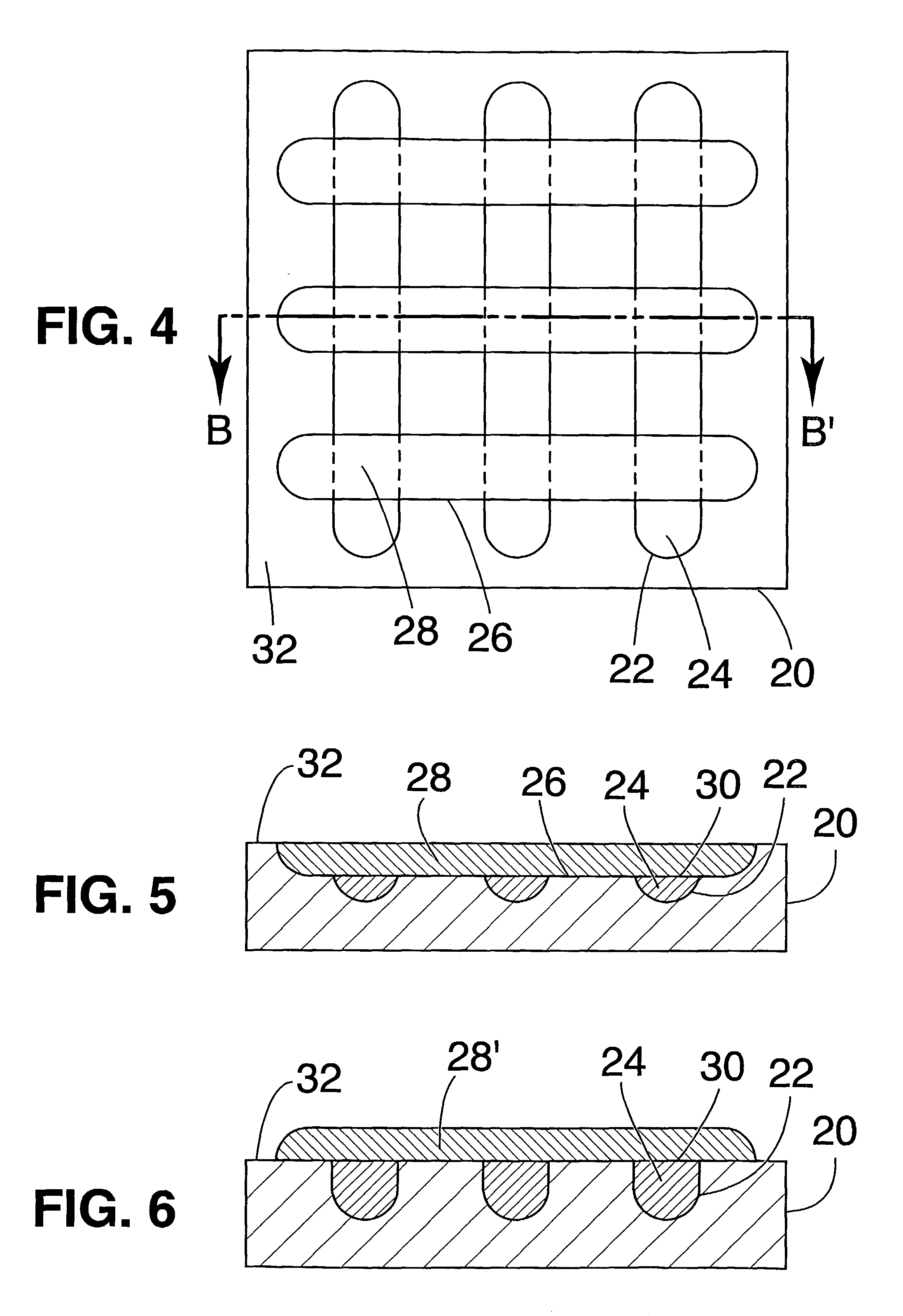

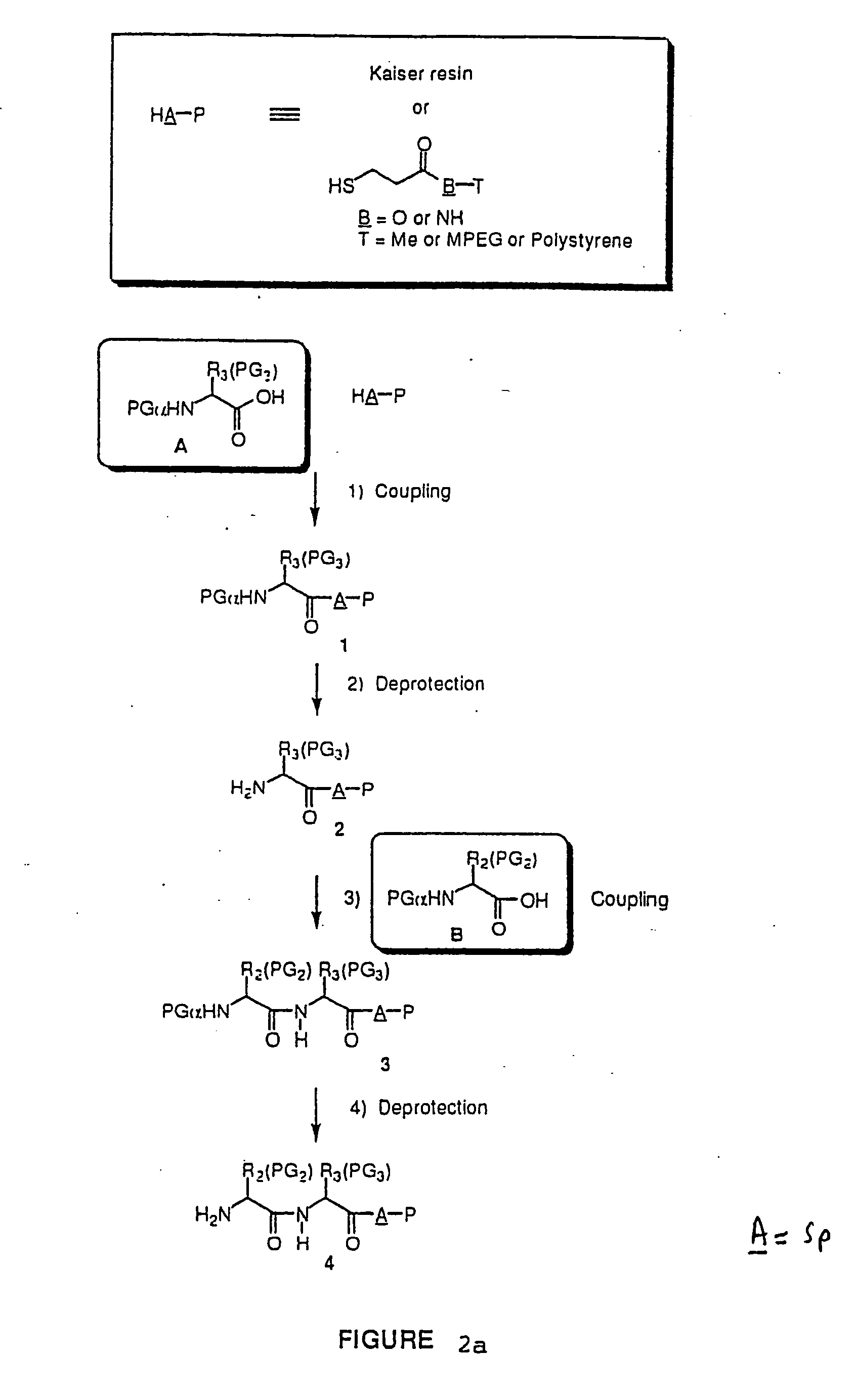

Method for the parallel and combinatory synthesis of compounds bound to a continuous polymeric solid phase supporting material

InactiveUS6515039B1Improve performanceImprove accessibilitySequential/parallel process reactionsMacromolecular librariesSimple Organic CompoundsPolymer science

The invention relates to a method for the parallel and combinatory synthesis of compounds bound to a continuous polymeric solid phase supporting material. According to the method, a continuous polymeric solid phase supporting material is prepared, the material comprising a matrix of a supporting polymeric material and graft copolymer chains covalently bound to the supporting matrix, the graft copolymer chains having reactive groups being able to react with organic compounds, thereby forming spatially defined reaction sites. The method then comprises the sequential spotting of synthesis building blocks or reagents at the various reaction sites on the continuous solid phase supporting material to yield a substrate library of compounds bound to the solid phase supporting material, whereby each reaction site on the continuous solid phase supporting material determines the composition of the synthesized compound, which is bound directly on the supporting matrix via the reactive groups of the graft polymer chain.

Owner:POLY AN

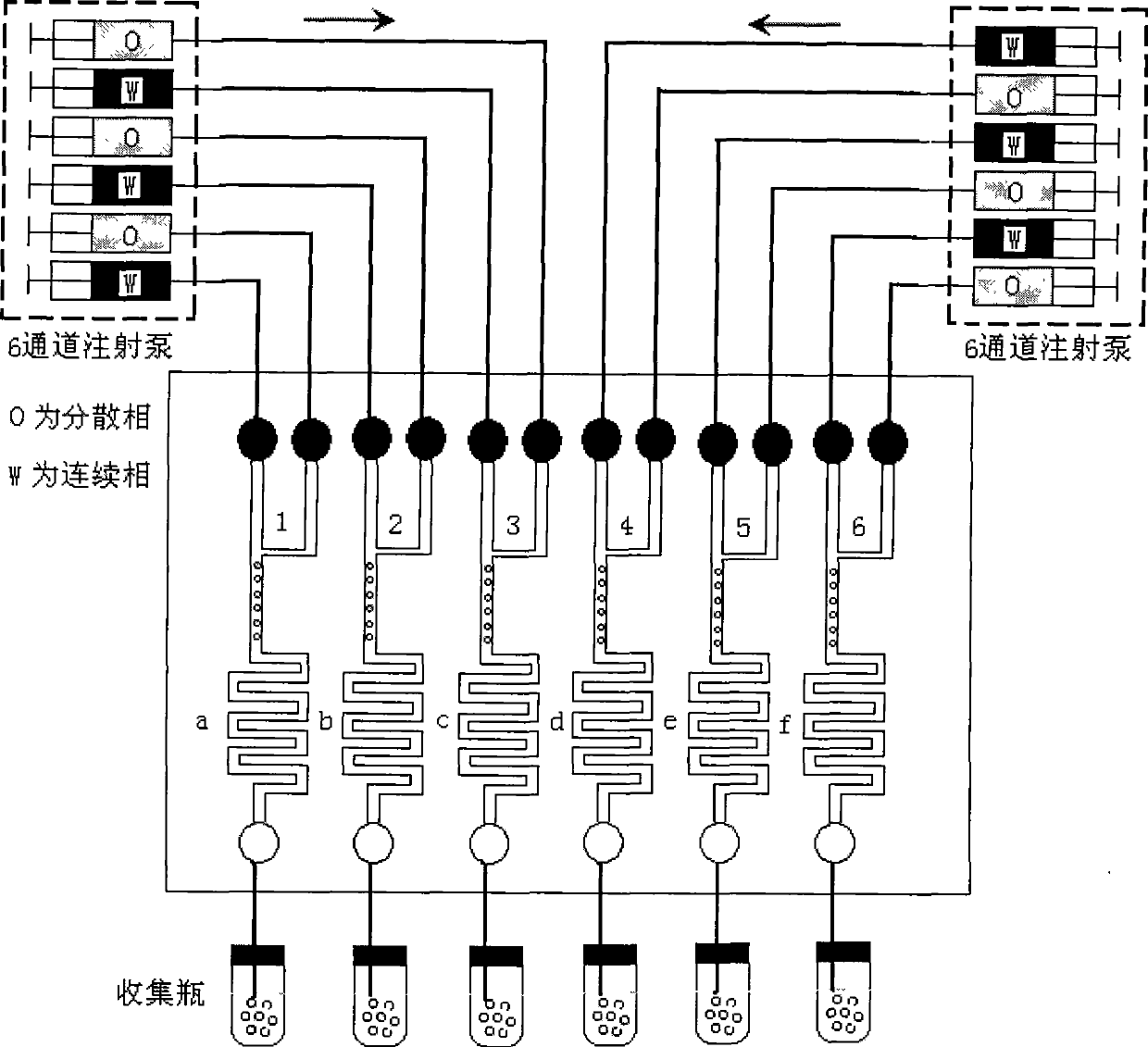

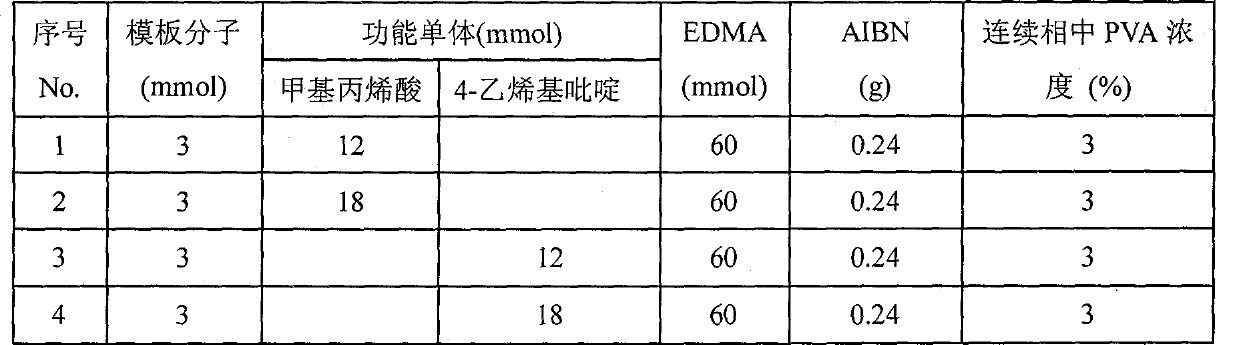

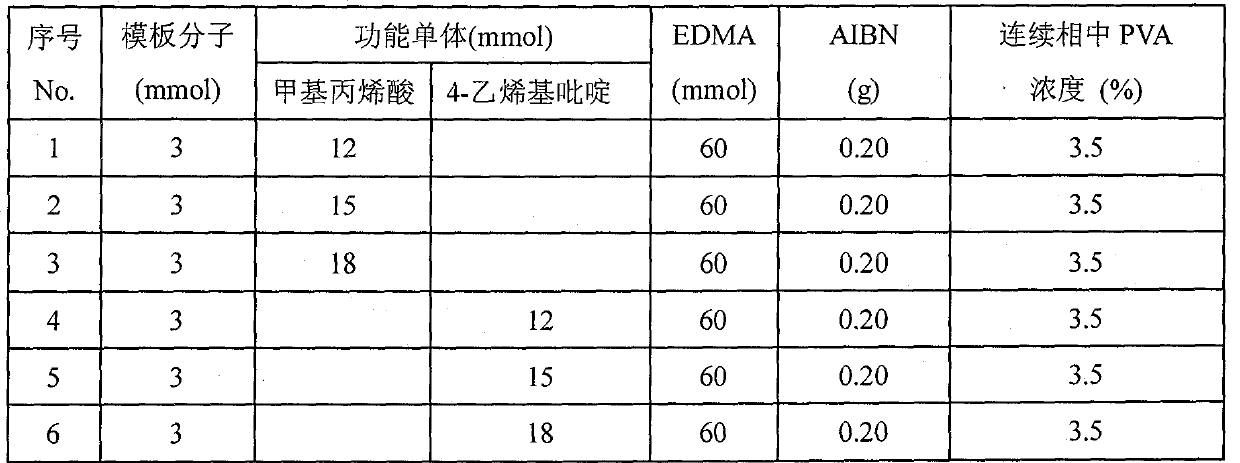

Molecular engram microspheres preparation method using micro-fluidic reactor

InactiveCN101507909AOther chemical processesChemical/physical/physico-chemical processesReactor systemMicrosphere

