Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Meet the target requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

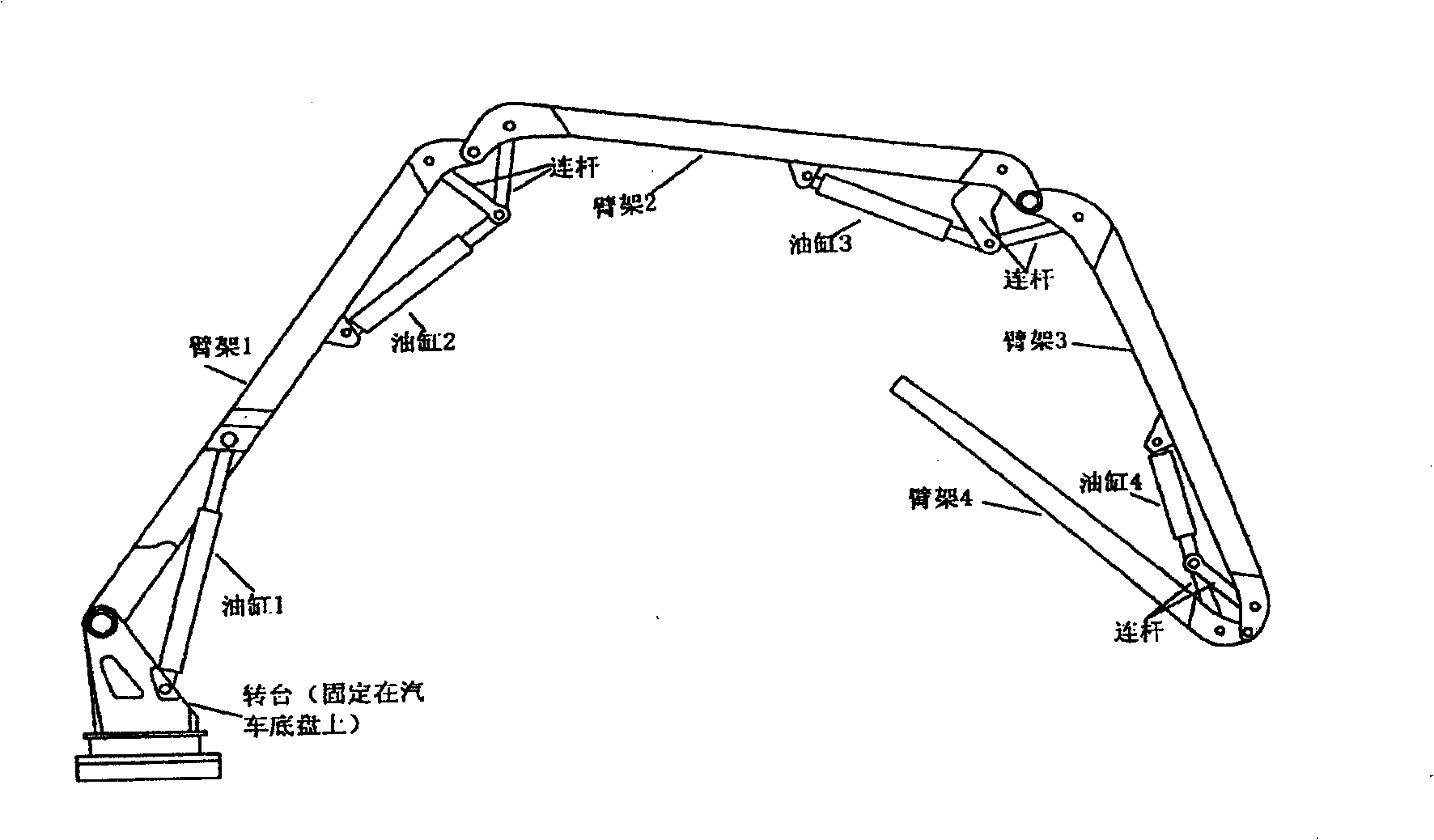

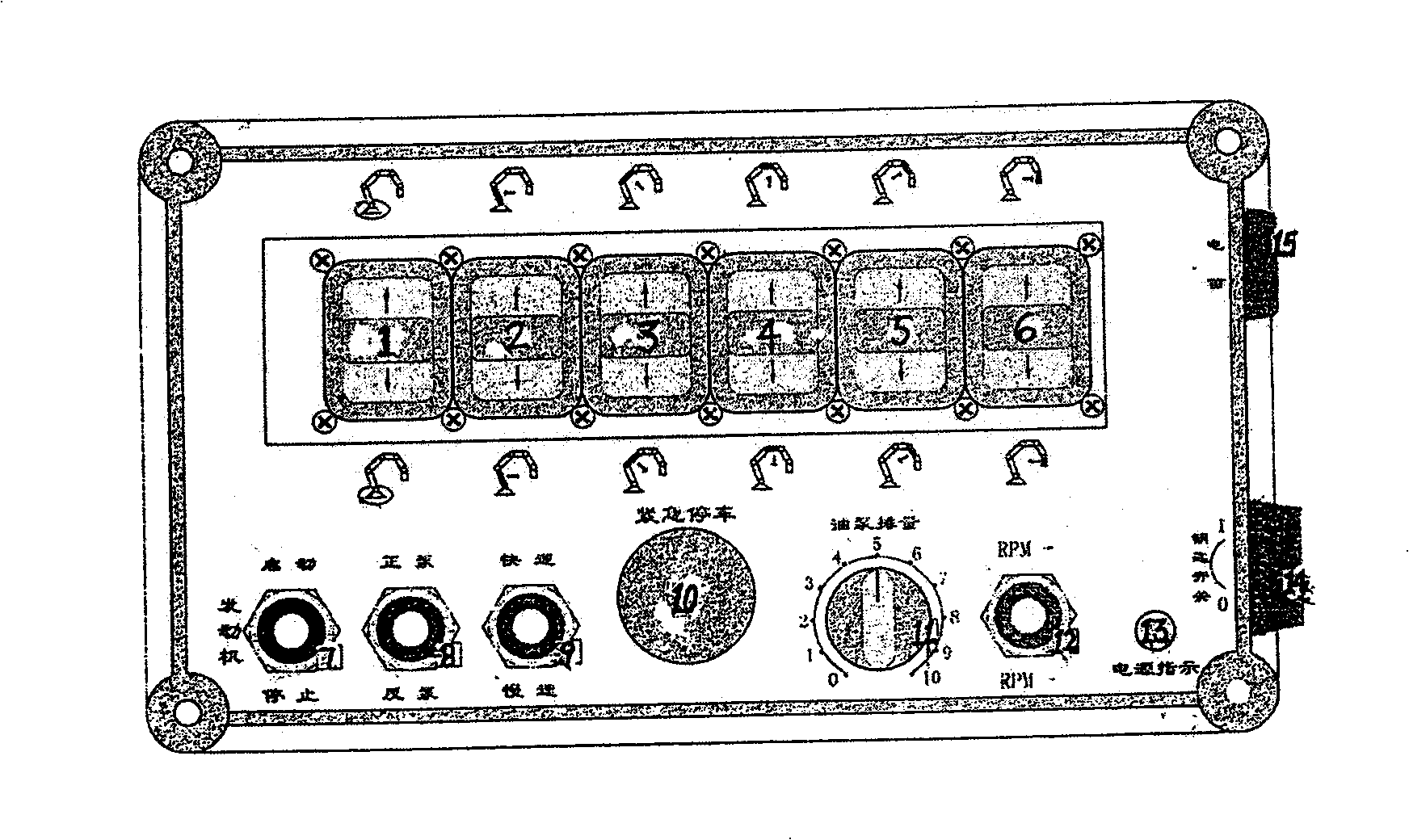

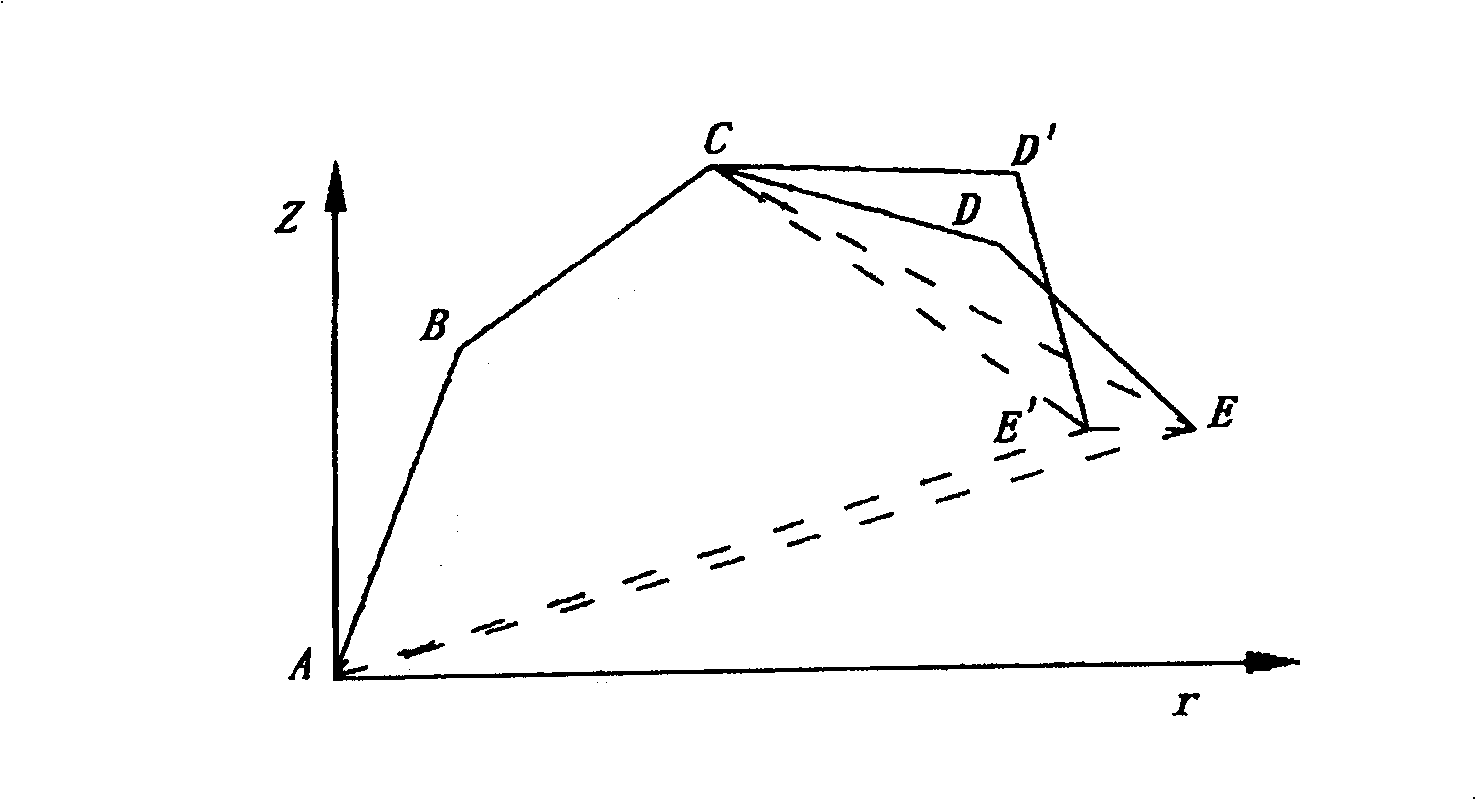

Concrete pump truck intelligent arm support control system and control method thereof

InactiveCN101525944AGuaranteed accuracyGuaranteed reasonablenessBuilding material handlingLocation detectionControl system

The invention provides a concrete pump truck intelligent arm support control system and a control method thereof. The control system comprises an arm support, a controller, an operating device and an actuator. The control system is characterized in that the control system also comprises an arm support detecting device which is used for detecting the spatial location of each segment of the arm support and transmitting detected spatial location signals of each segment of the arm support to the controller. The control method comprises: the construction of an arm support coordinate system; the detection of the current arm support position; the control of the actions of the arm support. In the concrete pump truck intelligent arm support control system, an operator is not required to manually regulate the position the gyratory angle of each segment of the arm support, the pouring accuracy and the operational reasonability are guaranteed, and the construction efficiency and the whole service life of the truck are improved greatly; within the stress impact allowable range and on the basis of the consideration of the concrete fluidity, coordinated actions of a plurality of segments of the arm support are realized; simultaneously, during the controlling process, extreme conditions and unreasonable operations of the movements of a plurality of the segments of the arm support are limited, the labor intensity and the experience requirement of the operator are alleviated greatly, and influences of unreasonable operations on the arm support structure and the service life of a hydraulic system are avoided.

Owner:BEIJING EASYSOLUTION ELECTRONICS

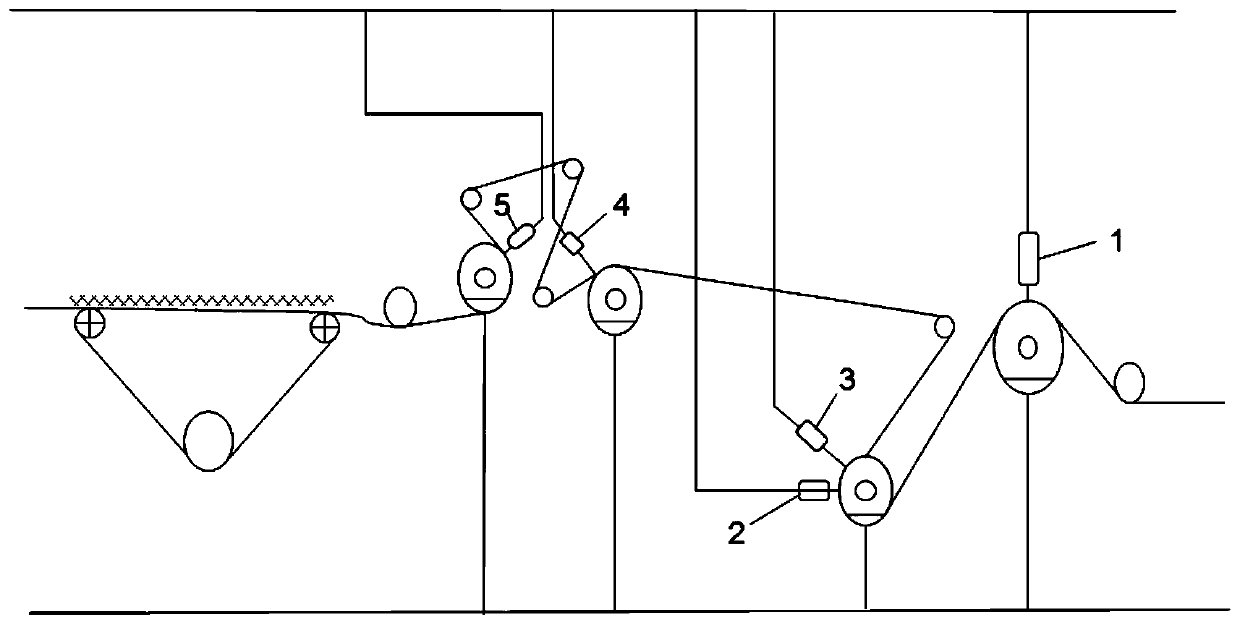

Terylene half speed blended spinning-type ammonia-substituted fiber blended spinning method and its apparatus

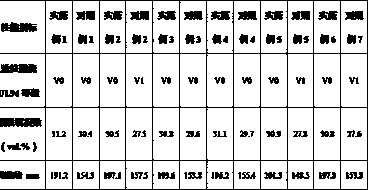

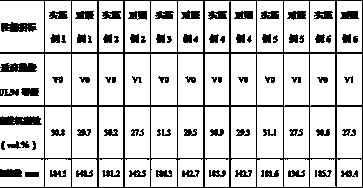

InactiveCN101265627AMeet the target requirementsStable Intrinsic IndexFilament/thread formingHeating/cooling textile fabricsYarnSingle stage

The invention designs a blending method and a device for terylene medium-speed blended ammoniac fibers, and includes section transporting and screening, section drying, screw extrusion, melting and spinning, and air blast cooling. The invention is characterized by the following steps: respectively enter POY spinning and FDY spinning after cooling, entering a nozzle for oiling after POY spinning, and then entering a pre-network; entering a tanker for oiling after FDY spinning, entering the pre-network, entering hot-rolling and drafting, enabling POY filaments and FDY filaments to enter into a guiding flute-type draw-off godet for combining and compounding, entering a go-between after compounding, hot-rolling and sizing, and winding and forming after entering a primary network. The blending method for the terylene medium-speed blended ammoniac fibers can produce FDY and POY composite network yarn by the single-stage process, the combined network yarn ITY product produced by the method has stable inner index and quality, little influencing factor, uniform waster-water shrinkage rate, stable chromaticity, and great economic benefit.

