Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

430 results about "Post annealing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

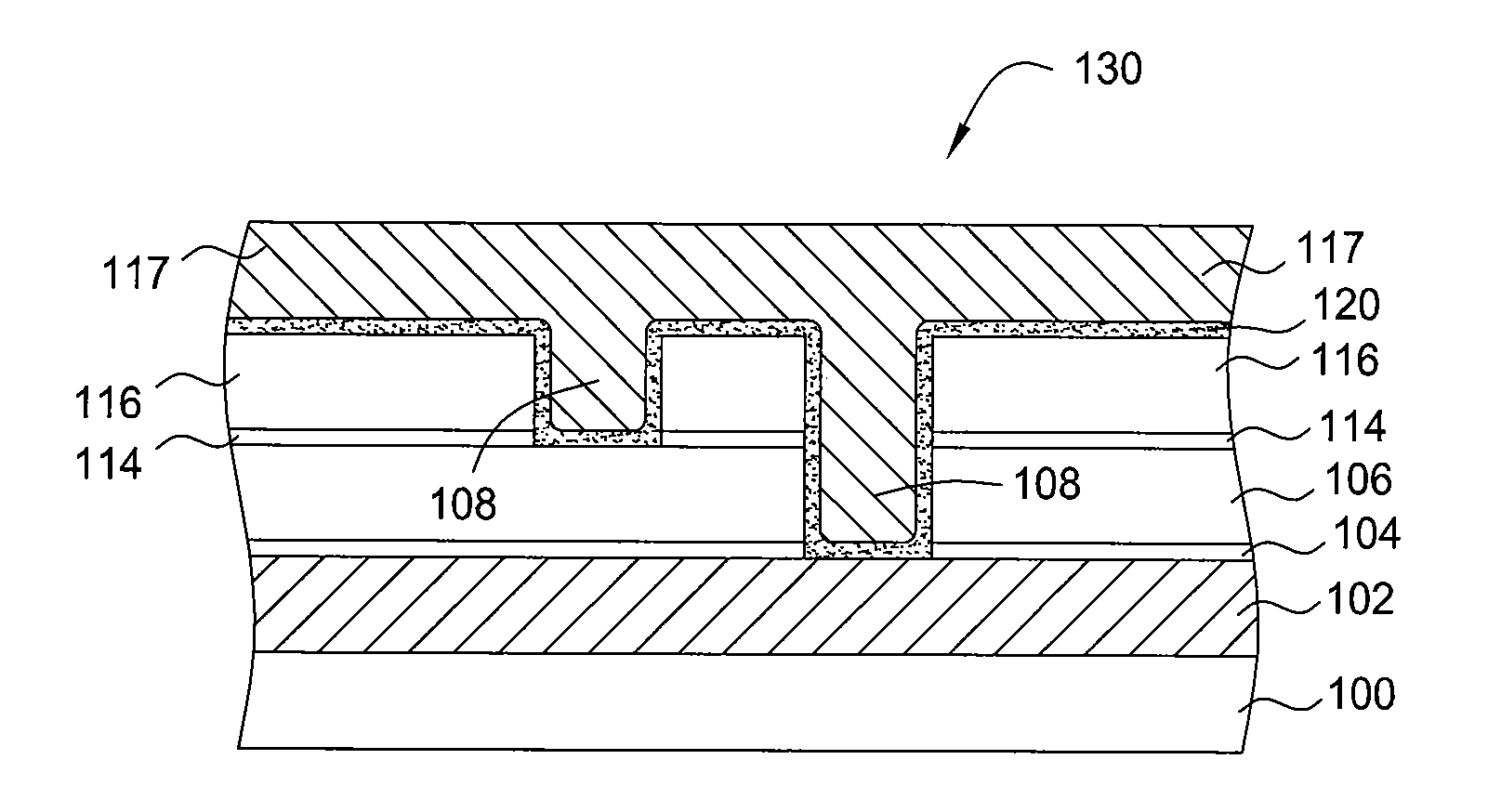

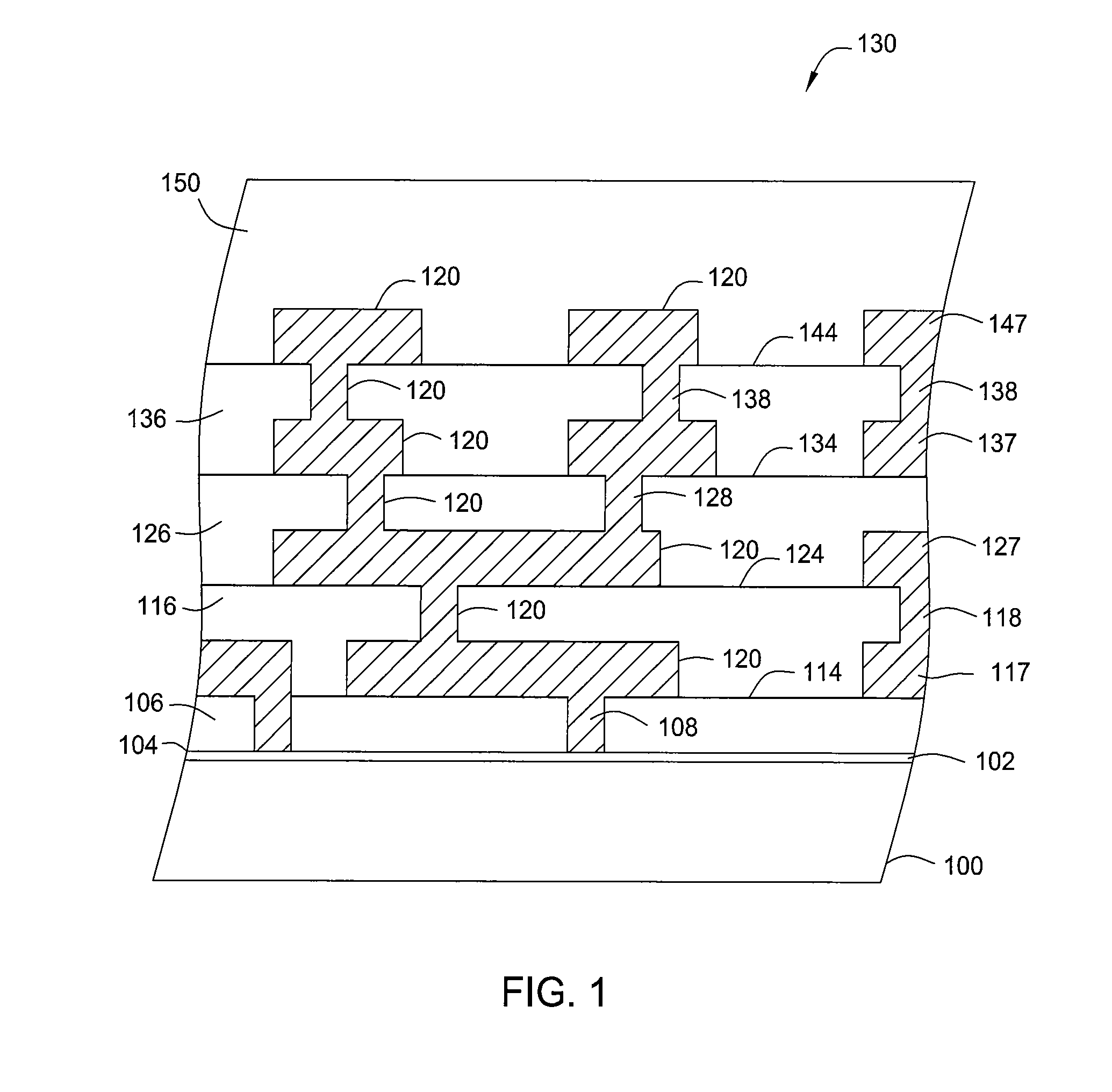

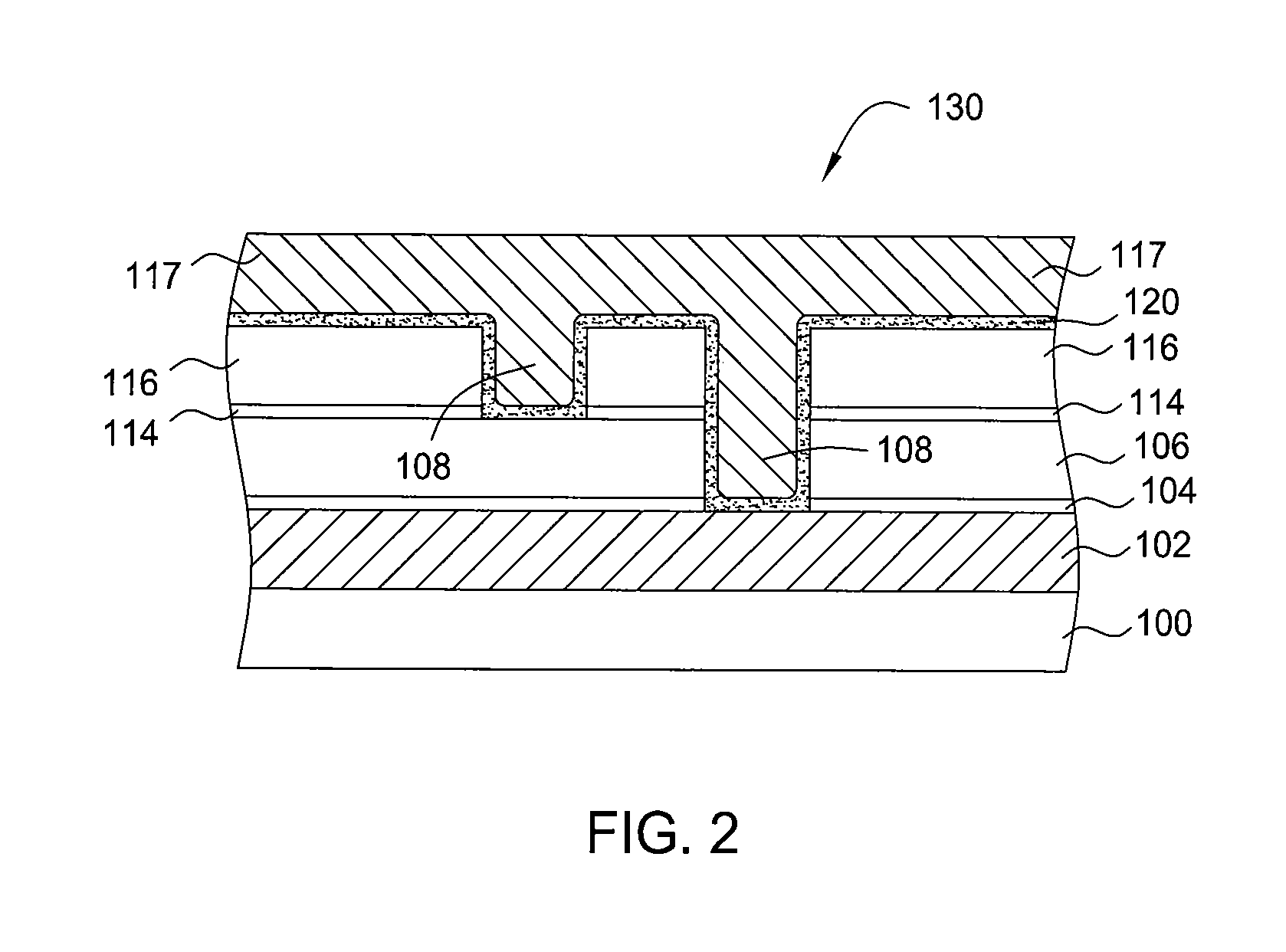

Method of forming a structure including silicon oxide

PendingUS20210143003A1Readily apparentSemiconductor/solid-state device manufacturingChemical vapor deposition coatingMetallurgyPhysical chemistry

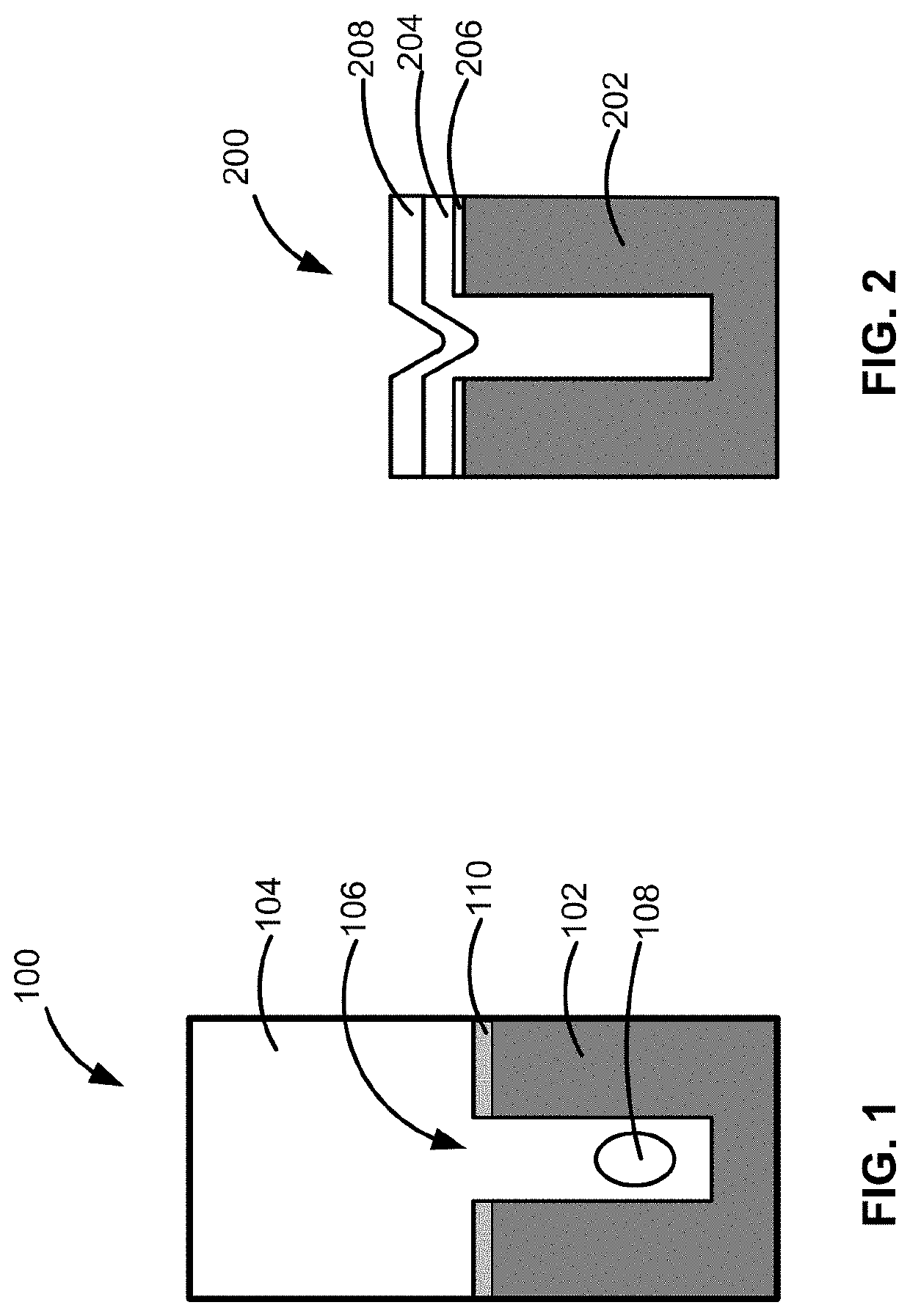

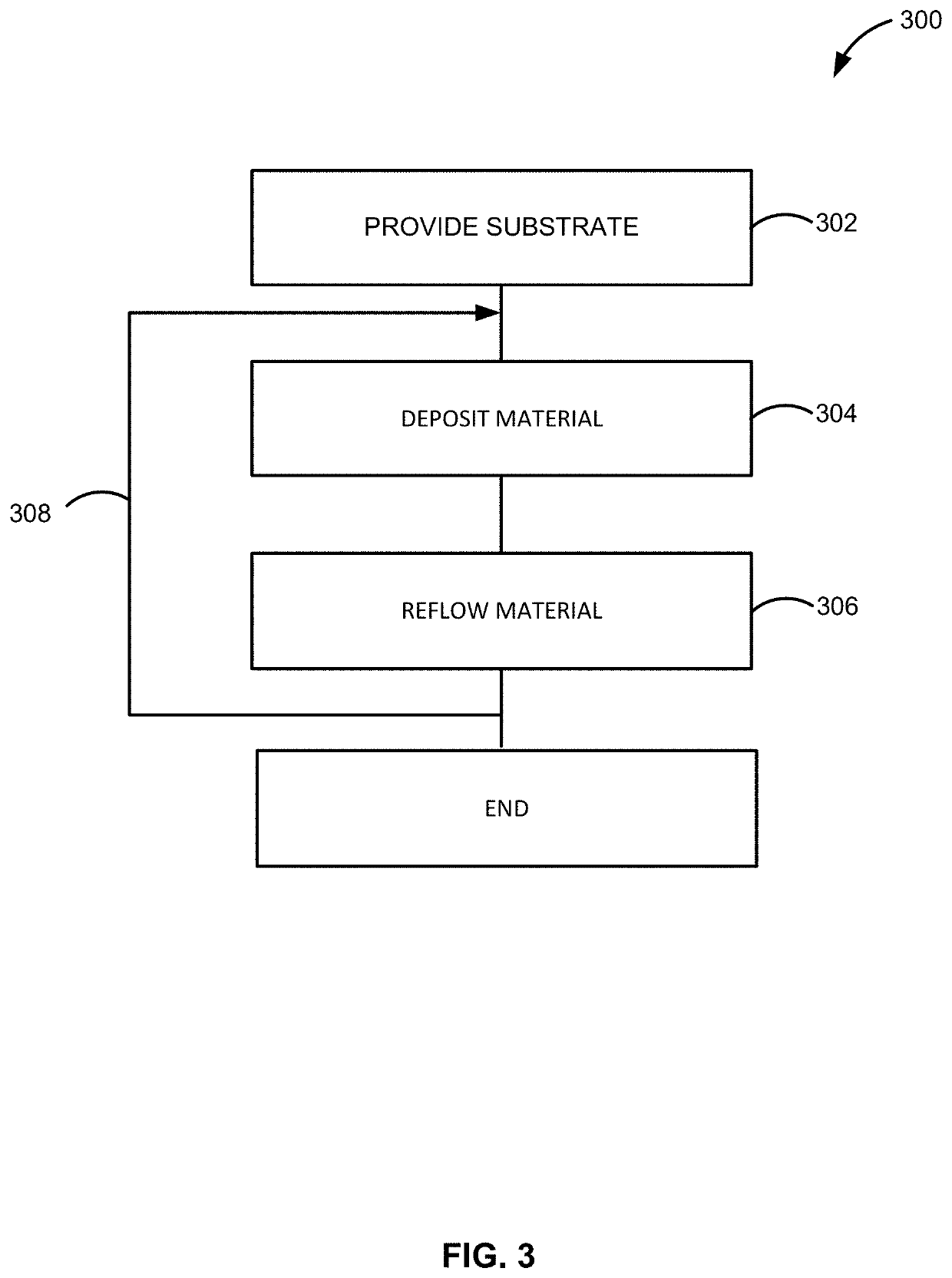

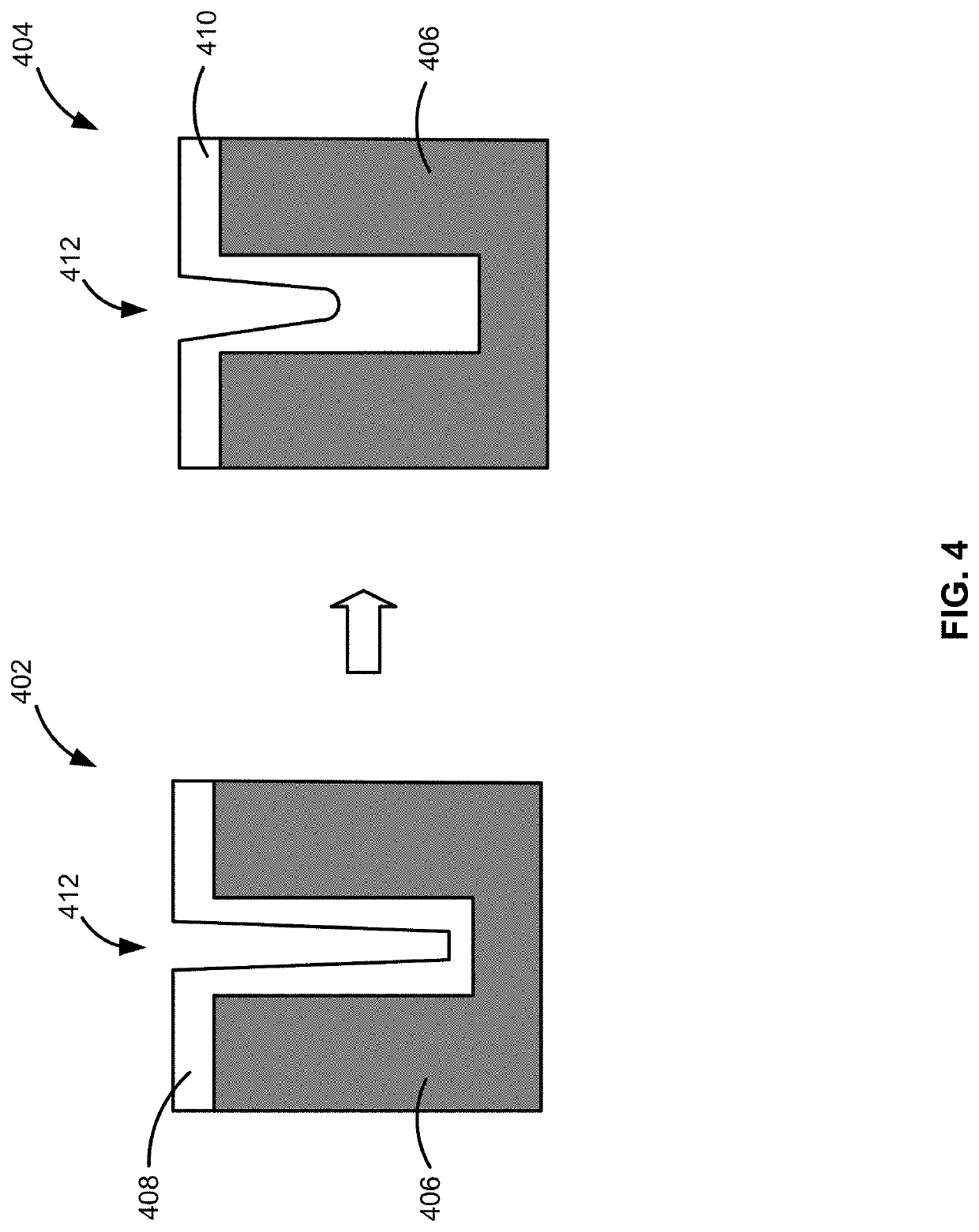

Methods for depositing on a surface of a substrate are disclosed. Exemplary methods include depositing a silicon oxide material using a cyclical deposition process, and reflowing the material during one or more of the step of depositing and a post-deposition anneal step. Structures including a layer of the material are also disclosed.

Owner:ASM IP HLDG BV

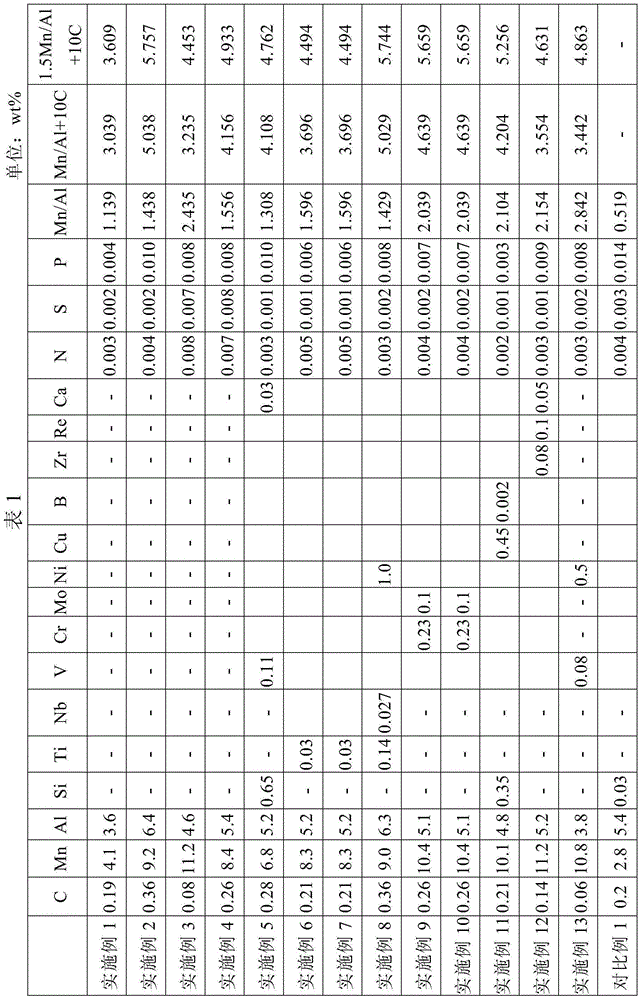

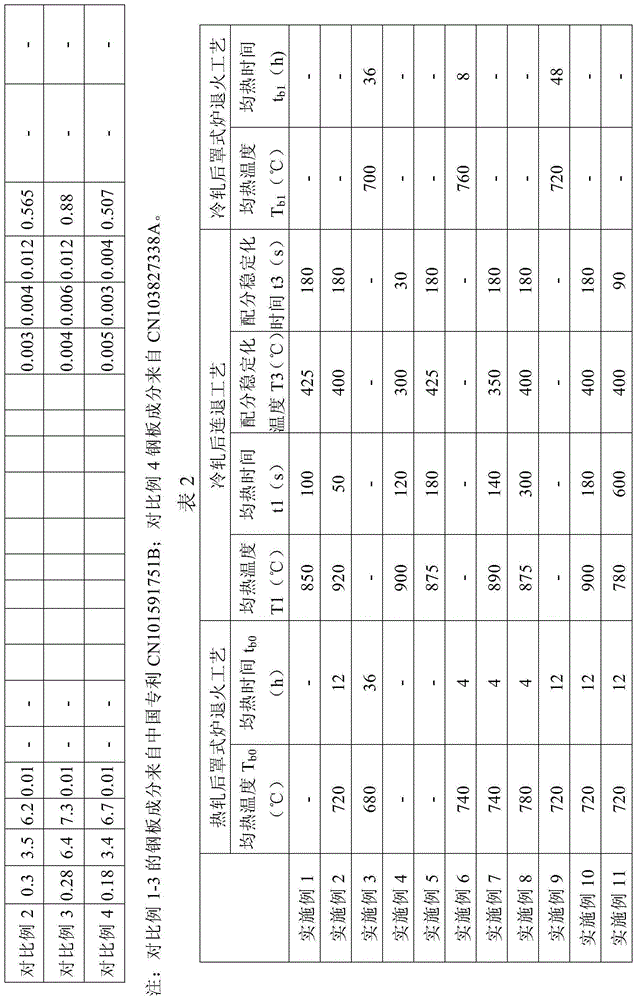

Ferrite low-density high-strength steel and manufacturing method thereof

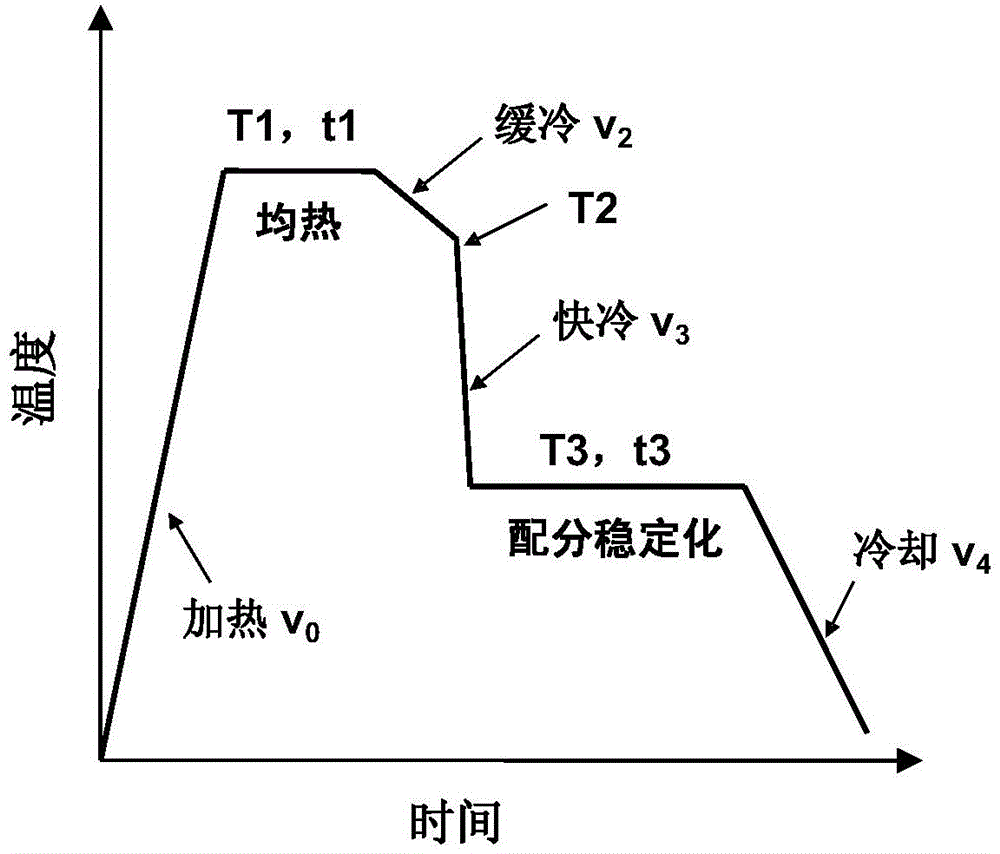

A ferrite low-density high-strength steel and manufacturing method thereof. The ferrite low-density high-strength steel chemical comprises the following chemical components composition by mass percentage: 0.05-0.40% of C, 4.0-12.0% of Mn, 3.0-7.0% of Al, no more than 0.02% of P, no more than 0.01% of S, no more than 0.01% of N, and the balance of Fe and inevitable impurity elements. The above elements satisfy the following relationship: 1.0<Mn / Al, 3.5 <1.5Mn / Al+10C, and Mn / Al + 10C <5.2 The manufacturing method comprises hot rolling, annealing, pickling, cold rolling and annealing to prepare the low-density high-strength steel plate. In addition to ferrite, the microstructure of the steel plate also contains 6-40% of residual austenite. The low-density high-strength steel plate has tensile strength no less than 800MPa, elongation no less than 25%, and density less than 7500kg / m<3>.

