Integrated forming method of multi-material part adopting gradient lattice structure

A lattice structure, multi-material technology, applied in the direction of additive processing, process efficiency improvement, transportation and packaging, etc., can solve the difficulty of forming lattice structure of aluminum matrix composite materials, difficult to control the bonding of interfaces, and the absorption of laser light by aluminum. Low problems, to achieve the effect of solving interface mismatch, high processing flexibility, and good interface bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

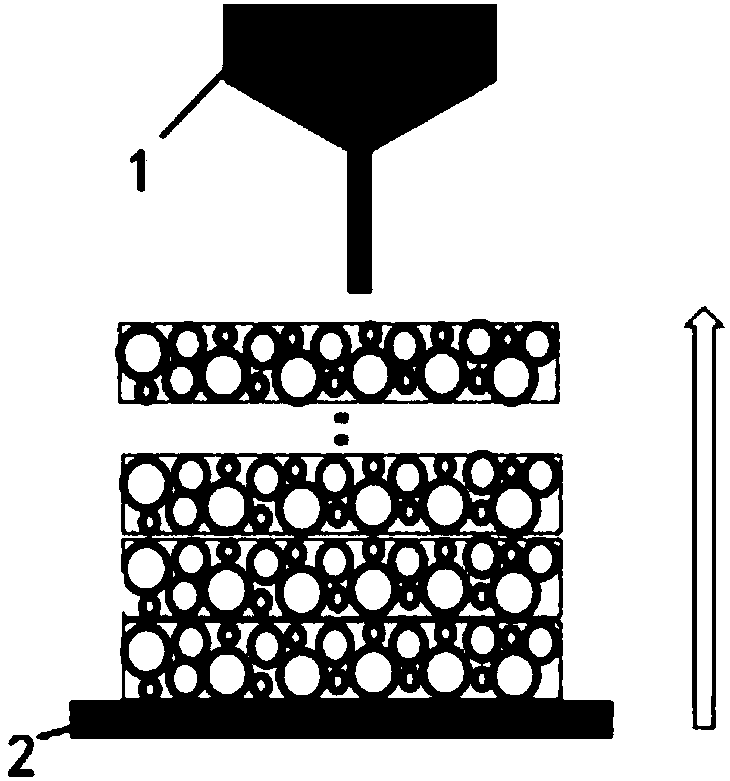

Image

Examples

Embodiment 1

[0028] (1) Select AlSi10Mg powder with a particle size of 15-50um and a spherical SiC powder with an average particle size of 40nm prepared by the gas atomization method, and carry out low-speed processing according to the mass ratio of 99:1, 98:2, and 97:3, respectively. Three parts of aluminum-based composite powder 1 were obtained by ball milling, wherein the ball milling speed was 150 rpm and the time was 1.5 h.

[0029] (2) Fix and preheat the aluminum substrate 2 to 150° C., and pump the oxygen content in the forming cavity to below 0.01%.

[0030] (3) Slice the 3D CAD model of the optimized gradient lattice to obtain the corresponding STL format file, input it into the computer, and the SLM equipment is controlled by the computer under the protective atmosphere, and the powder dropping cylinder drops a certain layer thickness according to the processing layer thickness each time The powder is finished with a powder spreading stick, the laser source is a 400W fiber laser...

Embodiment 2

[0033] (1) Select AlSi10Mg powder with a particle size of 15-50um normally distributed and spherical Al2O3 powder with an average particle size of 30nm prepared by the gas atomization method, and perform low-speed ball milling according to the mass ratio of 99:1, 98:2, and 97:3 , to obtain three parts of aluminum-based composite powder 1, wherein the ball milling speed is 100 rpm and the time is 2 h.

[0034] (2) Fix and preheat the aluminum substrate 2 to 200°C, and pump the oxygen content in the forming cavity to below 0.01%.

[0035](3) Slice the 3D CAD model of the optimized gradient lattice to obtain the corresponding STL format file, input it into the computer, and the SLM equipment is controlled by the computer under the protective atmosphere, and the powder dropping cylinder drops a certain layer thickness according to the processing layer thickness each time The powder is finished with a powder spreading stick, the laser source is a 400W fiber laser, the power is set ...

Embodiment 3

[0038] (1) Select AlSi10Mg powder with a particle size of 15-50um normally distributed and spherical TiB2 powder with an average particle size of 50nm prepared by the gas atomization method, and perform low-speed ball milling according to mass ratios of 99:1, 98:2, and 97:3 , to obtain three parts of aluminum-based composite powder 1, wherein the ball milling speed is 200 rpm and the time is 1 h.

[0039] (2) Fix and preheat the aluminum substrate 2 to 100°C, and pump the oxygen content in the forming cavity to below 0.01%.

[0040] (3) Slice the 3D CAD model of the optimized gradient lattice to obtain the corresponding STL format file, input it into the computer, and the SLM equipment is controlled by the computer under the protective atmosphere, and the powder dropping cylinder drops a certain layer thickness according to the processing layer thickness each time The powder is finished with a powder spreading stick, the laser source is a 400W fiber laser, the power is set at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com