Owner:TONGKUN GRP

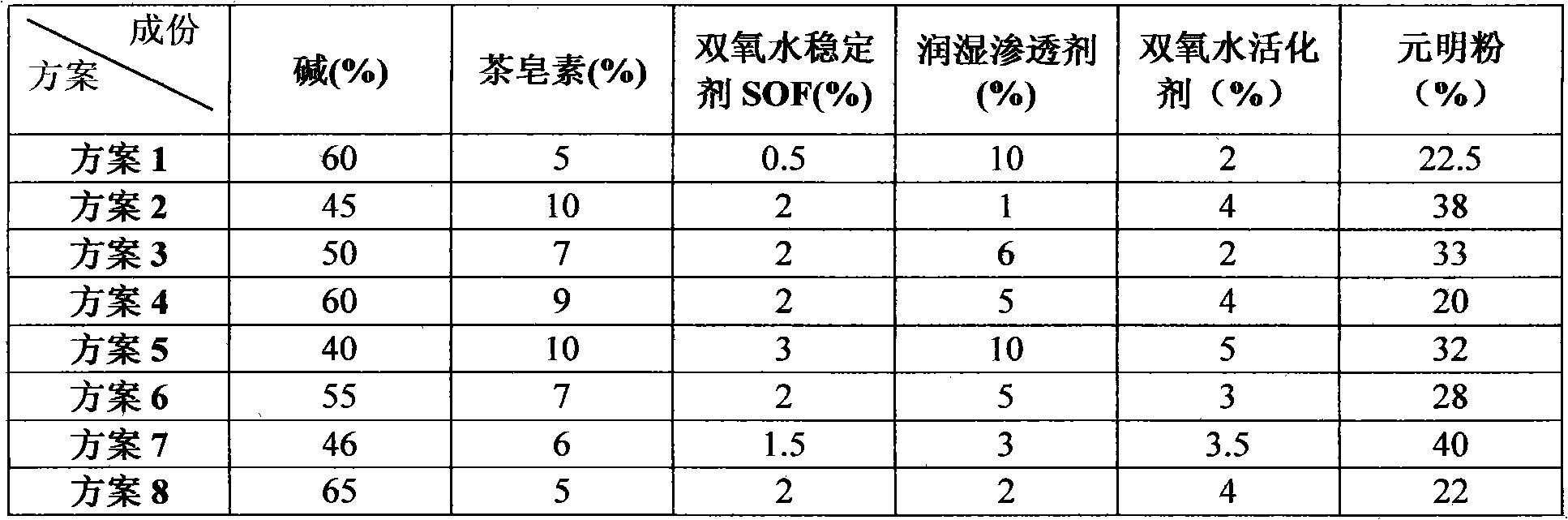

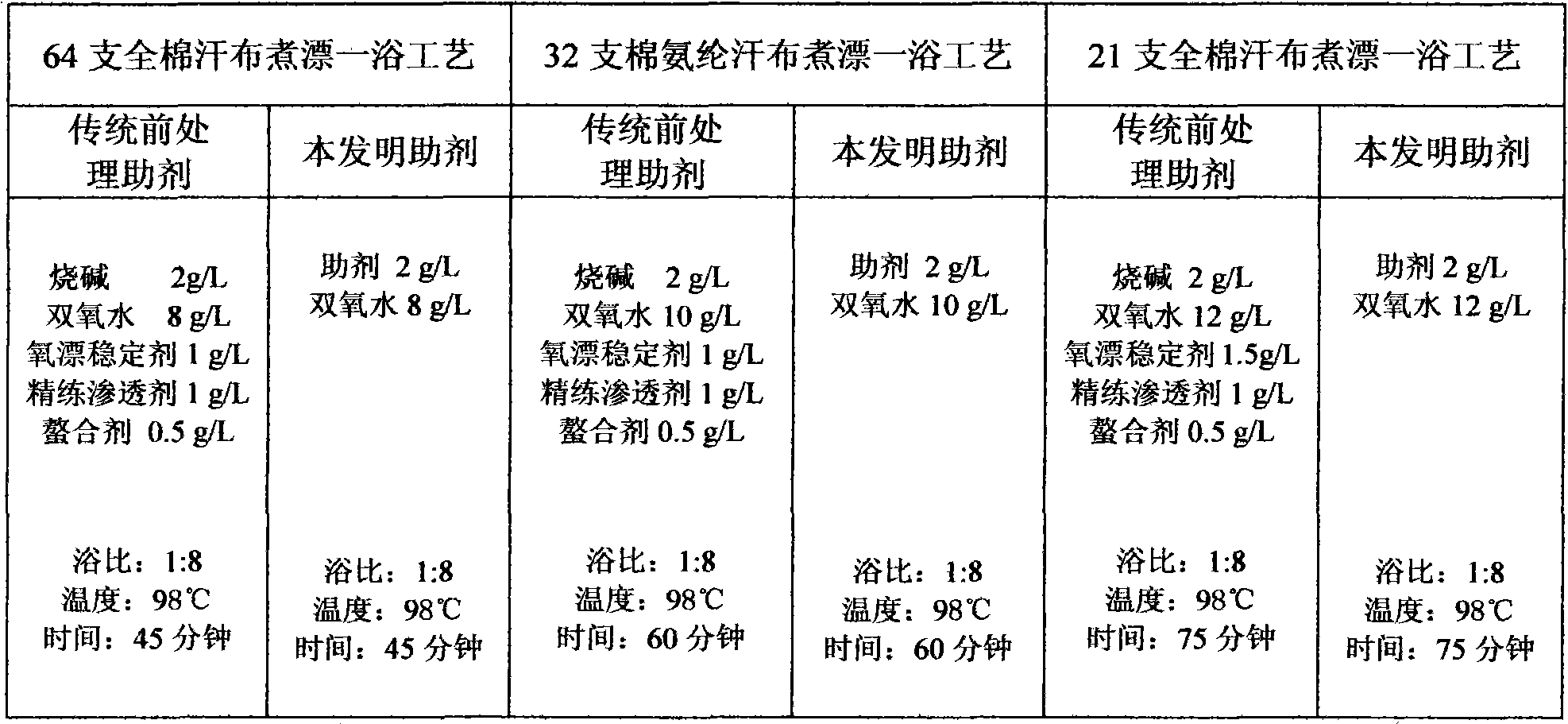

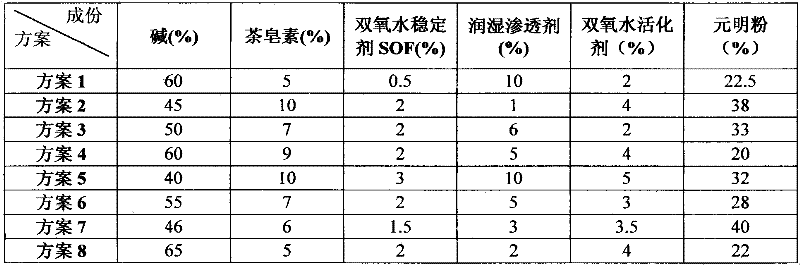

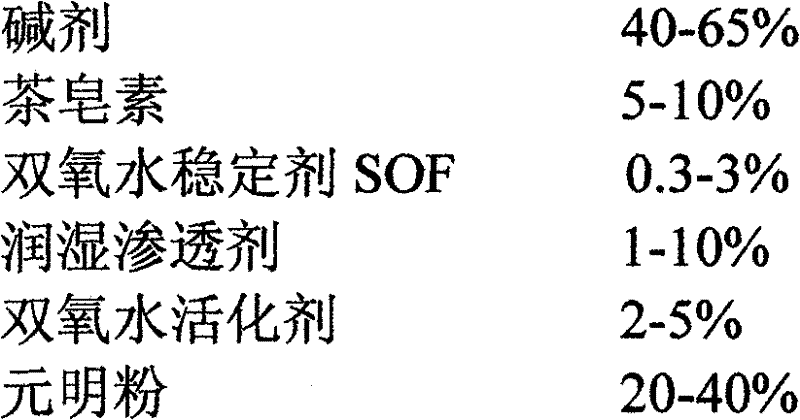

Pre-treatment auxiliary agent for cotton knitted fabrics, preparation method and application thereof

InactiveCN101914848AEasy to operateAvoid damageBleaching apparatusVegetal fibresPre treatmentNuclear chemistry

The invention discloses a pre-treatment auxiliary agent for cotton knitted fabrics, a preparation method and application thereof, belonging to the technical field of pre-treatment process formulas of the cotton knitted fabric dyeing and finishing industry. The auxiliary agent comprises the following components in percentage by weight: 40-65 percent of alkali agent, 5-10 percent of tea saponin, 0.3-3 percent of hydrogen peroxide stabilizer SOF, 1-10 percent of wetting penetrating agent, 2-5 percent of hydrogen peroxide activating agent and 20-40 percent of anhydrous sodium sulphate. By applying the auxiliary agent, the whiteness and capillary standards of the traditional process can be achieved only by using the auxiliary agent with hydrogen peroxide. The invention has the advantages of simple operation, low production cost, good environmental protection, and the like.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH +1

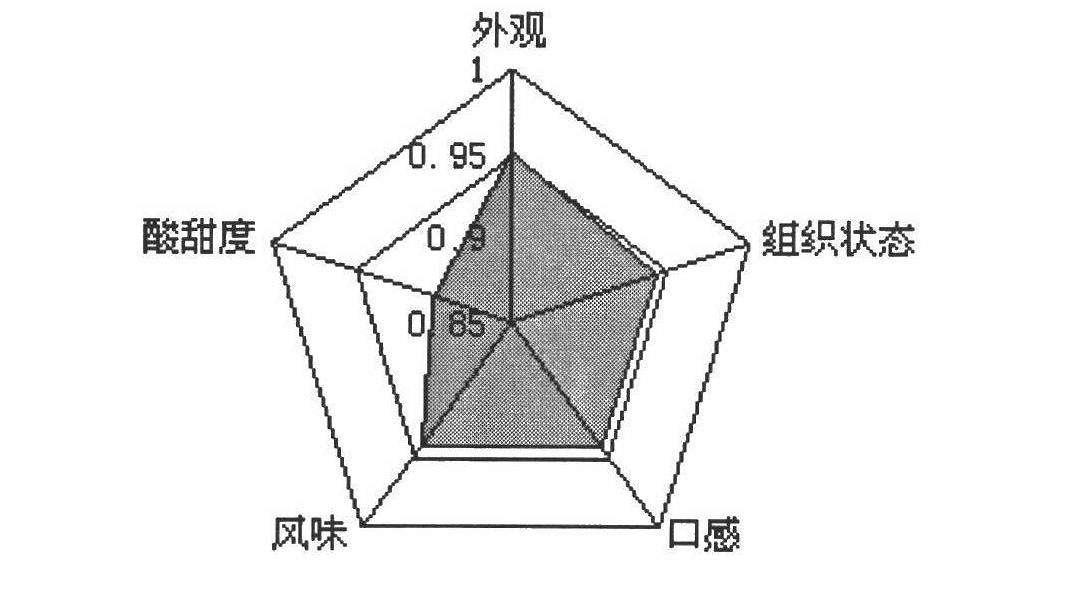

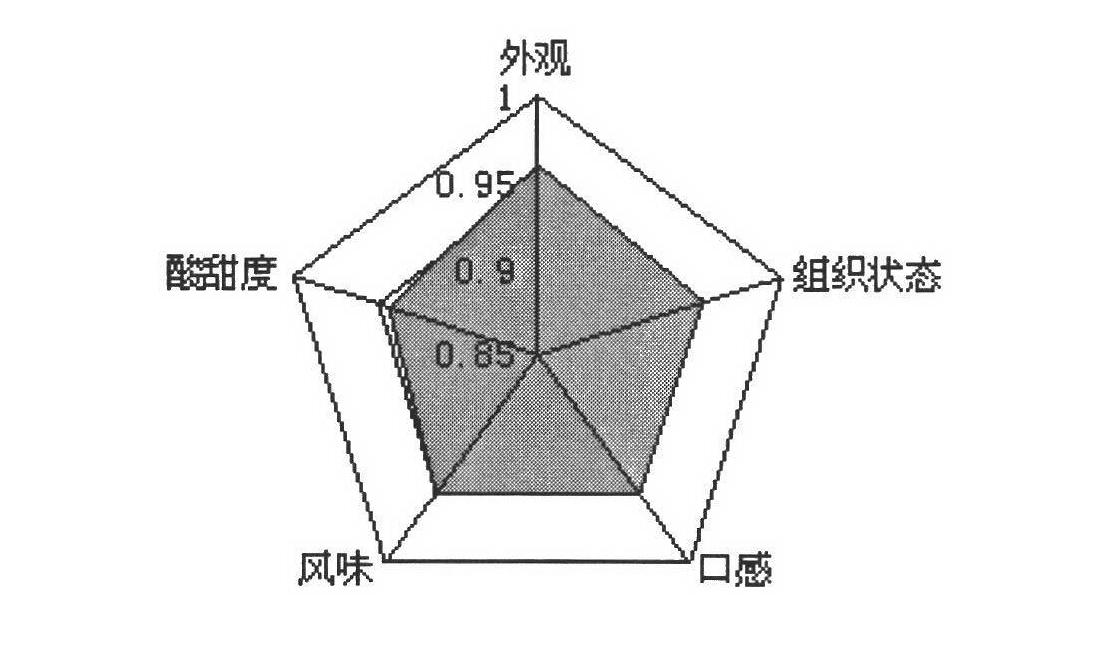

Vanilla-seed fermented milk and formulation, preparation method as well as semiquantitative analysis method thereof

The invention discloses a raw material formulation for vanilla-seed fermented milk, which includes raw milk, lactalbumin powder, a milk-fat product, a sweet substance, a thickening agent, zymogen and vallina-seed jam with viscosity not being higher than 10cm / (20 DEG C, 60s); and the invention discloses a semiquantitative analysis method for addition of the jam, which comprises steps of 1) covering vanilla-seed fermented milk uniformly on an entire filter-paper surface; 2) drying filter-paper surface with the vanilla-seed fermented milk for 15 to 40 minutes; and 3) comparing with a series standard sample. The invention also discloses a preparation method of the vanilla-seed fermented milk, which comprises the steps of: 1, mixing the fermented milk and the vanilla-seed jam to be canned; and 2, implementing the analysis according to the semiquantitative analysis method and fetching the vanilla-seed fermented milk reaching the target addition of the jam. The invention also discloses the vanilla-seed fermented milk prepared through the preparation method. The vanilla-seed fermented milk combines the light fermented flavor of the fermented milk and the fragrance of the vanilla and has rich color, the addition of the jam can be semiquantitatively monitored, the quality of different product batches is stable, and the market potential is remarkable.

Owner:BRIGHT DAIRY & FOOD

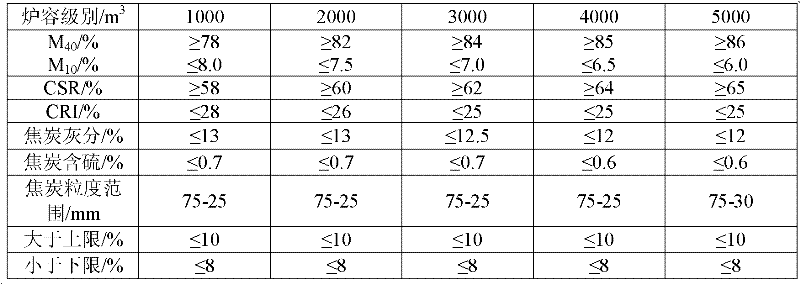

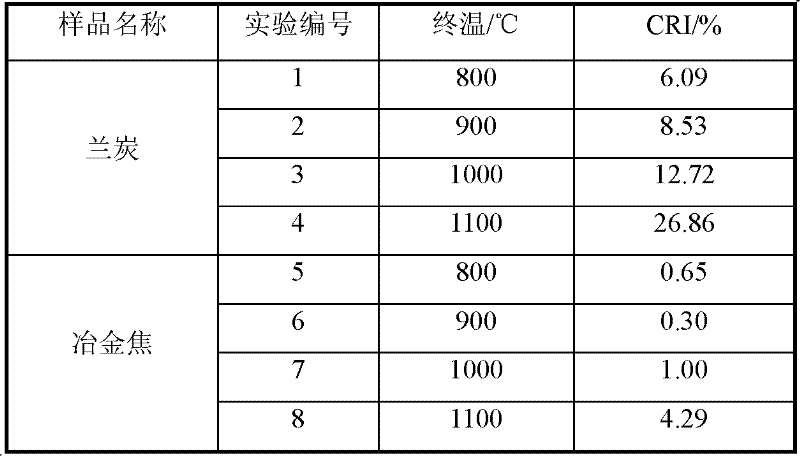

Low-cost blast furnace iron-smelting method

The invention relates to a low-cost blast furnace iron-smelting method, which is characterized in that: blocky carbon-lan (semi-coked) and rammed coke are matched and used for blast furnace iron smelting, and at the same time, small-particle or powdery carbon-lan (semi-coked) is used as an injected fuel to be used for blast furnace iron smelting. In the method, rammed coke is adopted, thus the consumption of high-quality coking coal is reduced, and the cost of the coking blend is lower than that of the top charging coke; and at the same time, a part of non-coking coal carbonization product, namely carbon-lan (semi-coked) is matched, thus the production cost of steel enterprises is lowered to a greater extent and high-quality coking coal is saved. In addition, small-particle or powdery carbon-lan (semi-coked) is used as the injected fuel, thus the problems that anthracite, lean coal and meager lean coal resources are limited and expensive are alleviated and the production cost of the steel enterprises is further lowered. According to the invention, the problems of shortage in high-quality coking coal resources and high-quality blowing coal resources in China are solved to a certain extent, and a new way is opened for persistent health development of the steel enterprises.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

