Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50 results about "La element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lanthanum is element number 57 with element symbol La. It is a soft, silver-colored, ductile metal known as the starting element for the lanthanide series. Here is a collection of La element facts, along with the atomic data for lanthanum.

Hot dipping alloy plating added with La element and preparation method thereof

InactiveCN101560636AAccelerated corrosionImprove antioxidant capacityHot-dipping/immersion processesLa elementCorrosion resistant

The invention relates to a hot dipping alloy plating added with La element and a preparation method thereof. The hot dipping alloy plating comprises the components based on mass percent: 52-58% of Al, 39.8-46.75% of Zn, 1.2-2.0% of Si and 0.05-0.20% of La. The preparation method comprises: the raw material aluminium pig is heated and melted into aluminium liquid which is then added into a melting device provided with a stirrer, and the 1.2-2.0% of Si, the 0.05-0.20% of La and the rest of Zn are mixed into the aluminium liquid, so that alloy is formed in a stirring state. By adopting the alloy for hot dip plating, the corrosion-resistant property and the high temperature antioxygenic property of an alloy plating layer can be enhanced, the surface quality of galvanized steel material can be improved, the service life of the galvanized steel material is prolonged, the crystal pattern of the plating layer is regular in size, uniform and clear, and the bare board of the alloy plating layer can be directly used without color coating.

Owner:HULUDAO ZINC IND CO LTD

Multi-main phase Ho-containing NdFeB (neodymium iron boron) permanent magnet and manufacturing method thereof

ActiveCN104252938ACorrosion resistantImprove performanceInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementLa element

The invention discloses a multi-main phase Ho-containing NdFeB (neodymium iron boron) permanent magnet and a manufacturing method thereof. The permanent magnet contains multiple main phases with different rare earth element contents. Oxide phases exist among the main phases. Oxygen contents of the oxide phases are higher than those of the main phases. The main phases with the high Ho content exist. Crystal grains composed of the main phases are isolated by grain boundaries. Average grain size is 6-14 um. The manufacturing method includes smelting a first alloy, smelting a second alloy, smelting a third alloy, performing hydrogen decrepitation, mixing the alloys, performing grinding powder, pressing under magnetic field, performing vacuum sintering, performing aging and the like. The method smelting the first alloy includes preparing the first alloy containing La element, Ce element, Pr element and Nd element. The method smelting the second alloy includes preparing the second alloy containing the element Pr, the element Nd, the element Dy and the element Ho. The method smelting the third alloy includes preparing the third alloy containing the element Pr, the element Nd, the element Dy and the element Gd.

Owner:SHENYANG GENERAL MAGNETIC

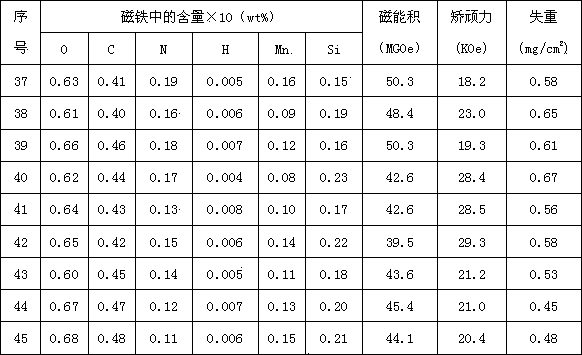

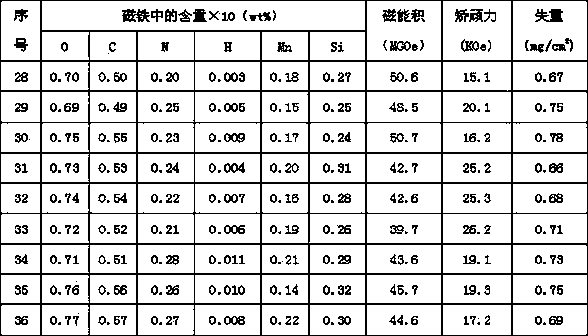

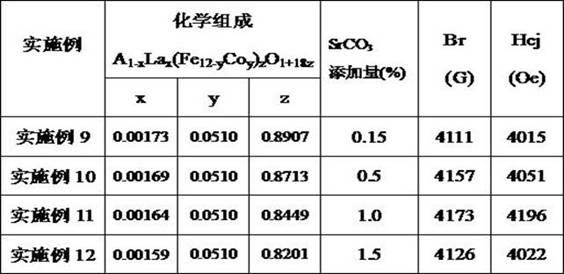

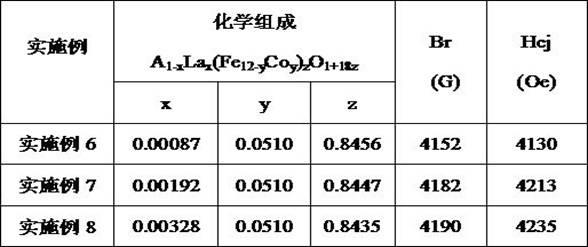

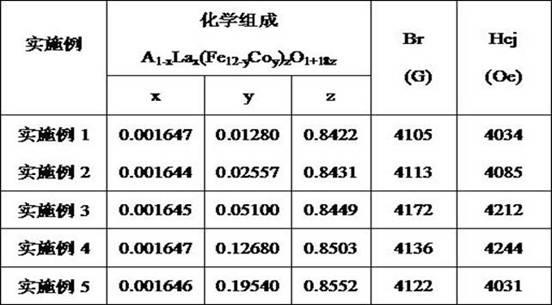

Ferrite magnetic material and manufacturing method thereof

ActiveCN102436899AIncrease solid solutionImprove magnetismMagnetsInorganic material magnetismStrontium carbonateMetallurgy

The invention discloses a ferrite magnetic material and a manufacturing method thereof. In the ferrite magnetic material, a composition shown by a combined formula of A1-xLax(Fe12-yCoy)zO1+18Z is used as a main component; in the formula, A is at least one element selected from Sr, Ba and Ca; x is 0.001-0.039; y is 0.01-0.2; and z is 0.80-0.89. According to the invention, by adding strontium carbonate and trace La element into a ball milling process, solid solubility of Co element in the ferrite can be improved, the magnetic performance of the ferrite can be greatly improved, and the production cost is low; and through the material and the method, permanent magnetic ferrite with Br greater than or equal to 4,100 G and Hcj greater than or equal to 4,000 Oe can be obtained.

