Method and device for preparing high-performance aluminum-base composite material under the action of pulsed magnetic field

An aluminum-based composite material and pulsed magnetic field technology, applied in the field of composite material preparation, can solve the problem of uneven distribution of particle segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

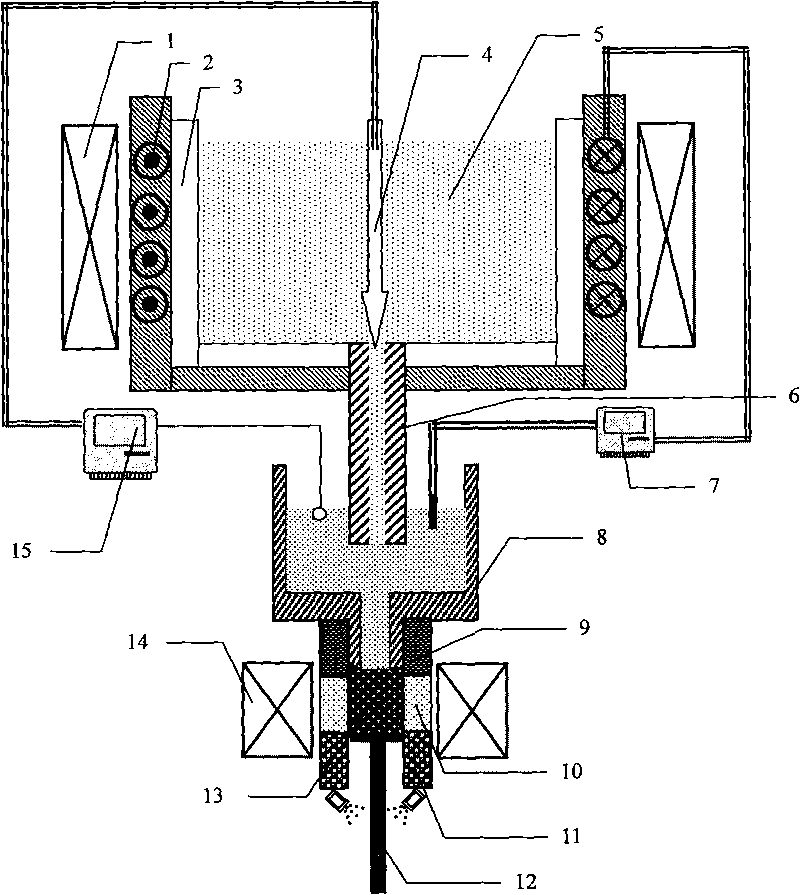

Method used

Image

Examples

Embodiment 1

[0029] Implementation example 1 Preparation of primary silicon reinforced aluminum matrix composite material by in-situ crystallization under pulsed magnetic field

[0030] High-silicon aluminum alloy Al-18% Si is prepared from pure aluminum and crystalline silicon, the synthesis temperature is 850°C, the parameters of the electromagnetic stirring magnetic field during the preparation process are 15Hz, and the current is 250A. During the solidification process, the pulse width of the pulsed magnetic field was 10 ms, the intensity of the pulsed magnetic field was 30 T, and the ingot drawing speed was 15 cm / min, and the aluminum matrix composite material reinforced by primary crystal silicon was obtained.