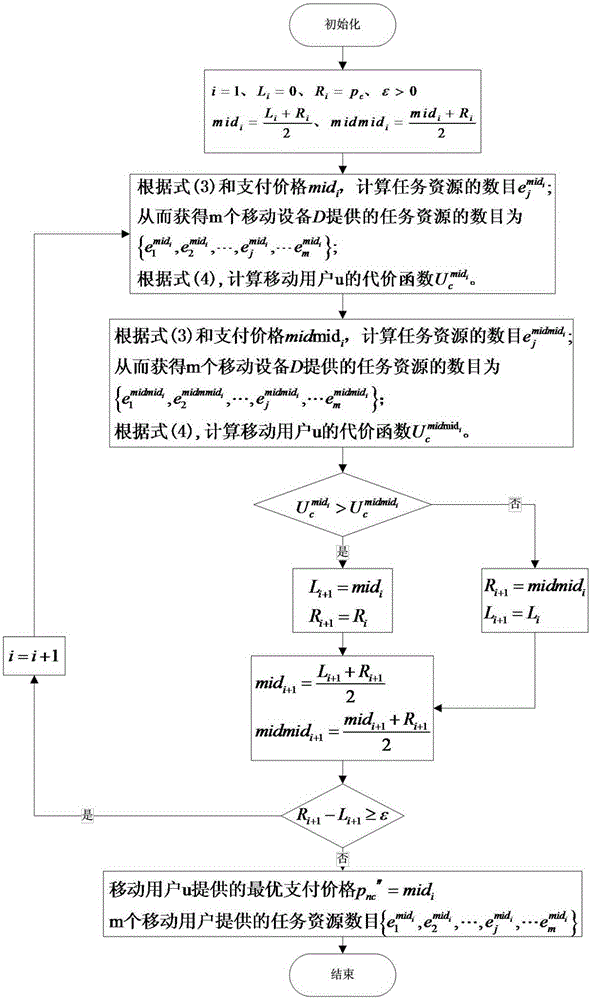

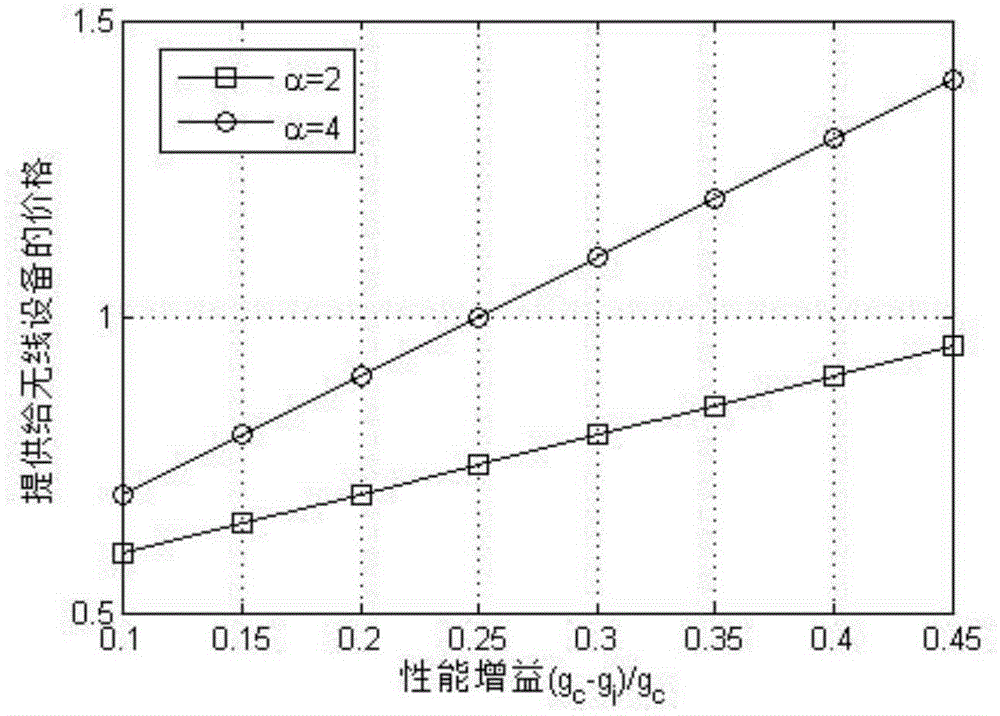

Task collaborative execution method based on Stackelberg Game

InactiveCN105338064AImprove resource utilizationBalanced solutionTransmissionPaymentResource utilization

The invention discloses a task collaborative execution method based on the Stackelberg Game in mobile cloud computing. The task collaborative execution method is characterized in that the task collaborative execution method is performed according to the following steps that 1. a utility function of mobile equipment and a cost function of mobile users are defined; 2. the mobile users provide payment price of task resources of the mobile users for the mobile equipment; 3. the mobile equipment provides the number of the task resources for the mobile users; 4. The mobile users provide updated payment price for the mobile equipment; and 5. the only equilibrium point between the optimal payment price of the mobile users and the task resources of the mobile equipment is searched by utilizing a triple search algorithm. The mobile equipment can be promoted to share mobile computing resources which are not used by the mobile equipment so that utilization rate of the resources can be enhanced.

Owner:HEFEI UNIV OF TECH

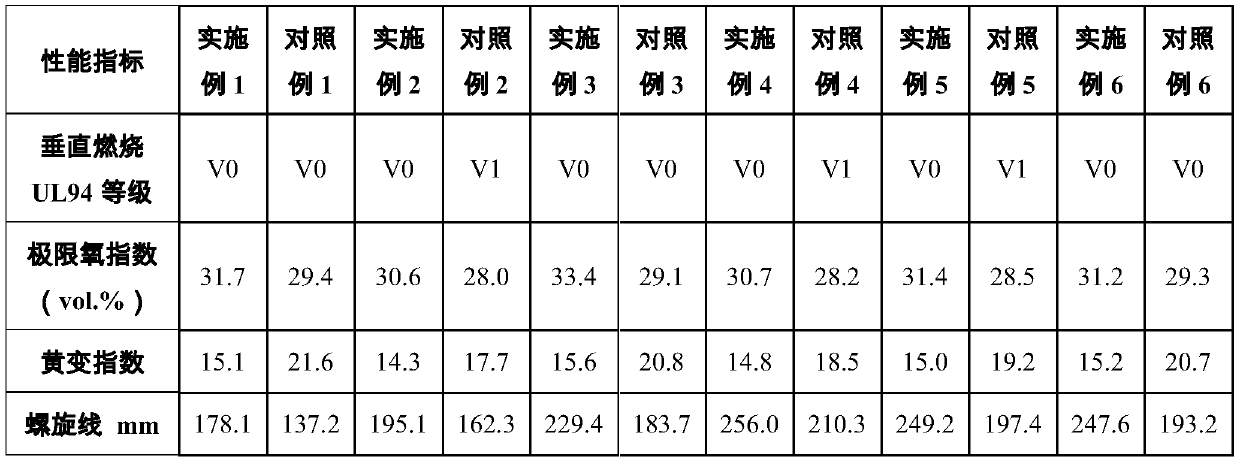

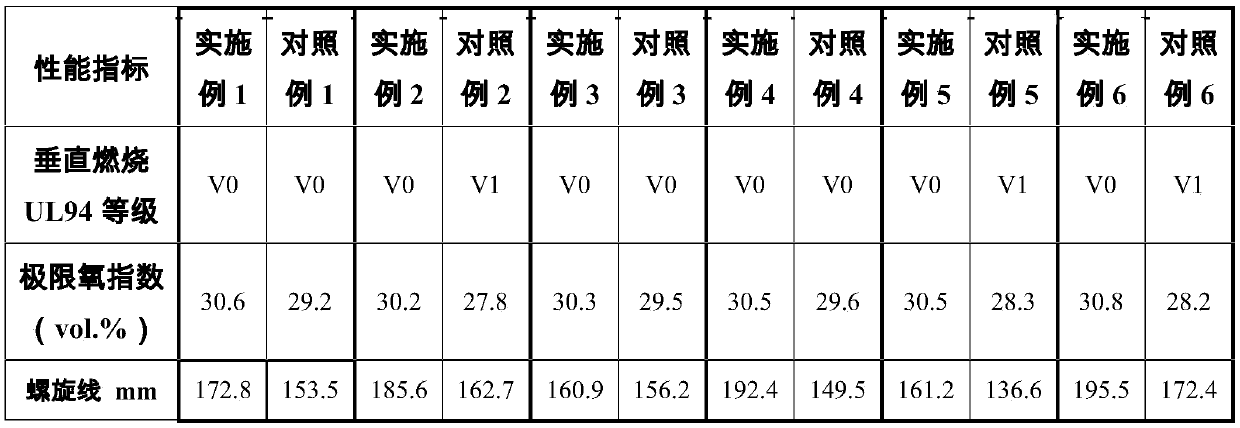

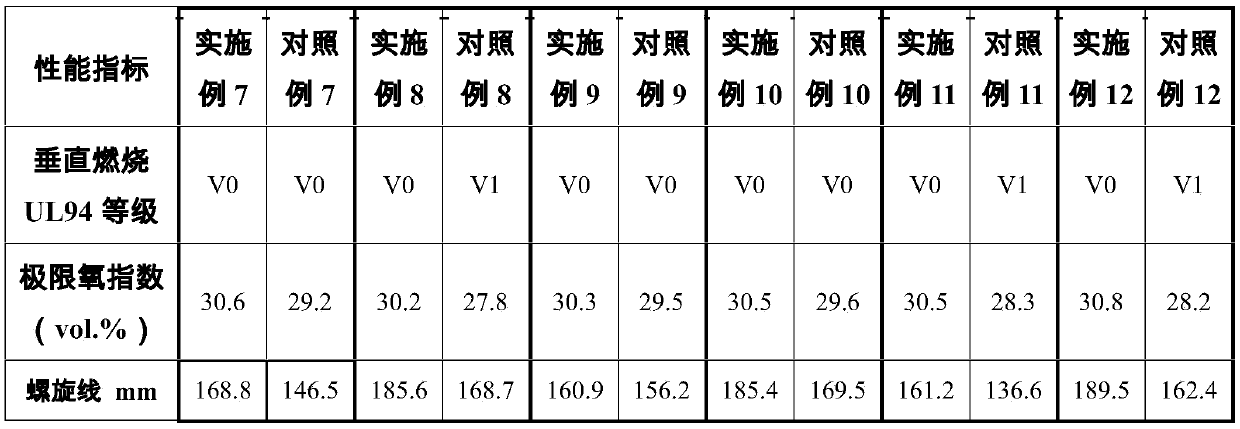

Special halogen-free flame-retardant synergistic masterbatch for modification of nylon resin and preparation method of halogen-free flame-retardant synergistic masterbatch

ActiveCN110591341AEffective protectionImprove thermal protection performanceAcrylonitrilePolytetrafluoroethylene

The invention relates to the technical field of modification and processing of plastics, in particular to special halogen-free flame-retardant synergistic masterbatch for modification of nylon resin and a preparation method of the halogen-free flame-retardant synergistic masterbatch. Multiple-compounded coated aluminum diethylphosphinate is adopted as a phosphorous-based flame retardant of the functional masterbatch, and the functional masterbatch comprises the compositions: in percent by mass, 55.0-65.0% of multiple-compounded coated aluminum diethylphosphinate, 20.0-30.0% of anhydrous zinc borate, 8.0-10.0% of nylon 6 resin, 3.0-5.0% of star-shaped nylon, 0.5-1.0% of styrene-acrylonitrile copolymer-coated polytetrafluoroethylene, 0.5-1.0% of a dispersant and 0.3-0.5% of a lubricant. Whenthe prepared functional masterbatch is compared with traditional flame-retardant functional masterbatch, the heat resistance and thermal stability of aluminum diethylphosphinate are improved significantly, aluminum diethylphosphinate is adaptive to a high processing temperature of nylon resin, so that the flame retardant effect of aluminum diethylphophinate on nylon resin is improved more effectively.