Owner:BAOSHAN IRON & STEEL CO LTD

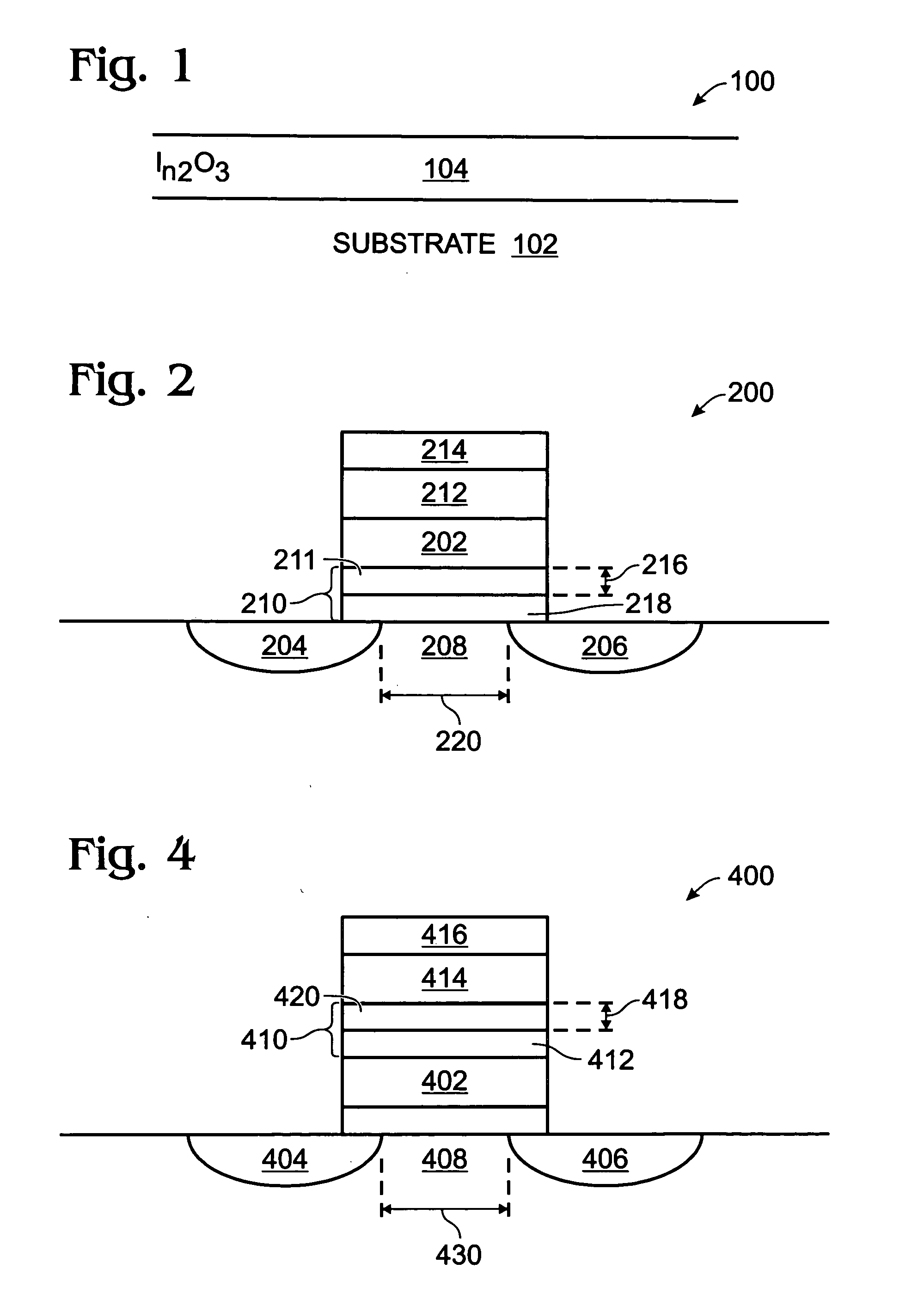

Method of making oxide thin film transistor array

InactiveUS8530273B2Improve economyImprove conductivitySolid-state devicesSemiconductor/solid-state device manufacturingOxide thin-film transistorRoom temperature

Owner:GUARDIAN GLASS LLC

Low-temperature high-strength, high-toughness steel and preparing method therefor

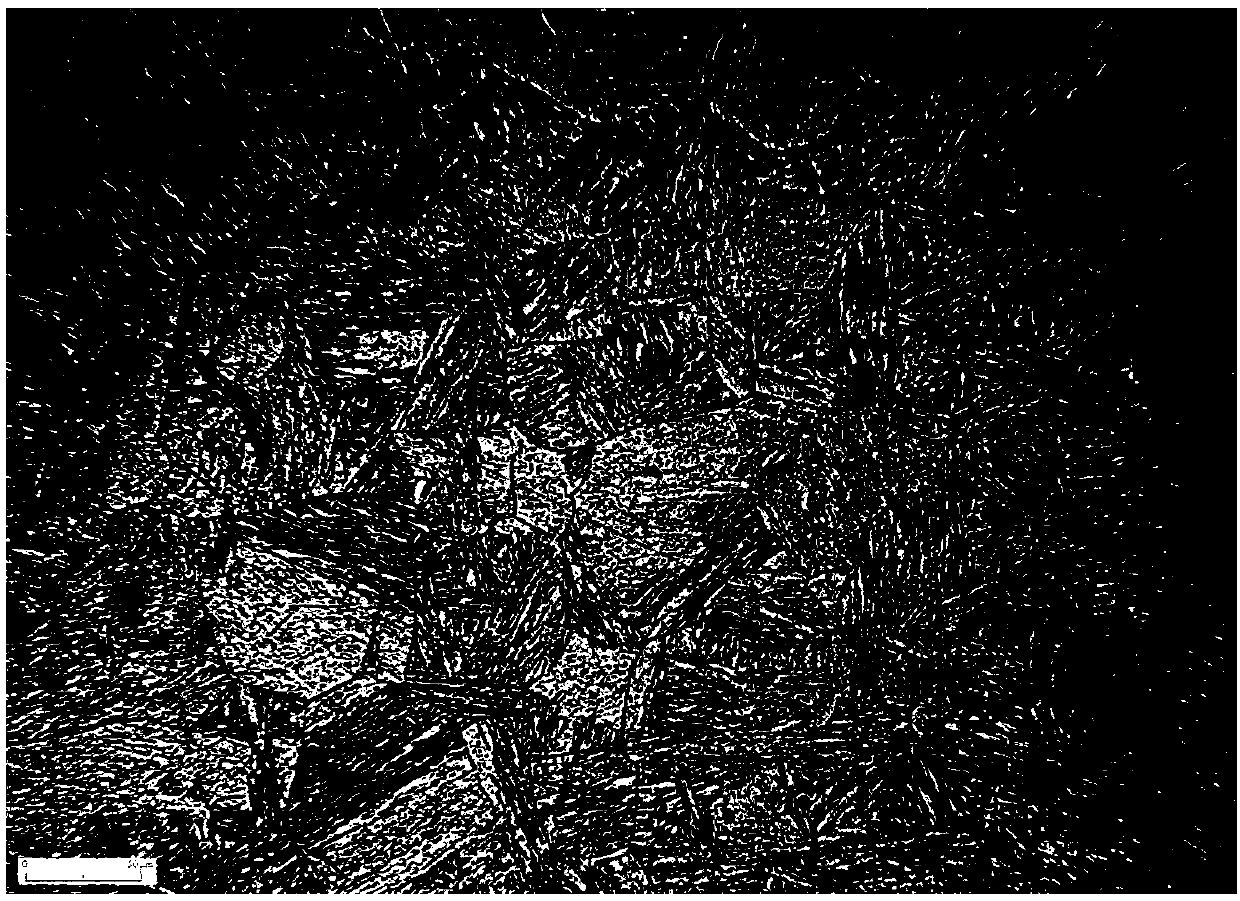

InactiveCN101024870AHigh strengthGuaranteed toughnessHeat treatment process controlLift systemThermal treatment

The invention relates to a low-temperature, high-intensity, high-toughness steel and the making method thereof, applicable to the environment down to -60 deg.C, adopting low-carbon Cr-Ni-Si-Mn-Mo-V alloy, and its chemical composition includes in mass percent (mass%): C: 0.16-0.24,Si:1.0-1.4, Mn:1.10-1.50,Cr:0.80-1.20,Ni:1.00- 1.40,Mo:0.20-0.40,V:0.05-0.20,S=<0.035,P=<0.035,Cu =<0.050, and the rest Fe. And its making method comprises: (1) smelting; (2) forging: heating at 1280-1320deg.C, where initial forging temperature: 1100-1250deg.C, final forging temperature >=850deg.C; annealing after forging, where heating temperature: 700+-30deg.C, and tapping temperature =<300deg.C; (3) thermal treatment: normalizing: air cooling at 930-950deg.C; tempering: air cooling at 790-720deg.C; quenching: oil cooling at 900-930deg.C; and tempering: air cooling at 200-260deg.C; (4) supersonic crack detection and magnetic particle crack detection. And it is especially applied to the materials for flying rings, hocks, pin shafts, etc, in the lifting systems of mechanical facilities.

Owner:RG PETRO MACHINERY GROUP

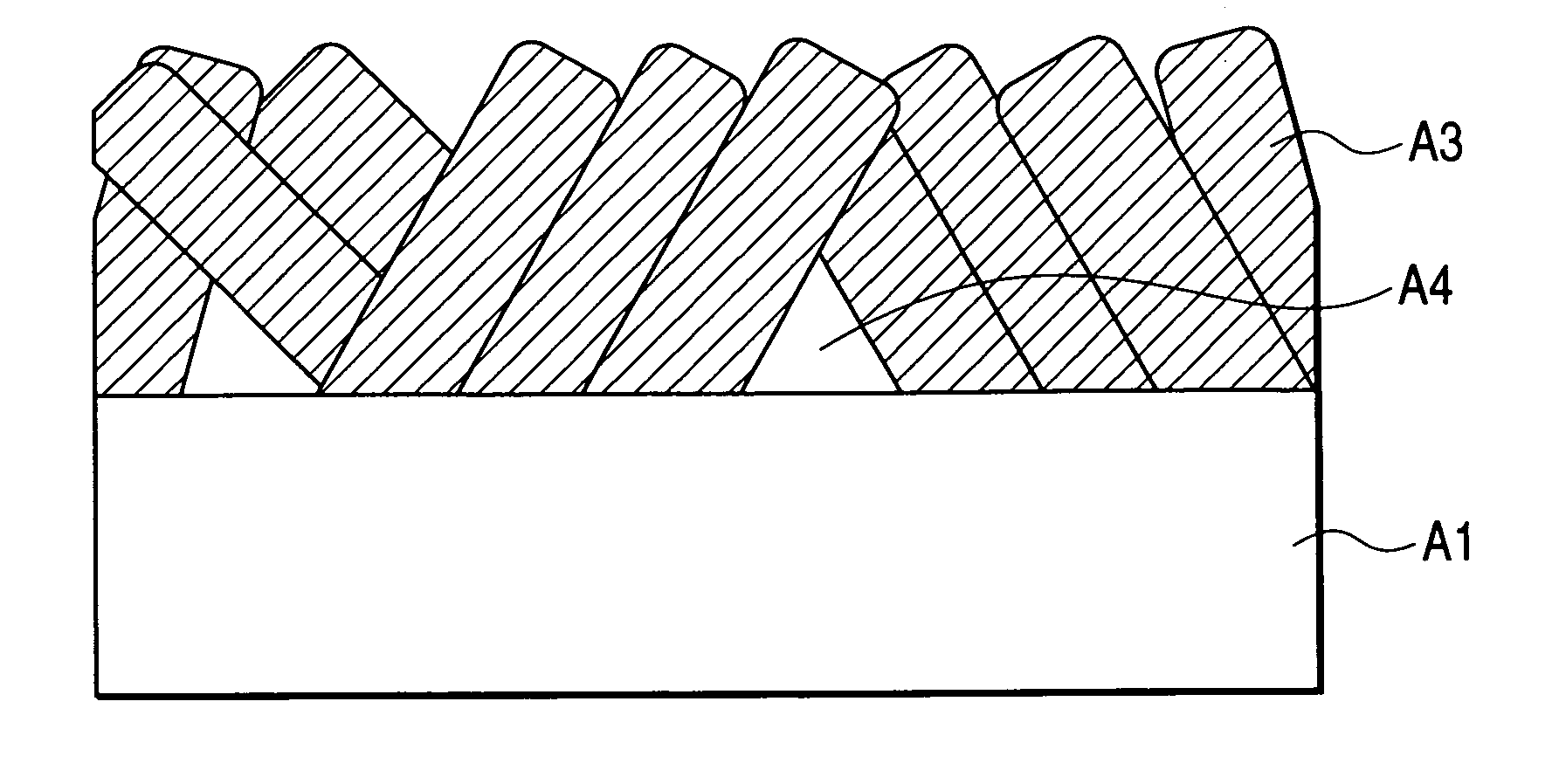

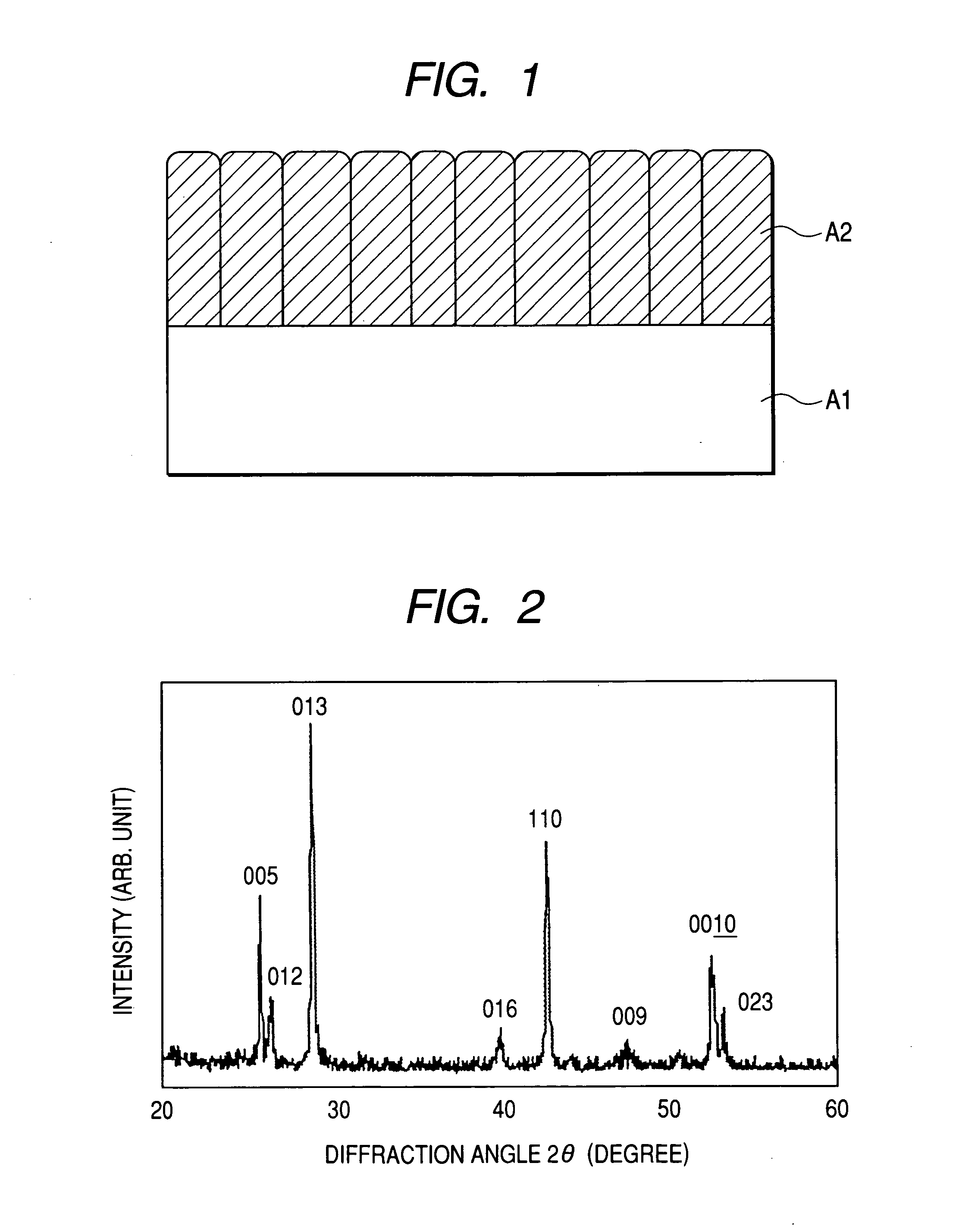

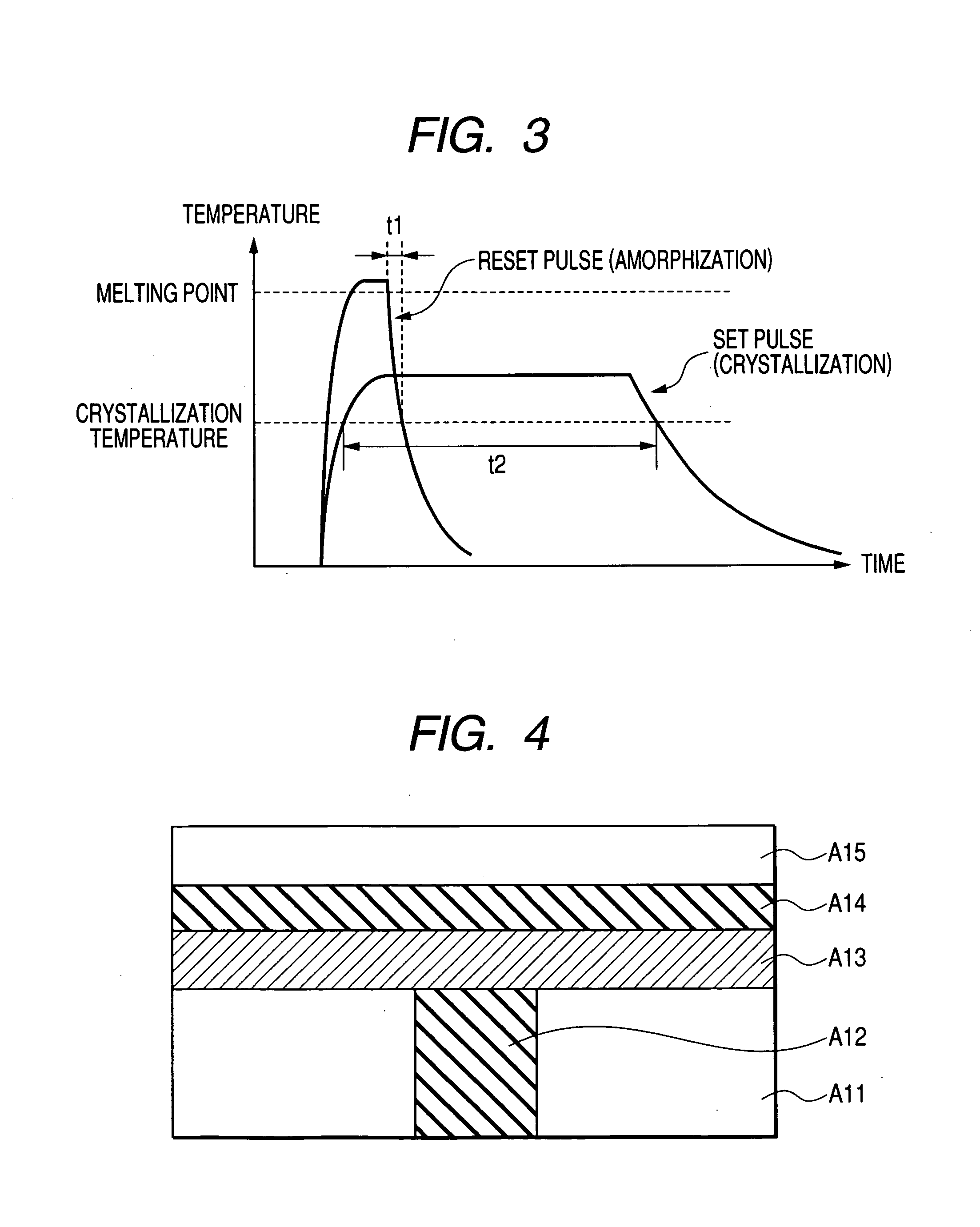

Semiconductor device and method of manufacturing the same

ActiveUS20060105556A1Non-uniform characteristicPrevent peelingVacuum evaporation coatingSolid-state devicesElectrical resistance and conductancePhase-change memory

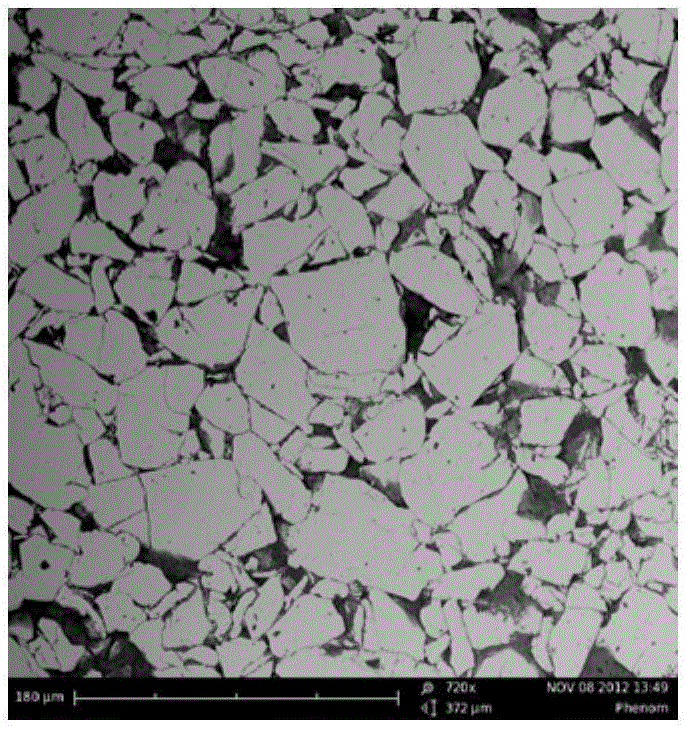

The annealing process at 400° C. or more required for the wiring process for a phase change memory has posed the problem in that the crystal grains in a chalcogenide material grow in an oblique direction to cause voids in a storage layer. The voids, in turn, cause peeling due to a decrease in adhesion, variations in resistance due to improper contact with a plug, and other undesirable events. After the chalcogenide material has been formed in an amorphous phase, post-annealing is conducted to form a (111)-oriented and columnarly structured face-centered cubic. This is further followed by high-temperature annealing to form a columnar, hexagonal closest-packed crystal. Use of this procedure makes it possible to suppress the growth of inclined crystal grains that causes voids, since crystal grains are formed in a direction perpendicular to the surface of an associated substrate.

