Automobile engine cylinder cover intelligent production line and technological process thereof

A technology for automobile engines and production lines, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as low production efficiency, lack of determination of system target requirements, lack of detection, cleaning and quality analysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

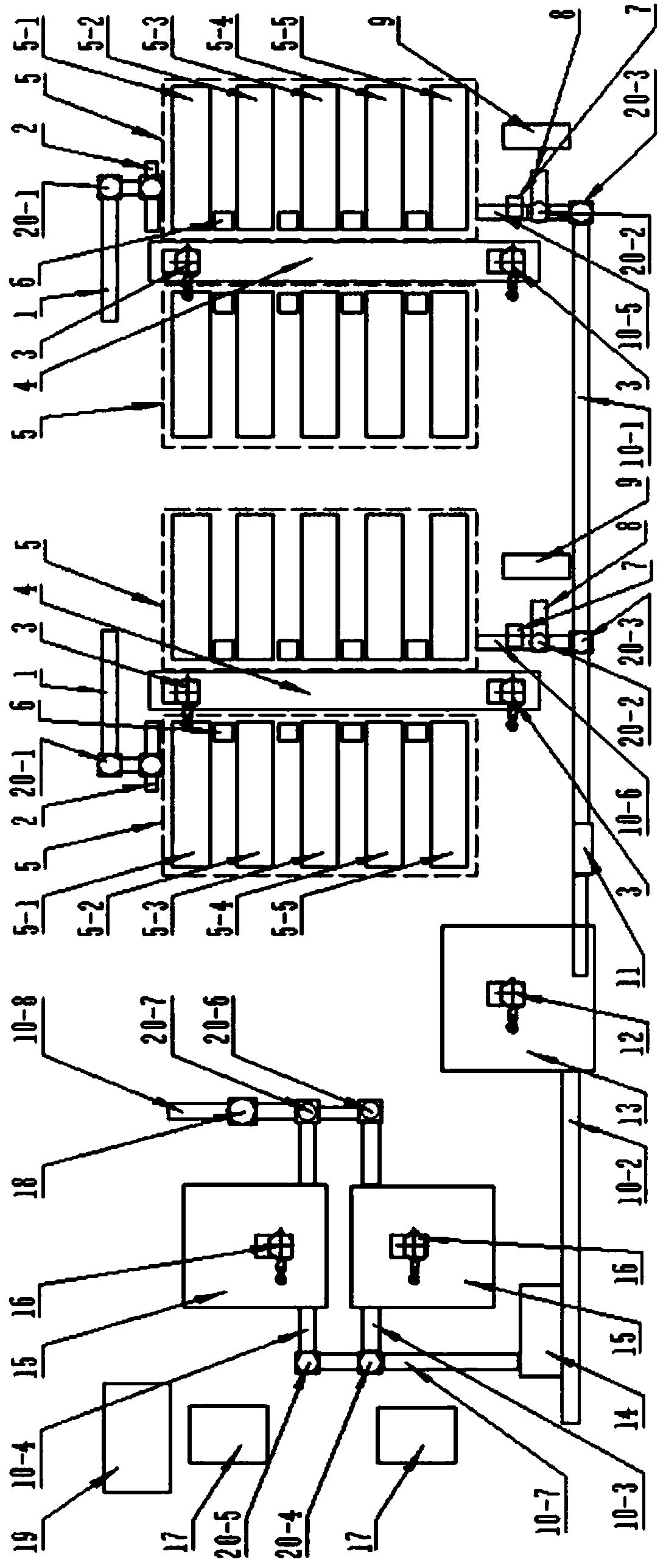

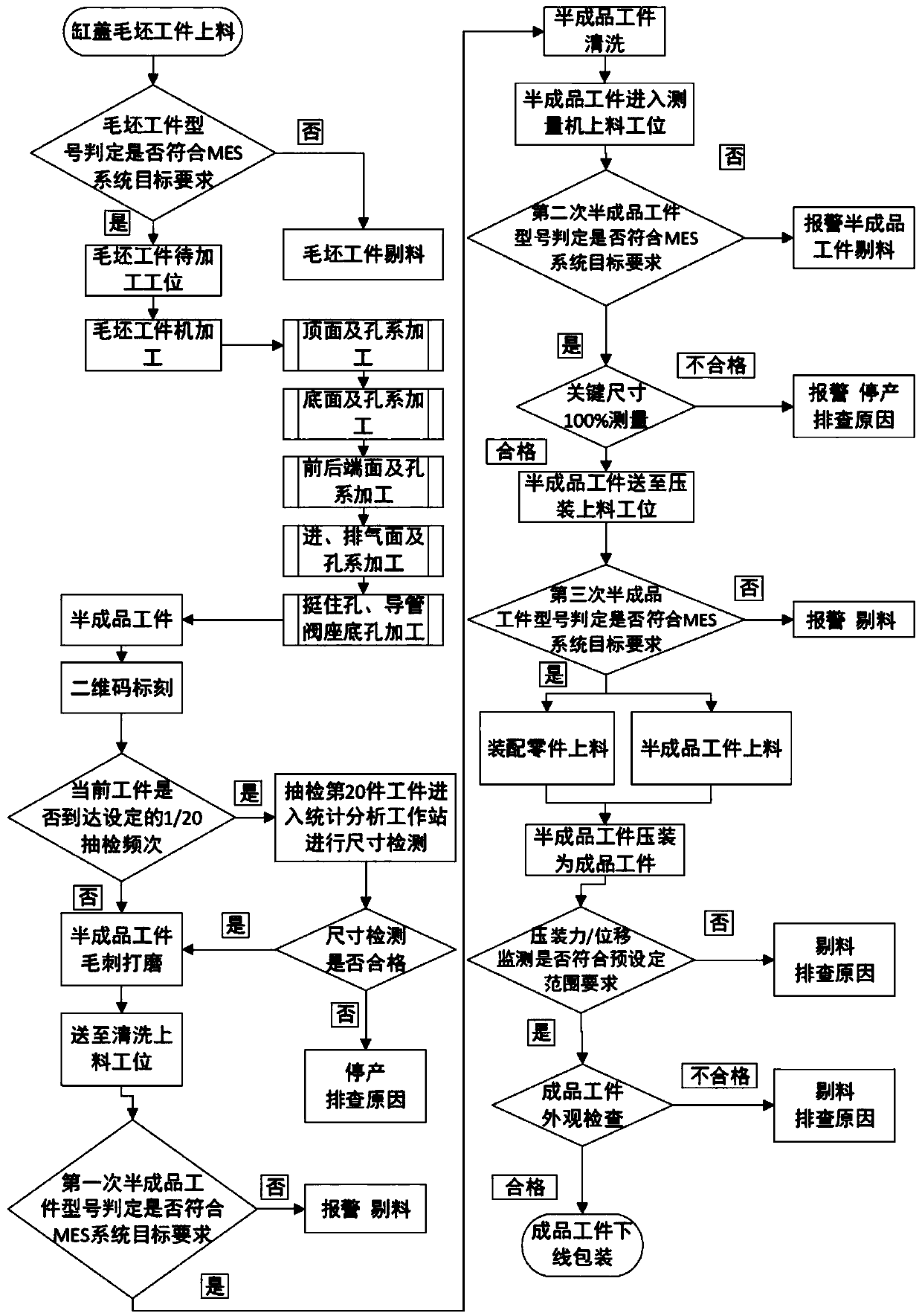

[0095] Such as figure 1 As shown, the present invention includes 4 rows, 5 sets in each row, 20 processing centers in total, and a processing center unit 5 is formed by 5 processing centers in each row. Hole processing center 5-1, bottom surface and hole system including assembly positioning hole processing center 5-2, front and rear end surface and hole system processing center 5-3, air intake surface and hole system and exhaust surface and hole system processing center 5-4 And tappet hole and conduit valve seat bottom hole machining center 5-5, in each machining center unit 5, a cache mechanism 6 is installed between every adjacent 2 machining centers, between every 2 machining center units 5 One floor rail 4 and two six-axis joint handling robots 3 are installed in each room, and one motorized roller table 1 for feeding and the blank workpiece model shared by the two processing units are installed at the starting ends of each two machining center units 5. Identification me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com