Owner:江苏万纳普新材料科技有限公司

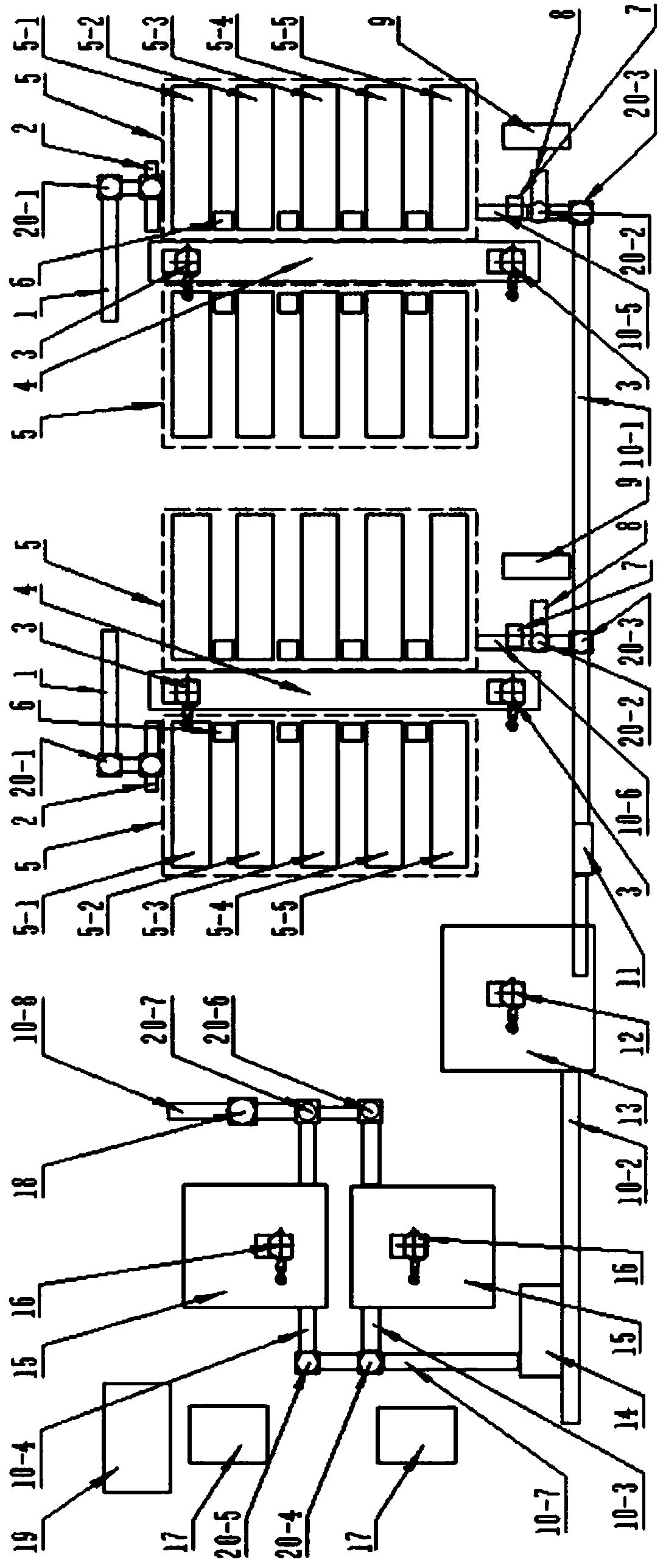

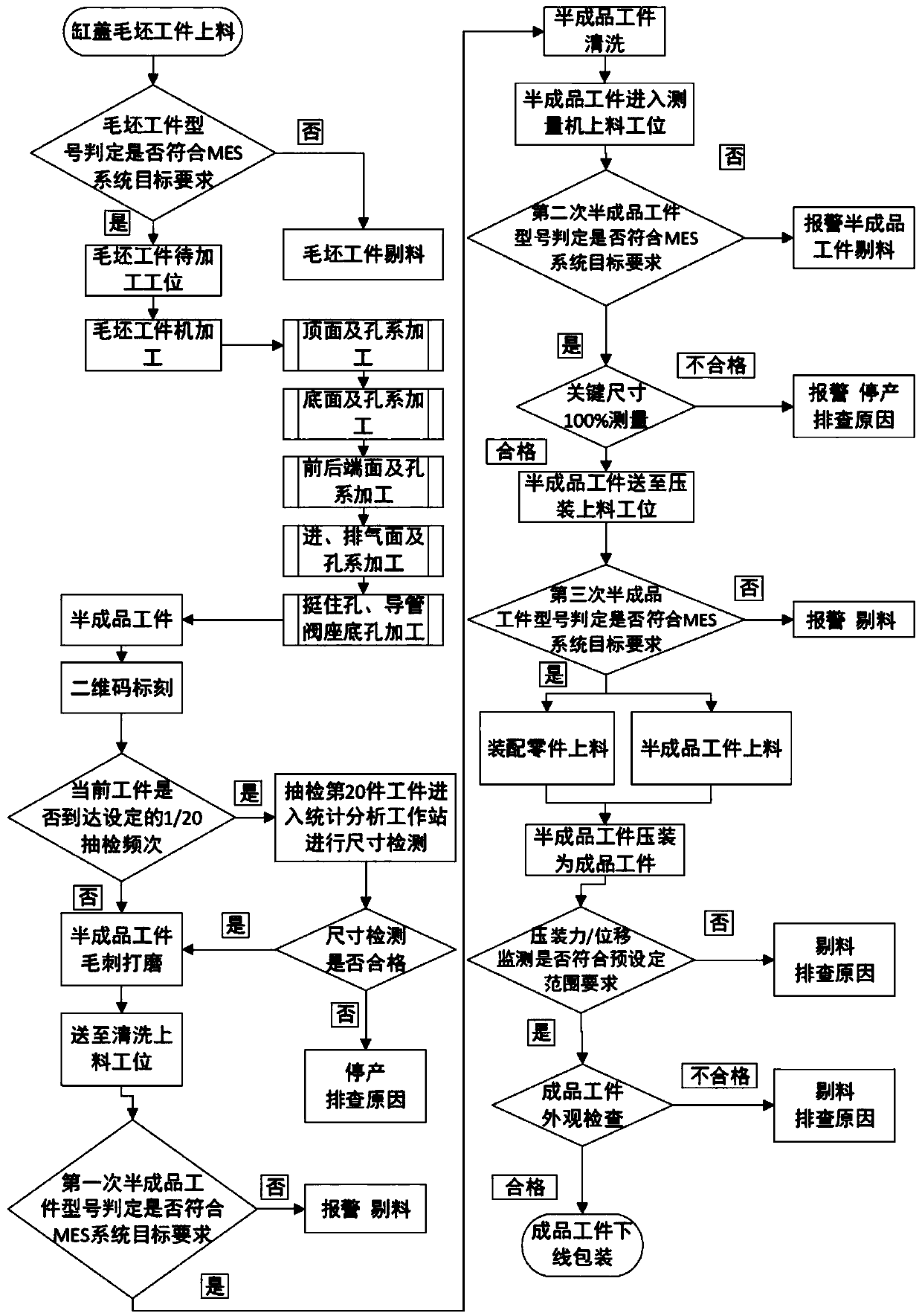

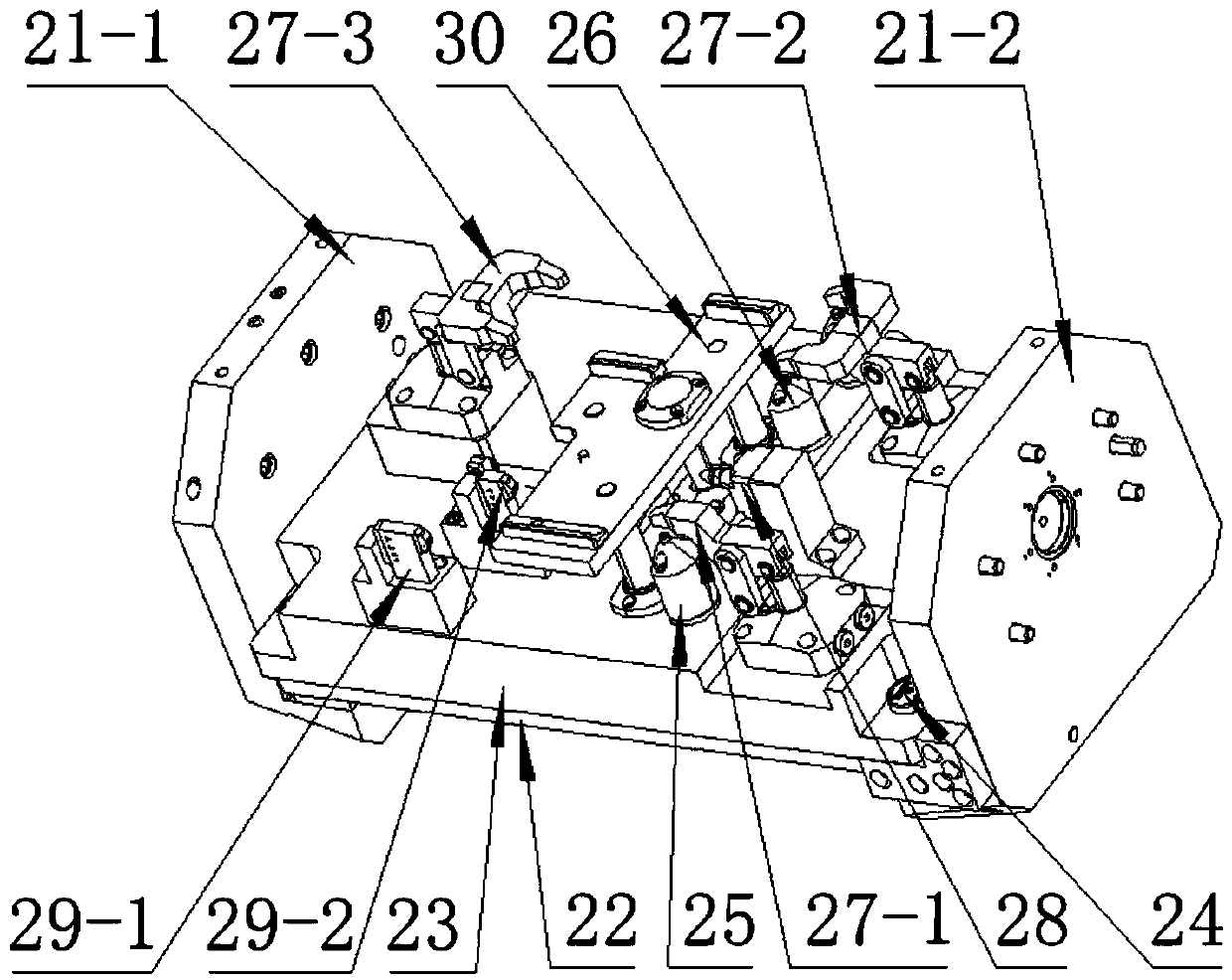

Automobile engine cylinder cover intelligent production line and technological process thereof

PendingCN109531279AAdapt to the needs of product transformation and productionAdapt to the needs of transformation productionMetal working apparatusProduction lineWork in process

The invention discloses an automobile engine cylinder cover intelligent production line and a technological process thereof. The automobile engine cylinder cover intelligent production line overcome the problem that the prior art cannot adapt to continuously changing product transformation production, and is characterized in that a blank workpiece model recognition mechanism is installed at the start end of a machining center unit, a marking machine, a feeding and detecting mechanism and an SPC measuring station are installed at the terminal of the machining center unit, a cleaning machine, ameasuring machine, a press-fitting machine and an auxiliary appearance inspection mechanism are arranged on a PZR material channel; the technological process comprises the following steps that the blank workpiece is fed, the blank workpiece model is identified, the blank workpiece is machined into a semi-finished workpiece, the semi-finished workpiece is cleaned, the semi-finished workpiece is measured, and the semi-finished workpiece is subjected to press fitting and the appearance is inspected. The automobile engine cylinder cover intelligent production line and the technological process thereof has the beneficial effects that the model switching is carried out through a quick-change mechanism, so that the wire-mixing production of the multiple-model cylinder cover is realized, the repeated positioning precision of 0.003 mm can be realized, after a sub-board is replaced, adjustment and compensation of parameters do not need to be carried out, the production state can be normally entered, and the technological process is suitable for the requirement of continuously changing product transformation production.

Owner:沈阳航天誉兴机械制造有限公司

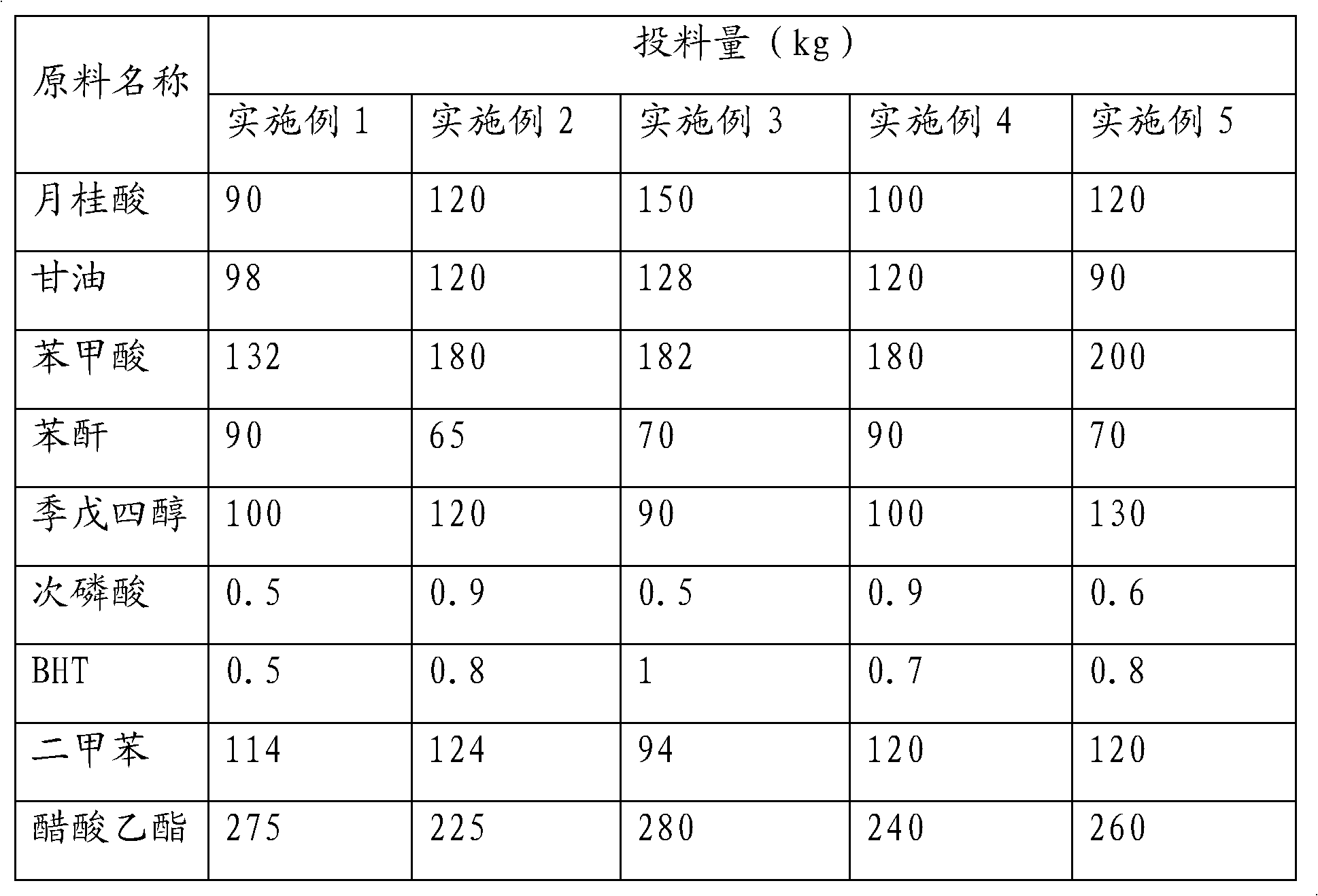

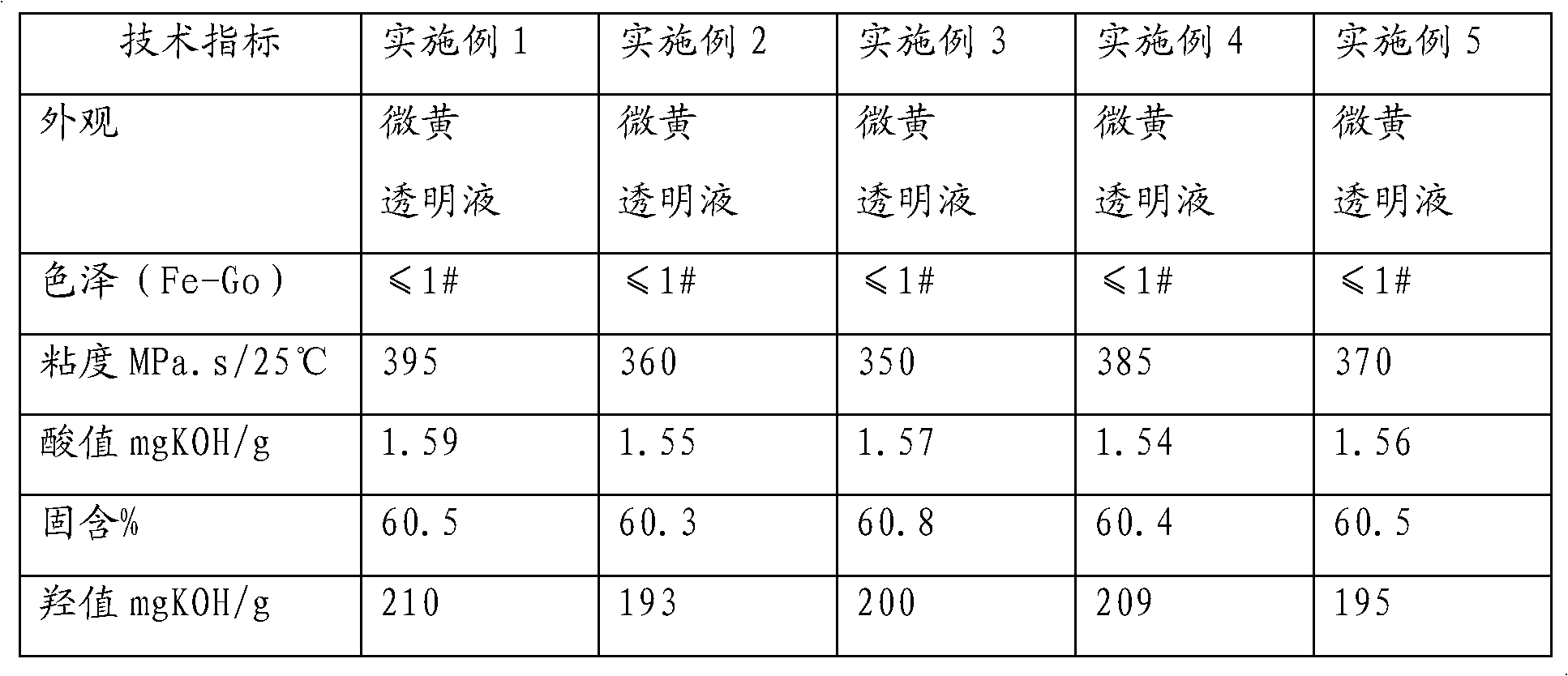

High hydroxy alkyd resin for polyurethane curing agent and preparation method thereof

The invention discloses a high hydroxy alkyd resin for modifying a polyurethane curing agent, which is prepared from the following raw materials in parts by weight: 9-15 parts of lauric acid, 8-14 parts of benzoic acid, 16-22 parts of phthalic anhydride, 6-10 parts of pentaerythritol, 9-15 parts of glycerol, 0.05-0.1 part of hypophosphorous acid, 0.05-0.1 part of 2,6-ditertiary butyl-4-methylphenol, 9-13 parts of xylene and 22-28 parts of ethyl acetate. According to the formula, a small amount of lauric acid, and large amounts of aromatic polybasic acids containing benzene ring structure (benzoic acid and phthalic anhydride) are added to the alkyd resin, so that the resin has high glass transition temperature; and in addition, excessive polybasic alcohols are added to the resin, so that the content of effective hydroxyl groups in the molecular structure of the resin is high.