Owner:RENESAS ELECTRONICS CORP

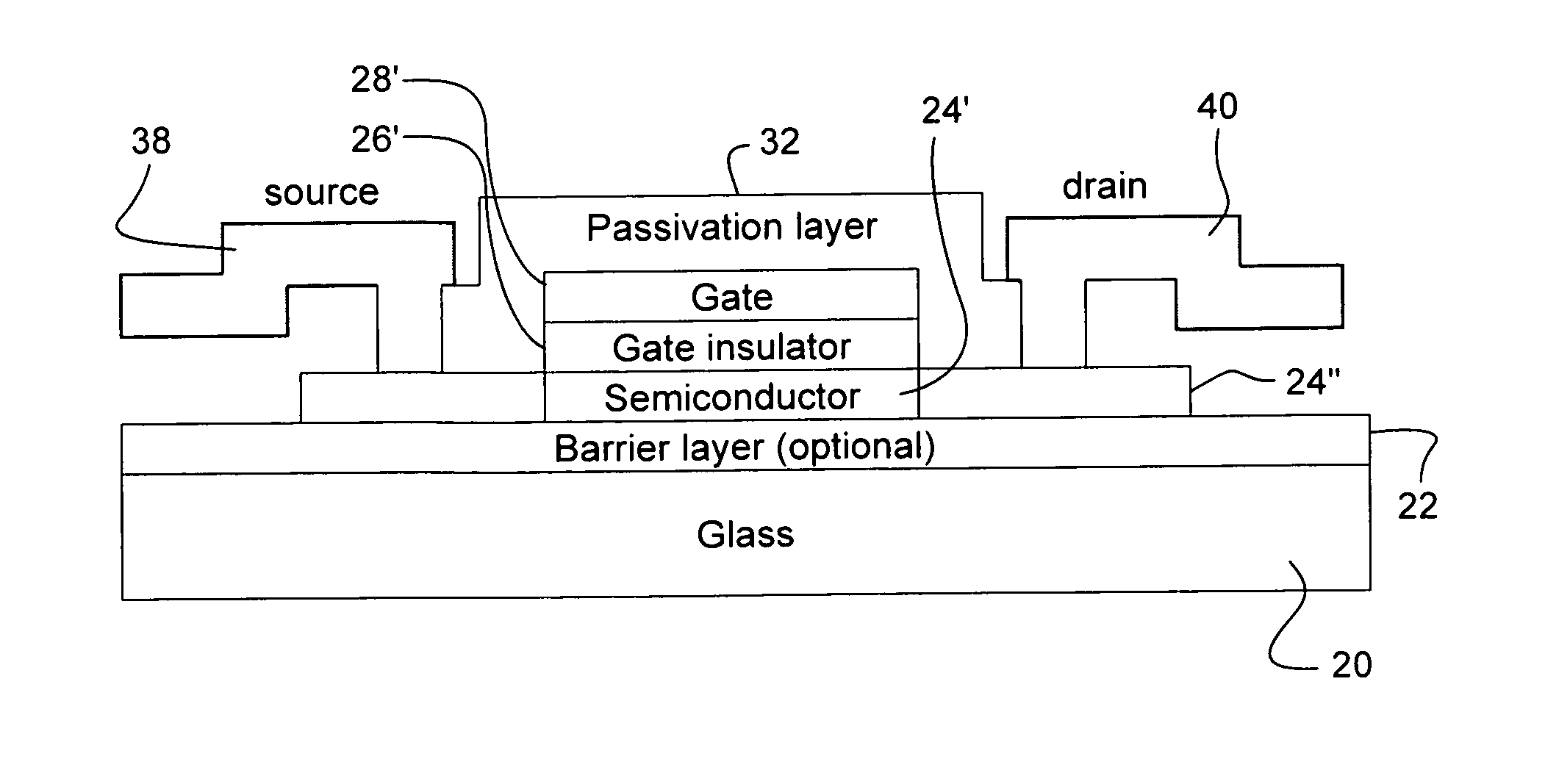

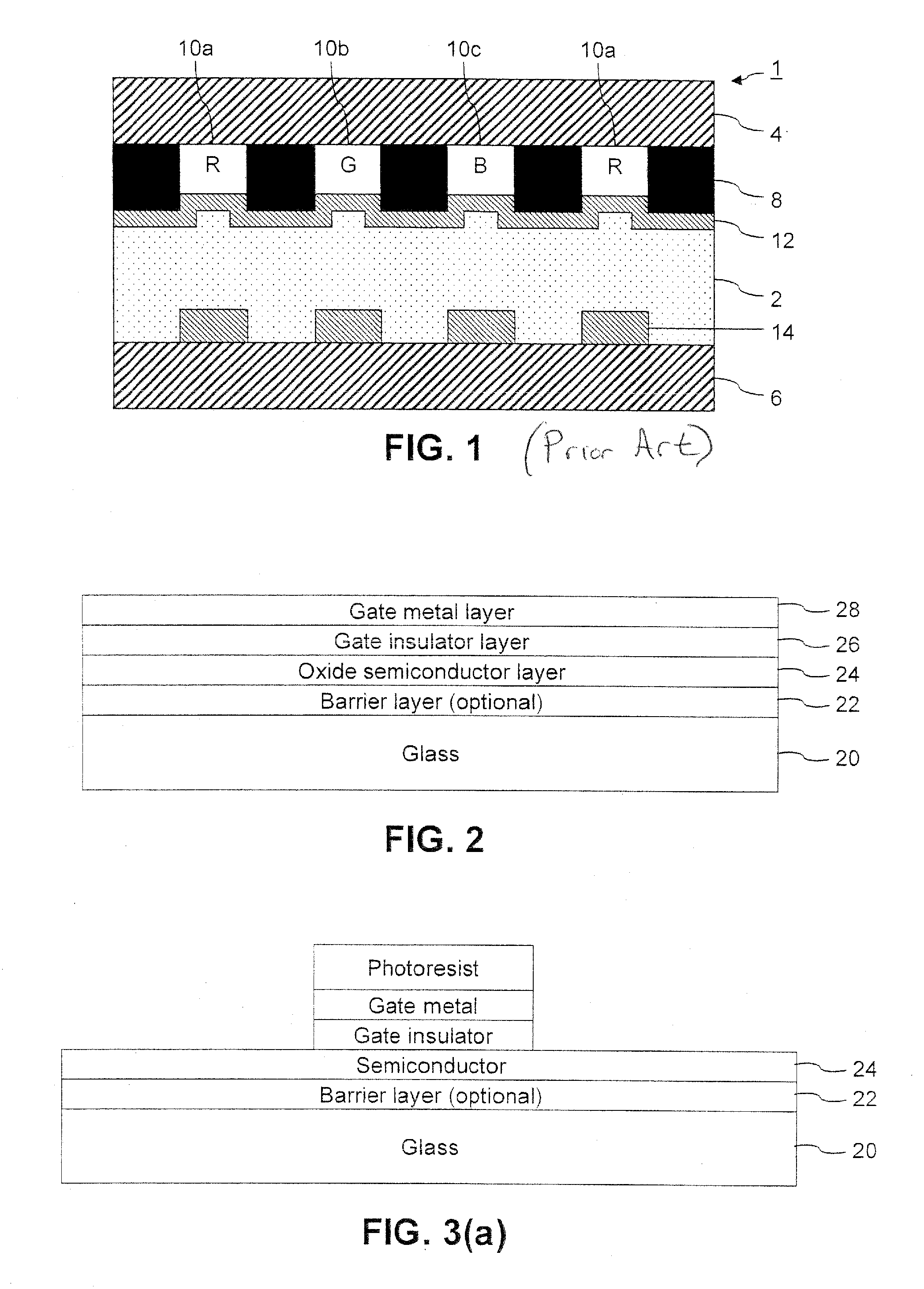

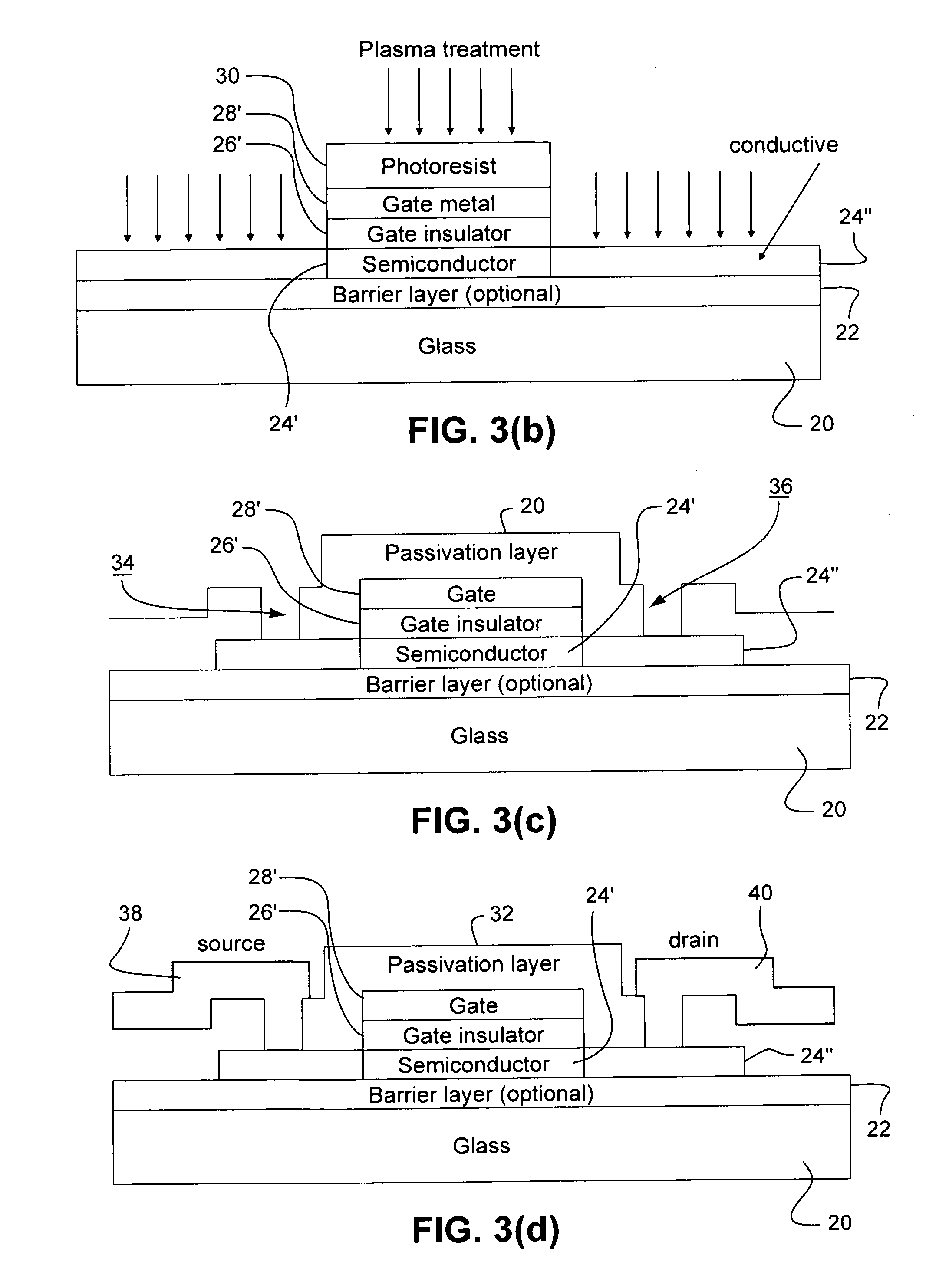

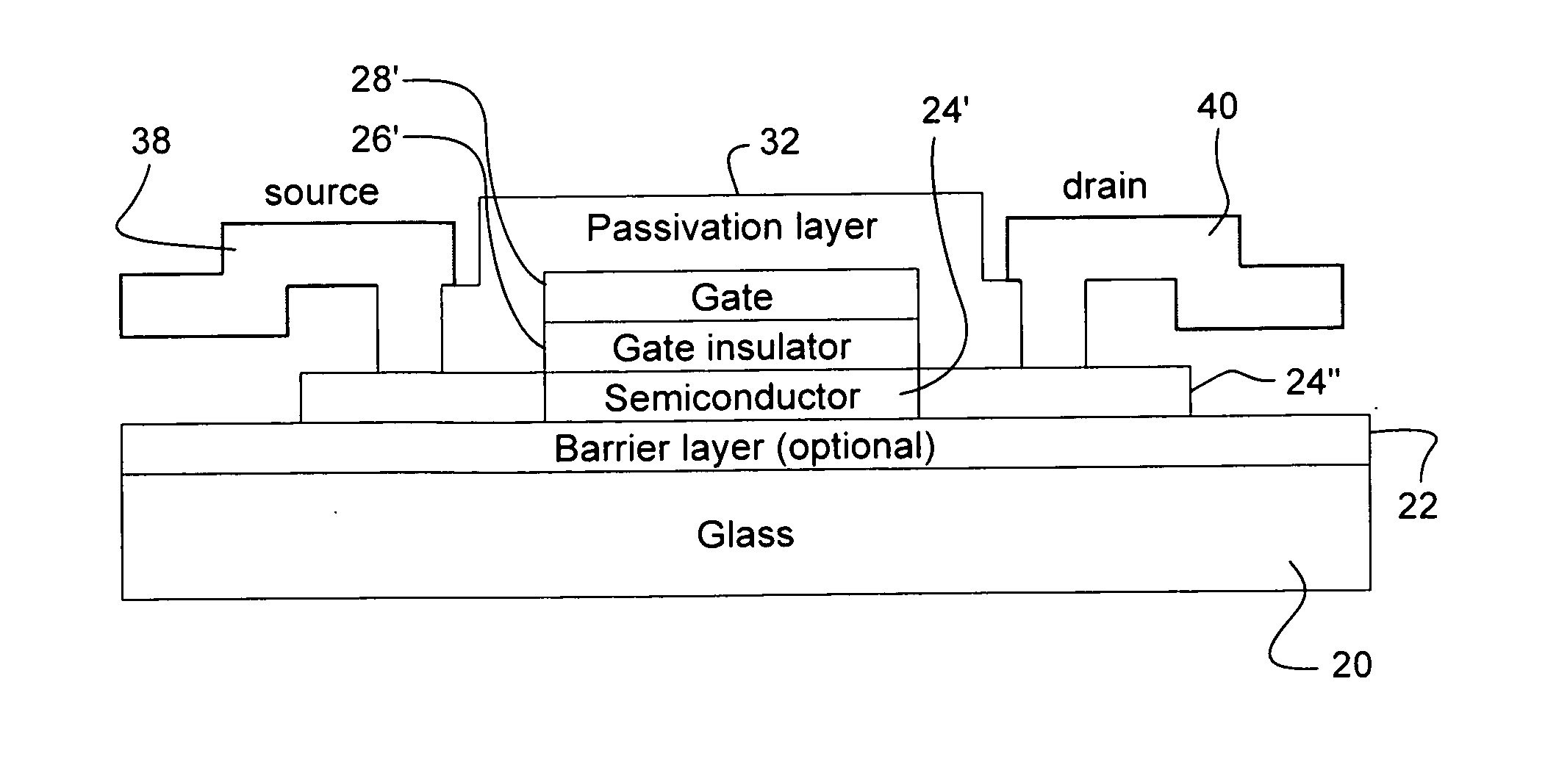

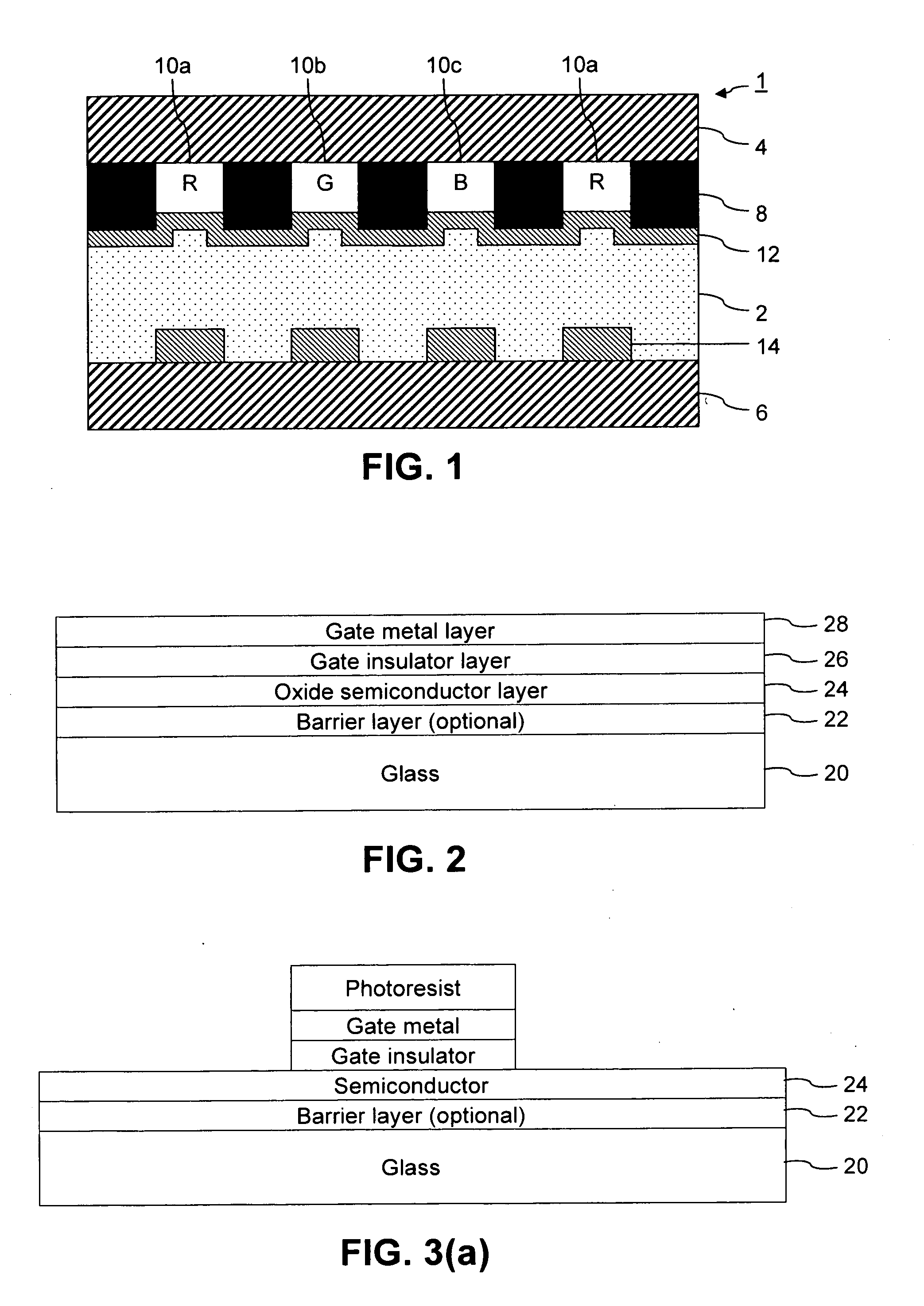

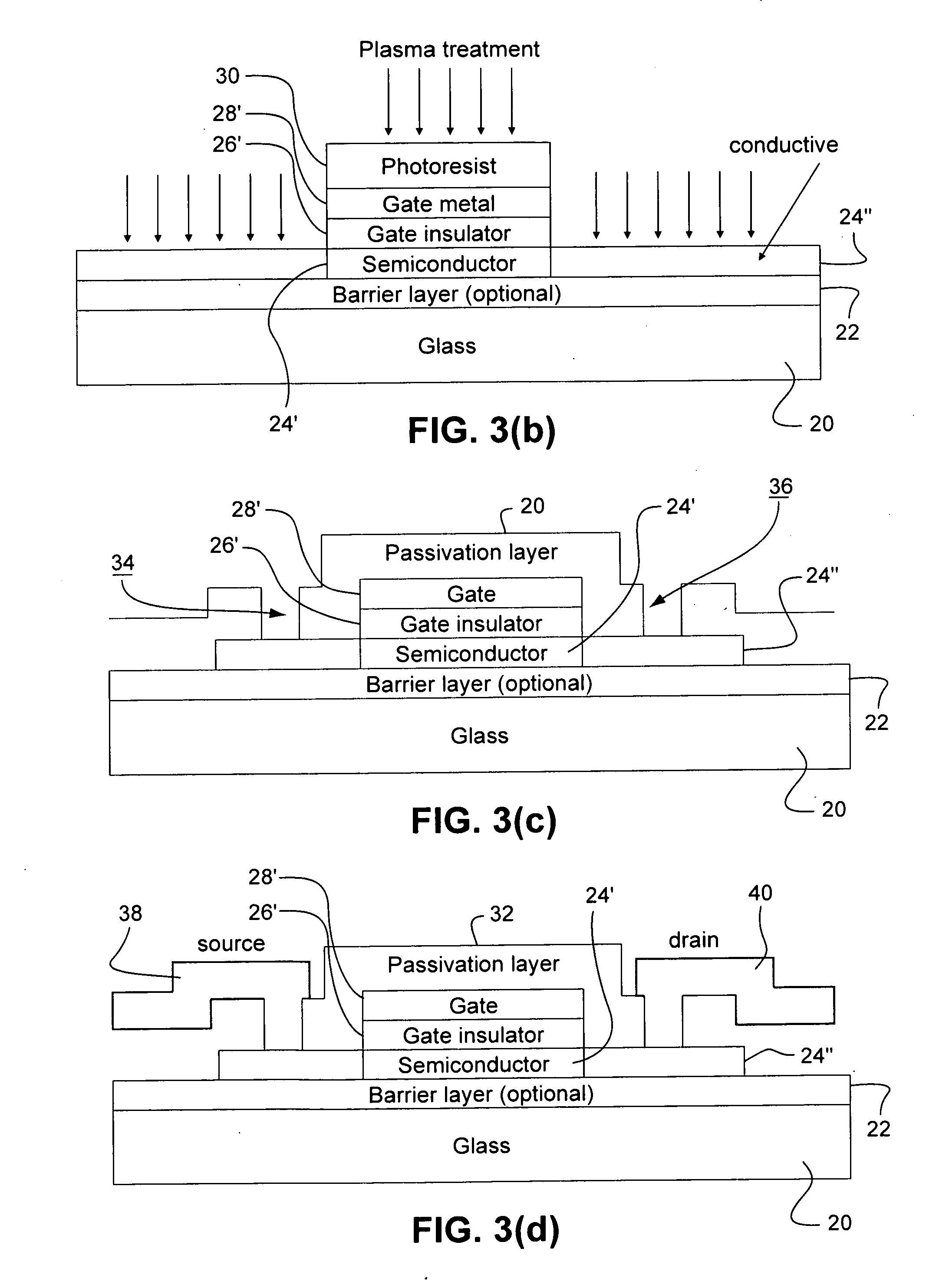

Method of making oxide thin film transistor array, and device incorporating the same

InactiveUS20120074399A1Improve conductivityImprove economyTransistorSolid-state devicesOxide thin-film transistorRoom temperature

Certain example embodiments relate to methods of making oxide thin film transistor arrays (e.g., IGZO, amorphous or polycrystalline ZnO, ZnSnO, InZnO, and / or the like), and devices incorporating the same. Blanket layers of an optional barrier layer, semiconductor, gate insulator, and / or gate metal are disposed on a substrate. These and / or other layers may be deposited on a soda lime or borosilicate substrate via low or room temperature sputtering. These layers may be later patterned and / or further processed in making a TFT array according to certain example embodiments. In certain example embodiments, all or substantially all TFT processing may take place at a low temperature, e.g., at or below 150 degrees C., until a post-annealing activation step, and the post-anneal step may take place at a relatively low temperature (e.g., 200-250 degrees C.).

Owner:GUARDIAN GLASS LLC

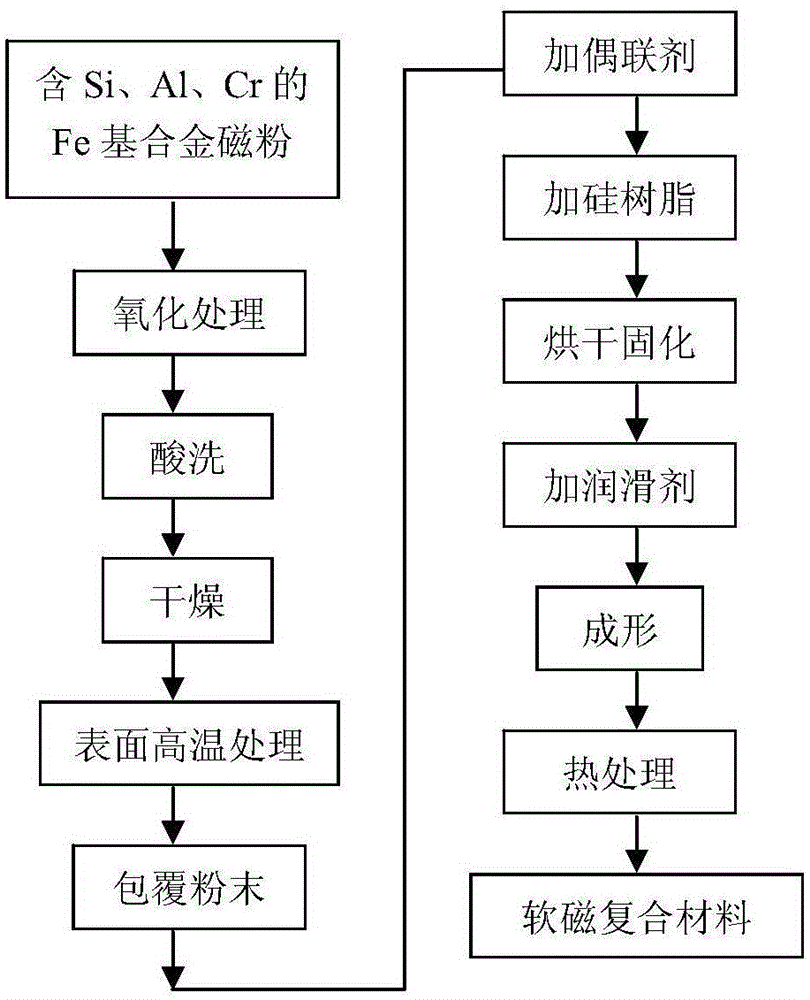

Coating method iron-based magnetically soft alloy powder and preparation method of soft magnet composite material

ActiveCN105149574AHigh resistivityImprove compactnessInorganic material magnetismMagnetic powderOxide

The invention relates to a coating method for iron-based magnetically soft alloy powder and a preparation method of soft magnet composite material. The coating method for iron-based magnetically soft alloy powder comprises the following steps: carrying out accelerated oxidation on iron-based magnetic metal powder at high temperature, forming an oxide layer on the surface of the powder and then carrying out acid pickling, thus obtaining powder with surface coated with SiO2, Al2O3 and Cr2O3 oxides. The preparation method of the soft magnet composite material comprises the following steps: adding coupling agent, silicon resin and lubricating agent to the coated powder, carrying out pressing forming, and then carrying out annealing heat treatment, thus obtaining the soft magnet composite material. According to the invention, the advantage that an oxide produced in reaction of elements including Si, Al and Cr contained in the iron-based magnetically soft alloy powder with oxygen is high in electrical resistivity, small in thermal expansion coefficient and steady in chemical performance and can resist high temperature is fully utilized; the adopted coating technology is to produce a coating layer in situ on the surface of the alloy magnetic powder, and is simple in process, easy to operate and low in cost; the metal soft magnet composite material prepared by adopting the method disclosed by the invention has good magnetic property and frequency stability.

Owner:CENT SOUTH UNIV

Method for making a current-perpendicular-to-the-plane (CPP) magnetoresistive sensor containing a ferromagnetic alloy requiring post-deposition annealing

InactiveUS20130236639A1Improve microstructureMagnetic measurementsMagnetic-field-controlled resistorsGiant magnetoresistanceAlloy

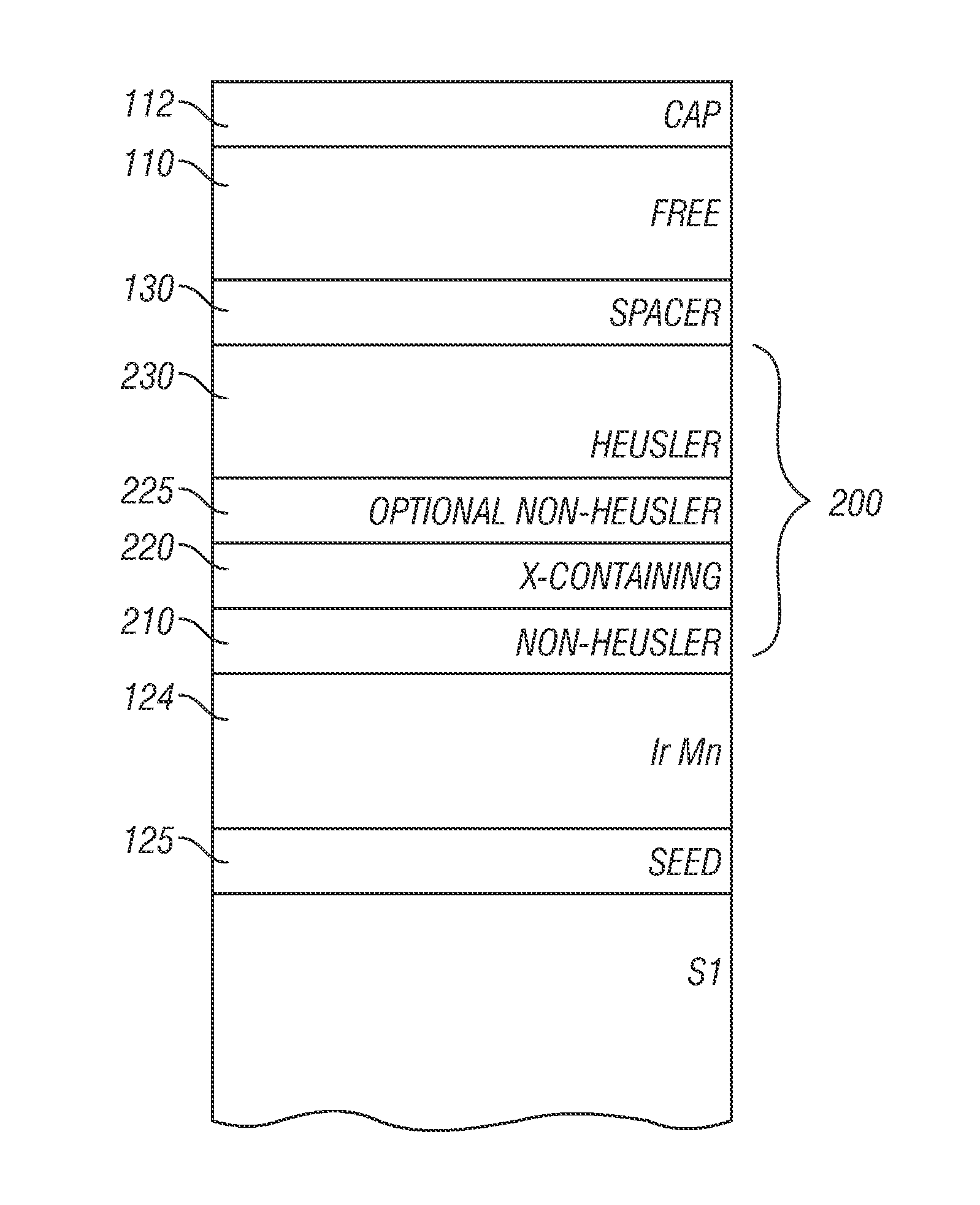

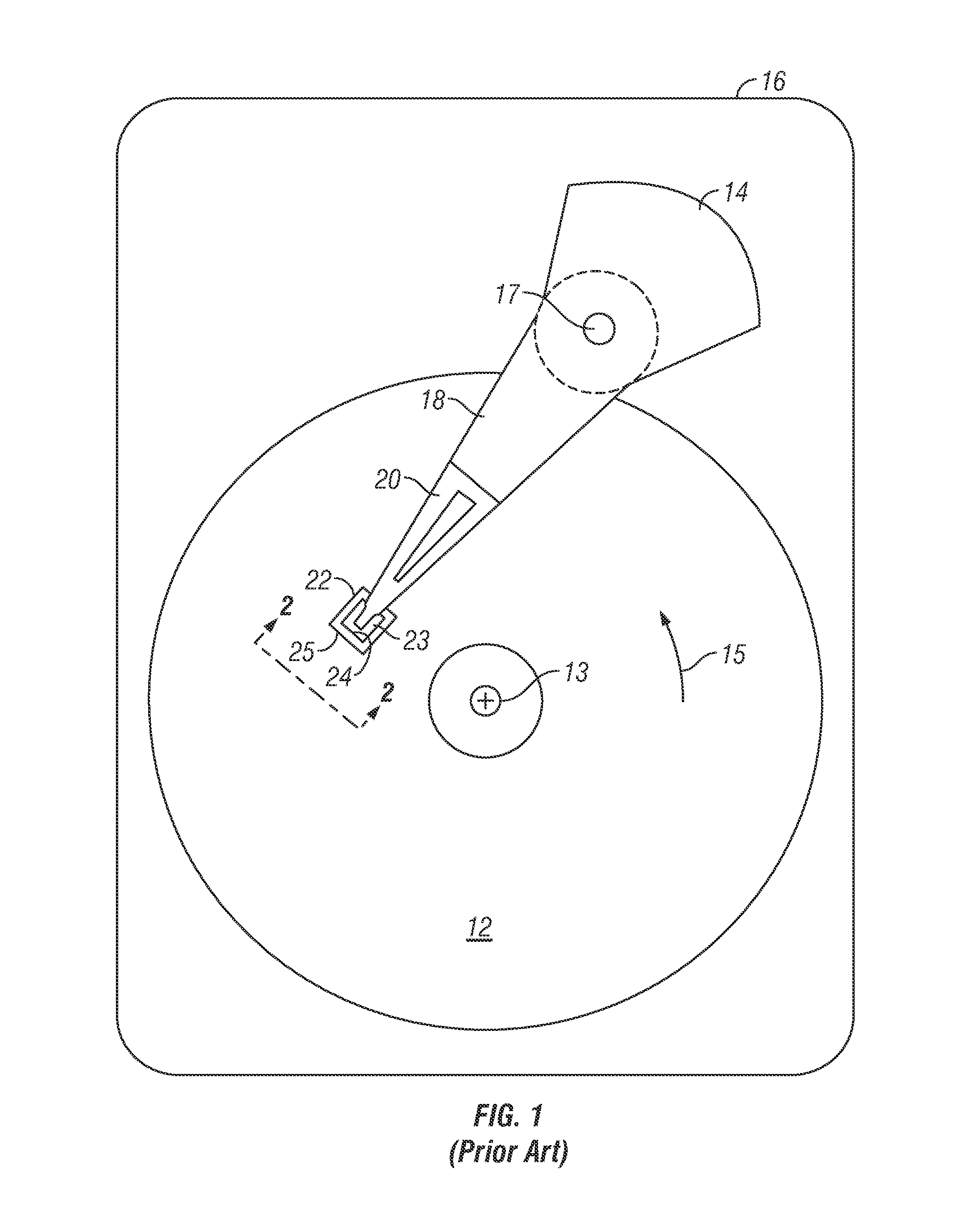

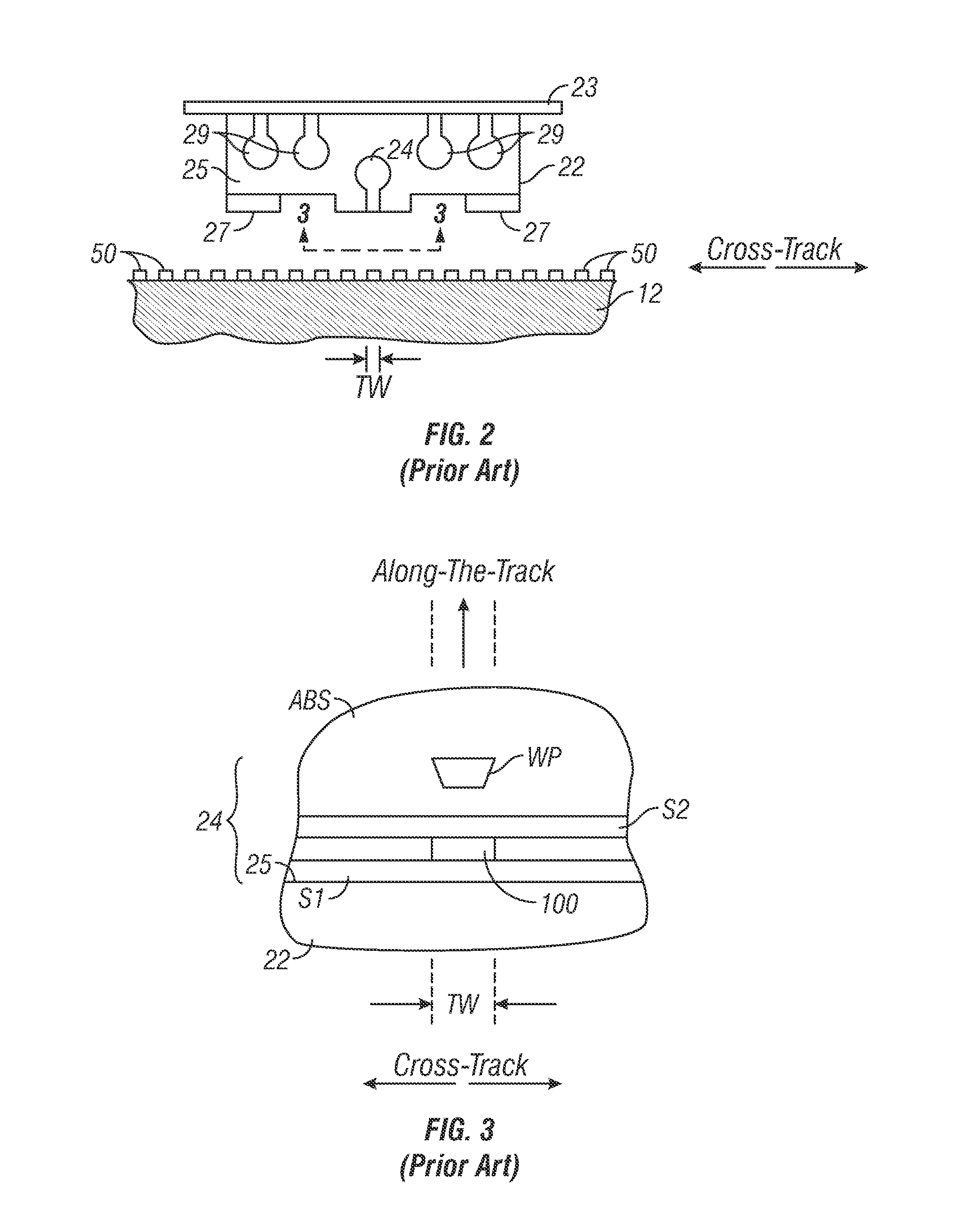

A method for making a current-perpendicular-to the-plane giant magnetoresistance (CPP-GMR) sensor with a Heusler alloy pinned layer on the sensor's Mn-containing antiferromagnetic pinning layer uses two annealing steps. A layer of a crystalline non-Heusler alloy ferromagnetic material, like Co or CoFe, is deposited on the antiferromagnetic pinning layer and a layer of an amorphous X-containing ferromagnetic alloy, like a CoFeBTa layer, is deposited on the Co or CoFe crystalline layer. After a first in-situ annealing of the amorphous X-containing ferromagnetic alloy, the Heusler alloy pinned layer is deposited on the amorphous X-containing ferromagnetic layer and a second high-temperature annealing step is performed to improve the microstructure of the Heusler alloy pinned layer.

