A microcrystalline high-strength corrosion-resistant titanium alloy pipe and its preparation method

A titanium alloy and pipe technology, which is applied in the field of microcrystalline high-strength and corrosion-resistant titanium alloy pipe and its preparation field, can solve the problems of complicated preparation methods, low strength, coarse structure, etc. Small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Forged tube billet: using sponge titanium Ti80 (brand Ti-6Al-3Nb-2Zr-1Mo) as raw material, the measured ratio of alloying elements is Al: 6.1%, Nb: 2.5%, Zr: 2.0%, Mo : 1.1%, Fe: 0.03%, Si: 0.02%, and the balance is Ti. It is smelted in a vacuum consumable furnace and smelted three times to achieve uniform composition. After 5 to 8 times of drawing-compression forging to form a blank, then peel off the skin to remove the 0.5-1mm surface layer to obtain a Ф92mm round tube blank, that is, the tube blank; the measurement found that the volume percentage of the β phase in the tube blank is less than 7%, which is close to α Titanium alloy;

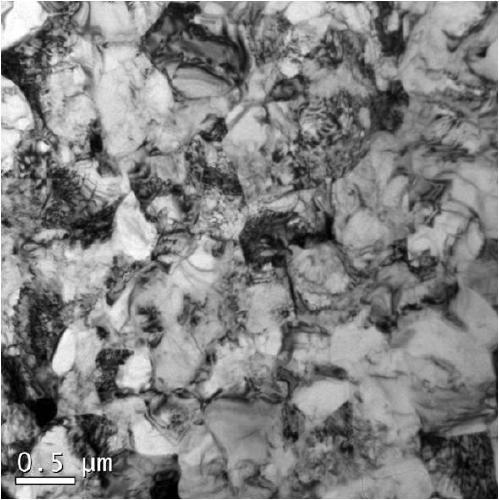

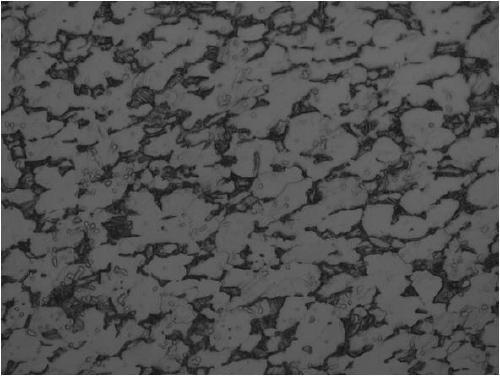

[0029] (2) Preparation of capillary tube: send the tube billet into the annular heating furnace, heat it with the furnace to 995 ° C for 70 minutes, and then roll it through cross-rolling and piercing, and cool it by external spraying and internal spraying to make the capillary tube; it is found that the capillary tube The microstr...

Embodiment 2

[0035] (1) Forged tube billet: Ti80 (brand Ti-6Al-3Nb-2Zr-1Mo) is used as the sponge titanium raw material, and the ratio of alloy elements measured is Al: 6.0%, Nb: 2.4%, Zr: 1.9%, Mo : 0.9%, Fe: 0.04%, Si: 0.02%, and the rest is Ti. It is smelted in a vacuum consumable furnace and smelted three times to achieve uniform composition. After 5 to 8 times of drawing-compression forging to form a blank, then peel off the skin to remove the 0.5-1mm surface layer to obtain a Ф115mm round tube blank, that is, the tube blank; the measurement found that the volume percentage of the β phase in the tube blank is less than 7%, which is close to α Titanium alloy;

[0036] (2) Preparation of capillary tube: send the tube billet into the annular heating furnace, heat it to 1015°C and keep it for 70 minutes, then roll it through cross-rolling and piercing, and cool it by external spraying and internal spraying to make capillary tube; the measurement found that the microstructure of the capil...

Embodiment 3

[0042] (1) Forged tube billet: Ti80 (brand Ti-6Al-3Nb-2Zr-1Mo) is used as the sponge titanium raw material, and the measured chemical composition content (wt.%) of alloy elements is: Al: 6.0%, Nb: 2.8%, Zr : 2.0%, Mo: 1.1%, Fe: 0.03%, Si: 0.02%, and the rest is Ti. It is smelted in a vacuum consumable furnace and smelted three times to achieve the purpose of uniform composition. After 5 to 8 times of drawing-compression forging to form a blank, and then peel off the skin to remove the 0.5-1mm surface layer, the Ф96mm round tube billet is obtained, that is, the tube blank; the measurement found that the volume percentage of the β phase in the tube blank is less than 7%, which is close to α Titanium alloy;

[0043] (2) Preparation of capillary tube: send the tube billet into the annular heating furnace, heat it to 1030°C and keep it for 70 minutes, then roll it through cross-rolling and piercing, and cool it by external spraying and internal spraying to make the capillary tube; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com