Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "High tissue density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

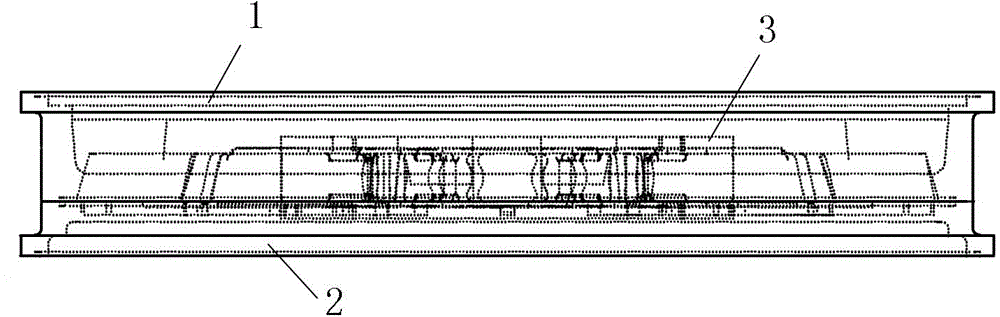

Process for controlling center porosity of large and round continuous casting billet

The invention belongs to the technical field of metallurgy, and particularly relates to a process for controlling center porosity of a large and round continuous casting billet. The process comprises steps as follows: qualified molten steel in tundish is injected into a mold through a four-slitting sided cyclone submerged nozzle; mold fluxes are added, and the depth of the submerged nozzle of the mold is controlled to range from 110 mm to 130 mm; a mold liquid level automatic control system is used for stabilizing a mold liquid level and a pulling rate, and the superheat degree of the molten steel in the tundish is stabilized; the secondary cooling speed of a casting billet is controlled; and M-EMS (mold electromagnetic stirring) and F-EMS (final electromagnetic stirring) parameters are optimized. With the adoption of the process, the large and round billet is produced, melting of the mold fluxes is facilitated, the temperature gradient from a billet shell to molten steel at the core part of the casting billet can be reduced, the overheat degree of the molten steel in the center is decreased, the isometric crystal proportion of the casting billet is increased, the tissue density of the casting billet is increased, and the grade of the center porosity of the large and round continuous casting billet can be controlled.

Owner:SHANDONG XIWANG SPECIAL STEEL

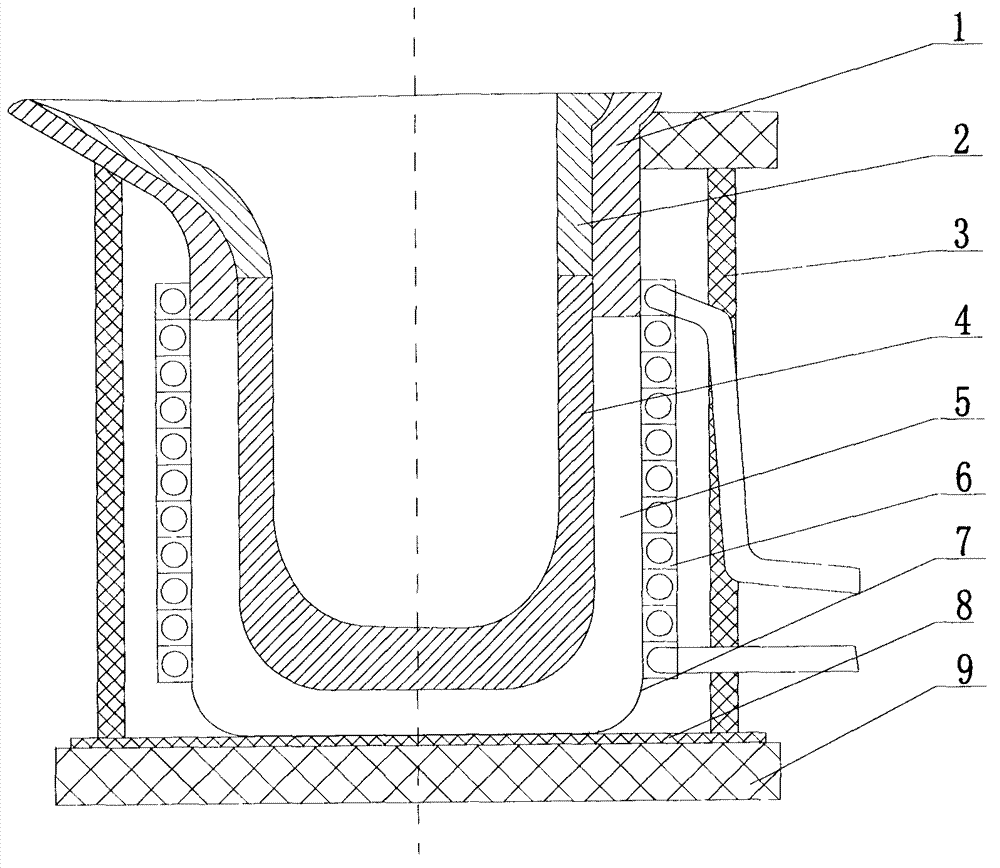

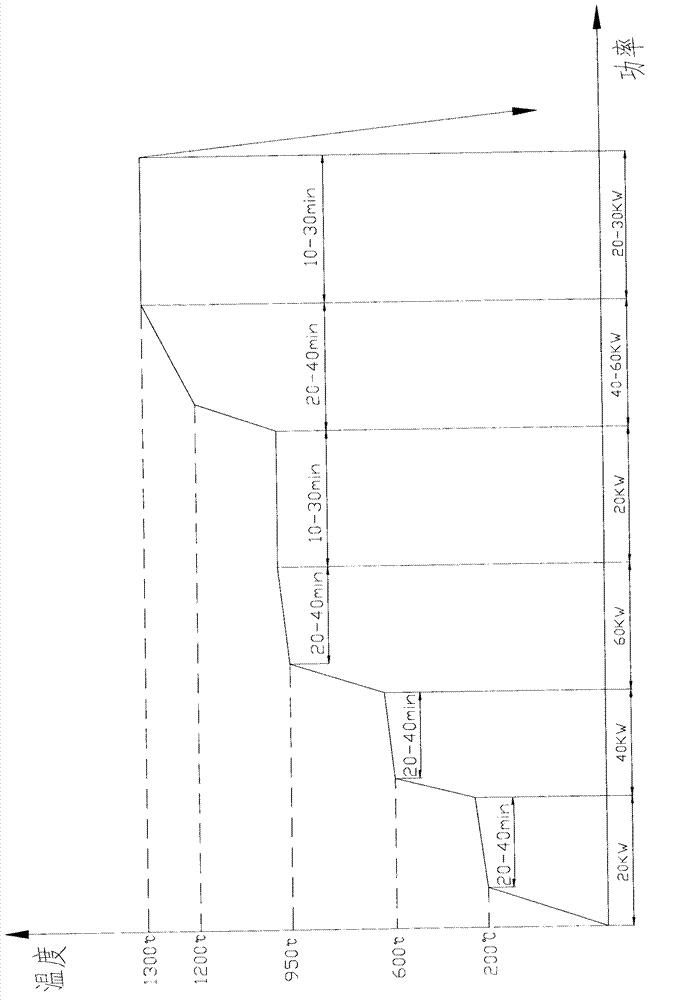

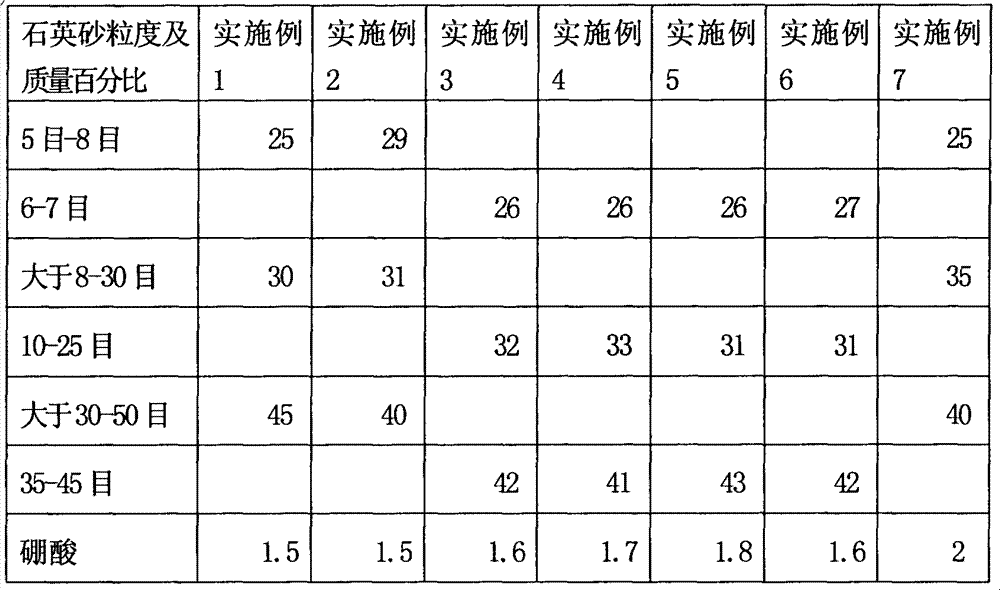

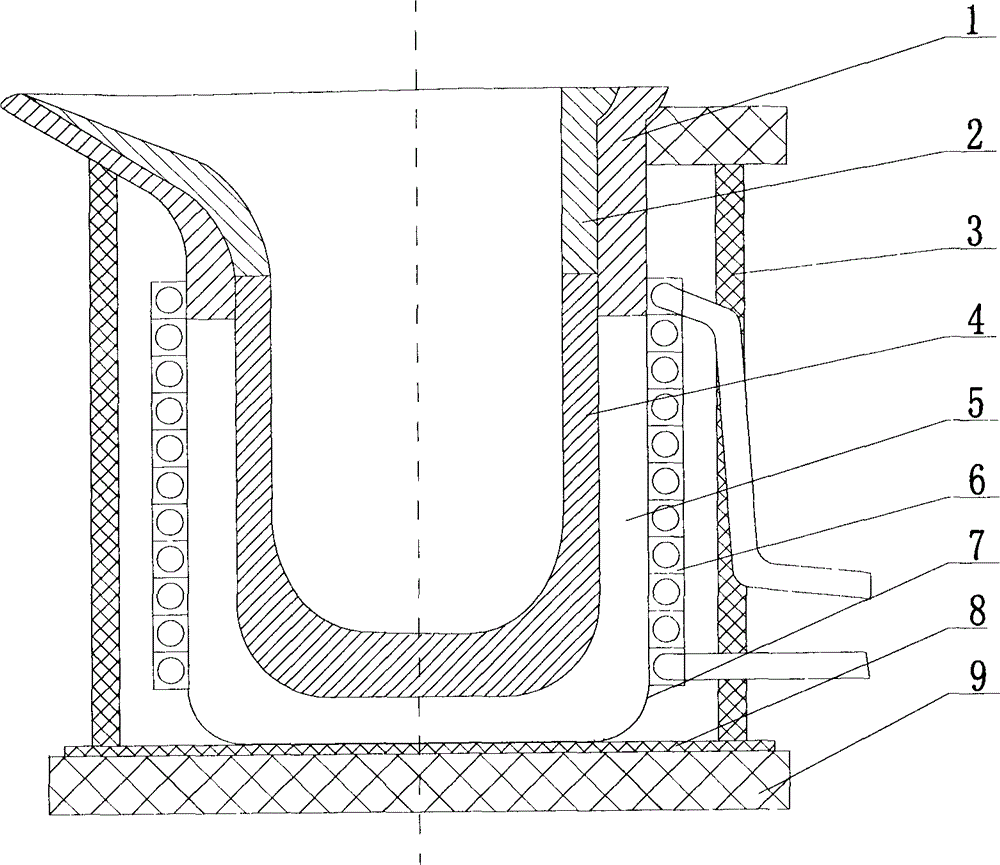

Furnace building method of intermediate-frequency induction furnace for copper alloy smelting

ActiveCN102889789AReduce adverse effectsHigh densityLinings repairIntermediate frequencyCrystal transformation

The invention relates to a furnace building method of an intermediate-frequency induction furnace for copper alloy smelting, which comprises the following steps: firstly, preparing a lining material of a furnace-body outer lining and a fire-door lute, and laying a layer of epoxy plate and placing an induction coil on an asbestos board base; laying a glass fiber fabric on the inner wall of the induction coil and the epoxy plate, so that the glass fiber fabric is formed into a pocket shape; hierarchically adding the lining material of the furnace-body outer lining into the glass fiber fabric pocket, and hierarchically tamping and knotting the obtained product so as to form a furnace bottom; then, placing a graphite crucible on the midmost position of the furnace bottom and compacting the furnace bottom; hierarchically adding the lining material of the furnace-body outer lining into a space between the glass fiber fabric bag and the graphite crucible, and tamping and knotting the lining material so as to obtain the furnace-body outer lining, so that the top surface of the furnace-body outer lining is lower than the top surface of the graphite crucible and the top surface of the induction coil; adhering a fire door to the top surface of the graphite crucible through the fire-door lute, filling the fire-door lute between the fire door and the glass fiber fabric bag, and carrying out tamping and flattened-brushing on the fire-door lute so as to obtain a fire-door outer lining; carrying out sintering on the outer lining by using an oven, so that silica has crystal transformation; and after the whole furnace is hardened, stopping heating so as to complete the furnace building. The method disclosed by the invention has the characteristics of high strength, good furnace-body combined performances and long service life.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