Owner:CARPOLY CHEM GRP

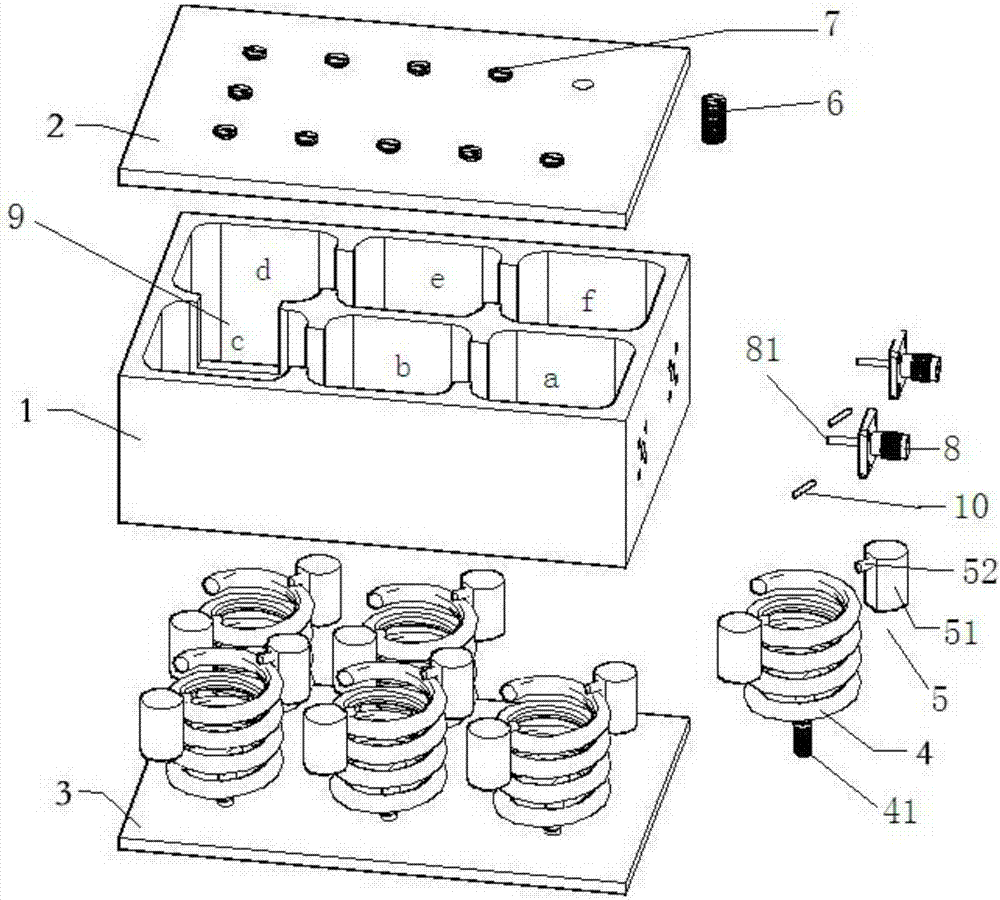

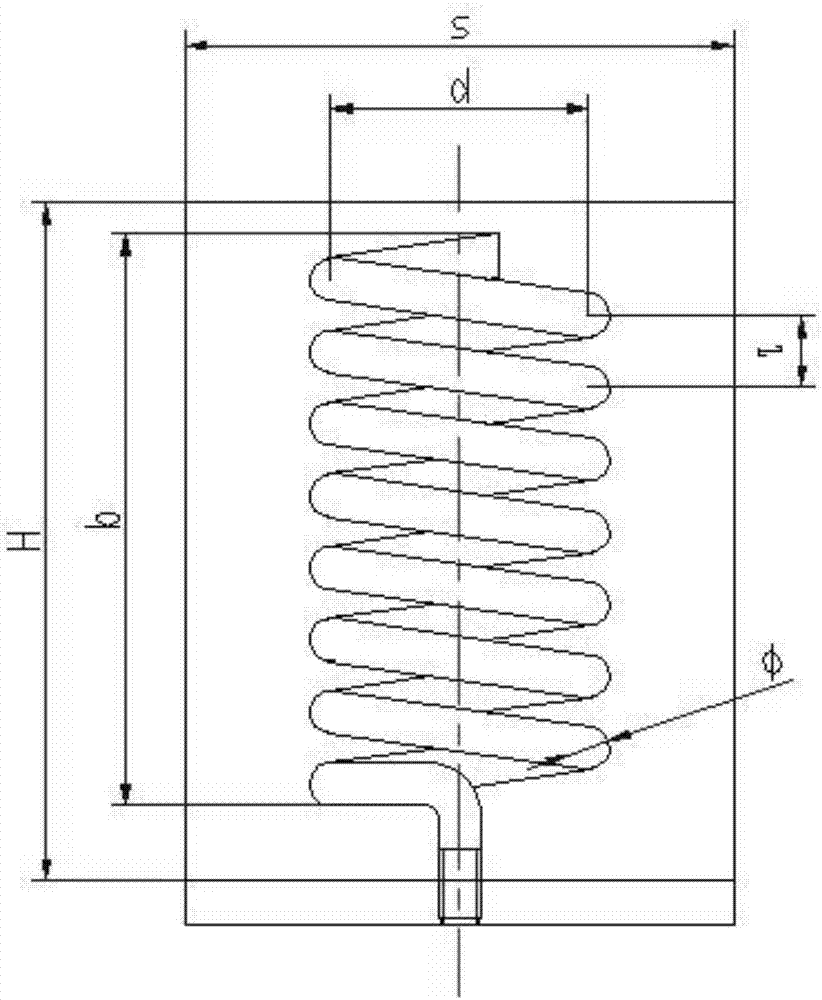

Spiral filter and design method thereof

The invention discloses a spiral filter and a design method thereof. The spiral filter comprises a cavity, an upper cover plate, a lower base plate, spiral harmonic oscillators, medium fixed columns, tuning screws, coupling screws, a connector and a connecting wire, wherein a plurality of single cavities are formed in the cavity, and every two adjacent single cavities are communicated through a window; the spiral harmonic oscillators are mounted in the single cavities, and the bottoms of the spiral harmonic oscillators are in short-circuited connection with the lower base plate; and the medium fixed columns are arranged in gaps between the spiral harmonic oscillators and the inner walls of the single cavities. The spiral filter disclosed by the invention can be applied to very high frequency (VHF) and ultrahigh frequency (UHF) wave bands, and has the advantage of small size; each single cavity is internally provided with the corresponding medium fixed column, and the spiral harmonic oscillators are effectively prevented from being deformed under the effect of gravity, so that the reliability and stability of the spiral filter are improved; the resonant frequency and coupling coefficient can be quickly and reliably adjusted through the tuning screws and the coupling screws; and moreover, the design method in the invention is high in operability, and can obtain the device meeting the target requirement.

Owner:南京华德通信技术有限公司

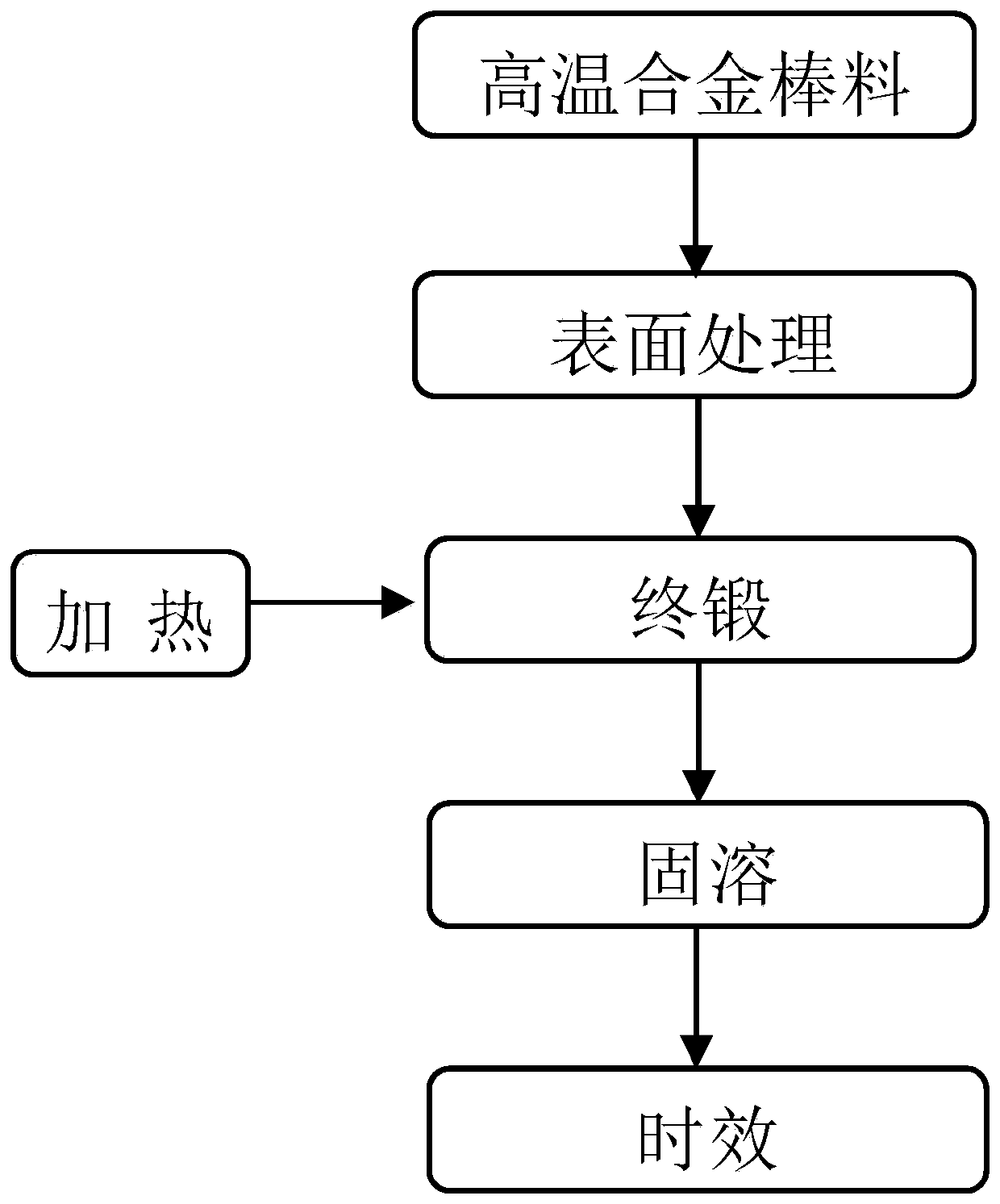

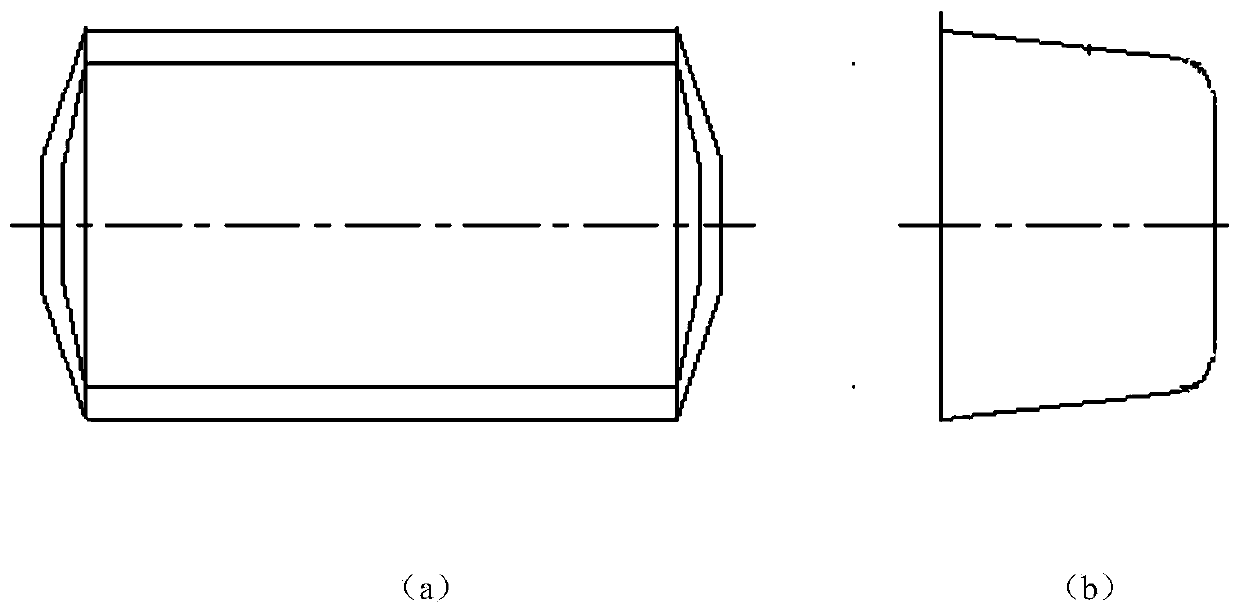

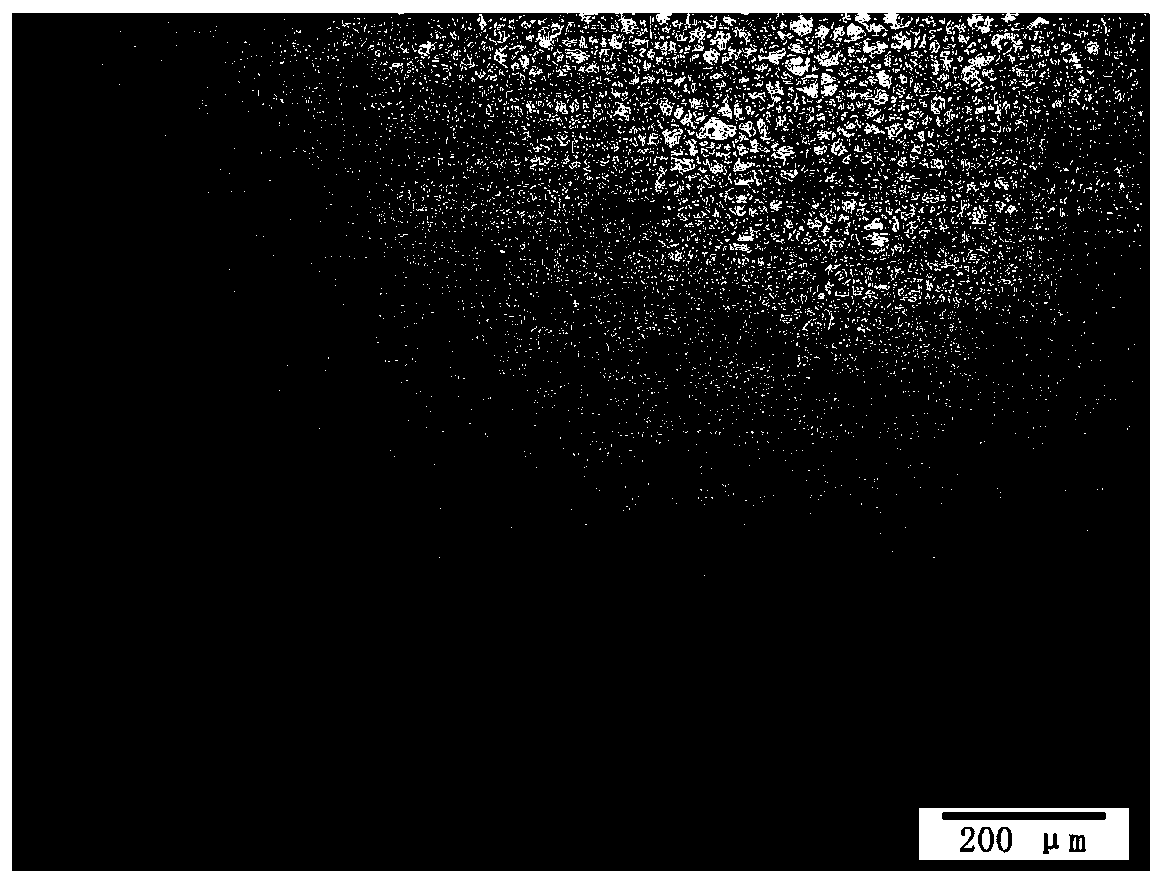

Forging method of GH4586 high-temperature alloy

ActiveCN110434275AGuaranteed Dimensional ConsistencyPrecisely control the amount of deformationEngine componentsAlloyScrew press

The invention discloses a forging method of a GH4586 high-temperature alloy. For a GH4586 high-temperature alloy forge piece, the surface of the forge piece is firstly coated with a high temperature resisting glass coating, and the surface of the forge piece is prevented from being oxidized or cracking in the forging process; in the forging process, an electric spiral press machine is adopted forforging for the first time, the blow energy and deformation of the forge piece can be precisely controlled, the forge piece achieves precise deformation, size consistency is high, meanwhile, a more uniform structure is obtained, and then good mechanical performance is obtained; and the spiral press machine is more stable than a forging hammer, the blow energy can be strictly controlled, forge piece flow lines can be uniformly distributed along the appearance, and the mechanical performance is greatly improved. In the forging method, an electric furnace is adopted for heating both during advanced heating and subsequent heat treatment of the forge piece, and the heating temperature can be precisely controlled within the range of + / -10 DEG C.