Owner:WESTERN DIGITAL TECH INC

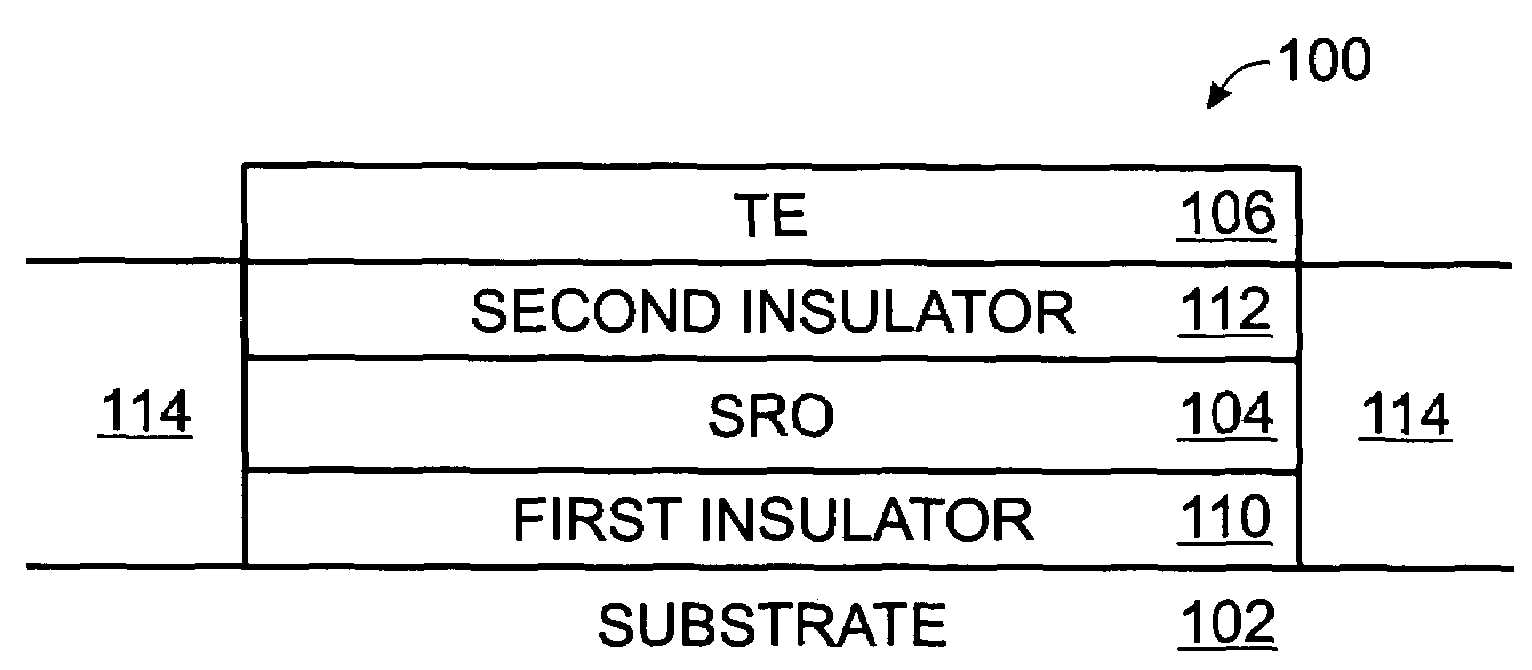

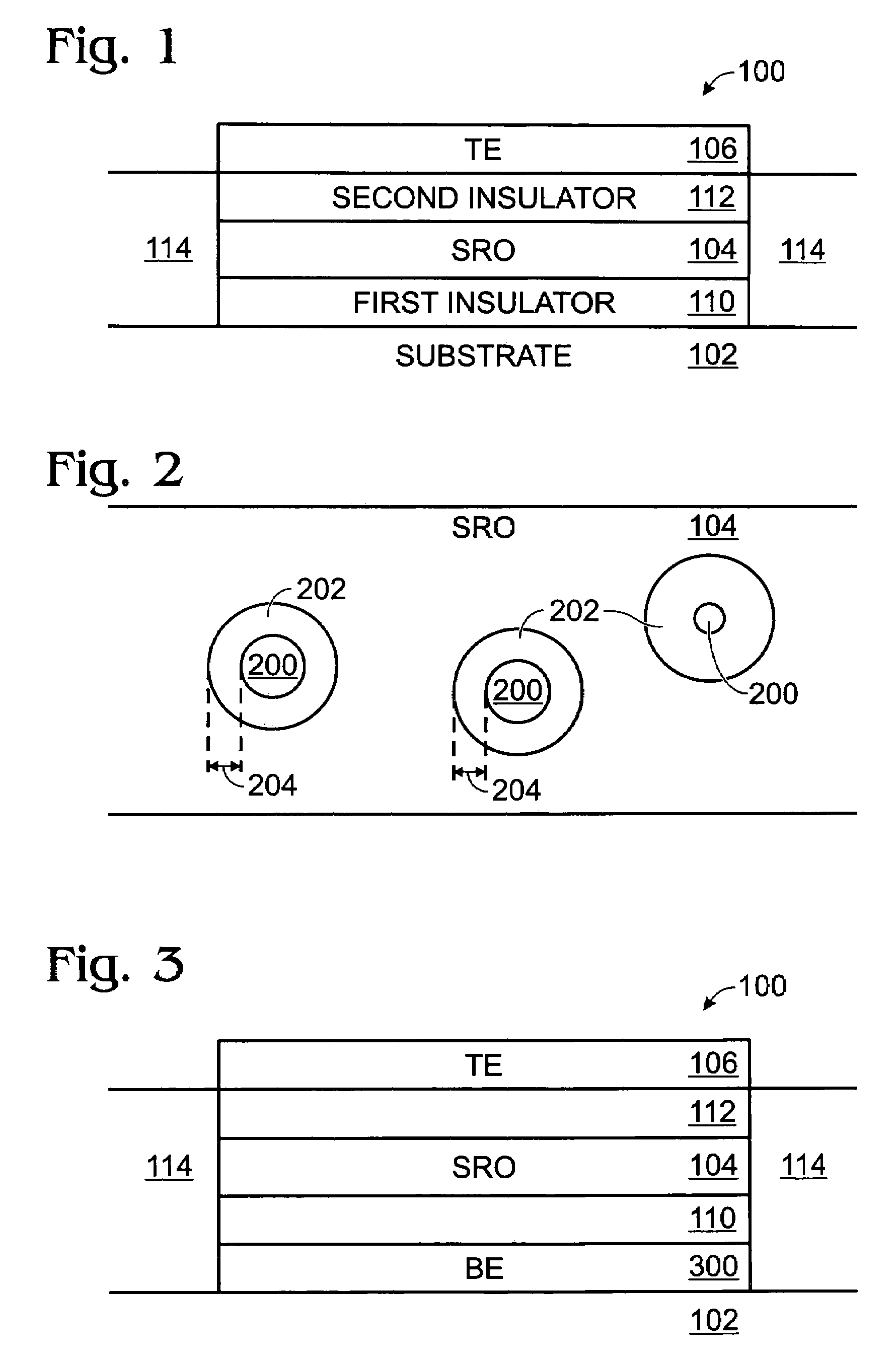

High-luminescence silicon electroluminescence device

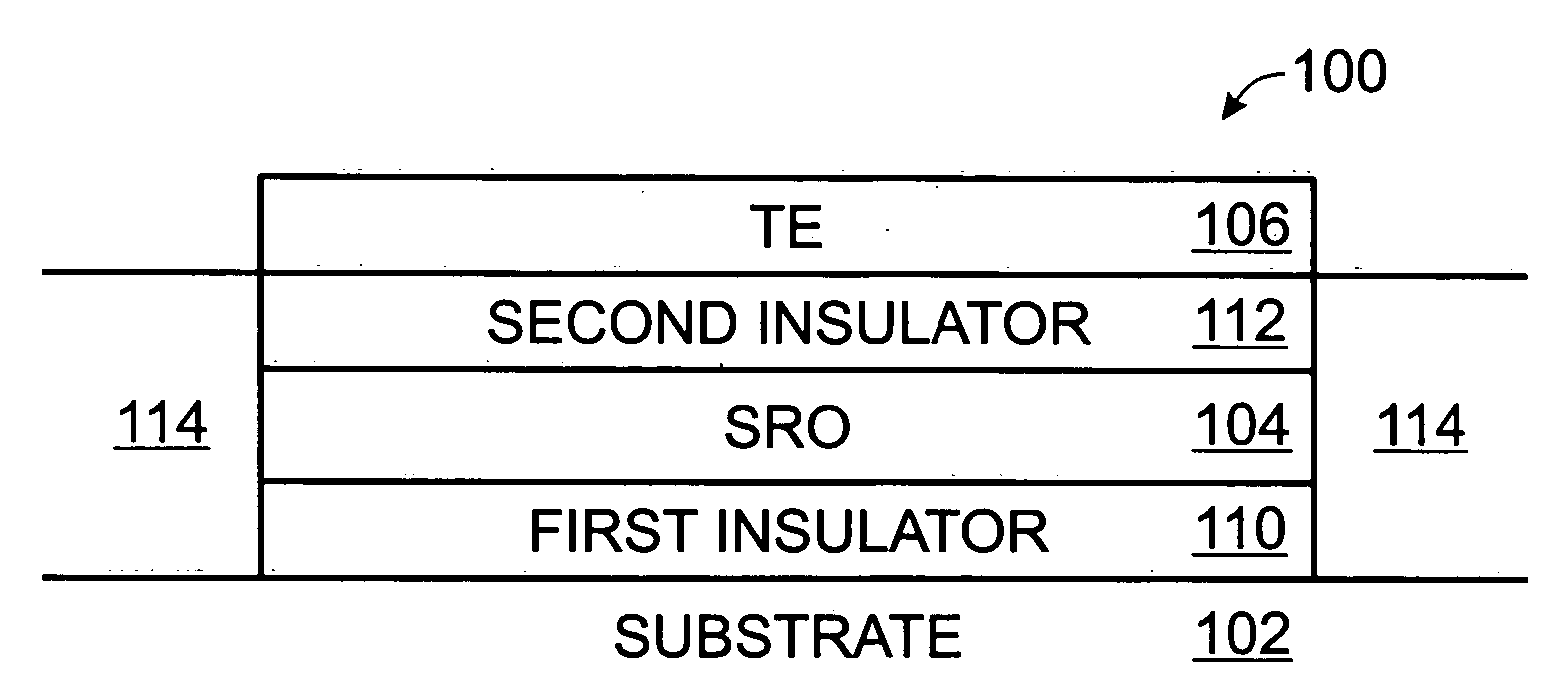

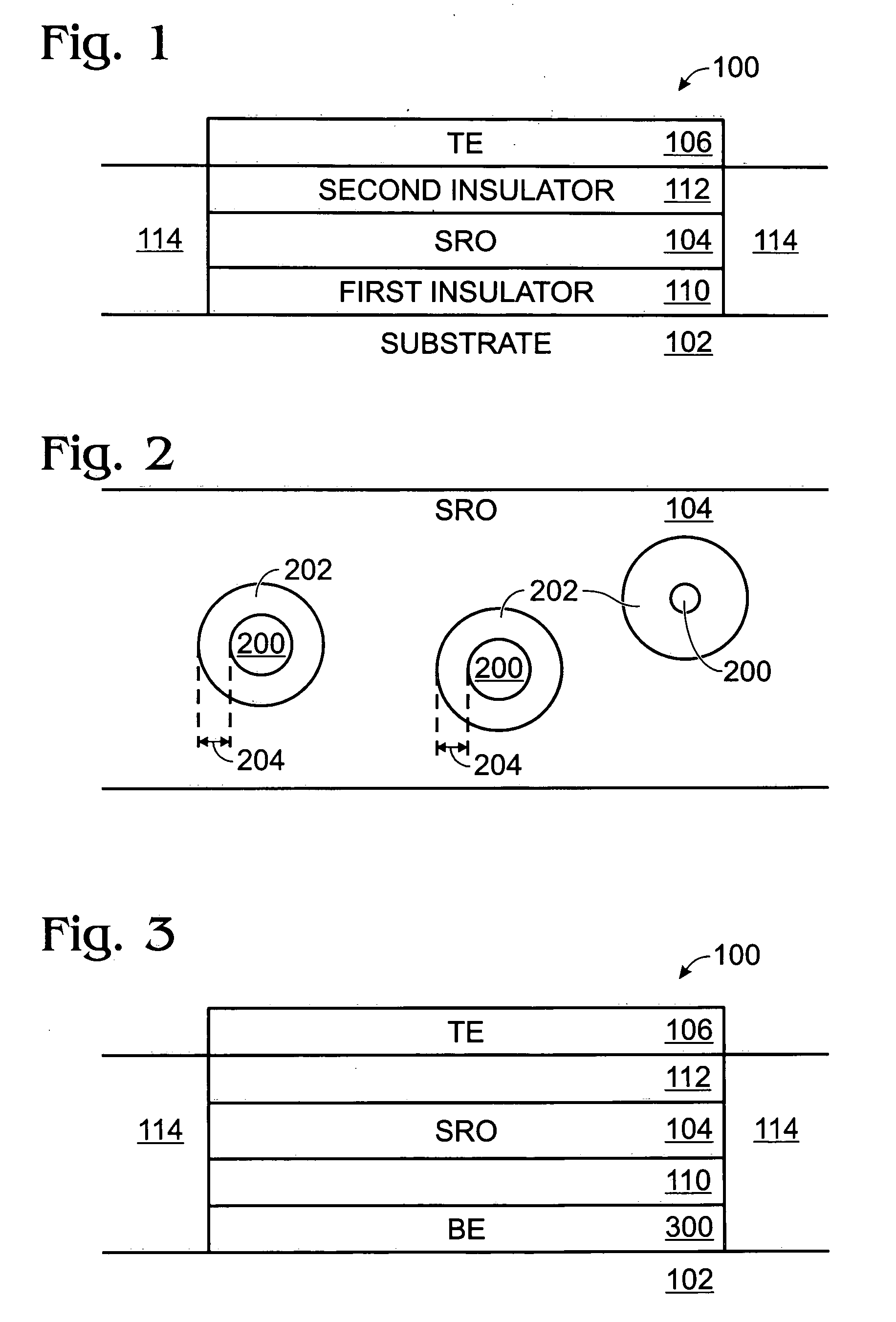

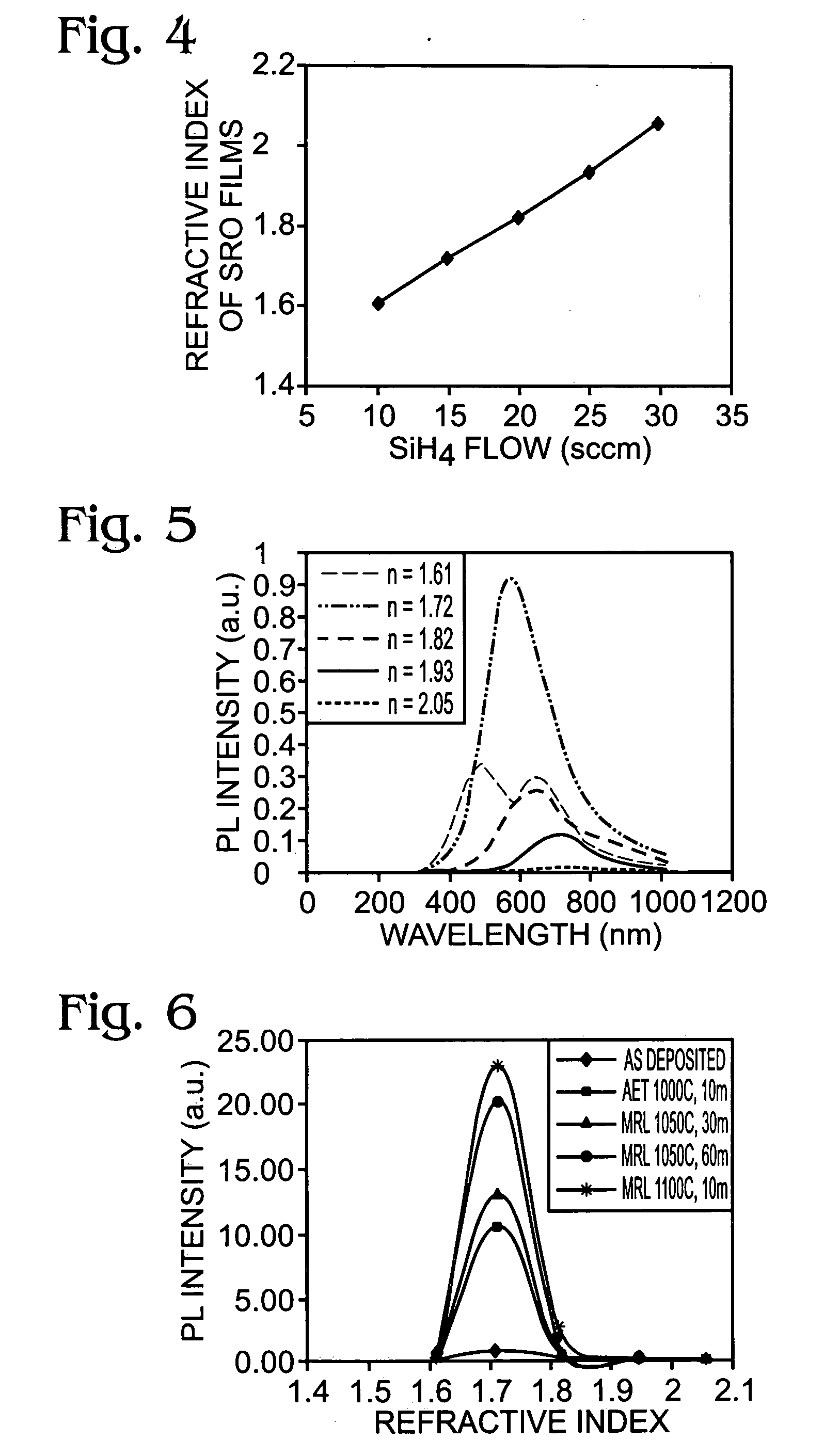

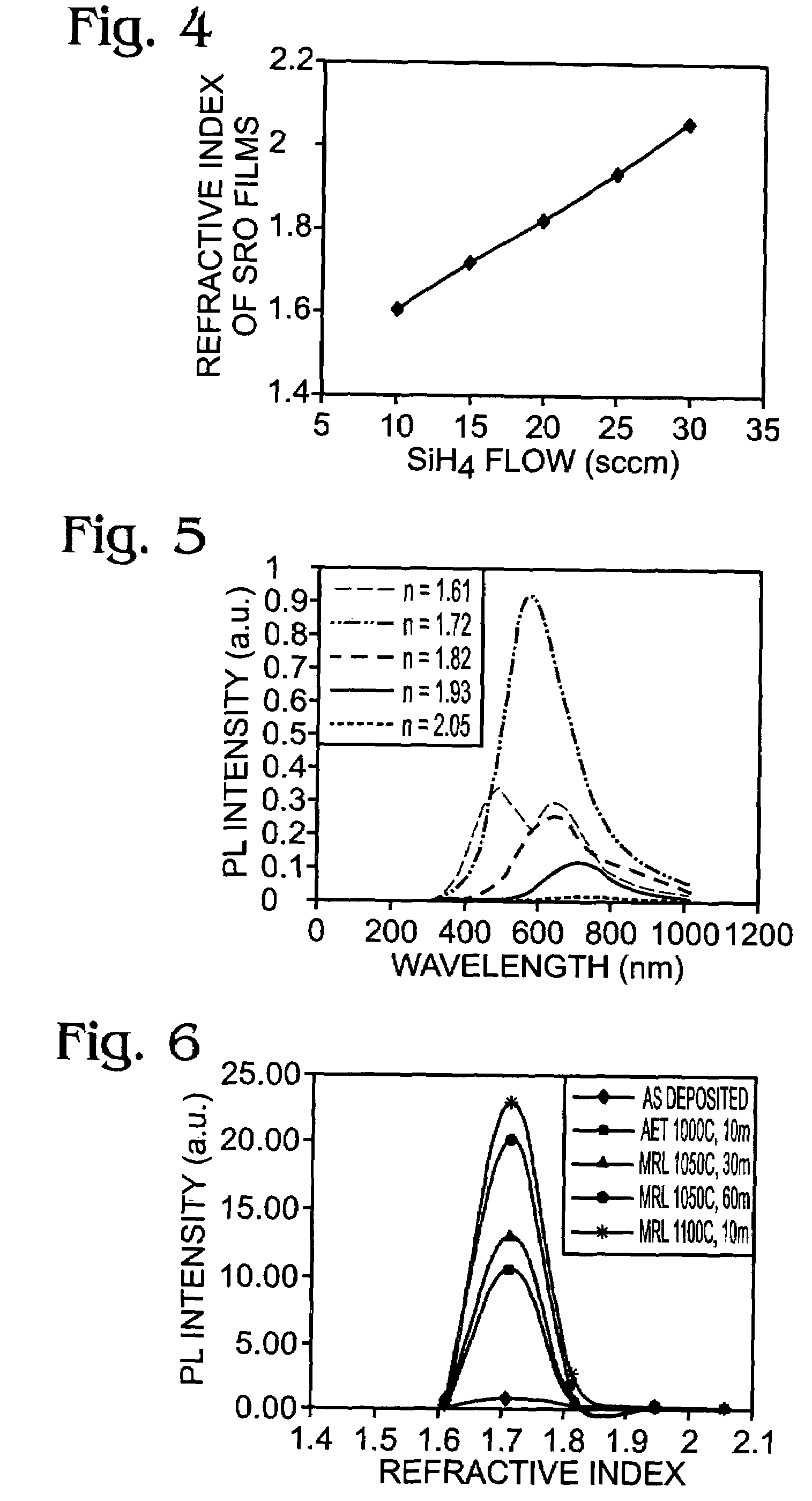

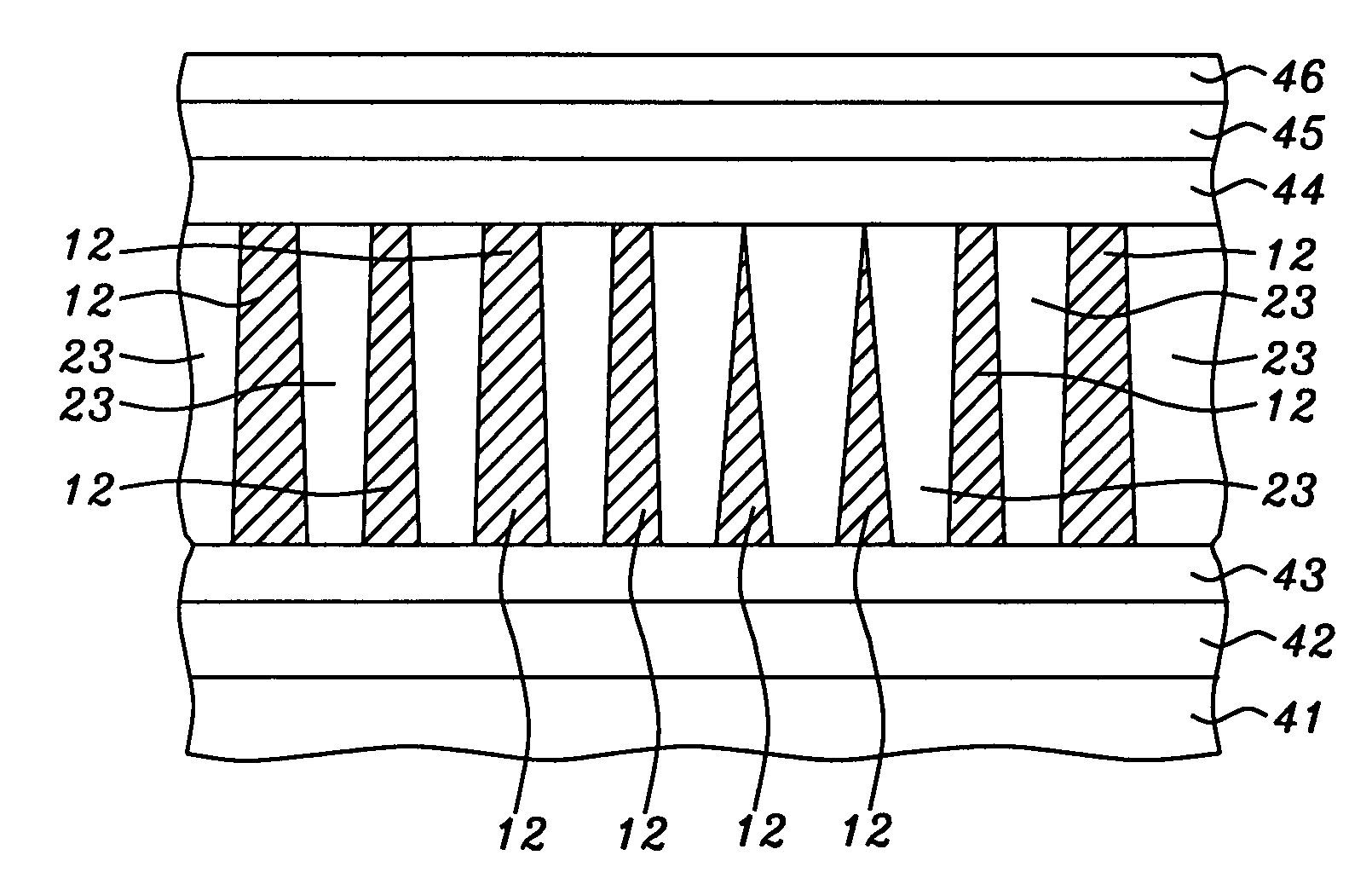

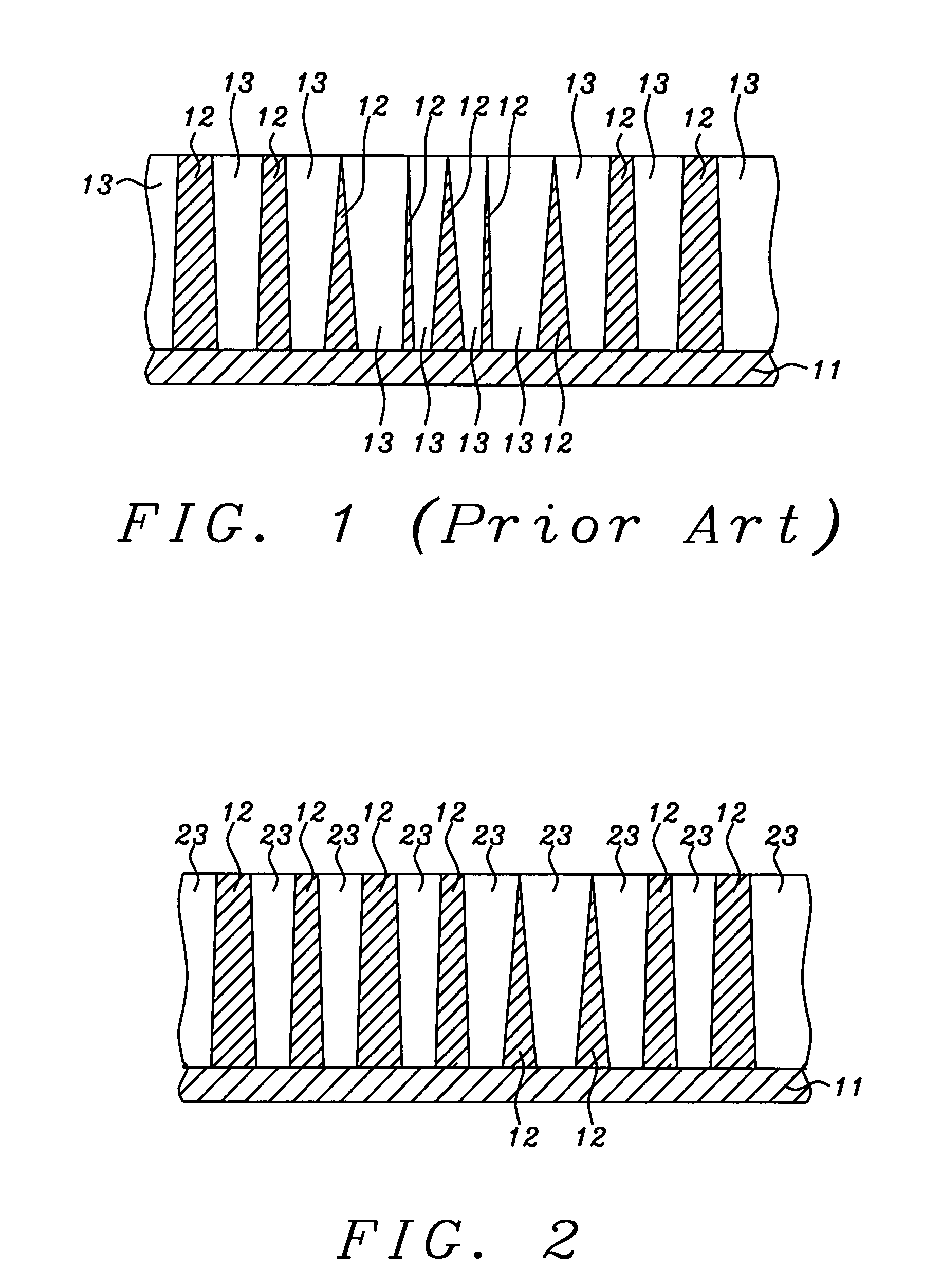

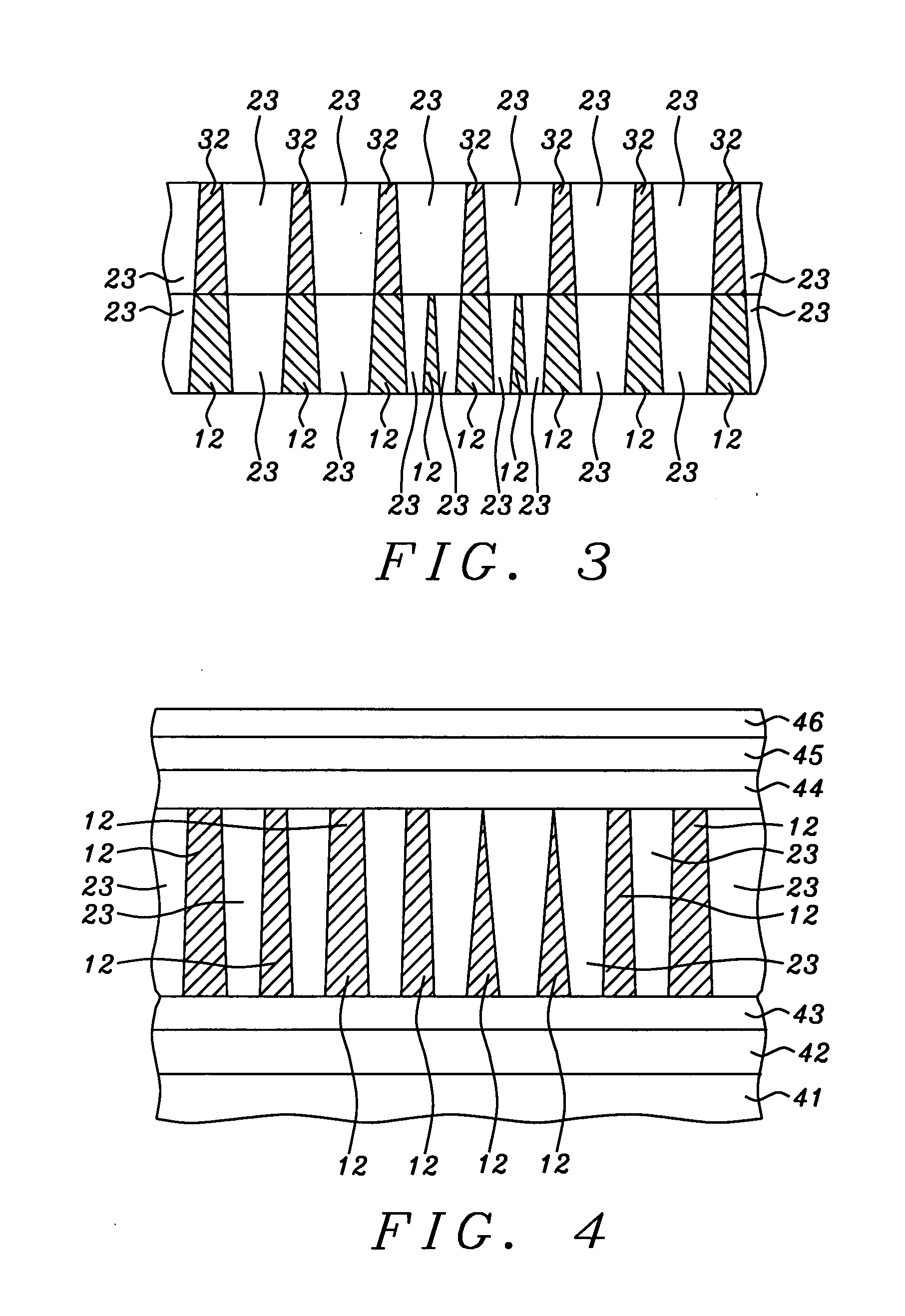

InactiveUS20060189014A1Enhance homogeneous oxidation of nano-SiFacilitated DiffusionFinal product manufactureSemiconductor/solid-state device detailsPorosityRefractive index

A method for forming a high-luminescence Si electroluminescence (EL) phosphor is provided, with an EL device made from the Si phosphor. The method comprises: depositing a silicon-rich oxide (SRO) film, with Si nanocrystals, having a refractive index in the range of 1.5 to 2.1, and a porosity in the range of 5 to 20%; and, post-annealing the SRO film in an oxygen atmosphere. DC-sputtering or PECVD processes can be used to deposit the SRO film. In one aspect the method further comprises: HF buffered oxide etching (BOE) the SRO film; and, re-oxidizing the SRO film, to form a SiO2 layer around the Si nanocrystals in the SRO film. In one aspect, the SRO film is re-oxidized by annealing in an oxygen atmosphere. In this manner, a layer of SiO2 is formed around the Si nanocrystals having a thickness in the range of 1 to 5 nanometers (nm).

Owner:SHARP KK

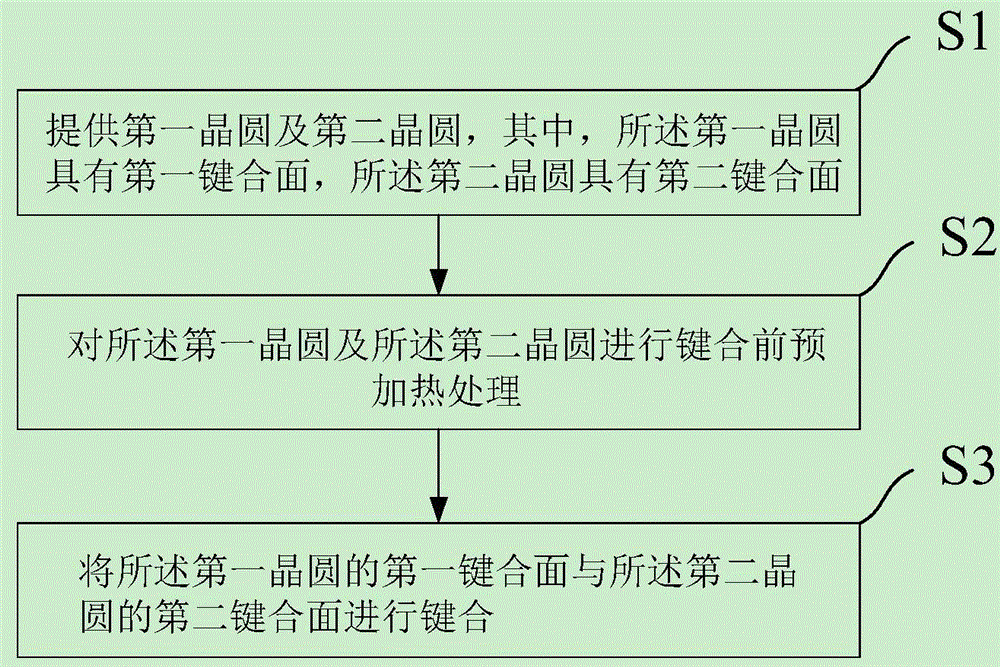

Wafer bonding method and preparation method for foreign substrate

ActiveCN106711027AReduce thermal strainImprove reliabilityPrecision positioning equipmentSoldering apparatusEngineeringWafer bonding

The invention provides a wafer bonding method and a preparation method for a foreign substrate. The wafer bonding method at least comprises the following steps: S1) supplying a first wafer and a second wafer, wherein the first wafer is equipped with a first bonding surface, and the second wafer is equipped with a second bonding surface; S2) preheating before bonding the first wafer and the second wafer; and S3) bonding the first bonding surface of the first wafer with the second bonding surface of the second wafer. According to the scheme, the preheating before the bonding for the wafers is capable of effectively reducing the thermal strain of the foreign bonding structure in a high-temperature post-annealing process, so that the use scope of the foreign bonding can be widened and the reliability of a foreign integrated material can be promoted. Meanwhile, the problems of de-bonding and broken bonding structure caused by thermal strain of the foreign bonding structure in the high-temperature post-annealing process can be solved.

Owner:SHANGHAI NOVEL SI INTEGRATION TECH CO LTD

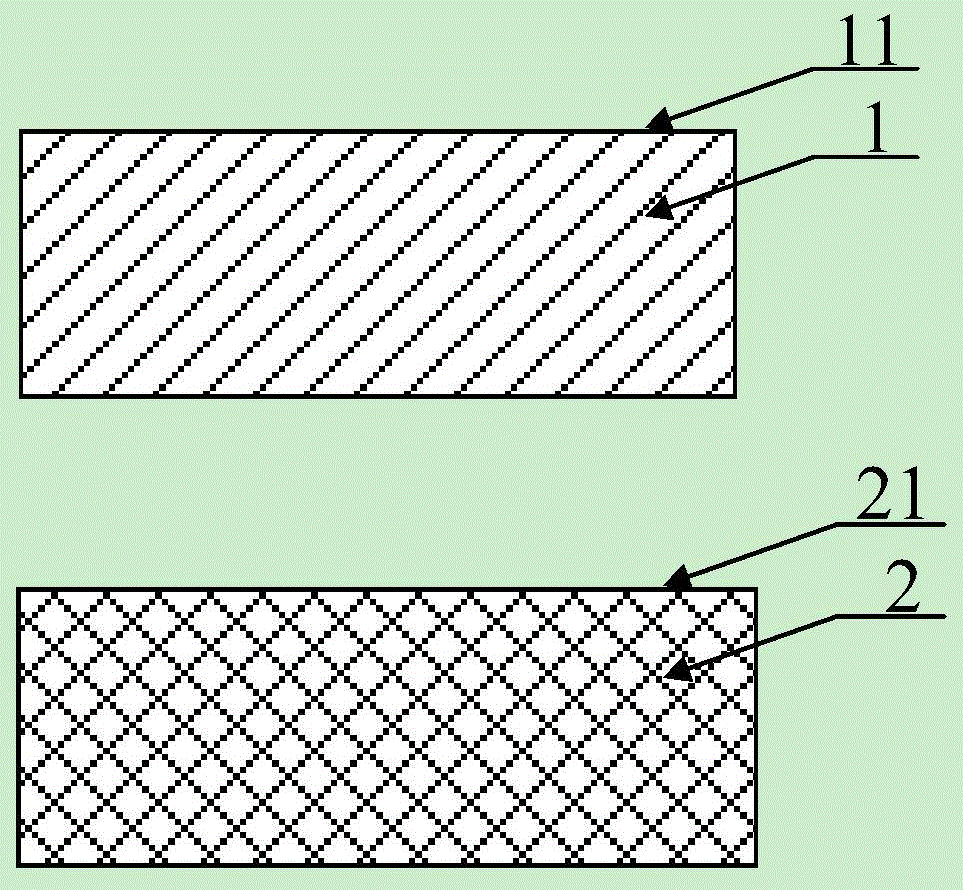

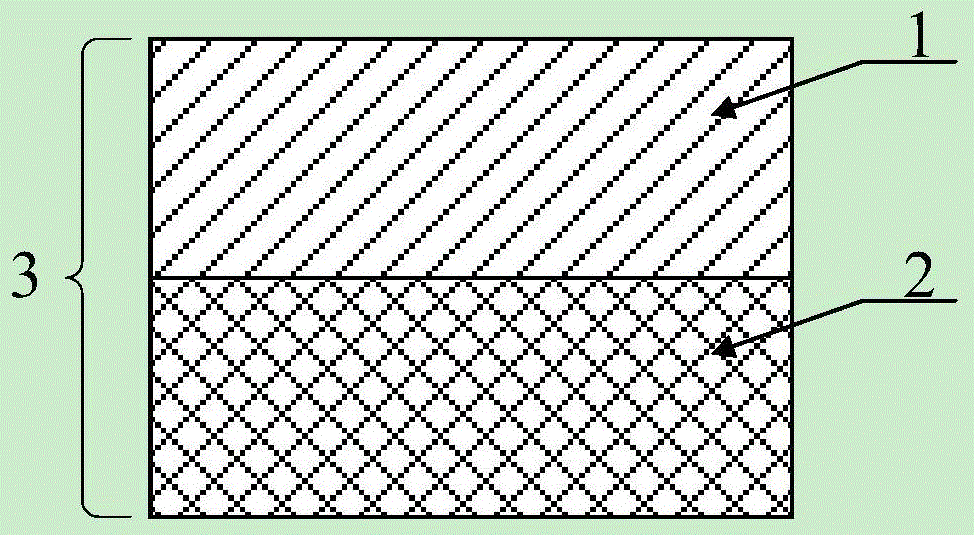

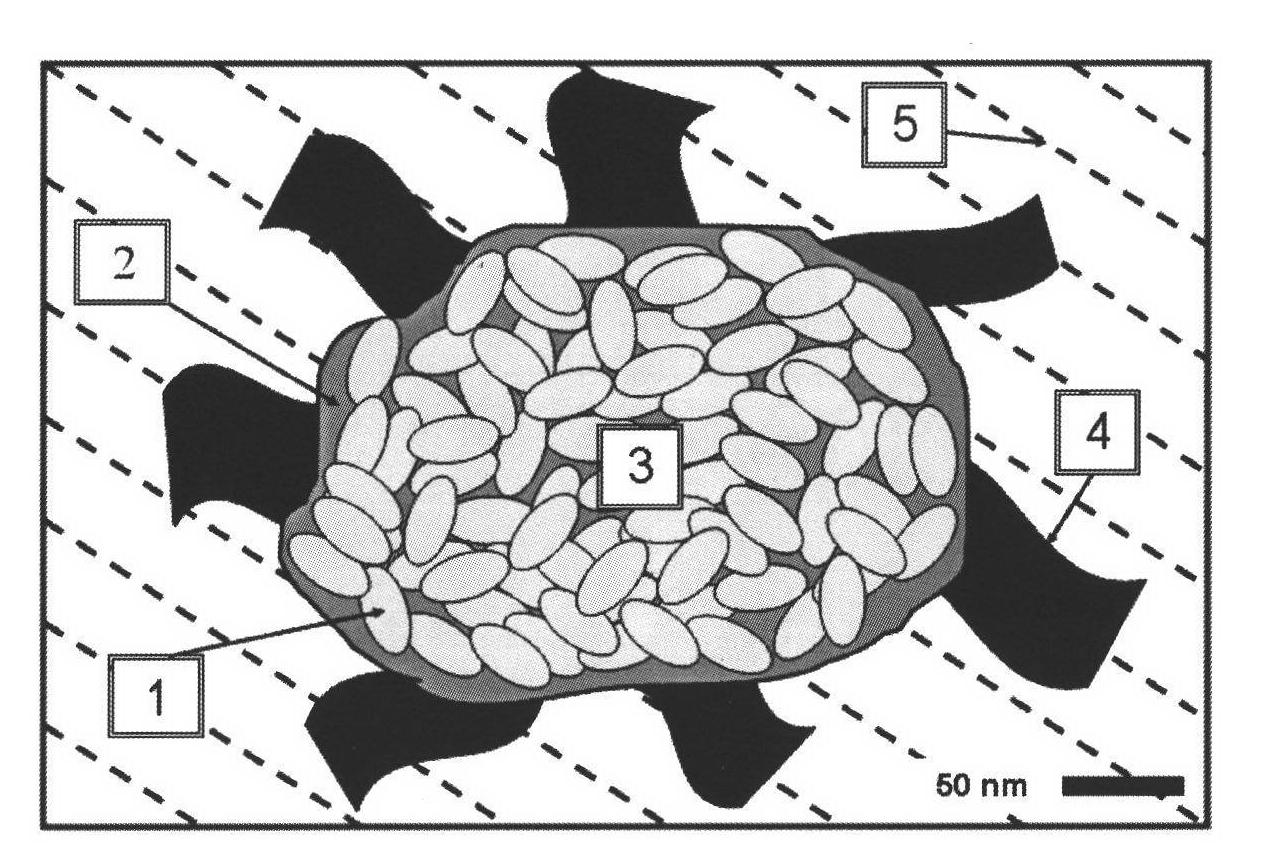

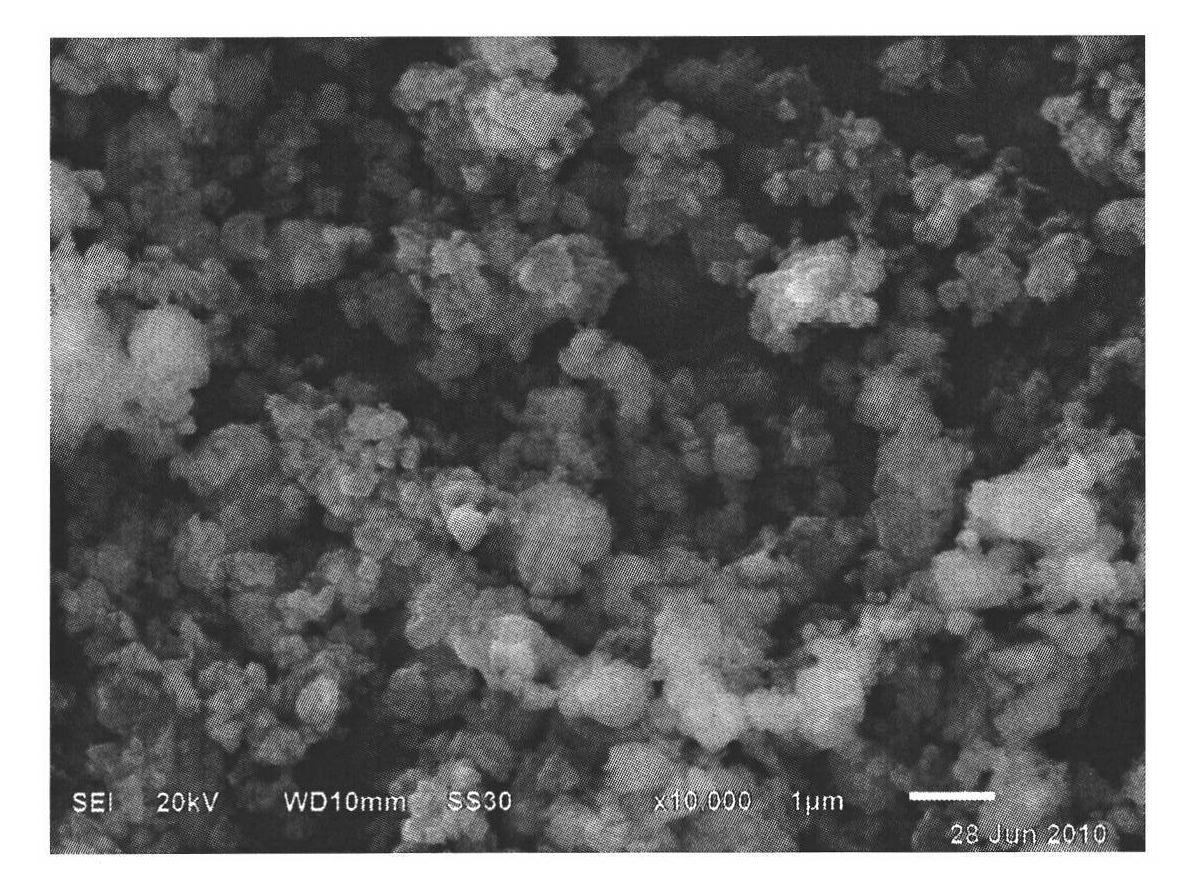

Mixed conductor composite material LiFePO4-MXy and preparation method thereof

InactiveCN102427134AHigh tap densityImprove discharge stabilityCell electrodesElectrical conductorHigh rate