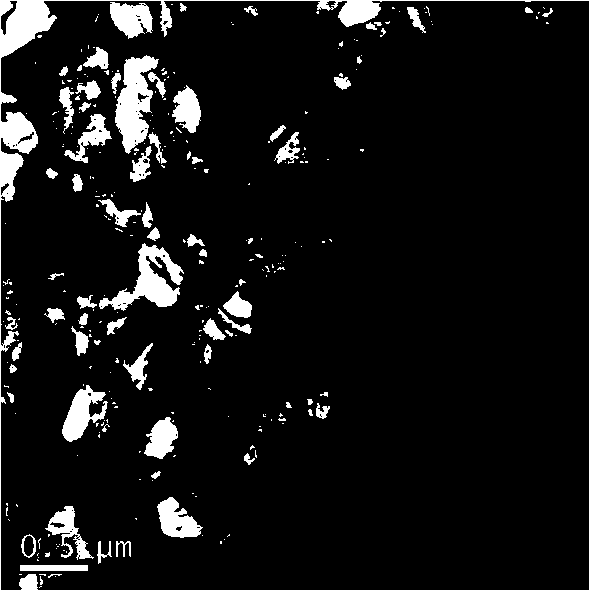

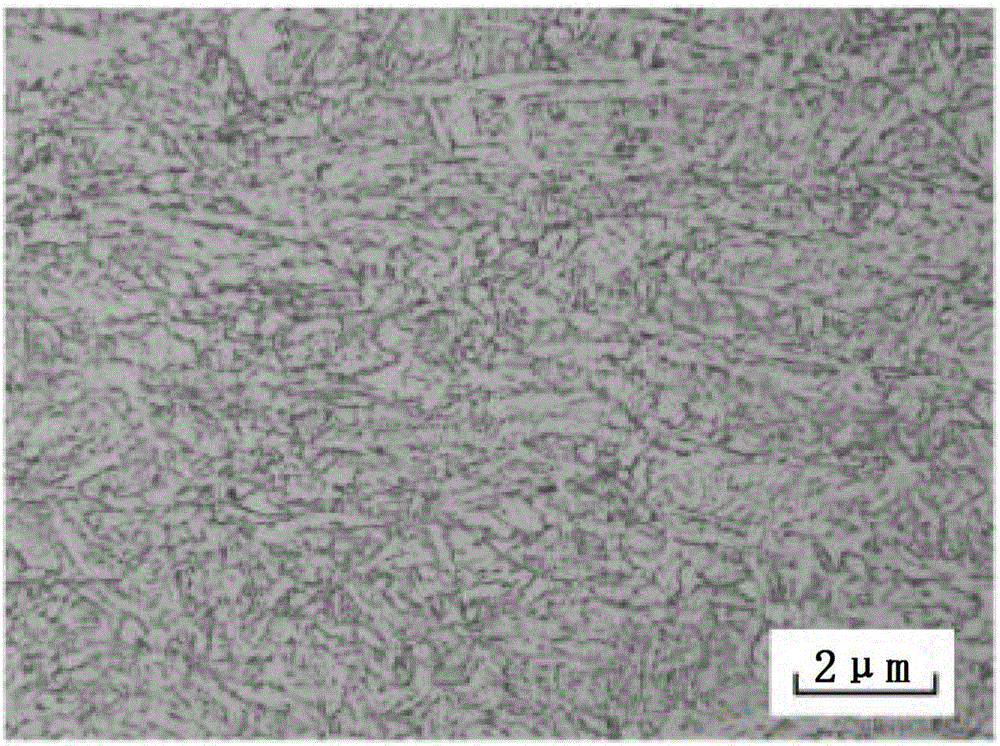

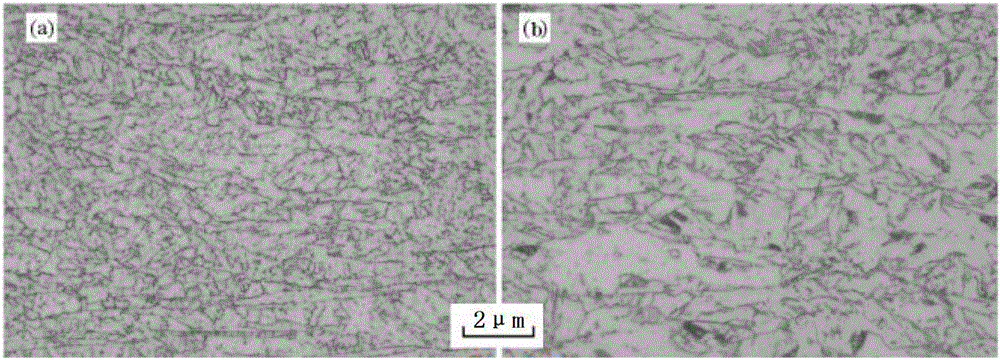

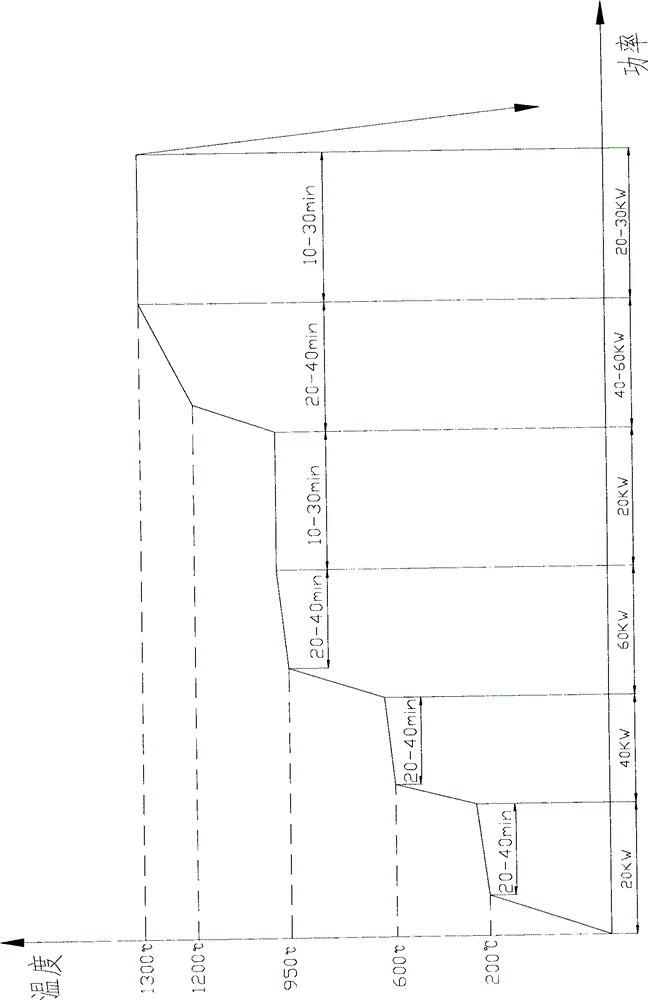

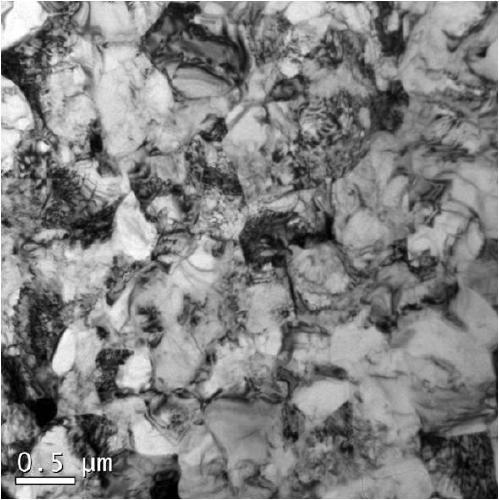

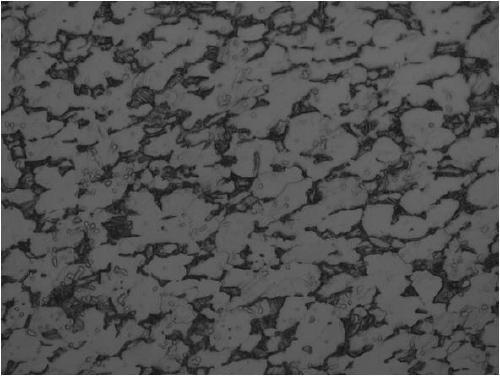

Microcrystalline and high corrosion resistance type titanium alloy pipe and preparation method thereof

InactiveCN108611529AHigh tissue densitySmall grain sizeMetal-working apparatusFurnace typesChemical compositionBeta phase

The invention discloses a microcrystalline and high corrosion resistance type titanium alloy pipe and a preparation method thereof, and belongs to the technical field of titanium alloy pipes. According to the technical scheme, the preparation method is characterized by comprising the steps of preparing titanium sponge as a raw material; controlling the following chemical components in percentage by mass: 5.0-7.0% of Al, 2.0-3.0% of Nb, 0.5-2.0% of Zr, 0.7-1.2% of Mo, 0.02-0.05% of Fe, 0.01-0.03% of Si, and the balance Ti; smelting and forging to obtain a pipe blank; maintaining the temperatureof 990-1040 DEG C for 60-120min; performing cross piercing rolling; cooling; maintaining the temperature of 700-900 DEG C for 20-40min; rolling to obtain a pre-fabricated pipe; annealing for 30min to2h under the temperature of 350-550 DEG C; and cooling to obtain the pipe. The pipe structure contains an alpha phase and a beta phase; the grain size of the alpha phase is 0.5-1 micron; the grain size of the beta phase is 0.1-0.3 microns; and the intensity, the toughness and the corrosion resistance are greatly improved.

Owner:YANSHAN UNIV

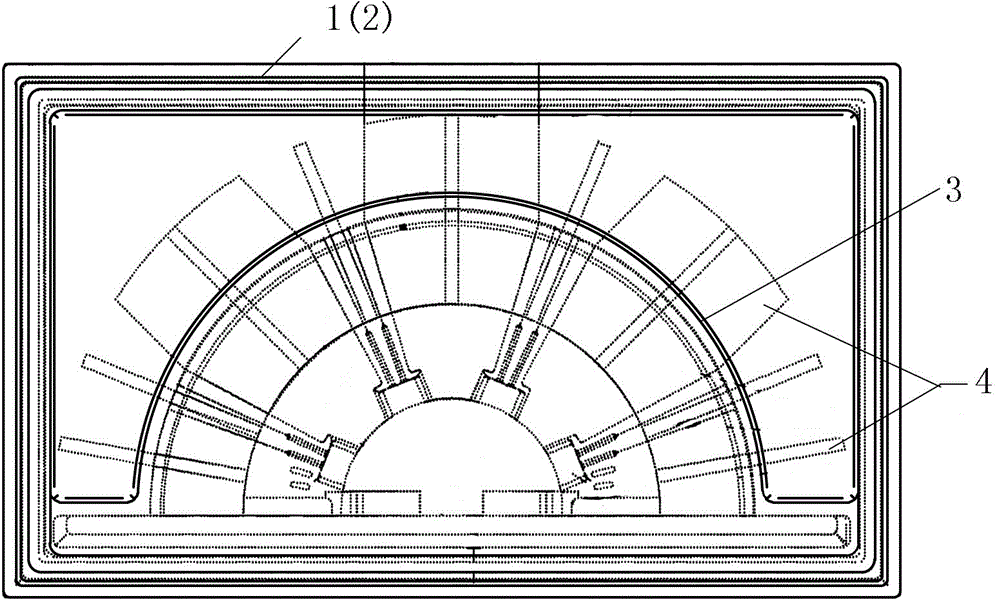

Lost foam casting die and method for braking disc

InactiveCN104889327ASmall dimensional toleranceSmall surface finishFoundry mouldsFoundry coresHardnessLost-foam casting

The invention relates to a lost foam casting die and method for a braking disc and belongs to the technical field of lost foam casting and aims to solve the technical problem of short service life. According to the lost foam casting die and method for the braking disc, lost foam casting is adopted, the hardness of a friction surface of the braking disc is uniform and the service life is long. According to the technical scheme, the lost foam casting die comprises an upper die, a lower die and a semi-circular casting lost foam pattern, wherein cavities are formed in inner surfaces of the upper die and the lower die, a casting cavity is formed between the upper die and the lower die after the upper die and the lower die are buckled, the semi-circular casting lost foam pattern is arranged in the casting cavity, multiple movable blocks are arranged in the semi-circular casting lost foam pattern, and sprue gates are formed in tops of the upper die and the lower die. The lost foam casting die and method for the braking disc are widely used for casting of the braking disc.