Owner:AECC AVIATION POWER CO LTD

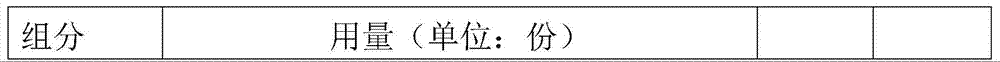

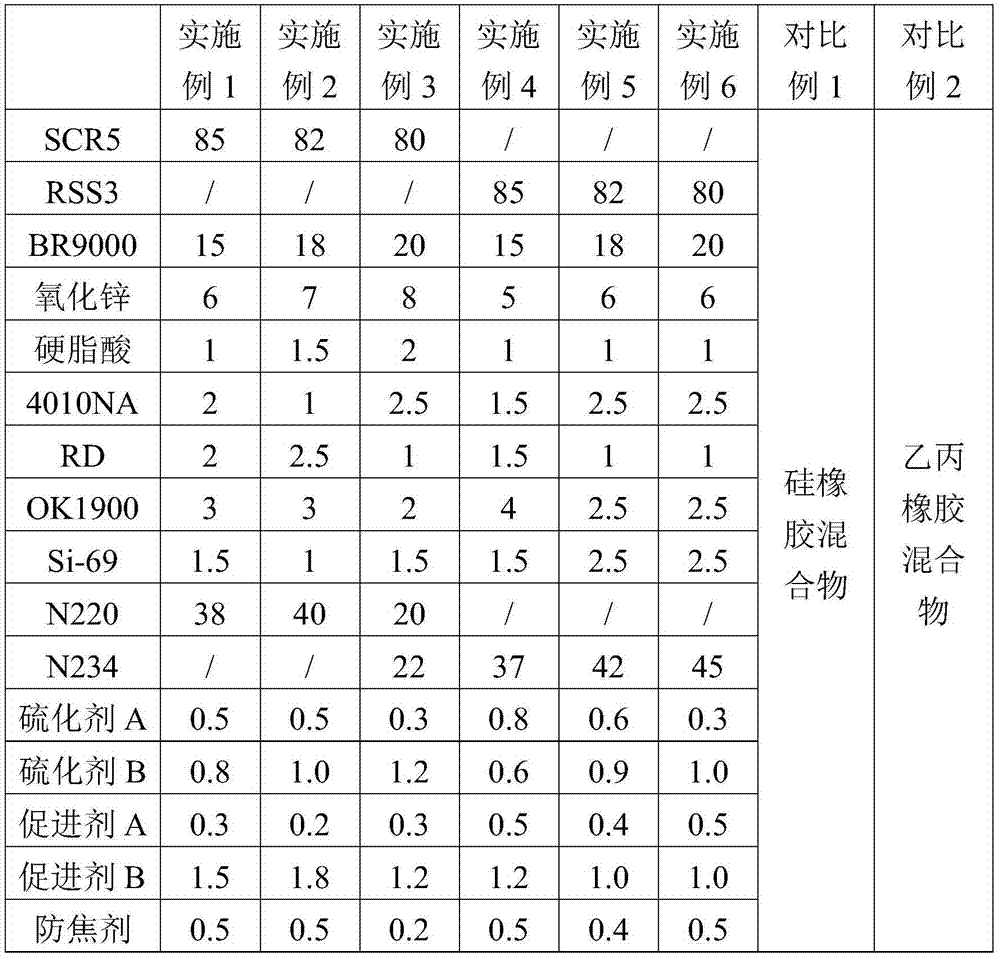

Rubber material, and preparation method and use thereof

The invention discloses a rubber material, and a preparation method and a use thereof. The rubber material comprises natural rubber, butadiene rubber, a diaryl secondary amine antioxidant, a dihydroquinoline antioxidant, a physical antioxidant, an activator zinc oxide, stearic acid, a silane coupling agent, carbon black, sulfur, 4,4'-dithiodimorpholine, tetramethylthiuram disulfide, N-cyclohexyl-2-benzothiazole sulfenamide and an anti-scorching agent. The rubber material has the advantages of low damping coefficient, good mechanical strength, good elastic ductility and satisfactory temperature resistance. The preparation method of the rubber material has the advantages of simple steps, convenience in operation, and suitableness for industrial production. An exhaust system cold end hanger made of the rubber material has the advantages of large pulling strength, long service life, wide vibration isolation frequency, and excellent NVH control efficiency in the acceleration stage in the high speed (90 km / h or more) driving process of an automobile.

Owner:JIANGSU LUOSHI DAMPING MEMBER CO LTD

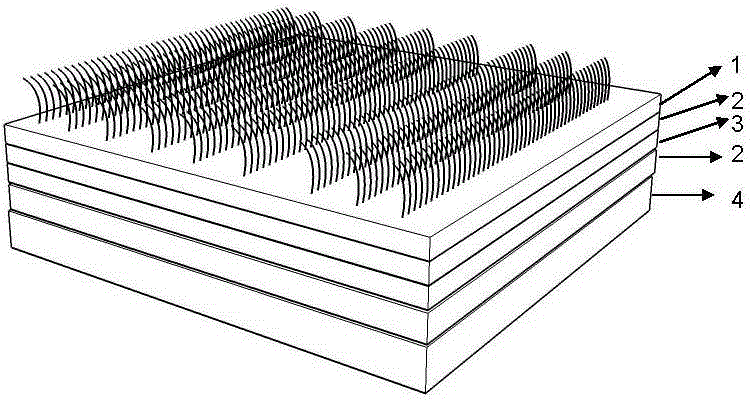

High-temperature-resistant composite filter material with good dust removal effect

InactiveCN111228893AHigh temperature resistanceCorrosiveMembrane filtersFiltration separationComposite filterFilter material

The invention discloses a high-temperature-resistant composite filter material with a good dust removal effect. The composite filter material comprises a base cloth layer, wherein a head-on layer is arranged at the top of the base cloth layer, and a bottom layer is arranged at the bottom of the base cloth layer. A preparation method comprises the following steps: mixing chopped polyimide fibers and chopped basalt fibers, and then opening and carding to prepare mixed fibers; taking the prepared mixed fibers as the head-on layer and the bottom layer; putting a basalt fiber woven fabric serving as the base cloth layer between the head-on layer and the bottom layer; putting the head-on layer, the base cloth layer and the bottom layer into a needling machine for pre-needling; after pre-needling, putting the product into a spunlace production line for spunlace; after spunlace, putting the product into impregnation liquid for post-treatment; after post-treatment, putting the product into heatsetting equipment for drying and setting, so as to prepare the high-temperature-resistant composite filtering material with a good dust removal effect. The composite filter material prepared by the invention has good high-temperature resistance, dust removal effect and breaking strength. The invention belongs to the technical field of composite filter materials.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST

Method for smelting TA2 flat ingot by cold cathode electron beam

The invention provides a method for smelting TA2 flat ingot by cold cathode electron beam. The method comprises the following steps of A, feeding a conventional titanium raw material block into an electron beam cold bed smelting furnace, starting an EB gun 1-5, and melting the titanium raw material block in the cold bed; B, adjusting the scanning patterns of EB guns 6 and 7 to completely melt thetitanium raw material block to liquid; C, putting the molten liquid in the cooling bed into a crystallizer, and covering the whole crystallizer with scanning patterns of EB guns 6 and 7; and D, adjusting the current of the EB gun 1-4 to be 2-6 A, adjusting the current of the EB gun 5 to be 4-6 A, adjusting the current of the EB gun 6-7 to be 2-4 A, smelting and ingot drawing at a speed of 600-800kg / h, and cooling to obtain the TA2 flat ingot. The method is low in cost, high in production and yield, stable in chemical composition and excellent in surface quality.

Owner:YUNNAN TITANIUM IND

Method for synthesizing carbon hydrocarbon compound through CO2 hydrogenation

ActiveCN113583698ASolve the resource crisisMeet the target requirementsPhysical/chemical process catalystsHydrocarbon from carbon oxidesPtru catalystDoped graphene

The invention relates to a method for synthesizing a carbon hydrocarbon compound through CO2 hydrogenation. A catalyst is adopted, the catalyst is a K-M co-promoted Fe-based catalyst and is composed of carbon black, Fe2O3NGr, transition metal M and alkali metal K, and Fe2O3NGr is nitrogen-doped graphene half-coated Fe2O3 particles. In the K-M co-promoted Fe-based catalyst, the content of the Fe element is 1-40 wt%, the content of the transition metal M is 1-30 wt%, and the content of the alkali metal K is 1-5 wt%. The transition metal M is one or more of palladium, nickel, cobalt, indium and chromium. The alkali metal K is alkali metal potassium. After the CO2 hydrogenation reaction is finished, the conversion rate of CO2 is 22.73 to 40.62 percent, the selectivity of CH4 is 15.26 to 37.12 percent, the selectivity of CO is 13.05 to 89.96 percent, the selectivity of carbon hydrocarbon with the carbon atom number of 2 to 4 is 12.22 to 43.99 percent, and the selectivity of carbon hydrocarbon with the carbon atom number of more than or equal to 5 is 22.64 to 72.51 percent. The method disclosed by the invention is simple, and the problem of low selectivity of high hydrocarbon in the existing method for synthesizing the carbon hydrocarbon compound through CO2 hydrogenation is effectively solved by adopting the K-M to jointly promote the Fe-based catalyst to serve as the catalyst for synthesizing the carbon hydrocarbon compound through CO2 hydrogenation.

Owner:SHANGHAI UNIV OF ENG SCI

Flame-retardant synergistic functional master batch special for polyethylene modification and preparation method thereof

PendingCN110643098AImprove flame retardant effectReduce usageBrominated flame retardantPolytetrafluoroethylene

The invention relates to the technical field of plastic modification processing, in particular to a flame-retardant synergistic functional master batch special for polyethylene modification and a preparation method thereof. The functional master batch takes multi-composite coated decabromodiphenylethane as a main flame retardant, and the functional master batch comprises the following components by mass percentage: 55.0-70.0 wt.% of multi-composite coated decabromodiphenylethane, 15.0-30.0 wt.% of antimony trioxide, 9.0-13.0 wt.% of an ethylene-octene copolymer, 1.0-2.0 wt.% of styrene-acrylonitrile copolymer coated polytetrafluoroethylene, 0.5-1.0 wt.% of a dispersant, and 0.3-0.5 wt.% of a lubricant. Compared with traditional flame-retardant functional master batch, the functional masterbatch prepared by the invention significantly improves the thermal stability of brominated flame retardants, effectively reduces the material yellowing phenomenon in the thermal machining process, and enhances the flame-retardant effect of domestic brominated flame retardants on polyethylene.

Owner:江苏万纳普新材料科技有限公司

Special halogen-free flame-retardant synergistic functional masterbatch for polyolefin resin modification and preparation method thereof

The invention relates to the technical field of plastic modification processing, in particular to special halogen-free flame-retardant synergistic functional masterbatch for polyolefin resin modification and a preparation method thereof. According to the functional masterbatch, multiple composite coated ammonium polyphosphate is used as a phosphorus-based flame retardant; the functional masterbatch is prepared from the following components in percentage by mass: 55.0-65.0 wt.% of the multiple composite coated ammonium polyphosphate, 25.0-35.0 wt.% of a nitrogen flame retardant, 7.0-11.0 wt.% of carrier resin, 0.5-1.0 wt.% of styrene-acrylonitrile copolymer coated polytetrafluoroethylene, 0.5-1.0 wt.% of a dispersing agent and 0.3-0.5 wt.% of a lubricating agent. Compared with the traditional flame-retardant functional masterbatch, the functional masterbatch prepared by the invention has the advantages that the thermal stability of ammonium polyphosphate is remarkably improved, and thewater resistance of the ammonium polyphosphate is enhanced, so that the flame-retardant effect of the ammonium polyphosphate on polyolefin resin is more effectively improved.

Owner:江苏万纳普新材料科技有限公司

Environment-friendly composite material for sphygmomanometers

ActiveCN102501489BHigh tensile strengthImprove mechanical propertiesSynthetic resin layered productsEvaluation of blood vesselsSphygmomanometerYarn

The invention relates to an environment-friendly composite material for sphygmomanometers. The environment-friendly composite material is prepared by the following method: (1) high-strength, low-shrinkage polyester yarns as material are warped, woven, divided and rolled, so that a base fabric as framework material is produced; (2) the framework material is soaked in PU paste, coated, dried and preshaped, and a PVC (polrvinyl chloride) film is then attached on one surface of the framework material by a way of hot melting; (3) a layer of PU paste is applied on the surface of a non-woven fabric, dried and then attached on the other surface of the framework material by way of hot melting, and finally, after embossing, cooling for shaping and trimming, the environment-friendly composite material for sphygmomanometers is produced. Because both surfaces of the framework material of the environment-friendly composite material for sphygmomanometers is provided with the PU (Poly Urethane) paste layers, the peeling strength of the product is greatly enhanced, and the product can be used for not less than 20000 times. As the living standard of people is increased, people pay more attention to health, and such products have a broad market prospect.

Owner:浙江明士达股份有限公司

Environment-friendly composite material for sphygmomanometers

ActiveCN102501489AHigh tensile strengthImprove mechanical propertiesSynthetic resin layered productsEvaluation of blood vesselsSphygmomanometerEnvironmental resistance

The invention relates to an environment-friendly composite material for sphygmomanometers. The environment-friendly composite material is prepared by the following method: (1) high-strength, low-shrinkage polyester yarns as material are warped, woven, divided and rolled, so that a base fabric as framework material is produced; (2) the framework material is soaked in PU paste, coated, dried and preshaped, and a PVC (polrvinyl chloride) film is then attached on one surface of the framework material by a way of hot melting; (3) a layer of PU paste is applied on the surface of a non-woven fabric, dried and then attached on the other surface of the framework material by way of hot melting, and finally, after embossing, cooling for shaping and trimming, the environment-friendly composite material for sphygmomanometers is produced. Because both surfaces of the framework material of the environment-friendly composite material for sphygmomanometers is provided with the PU (Poly Urethane) paste layers, the peeling strength of the product is greatly enhanced, and the product can be used for not less than 20000 times. As the living standard of people is increased, people pay more attention to health, and such products have a broad market prospect.

Owner:浙江明士达股份有限公司

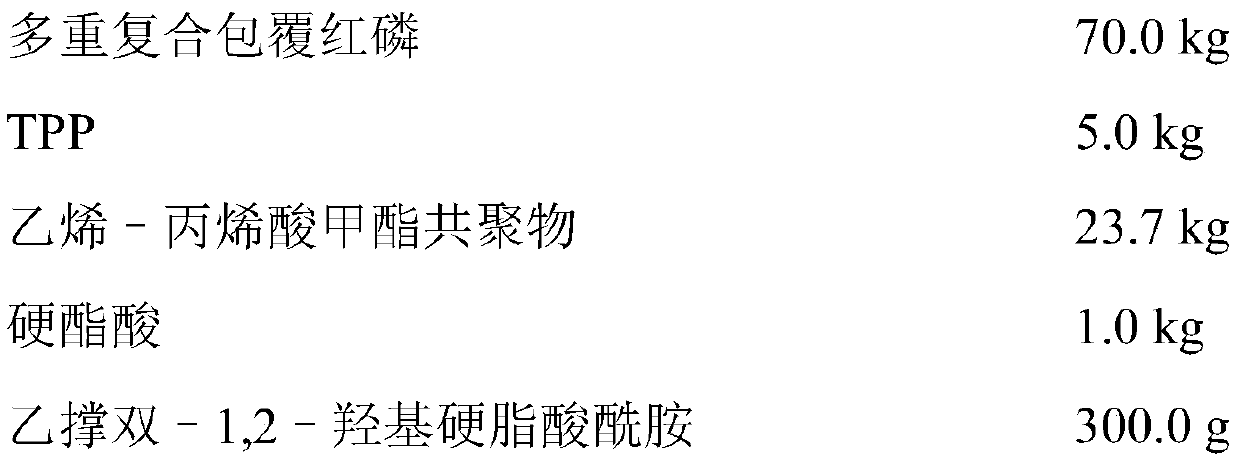

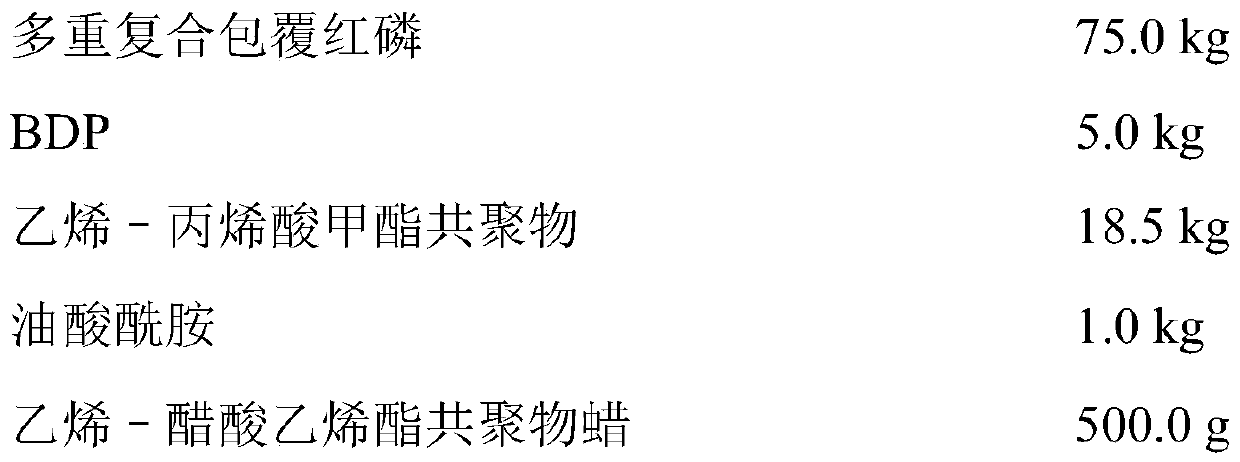

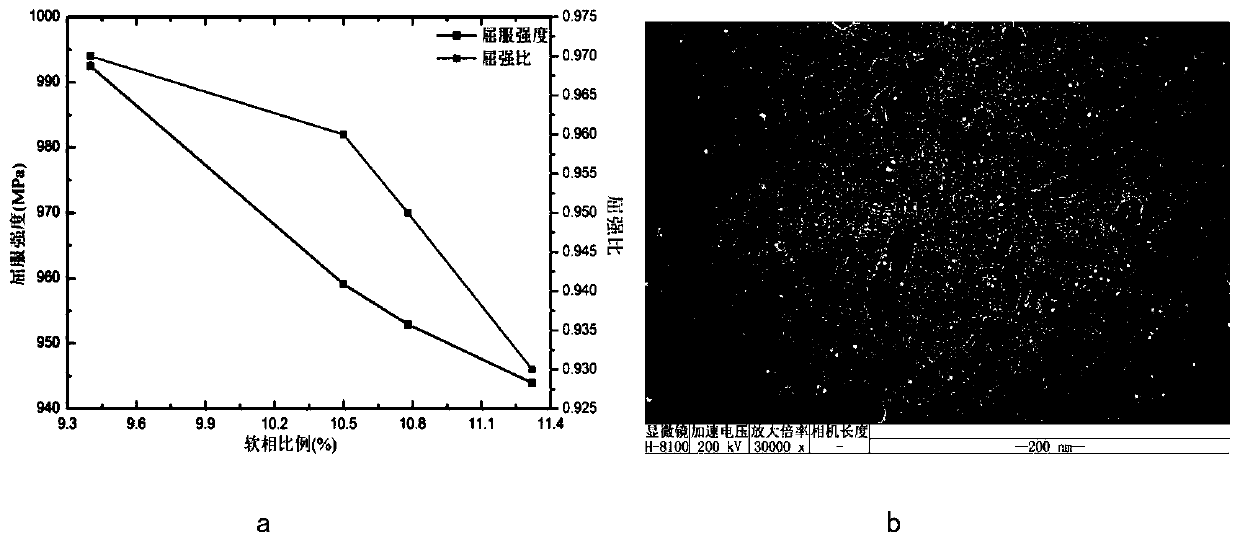

Halogen-free flame-retardant synergistic functional masterbatch special for polyphenyl ether modification and preparation method thereof

ActiveCN110615937AEnhanced compactness and structural stabilityImprove flame retardant performanceCorrosionPhosphate

The invention relates to the technical field of plastic modification processing, in particular to halogen-free flame-retardant synergistic functional masterbatch special for polyphenyl ether modification and a preparation method thereof. According to the functional masterbatch, multiply composited coated red phosphorus is used as a phosphorus flame retardant; and the functional masterbatch is prepared from the following components in percentage by mass: 70.0 wt.%-80.0 wt.% of the multiply composited coated red phosphorus, 3.0 wt.%-5.0 wt.% of organic phosphate, 17.0 wt.%-25.0 wt.% of an ethylene-methyl acrylate copolymer, 0.5 wt.%-1.0 wt.% of a dispersing agent and 0.3 wt.%-0.5 wt.% of a lubricating agent. Compared with the traditional flame-retardant functional masterbatch, the functionalmasterbatch prepared by the method has the advantages that thermal stability and water resistance of red phosphorus are remarkably enhanced, the activity of red phosphorus and the corrosion of red phosphorus to a base material are reduced, and the compatibility with a resin matrix is improved, so that the flame-retardant effect of red phosphorus to polyphenyl ether is more effectively improved.

