High temperature resistant samarium cobalt permanent magnet and preparation method thereof

A permanent magnet, high temperature resistant technology, used in magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc. Few problems, to achieve the effect of improving magnetic performance, high coercivity, and high magnetic energy product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

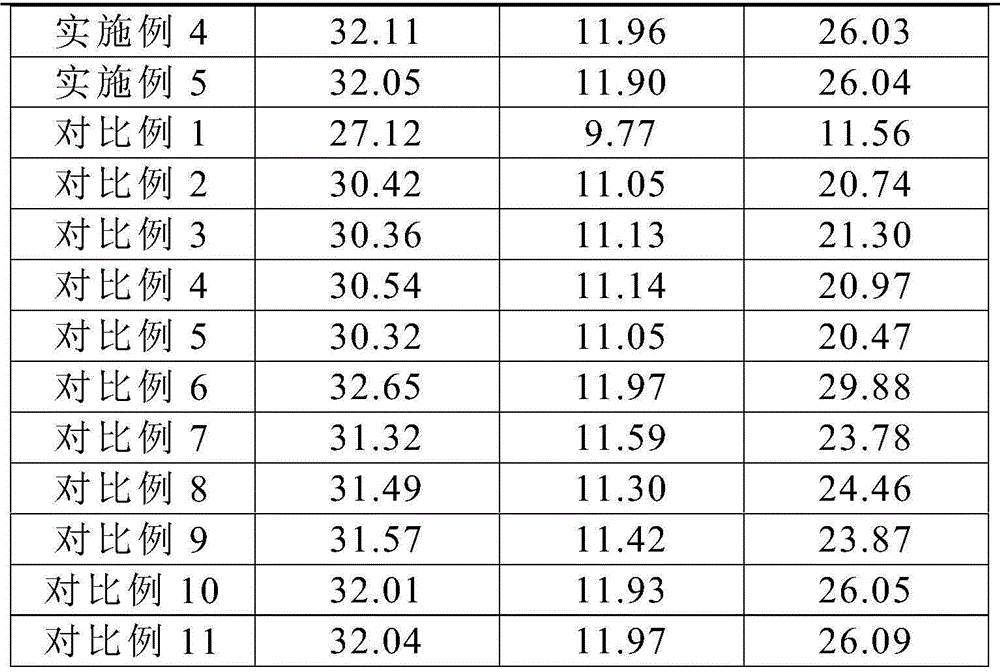

Examples

Embodiment 1

[0046] According to the composition of the samarium-cobalt permanent magnet powder in Example 1 in Table 1 and its mass percentage, batching and smelting, the alloy solution obtained after smelting is poured on a rotating water-cooled copper roller in an inert atmosphere and cooled rapidly to obtain a thickness of 0.03mm. alloy sheet.

[0047] Then the prepared alloy sheet is subjected to hydrogen crushing to obtain powder, and the powder is not subjected to dehydrogenation treatment, but is directly processed into a powder with a particle size of 3-5 μm through a jet milling process.

[0048] Then, the glass fiber with a volume percentage content of 15% and the powder material with a volume percentage content of 85% are put into a molding press mold under the protection of an inert gas, and a magnetic field is applied for orientation. After orientation, press molding, demagnetization and vacuum packaging to obtain Green body, put the green body into the isostatic pressing pro...

Embodiment 2

[0052] According to the composition and mass percentage of the samarium cobalt permanent magnet powder of embodiment 2 in table 1, batching and smelting, the alloy solution obtained after smelting is poured on the rotating water-cooled copper roller in an inert atmosphere and cooled rapidly to obtain a 1mm thick alloy sheet.

[0053] Then the prepared alloy sheet is subjected to hydrogen crushing to obtain powder, and the powder is not subjected to dehydrogenation treatment, but is directly processed into a powder with a particle size of 3-5 μm through a jet milling process.

[0054] Then, put the aramid fiber with a volume percentage of 15% and the powder with a volume percentage of 85% under the protection of an inert gas into a molding press mold and apply a magnetic field for orientation. After orientation, press molding, demagnetization and vacuum packaging, Obtain the green body, put the green body into the isostatic pressing process, and then take it out.

[0055] Then...

Embodiment 3

[0058] According to the composition of the samarium-cobalt permanent magnetic powder of Example 3 in Table 1 and its mass percentage, batching and smelting, the alloy solution obtained after smelting is poured on the rotating water-cooled copper roll in an inert atmosphere and cooled rapidly to obtain a 3mm thick alloy sheet.

[0059] Then the prepared alloy sheet is subjected to hydrogen crushing to obtain powder, and the powder is not subjected to dehydrogenation treatment, but is directly processed into a powder with a particle size of 3-5 μm through a jet milling process.

[0060] Then, the carbon fiber with a volume percentage content of 15% and the powder material with a volume percentage content of 85% are put into a molding press mold under the protection of an inert gas, and a magnetic field is applied for orientation. After orientation, press molding, demagnetization and vacuum packaging to obtain raw The green body is put into the isostatic pressing process and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com