Owner:山西威龙铁路机车制动配件制造有限公司

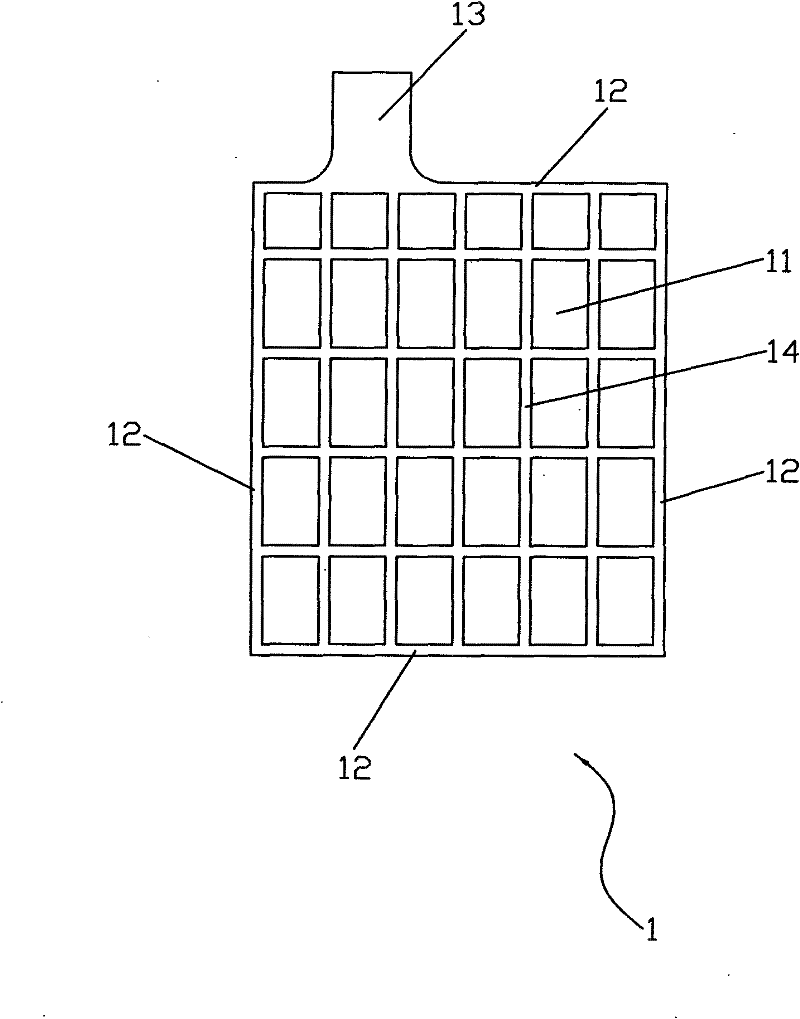

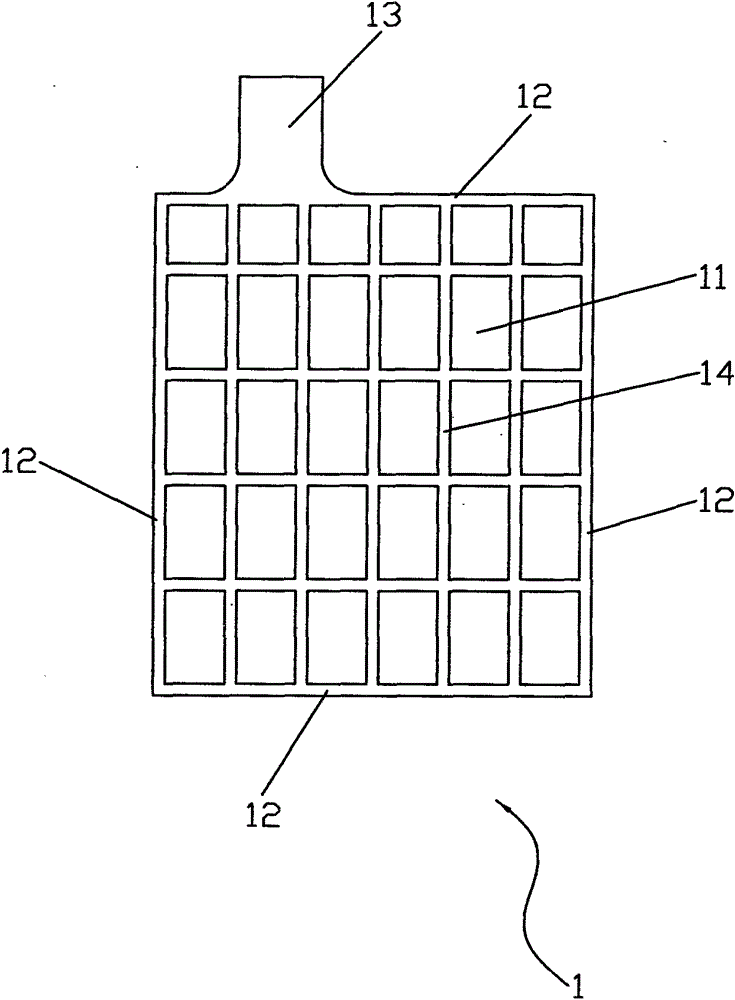

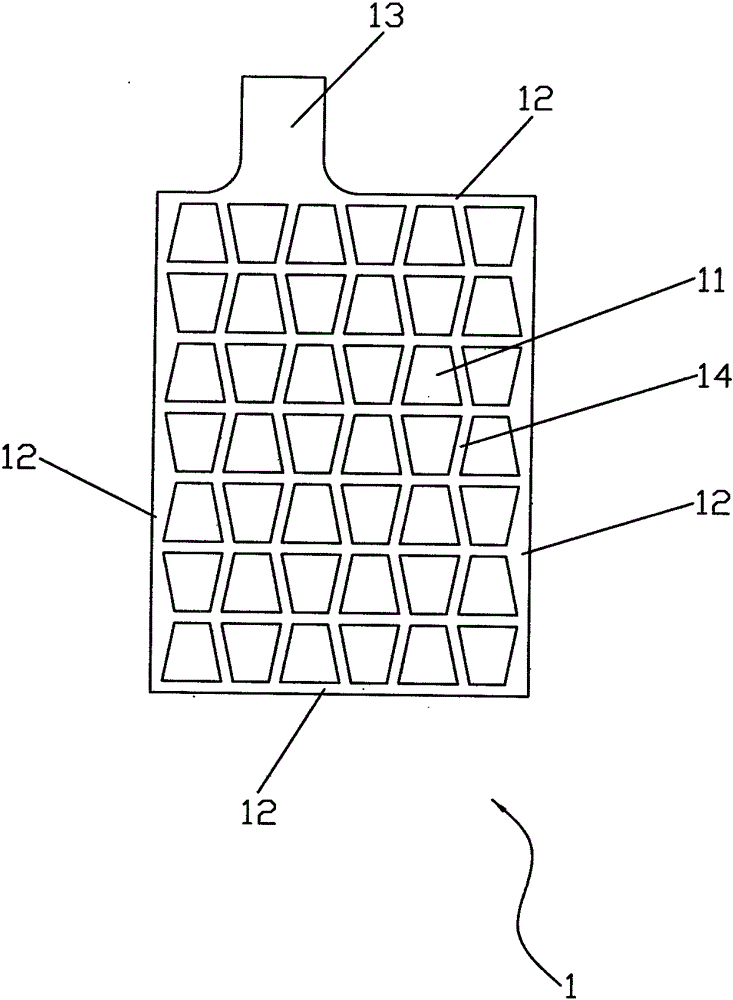

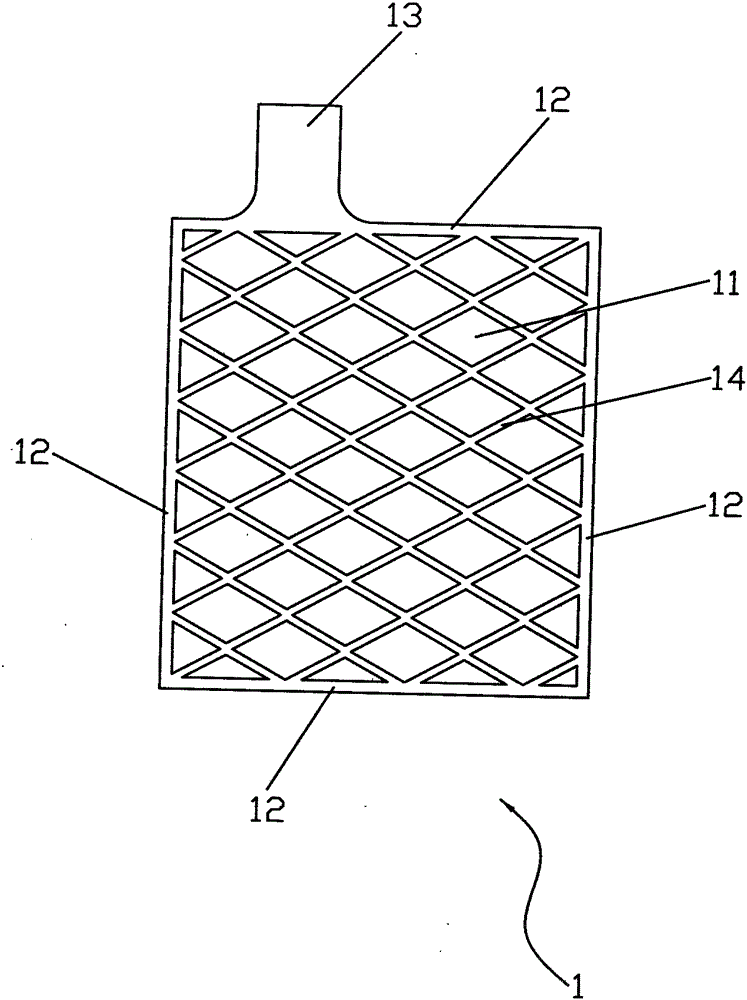

Electrode grid of lead acid battery and manufacturing process thereof

InactiveCN102227025ASave lead consumptionExtended service lifeElectrode carriers/collectorsTissue densityRedox

The invention relates to an electrode grid of a lead acid battery. The electrode grid is characterized in that: the grid comprises a lead substrate; the substrate is punched with a plurality of meshes which distribute uniformly; each side of the substrate is provided with a frame; and one frame is provided with a tab which bulges outwardly. When the electrode grid of the present invention is used on the lead acid battery, and active electrolytic substances are filled in the meshes of the electrode grid, a current which is generated when the active electrolytic substances are subjected to a redox reaction is transmitted out through the tab to realize power supply. Rolled lead strips are used, the tissue density is substantially higher than the density of cast grids with loosened tissue structures, so the electrode grid of the present invention which is more corrosion resistant allows the service life of the battery to be prolonged. When conductive properties are guaranteed, ribs of the grid of the present invention can be finer than the ribs of the cast grids, so the lead consumption amount can be saved. The invention also provides a manufacturing process of the electrode grid of the lead acid battery, and the process has the advantages of energy saving, environmental protection, high production efficiency and grid consumption saving.

Owner:吴铭荣

Processing technology for super-strength corrosion-resistant steel product and rolling unit thereof

ActiveCN106399867ALow costHigh strengthTemperature control deviceRollsTemperature controlHeating furnace

The invention relates to a processing technology for a super-strength corrosion-resistant steel product and a rolling unit thereof and aims to provide a production means of an improved steel product 00Cr9MoNi. The processing technology comprises the following steps of: Stp1, taking a steel billet which meets required components; Stp2, heating the steel billet in a heating furnace and controlling the heating temperature not to be less than solution temperature; Stp3, after discharging the steel billet, removing phosphorous at a high pressure, and performing first-stage rolling in an austenite recrystallization region, wherein the first-pass rolling reduction is not smaller than 65% of thickness of the steel billet, the average pass reduction is greater than 50% of thickness of the steel billet and a demand on total deformation is satisfied; and Stp4, performing second-stage rolling in the austenite recrystallization region, wherein the finish rolling temperature is controlled to be Ar3 above, and in the Stp2-Stp4, the rolling cooling speed is controlled at 15-30 DEG C / h. By virtue of the scheme, the steel product which is proper in cost and has super strength, toughness and corrosion resistance is obtained. The steel product processed by the technology is widely applied to the field of petroleum, sea, urban buildings and the like as a result of the protruding comprehensive property.

Owner:ZHEJIANG RUIZHI STEEL CO LTD

Aluminum alloy strip for battery shell and manufacturing method of aluminum alloy strip

InactiveCN112195373AReduce cooling and solidification speedHigh tissue densityElectrical batteryUltimate tensile strength

The invention discloses an aluminum alloy strip for a battery shell and a manufacturing method of the aluminum alloy strip. The aluminum alloy strip comprises the following components in percentage byweight: 0.55%-0.75% of Fe, 0.20%-0.40% of Si, 0.08%-0.10% of Cu, 0.95%-1.15% of Mn, 0.015%-0.020% of delta Ti and the balance of Al. Delta Ti is the content difference value of Ti in a launder and astanding furnace. The manufacturing method comprises the steps of smelting and refining; continuous casting and rolling; double-stage desolventizing annealing; and cold rolling. The alloy cooling solidification speed in the continuous casting and rolling process is effectively reduced, the solid solution amount of Mn in the alloy is reduced, segregation and unbalanced crystalline structures are eliminated, fine grain structures are formed in the alloy, and the distribution uniformity of alloy elements is improved; and the tensile strength of a finished product of the prepared aluminum alloy strip ranges from 140 MPa to 165 MPa, the yield strength is larger than or equal to 130 MPa, the ductility is larger than or equal to 8%, and the mechanical property is excellent.

Owner:JIANGSU ALCHA ALUMINUM CO LTD

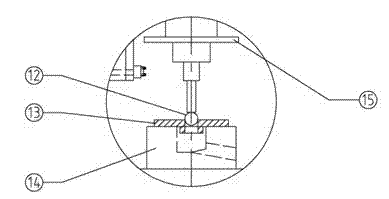

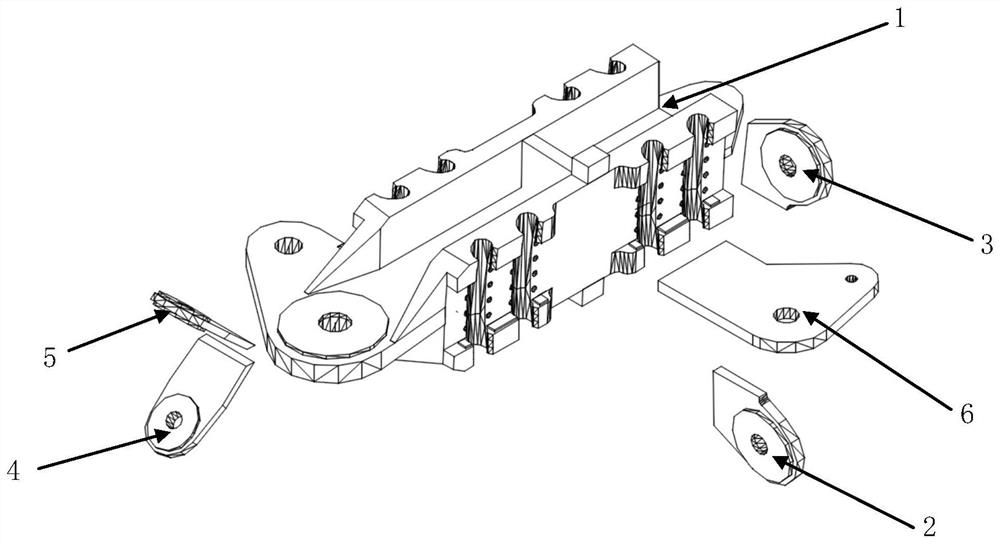

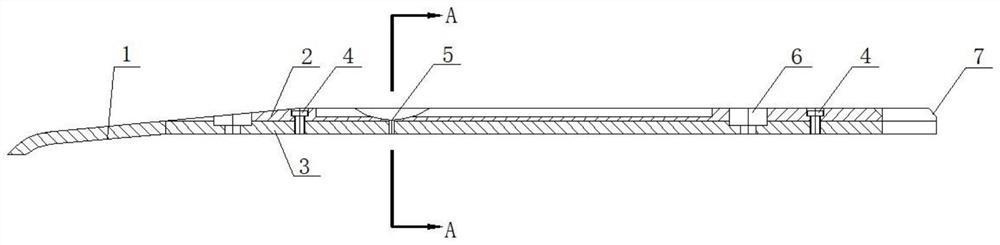

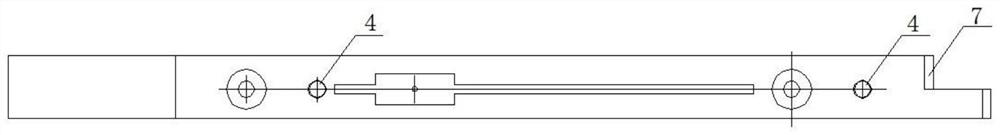

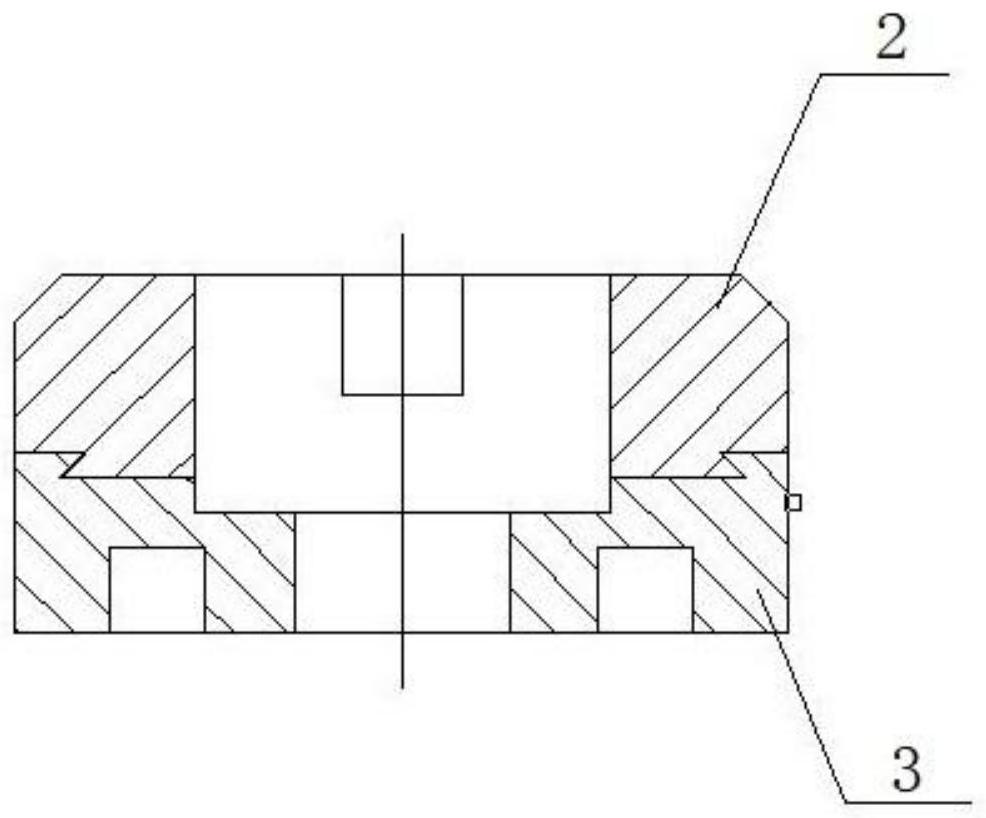

Device for machining hole

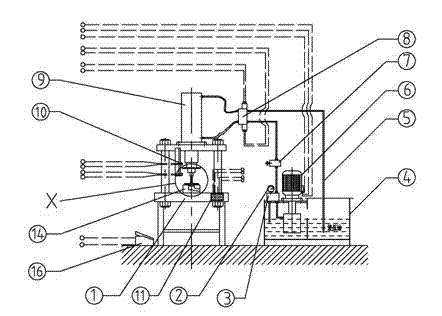

InactiveCN102922218AImprove the qualified rate of finished products and the quality and roughness requirements of holesIncreased tissue densityPass rateEngineering

The invention belongs to the field of machinery machining and manufacturing, and particularly relates to a machining device which is used for improving the surface quality and inner quality of a hole of a product. The device for machining the hole comprises a hydraulic system, a control system and a machining system. The machining system comprises a steel ball which is matched with the bore diameter of a workpiece. The hydraulic system machines the hole on the workpiece by extruding the steel ball. The device for machining the hole is mainly characterized in that the hole on the workpiece is machined by extruding the certain-size steel ball. A traditional boring mode is changed, a certain extruding allowance is reserved before extruding, an end-product hole is machined by the fact that the certain-size steel ball is extruded, the end product pass rate of the hole is improved, the quality and the roughness requirements of the hole are improved, the organizing density of the interior of the hole is strengthened, pulling-out force (pulling-out face used for matching of a shaft and a hole) requirements of a product hole is greatly increased, and production efficiency is improved.