The invention relates to a method for combined synthesis of molecular engram microspheres through a micro-fluidic reactor, which is characterized in that a micro-fluidic reactor system comprises a fluid drive unit (an injection pump group), a liquid droplet or milk droplet forming unit and an ultraviolet illumination and polymerization unit, wherein the micro-fluidic reactor comprises n groups of '*'-shaped microchannels with the same structure, and can simultaneously prepare the molecular engram microspheres under n conditions or prepare the molecular engram microspheres of n template molecules; and dispersed phases and continuous phases are driven by injection pumps to enter respective microchannels and form milk droplets when encountering each other on crossings of the microchannels, and the prepared milk droplets arrive at the ultraviolet illumination unit for polymerization reaction.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

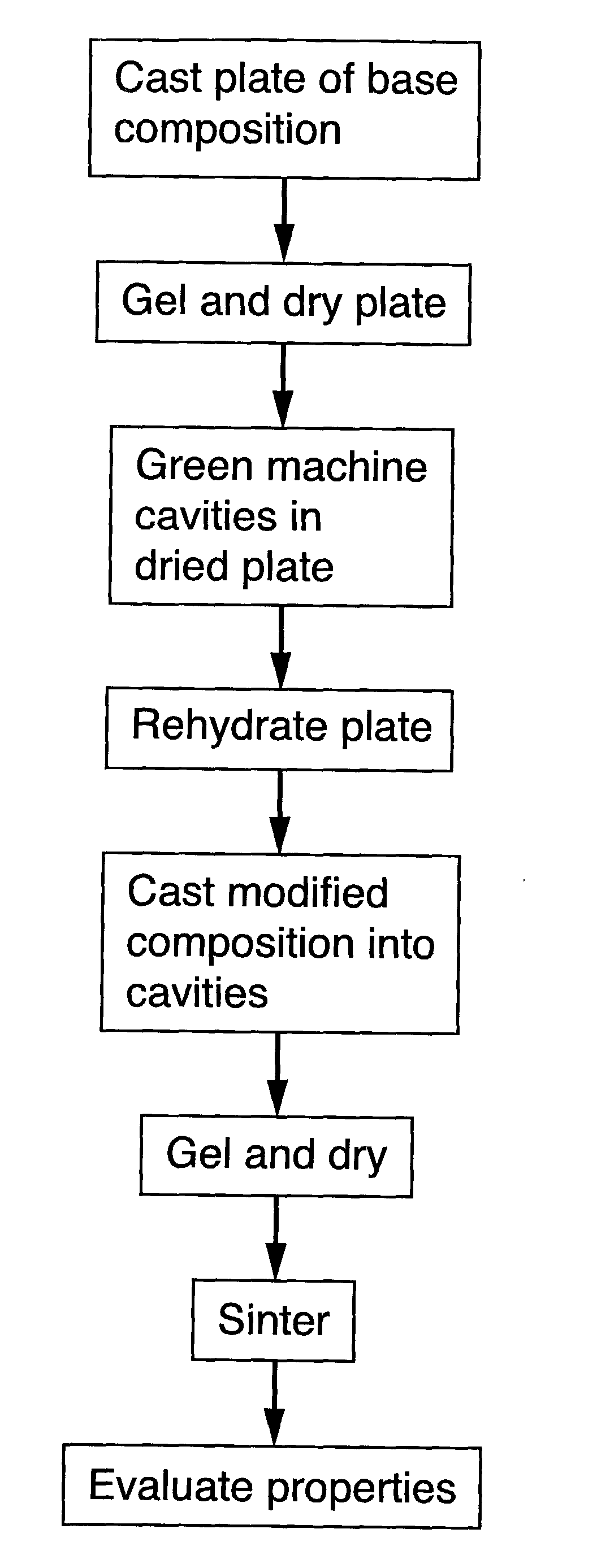

Combinatorial synthesis of ceramic materials

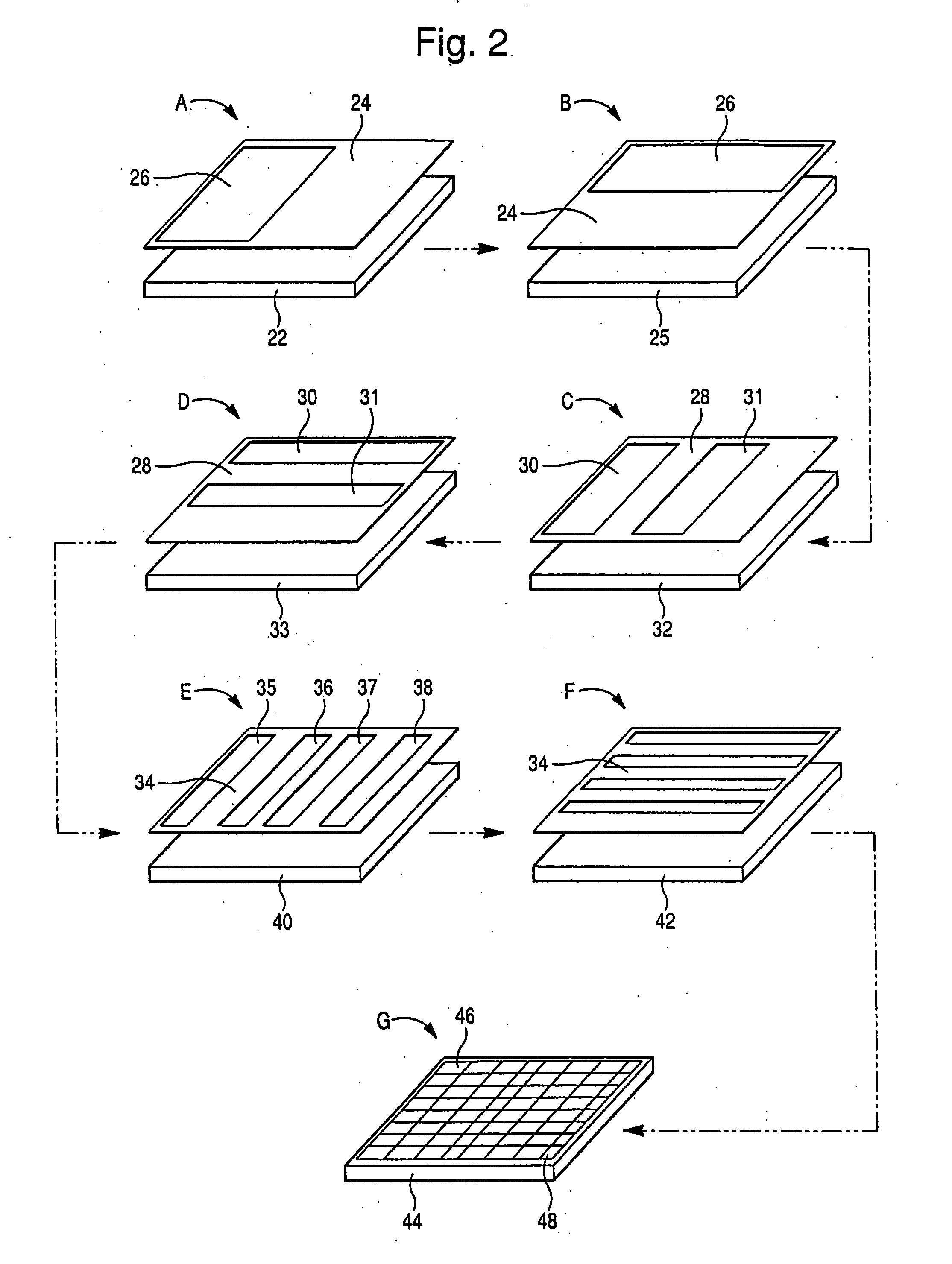

InactiveUS20040062911A1Overcome limitationsRealistic and physical propertyButtonsLayered productsTest materialCombinatorial synthesis

A combinatorial library includes a gelcast substrate defining a plurality of cavities in at least one surface thereof; and a plurality of gelcast test materials in the cavities, at least two of the test materials differing from the substrate in at least one compositional characteristic, the two test materials differing from each other in at least one compositional characteristic.

Owner:UT BATTELLE LLC

Combinatorial synthesis and screening of non-biological polymers

Methods and apparatus for the preparation and use of a substrate having an array of diverse materials in predefined regions thereon. A substrate having an array of diverse materials thereon is generally prepared by delivering components of materials to predefined regions on a substrate, and simultaneously reacting the components to form at least two materials. Materials which can be prepared using the methods and apparatus of the present invention include, for example, covalent network solids, ionic solids and molecular solids. More particularly, materials which can be prepared using the methods and apparatus of the present invention include, for example, inorganic materials, intermetallic materials, metal alloys, ceramic materials, organic materials, organometallic materials, non-biological organic polymers, composite materials (e.g., inorganic composites, organic composites, or combinations thereof), etc. Once prepared, these materials can be screened for useful properties including, for example, electrical, thermal, mechanical, morphological, optical, magnetic, chemical, or other properties. Thus, the present invention provides methods for the parallel synthesis and analysis of novel materials having useful properties.

Owner:INTERMOLECULAR

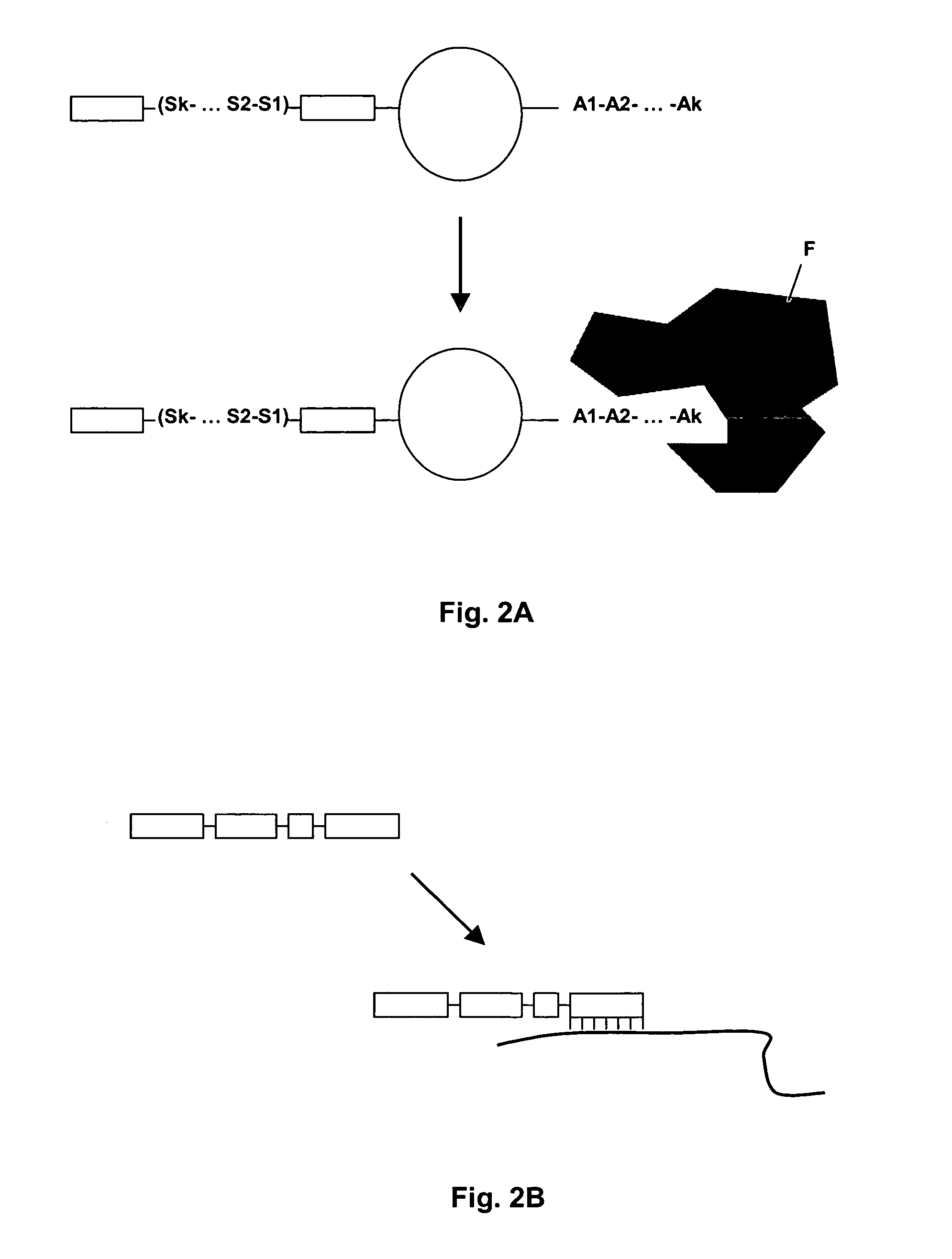

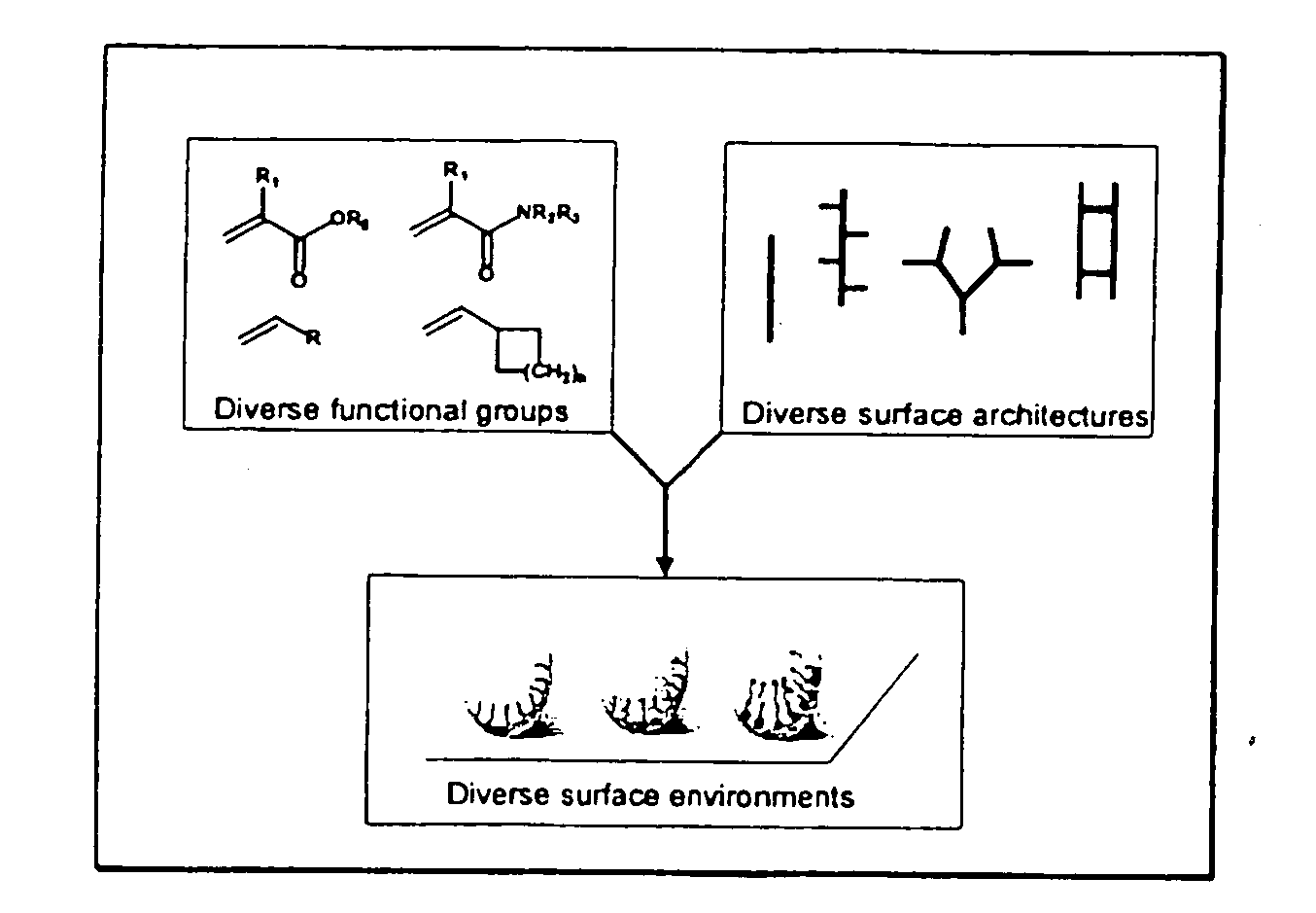

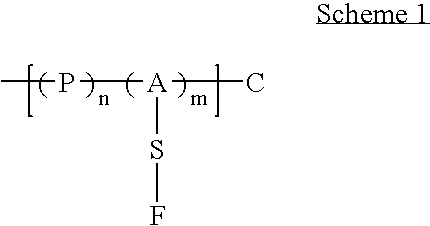

Generation of surface coating diversity

InactiveUS20060083858A1Generation of surfaceControl generationMembranesSequential/parallel process reactionsChemical compositionSynthon