Owner:HUNAN AEROSPACE MAGNET & MAGNETO

Integrally-extruded honeycomb catalyst for selective catalytic reduction (SCR) smoke denitration and preparation process of catalyst

InactiveCN102886266AEasy to shapeHigh mechanical strengthDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsStructural phaseDesorption

The invention discloses an integrally-extruded honeycomb catalyst for selective catalytic reduction (SCR) smoke denitration. The catalyst consists of the following active ingredients: 65 to 80 percent of titanium dioxide, 5 to 15 percent of ferrous sulfate, 5 to 15 percent of tungsten trioxide, 1 to 4.5 percent of vanadium pentoxide and 0.05 to 0.5 percent of lanthanum nitrate. The catalyst has the advantages of high mechanical strength, wear resistance, long service life and low cost, and the catalyst is easy to form; particularly FeSO4 is added, so that a good catalyzing effect is achieved, and a synergistic effect of FeSO4 and Ti-V-W active ingredients is also achieved; because a La element is added, structural phase transition from an anatase to a rutile is greatly restrained, a phase transition temperature is obviously increased, the catalyst can be calcined at a temperature of 800 DEG C, and the catalyst of an anatase ontology is obtained; and moreover, the catalyst has a good denitration effect, is wide in applicable temperature range, and can help to achieve a desorption efficiency of 60 to 90 percent at the temperature of between 180 DEG C and 450 DEG C.

