Method for connecting plastic and metal heterostructure

A technology of heterogeneous structure and connection method, applied in metal processing equipment, welding equipment, laser welding equipment, etc., can solve the problem of difficult to meet the strength and air tightness of plastic/metal heterogeneous sealing structure, and avoid poor interface bonding. , high reliability, increased controllability and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

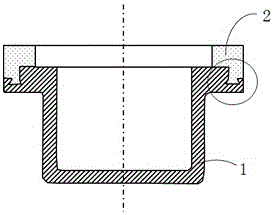

[0024] Embodiment 1: as figure 1 The shown plastic / metal heterogeneous sealing structure is composed of a metal part 1 and a plastic part 2. The present invention provides a laser-assisted thermocompression joining method for a plastic / metal heterogeneous sealing structure, which includes the following steps:

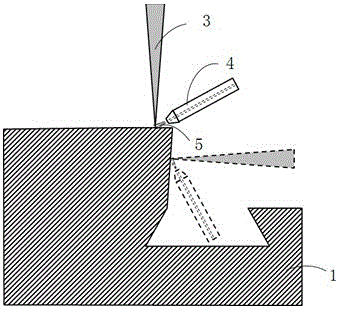

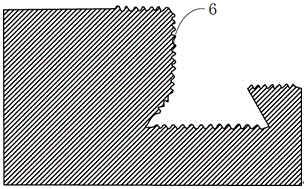

[0025] S1, such as figure 2 As shown, the laser roughening treatment is carried out on the surface of the metal part 1, and the pulsed laser 3 is used, and under the action of the auxiliary gas 5 ejected from the nozzle 4, the desired part of the metal surface is generated. image 3 Local protrusions and depressions required in 6;

[0026] S2. Laser connection of plastic part 2 and metal part 1, such as Figure 4 As shown, the defocused laser beam 3 penetrates the plastic and reaches the plastic / metal interface, the laser energy is absorbed by the metal at the interface, generates heat, and is conducted from the metal to the plastic through the interface, resulting i...

Embodiment 2

[0030] Embodiment 2: For the plastic / metal heterogeneous sealing structure described in Embodiment 1, the same surface morphology and airtightness testing methods as in Embodiment 1 are used. The base material is aluminum alloy, fiber laser is used, the focus spot diameter is 0.6mm, the laser power is 1500W-3000W, the scanning speed is in the range of 2.4m / m-36m / min, the pulse frequency is 100Hz-1000Hz, and the duty cycle is in the Between 50% and 75%, the auxiliary gas is Ar, the side blowing angle is 20% to 30%, the air flow is 10 to 15L / min, and the number of laser scans is a single time. It can be adjusted between 5μm and 30μm, and the oxide film thickness is 0~10μm. Preferably, the height difference between the bumps and depressions on the metal surface is not less than 15 μm, and the density is not less than 1 / mm 2 .

[0031] For plastic / aluminum alloy laser connection, the plastic substrate is PA, PET and PA6, the fiber laser is used, the focus spot diameter is 0.6mm, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com