The invention discloses a mixed conductor composite material LiFePO4-MXy. The mixed conductor composite material LiFePO4-MXy is prepared by synthesizing LiFePO4 from the oxides or sulfides of transition metals by a solid state method, and performing high-energy ball-milling and annealing on the transition metals to obtain the mixed conductor composite material LiFePO4-MXy. In the mixed conductor composite material (MCM) LiFePO4-MXy, MXy is not only a conductor of lithium ions but also a conductor of electrons, LiFePO4 particles are uniformly dispersed in the MXy, and the surface of the mixed conductor composite material in a lithium ion battery comprises a carbon material which is added in size mixing and electrolyte which is impregnated in the carbon material. The LiFePO4-MXy has the advantages of high electron conductivity, high ion conductivity, high high-rate charge and discharge capacity, high cycle performance, relatively higher tap density, simple and practical production process, cleanness, no pollution, low cost and the like, and is suitable for large-scale production.

Owner:XIANGTAN UNIV

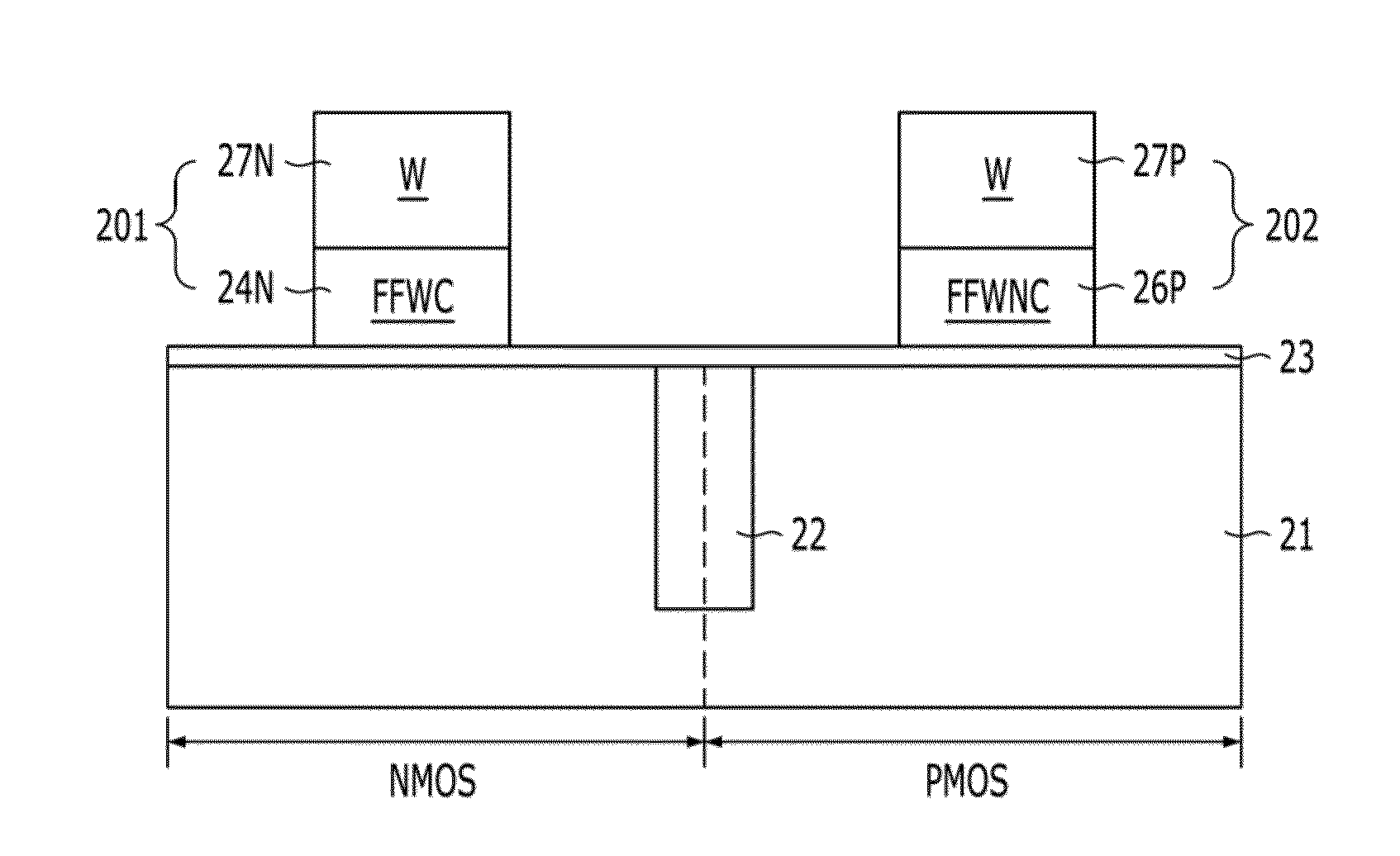

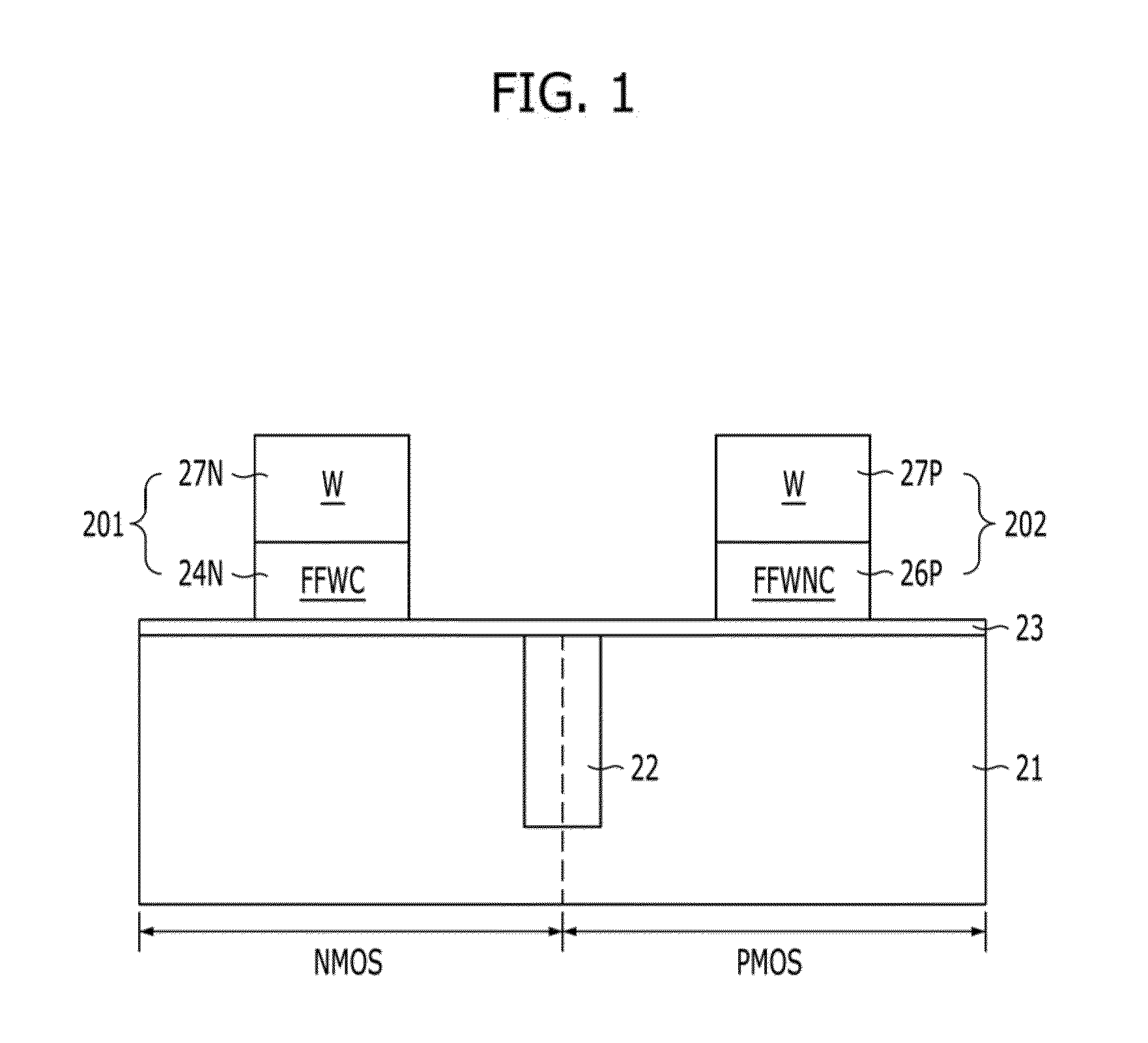

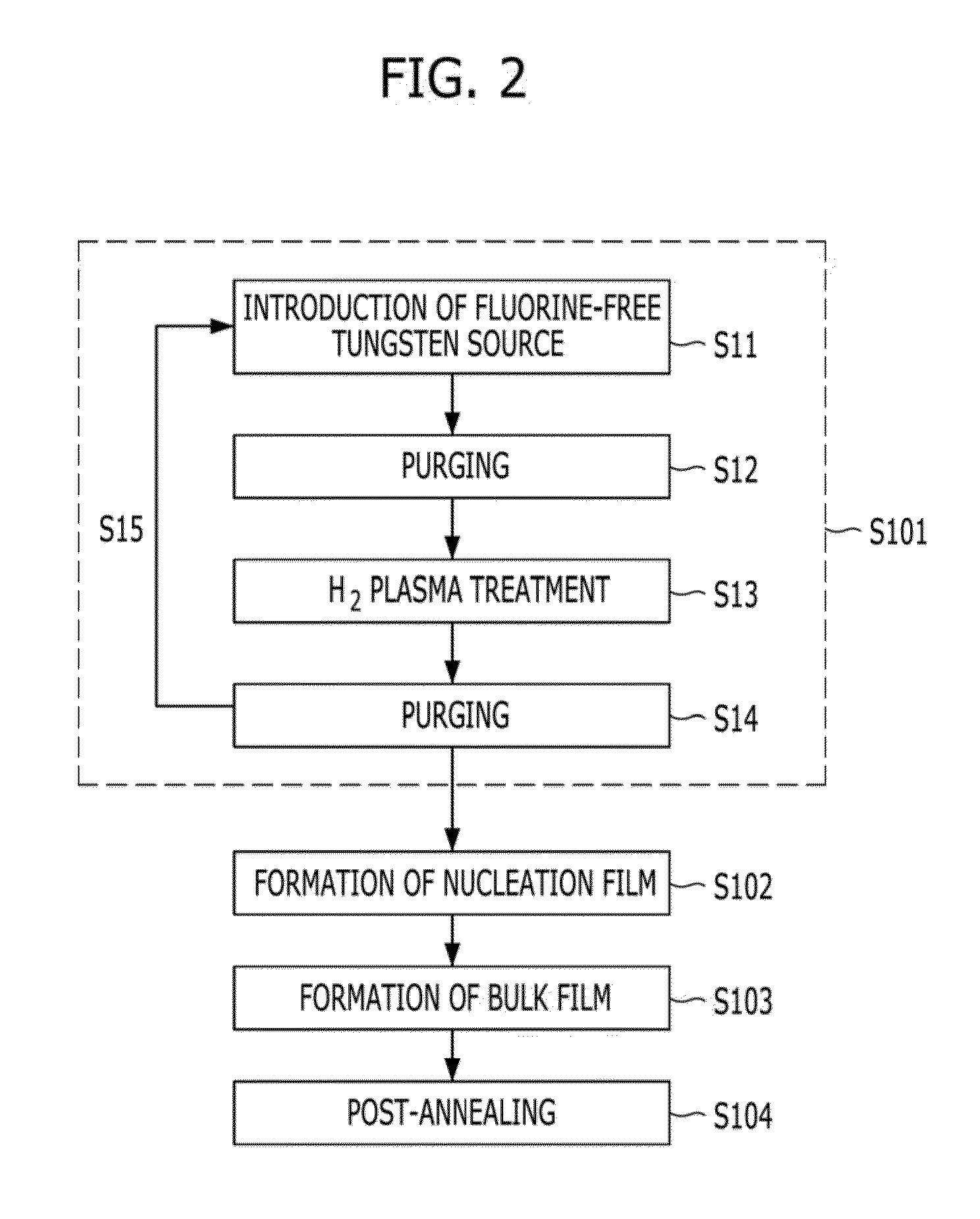

Semiconductor device having tungsten gate electrode and method for fabricating the same

ActiveUS20140061784A1TransistorSemiconductor/solid-state device manufacturingPower semiconductor deviceDevice material

The present invention provides a semiconductor device in which the threshold voltage of NMOS and the threshold voltage of PMOS are independently controllable, and a method for fabricating the same. The method includes: forming a gate insulating film over an NMOS region and a PMOS region of a semiconductor substrate; forming a carbon-containing tungsten over the gate insulating film formed over one of the NMOS region and the PMOS region; forming a carbon-containing tungsten nitride over the gate insulating film formed over the other one of the PMOS region or the NMOS region; forming a tungsten film over the carbon-containing tungsten and the carbon-containing tungsten nitride; post-annealing the carbon-containing tungsten and the carbon-containing tungsten nitride; and etching the tungsten film, the carbon-containing tungsten, and the carbon-containing tungsten nitride, to form a gate electrode in the NMOS region and the PMOS region

Owner:SK HYNIX INC

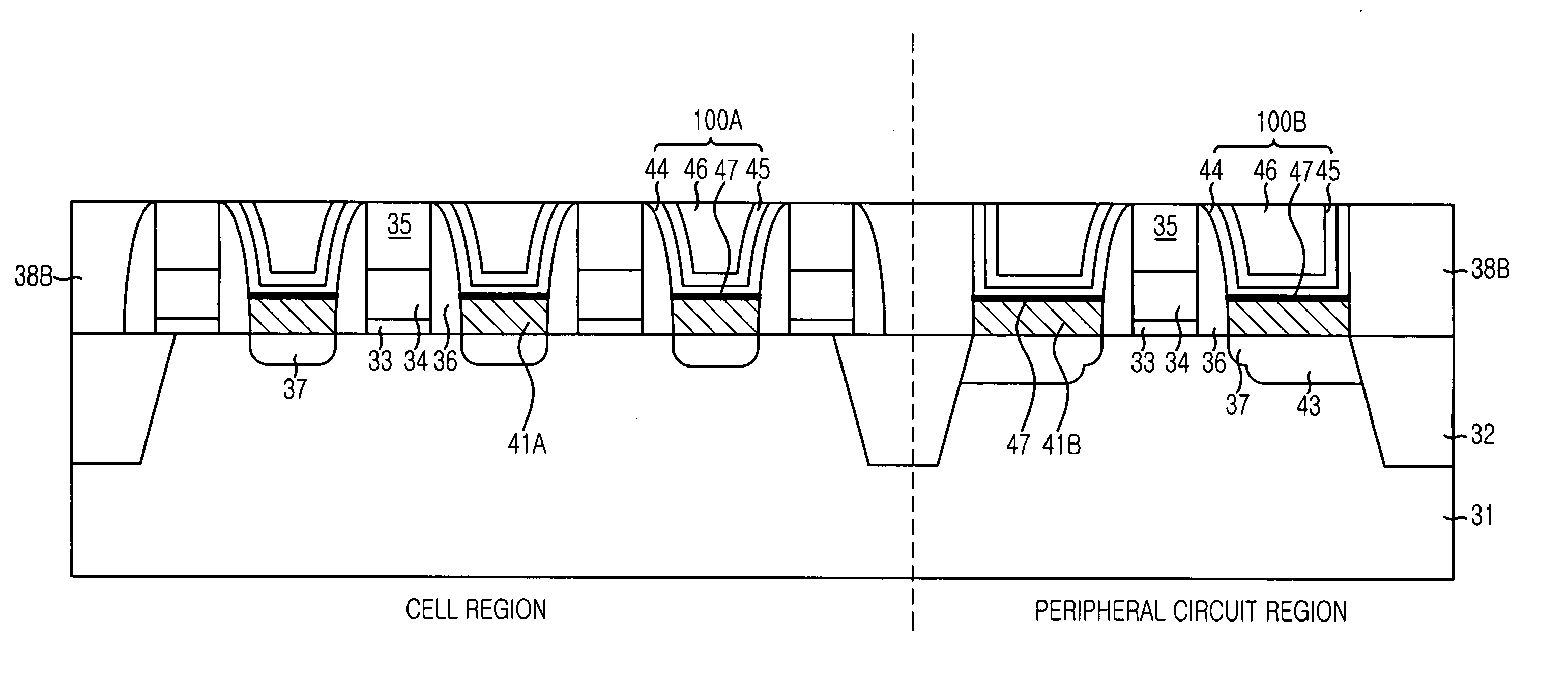

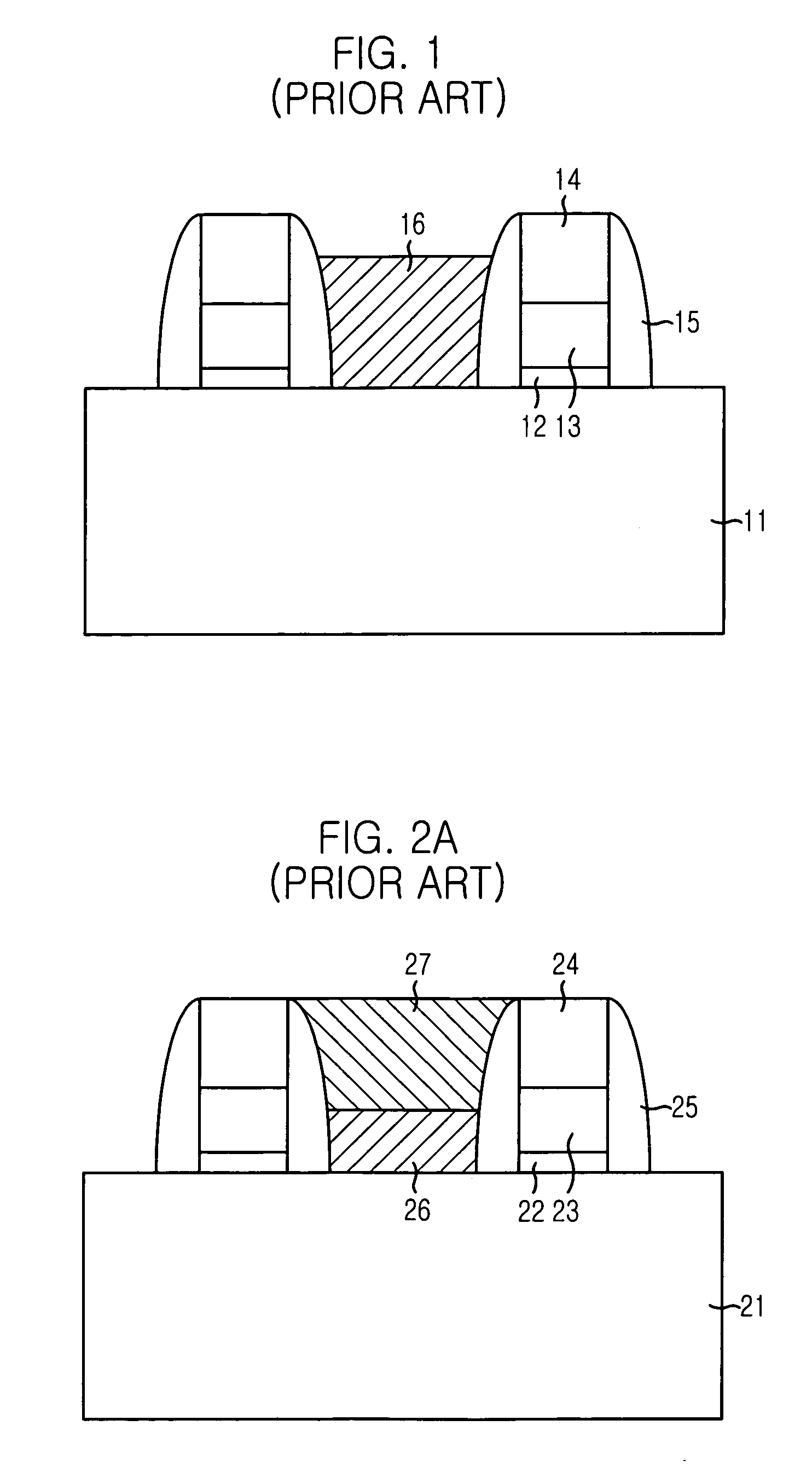

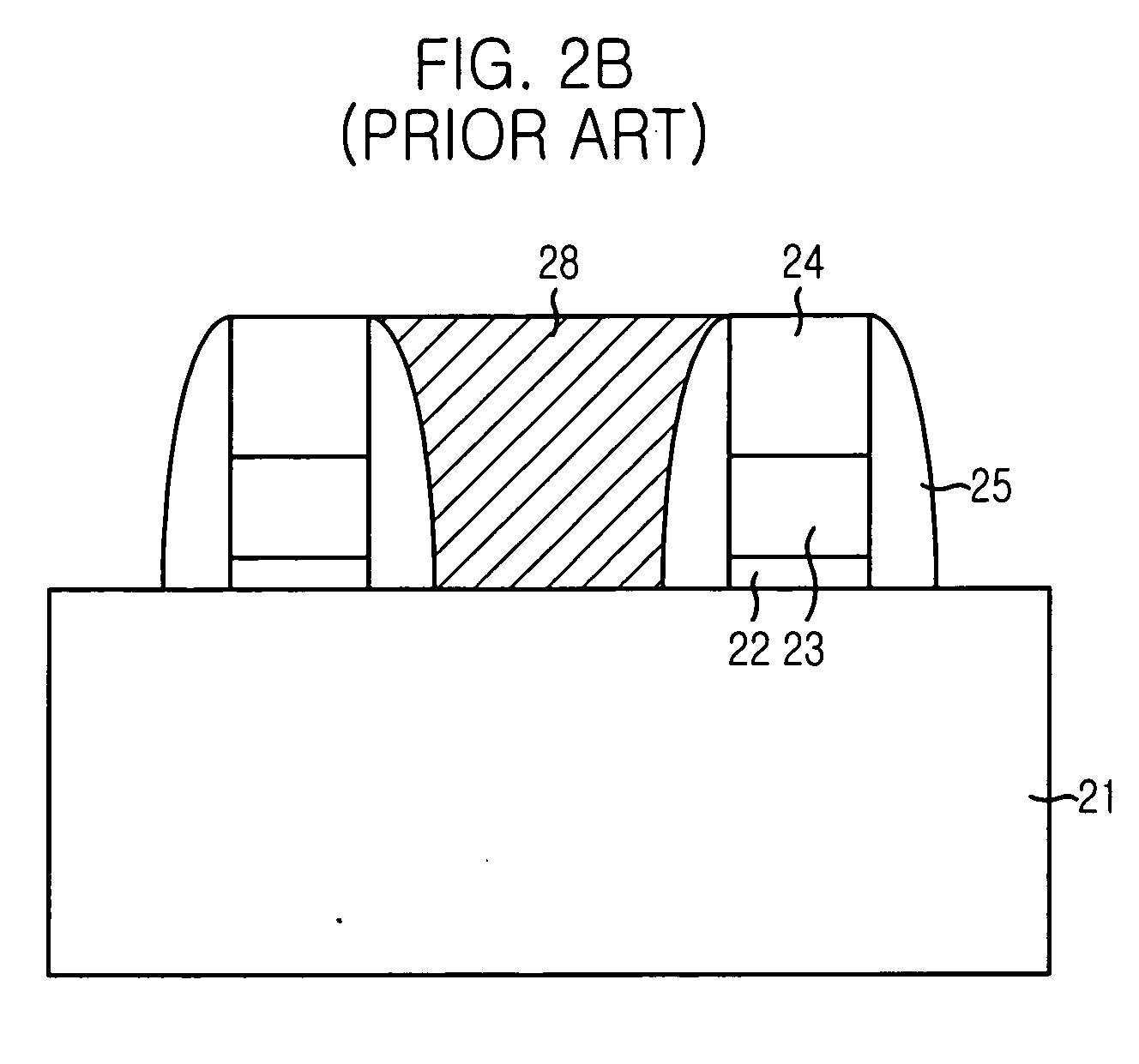

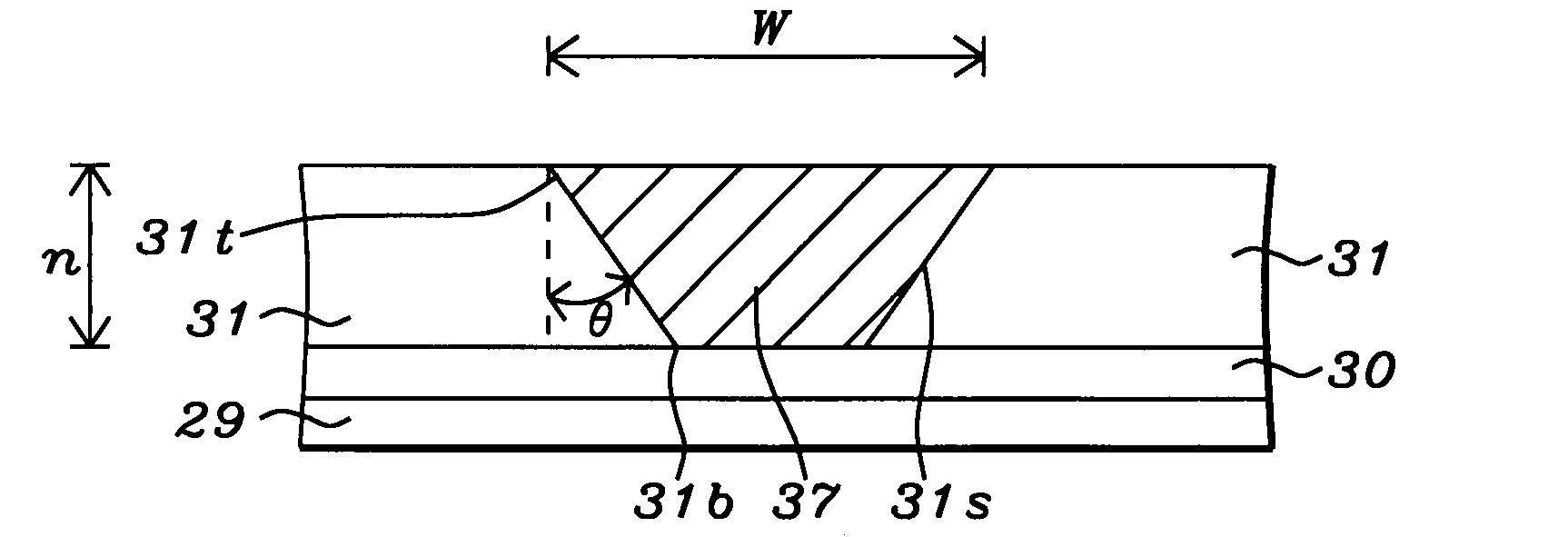

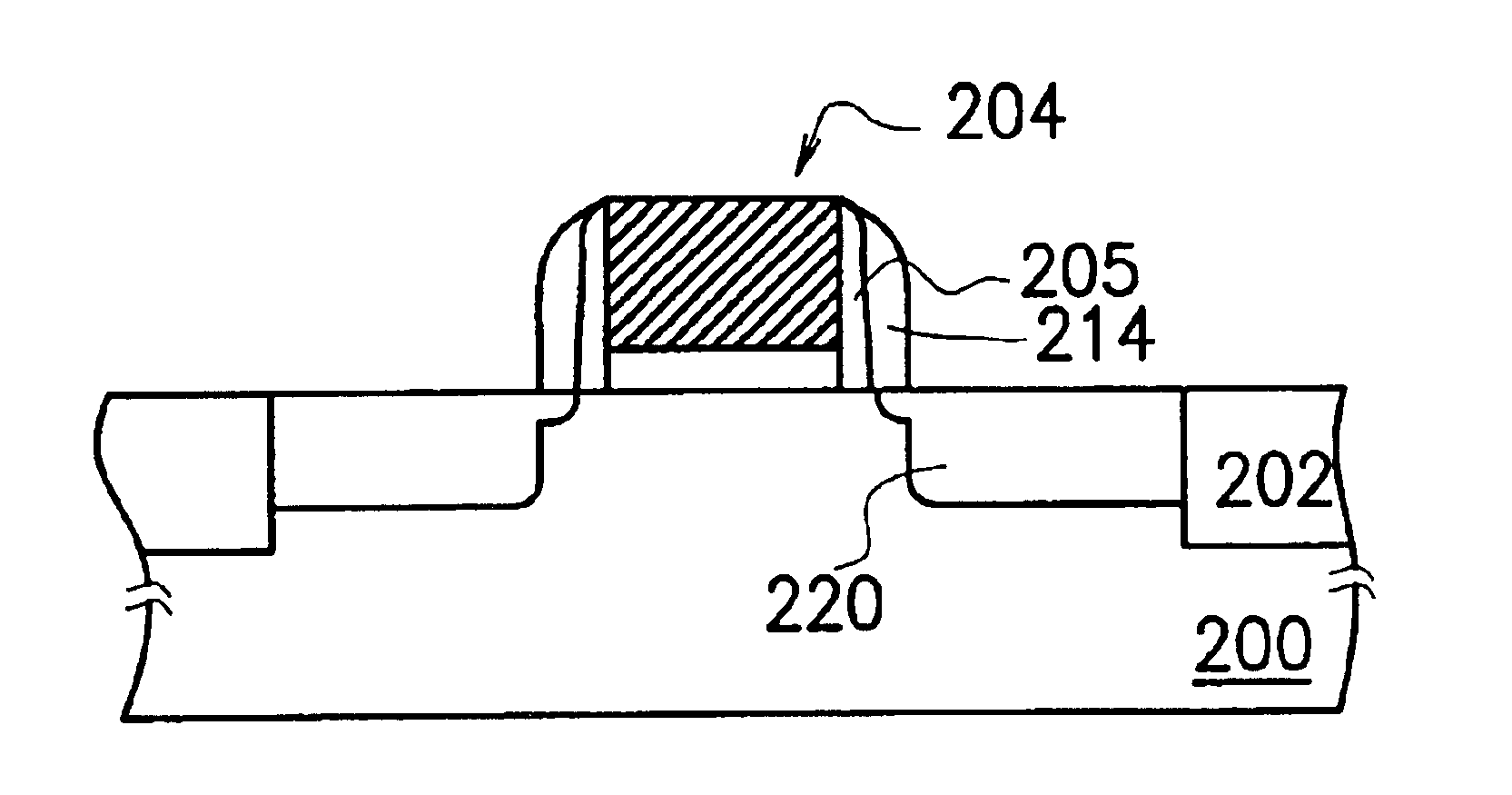

Semiconductor device using solid phase epitaxy and method for fabricating the same

InactiveUS20060237766A1Increase resistanceSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialMetal silicide

A semiconductor device includes an epitaxial layer using a solid phase epitaxy (SPE) process; a first metal layer on the epitaxial layer; a nitride-based barrier metal layer on the first metal layer; a second metal layer on the barrier metal layer; and a metal silicide layer formed between the epitaxial layer and the first metal layer after a post-annealing process.