Owner:山东蓝天节能环保科技有限公司

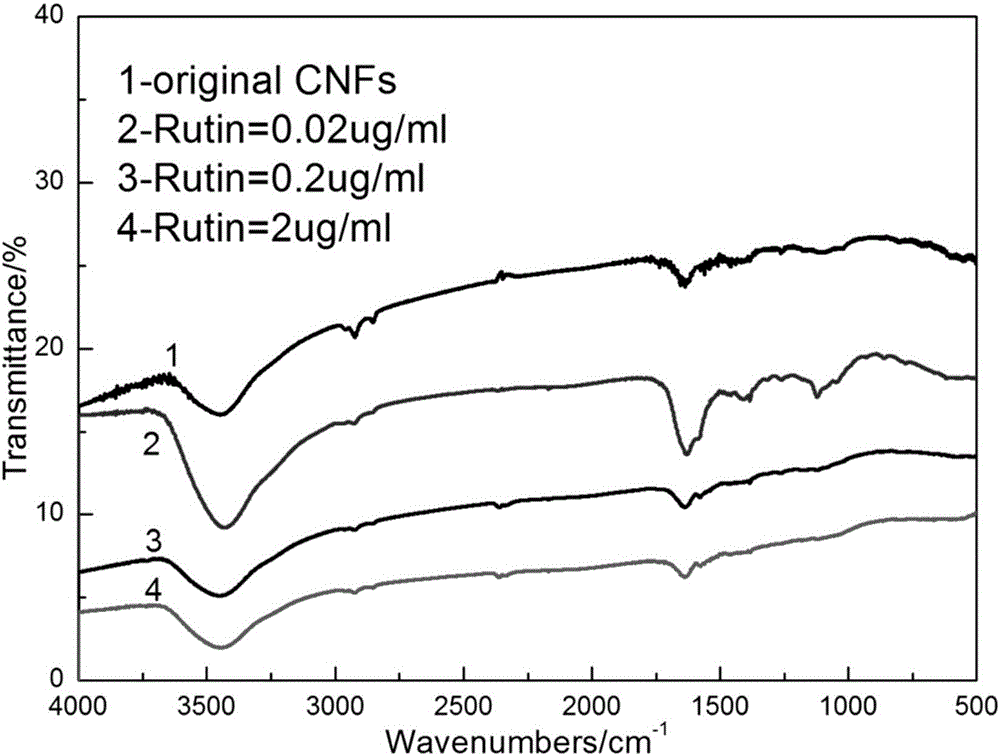

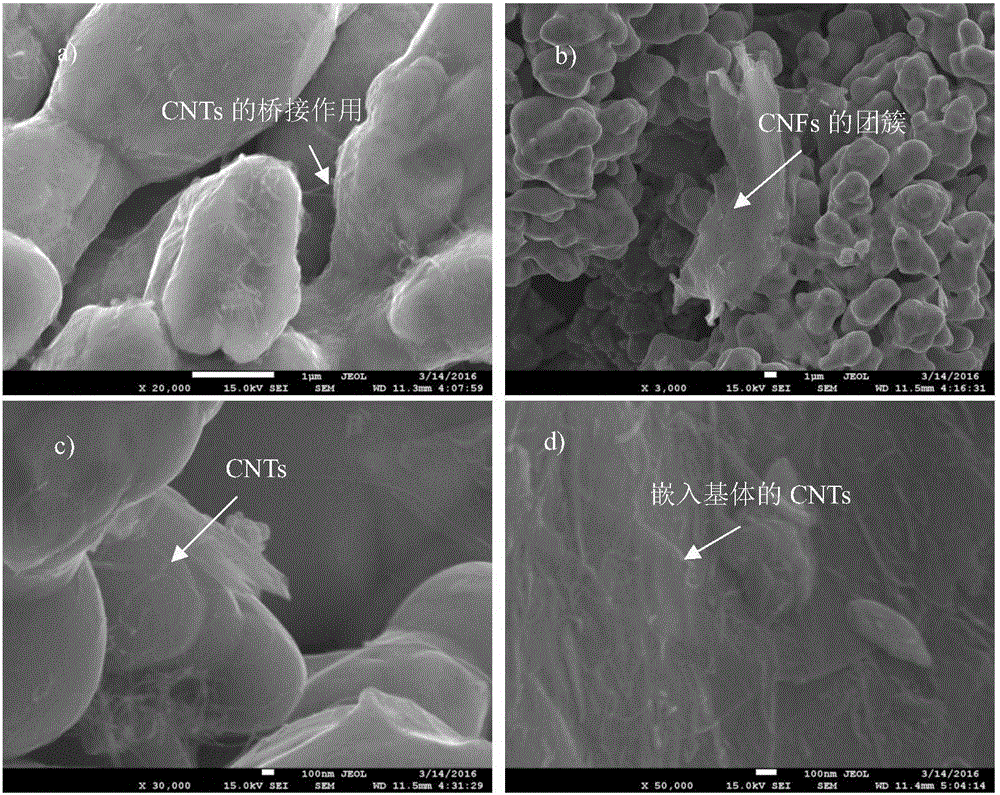

Carbon nanotube and carbon nanofiber synergetic enhanced copper base composite material and preparation method

The invention discloses a CNTs and CNFs synergetic enhanced copper base composite material. The copper base composite material comprises the following components in percentage by weight: the mass fraction sum of surface-modified CNFs and surface-modified CNTs is 0.1-5%; the content of graphite is 0.5-8%; the content of Ti3SiC2 is 6-15%; the content of La element is 0.01-0.5%; and the balance is copper; the surface-modified CNTs is obtained by modifying gallic acid water solution; and the surface-modified CNFs is obtained by modifying rutin water solution. In the copper base composite material, the CNTs and the CNFs are better in dispersibility and low in impurity content, keep complete surface topography, exert common reinforcement effect with graphite powder, Ti3SiC2 powder, La and copper matrix, prominently improve the mechanical performance and the friction wear resistance of the copper base composite material, and meanwhile, are excellent in strength and impact resistance.

Owner:SOUTHWEST JIAOTONG UNIV

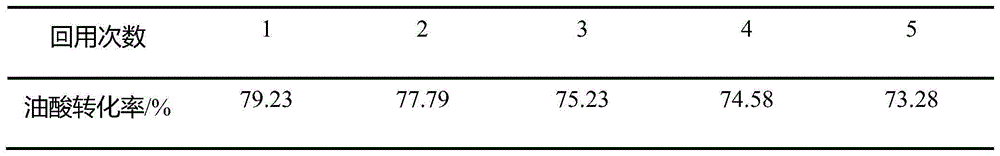

Method for catalyzing esterification reaction by means of high-stable-acidity mesoporous-microporous molecular sieve

InactiveCN104877762AImprove catalytic performanceImprove thermal stabilityMolecular sieve catalystsFatty acid esterificationMolecular sieveAlcohol

The invention relates to a method for catalyzing esterification reaction by means of a high-stable-acidity mesoporous-microporous molecular sieve. The method is characterized by comprising the following steps: compounding the high-stable-acidity mesoporous-microporous molecular sieve in a step-by-step crystallization method by using self-produced beta zeolite as a guiding agent, loading a rare-earth La element, and catalyzing the esterification reaction of oleic acid and methyl alcohol by using the compounded acidic mesoporous-microporous molecular sieve. When the ratio of alcohol to oil is 10:1, the consumption of catalyst is 5 percent of the total quantity, and reaction is performed for 8 hours at the temperature of 120 DEG C, the conversion rate of oleic acid is not less than 70 percent, and the catalyst is good in hydrothermal stability and reusability.

Owner:QINGDAO UNIV OF SCI & TECH

Method for manufacturing steel rail through nano bainite material containing rare earth La element and steel rail

ActiveCN105695849ALow costImprove the adaptability of production processFurnace typesHeat treatment furnacesRare earthUltimate tensile strength

The invention relates to a method for manufacturing a steel rail through a nano bainite material containing the rare earth La element and the steel rail. The method includes the steps that smelting is carried out, wherein smelting comprises the deoxidation and desulfuration step, the element adding step and the refining and vacuum degassing step; rolling is carried out; and cooling is carried out. According to the preparing method, as the rare earth La is added, the rare earth La and Mn, Cr and Si alloy elements will jointly strengthen the hardenability effect, and therefore the strengthening effect is improved; in addition, expensive alloy Ni is not added, grading cooling control after rolling is used in a combined manner, and therefore the strength of steel is further improved; and meanwhile, the toughness of the steel is improved through the effects of modifying inclusion, grain boundary purification, bainite wattle refining, dislocation generation promoting and the like of the rare earth in the bainite steel, and therefore the steel rail has the excellent toughness.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Catalyst for synthesis of isoprene and preparation method thereof

ActiveCN106540726AImprove conversion rateHigh selectivityPhysical/chemical process catalystsCatalystsRare-earth elementAlkaline earth metal