Owner:NANJING CHENCAN IND

Process and die for stamping girdle-free conical spheres

InactiveCN101513665AIncrease profitExtended service lifeForging/hammering/pressing machinesEngine componentsTissue densityEngineering

The invention discloses a process and a die for stamping girdle-free conical spheres. The process comprises the following steps that: a light process with one-off transverse extrusion is adopted to enable a material to have transverse deformation in the transverse direction so as to increase the tissue density of the material before being cut and forged; the cut-off length of the lightly pulled material is determined in a feeding structure; the lightly pulled material is cut off; and the cut material is sent into a tapering die cavity at an angle between 90 and 120 degrees and stamped so as to form sphere billets and manufacture the girdle-free conical spheres. The research and development of a novel girdle-free conical sphere die and a forging process increase the life span of the die and the utilization rate of the material, reduce the impact force of stamping, and ensure that the sphere billets can be knocked out more smoothly.

Owner:JIANGSU LIXING GENERAL STEEL BALL

Manufacturing method for high-performance 12Cr2Mo1 forgings

InactiveCN110106308AImprove purityImprove performance and stabilityMetal-working apparatusProcess efficiency improvementMelting tankManufacturing technology

The invention relates to the technical field of metallurgic manufacturing, in particular to a manufacturing method for high-performance 12Cr2Mo1 forgings. The method comprises the following steps: (1)smelting by an electric furnace: molten steel is obtained through charging, slagging, slag discharge, stirring in a molten pool, dephosphorization and desulfurization; (2) furnace external refining:the molten steel obtained in the step (1) is refined, and chemical components thereof are adjusted; (3) vacuum degassing: steel ingots are obtained through vacuumizing and casting; (4) casting: the heating insulation temperature is 1000-1250 DEG C; and the heating time is determined according to 1.5 times of the JB / T6052 standard; and (5) heat treatment: forged forgings are quenched and tempered in sequence; and once annealing or normalization is performed before quenching. The method improves the low-temperature impact power of the 12Cr2Mo1 forgings, reduces the tempering brittleness tendency, improves the performance stability of the forgings, and has the advantages of simple process, excellent comprehensive performances and stability.

Owner:无锡市法兰锻造有限公司

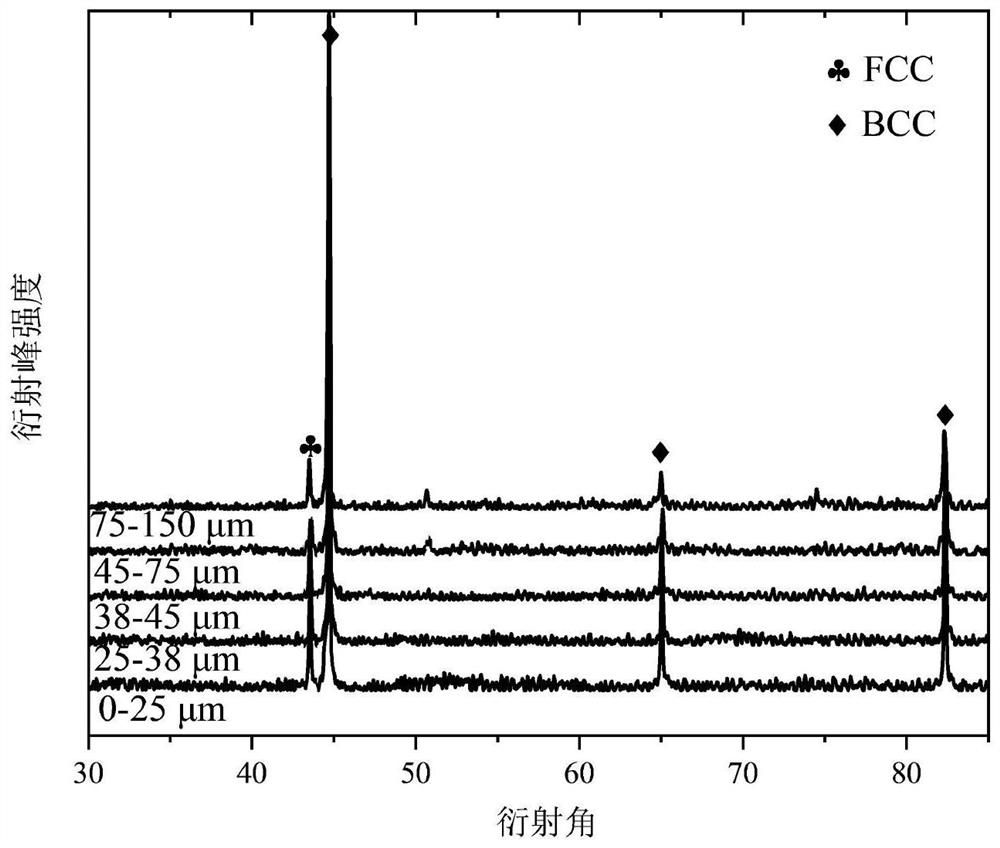

High-entropy alloy component and manufacturing method thereof

InactiveCN112267056AImprove organizationSmall grain sizeAdditive manufacturing apparatusSelective laser meltingMetallurgy

The invention discloses a high-entropy alloy component and a manufacturing method thereof, and relates to the technical field of high-entropy alloys. The problem of composition segregation of the high-entropy alloys is avoided. The manufacturing method of the high-entropy alloy component comprises the steps that a substrate is provided; metal powder is laid on the substrate, wherein the metal powder comprises Al, Co, Cr, Fe and Ni with the atomic ratio being a: b: c: d: e, a is larger than 0 and smaller than or equal to 1.2, and each of b, c, d and e is equal to 1; and the metal powder is subjected to melting forming treatment through a selective laser melting process, and the high-entropy alloy component is obtained. The high-entropy alloy component and the manufacturing method thereof are used for manufacturing the high-entropy alloy component.

Owner:TSC LASER TECH DEV BEIJING CO LTD

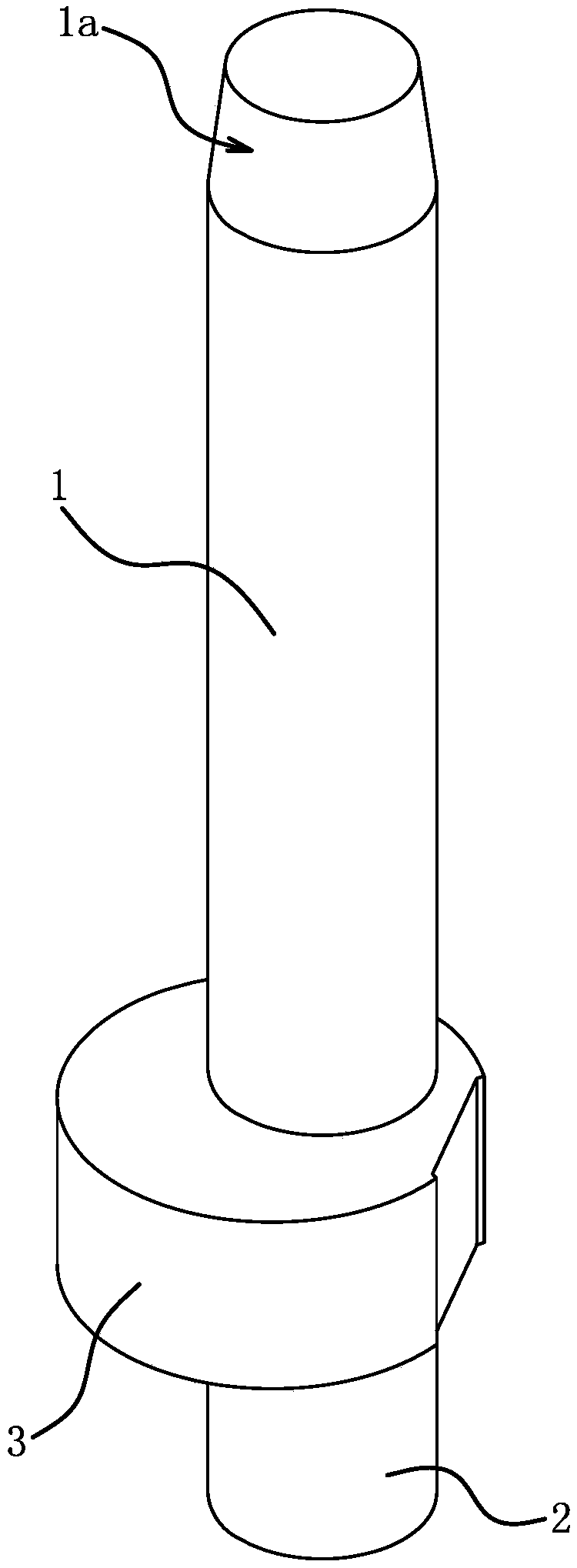

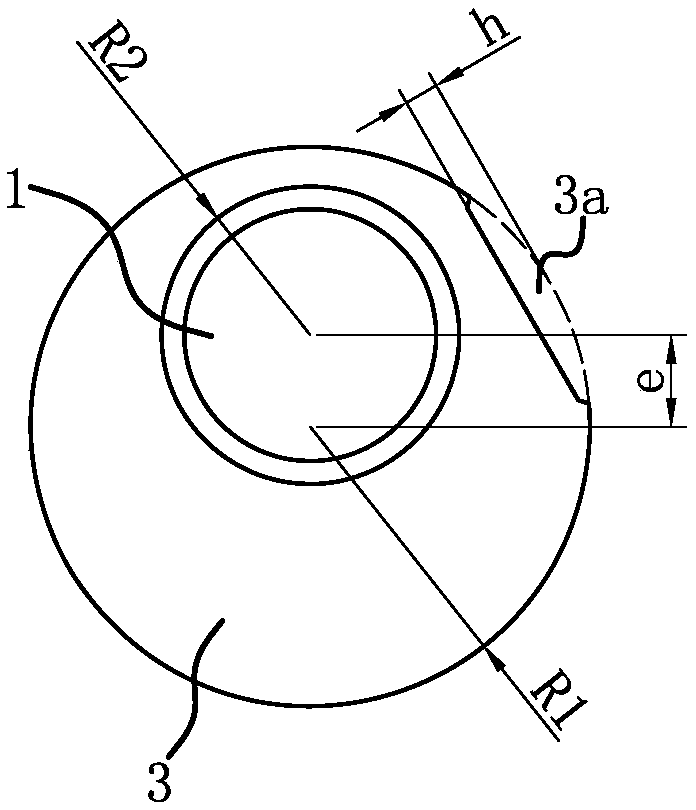

Manufacturing method of rotary type compressor crankshaft blank

InactiveCN108971252ANot easy to bend and deformImprove pass rateExtrusion diesAxial pressureLong axis

The invention provides a manufacturing method of a rotary type compressor crankshaft blank and belongs to the technical field of liquid variable capacity machinery, aiming at solving the problem thatan existing crankshaft blank is easy to bend and deform in a cold heading molding process. The manufacturing method of the rotary type compressor crankshaft blank is carried out according to the following steps: first step, selecting materials and blanking; selecting a round steel rod with the diameter which is greater than that of a long shaft part and smaller than that of an eccentric crankshaftpart; second step, coldly extruding and molding the long shaft part, wherein a transition part is provided with the long shaft part and a cylindrical part connected with one end of the long shaft part; and third step, coldly extruding and molding the eccentric crankshaft part and a short shaft part, and applying axial pressure to the transition part to enable the cylindrical part in the transition part to be deformed, fully fill an eccentric crankshaft molding cavity and enable residual materials to flow into a short shaft molding cavity. In a production process of the rotary type compressorcrankshaft blank, the eccentric crankshaft part and the short shaft part are nearly subjected to an axial bearing force in a molding process, so that the rotary type compressor crankshaft blank is noteasy to bend and deform.

Owner:浙江百达精工股份有限公司

Automobile air-conditioning compressor swash plate and production method thereof

InactiveCN111349828AIncreased tissue densityImprove wear resistancePositive displacement pump componentsSolid state diffusion coatingRheniumManganese

The invention discloses an automobile air-conditioning compressor swash plate. The automobile air-conditioning compressor swash plate is prepared from the following component aluminum alloys in percentage by weight: 10%-12% of silicon, 3%-4% of copper, 0.2%-0.3% of magnesium, 0.6%-1.2% of nickel, 0-0.2% of manganese, 0.2%-0.4% of molybdenum, 0-0.4% of iron, 0-0.1% of zinc, 0.2%-0.6% of chromium, 0-0.2% of titanium, 0.1%-0.2% of carbon, 0.2%-0.4% of rhenium, and the balance of aluminum. A production method of the automobile air-conditioning compressor swash plate comprises the steps that step one, preheating is carried out; step two, gold melting is carried out; step three, deterioration is carried out; step four, heat treatment is carried out; step five, rough machining is carried out; step six, cryogenic nitrogen treatment is carried out; and step seven, finish machining is carried out. According to the Automobile air-conditioning compressor swash plate and the production method thereof, the tissue density of products can be enhanced, the abrasive resistance and strength of the products are improved, transformation of the products is avoided, internal stress of the products is eliminated, the life is prolonged, and the actual use requirement is met.