The present invention relates to a surface discovery system comprising chemical compositions and high-throughput combinatorial synthesis methods for generating large numbers of diverse surface coatings on solid substrates. This surface discovery platform is built upon a fundamental chemical unit refereed to as a synthon. Each synthon comprises at least three elements: a chemical backbone coating on the solid substrate that comprises a passive (P) constituent and an active (A) constituent; a spacer unit (S) separating the backbone from a functional group; and a functional group (F). Variation of these synthon elements allows generation of large libraries surface coatings with a broad range of molecular and macroscopic properties. Further the spectrum of surfaces provided by the invention permits optimization of the wide range of solid-phase applications that involve surface immobilization of molecules.

Owner:ANTEO TECH

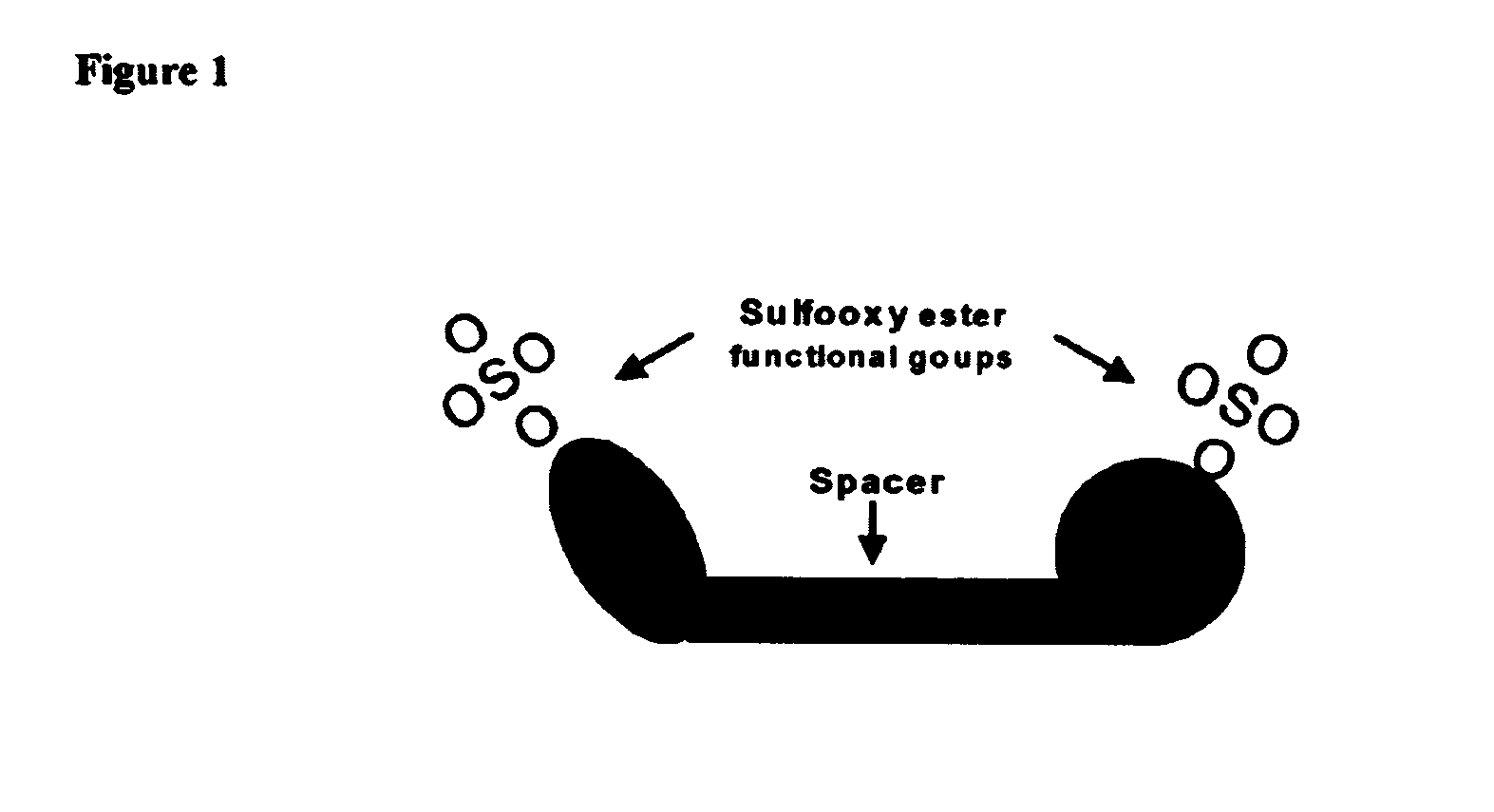

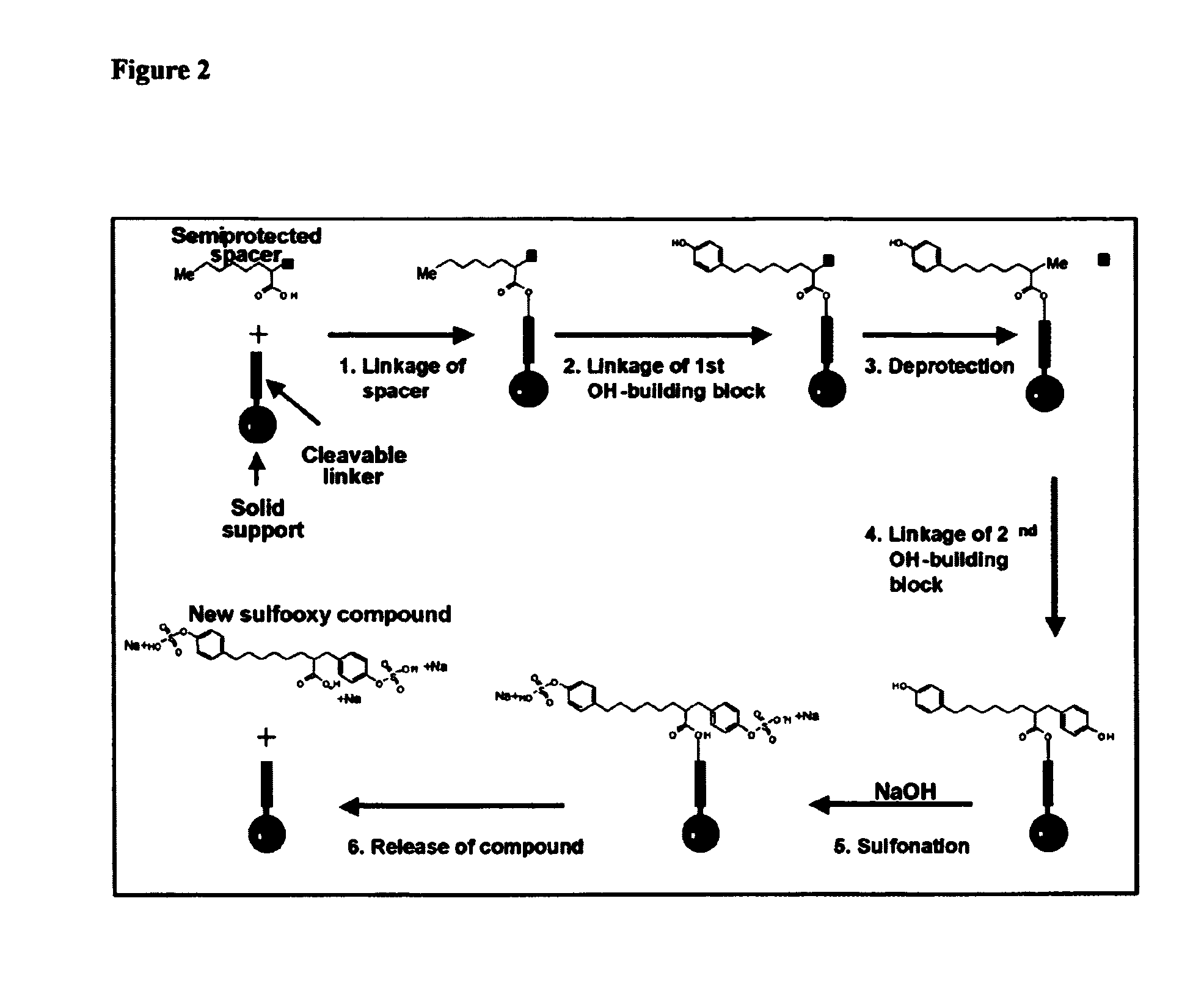

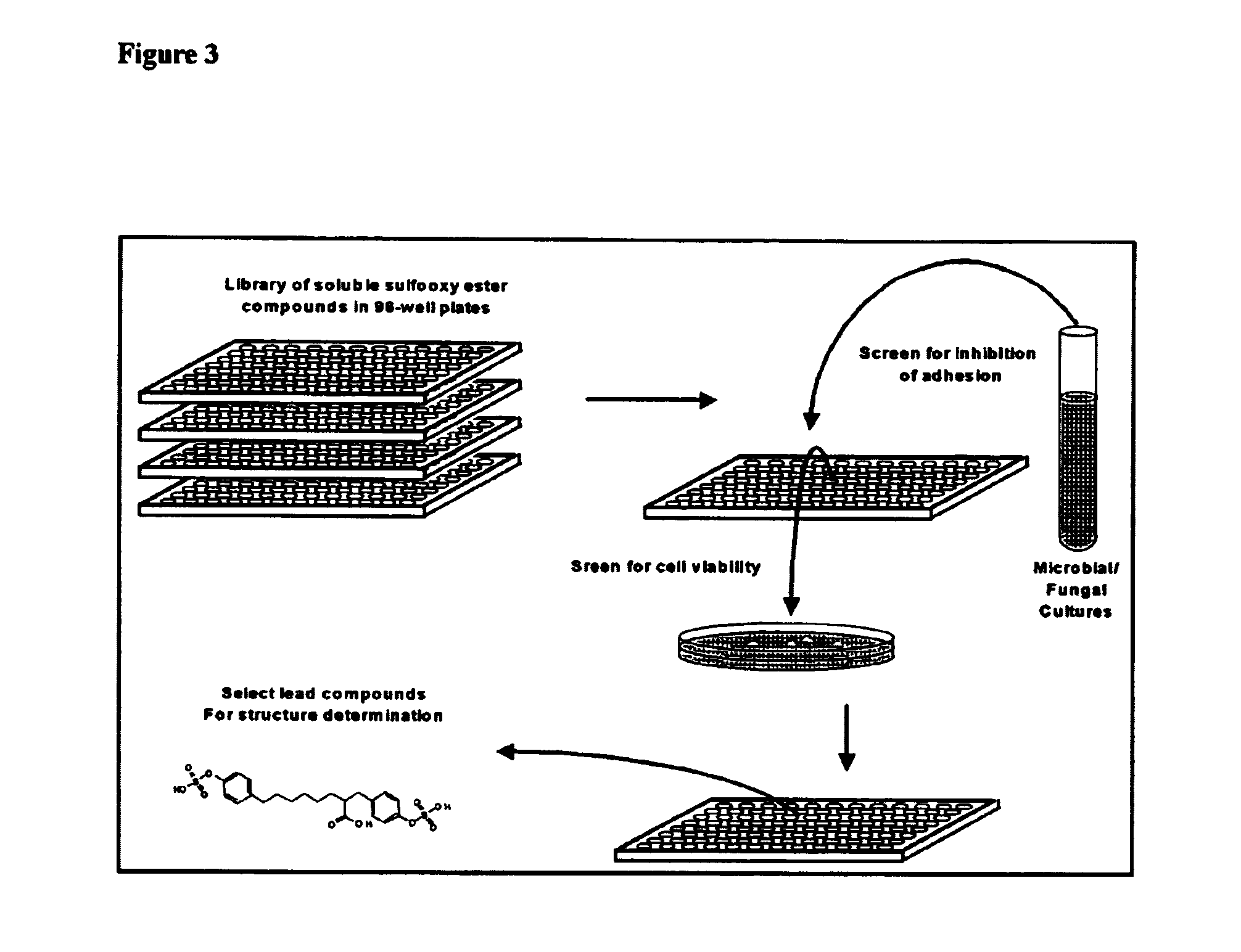

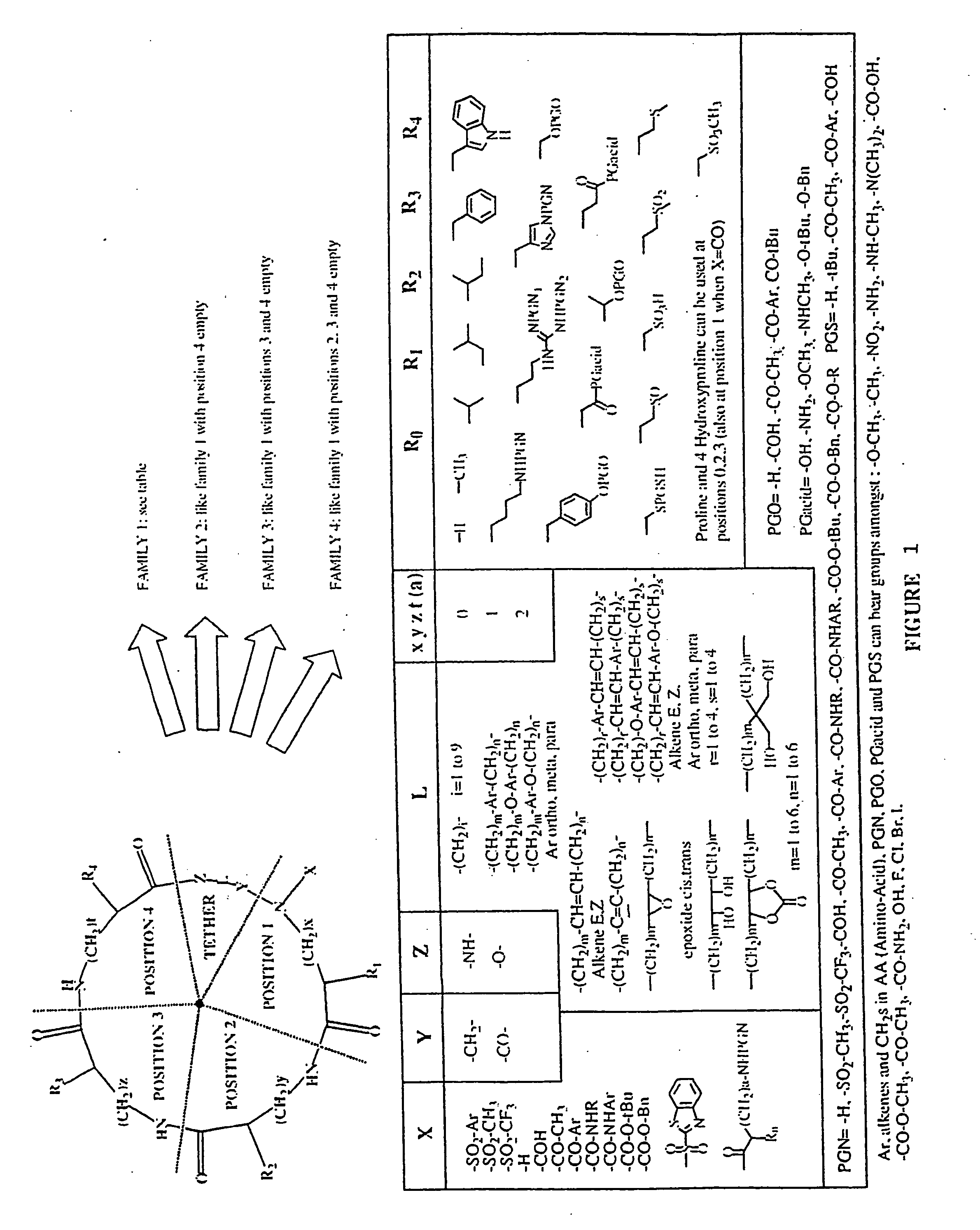

Generation of combinatorial synthetic libraries and screening for proadhesins and nonadhesins