The invention provides a catalyst for synthesis of isoprene. The catalyst comprises active components and a carrier. The active components comprise a Cr element, a Mo element, a P element, a rare earth element and an alkali metal / alkaline earth metal element. The rare earth element comprises one or more of La, Ce, Nd, Sm, Gd and Lu. Compared with the existing catalyst, the catalyst provided by the invention is based on the Cr-Mo-P bimetallic active center, contains the rare earth element and the alkali metal / alkaline earth metal element for forming a five-membered active component having synergistic effects so that the catalyst has a higher conversion rate and selectivity in the gas phase one-step synthesis of isoprene. The experimental result shows that the selectivity of isobutylene is 80% or more in the process of synthesis of isoprene by a gas phase one-step method, the conversion rate of formaldehyde is 80% or more and the selectivity of formaldehyde is 79% or more.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

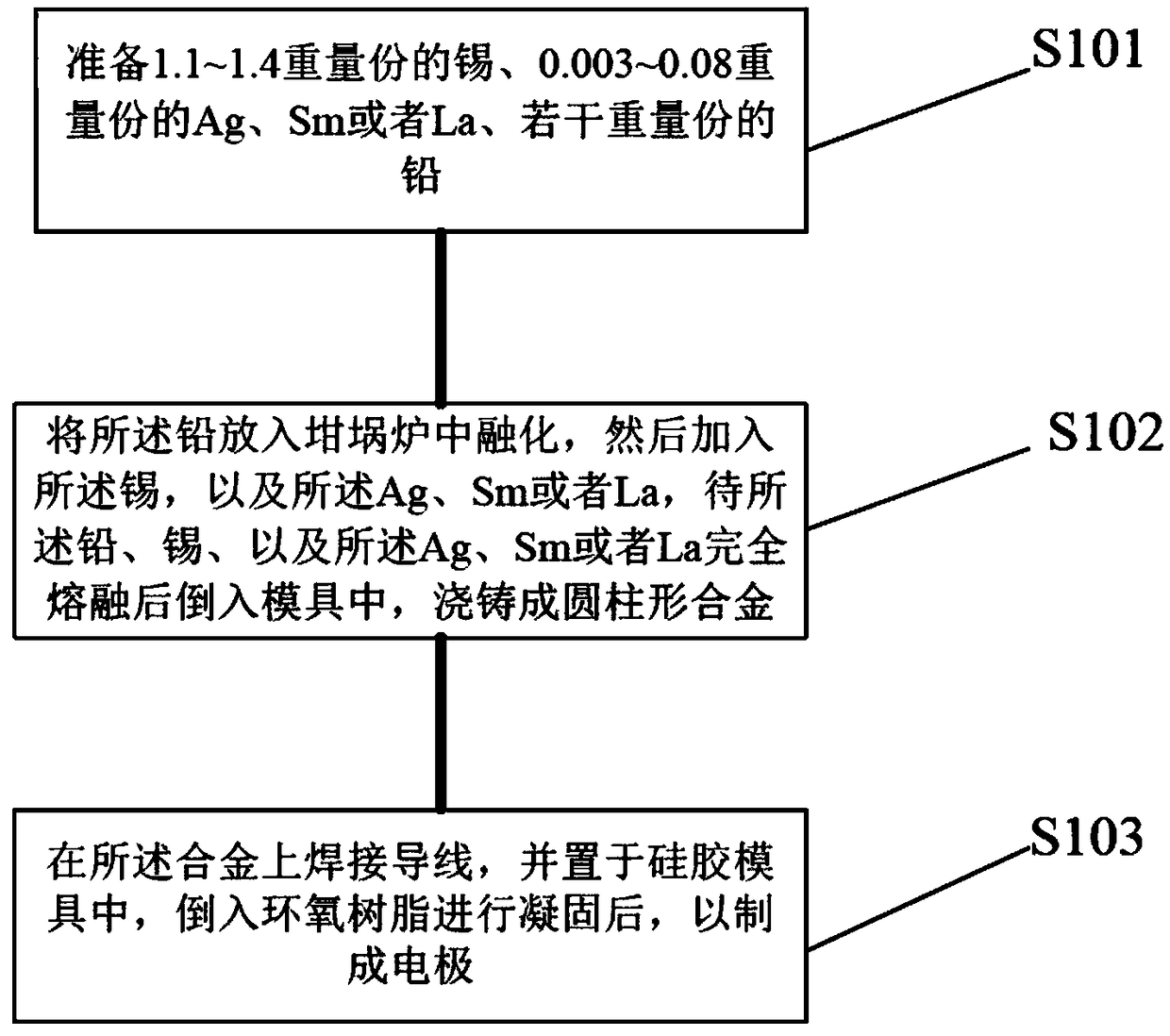

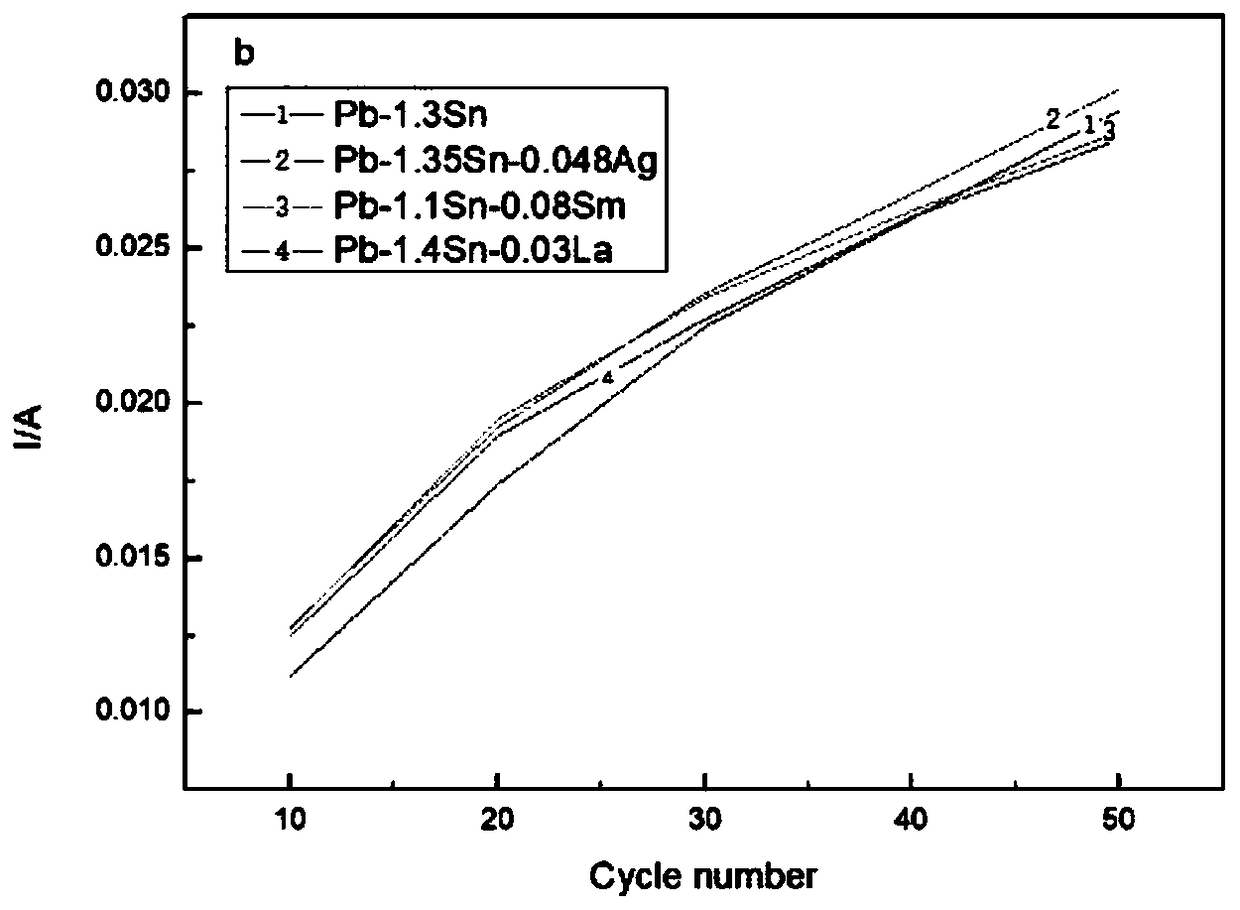

Pb-Sn grid alloy and preparation method

InactiveCN109402419AImprove work performanceReduce corrosion rateElectrode carriers/collectorsWork PerformancesOxygen evolution

The invention provides a Pb-Sn grid alloy on one hand. The Pb-Sn grid alloy is prepared from components in parts by weight as follows: 1.1-1.4 parts of Sn, 0.003-0.08 parts of Ag, Sm or La and multiple parts of Pb. The Pb-Sn grid alloy has beneficial effects as follows: by addition of Ag, Sm or La element to the Pb-Sn grid alloy, the corrosion rate of the alloy can be effectively reduced, and corrosion resistance of the alloy is improved; moreover, after the Ag, Sm or La element is