Owner:滁州市爱科知识产权代理有限公司

Preparation process of volute spiral spring

InactiveCN110358893AIncreased tissue densityQuality improvementFurnace typesWire springsCoil springWork in process

The invention discloses a preparation process of a volute spiral spring and relates to the technical field of spring preparation. The preparation process includes the following steps: S1: a spring rawmaterial is prepared; S2: hole punching treatment is performed on the raw material, and a hole punched material is obtained; S3: forming treatment is performed on the hole punched material, and a formed material is obtained; S4: winding treatment is performed on a special mandrel for the formed material, and a coil spring intermediate material is obtained; S5: normalizing, quenching and temperingtreatment is sequentially performed on the coil spring intermediate material, and a semi-finished coil spring is obtained; S6: reaming and shot blasting aftertreatment is performed on the semi-finished coil spring, and an aftertreatment semi-finished product is obtained; and S7: size inspection is performed on the aftertreatment semi-finished product, surface treatment is performed after qualifying, and finally the finished volute spiral spring is obtained. The preparation method has the advantages of improving the finished product quality of the volute spiral spring.

Owner:浙江裕荣弹簧有限公司

Cold precision forging forming technology for inner spline lock ring with inverted cone

The invention discloses a cold precision forging forming technology for an inner spline lock with an inverted cone. According to the body of the technology, precision forging forming of an end face ratchet and an inner spline is synchronously finished through a cold blocking forming procedure. The technology specifically comprises the following procedures of material preparing, ring rolling blankmanufacturing, annealing treatment, surface treatment, blank turning, phosphating, cold precision forging and finish machining. Few procedures are adopted, the work efficiency is high, and most importantly, machining of the end face ratchet and the inner spline is synchronously finished through one-time cold blocking forming work. Due to the fact that the position degrees of the ratchet and the inner spline in a lock ring are achieved through a die, precision is guaranteed, and consistency is good. In addition, the rolling and cold precision forging forming technology is adopted, on one hand,the original metal flow line is kept in the forming process, and on the other hand, the tissue density of the raw material is greatly improved; and accordingly, the abrasion resistance and strength ofproducts can be better improved, and the manufactured lock ring completely meets the requirement for automobile matching

Owner:JIANGSU PACIFIC PRECISION FORGING +1

WC-Co-Si-Ti nanometer coating and preparing method thereof

InactiveCN106086752AUniform shapeParticle integrityMolten spray coatingNanotechnologyTrace elementVolumetric Mass Density

The invention relates to a WC-Co-Si-Ti nanometer coating and a preparing method thereof. The WC-Co-Si-Ti nanometer coating comprises, by mass, 20-45 parts of Ni60A, 45-55 parts of TiO2, 0.5-2 parts of Al2O3 and 1-2 parts of trace elements. The preparing method comprises the following steps that firstly, a WC-Co-Si-Ti nanometer ball is prepared through a dry type pulverizing method; secondly, the nanometer ball prepared in the first step is mixed with ground B, Cr, Mn and C through a surface active agent protection method to prepare mixed powder; and thirdly, the nanometer powder prepared in the second step is utilized for preparing a WC-Co-Si-Ti nanometer welding layer on the surface of a workpiece through a plasma spraying technology. The prepared nanometer material is uniform in feature, particles are integral, and a good organization structure and good macroscopic properties are achieved; and hardness is high, abrasion resistance is good, the high-temperature oxidation resistance and other properties are good, the bonding strength is good, and the structure density is good.

Owner:WUHU DINGHENG MATERIAL TECH

Preparation method of wear-resistant sole material

The invention relates to a preparation method of a wear-resistant sole material. The composite material comprises nitrile butadiene rubber and tungsten-cobalt alloy particles. The preparation method of the wear-resistant sole material comprises the following steps: mixing nitrile rubber through an open mill and a calender for 1 hour to prepare a rubber material, vulcanizing the rubber material through a press vulcanizer through a heat-vulcanization process with pressurization at the same time to obtain a rubber product which is compact in structure, free of bubbles and smooth in surface; weighing tungsten powder, pushing the tungsten powder into conventional carbonization equipment, carbonizing at a low temperature of 1400 DEG C with hydrogen being fed, and cleaning, crushing and screeningthe tungsten carbide to prepare tungsten carbide powder; reducing the cobalt oxide through hydrogen at the temperature of 600 DEG C in a direct-heating four-tube electric furnace to prepare cobalt powder, screening the reduced cobalt powder through a screening machine (100-200 meshes), and finally preserving the prepared tungsten carbide powder and cobalt powder in a sealed mode in carbon dioxidegas; mixing tungsten carbide powder and cobalt powder, pouring the mixture into a rolling ball mill, and adding an alcohol wet milling medium for rolling ball milling.

Owner:YANGZHOU AIFEIKE SHOES CO LTD

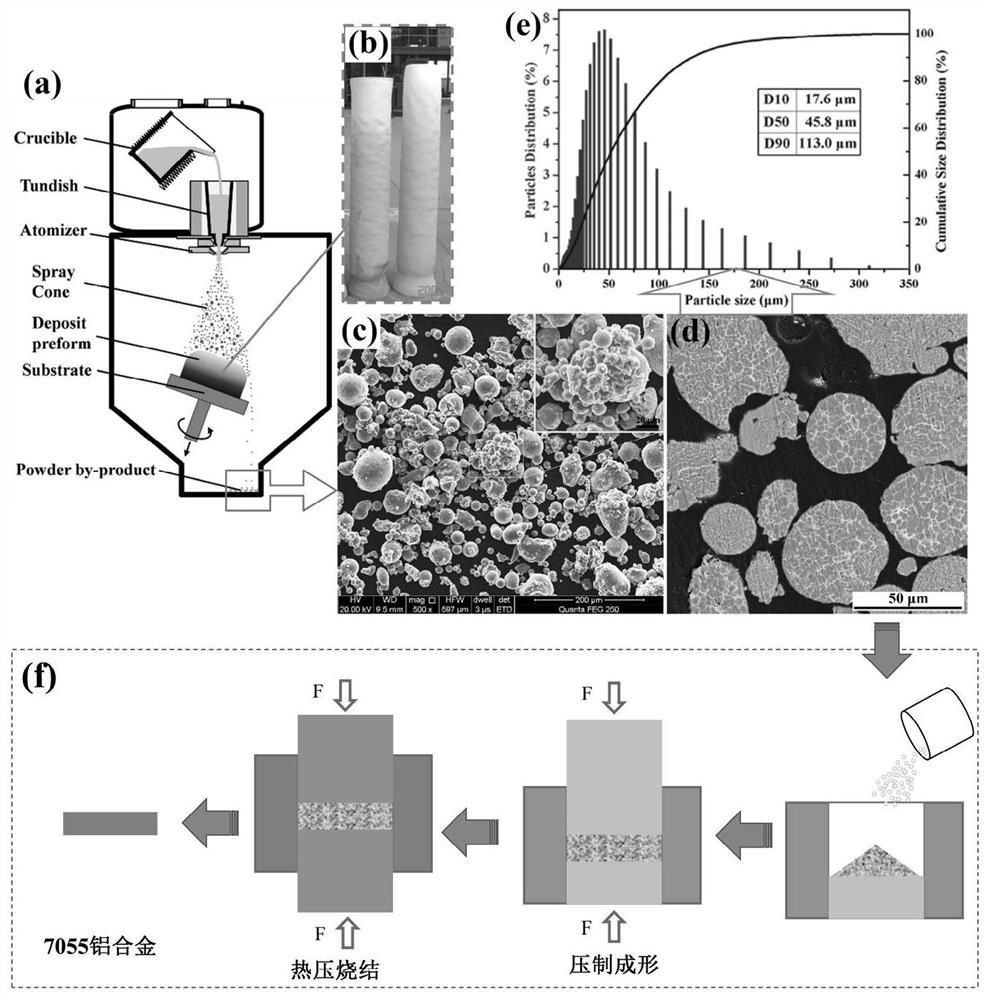

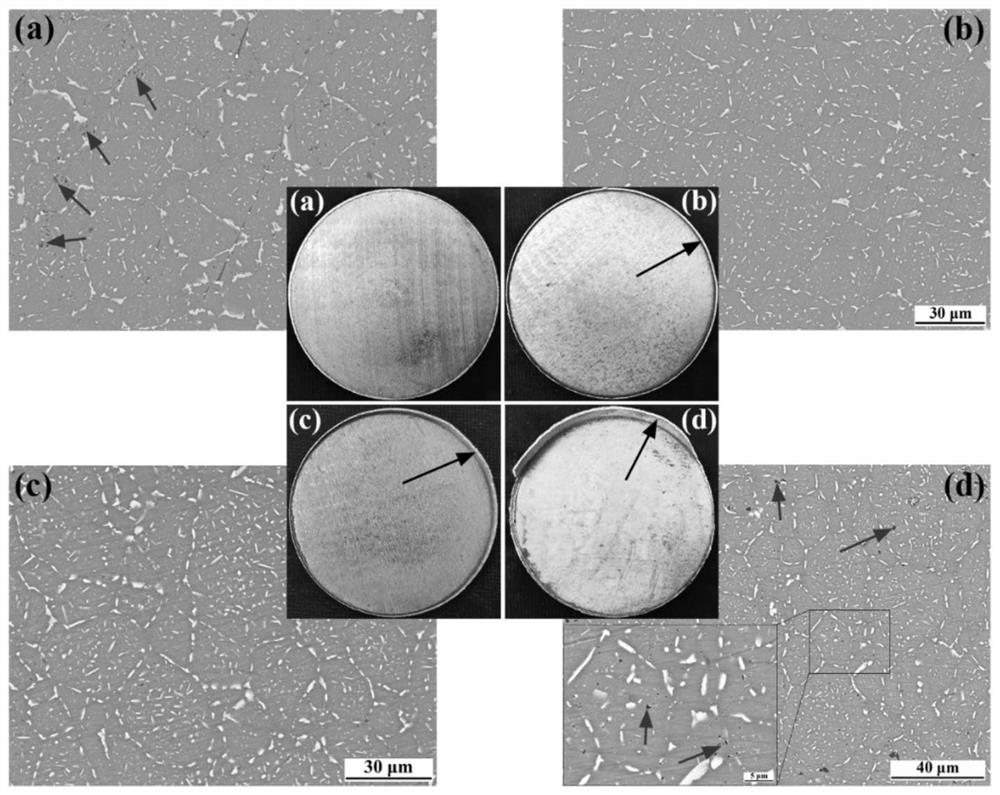

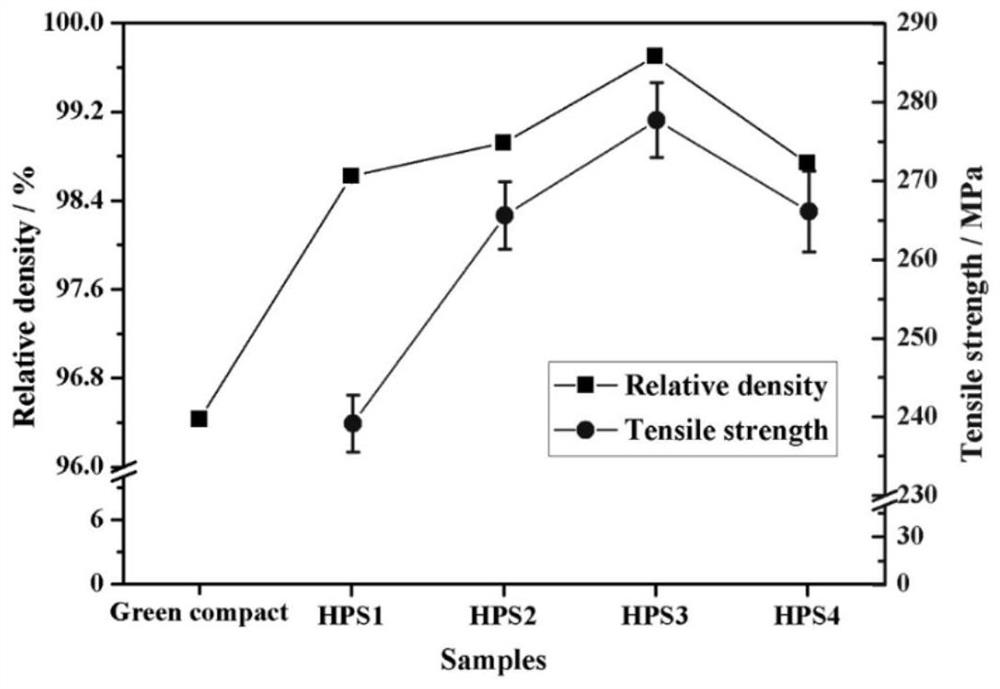

Comprehensive utilization method of powder by-products generated in spray forming process and product application

The invention provides a comprehensive utilization method of powder by-products generated in the spray forming process. The method comprises the steps that powder by-products are pressed, formed and sintered directly; the powder by-products mainly from extra powder generated in the spray forming green part preparation process, and are named as powder by-products in order to differ from a spray forming green part; according to the pressing forming, a hydraulic single column press or a four-column hydraulic press is adopted for loading the powder by-products into a steel mold to be formed, and agreen body is prepared; according to sintering, a vacuum hot pressing furnace is adopted for performing sintering densification, an alloy is prepared, and therefore the powder by-products are comprehensively utilized. According to the comprehensive utilization method of powder by-products generated in the spray forming process, the preparation technological process is short, the cost is low, operation is easy, convenient and flexible, the prepared materials have the structure and performance advantages of being fine in grain, uniform in structure, free of segregation and high in strength. Themethod can effectively achieve comprehensive utilization of powder by-products, the material utilization rate is increased, and the certain economic benefits are obtained.