Owner:江苏万纳普新材料科技有限公司

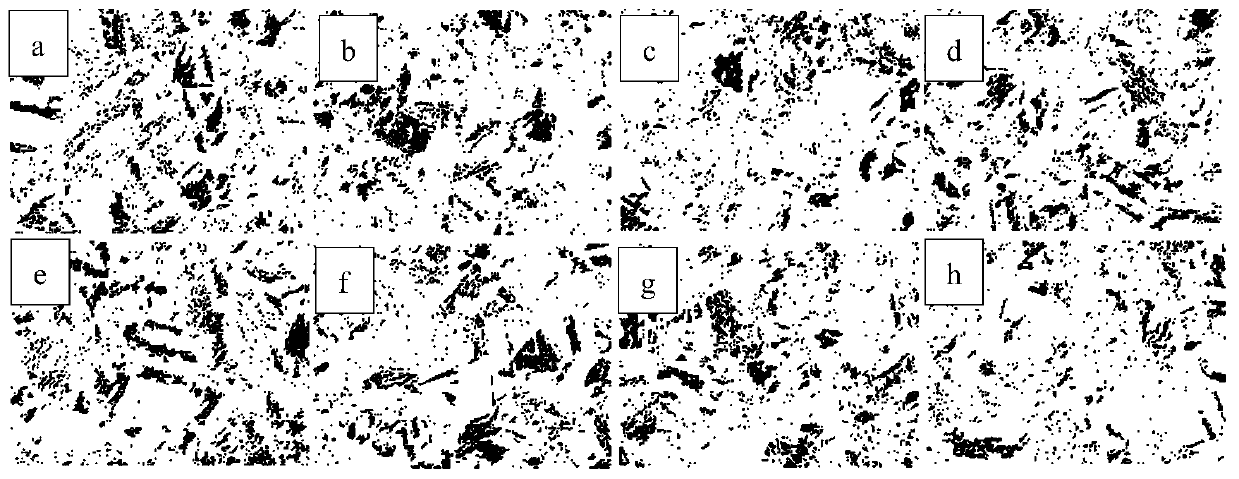

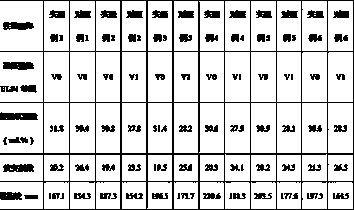

Methods for preparation of low-carbon high-strength ship plate steel and regulation and evaluation of yield ratio

ActiveCN110396646AStrong enoughMeet the target requirementsMaterial analysis by optical meansChemical compositionNanoparticle

The invention discloses methods for preparation of low-carbon high-strength ship plate steel and regulation and evaluation of a yield ratio, and belongs to the field of metal materials. According to the methods, the required yield ratio is achieved through process regulation. Materials comprises the following components of 0.05wt%-0.07wt% of C, less than or equal to 0.001wt% of Si, 1.2wt%-1.5wt% of Mn, 5.1wt%-5.3wt% of Ni, 0.45wt%-0.80wt% of Cr, 0.55wt%-0.80wt% of Mo, 0.03wt%-0.04wt% of V, 0.05wt%-0.06wt% of Nb, 0.008wt%-0.0012wt% of Ti, 0.02wt%-0.03wt% of Al, less than or equal to 0.01wt% ofP, less than or equal to 0.004wt% of S, and the balance Fe and certain unavoidable impurities. The preparation method has the advantages that under the low-carbon and low-alloy condition, the high material strength is guaranteed through the reinforcing effect of nano-particles; when the chemical components of the materials are certain, the shape, the type, the proportion and the like of phases canbe changed through rolling and heat treatment processes so as to obtain the required yield ratio; and the methods relate to the high-strength and ultrahigh-strength ship plate steel, and have a wideapplication prospect.

Owner:UNIV OF SCI & TECH BEIJING

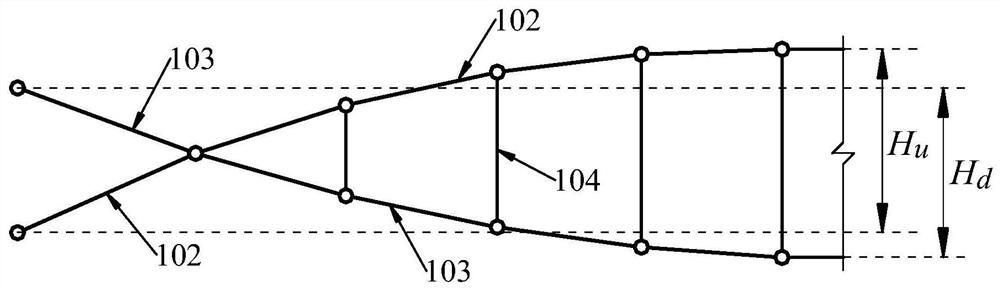

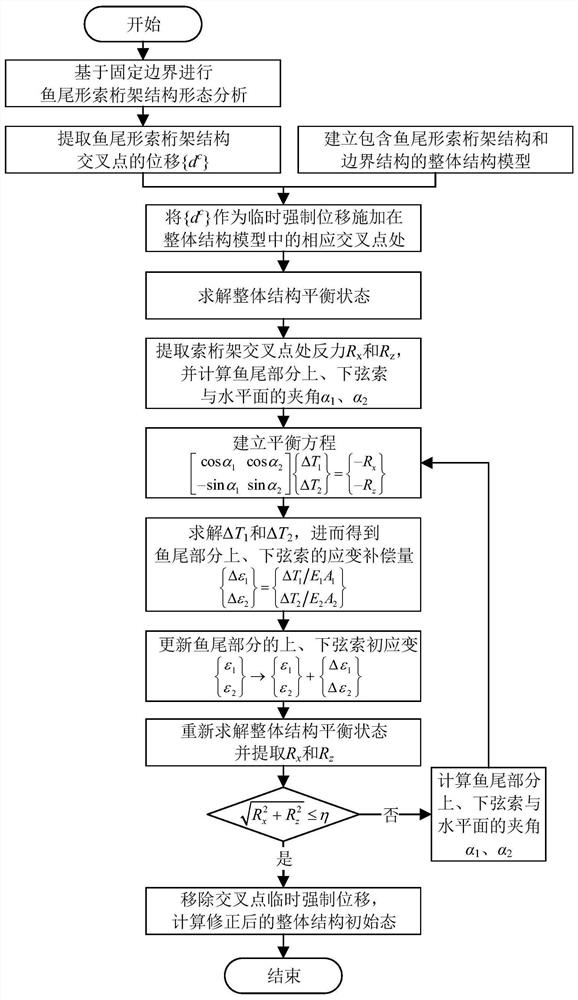

Fishtail-shaped cable truss structure form control method capable of eliminating boundary deformation influence

ActiveCN113626924AClear conceptMeet the target requirementsGeometric CADConstraint-based CADForm analysisStructural engineering

The invention relates to the technical field of structural design and analysis of constructional engineering, in particular to a fishtail-shaped cable truss structure form control method capable of eliminating boundary deformation influence, which comprises the following steps: performing form analysis on a fishtail-shaped cable truss structure based on a fixed boundary, and extracting displacement {dc} of a cable truss intersection point; establishing an integral structure model comprising a fishtail-shaped cable truss structure and a boundary structure, and applying displacement {dc} as temporary forced displacement to corresponding cross points in the integral structure model; iteratively correcting the initial strain of an upper string cable and a lower string cable of the fishtail part by taking the reaction force at the intersection point of the overall structure model in a balanced state as a convergence control index; and removing the temporary forced displacement at the cross point in the overall structure model, and calculating the initial state of the corrected overall structure by using the corrected initial strain of the upper string cable and the lower string cable of the fishtail part. According to the method, the influence of boundary deformation on the fishtail-shaped cable truss form can be eliminated only by correcting the initial strain of part of cables, the concept is clear, and the construction difficulty is low.

Owner:BEIJING INST OF ARCHITECTURAL DESIGN

Special thermoplastic polyurethane modification flame-retardant synergetic functional master batch and preparation method thereof

ActiveCN110591336AGood heat protectionHigh thermal decomposition temperatureBromineBrominated flame retardant

The invention relates to the technical field of plastic modification processing and in particular to a special thermoplastic polyurethane modification flame-retardant synergetic functional master batch and a preparation method thereof. The functional master batch adopts multiple composite coated ethylene di(tetrabromo phthalic diamide) as main body flame retardant, and comprises the following components in percentage by mass: 60.0-75.0wt.% of multiple composite coated ethylene di(tetrabromo phthalic diamide), 10.0-25.0wt.% of zinc phosphate, 9.0-13.0wt.% of thermoplastic polyurethane, 1.0-2.0wt.% of styrene-acrylonitrile copolymer coated polytetrafluoroethylene, 0.5-1.0wt.% of a dispersant and 0.3-0.5wt.% of a lubricant. Compared with a conventional flame-retardant functional master batch,the functional master batch disclosed by the invention is capable of remarkably improving the thermal stability of brominated flame retardant, a material yellowing phenomenon in a thermal mechanicalprocessing process can be effectively reduced, and the flame retardant effect of domestic brominated flame retardant on the thermoplastic polyurethane can be improved.

Owner:江苏万纳普新材料科技有限公司

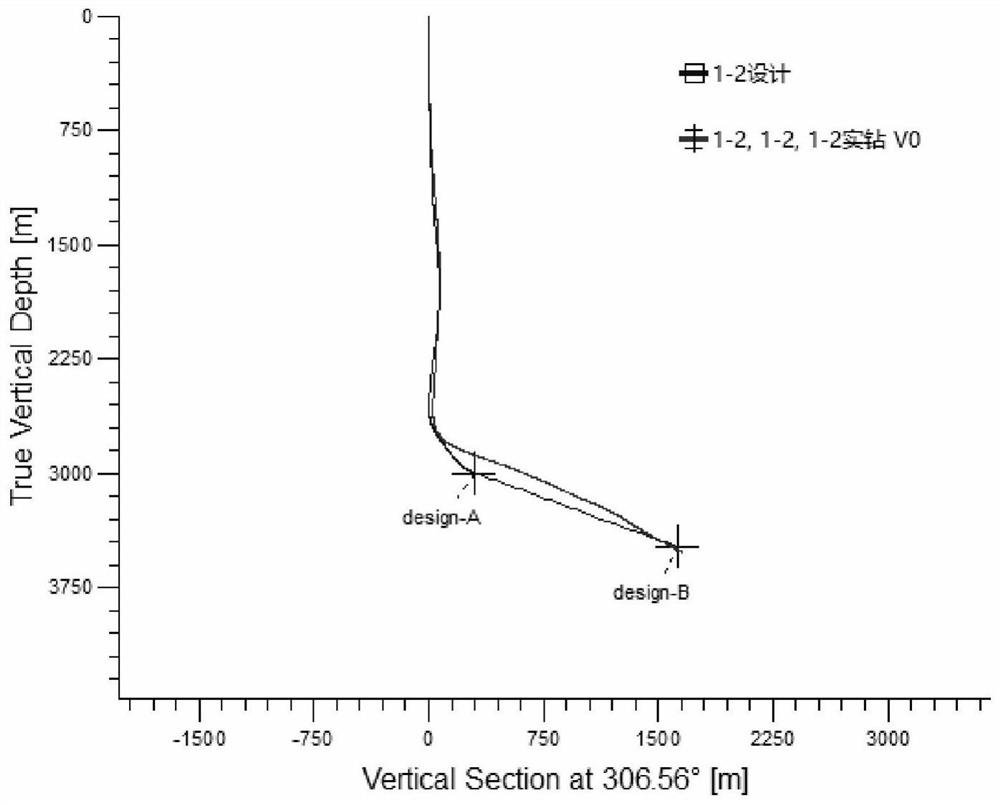

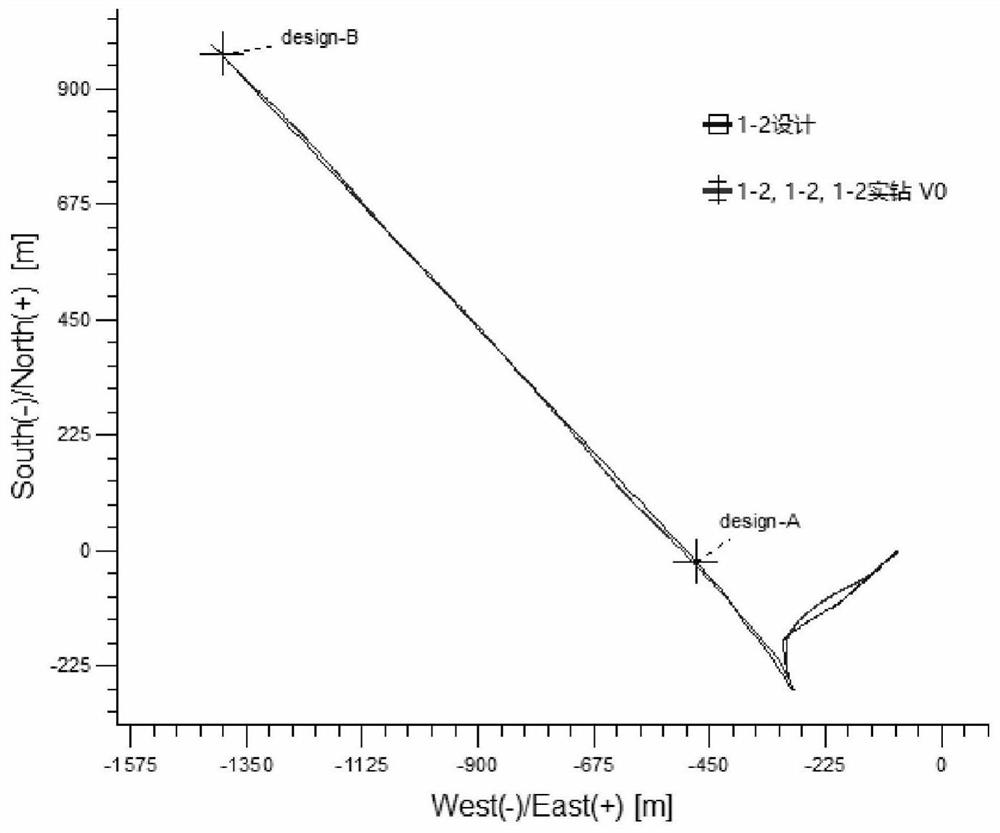

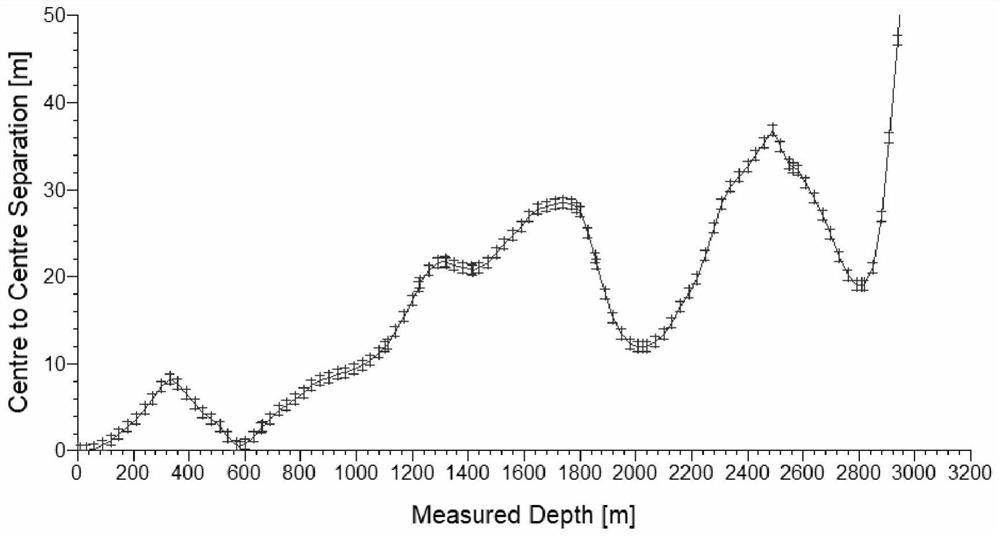

Shale gas horizontal well self-adaptive track forming method

PendingCN114016908AAvoid OrientationIncrease the compound interest rateDirectional drillingShale gasThermodynamics