added, oxygen evolution overpotential of the alloy is increased, and an oxygen evolution reaction is inhibited; furthermore, after the Ag, Sm or La element is added, resistance of an alloy corrosion film is reduced, growth of Pb(II) oxide with poorer electrical conductivity is inhibited, and electrical conductivity of the corrosion film is improved. By addition of the Ag, Sm or La element to the Pb-Sn grid alloy, working performance of the Pb-Sn grid alloy is greatly improved.

Owner:CHINA ELECTRIC POWER RES INST +3

Special high-strength aluminum-magnesium alloy for storage racks and manufacturing method of special high-strength aluminum-magnesium alloy

The invention discloses a special high-strength aluminum-magnesium alloy for storage racks. The aluminum-magnesium alloy comprises the following components in percentage by mass: 1.23-1.45% of Sr, 4.7-5.5% of Mg, 0.12-0.32% of Fe, 0.09-0.12% of Si, 0.05-0.11% of Cu, 0.32-0.46% of Mn, 0.05-0.1% of Zn, 0.15-0.24% of Mo, 0.25-0.41% of Ti, 0.05-0.15% of Zr, 0.02-0.05% of Y, 0.001-0.005% of Na, 0.001-0.003% of Ni, 0.22-0.38% of La elements, 0.15% or lower of remaining impurities and the balance of Al, wherein the impurities comprise 0.005% or lower of P, 0.0056% or lower of S, 0.003% or lower of H, 0.006% or lower of N and 45 ppm or lower of O; the La elements comprise 23-27% of Nd, 0-4% of Ce, 6-10% of Er, 1-5% of Pr, 1-6% of Pm, 0-2% of Dy and the balance of La. By virtue of the components, the corrosion resistance of an aluminum alloy can be improved; by virtue of a heat treatment process, not only is the processing cost reduced and the processing period shortened, but also the corrosion resistance and the welding performance of the aluminum alloy can be improved, and the quality of products is improved.