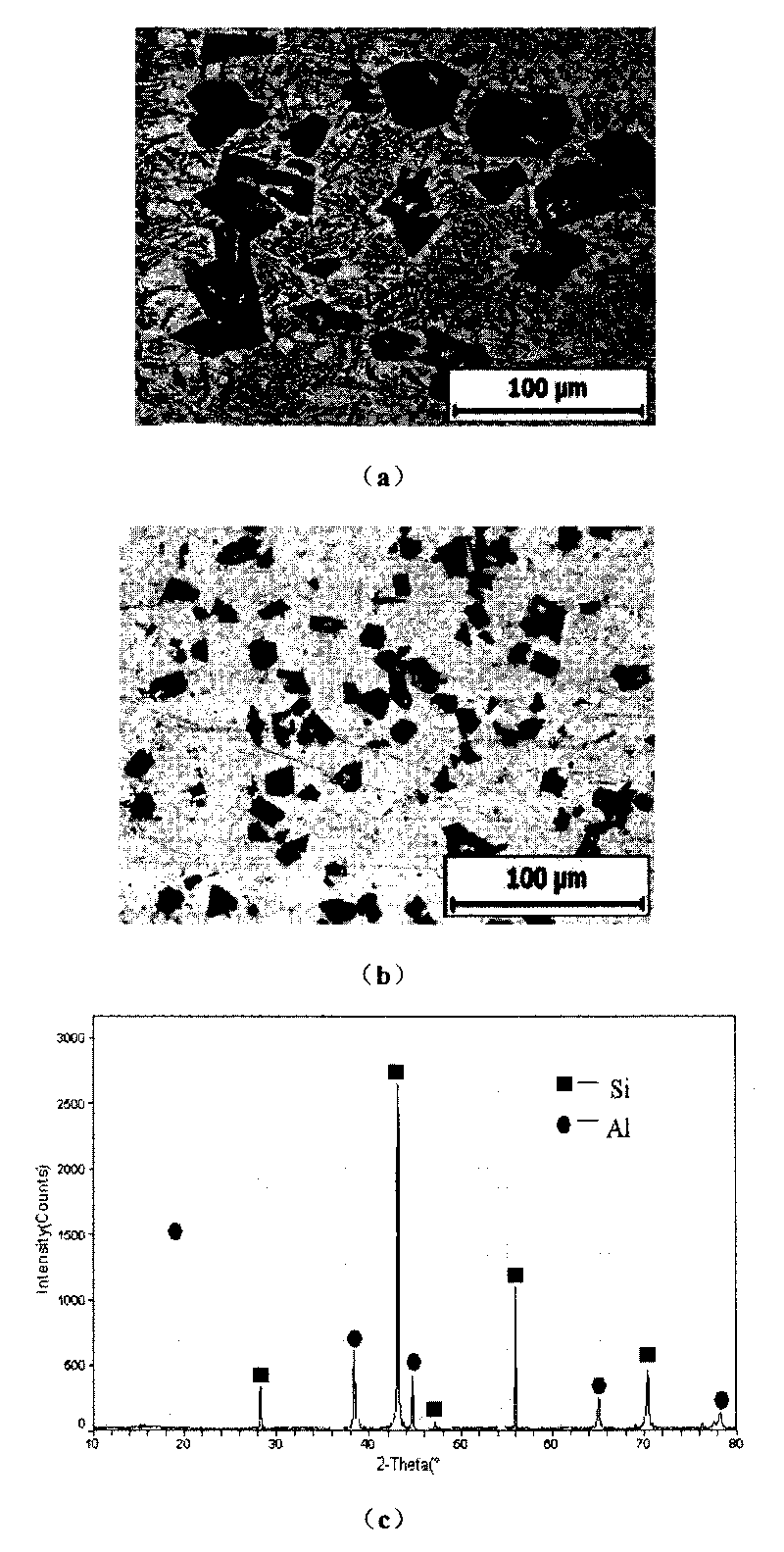

[0031] figure 2 It is the solidification structure and XRD detection result of Si particle reinforced aluminum matrix composite before and after applying pulsed magnetic field. Depend on figure 2 It can be seen that: (1) It can be seen from XRD that the types of phases in...

Embodiment 2

[0032] Preparation of Al by in-situ crystallization method under implementation example 2 pulsed magnetic field 3 Ti Particles Reinforced Aluminum Matrix (A356) Composite

[0033] A356 aluminum alloy and aluminum-titanium alloy were used to synthesize aluminum-titanium alloy melt Al-5%Ti at 840°C. During the synthesis process, the parameters of the electromagnetic stirring field were 1Hz and the current was 350A. The pulse width of the pulsed magnetic field during the solidification process is 500ms, the pulsed magnetic field intensity is 10T, and the ingot drawing speed is 10cm / min, and the Al 3 Ti particles reinforced A356-based composites.

[0034] image 3 is the Al before and after applying the pulsed magnetic field 3 Solidification structure and XRD detection results of Ti particle reinforced aluminum matrix composites. It can be seen from the figure: (1) From the XRD pattern, it can be concluded that the phase types in the solidification structure are α(Al) and Al ...

Embodiment 3

[0035] 20% Mg prepared by in situ crystallization method under the implementation example 3 pulsed magnetic field 2 Si Particle Reinforced Aluminum Matrix Composite

[0036] Preparation of Al-20%Mg from pure aluminum, pure silicon and Al-Mg alloy 2 For Si alloy, the synthesis temperature is 750°C, the parameters of the electromagnetic stirring magnetic field during the preparation process are 30Hz, and the current is 150A. The pulse width of the pulsed magnetic field in the solidification process is 100ms, the pulsed magnetic field intensity is 2T, and the ingot drawing speed is 10cm / min, and 20% Mg 2 Si particles reinforced aluminum matrix composites.

[0037] Figure 4 is the Mg before and after applying the pulsed magnetic field 2 Solidification structure and XRD detection results of Si particle reinforced aluminum matrix composites. It can be seen from the figure: (1) From the XRD pattern, the phase types in the solidified structure are α(Al) and Mg 2 Si phase; (2) I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com