Preparation method of in-situ reduced graphene reinforced magnesium-matrix composite

A technology of composite materials and graphene, which is applied in the field of preparation of magnesium-based composite materials, can solve the problems that the mechanical properties of composite materials do not reach the theoretical calculation value, the enhancement effect of graphene is not obvious, and the quality of interface bonding is poor, so as to achieve better reinforcement effect Good, low cost, and the effect of improving the interface bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

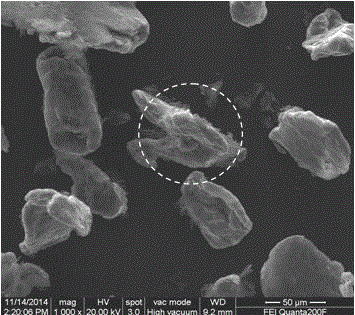

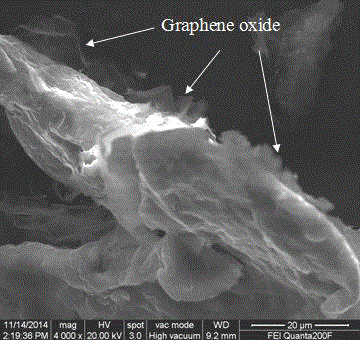

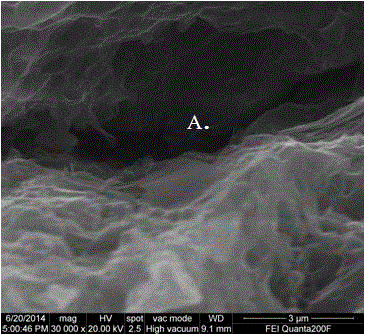

[0017] Firstly, add 0.3g of graphite oxide into 300ml of ethanol solution and dissolve it by ultrasonic for 30min to obtain a graphene oxide-ethanol mixture with a concentration of 1mg / ml; add 99.7g of AZ91 magnesium alloy powder with a particle size of 325 mesh into the above mixture, and then ultrasonically and mechanically stir After dispersing for 2 hours, a uniformly dispersed mixed slurry was obtained; the mixed slurry was vacuum-dried after suction filtration, and then transferred to a mold, and pressed at room temperature with a pressure of 100 MPa to form a composite material green body; Under protection, it was sintered for 2 h; then the sintered composite was hot-extruded at 350 °C to obtain the AZ91 / 0.3wt.% GO composite. The mechanical properties of the AZ91 / 0.1wt.% GO composite were tested. The tensile strength was 251-290MPa, the elongation was 6-8%, and the hardness was 80-90HV. It is a composite material with excellent mechanical properties.

Embodiment 2

[0019] First, add 0.5g of graphite oxide to 500ml of ethanol solution and dissolve it by ultrasonic for 30min to obtain a graphene oxide-ethanol mixture with a concentration of 1mg / ml; add 99.5g of AZ91 magnesium alloy powder with a particle size of 325 mesh into the above mixture, and then ultrasonically and mechanically stir After dispersing for 2 hours, a uniformly dispersed mixed slurry was obtained; the mixed slurry was vacuum-dried after suction filtration, and then transferred to a mold, and pressed at room temperature with a pressure of 100 MPa to form a composite material green body; Under protection, it was sintered for 2 h; then the sintered composite was hot-extruded at 350 °C to obtain the AZ91 / 0.5wt.% GO composite. The mechanical properties of the AZ91 / 0.5wt.% GO composite were tested. The tensile strength was 345.8-364MPa, the elongation was 8-10%, and the hardness was 85-95HV. It is a composite material with excellent mechanical properties.

[0020] attached f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com