One aspect of the present invention relates to compounds, comprising at least two moieties selected from the group consisting of aryl sulfonates and aryl sulfates. A second aspect of the present invention relates to combinatorial libraries of the aforementioned compounds. The present invention also relates to compositions comprising a compound of the present invention. A fourth aspect of the present invention relates to the use of a compound or composition of the present invention in a method for inhibiting bioadhesion to a surface. Another aspect of the present invention relates to the use of a compound or composition of the present invention in a method for enhancing bioadhesion to a surface.

Owner:CERNOFINA

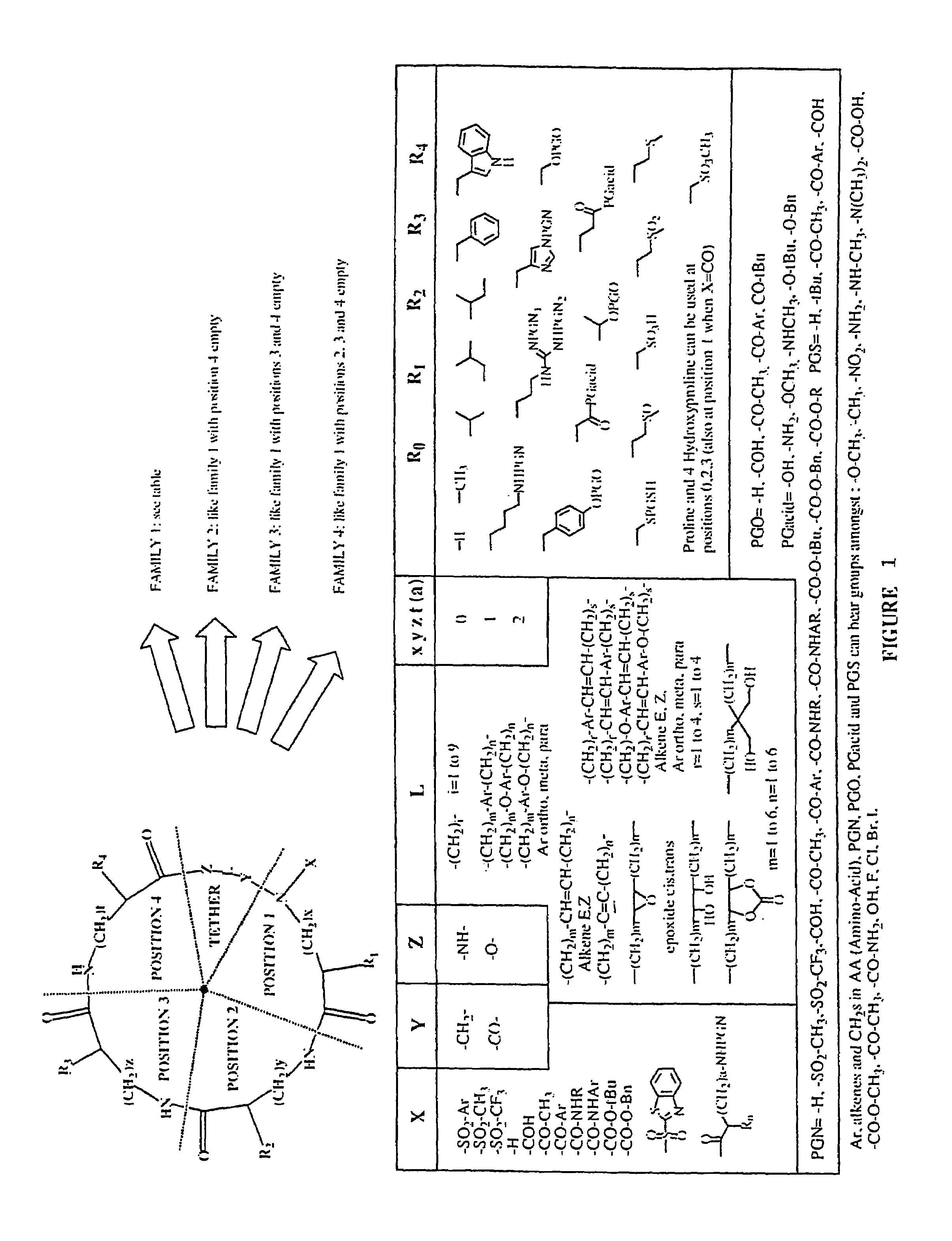

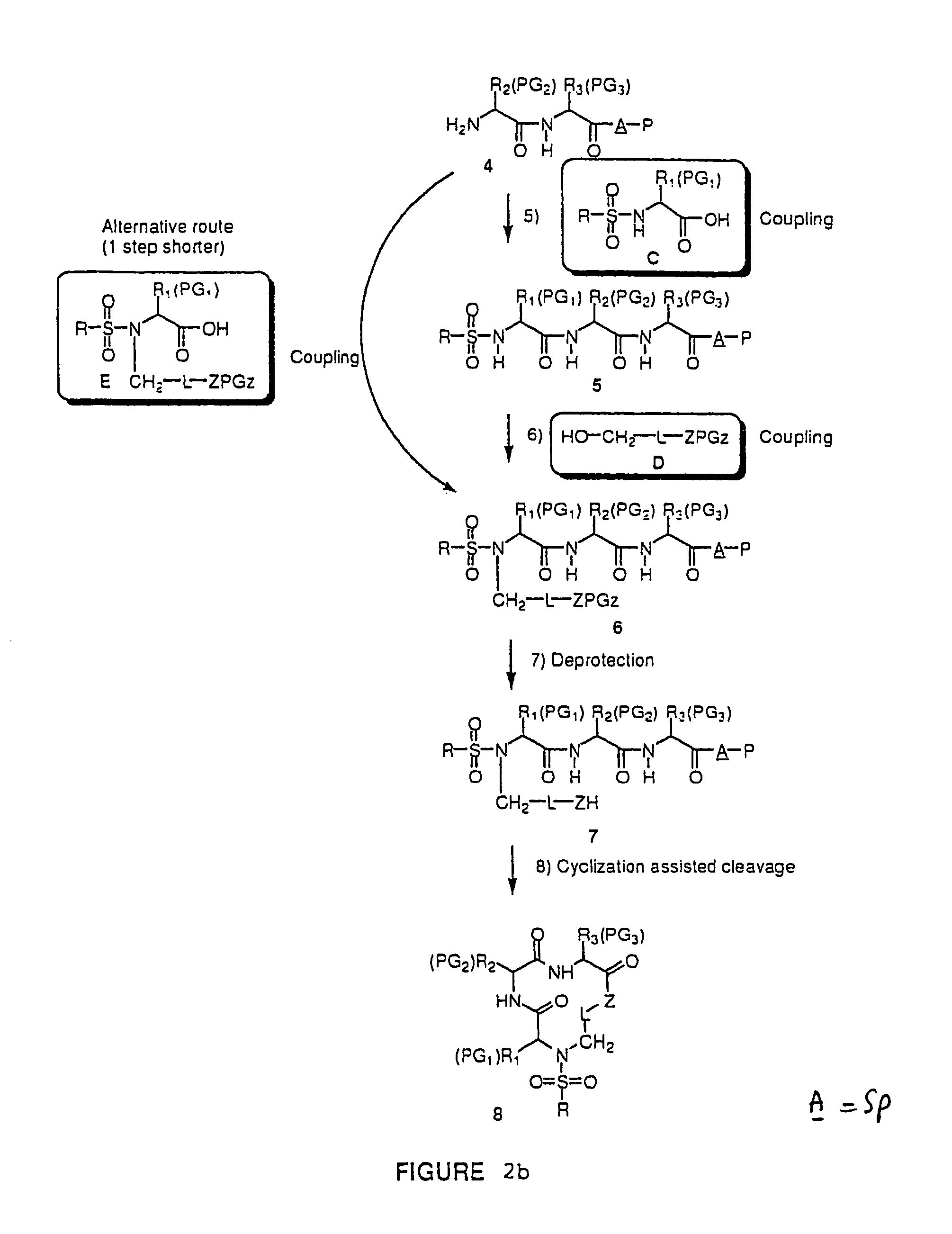

Combinatorial synthesis of libraries of macrocyclic compounds useful in drug discovery

ActiveUS20050049234A1Organic active ingredientsPeptide/protein ingredientsCombinatorial synthesisDrug discovery

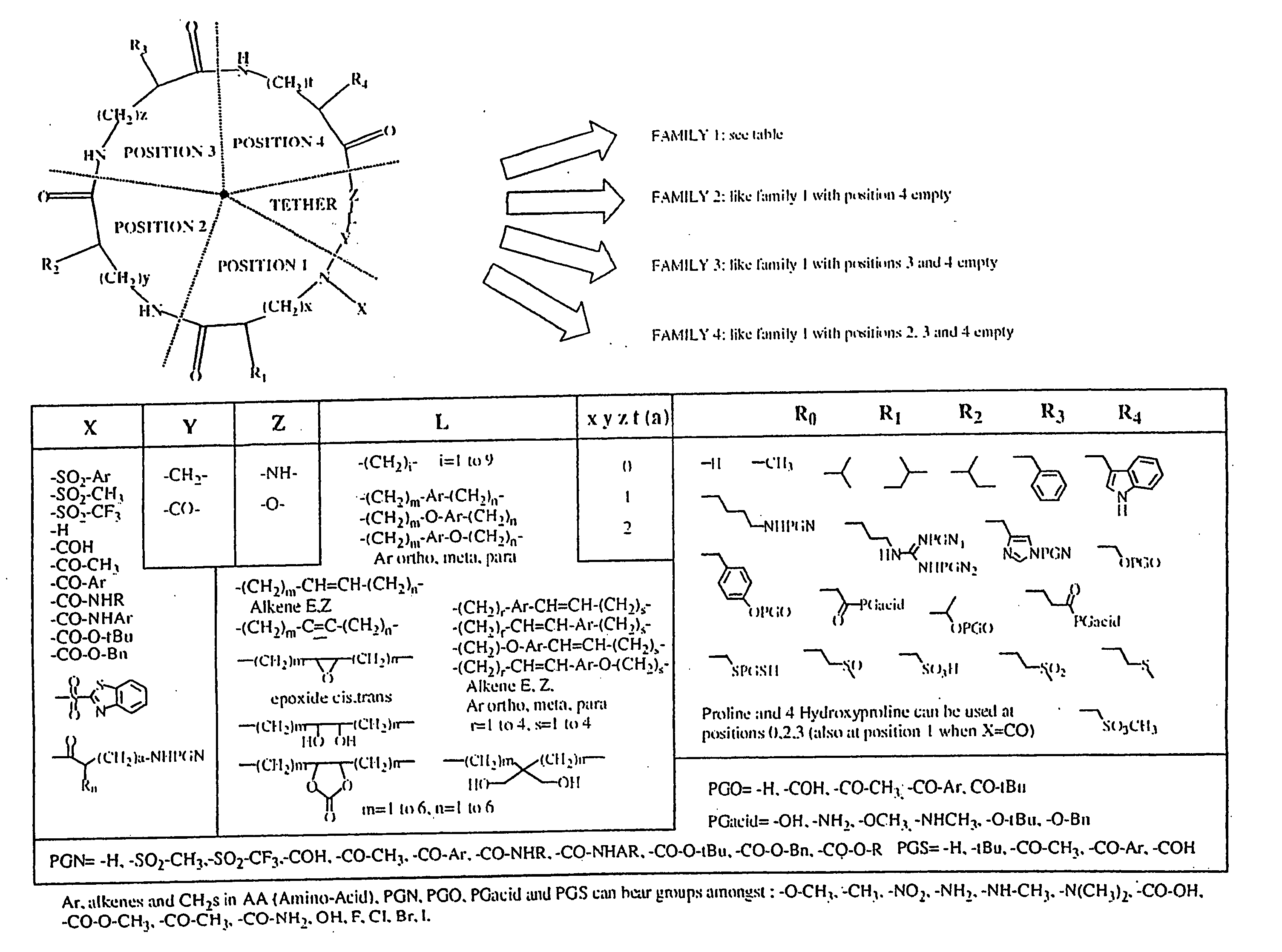

A library of macrocyclic compounds of the formula (I) where part (A) is a (CH2)y—NH— bivalent radical, a —(CH2)y— bivalent radical or a covalent bond; where part (B) is a (CH2)z—NH— bivalent radical, a —(CH2)z— bivalent radical, or a covalent bond; where part (C) is a (CH2)t—NH— bivalent radical, a —(CH2)t— bivalent radical, or a covalent bond; and where part (T) is a —Y-L-Z— radical wherein Y is CH2 or CO, Z is NH or O and L is a bivalent radical. These compounds are useful for carrying out screening assays or as intermediates for the synthesis of other compounds of pharmaceutical interest. A process for their preparation of these compounds in a combinatorial manner, is also disclosed.