Owner:SK HYNIX INC

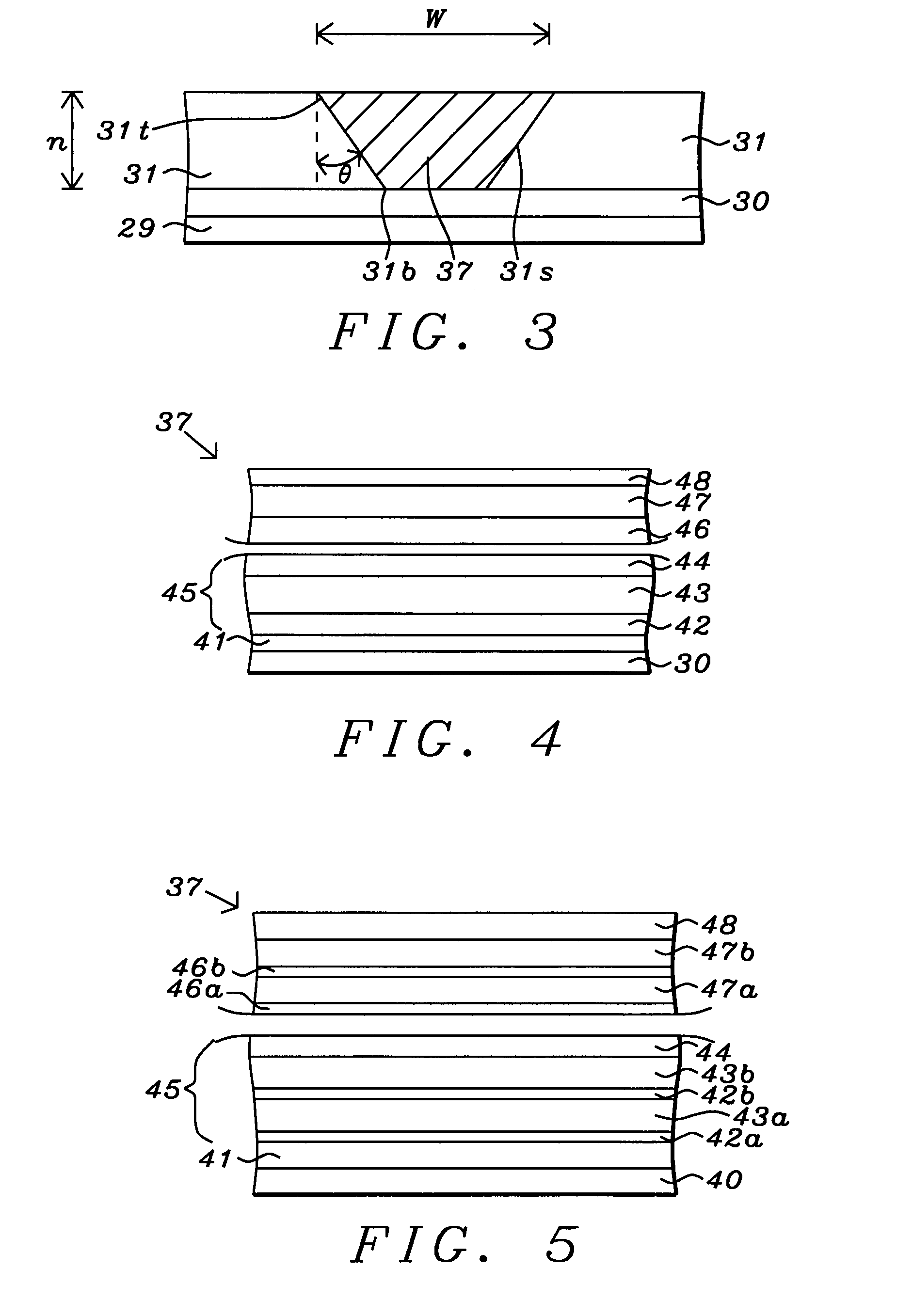

Laminated film for head applications

ActiveUS20090009907A1Minimize applicationHigh moment material softnessRecord information storageHeads for perpendicular magnetisationsRemanenceCoupling

Owner:HEADWAY TECH INC

Method of forming high-luminescence silicon electroluminescence device

InactiveUS7259055B2Enhance homogeneous oxidation of nano-SiFacilitated DiffusionFinal product manufactureSemiconductor/solid-state device detailsPorosityRefractive index

A method for forming a high-luminescence Si electroluminescence (EL) phosphor is provided, with an EL device made from the Si phosphor. The method comprises: depositing a silicon-rich oxide (SRO) film, with Si nanocrystals, having a refractive index in the range of 1.5 to 2.1, and a porosity in the range of 5 to 20%; and, post-annealing the SRO film in an oxygen atmosphere. DC-sputtering or PECVD processes can be used to deposit the SRO film. In one aspect the method further comprises: HF buffered oxide etching (BOE) the SRO film; and, re-oxidizing the SRO film, to form a SiO2 layer around the Si nanocrystals in the SRO film. In one aspect, the SRO film is re-oxidized by annealing in an oxygen atmosphere. In this manner, a layer of SiO2 is formed around the Si nanocrystals having a thickness in the range of 1 to 5 nanometers (nm).

Owner:SHARP KK

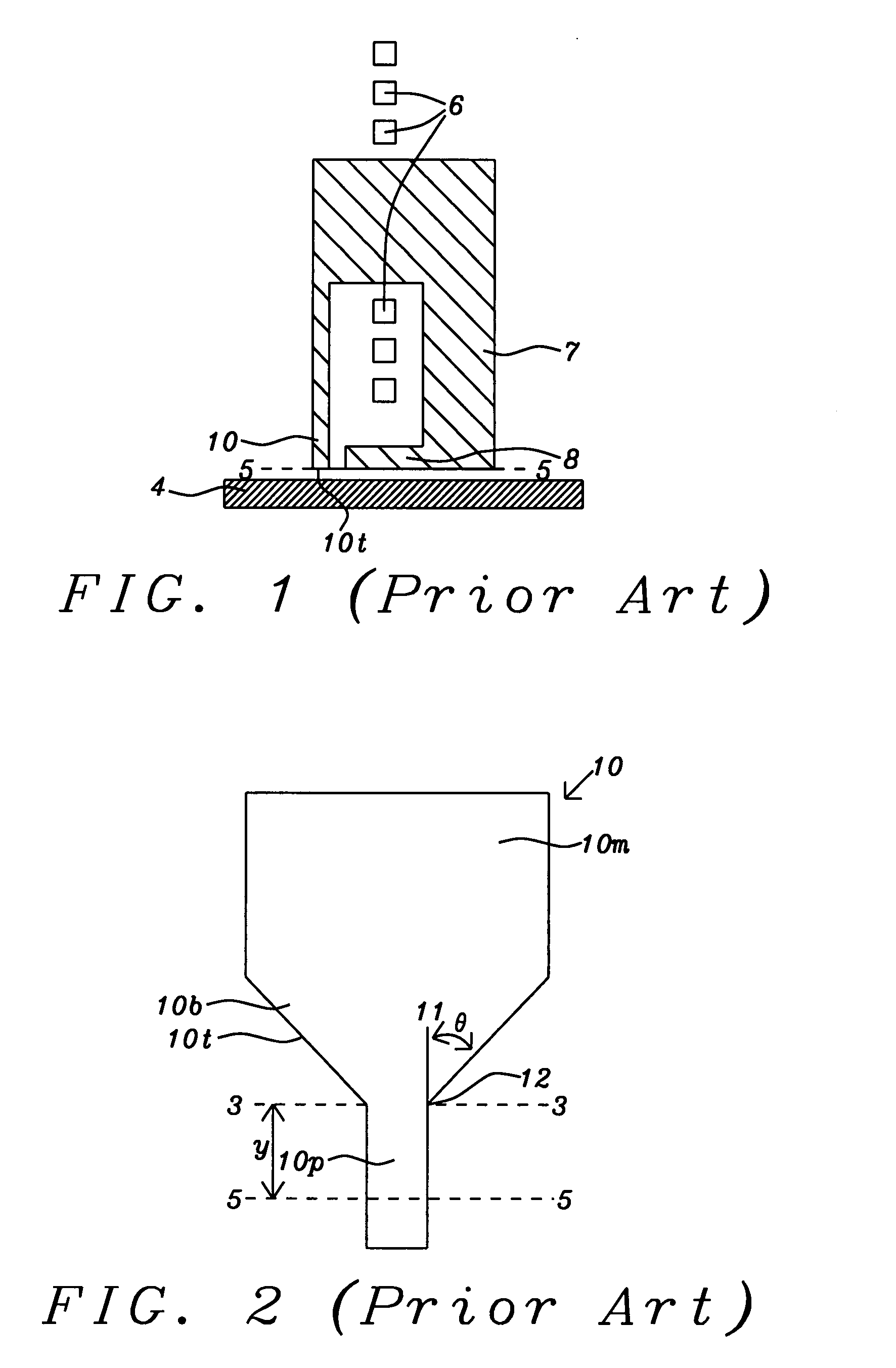

CPP device with improved current confining structure and process

InactiveUS20090059441A1Easy to adaptBetter dR/RElectrical transducersNanomagnetismCurrent limitingPlasma nitridation

Plasma nitridation, in place of plasma oxidation, is used for the formation of a CCP layer. Al, Mg, Hf, etc. all form insulating nitrides under these conditions. Maintaining the structure at a temperature of at least 150° C. during plasma nitridation and / or performing post annealing at a temperature of 220° C. or higher, ensures that no copper nitride can form. Additionally, unintended oxidation by molecular oxygen of the exposed magnetic layers (mainly the pinned and free layers) is also avoided

Owner:HEADWAY TECH INC

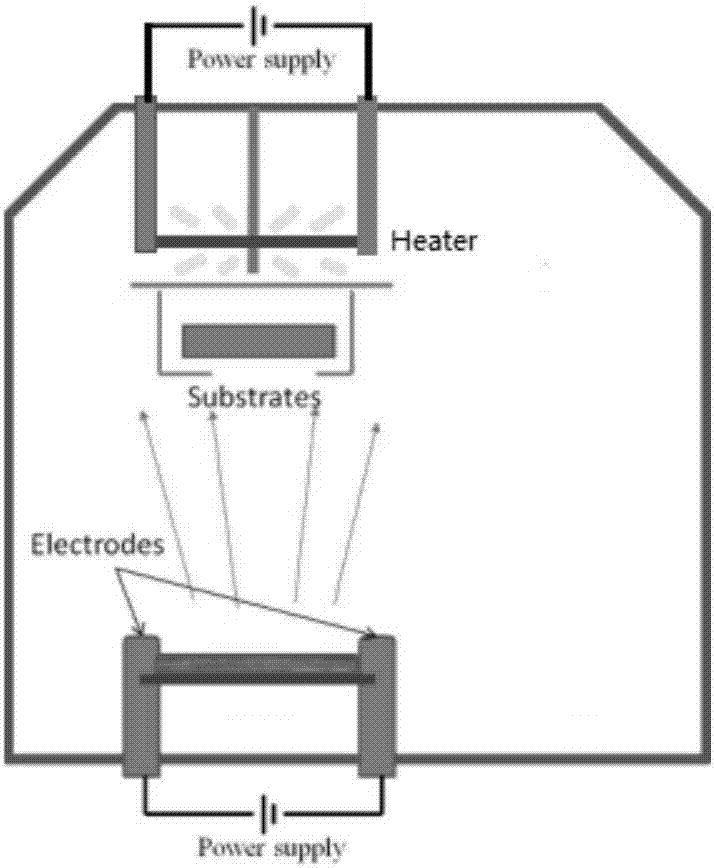

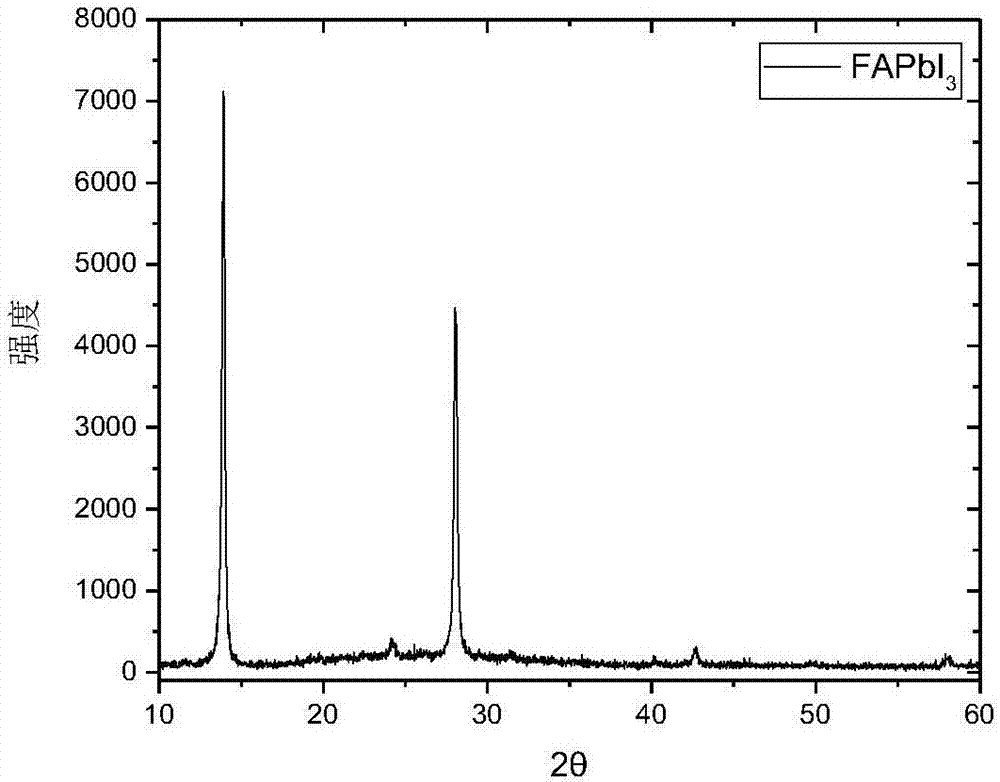

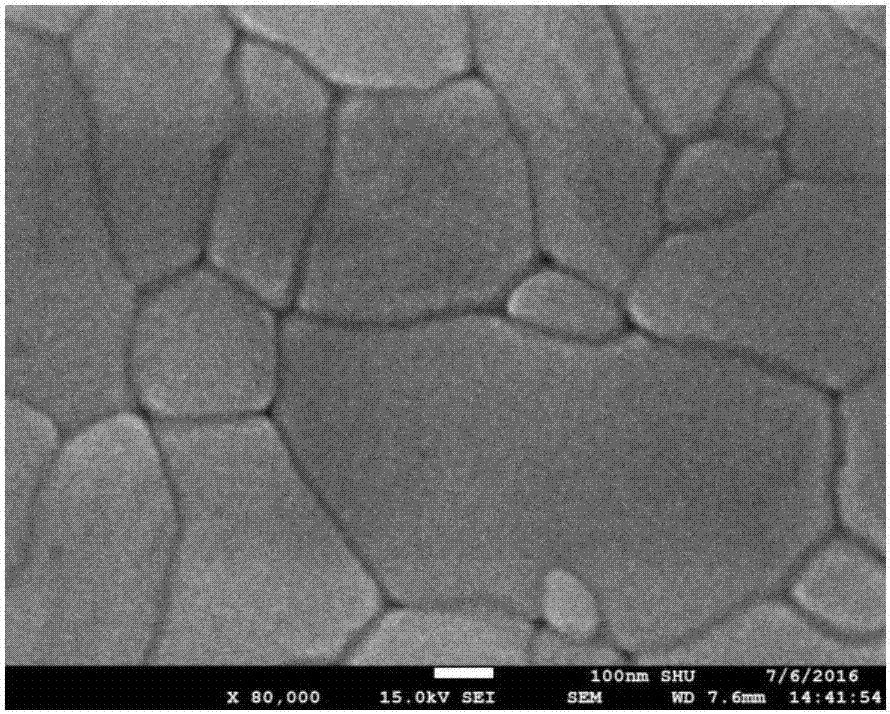

Preparation method for growing ABX3-type perovskite thin film through single-step in-situ flash method

InactiveCN106917064ASimple methodEasy to operateSolid-state devicesVacuum evaporation coatingPower flowEvaporation

The invention discloses a preparation method for growing an ABX3-type perovskite thin film through a single-step in-situ flash method. The preparation method is applied to the field of manufacturing processes for novel materials. The preparation method for the perovskite thin film comprises the following steps: taking the solution of a perovskite material as a single evaporation source; adding a heating device to a substrate; rapidly increasing a current to be not lower than 200A instantaneously under the condition that the temperature of the substrate of a sample is certain after a vacuum degree achieves a certain requirement, so that the temperature of an evaporation boat achieves a temperature of not lower than 1000 DEG C instantaneously, and the material is sublimated instantaneously; and finally directly carrying out post-annealing on the material in a vacuum cavity body to obtain the stable ABX3-type perovskite thin film. The perovskite thin film prepared by the preparation method disclosed by the invention through the single-step in-situ flash method is low in energy consumption, high in evaporation speed, short in time, void-free and uniform in large area, wide in substrate selection range, and suitable for a planar device.

Owner:SHANGHAI UNIV

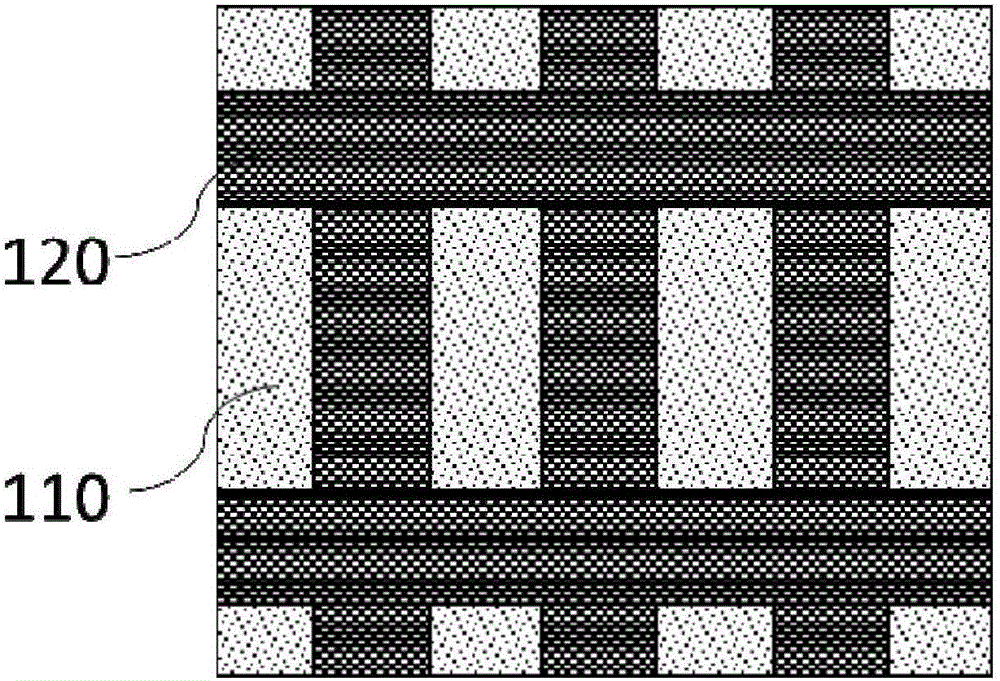

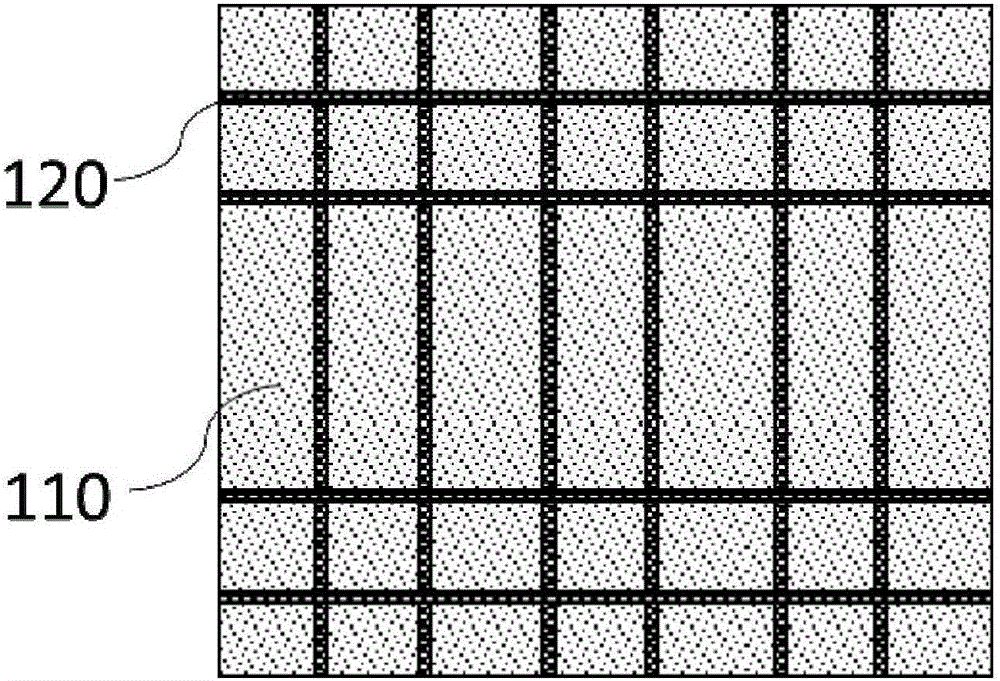

Inkjet printing preparation method of thin film, and preparation method of thin film transistor

InactiveCN106024589ALow costAvoid problemsTransistorSolid-state devicesThin film morphologyHydrophilic polymers

The invention provides an inkjet printing preparation method of a thin film. The inkjet printing preparation method is characterized in that the appearance of the thin film prepared by inkjet printing is defined by a hydrophobic coffee-ring grid, and the appearance of the thin film includes at least one of thin film pattern, thin film size, thin film thickness or thin film morphology. The specific inkjet printing preparation method comprises the steps of: a, preparing the coffee-ring grid; b, and directly spraying ink droplets into units of the coffee-ring grid, and performing drying and post-annealing to obtain the solid-state thin film, wherein the coffee-ring grid is a hydrophobic polymer coffee-ring grid or is composed of a hydrophilic polymer layer at the lower layer and a hydrophobic polymer layer at the upper layer. The inkjet printing preparation method can be used for preparing inorganic or organic material thin films, the prepared thin films are used as a gate electrode layer, a dielectric layer, an active layer or a source / drain electrode of the thin film transistor. The inkjet printing preparation method effectively controls the droplet spreading in the inkjet printing, solves the coffee-ring problem of the prepared film layer, and can be applied to the large-area preparation of the thin film transistor devices.

Owner:SOUTH CHINA UNIV OF TECH

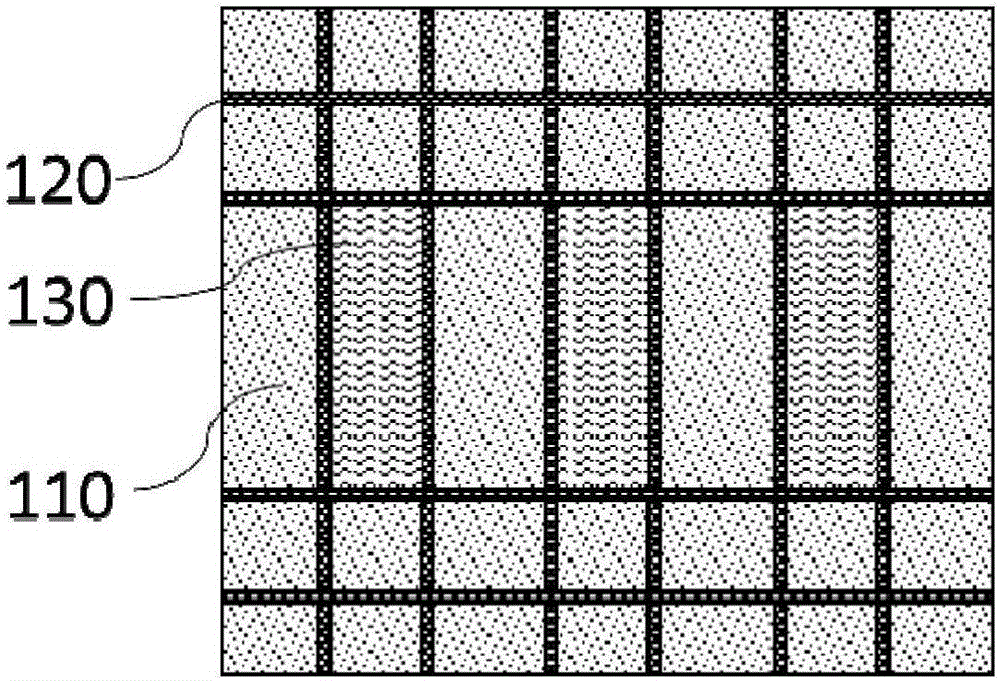

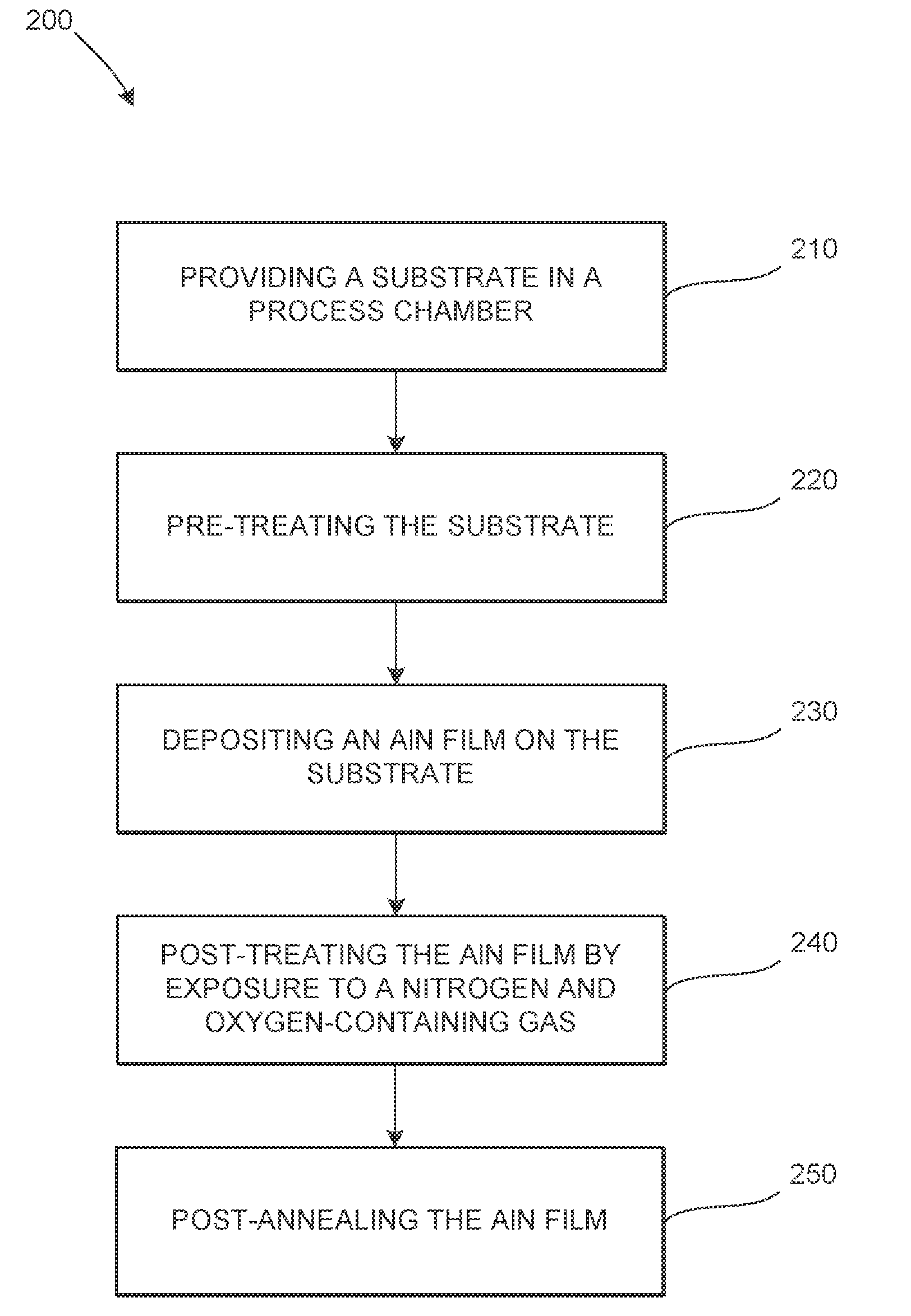

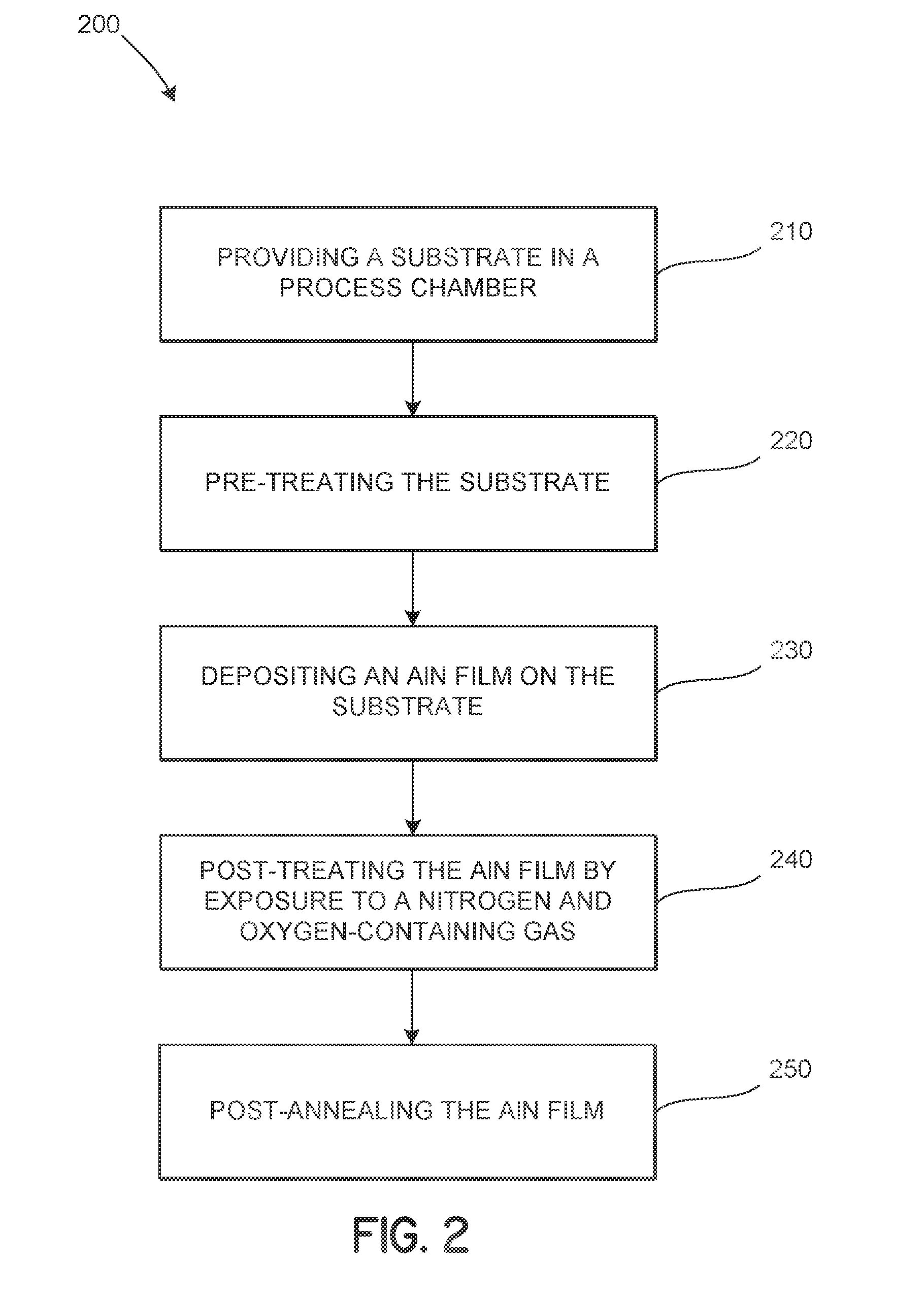

In-situ formation of oxidized aluminum nitride films

ActiveUS20070259534A1High dielectric constantReduce thicknessSemiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogenOxygen

A method is provided for in-situ formation of a thin oxidized AlN film on a substrate. The method includes providing the substrate in a process chamber, depositing an AlN film on the substrate, and post-treating the AlN film with exposure to a nitrogen and oxygen-containing gas. The post-treating increases the dielectric constant of the AlN film with substantially no increase in the AlN film thickness. The method can also include pre-treating the substrate prior to AlN deposition, post-annealing the AlN film before or after the post-treatment, or both.