Owner:CENT SOUTH UNIV

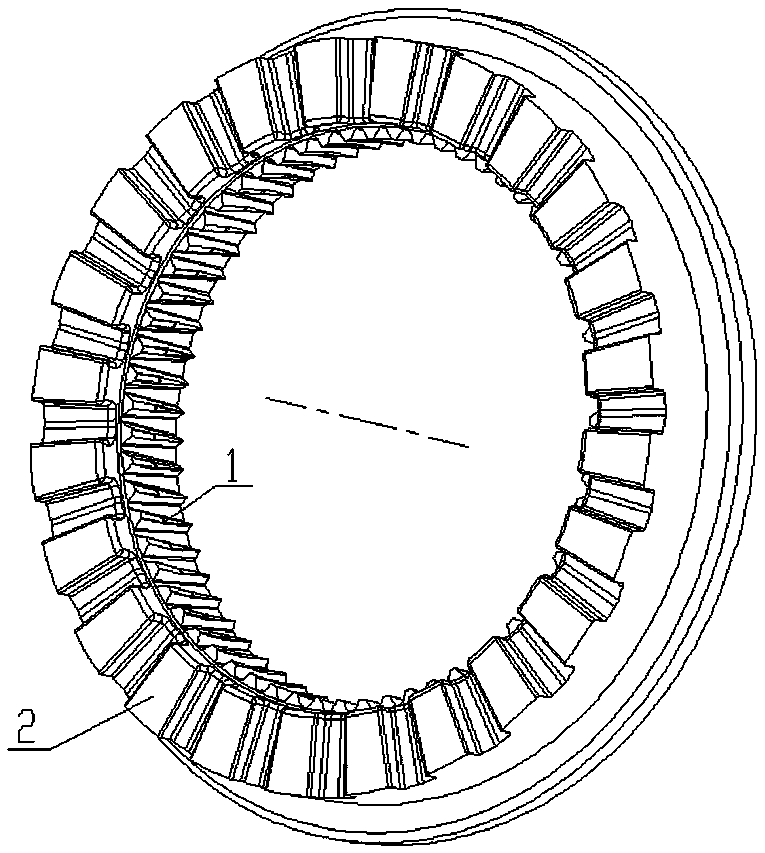

Center Porosity Control Technology of Continuous Casting Big Round Billet

ActiveCN103567410BGood for controlling porosity levelReduce temperature gradientPorosityAutomatic control

The invention belongs to the technical field of metallurgy, and particularly relates to a process for controlling center porosity of a large and round continuous casting billet. The process comprises steps as follows: qualified molten steel in tundish is injected into a mold through a four-slitting sided cyclone submerged nozzle; mold fluxes are added, and the depth of the submerged nozzle of the mold is controlled to range from 110 mm to 130 mm; a mold liquid level automatic control system is used for stabilizing a mold liquid level and a pulling rate, and the superheat degree of the molten steel in the tundish is stabilized; the secondary cooling speed of a casting billet is controlled; and M-EMS (mold electromagnetic stirring) and F-EMS (final electromagnetic stirring) parameters are optimized. With the adoption of the process, the large and round billet is produced, melting of the mold fluxes is facilitated, the temperature gradient from a billet shell to molten steel at the core part of the casting billet can be reduced, the overheat degree of the molten steel in the center is decreased, the isometric crystal proportion of the casting billet is increased, the tissue density of the casting billet is increased, and the grade of the center porosity of the large and round continuous casting billet can be controlled.

Owner:SHANDONG XIWANG SPECIAL STEEL

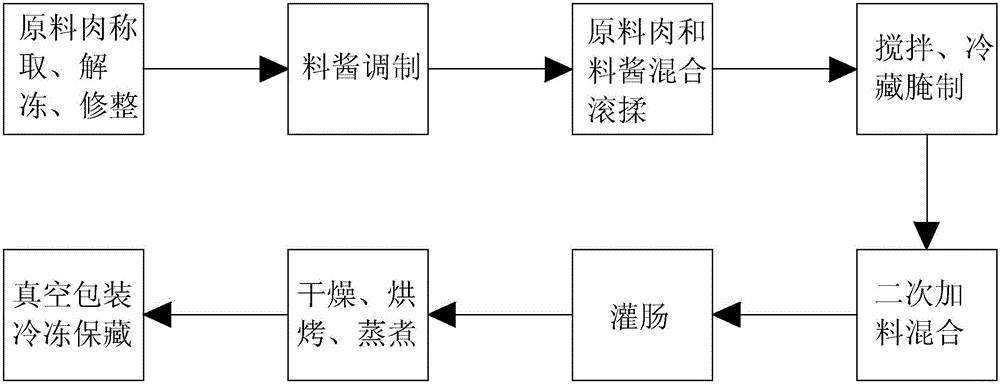

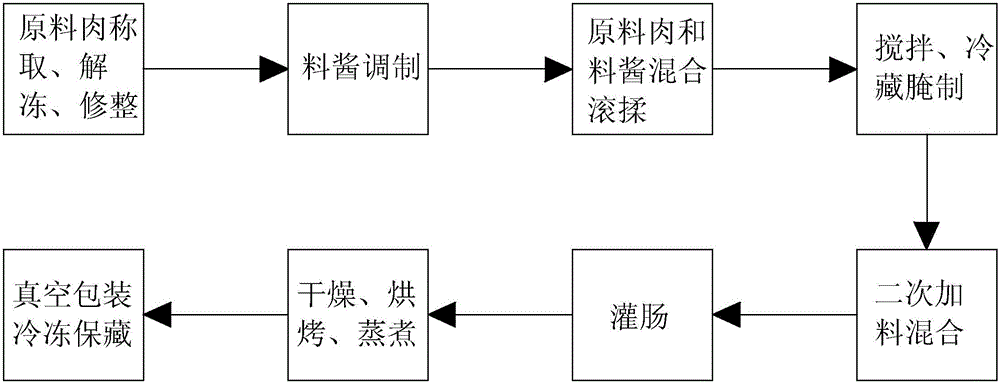

Taiwan sausage and preparation method thereof

InactiveCN106174111APlay the role of heat-clearing and detoxifyingAvoid burning problemsFood scienceMonosodium glutamateLean meat

The invention provides a Taiwan sausage which is prepared from lean meat, chicken big breast meat, shop fat and other accessories. The Taiwan sausage comprises the following ingredients in parts by weight: 300-400 parts of lean meat, 100-150 parts of chicken big breast meat, 200-300 parts of shop fat, 8-9 parts of table salt, 40-45 parts of white sugar, 7-8 parts of monosidum glutanate, 1-1.5 parts of five spice powder, 0.5-0.8 part of star aniseed powder, 0.5-0.8 part of white pepper powder, 0.5-0.8 part of oily cassia powder, 2-3 parts of phosphate, 0.4-0.8 part of sodium erythorbate, 0.01-0.02 part of sodium nitrite, 0.02-0.03 part of monascus red, 15-20 parts of potato powder, 5-10 parts of protein isolate, 1-2 parts of garlic powder and 0.5-1 part of bitter gourd powder, wherein the bitter gourd powder has the efficacies of clearing away heat and toxic materials, beautifying and tenderizing skin, reducing blood glucose, nourishing blood and liver, and the like, and garlic has certain pungent flavor which can cover the bitterness of bitter gourd, so that the original taste of the sausage can not be influenced, and thus the Taiwan sausage is well received by consumers.

Owner:NANJING JINSHIPENG COMMERCE & TRADE CO LTD

Furnace building method of intermediate-frequency induction furnace for copper alloy smelting

The invention relates to a furnace building method of an intermediate-frequency induction furnace for copper alloy smelting, which comprises the following steps: firstly, preparing a lining material of a furnace-body outer lining and a fire-door lute, and laying a layer of epoxy plate and placing an induction coil on an asbestos board base; laying a glass fiber fabric on the inner wall of the induction coil and the epoxy plate, so that the glass fiber fabric is formed into a pocket shape; hierarchically adding the lining material of the furnace-body outer lining into the glass fiber fabric pocket, and hierarchically tamping and knotting the obtained product so as to form a furnace bottom; then, placing a graphite crucible on the midmost position of the furnace bottom and compacting the furnace bottom; hierarchically adding the lining material of the furnace-body outer lining into a space between the glass fiber fabric bag and the graphite crucible, and tamping and knotting the lining material so as to obtain the furnace-body outer lining, so that the top surface of the furnace-body outer lining is lower than the top surface of the graphite crucible and the top surface of the induction coil; adhering a fire door to the top surface of the graphite crucible through the fire-door lute, filling the fire-door lute between the fire door and the glass fiber fabric bag, and carrying out tamping and flattened-brushing on the fire-door lute so as to obtain a fire-door outer lining; carrying out sintering on the outer lining by using an oven, so that silica has crystal transformation; and after the whole furnace is hardened, stopping heating so as to complete the furnace building. The method disclosed by the invention has the characteristics of high strength, good furnace-body combined performances and long service life.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

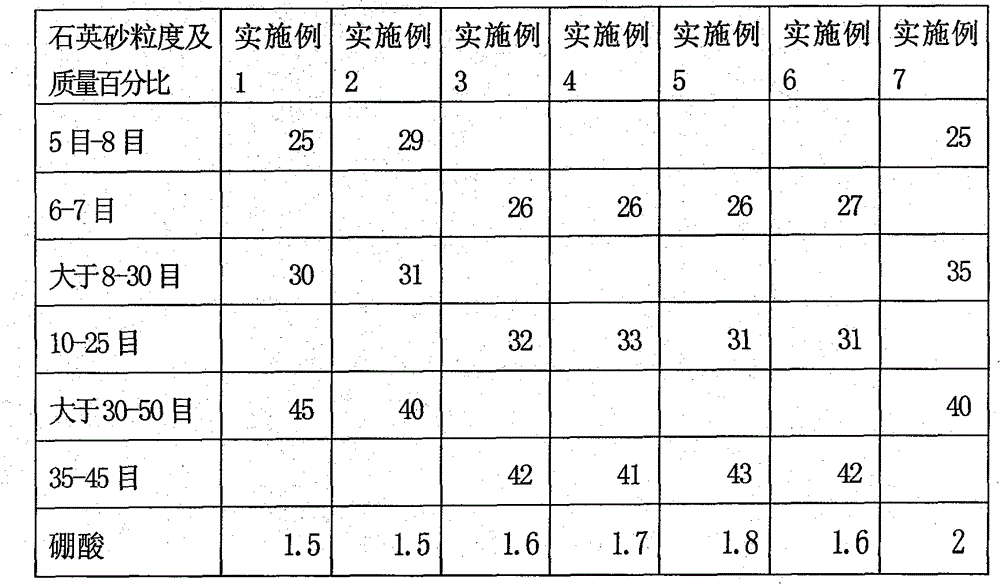

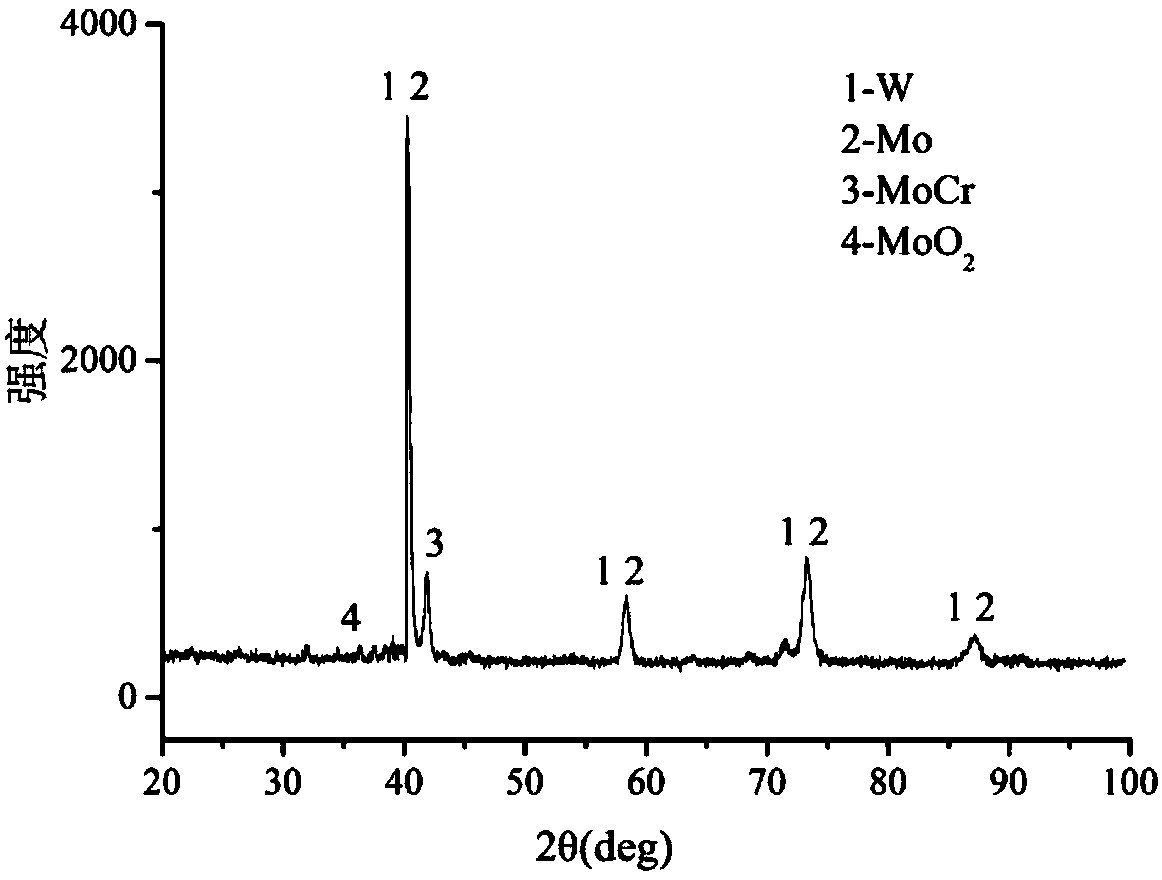

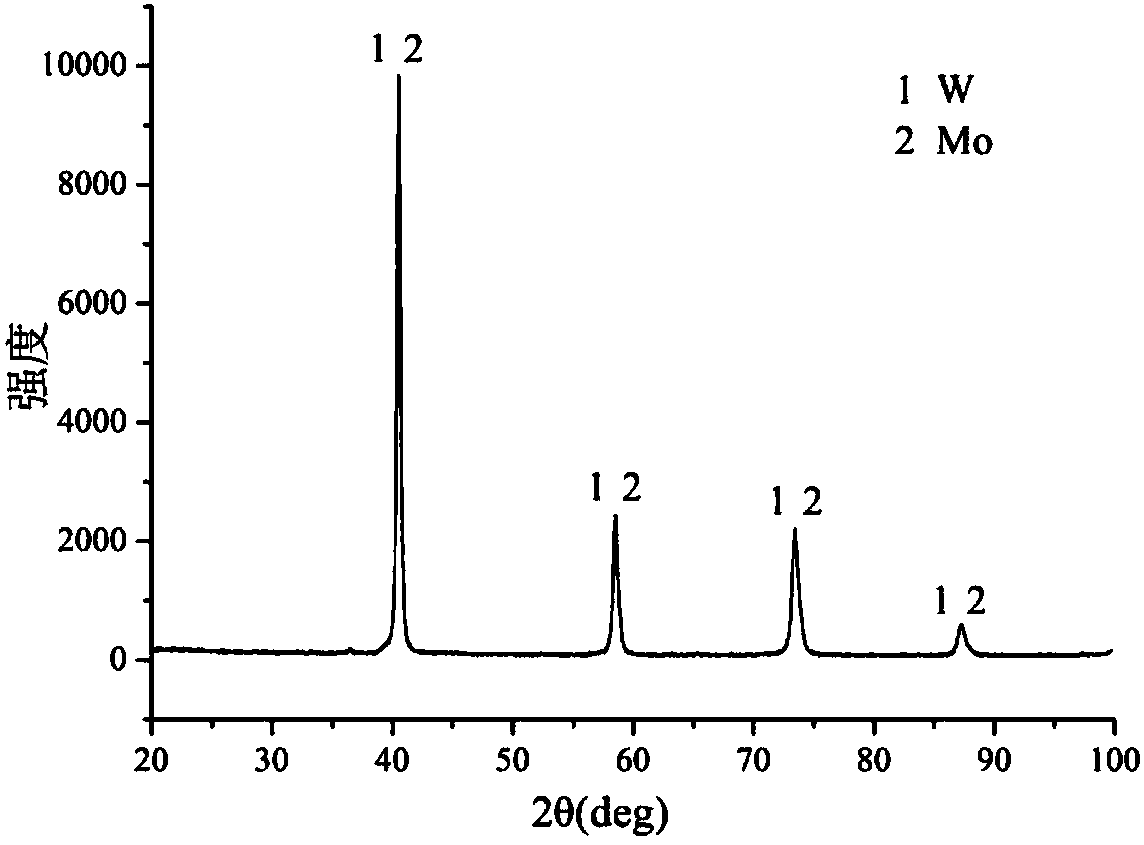

Preparation method of a novel w‑mo‑cr alloy polishing disc

ActiveCN106077653BImprove sinterabilityHigh tissue densityOther manufacturing equipments/toolsSteel ballAlloy

The invention belongs to the technical field of powder metallurgy, and discloses a preparing method for a novel W-Mo-Cr alloy polishing disk. The preparing method comprises the following steps that powder W, powder Mo, powder Cr and powder Y are evenly mixed, and alloy polishing disk raw materials are obtained; secondly, a high-powered ball mill is utilized for conducting ball milling on a stainless steel ball and the alloy polishing disk raw materials, and alloy powder is obtained; thirdly, the alloy polishing disk is prepared through vacuum heat pressing and sintering; and fourthly, the alloy polishing disk is finished, the alloy polishing disk end face with the bright, clean and smooth surface is obtained, and the novel W-Mo-Cr alloy polishing disk is prepared. The preparing method has the beneficial effects that the novel W-Mo-Cr alloy polishing disk is excellent in sintering effect, high in structure density, uniform in component distribution, high in hardness and high in preparing repeatability.

