Preparation method of silicon carbide reinforced aluminum base composite material

A composite material and slurry technology, which is applied in the field of preparation of silicon carbide reinforced aluminum matrix composite materials, can solve the problems of SiC reinforcements that are difficult to disperse evenly, and the interface between SiC and Al is difficult to control, so as to avoid segregation and discontinuity , good wettability, and the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step A) milling silicon oxide powder, polyacrylic acid ammonium dispersant and water for 1 hour with a ball milling medium, then adding carboxymethyl cellulose binder, and continuing ball milling for 3 hours to obtain a coating slurry with a solid content of 80wt%; wherein , The mass ratio of alumina powder: dispersant: water: ball milling medium: binder is 1:0.005:0.25:2:0.01.

[0030]Step B) immerse the porous SiC ceramics in the coating slurry, and after fully absorbing the coating slurry, centrifuge at 600 rpm to remove the excess coating slurry, and dry naturally to obtain the porous SiC ceramics coated for the second time.

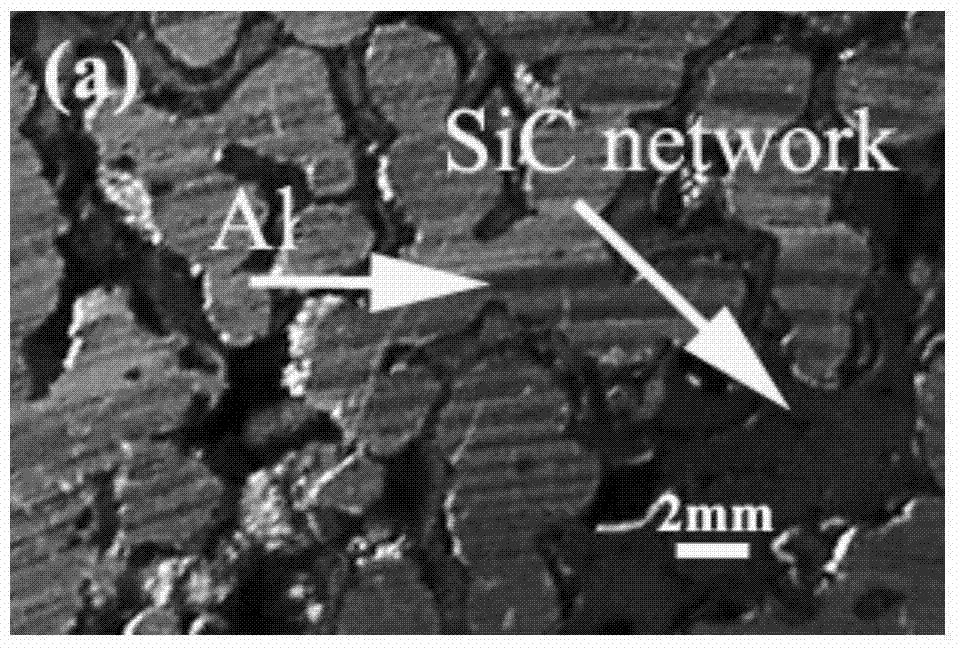

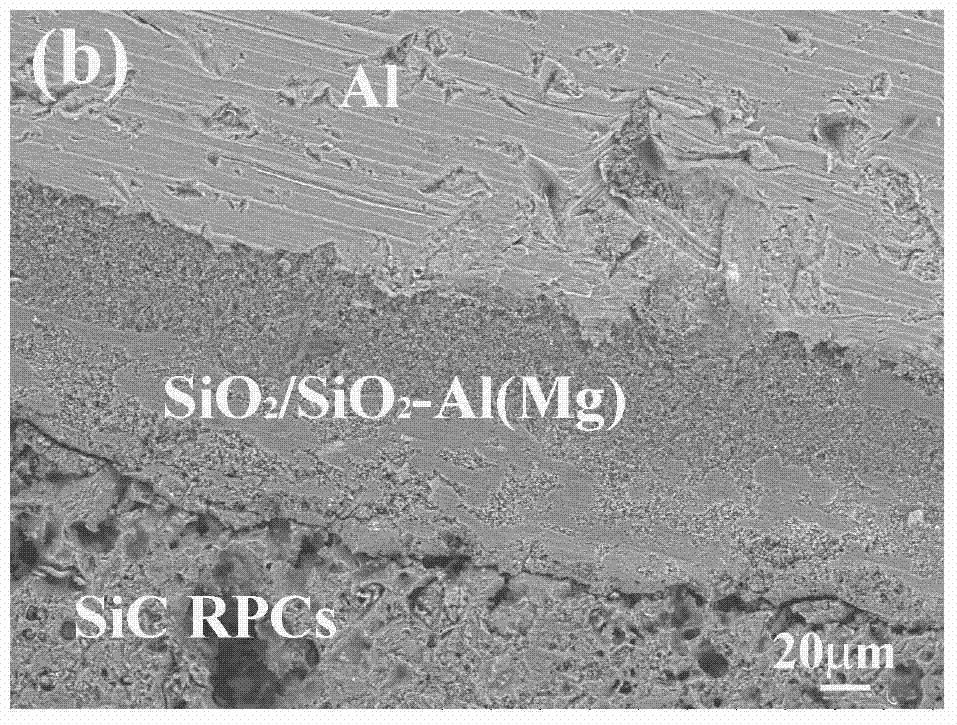

[0031] Step C) Embed the second-coated mesh porous SiC ceramic into the magnesium-aluminum alloy powder, evacuate to 5Pa, and then raise the temperature to 900°C to melt the magnesium-aluminum alloy powder, and then inject argon until the pressure is 0.6MPa , heat preservation and pressure for 1 hour, and then the SiC / Al composite material was...

Embodiment 2

[0034] Step A) adding alumina powder and sodium polyacrylate dispersant to water, milling with ball milling media for 1 hour, then adding polyvinyl alcohol binder, and continuing ball milling for 3 hours to obtain a coating slurry with a solid content of 70wt%; wherein, The mass ratio of alumina powder: dispersant: water: ball milling medium: binder is 1:0.01:0.4:2:0.02.

[0035] Step B) immerse the mesh porous SiC ceramics in the coating slurry, and after fully absorbing the coating slurry, centrifuge at 500 rpm to remove the excess coating slurry, and dry naturally to obtain the second coated mesh porous SiC ceramics.

[0036] Step C) Embed the secondary coated mesh porous SiC ceramics into the aluminum powder, evacuate to 3pa, and then raise the temperature to 1000°C to melt the aluminum powder, then inject argon gas until the pressure is 0.6MPa, keep the temperature and hold the pressure 1.5 hours, and then the SiC / Al composite material was obtained as the temperature of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com