Molecular engram microspheres preparation method using micro-fluidic reactor

A technology of molecularly imprinted microspheres and combinatorial synthesis, applied in the field of chemical engineering, can solve the problem of taking a lot of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

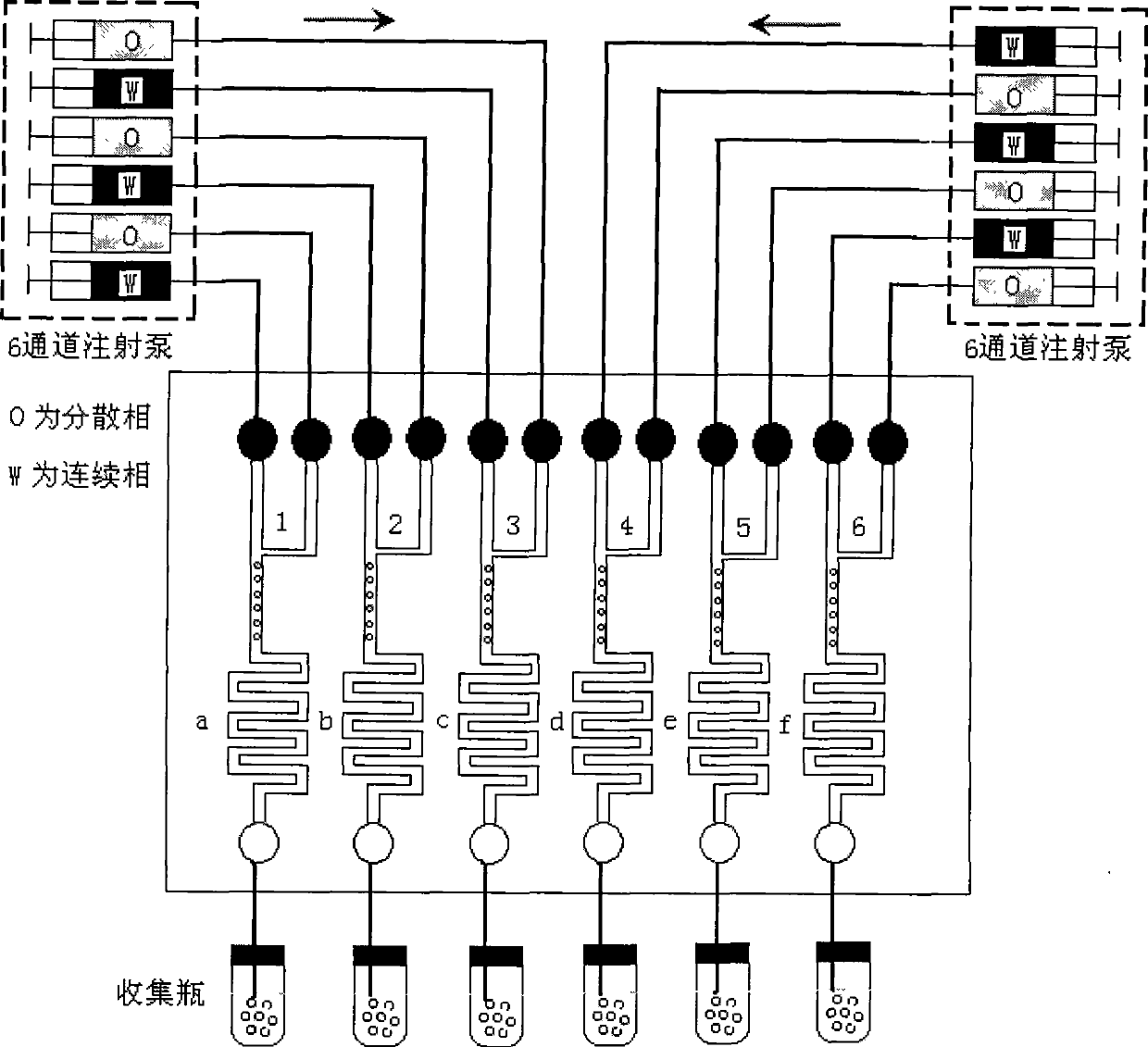

Method used

Image

Examples

Embodiment 1

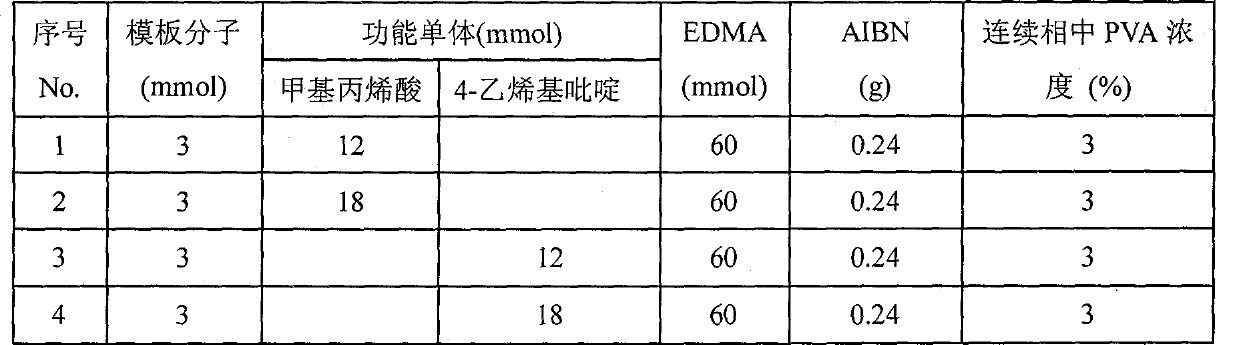

[0033] Screening of synthesis conditions of chloramphenicol molecularly imprinted microspheres.