Owner:TOKYO ELECTRON LTD

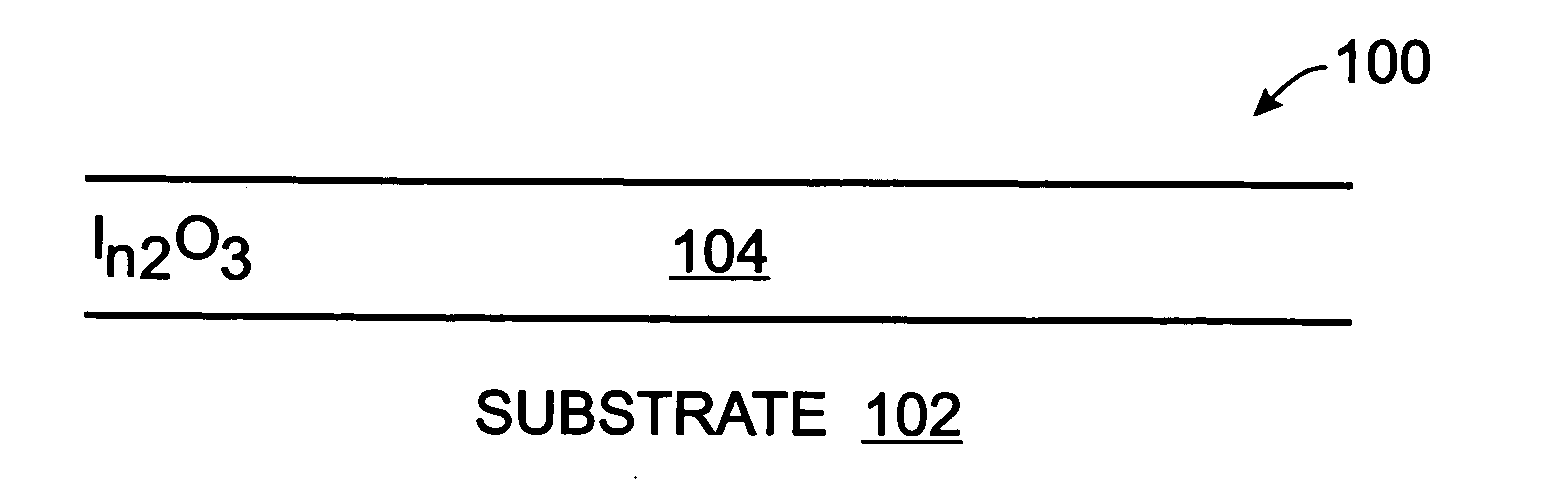

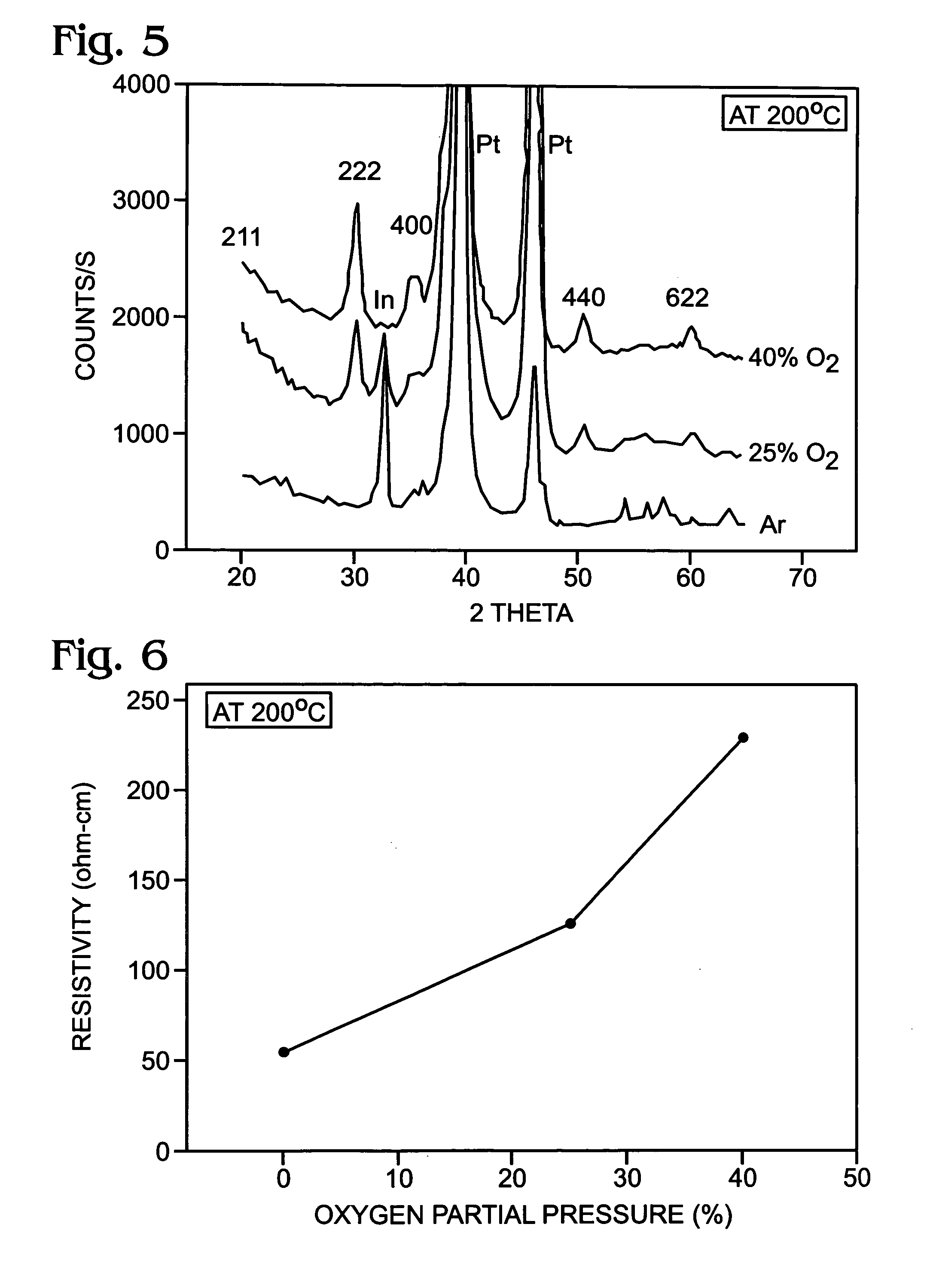

Indium oxide conductive film structures

One-transistor ferroelectric memory devices using an indium oxide film (In2O3), an In2O3 film structure, and corresponding fabrication methods have been provided. The method for controlling resistivity in an In2O3 film comprises: depositing an In film using a PVD process, typically with a power in the range of 200 to 300 watts; forming a film including In overlying a substrate material; simultaneously (with the formation of the In-including film) heating the substrate material, typically the substrate is heated to a temperature in the range of 20 to 200 degrees C.; following the formation of the In-including film, post-annealing, typically in an O2 atmosphere; and, in response to the post-annealing: forming an In2O3 film; and, controlling the resistivity in the In2O3 film. For example, the resistivity can be controlled in the range of 260 to 800 ohm-cm.

Owner:SHARP KK

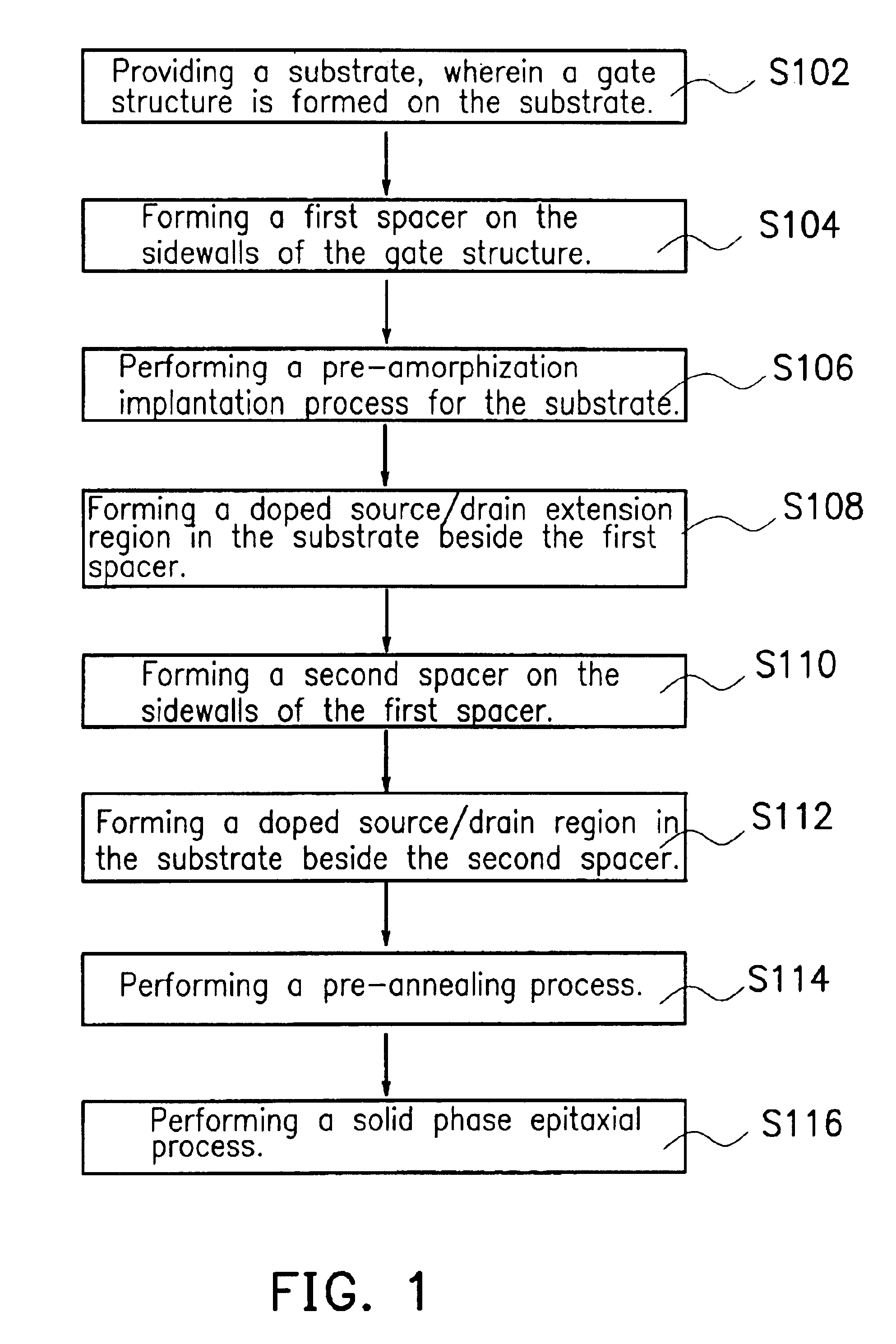

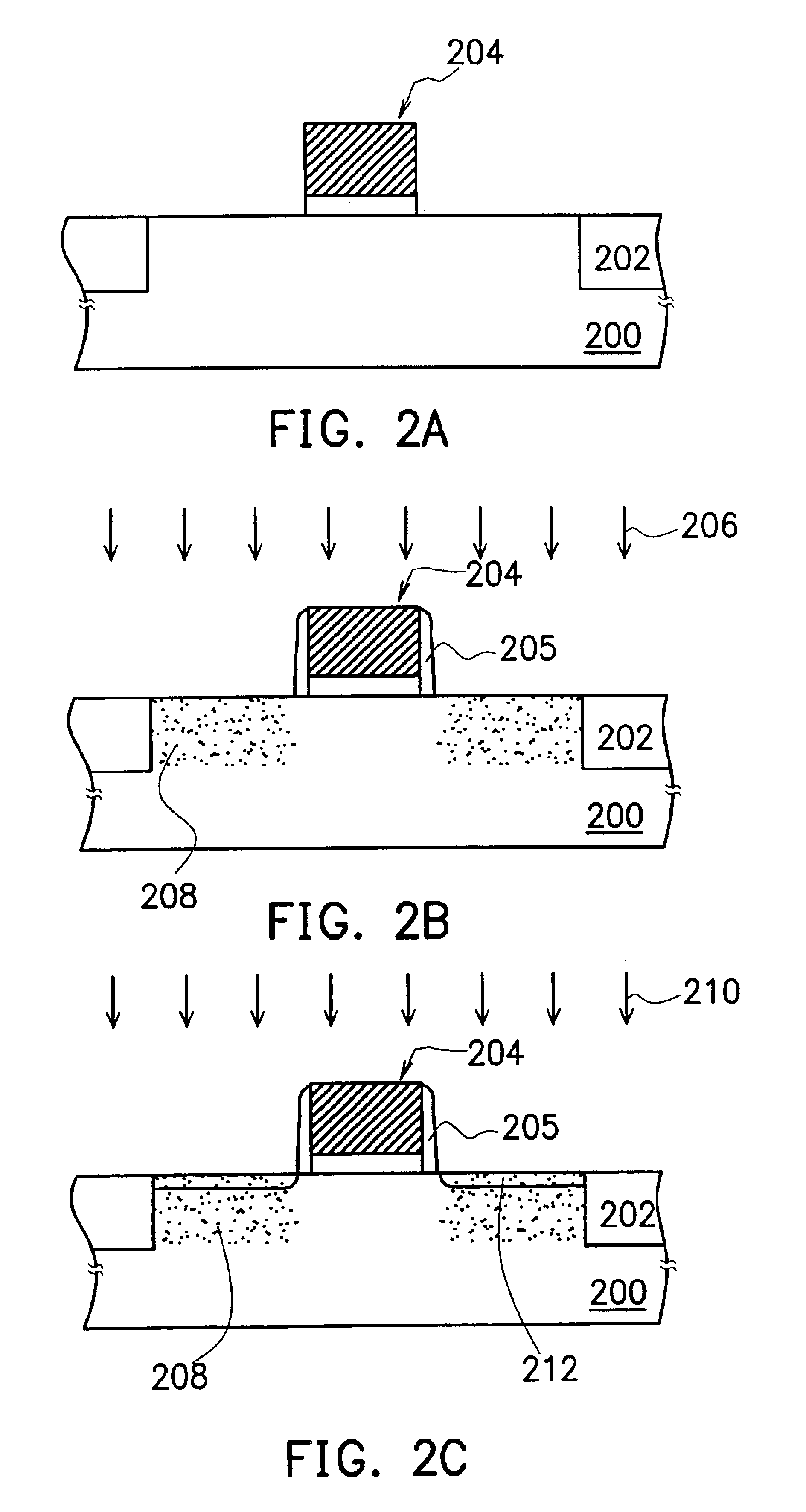

Method of manufacturing metal-oxide-semiconductor transistor

InactiveUS6943085B2Reduce sheet resistanceImprove electrical performanceTransistorSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A method of manufacturing a MOS transistor is provided. A substrate having a gate structure thereon is provided. A first spacer is formed on the sidewall of the gate structure. A pre-amorphization implantation is carried out to amorphize a portion of the substrate. A doped source / drain extension region is formed in the substrate on each side of the first spacer. A second spacer is formed on the sidewall of the first spacer. A doped source / drain region is formed in the substrate on each side of the second spacer and then a pre-annealing operation is performed. Thereafter, a solid phase epitaxial process is carried out to re-crystallize the amorphized portion of the substrate and activate the doped source / drain extension region and the doped source / drain region to form a source / drain terminal. Finally, a post-annealing operation is performed.

Owner:UNITED MICROELECTRONICS CORP

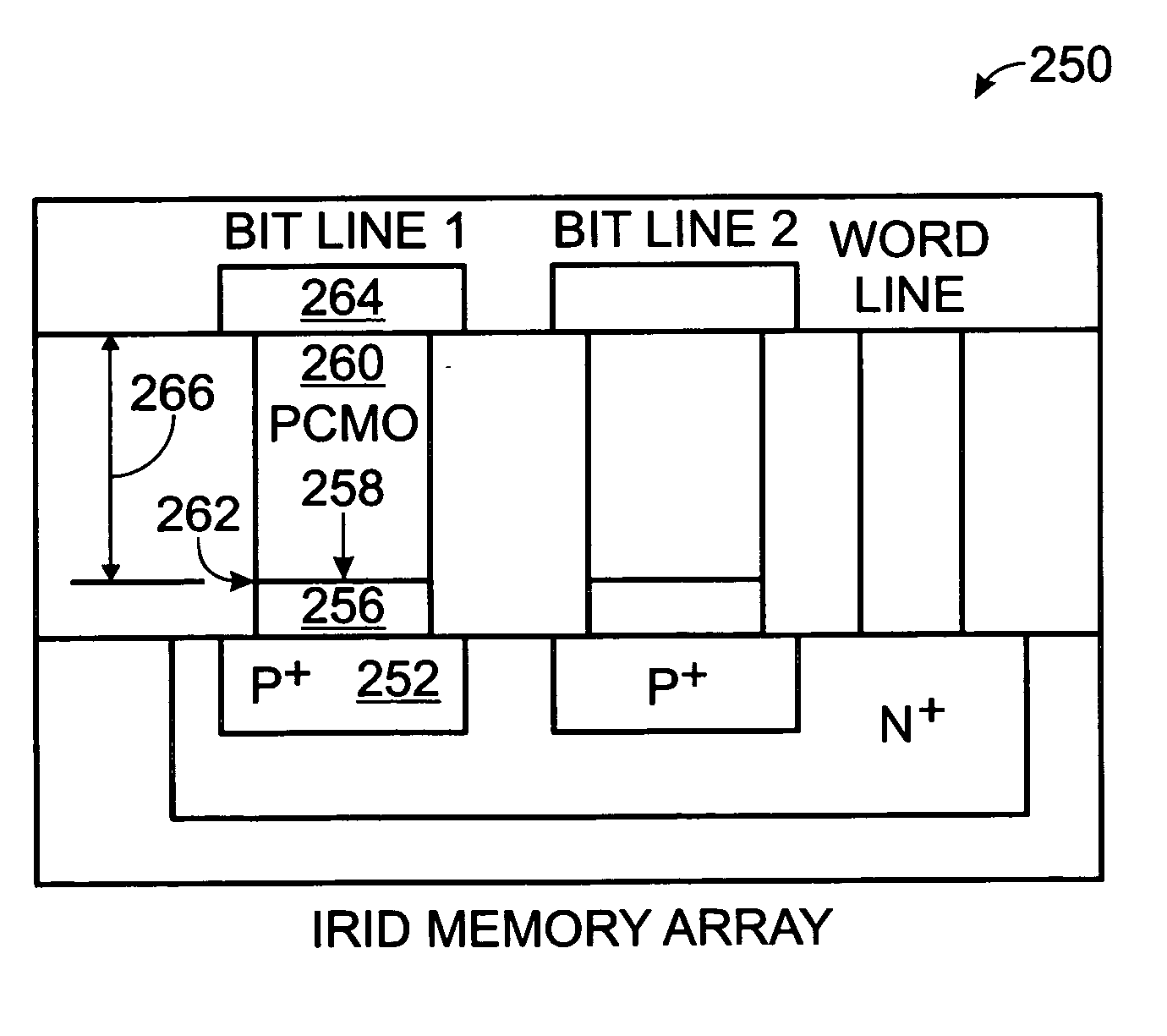

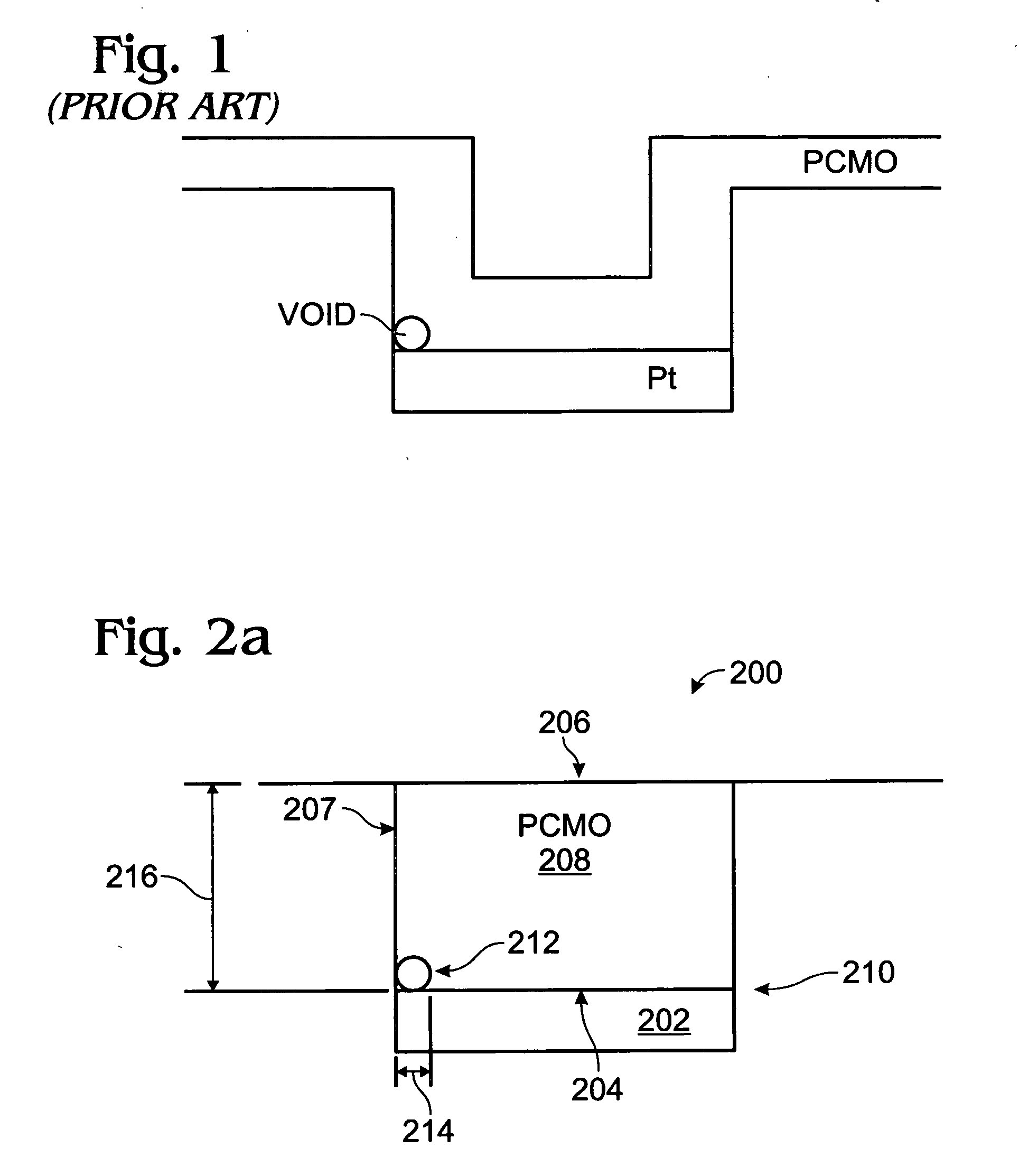

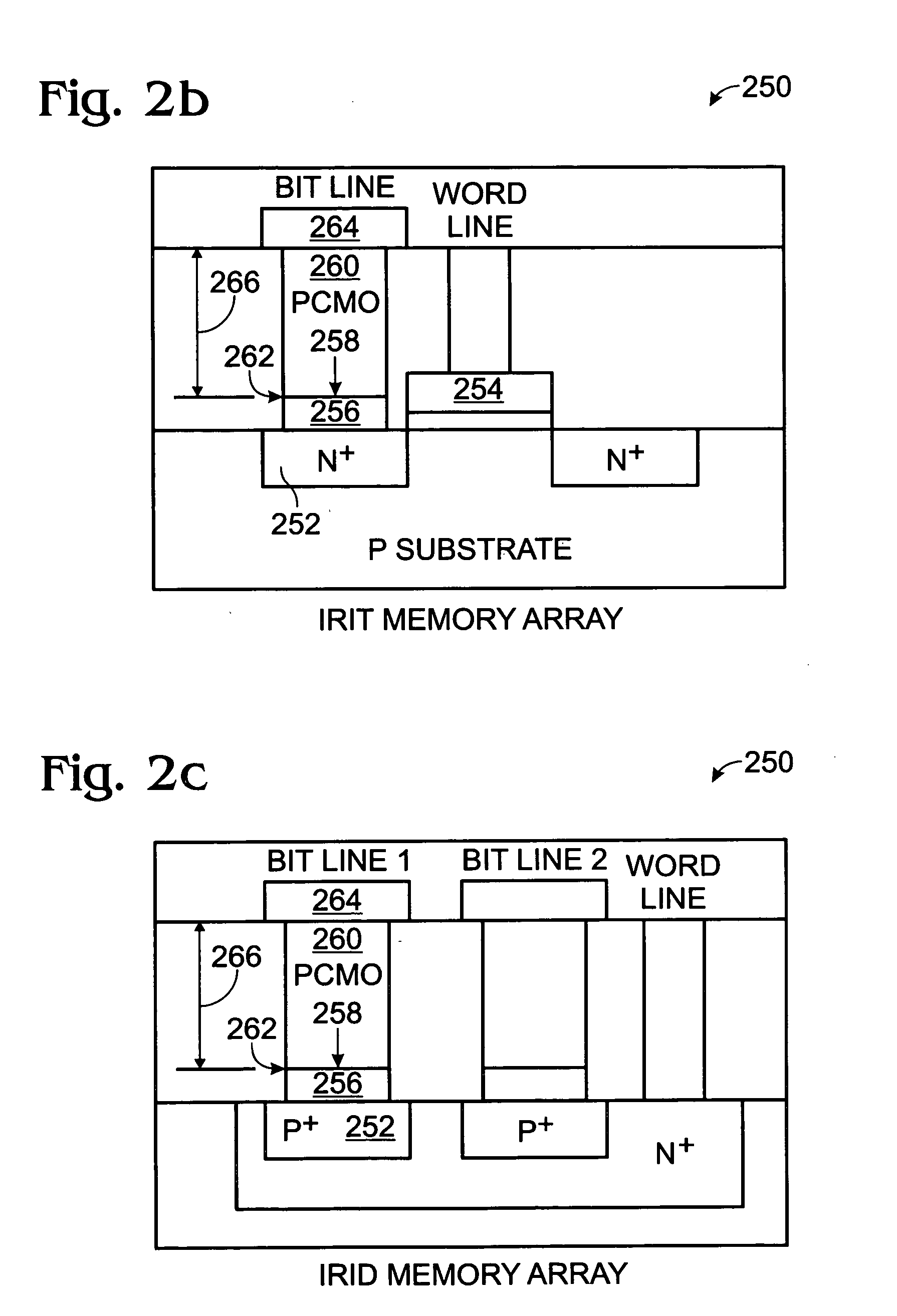

PCMO spin-coat deposition

InactiveUS20050158994A1Semiconductor/solid-state device detailsSolid-state devicesCooking & bakingFree interface

A Pr1-XCaXMnO3 (PCMO) spin-coat deposition method for eliminating voids is provided, along with a void-free PCMO film structure. The method comprises: forming a substrate, including a noble metal, with a surface; forming a feature, such as a via or trench, normal with respect to the substrate surface; spin-coating the substrate with acetic acid; spin-coating the substrate with a first, low concentration of PCMO solution; spin-coating the substrate with a second concentration of PCMO solution, having a greater concentration of PCMO than the first concentration; baking and RTA annealing (repeated one to five times); post-annealing; and, forming a PCMO film with a void-free interface between the PCMO film and the underlying substrate surface. The first concentration of PCMO solution has a PCMO concentration in the range of 0.01 to 0.1 moles (M). The second concentration of PCMO solution has a PCMO concentration in the range of 0.2 to 0.5 M.

Owner:XENOGENIC DEV LLC

Alloy forged steel and production method and application thereof

ActiveCN103352170AImprove the mechanical properties at room temperatureReduce manufacturing costFriction liningSmeltingFerric

The invention relates to alloy forged steel and a production method thereof. The production method comprises the following steps: alloy smelting, wherein the alloy comprises the following components by weight percent: 0.24 percent to 0.31 percent of carbon, 0.20 percent to 0.50 percent of silicon, 0.50 percent to 0.90 percent of manganese, 1.10 percent to 1.50 percent of chromium, 0.50 percent to 0.89 percent of molybdenum, 0.20 percent to 0.40 percent of vanadium, less than or equal to 0.015 percent of phosphorus, less than or equal to 0.012 percent of sulfur, the balance of iron and unavoidable impurities; pouring a steel ingot; diffusion annealing, warming the steel ingot, heat preservation, furnace cooling, and then drawing a charge and wind cooling; forging blank; annealing after forging, warming the blank, heat preservation, furnace cooling, and then drawing a charge and wind cooling; heat treatment, quenching and then tempering. The production method of the alloy forged steel is relatively simple, can produce the alloy forged steel with fine comprehensive mechanical property and higher coefficient of thermal conductivity in the ordinary temperature state and the high temperature state.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