Owner:DALIAN UNIV OF TECH

Lead-acid battery electrode grid and its manufacturing process

InactiveCN102227025BSave lead consumptionExtended service lifeElectrode carriers/collectorsEnvironmental resistanceElectrolysis

A lead-acid storage battery electrode grid, which includes a lead substrate, a number of uniformly distributed mesh holes are punched on the substrate, a frame is respectively arranged around the substrate, and an outwardly protruding tab is provided on one of the frames. After the electrode grid of the present invention is used on a lead-acid battery, the mesh of the electrode grid is filled with active electrolytic substances, and the current generated by the oxidation-reduction reaction of the active electrolytic substances is transmitted through the tabs to achieve the purpose of power supply; the electrode of the present invention The grid uses rolled lead strips, the structure density is much higher than that of the cast grid with loose structure, which is more corrosion-resistant and effectively prolongs the service life of the battery; under the condition of ensuring the electrical conductivity, the grid ribs of the present invention can be compared with the cast grid It is thinner and saves lead consumption of the grid. The invention also provides a manufacturing process of the lead-acid storage battery electrode grid, which has the advantages of energy saving, environmental protection, high production efficiency and saving grid consumption.

Owner:吴铭荣

A microcrystalline high-strength corrosion-resistant titanium alloy pipe and its preparation method

InactiveCN108611529BHigh tissue densitySmall grain sizeMetal-working apparatusFurnace typesChemical compositionTitanium

The invention discloses a microcrystalline and high corrosion resistance type titanium alloy pipe and a preparation method thereof, and belongs to the technical field of titanium alloy pipes. According to the technical scheme, the preparation method is characterized by comprising the steps of preparing titanium sponge as a raw material; controlling the following chemical components in percentage by mass: 5.0-7.0% of Al, 2.0-3.0% of Nb, 0.5-2.0% of Zr, 0.7-1.2% of Mo, 0.02-0.05% of Fe, 0.01-0.03% of Si, and the balance Ti; smelting and forging to obtain a pipe blank; maintaining the temperatureof 990-1040 DEG C for 60-120min; performing cross piercing rolling; cooling; maintaining the temperature of 700-900 DEG C for 20-40min; rolling to obtain a pre-fabricated pipe; annealing for 30min to2h under the temperature of 350-550 DEG C; and cooling to obtain the pipe. The pipe structure contains an alpha phase and a beta phase; the grain size of the alpha phase is 0.5-1 micron; the grain size of the beta phase is 0.1-0.3 microns; and the intensity, the toughness and the corrosion resistance are greatly improved.