Owner:OCERA THERAPEUTICS INC

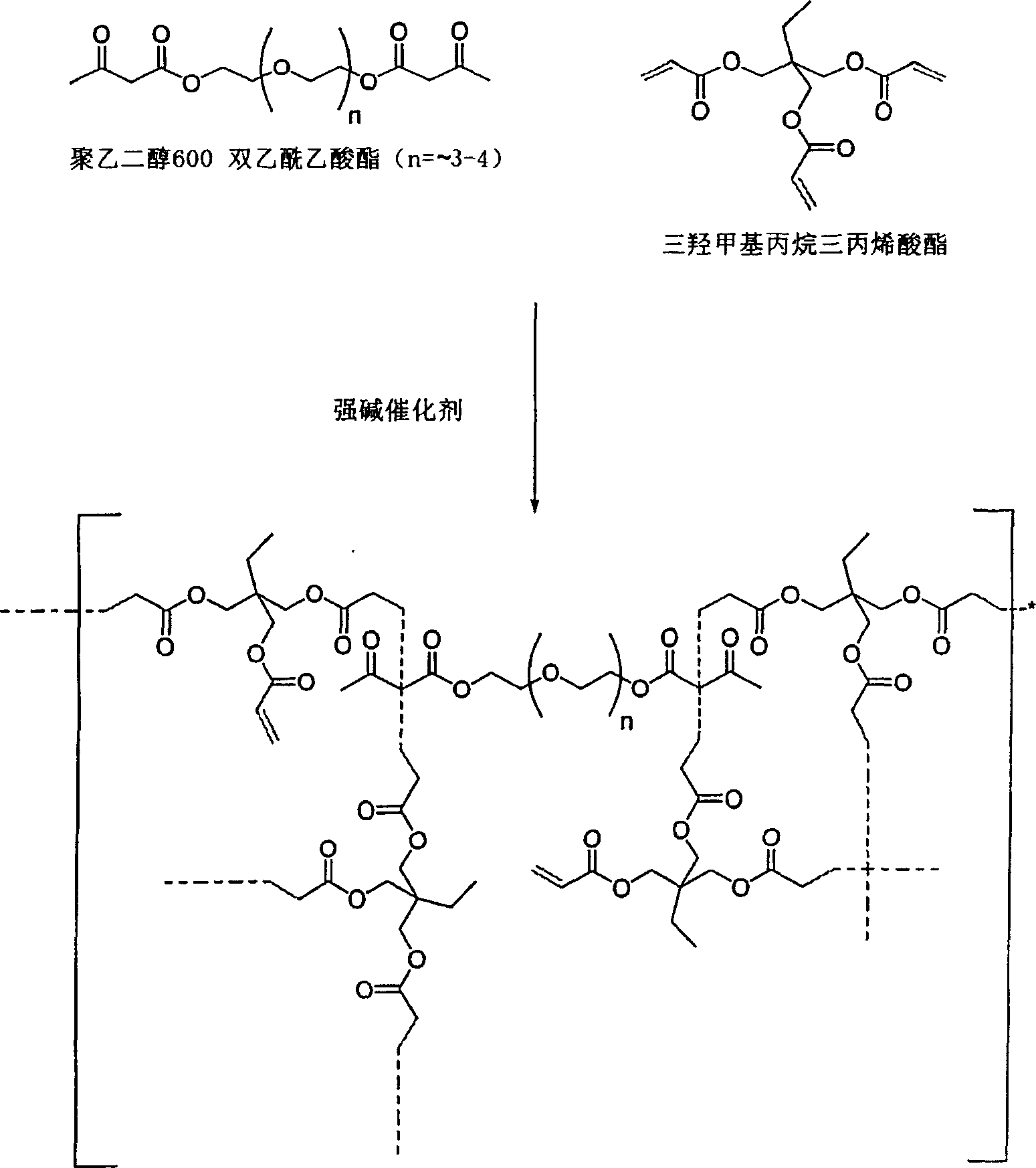

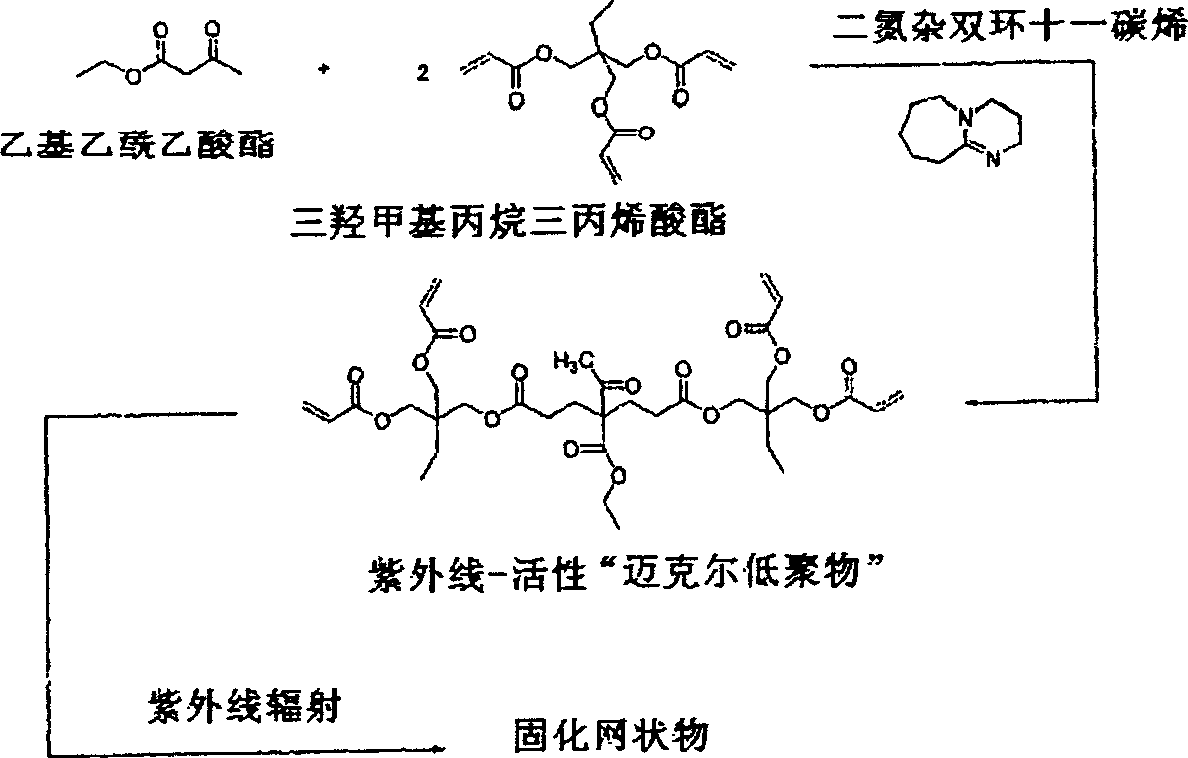

Dual cure reaction products of self-photoinitiating multifunctional acrylates with cycloaliphatic epoxy compounds

Owner:ASHLAND LICENSING & INTPROP LLC

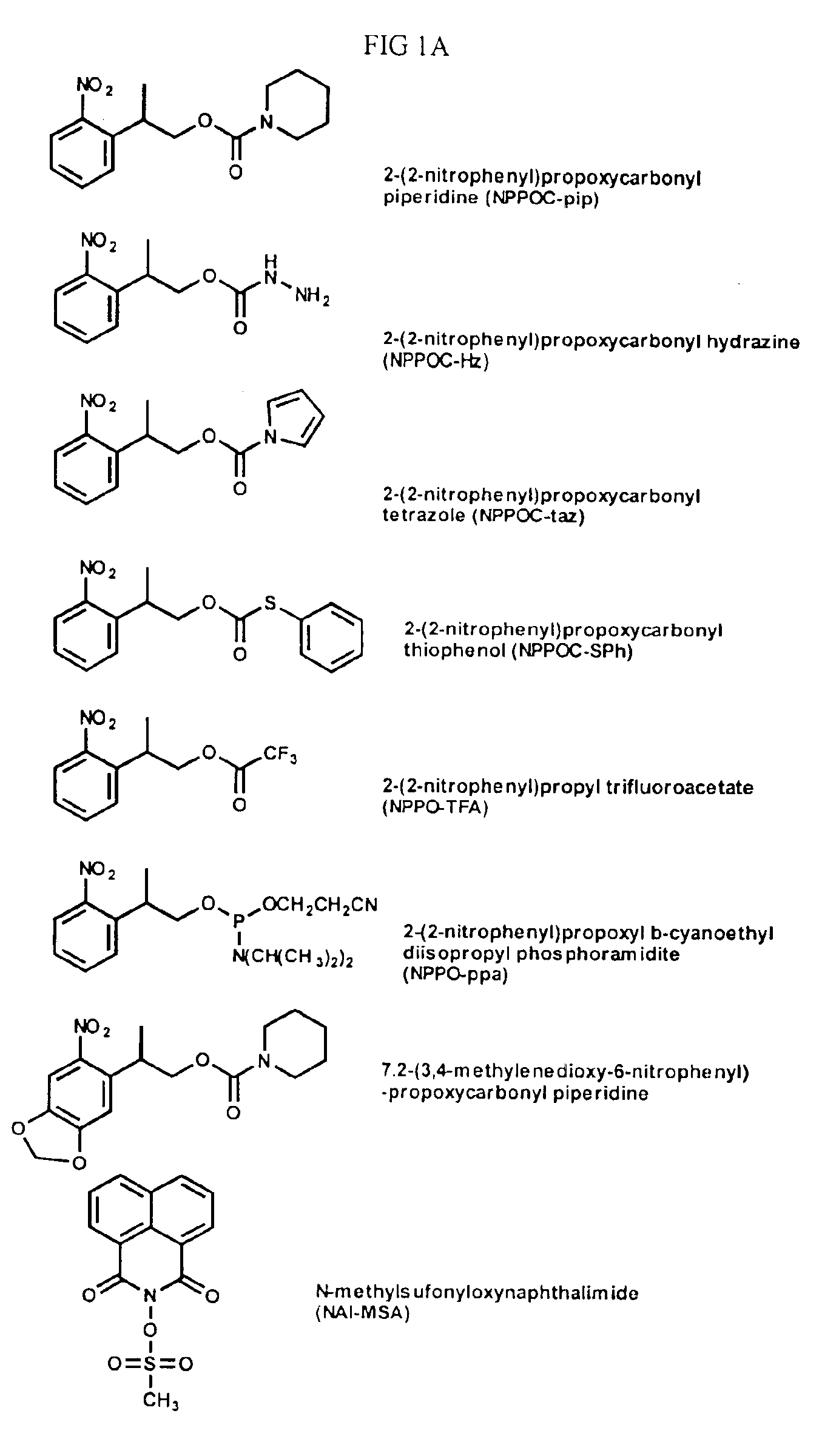

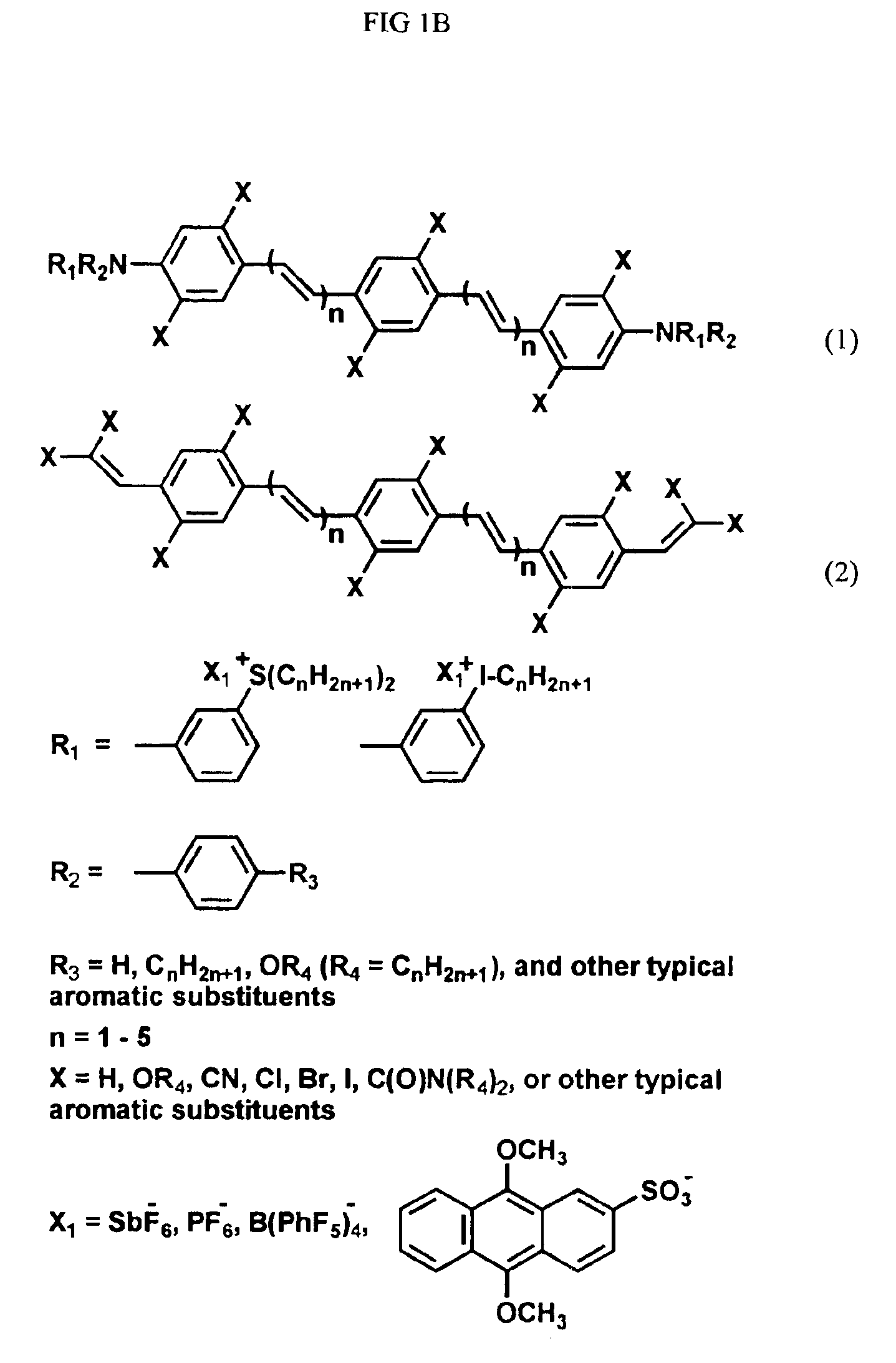

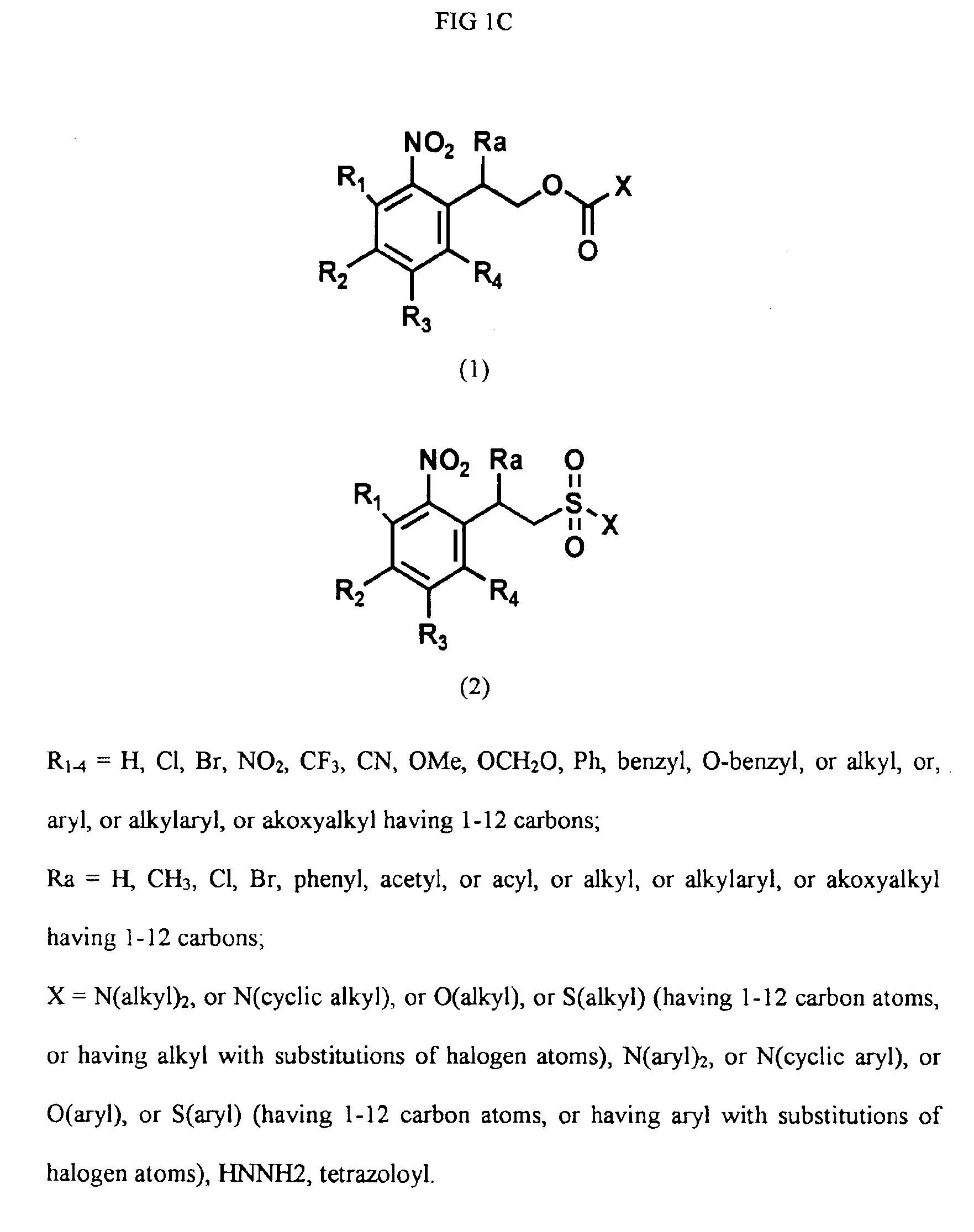

Photogenerated reagents

ActiveUS6965040B1Suppressing formation of photoreactionEffect efficiencySugar derivativesOrganic compound preparationChemical reactionCombinatorial synthesis