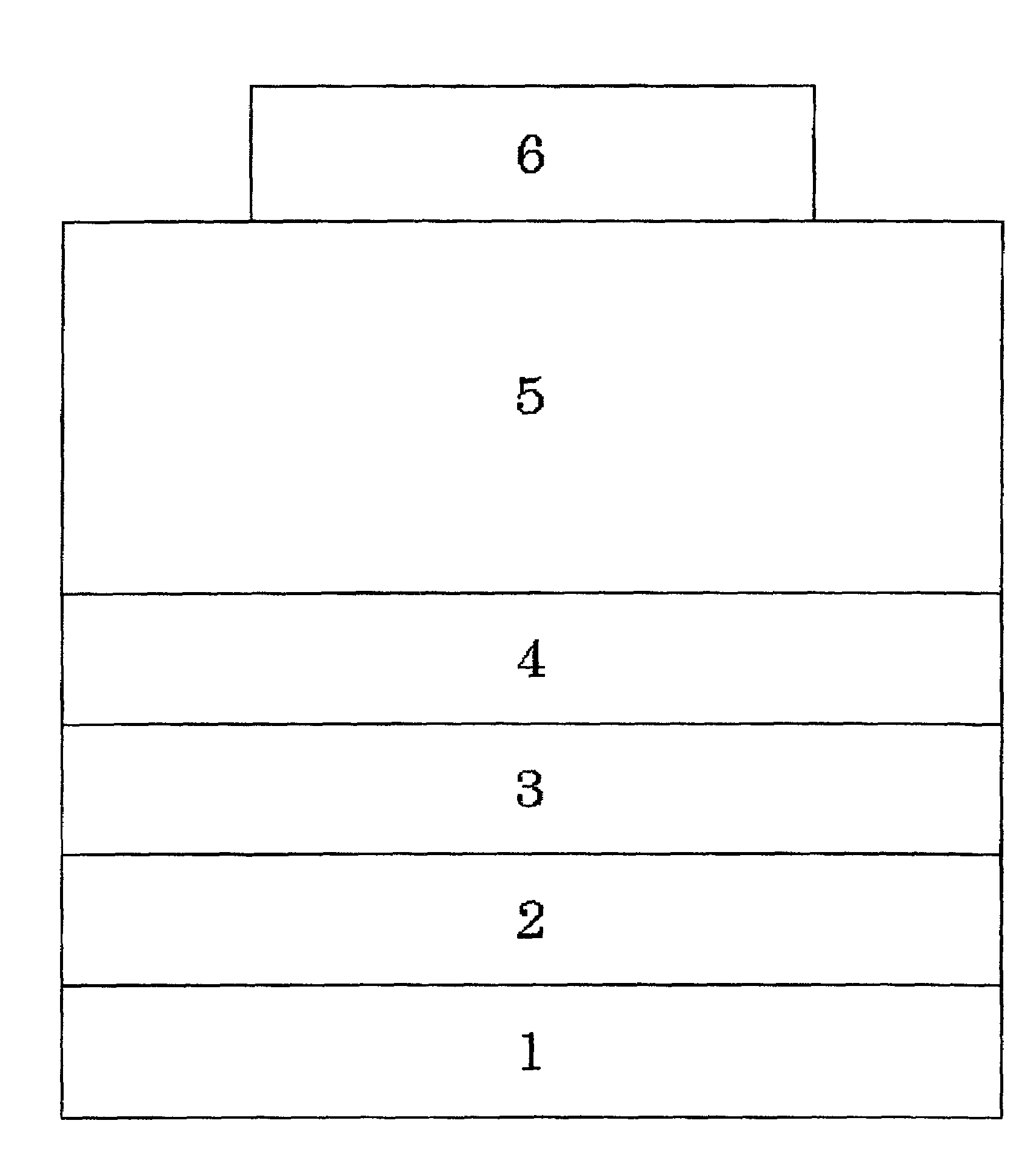

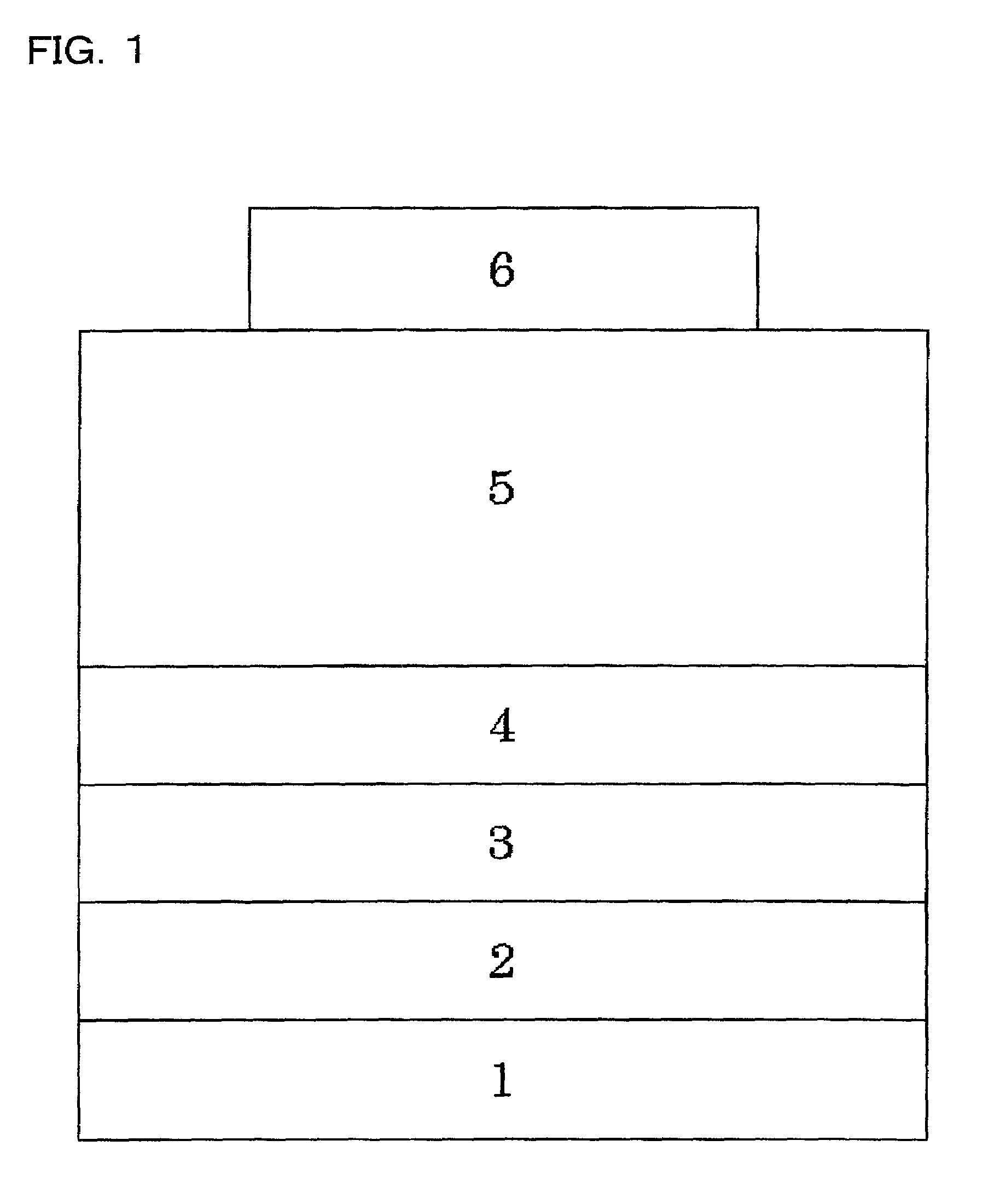

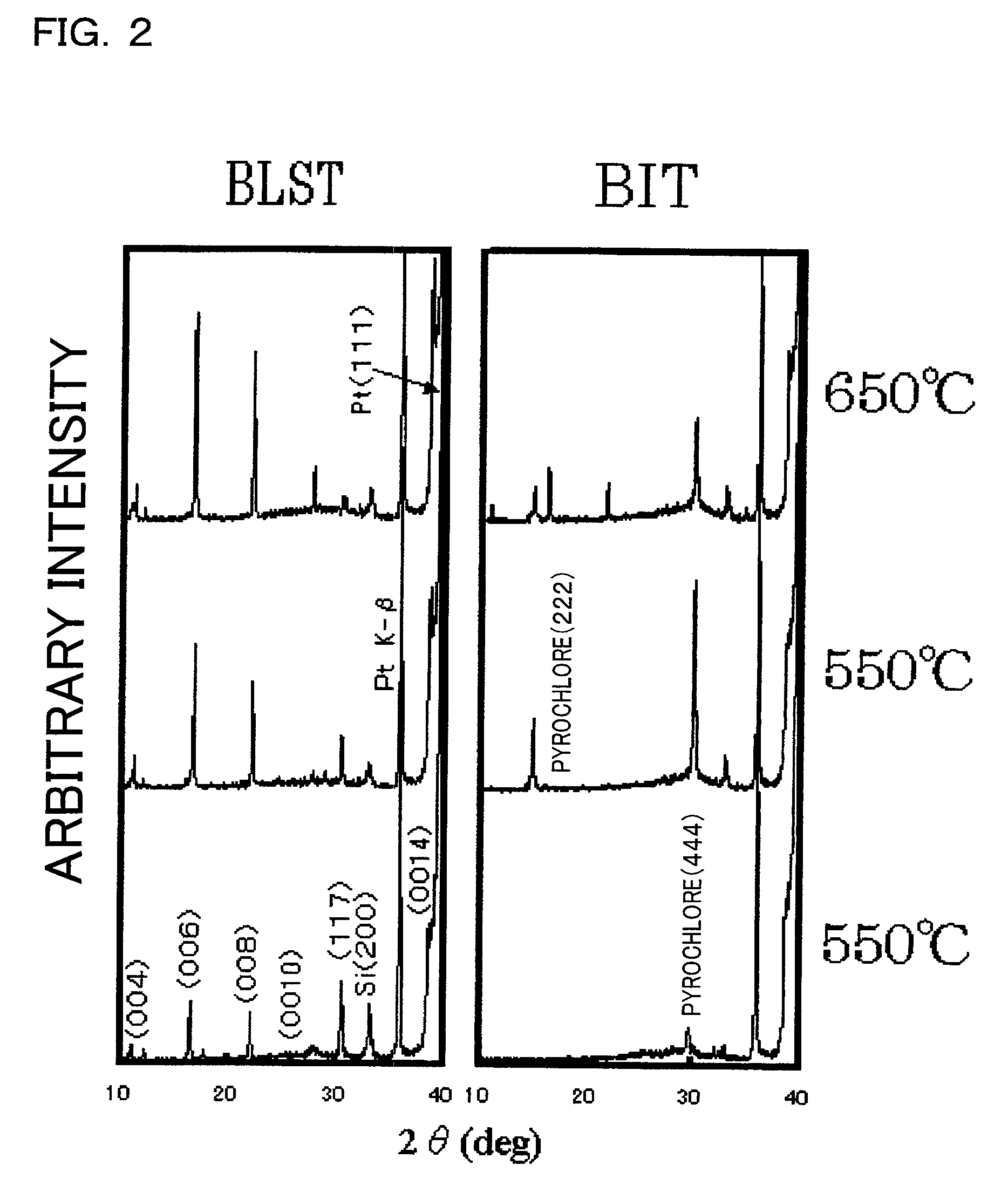

Ceramic and method of manufacturing the same, dielectric capacitor, semiconductor device, and element

InactiveUS7008669B2Reduce crystallizationImprove surface morphologyPiezoelectric/electrostrictive device manufacture/assemblyVacuum evaporation coatingCatalytic effectCeramic

A method of manufacturing a ceramic includes forming a film which includes a complex oxide material having an oxygen octahedral structure and a paraelectric material having a catalytic effect for the complex oxide material in a mixed state, and performing a heat treatment to the film, wherein the paraelectric material is one of a layered catalytic substance which includes Si in the constituent elements and a layered catalytic substance which includes Si and Ge in the constituent elements. The heat treatment includes sintering and post-annealing. At least the post-annealing is performed in a pressurized atmosphere including at least one of oxygen and ozone. A ceramic is a complex oxide having an oxygen octahedral structure, and has Si and Ge in the oxygen octahedral structure.

Owner:SEIKO EPSON CORP

High-carbon cold-rolled automobile diaphragm spring steel and production method thereof

The invention discloses high-carbon cold-rolled automobile diaphragm spring steel. The high-carbon cold-rolled automobile diaphragm spring steel is prepared from the following constituents in percentage by weight: 0.70-0.90% of C, 0.15-0.35% of Si, 0.50-1.00% of Mn, P smaller than or equal to 0.008%, S smaller than or equal to 0.002%, 0.010-0.030% of Alt, 0.10-0.30% of V, 1.20-2.00% of Cr, 1.20-2.00% of Ni, 0.002-0.006% of Ca, and N smaller than or equal to 0.004%, and is prepared by the following production steps: molten iron desulphurization, smelting in a converter, refining in an LF (Ladle Furnace) furnace, processing in a RH vacuum furnace, continuous casting to form blanks, pit type slow cooling after cutting of cast blanks, cast blank heating, segmented hot rolling, reeling, slow cooling, annealing after cutting, cold rolling, quenching, tempering, and inspection for standby. The steel disclosed by the invention is rolled and thermally treated to achieve high strength, high elasticity, high limit of yielding, high fatigue limit resistance, low-temperature toughness and longer service life, and can be used for manufacturing various vehicle clutch assemblies, especially the large engineering machinery at the low temperature environment.

Owner:武汉钢铁有限公司

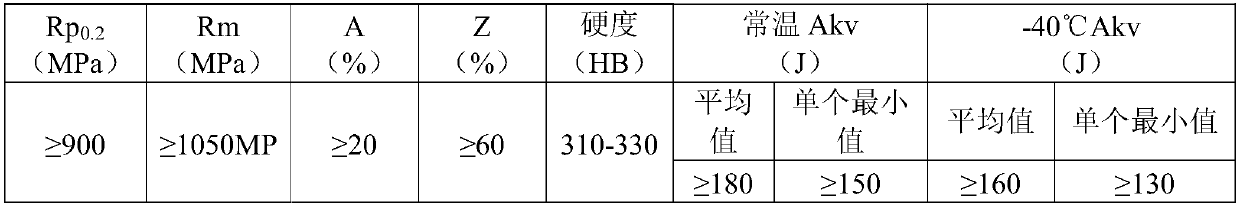

Manufacturing process of soft martensitic stainless steel valve box forging

The invention relates to a manufacturing process of a stainless steel valve box forging. The stainless steel valve box forging is manufactured by adopting low-carbon (preferential ultralow-carbon) soft martensitic stainless steel, and comprises the following chemical components (wt%): C not more than 0.06, Si not more than 0.80, Mn not more than 1.0, P not more than 0.015, S not more than 0.010, 12-16 of Cr, 3.5-6.0 of Ni, Mo not more than 1.0, 0.01-0.02 of N, Cu not more than 0.010, and 0.01-0.015 of Al. The process comprises the steps of forging, annealing after forging, flaw detection afterrough machining, solid solution treatment, tempering, and sampling detection. In heating of the forging and the solid solution treatment, a gradient heating mode is adopted. After preheating, a higher heating speed is adopted to reach higher overheating degree to obtain finer austenite grains; through multi-directional forging and increment of a forging ratio, a forging material is more compact,and the mechanical performances are non-directional; and the solid solution treatment and the tempering treatment are combined to control a proper amount of reversed austenite to disperse among martensitic laths or substructures. The manufactured valve box forging is high in comprehensive and mechanical performances, wear resistance and corrosion fatigue limit resistance, and is excellent in coldand hot working performances.

Owner:山西同航特钢有限公司

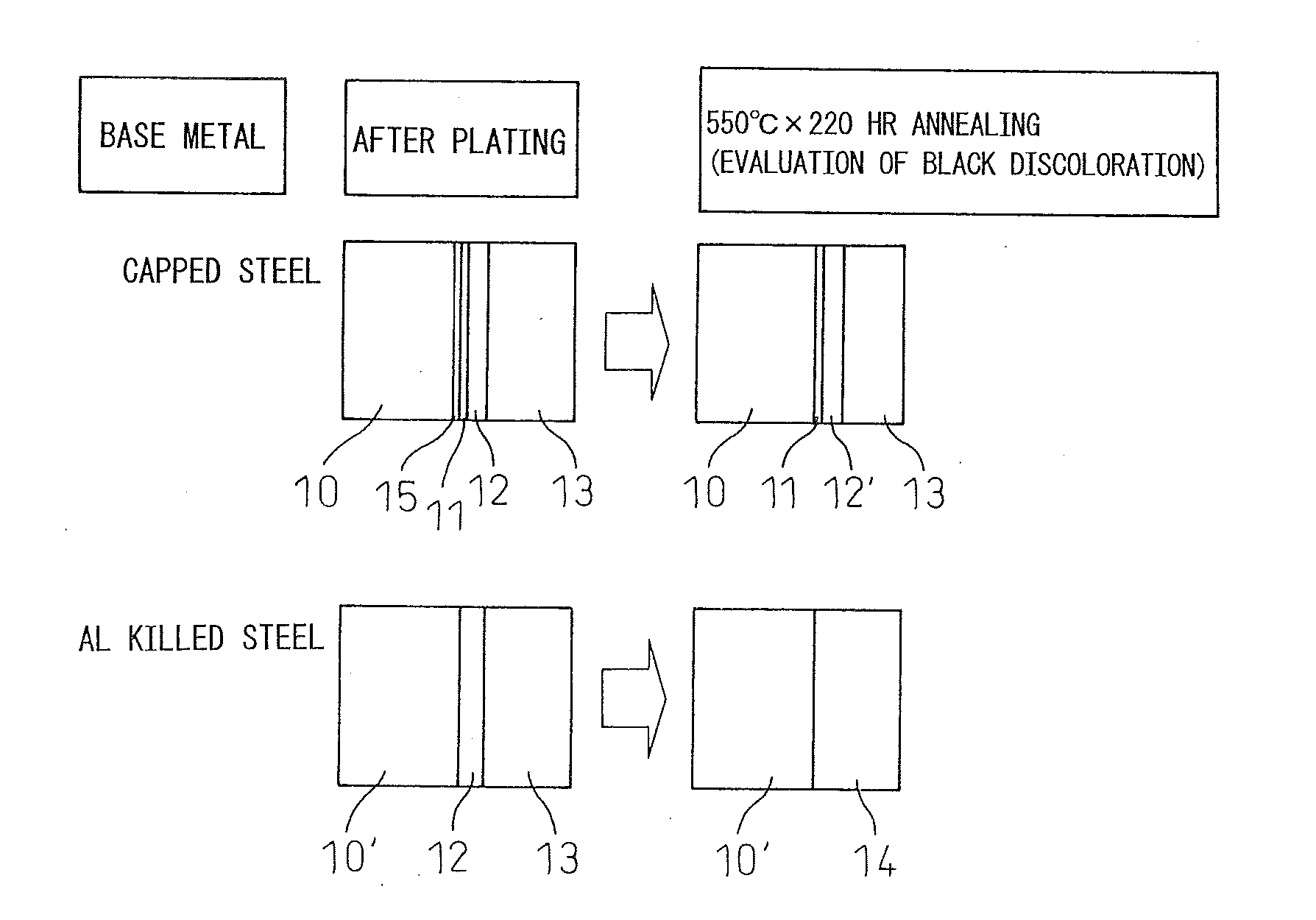

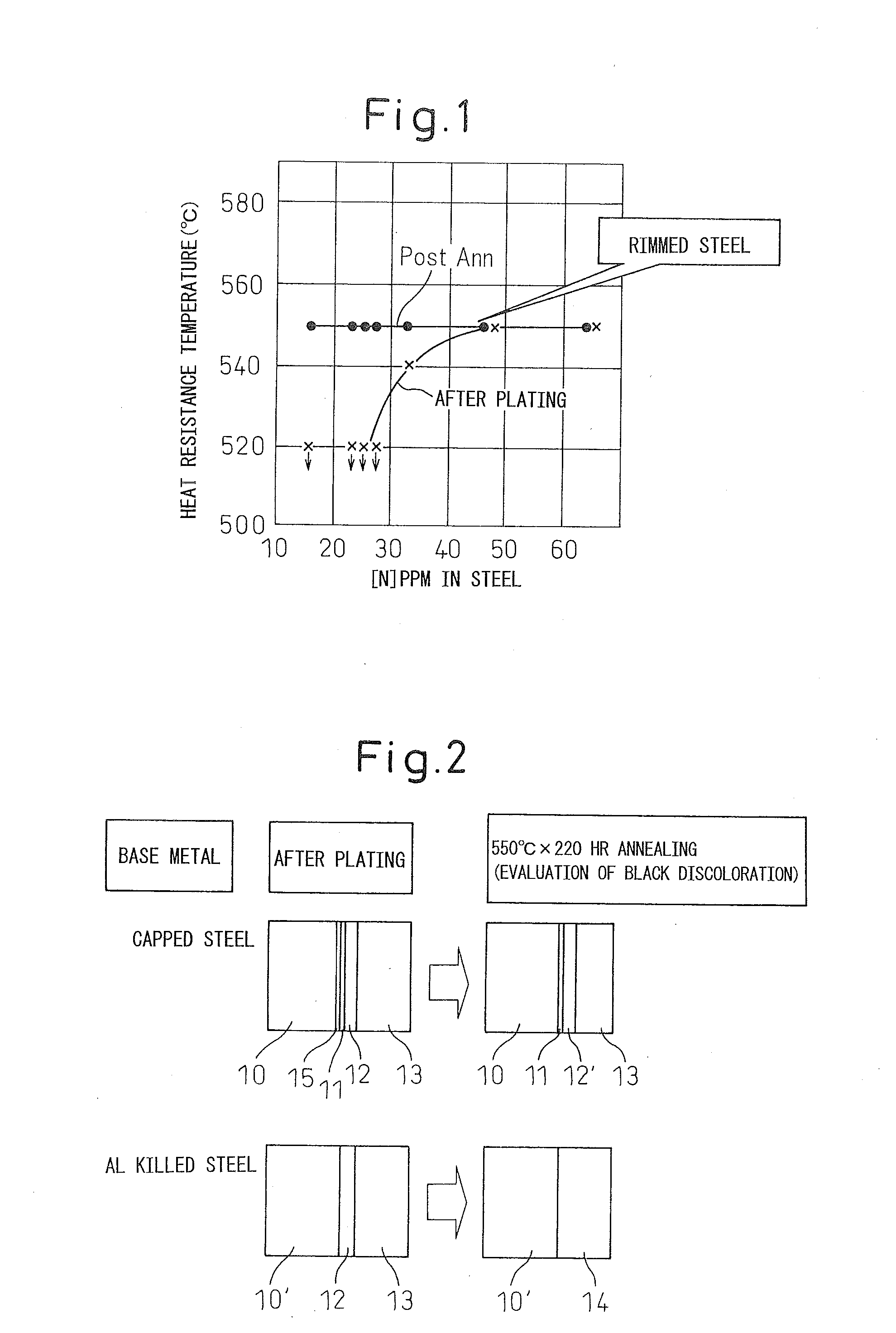

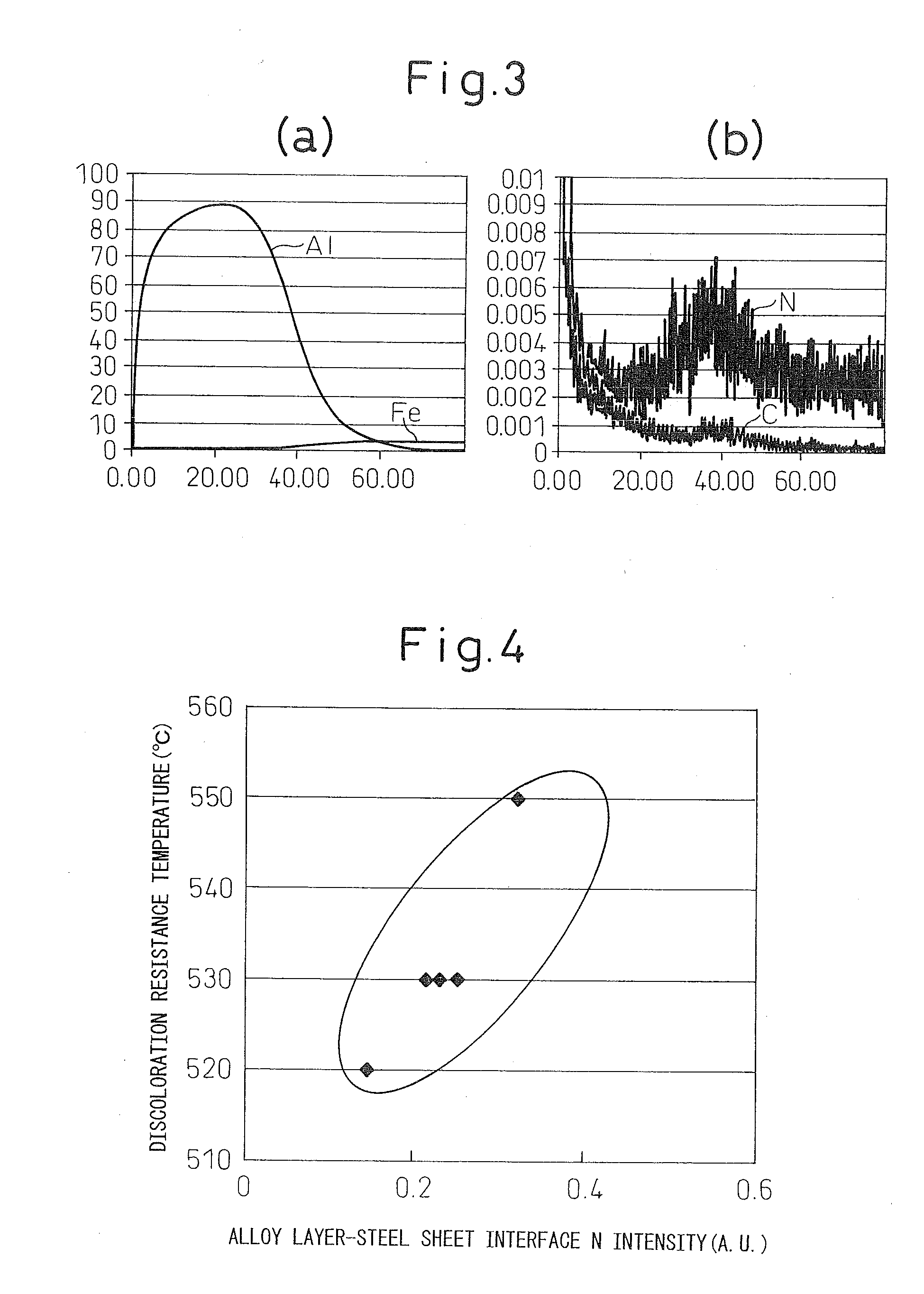

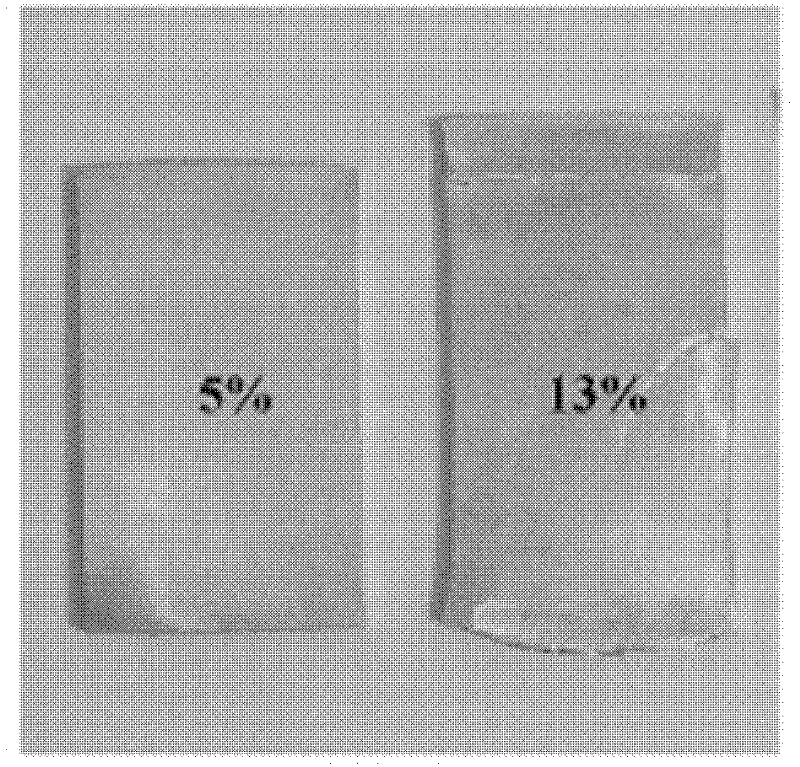

Hot Dip Al Coated Steel Sheet Excellent in Heat Black Discoloration Resistance and Method of Production of Same

ActiveUS20130095345A1Increase production capacityReduce manufacturing costHot-dipping/immersion processesLiquid surface applicatorsIntermetallicMetal

In conventional Al coated steel sheet, with the Al coating as it is, black discoloration cannot be prevented at 550° C. or more. For this reason, post annealing is used to form a barrier layer and suppress the formation of Fe—Al intermetallic compounds. However, with this method, there were the problems that the steel sheet became poor in workability and, further, high temperature, long time heating was required, so there were problems from the workability, economy, and environmental aspect. The present invention provides steel sheet which has a heat black discoloration resistance even at a 550° C. or more high temperature without additional annealing after Al coating and further is excellent in workability.That is, it is hot dip Al coated steel sheet which comprises steel sheet which contains predetermined ingredients of C, Si, P, S, Al, N, and O plus one or both of furthermoreNi: 0.01 to 0.1% orCu: 0.01 to 0.1% andsatisfies 10×C+Ni+Cu>0.03 and an Al coating layer which contains Si: 4 to 11% on the surface of that steel sheet and which have a thickness 5 μm or less Al—Fe—Si alloy layer in the interface between the Al coating layer and the steel sheet.

Owner:NIPPON STEEL CORP

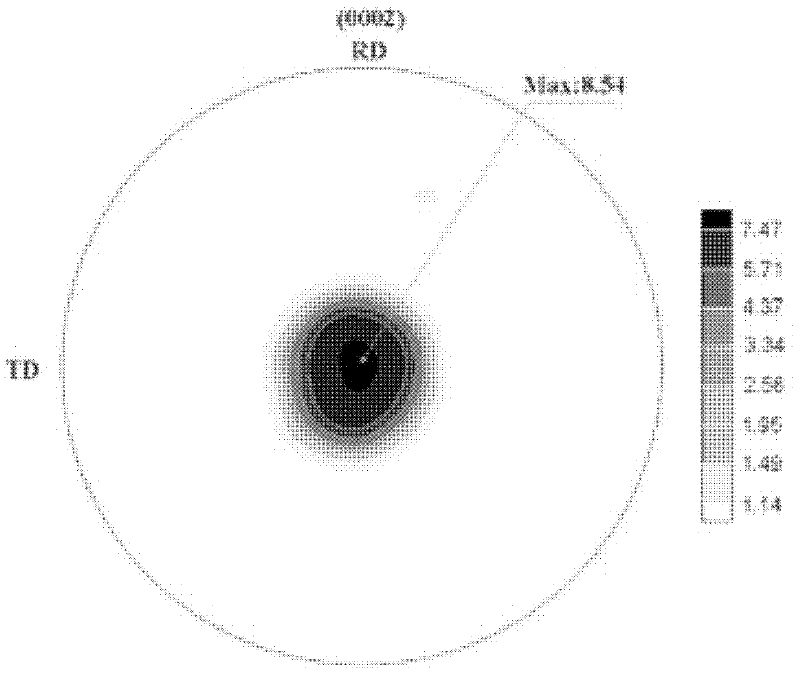

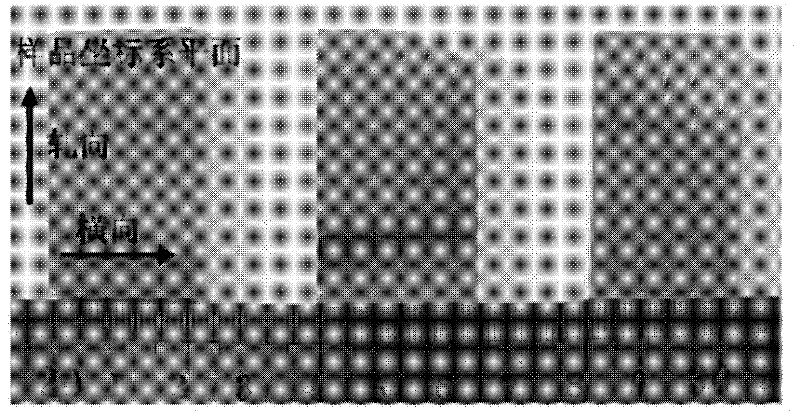

Cold-rolling method of magnesium alloy deformation material with non/weak-basal texture and cold-rolled sheet obtained thereby

The invention relates to the technical field of metal materials, and specifically relates to a cold-rolling method of a magnesium alloy deformation material with a non / weak-basal texture and a cold-rolled sheet obtained thereby. The cold-rolling method comprises the following steps: carrying out pre-treatment on a magnesium alloy deformation material blank with a non / weak-basal texture, and then carrying out cold-rolling processing, wherein the non / weak-basal texture plane of the blank is selected as the rolling plane during cold rolling, the rolling direction is parallel to the plane, and the blank is cold-rolled at room temperature into a sheet or foil with a thickness of 0.1-100 mm by single-pass or multiple-pass cold rolling; and annealing the sheet or foil after cold rolling at the annealing temperature of 200-400 DEG C for 10 minutes to 48 hours. Compared with the Mg-RE-Zn magnesium alloy deformation material blank with a non / weak-basal texture for cold rolling, the strength of the cold-rolled sheet is increased by 15% or above, and the strength of the cold-rolled and annealed sheet can be ensured to be increased by not less than 10%. Simultaneously, the rolling-direction elongation rate delta of the sheet is greater than or equal to 25%.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for improving electromigration lifetime of copper interconnection by extended post anneal

InactiveUS20100167526A1Reduce copper electromigrationSemiconductor/solid-state device manufacturingInterconnectionOptoelectronics

Methods for improving electromigration of copper interconnection structures are provided. In one embodiment, a method of annealing a microelectronic device includings forming microelectronic features on a substrate, forming a contact structure over the microelectronic features, and forming a copper interconnection structure over the contact structure. A passivation layer is deposited over the copper interconnection structure and the substrate is subjected to a first anneal at a temperature of about 350° C. to 400° C. for a time duration between about 30 minutes to about 1 hour. The substrate is subjected to a second anneal at a temperature of about 150° C. to 300° C. for a time duration between about 24 to about 400 hours.

Owner:APPLIED MATERIALS INC

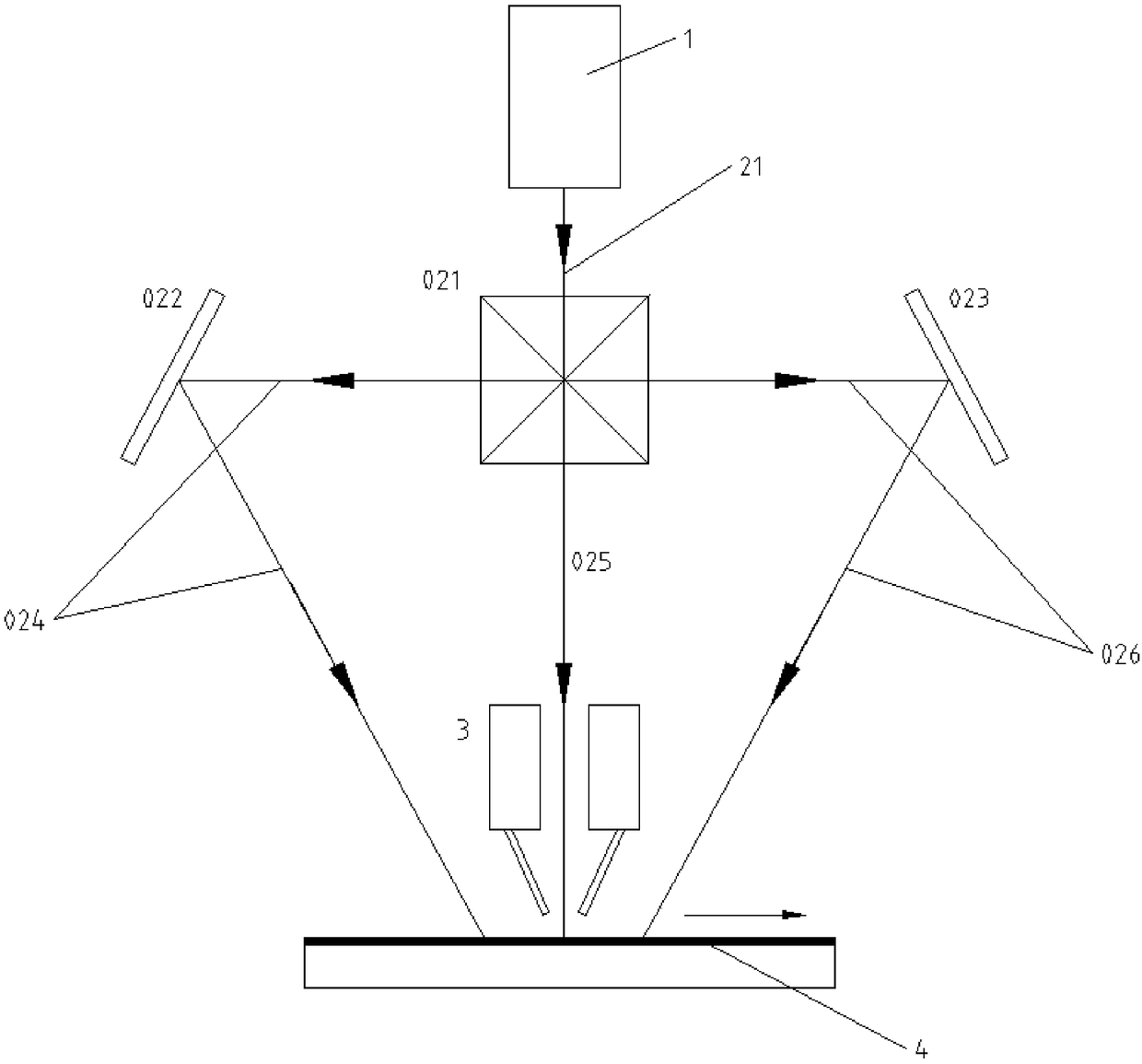

Laser cladding method, laser head, laser and cladding system for realizing laser cladding method

PendingCN108411301AReduces the possibility of crackingAvoid crackingMetallic material coating processesAlloyOptoelectronics

The invention relates to the technical field of laser cladding, and provides a laser cladding method, and a laser head, a laser and a cladding system for realizing the laser cladding method aiming atthe problems of deformation and performance degradation due to the fact that an existing method of laser cladding preheating on a machined workpiece base body cannot realize real-time online heat treatment and high heating input for preheating. The laser cladding method comprises the following steps that 1, outgoing lasers of the laser are divided into preheating lasers, cladding lasers and post-processing lasers; 2, the preheating lasers are irradiated on a workpiece to be processed, and the workpiece is preheated; 3, the cladding lasers are irradiated on the preheated workpiece to be processed to form a molten pool, and at the same time, alloy powder is blown into the molten pool formed on the surface of the workpiece to be processed; and 4, the post-processing lasers are irradiated on acladding layer after cladding, and post-annealing treatment is carried out on the cladding layer.

Owner:XIAN BESAME LASER TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com