Owner:YANSHAN UNIV

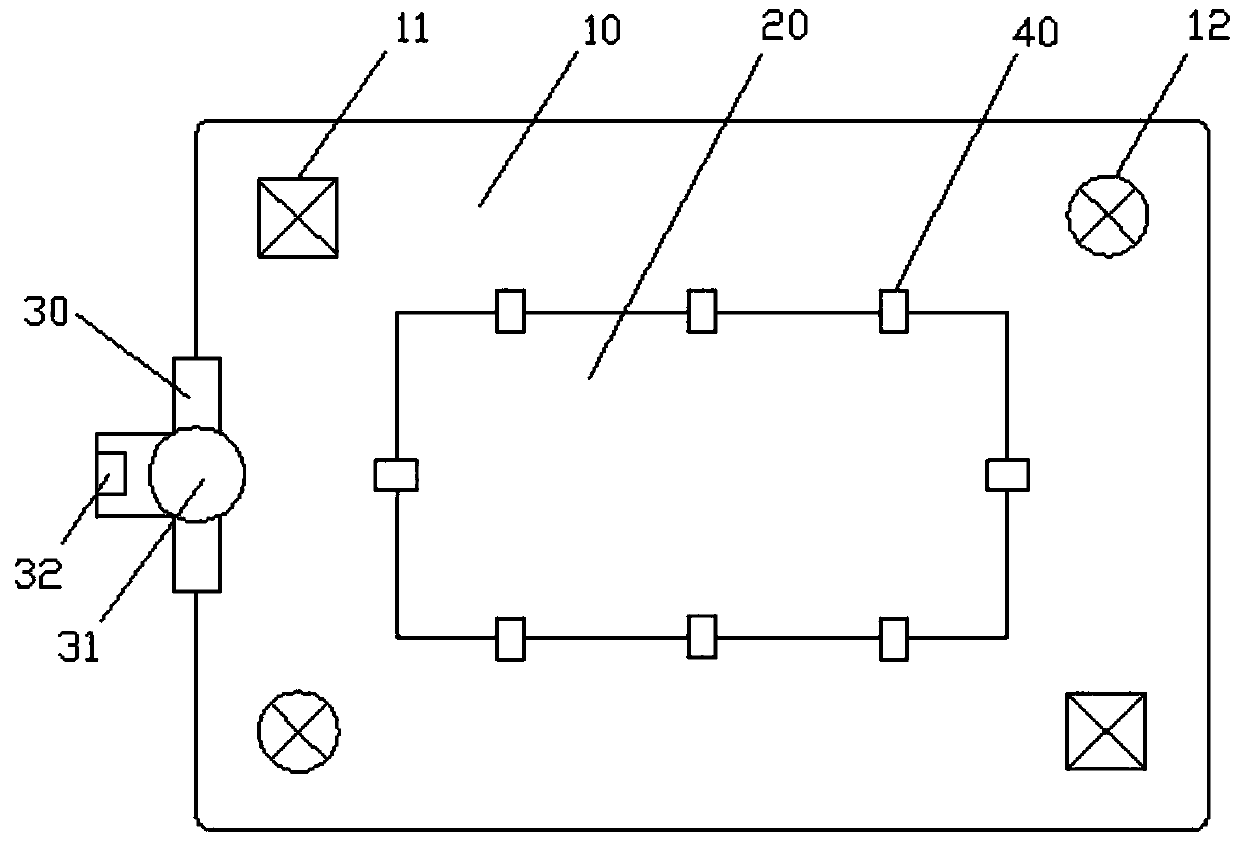

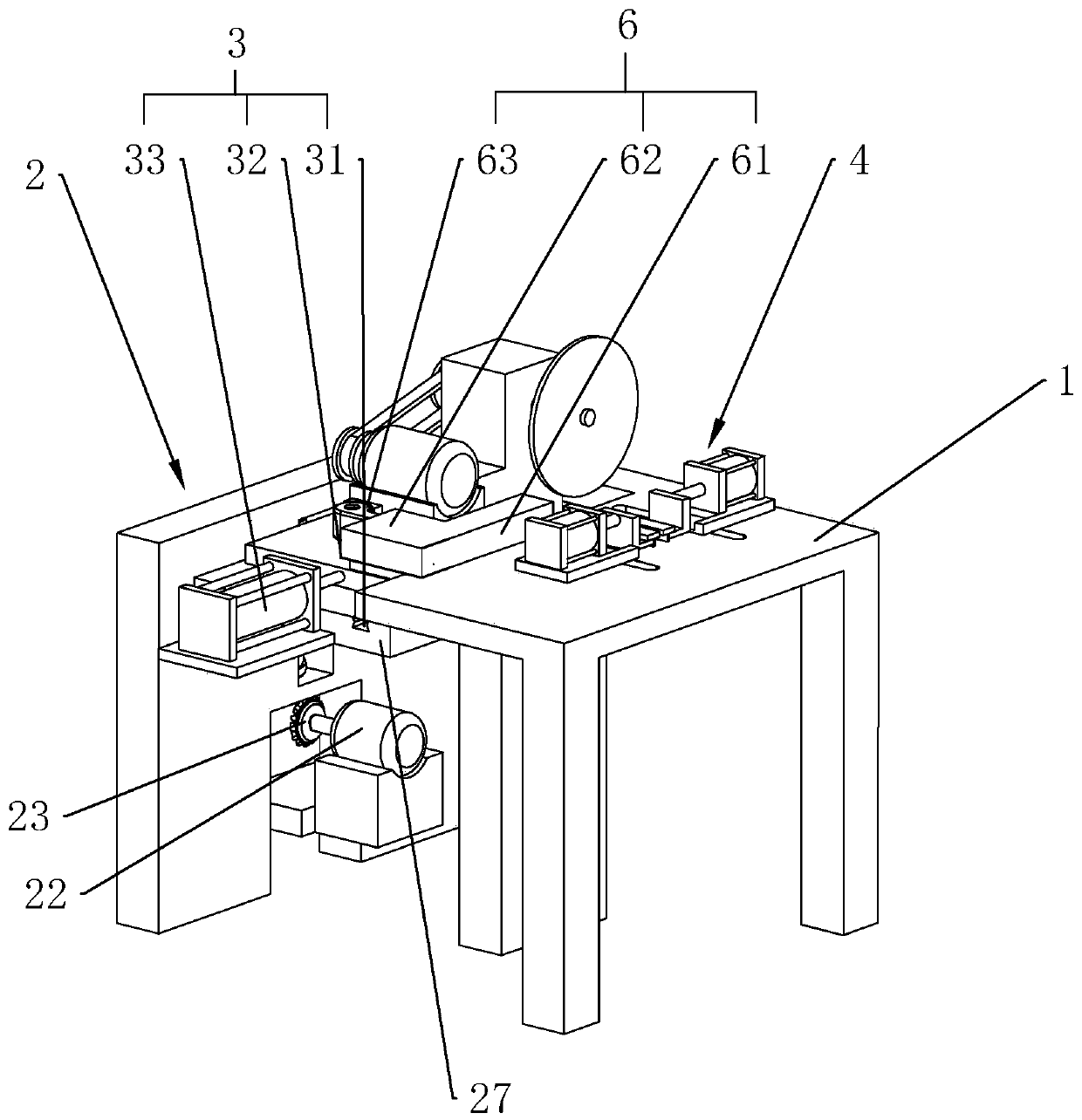

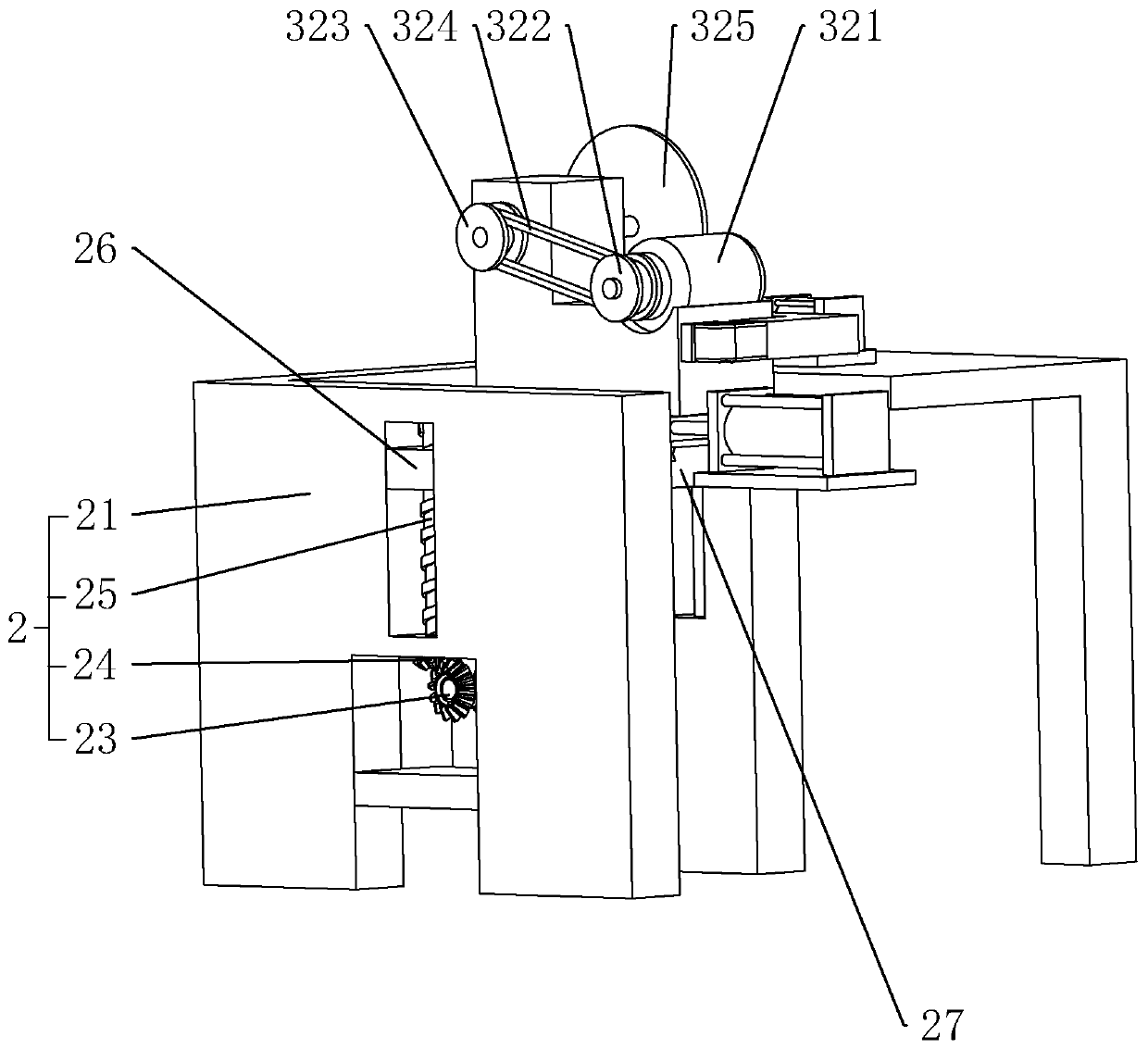

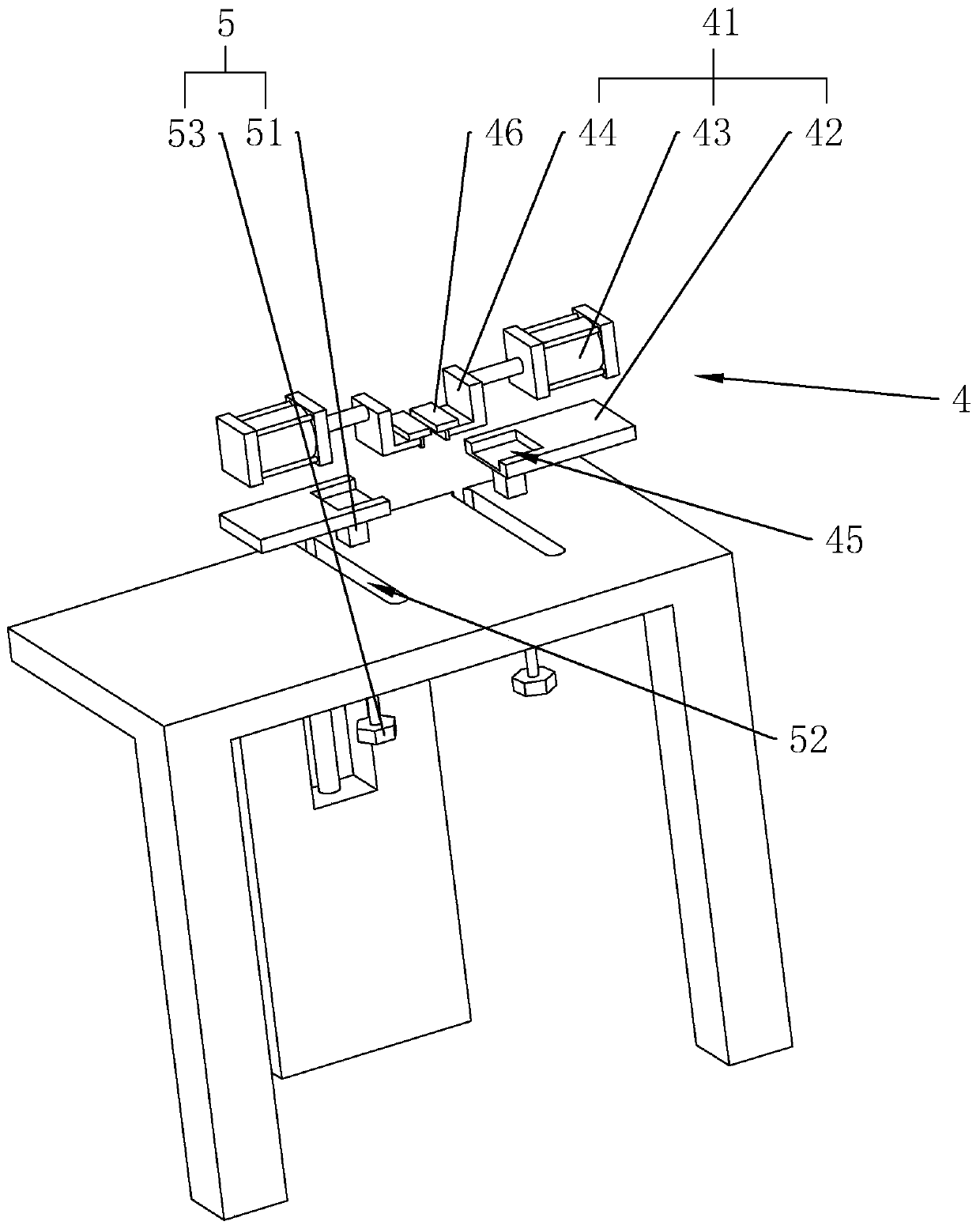

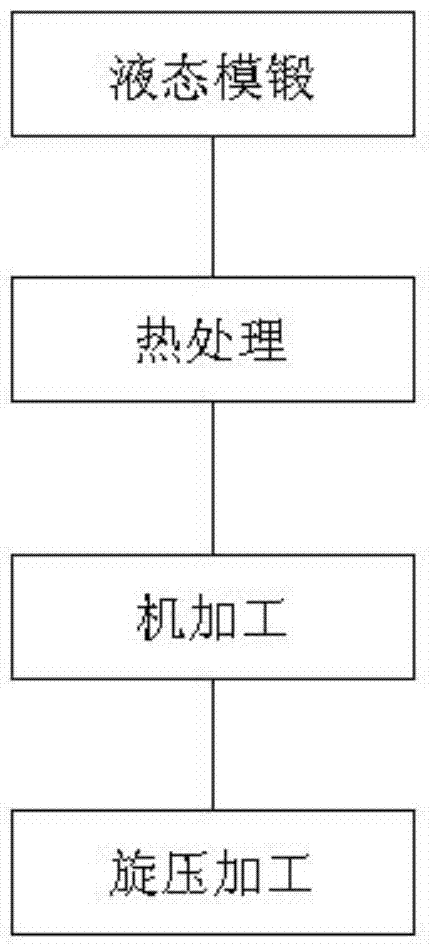

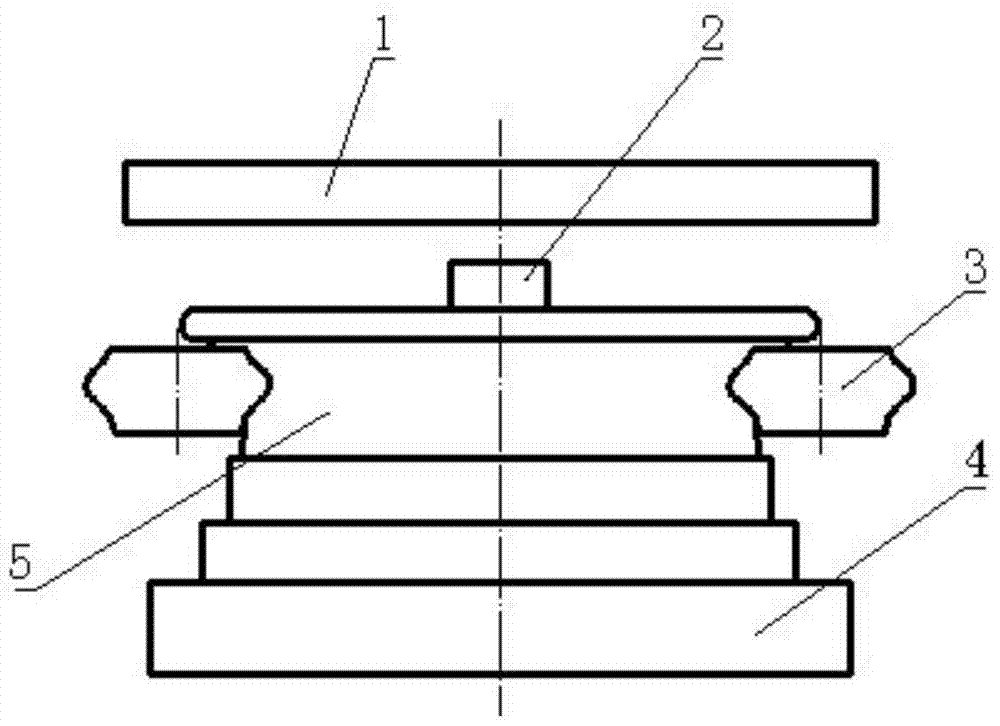

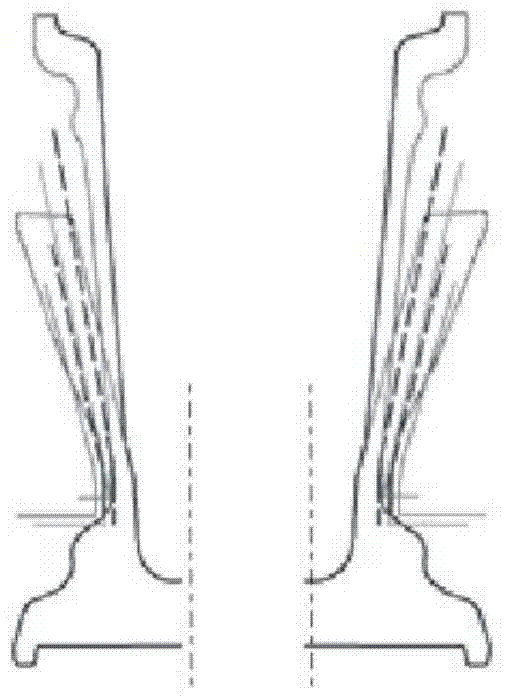

A liquid die forging and spinning processing system for aluminum alloy wheels

ActiveCN104551691BHigh tissue densityImprove mechanical propertiesOther manufacturing equipments/toolsMachining systemAlloy wheel

The invention relates to an aluminum alloy wheel liquid forging and spinning processing system, which comprises liquid forging equipment, a heat treatment device, a machining device and a spinning device, wherein aluminum alloy wheel workblanks produced by a liquid forging machine sequentially pass through the heat treatment device, the machining device and the spinning device. The aluminum alloy wheel liquid forging and spinning processing system has the advantages that the liquid forging is utilized for improving the spoke performance, and the spinning processing is utilized for improving the wheel rim performance, so that the integral performance of a wheel product is improved, the product performance is improved, the rejection rate is reduced, the cost is reduced, and the integral production efficiency is improved.

Owner:TIANJIN LIZHONG GRP CO LTD

Vesuvianite roast sausage and preparation method thereof

The invention relates to a vesuvianite roast sausage. The vesuvianite roast sausage is prepared from the following components in parts by weight: 545 parts of lean meat, 253 parts of fat, 8.6 parts of edible salt, 46 parts of white granulated sugar, 6.5 parts of monosidum glutamate, 2.5 parts of phosphate, 1 part of compound essence material, 0.5 part of five spice powder, 0.26 part of star aniseed powder, 0.46 part of white pepper powder, 0.31 part of liquorice root powder, 0.25 part of cinnamon powder, 0.62 part of sodium erythorbate, 0.013 part of sodium nitrite, 0.014 part of monascus color, 10 parts of potato flour, 5 parts of protein isolate, 1.7 parts of garlic powder, and 1.1 parts of bitter gourd flower. The vesuvianite roast sausage has the advantages that the bitter gourd powder has the effects of clearing heat and detoxifying, beautifying and tenderizing skin, decreasing blood glucose, nourishing blood and liver and the like, and the garlic has certain spicy taste and can cover the bitter flavor of bitter gourd, so that the influence to original mouth feel of the roast sausage is avoided, and the vesuvianite roast sausage is well received by consumers.

Owner:NANJING JINSHIPENG COMMERCE & TRADE CO LTD

2a12 aluminum alloy casting process

The invention relates to a 2Al2 aluminum alloy casting process. Firstly, intermediate alloys including a copper-aluminum alloy, an aluminum-manganese alloy and an aluminum-titanium alloy are prepared and smelted; then pure aluminum is arranged in a crucible, the copper-aluminum alloy, the aluminum-manganese alloy and the aluminum-titanium alloy are added in batch and in sequence, and sufficient stirring while adding is carried out; magnesium metal is added into the crucible, and aluminum alloy liquid is prepared; the aluminum alloy liquid is subject to refining, slag removal and modification treatment; after sampling analysis is qualified, pouring is carried out, and crude workpieces are prepared; the crude workpieces are settled and corrected; and the crude workpieces are arranged in an aging oven to be subject to aging treatment, and a finished product is prepared through slinging treatment and machining. The 2Al2 aluminum alloy casting process has the beneficial effects that operation is convenient, the workpieces are molded through casting, raw materials can be saved, the production cost is reduced, the casting tissue density is good, the degree of finish is high, the workpiece quality is good, the size deformation is small, the finished product rate is high, and the production efficiency is high.

Owner:喀左金牛机电设备科技有限公司

A kind of preparation method of lead-based layered composite material

The invention discloses a method for preparing a lead-base layer-shaped composite material and belongs to the technical field of preparing composite materials. Metal sheets of different specifications are used as inner core reinforcing bodies, a low-pressure casting method is used for enabling lead and alloy materials of the lead to wrap the metal sheets with inner cores of different specifications, and therefore the metallurgy-combined lead-base layer-shaped composite material is prepared. The lead-base layer-shaped composite material produced through a low-pressure casting technology is good in mold filling and feeding effect, the material organization of the produced lead-base composite material is compact, the mechanical property of the product is high, and the combining rate of compound interface layers can reach more than 95 percent. Compared with a traditional lead-base composite material preparing method, one-time forming can be achieved through the low-pressure casting method, the technological process is shortened, the production efficiency of the product is greatly improved, and labor intensity is lowered.

Owner:KUNMING HENDERA SCI & TECH

Welding manufacturing method of large-scale cast-welded structure hoop cable clamp

ActiveCN110935994BImprove yieldHigh tissue densityProcess efficiency improvementWelding accessoriesStructural engineeringStress relief

The welding manufacturing method of the large-scale cast-welding structure loop cable clamp of the present invention adopts welding materials and welding methods that match the cable clamp body and ear plates, controls the preheating before welding and the interlayer temperature, and selects appropriate welding process parameters to The cross cable lugs, membrane cable lugs and strut lugs are welded to the ring cable clamp body, which not only ensures the mechanical properties of the welded joints, but also greatly improves the production efficiency and saves manufacturing time; adopts groove design and welding sequence control Measures such as these ensure the manufacturing and installation accuracy of the weld seam of the hoop and cable clamp and reduce welding deformation; the method of overall stress relief annealing after welding reduces the internal stress of the weld seam and the entire cable clamp.

Owner:JULI SLING

Anti-lifting combined type fixed slide way of sintering machine and manufacturing method of anti-lifting combined type fixed slide way

The invention discloses a sintering machine anti-lifting combined type fixed slideway and a manufacturing method thereof.The sintering machine anti-lifting combined type fixed slideway comprises a first slideway, a second slideway, a third slideway and a fourth slideway, the first slideway is provided with a first composite plate composed of a first wear-resisting plate and a first steel plate, and the first wear-resisting plate and the first steel plate are connected through positioning fastening bolts; the first end of the first composite plate is provided with an anti-lifting structure, the second end of the first composite plate is provided with a chamfer, and the first composite plate is provided with an oil hole and a sealing plate fixing hole; an anti-lifting structure is designed on the first slide way, meanwhile, the first slide way is fully welded to the slide way base, chamfering treatment is also carried out on edges and corners of the second slide way and the third slide way on the advancing stress face of the trolley, and damage caused by an elastic sliding plate of the sintering machine trolley is effectively prevented; the fixed slide way adopts a double-metal-plate structural design, a wear-resisting plate is high in hardness and meets the process requirement, however, due to the fact that the hardness is too high and flexibility is lacked, the requirement for flexibility is just met when a steel plate is used as a base plate, and the design is the original intention of the double-layer composite plate.

Owner:SD STEEL RIZHAO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com