The invention discloses a shale gas horizontal well self-adaptive track forming method. On the premise of the actual condition that the composite drilling process is variable in well inclination and direction, the natural deflecting rule and the directional deflecting capacity of different stratums in a work area are determined through actual drilling well data in the work area, and the self-adaptive track forming method based on the multiple sections of arcs is formed by matching the composite drilling well design and the directional drilling well design. The method is advantaged in that shallow anti-collision pressure is effectively reduced, the full-well-section composite drilling proportion is increased, the full-well drilling period is shortened, the average mechanical drilling speed is increased, and therefore safe and efficient drilling is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

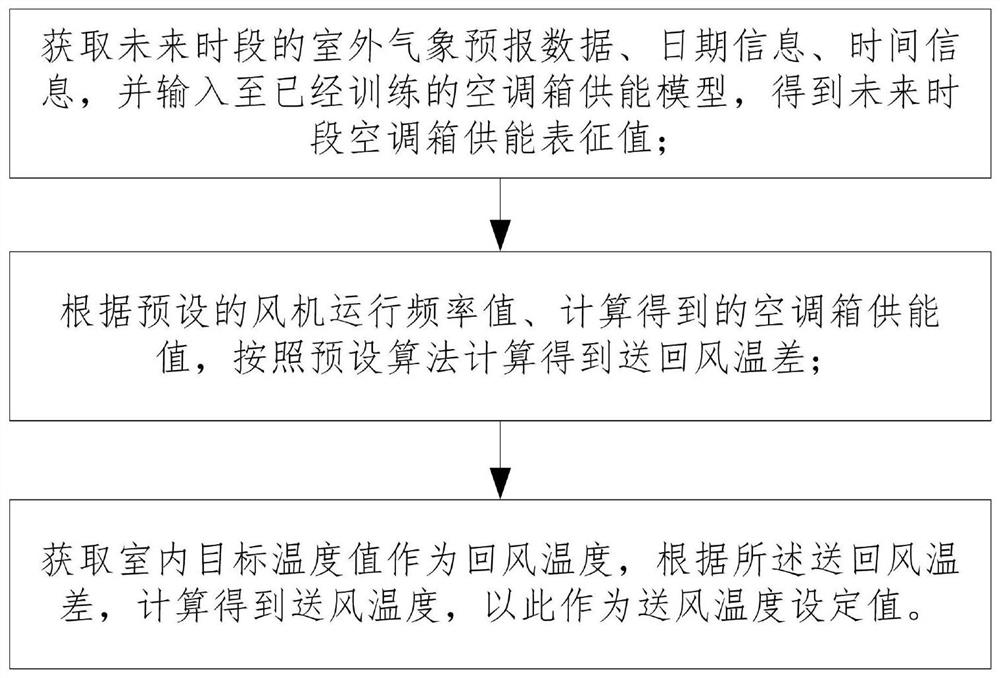

Air conditioning cabinet air supply temperature set value determining method and device based on algorithm prediction

ActiveCN112728739AAccurately determineAdjust in timeMechanical apparatusSpace heating and ventilation safety systemsSimulationEnergy supply

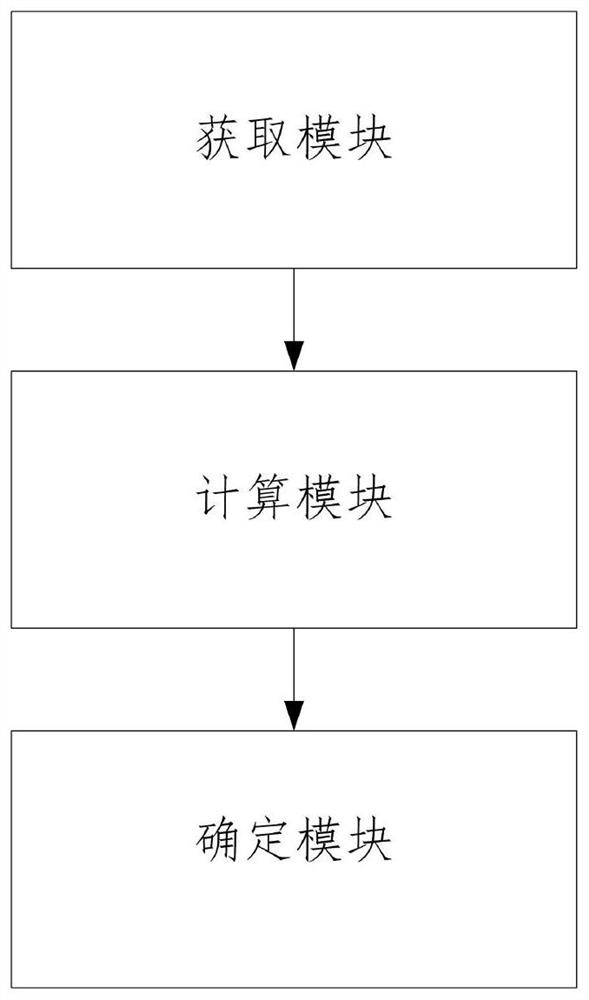

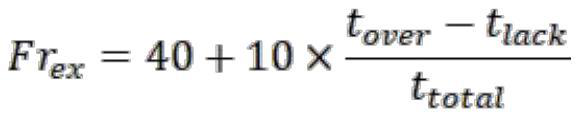

The embodiment of the invention provides an air conditioning cabinet air supply temperature set value determining method and system based on algorithm prediction and a computer readable storage medium. The method comprises the steps that outdoor weather forecast data, date information and time information in a future time period are acquired and input into a trained air conditioning cabinet energy supply model, so that an air conditioning cabinet energy supply characterization value in the future time period is obtained; according to a preset fan operation frequency value, the air conditioning cabinet energy supply characterization value obtained through calculation and a preset algorithm, the air supply and return temperature difference is calculated and obtained; and an indoor target temperature value is obtained and serves as the air return temperature, the air supply temperature is calculated according to the air supply and return temperature difference, and therefore an air supply temperature set value is obtained. According to the method, the model which is determined by various influence factors is adopted to predict the air supply temperature set value in the future time period, and therefore the air supply temperature set value can be more accurately determined under different outdoor weather conditions.

Owner:BEIJING PERSAGY ENERGY SAVING TECH

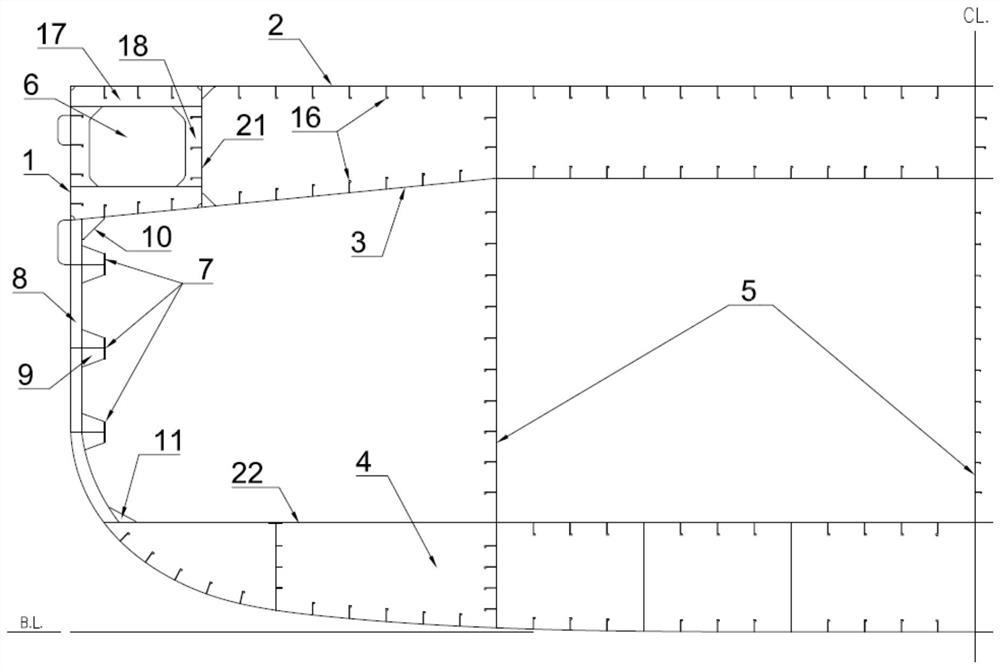

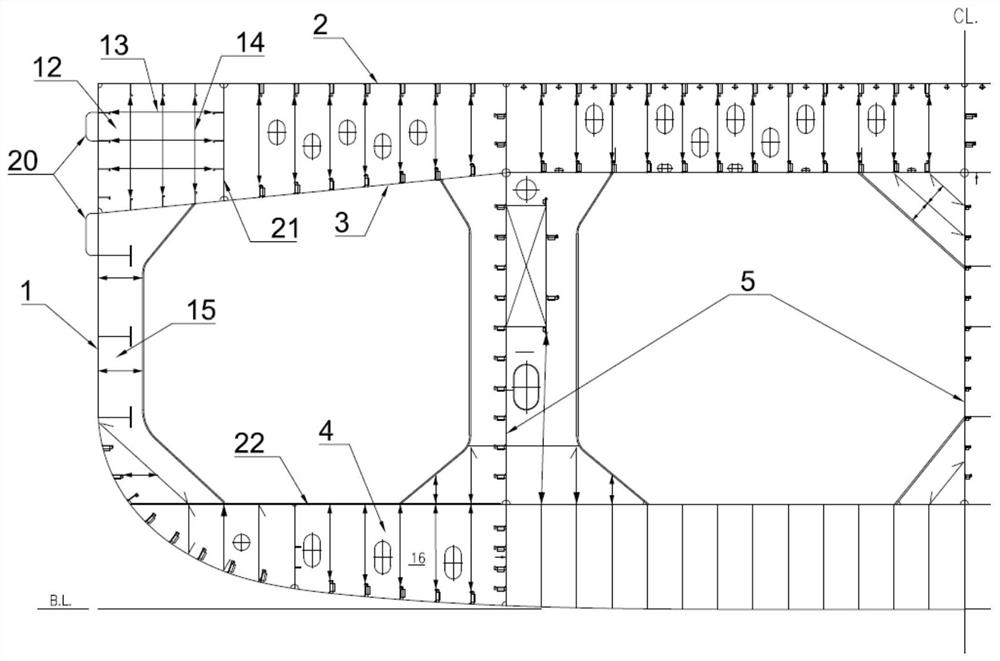

Ship body broadside structure of semi-submersible type multifunctional transporting, disassembling and assembling ship

PendingCN111791983AHigh strengthIncreased torsional strengthHull decksHull double bottomsMechanical engineeringHull

The invention discloses a ship body broadside structure of a semi-submersible type multifunctional transporting, disassembling and assembling ship. The ship body broadside structure comprises a ship body shell, a main deck, a second deck, a double-layer bottom, a longitudinal bulkhead and a box type unit. The double-layer bottom is connected with the bottom of the ship body shell. The main deck isarranged at the upper part of the ship body shell; the second deck is arranged below the main deck, the longitudinal bulkhead is arranged between the double-layer bottom in the cabin and the second deck, the box type unit is connected with the top of the ship body shell, the upper portion and the lower portion of the interior of the box type unit are respectively provided with cross beams connected with the main deck and the second deck, and the left side and the right side between the two cross beams are provided with rib plate connecting supports respectively. The ship body broadside structure has the beneficial effects that the overall bearing capacity is improved, and the broadside bearing capacity is improved; and the longitudinal fender plays a role in protecting the broadside structure.

Owner:COSCO SHIPPING

Pre-treatment auxiliary agent for cotton knitted fabrics, preparation method and application thereof

InactiveCN101914848BEasy to operateAvoid damageBleaching apparatusVegetal fibresPre treatmentNuclear chemistry

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH +1

Special polypropylene modified flame-retardant synergetic functional master batch and preparation method thereof

PendingCN110591228AImprove thermal protection performanceEffective protectionPolymer scienceTetrabromobisphenol A

The invention relates to the technical field of plastic modification processing and in particular relates to a special polypropylene modified flame-retardant synergetic functional master batch and a preparation method thereof. The functional master batch adopts tetrabromobisphenol A di(2,3-dibromopropyl) ether in multiple composite coating as main body flame retardant, and comprises the followingcomponents in percentage by mass: 55.0-70.0wt.% of tetrabromobisphenol A di(2,3-dibromopropyl) ether in multiple composite coating, 15.0-30.0wt.% of antimonous oxide, 7.0-10.0wt.% of high-flowabilitypolypropylene, 2.0-4.0wt.% of atactic polypropylene, 1.0-2.0wt.% of styrene-acrylonitrile copolymer coated polytetrafluoroethylene, 0.5-1.0wt.% of a dispersant and 0.3-0.5wt.% of a lubricant. Comparedwith a conventional flame-retardant functional master batch, the functional master batch provided by the invention is capable of remarkably improving the thermal stability of brominated flame retardant, effectively reducing material yellowing phenomena in the thermal mechanical processing process, and improving the flame retardance effect of domestic brominated flame retardant on polypropylene.

Owner:江苏万纳普新材料科技有限公司

RH chromium-free gunning material and preparation method thereof

ActiveCN104058762ASimple production methodImprove penetration resistanceChromium freeZirconium dioxide

The invention relates to an RH chromium-free gunning material and a preparation method thereof and belongs to the field of external refining of metallurgy production. The technical problem solved by the invention is to provide the RH chromium-free gunning material and the preparation method thereof. The RH chromium-free gunning material comprises the following components in parts by weight: 40-45 parts of fused magnesite coarse particle, 10-15 parts of fused magnesite fine particle, 20-30 parts of fused magnesite fine powder, 5-10 parts of nanometer zirconium dioxide, 1-3 parts of sodium hexametaphosphate, 1-2 parts of boric acid, 2-4 parts of silica powder, 2-4 parts of aluminium dihydrogen phosphate and 0.05-0.1 part of carboxymethylcellulose. The RH chromium-free gunning material provided by the invention is superior in performance and free of chromium and completely meets the specified environmental indexes and use requirements.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for recycling reagent-grade anhydrous sodium sulfate from basic cupric carbonate production waste liquid

ActiveCN102897802BEfficient removalRemove completelyAlkali metal sulfite/sulfate purificationAlkali metal sulfite/sulfate dehydrationPhosphateCopper sulfate

The invention provides a method for recycling reagent-grade anhydrous sodium sulfate from waste liquid generated in a process of producing basic cupric carbonate by using copper sulfate solution and alkali carbonate solution. The method comprises the following steps: adding a certain amount of sodium sulfide into waste liquid, and filtering out copper and other heavy metal impurities; removing excessive sulfion with a certain amount of reagent-grade hydrogen peroxide; adding a certain amount of aluminum sulfate into the liquid, stirring and heating till boiling, and adding a proper amount of activated carbon to adsorb, filter and remove phosphate; and regulating the pH value of filtered clear liquid with reagent-grade concentrated sulfuric acid, concentrating, centrifuging in hot state, eluting with hot water and drying to obtain the reagent-grade anhydrous sodium sulfate. The method for recycling the reagent-grade anhydrous sodium sulfate is simple to operate and mild in process condition, can effectively remove various impurities out of the waste liquid by few auxiliary materials and has high comprehensive recycling rate being above 95 percent, and inspection indicates that the product reaches chemical reagent analytic pure standard. According to the method, the reagent-grade anhydrous sodium sulfate can be recycled by virtue of treatment and comprehensive utilization of the waste liquid, so that the aims of saving energy and reducing emission, alleviating environment pollution and reducing production cost can be achieved.

Owner:GUANGDONG GUANGHUA SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com