Owner:SUZHOU TONGMING MACHINERY

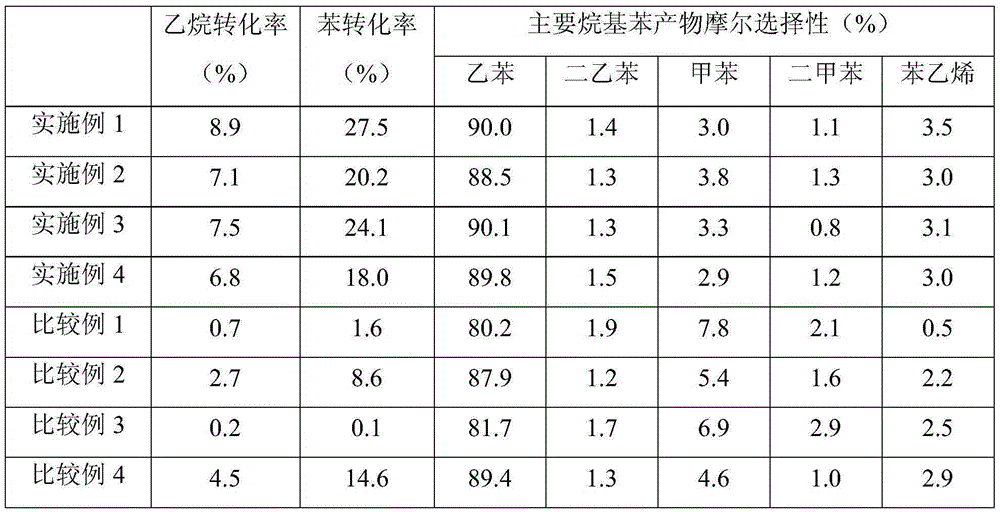

Catalyst for producing ethylbenzene from benzene and ethane

ActiveCN106582791AImprove conversion rateMolecular sieve catalystsHydrocarbon by hydrocarbon condensationMolecular sieveLa element

The invention relates to a catalyst for producing ethylbenzene from benzene and ethane. The catalyst mainly solves the problem that a Pt-loaded molecular sieve catalyst used in a reaction for producing ethylbenzene from benzene and ethane has a low conversion rate. The catalyst for producing ethylbenzene from benzene and ethane comprises the following components: (a) Pt or oxides thereof; (b) oxide of Zn; (c) simple substances or oxides of La elements; (d)molecular sieve. The technical scheme can better solve the technical problem, and is used in the reaction for producing ethylbenzene from benzene and ethane.