This invention describes reagent precursors and methods for chemical and biochemical reactions. These reagent precursors that can be activated in solution upon irradiation to generate reagents required for the subsequent chemical reactions. Specifically, photogenerated reagents (PGR) are useful for controlling parallel combinatorial synthesis and various chemical and biochemical reactions.

Owner:LC SCI LC

Combinatorial synthesis of libraries of macrocyclic compounds useful in drug discovery

A library of macrocyclic compounds of the formula (I)where part (A) is a bivalent radical, a —(CH2)y— bivalent radical or a covalent bond;where part (B) is a bivalent radical, a —(CH2)z— bivalent radical, or a covalent bond;where part (C) is a bivalent radical, a —(CH2)t— bivalent radical, or a covalent bond; andwhere part (T) is a —Y—L—Z— radical wherein number Y is CH2 or CO, Z is NH or O and L is a bivalent radical. These compounds are useful for carrying out screening assay or as intermediates for the synthesis of other compound of pharmaceutical interest. A process for their preparation of these compounds in a combinatorial manner, is also disclosed.

Owner:OCERA THERAPEUTICS INC

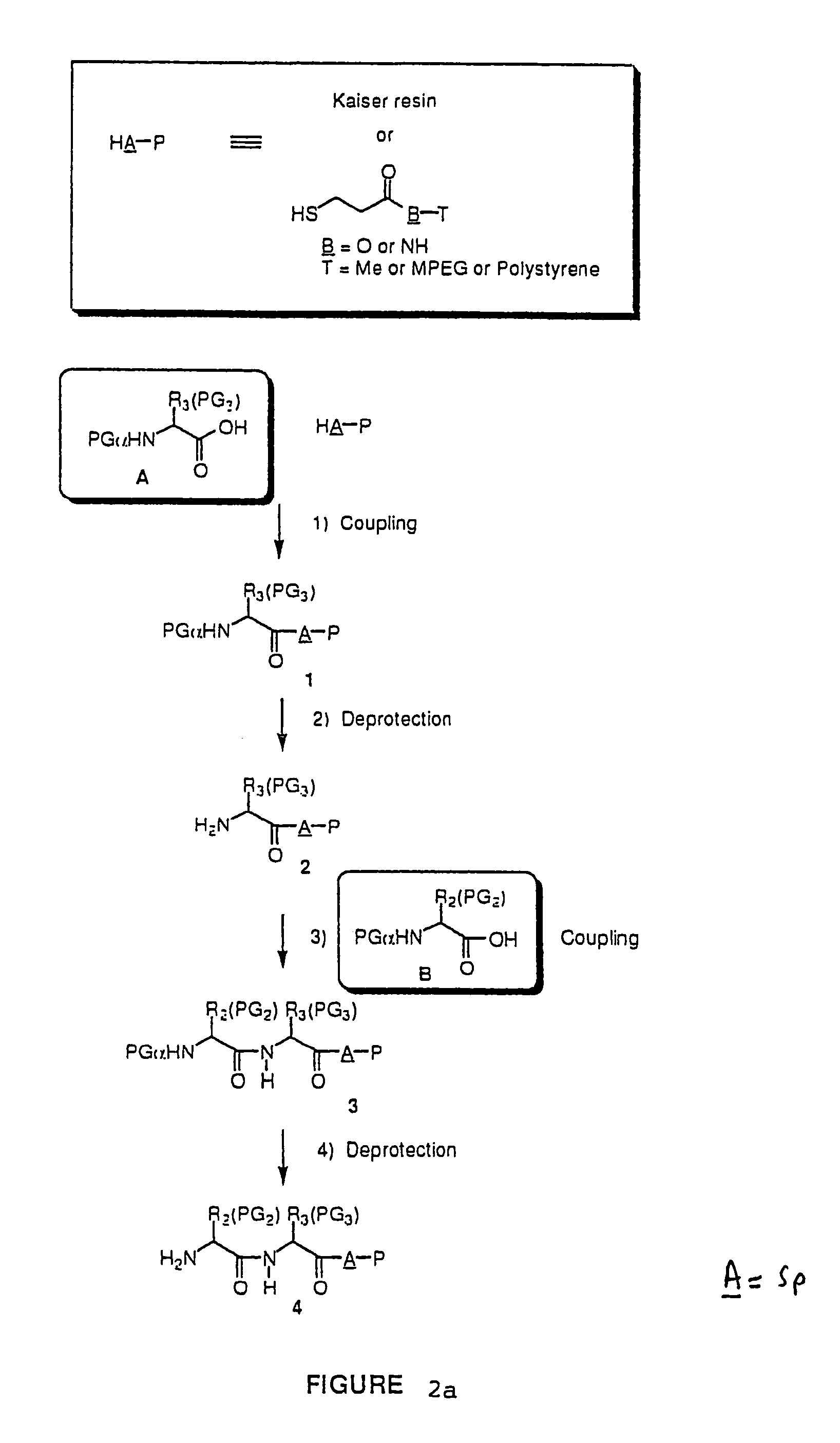

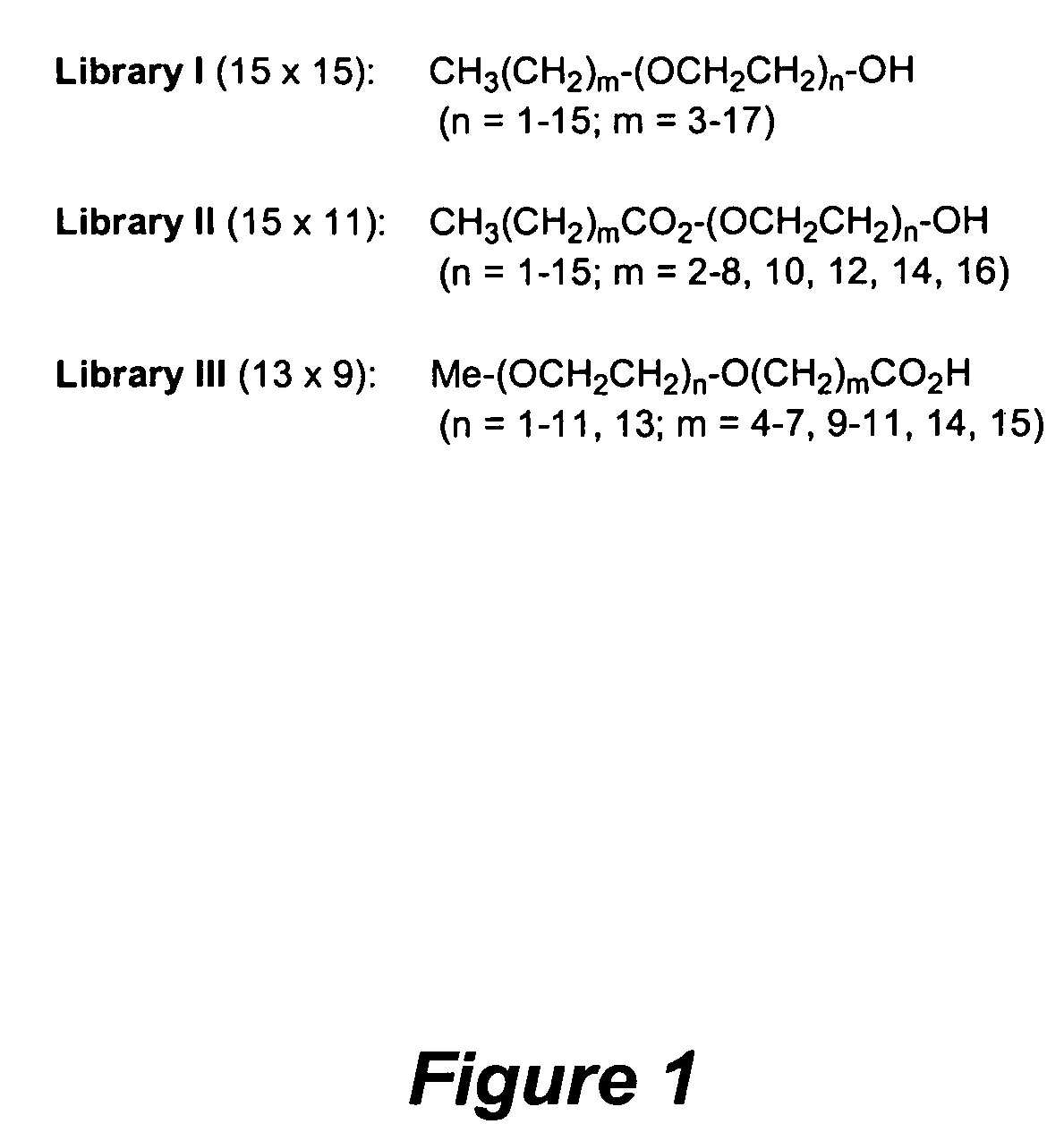

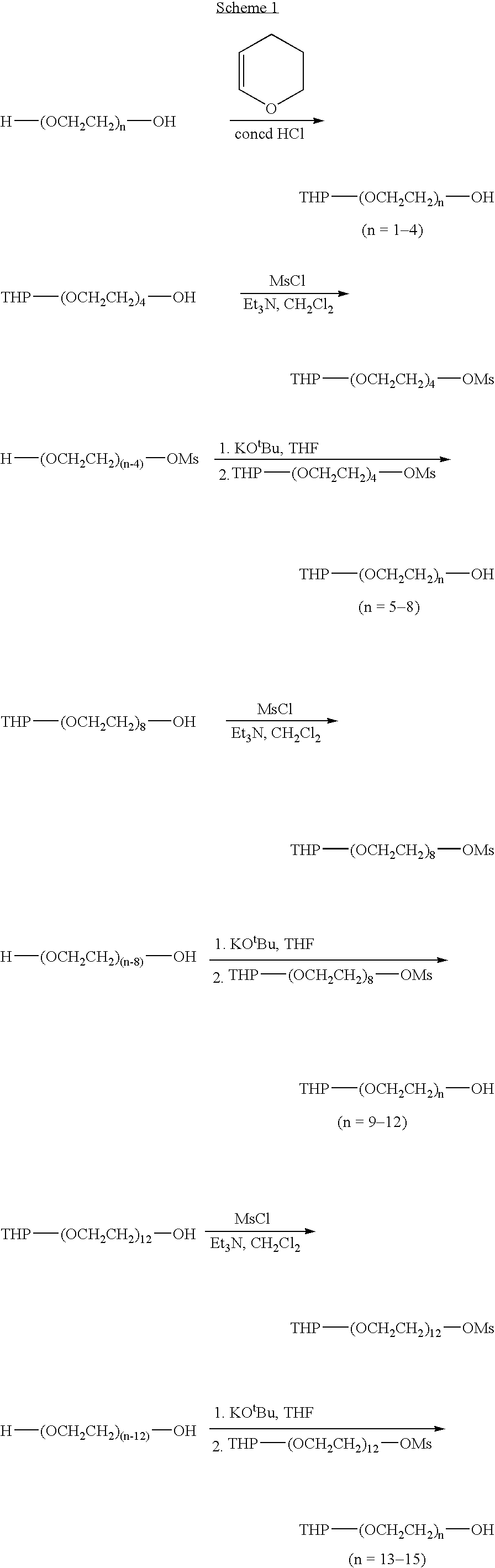

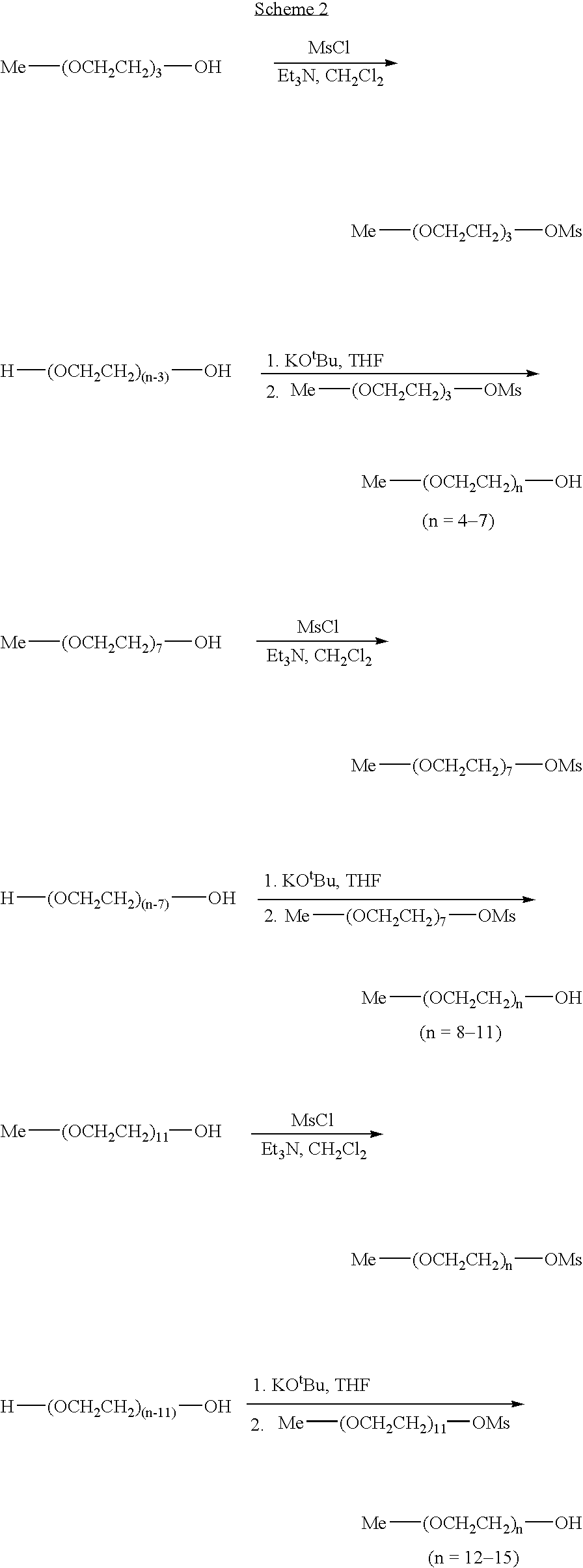

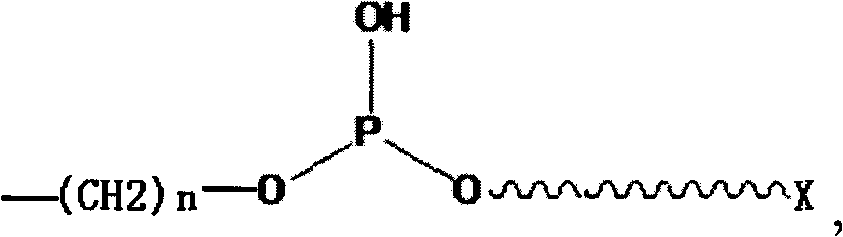

Combinatorial synthesis of PEG oligomer libraries

A simple chain-extending approach was established for the scale-up of the monoprotected monodisperse PEG diol materials. Reactions of THP-(OCH2CH2)n—OMs (n=4, 8, 12) with a large excess of commercially available H—(OCH2CH2)n—OH (n=1-4) under basic conditions led to THP-(OCH2CH2)n—OH (n=5-15). Similarly, Me-(OCH2CH2)n—OH (n=4-11, 13) were prepared from Me-(OCH2CH2)n—OMs (n=3, 7, 11). For the chain elongation steps, 40-80% yields were achieved through extraction purification. PEG oligomer libraries I and II were generated in 50-95% overall yields by alkylation or acylation of THP-(OCH2CH2)n—OH (n=1-15) followed by deprotection. Alkylation of Me-(OCH2CH2)n—OH (n=1-11, 13) with X—(CH2)m—CO2R (X=Br or OMs) and subsequent hydrolysis led to PEG oligomer library III in 30-60% overall yields. Combinatorial purification techniques were adapted to the larger-scale library synthesis. A total of 498 compounds, each with a weight of 2-5 g and a minimum purity of 90%, were synthesized.

Owner:BIOCON LTD

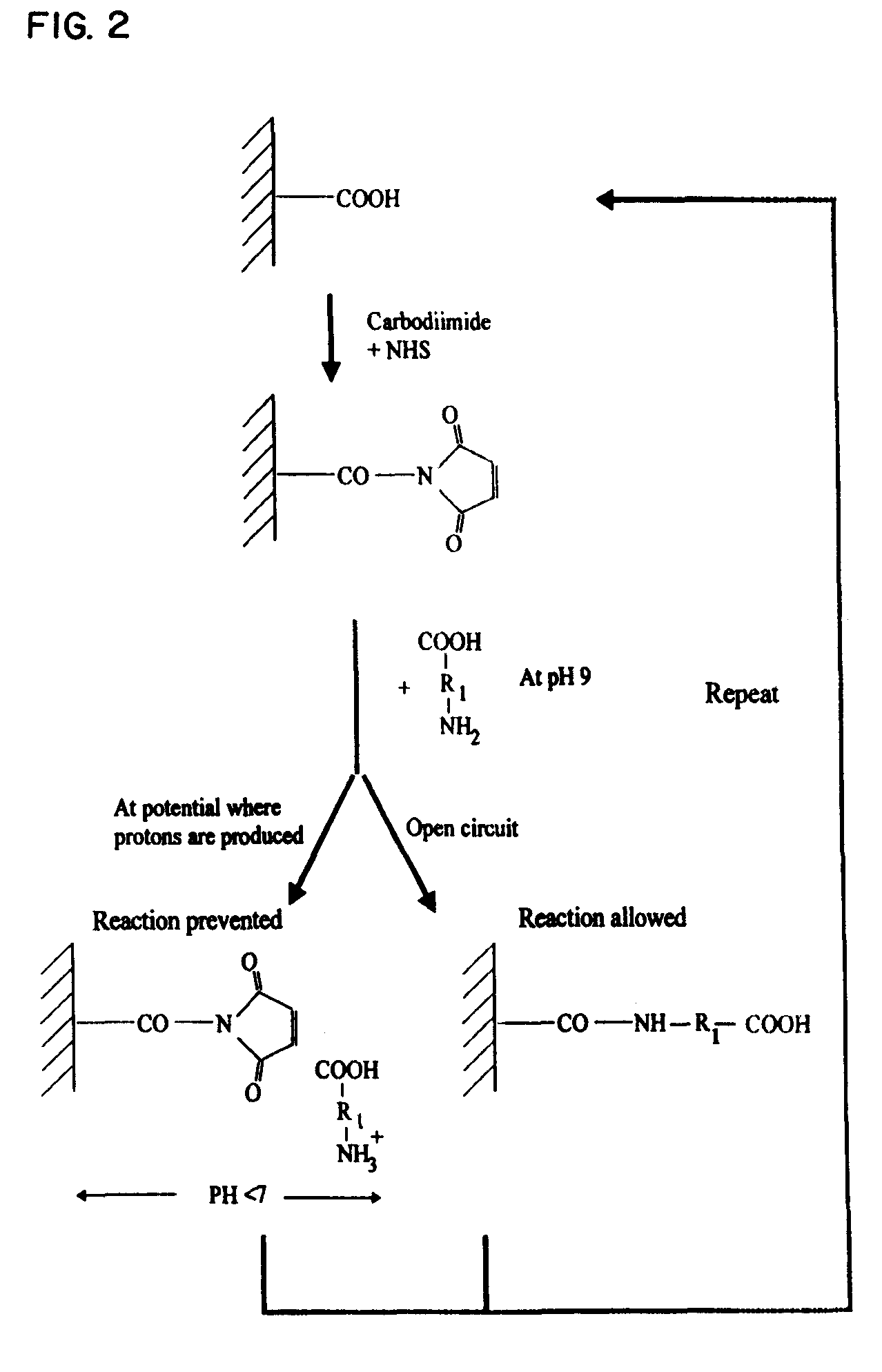

Combinatorial synthesis on arrays

InactiveUS20030111356A1Sequential/parallel process reactionsLiquid separation by electricityCombinatorial synthesisSynthetic polymer