[0034] in a set containing 4 In microfluidic reactors with microchannels, each group The type microchannel can synthesize microspheres under different conditions, and can obtain molecularly imprinted microspheres under four different conditions at the same time.

[0035]First prepare the dispersed phase solution, ultrasonically dissolve template molecule chloramphenicol in porogen or solvent chloroform, add functional monomer methacrylic acid or 4-vinylpyridine, crosslinking agent EDMA 60mmol, initiator azobisisobutyl Nitrile AIBN 0.24g, the solution was ultrasonically degassed for 5min, deoxygenated by nitrogen for 15min, and then the solution was moved into the syringe of the syringe pump (try to avoid air entering the syringe); to prepare a continuous phase solution, add the dispersant PVA to water, stir to dissolve , ultrasonic degassing for 5 minutes, nitrogen deoxygenati...

Embodiment 2

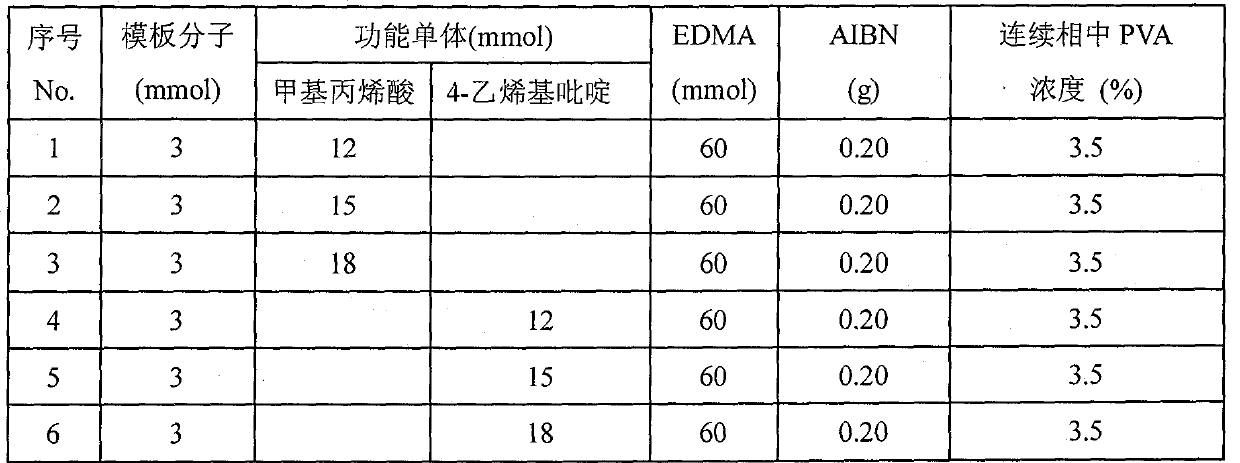

[0040] Screening of synthesis conditions of triazolone molecularly imprinted microspheres.

[0041] in a set containing 6 In microfluidic reactors with microchannels, each group The type microchannel can synthesize microspheres under different conditions, and can obtain molecularly imprinted microspheres under six different conditions at the same time.

[0042] First prepare the dispersed phase solution, ultrasonically dissolve the template molecule triazolone in porogen or solvent toluene, add functional monomer methacrylic acid or 4-vinylpyridine, crosslinking agent EDMA 60mmol, initiator azobisisobutyl Nitrile AIBN 0.20g, the solution was ultrasonically degassed for 6min, deoxygenated by nitrogen for 20min, and then the solution was moved into the syringe of the syringe pump (try to avoid air entering the syringe); to prepare a continuous phase solution, add the dispersant PVA to water, stir to dissolve , ultrasonic degassing for 5 minutes, nitrogen deoxygenation for 25...

Embodiment 3

[0047] Screening of synthesis conditions of oxytetracycline molecularly imprinted microspheres.

[0048] in a set containing 8 In microfluidic reactors with microchannels, each group The type microchannel can synthesize microspheres under different conditions, and can obtain 8 kinds of molecularly imprinted microspheres under different conditions at the same time.

[0049] First prepare the dispersed phase solution, ultrasonically dissolve template molecule oxytetracycline in porogen or solvent acetonitrile, add functional monomer methacrylic acid or 4-vinylpyridine, cross-linking agent EDMA 60mmol, initiator azodiiso Butyronitrile AIBN 0.20g, the solution was degassed by ultrasonic for 6min, deoxygenated by nitrogen for 20min, and then the solution was moved into the syringe of the syringe pump (try to avoid air entering the syringe); to prepare the continuous phase solution, add the surfactant Tween 80 Put it into liquid paraffin, stir to dissolve, ultrasonically degas f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com