Owner:STRATHMANN MICHAEL PAUL

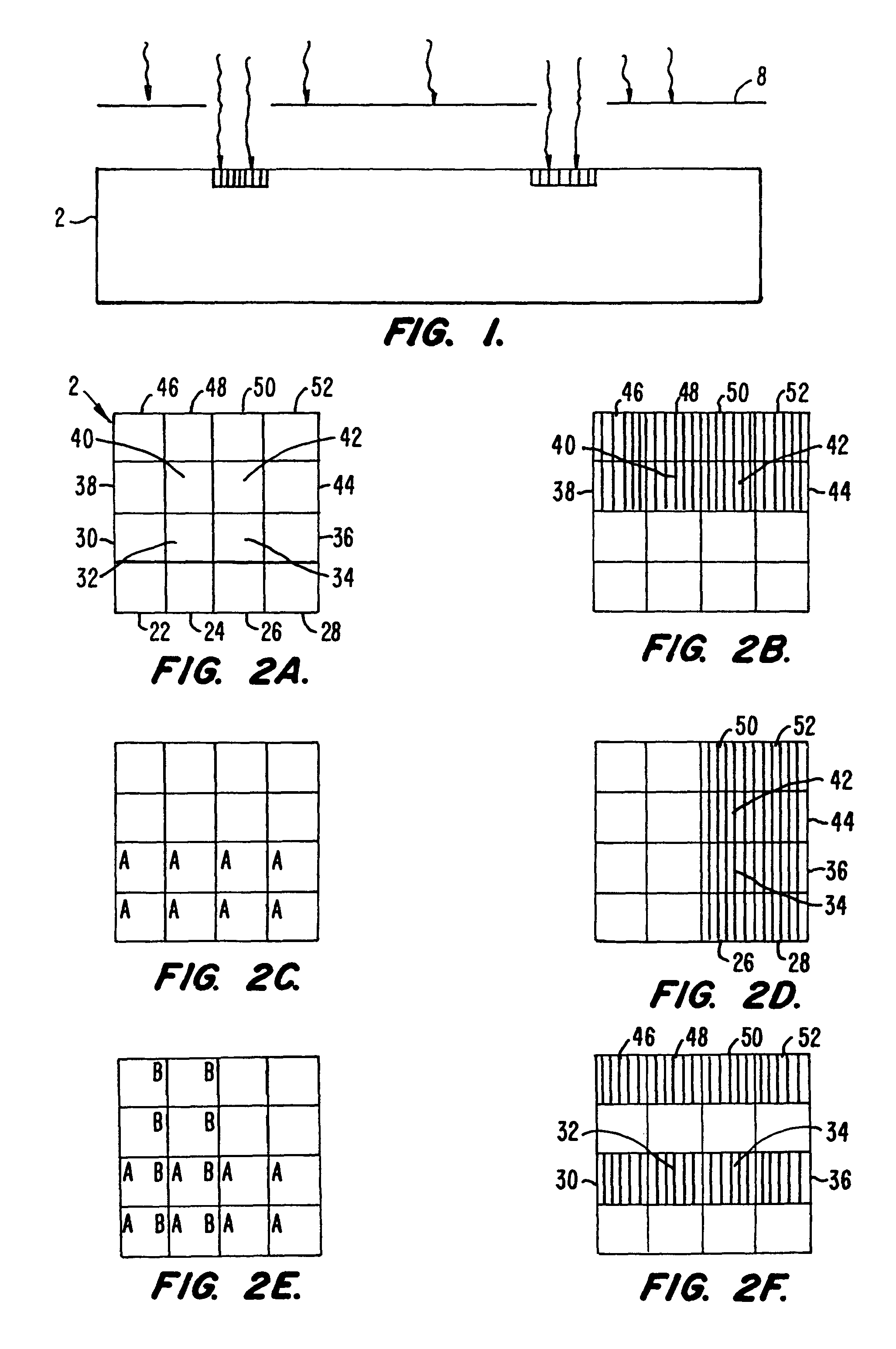

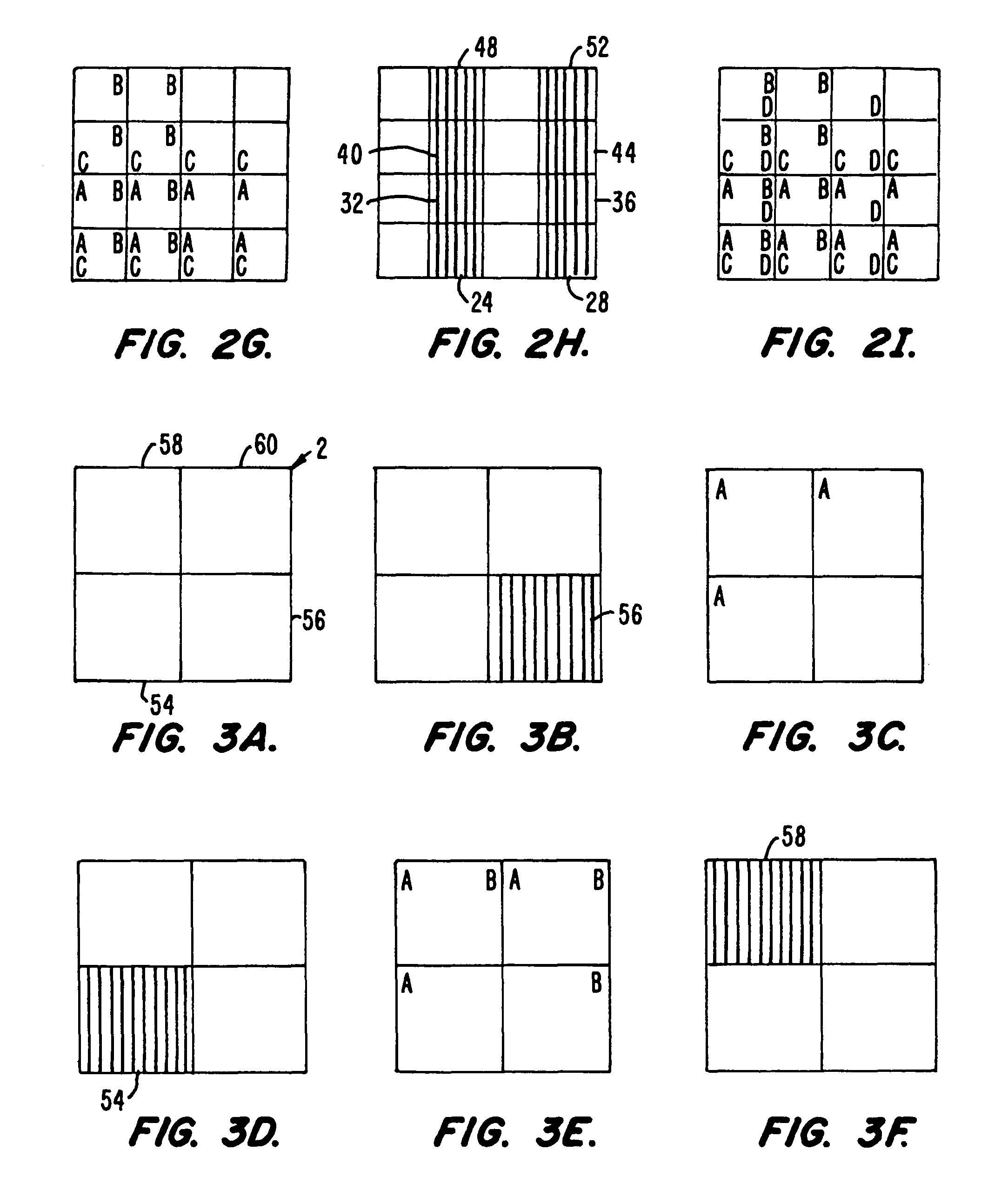

Combinatorial synthesis of inorganic or composite materials

InactiveUS7767627B1Improve responseEvenly distributedSequential/parallel process reactionsLibrary screeningMolecular solidAlloy

Methods and apparatus for the preparation and use of a substrate having an array of diverse materials in predefined regions thereon. A substrate having an array of diverse materials thereon is generally prepared by delivering components of materials to predefined regions on a substrate, and simultaneously reacting the components to form at least two materials or, alternatively, allowing the components to interact to form at least two different materials. Materials which can be prepared using the methods and apparatus of the present invention include, for example, covalent network solids, ionic solids and molecular solids. More particularly, materials which can be prepared using the methods and apparatus of the present invention include, for example, inorganic materials, intermetallic materials, metal alloys, ceramic materials, organic materials, organometallic materials, nonbiological organic polymers, composite materials (e.g., inorganic composites, organic composites, or combinations thereof), etc. Once prepared, these materials can be screened for useful properties including, for example, electrical, thermal, mechanical, morphological, optical, magnetic, chemical, or other properties. Thus, the present invention provides methods for the parallel synthesis and analysis of novel materials having useful properties.

Owner:RGT UNIV OF CALIFORNIA +1

Parallel high-performance liquid chromatography with post-separation treatment

InactiveUS20020190001A1High sample throughputEasy to findIon-exchange process apparatusSamplingChromatographic separationCombinatorial synthesis

High-performance liquid chromatography (HPLC) methods and systems are disclosed that combine parallel chromatographic separation of a plurality of samples with a detection technique that involves post-separation treatment of the plurality of samples to enhance one or more properties of the sample or of a component thereof, followed by detection of the one or more enhanced properties. Selective, tunable detection schemes are achievable, and are particularly advantageous as applied in connection with combinatorial chemistry, combinatorial material science and more particularly, combinatorial synthesis and screening of polymeric materials.

Owner:FREESLATE

Combinatorial synthesis of material chips

InactiveUS20050166850A1Promote exchangeLarge area uniformityLiquid surface applicatorsSequential/parallel process reactionsEngineeringCombinatorial synthesis

Systems and methods for providing in situ, controllably variable concentrations of one, two or more chemical components on a substrate to produce an integrated materials chip. The component concentrations can vary linearly, quadratically or according to any other reasonable power law with one or two location coordinates. In one embodiment, a source and a mask with fixed or varying aperture widths and fixed or varying aperture spacings are used to produce the desired concentration envelope. In another embodiment, a mask with one or more movable apertures or openings provides a chemical component flux that varies with location on the substrate, in one or two dimensions. In another embodiment, flow of the chemical components through nuzzle slits provides the desired concentrations. An ion beam source, a sputtering source, a laser ablation source, a molecular beam source, a chemical vapor deposition source and / or an evaporative source can provide the chemical component(s) to be deposited on the substrate. Carbides, nitrides, oxides, halides and other elements and compounds can be added to and reacted with the deposits on the substrate.

Owner:INTEMATIX

Combinatorial Synthesis of Diamond

InactiveUS20120040868A1High puritySuitable for applicationUltra-high pressure processesDiamondDecompositionHigh energy

Disclosed is a combinatorial synthesis of Diamond wherein a first reactive species is produced by catalytic treatment of Acetylene, a second reactive species is produced by decomposition of a hydrocarbon source having a low Hydrogen-to-Carbon ratio using a high energy discharge, and the two reactive species so obtained are combined in the vapor phase to yield Diamond without the need of post-treatments. The reaction is efficient and affords Diamond under mild conditions with high purity such that it may be useful for producing Diamond for semiconductor and microelectronics applications.

Owner:UNIT CELL DIAMOND

Parallel high-performance liquid chromatography with post-separation treatment

InactiveUS6776902B2High sample throughputPromote discoveryIon-exchange process apparatusSamplingChromatographic separationPhysical chemistry

High-performance liquid chromatography (HPLC) methods and systems are disclosed that combine parallel chromatographic separation of a plurality of samples with a detection technique that involves post-separation treatment of the plurality of samples to enhance one or more properties of the sample or of a component thereof, followed by detection of the one or more enhanced properties. Selective, tunable detection schemes are achievable, and are particularly advantageous as applied in connection with combinatorial chemistry, combinatorial material science and more particularly, combinatorial synthesis and screening of polymeric materials.

Owner:FREESLATE

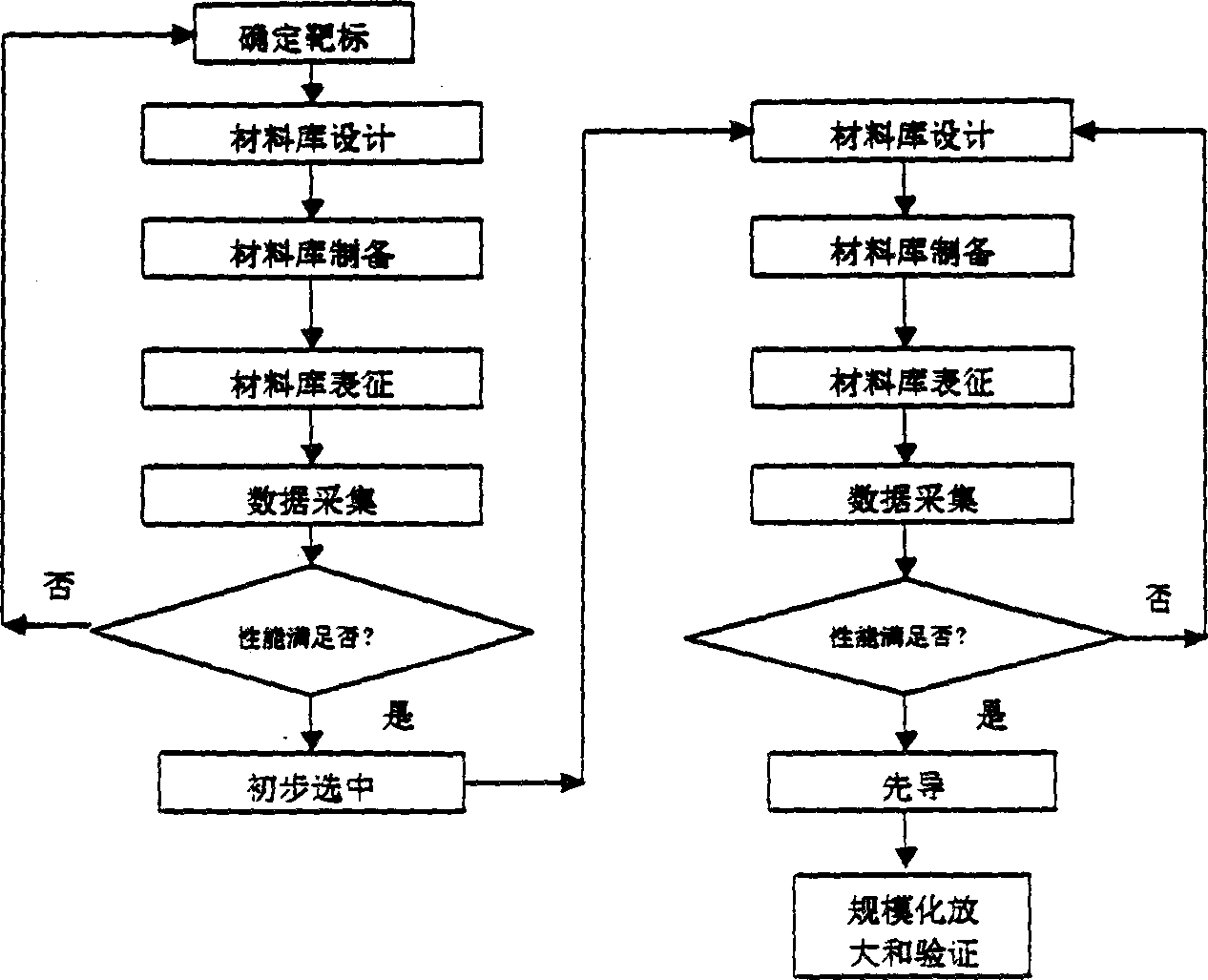

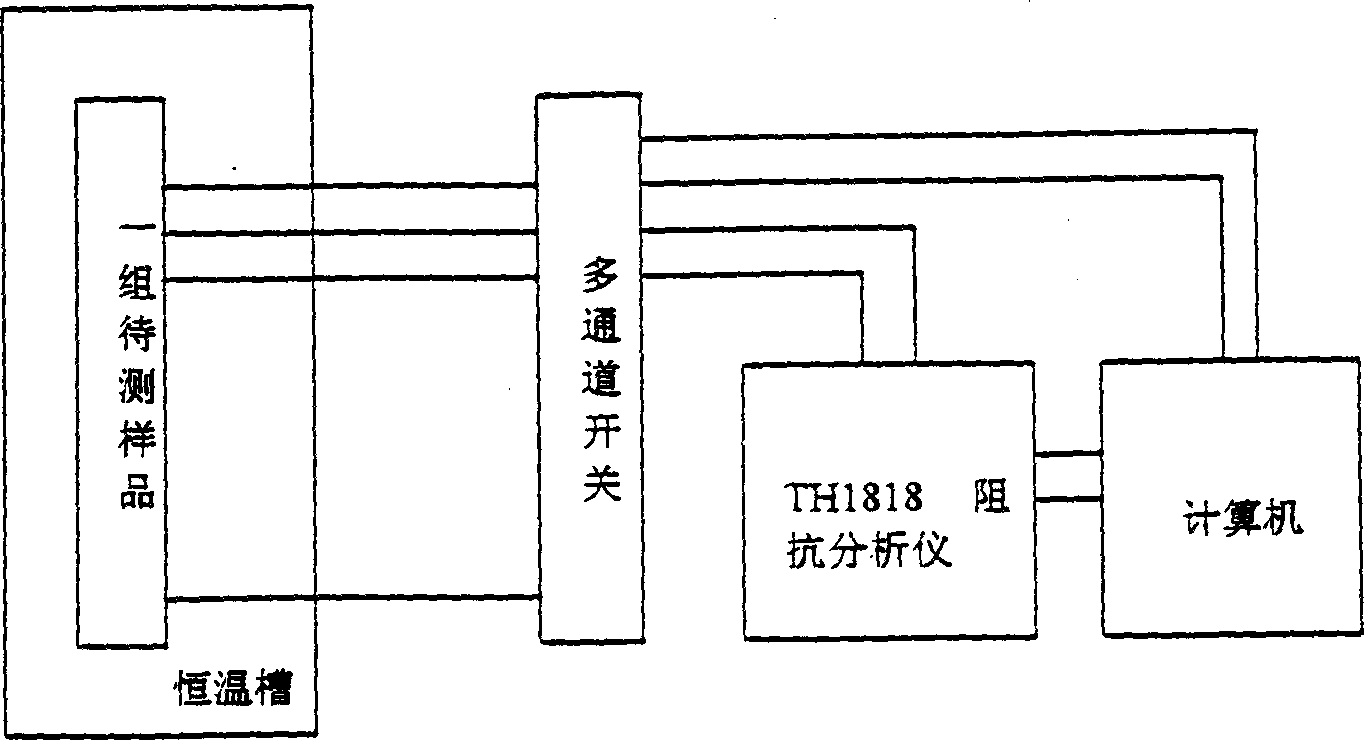

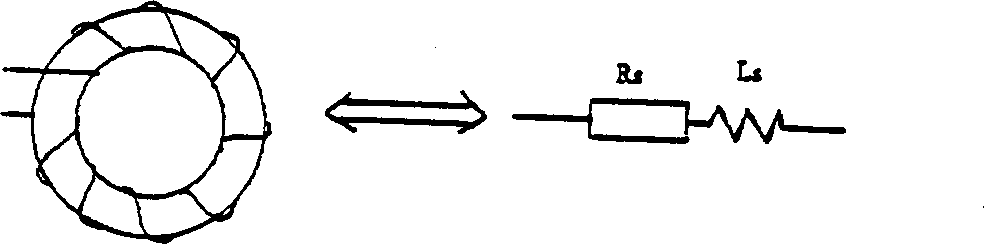

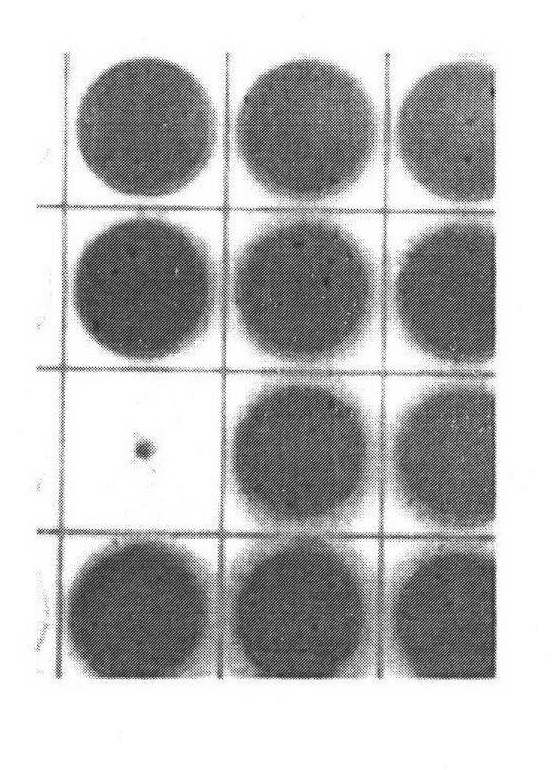

Heat-sensitive Mn-Zn ferrite series material combined synthesis and high throughput screening method

InactiveCN1401610AMeet the growing demandShort cycleInorganic material magnetismHigh-Throughput Screening MethodsHigh flux

A process for synthesizing and high throughput screening the thermosensitive Mn-Zn ferrite series with -40 - +160 deg.C of temp range, more than 2000 of magnetic conductivity and excellent characteristics includes creating specimen materials library for different formulas and technologies, computer controlled characteristics analysis to obtain library characterization, creating specimen components-preparing process-physical property database, classifying, choosing raw materials, optimizing, screening pilot materials, and experimental preparing. Its advantages are high efficiency and low cost.

Owner:SHANGHAI JIAO TONG UNIV +1

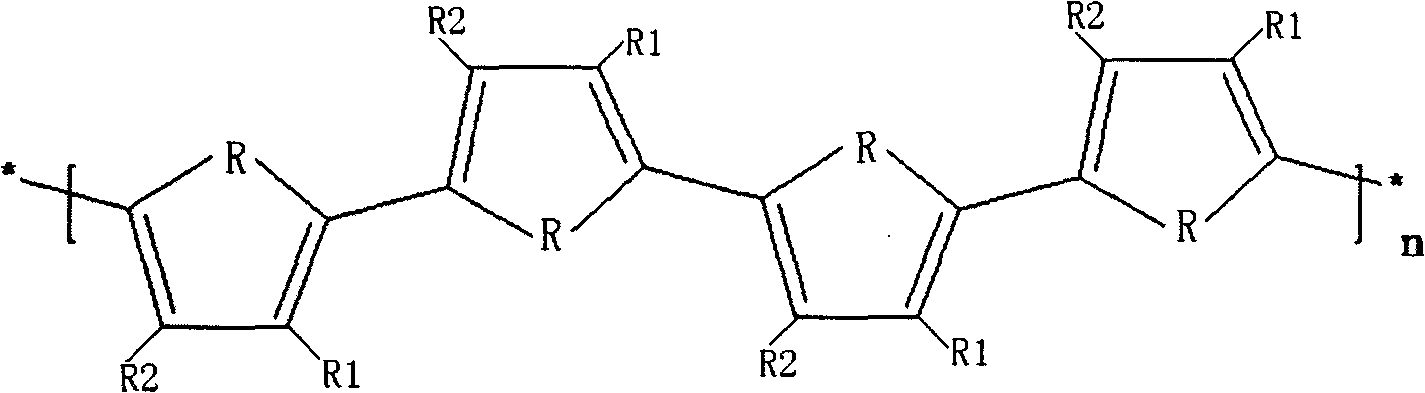

Conductive polymer for biosensor and preparation method thereof

InactiveCN101812171AHigh detection sensitivityShort reaction timeMaterial analysis by electric/magnetic meansDiseaseConductive polymer

The invention provides a conductive polymer for a biosensor and a preparation method thereof in order to solve the problem puzzling the academia for long time about how to combine a bioactive unit to a metal non-inactively and permanently and that bioactive molecules are connected to the conductive polymer in one step. The bioactive unit is first introduced into a conductive polymer monomer, and then the conductive polymer with bioactivity is directly formed in situ on the surface of an electrode in one step by adopting an in-situ electrochemical combinatorial synthesis method and an independent addressing microelectrode array technique so as to obtain a functional microelectrode array applied to the biosensor. The conductive polymer for the biosensor and the preparation method make the development of the biosensor towards the direction of intensification, microminiaturization and micro power consumption become possible, can promote the development of disease diagnosis, medicament screening, health care, judicial expertise, food detection, environmental monitoring, individualized medicament and the like and industrial chains thereof, and have far-reaching social meaning and broad market value.

Owner:WUXI ZHONGMEI YIXIN BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com