Owner:CHINA PETROLEUM & CHEM CORP +1

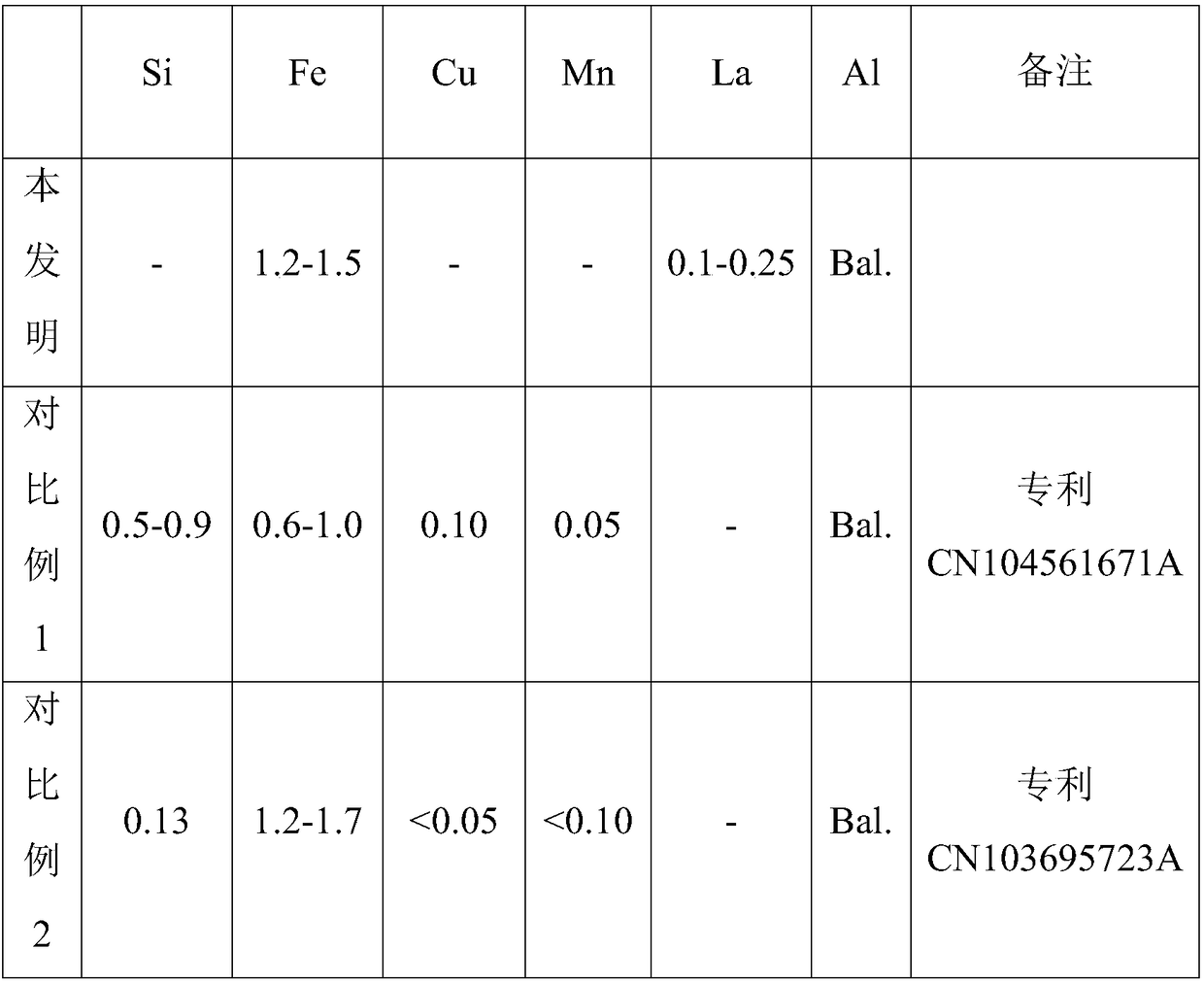

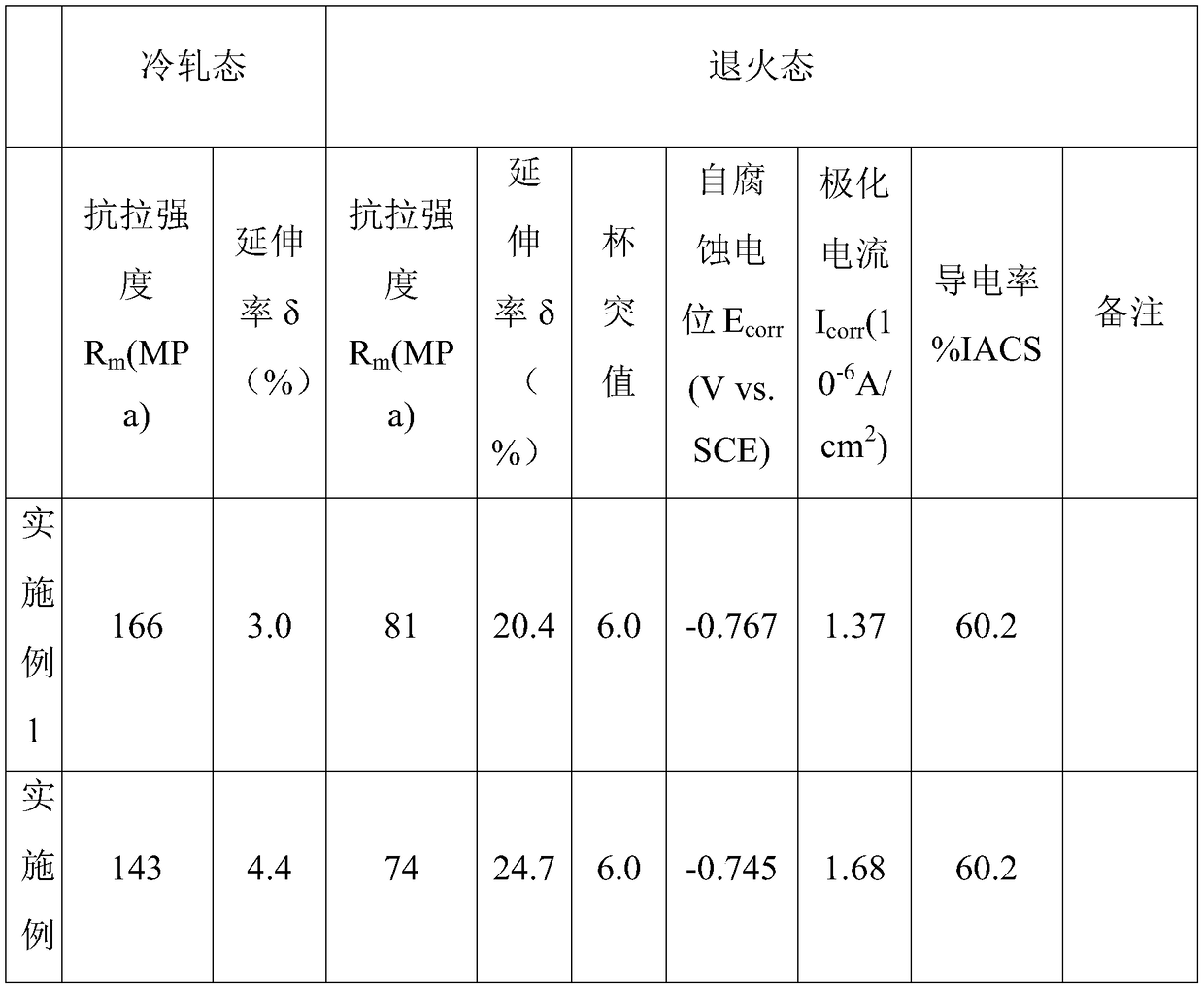

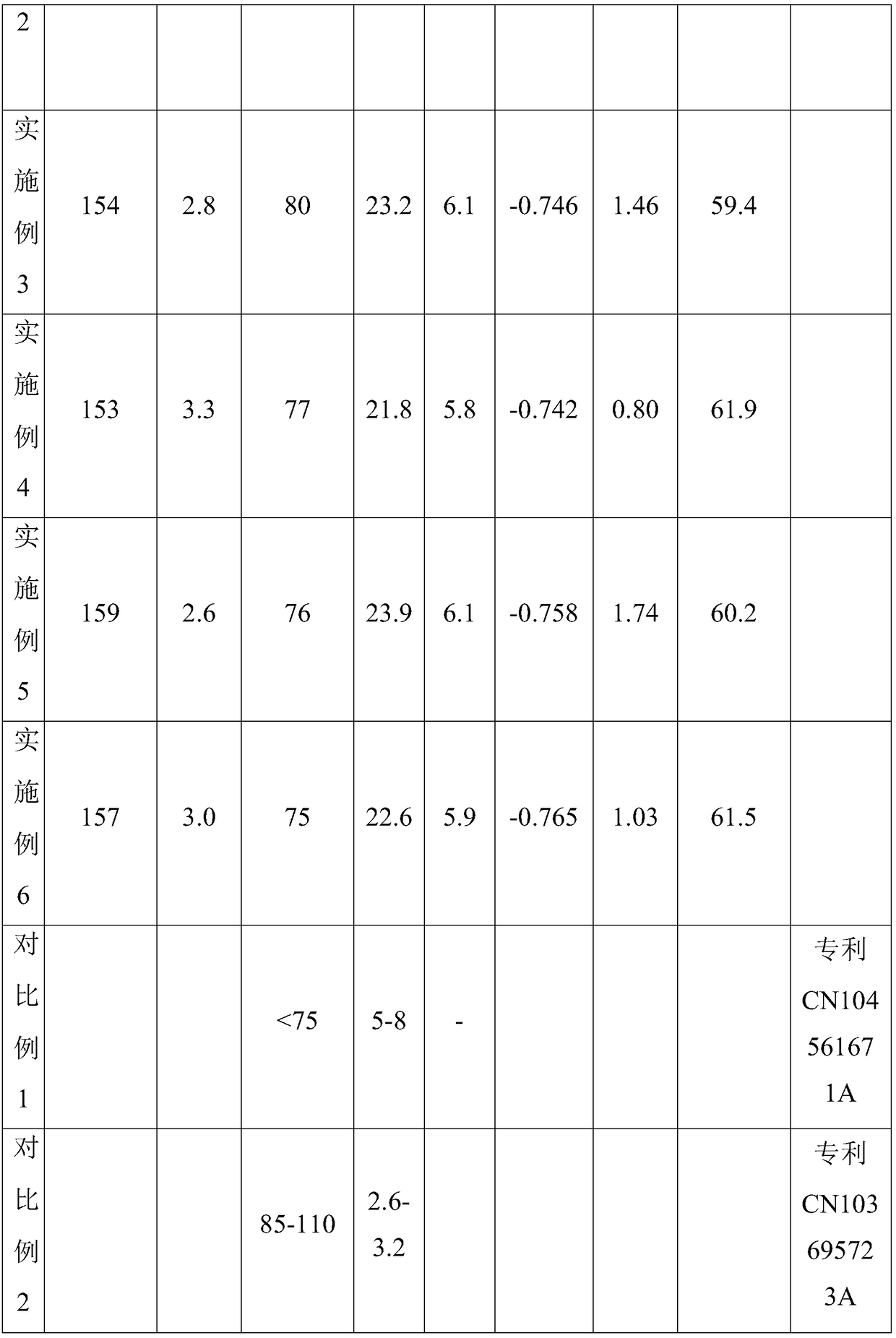

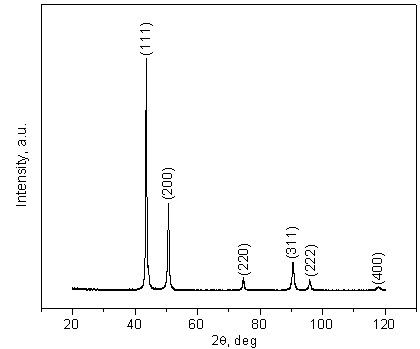

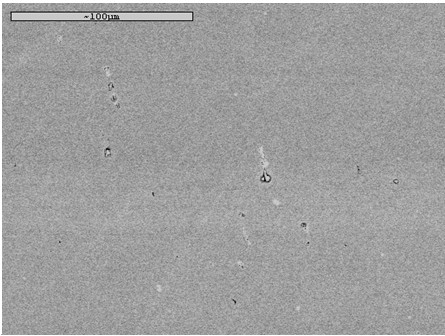

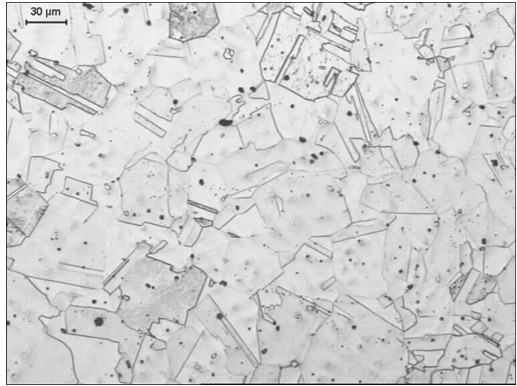

Rare-earth La added high-conductivity ternary aluminum alloy foil material and manufacture method thereof

The invention discloses a rare-earth La added high-conductivity ternary aluminum alloy foil material and a manufacture method thereof. The foil material is prepared from the following components in percentage by weight: 1.2-1.5 percent of Fe, 0.1-0.25 percent of La and the balance of aluminum. According to the aluminum alloy foil material, the high Fe ingredient design is favorable to forming a great amount of fine dispersed Al3Fe second phase; La element is added into aluminum alloy to refine grains, and the Al3Fe phase is balled and separation of AlFeLa phase is promoted. The aluminum alloyfoil material prepared by controlling the addition of alloy elements by adopting the processing process has tensile strength of 143-166MPa and ductility of more than 2.5 percent in a cold-rolled state, the tensile strength of 81MPa, ductility of over 20 percent, erishen value of over 5.8mm and conductivity of 59-61 percent IACS in an annealing state, so that the comprehensive performance of an aluminum alloy foil material can be effectively improved, and the application field of aluminum foils can be enlarged.

Owner:HUAFON NIKKEI ALUMINUM

High-toughness cast magnesium-rare earth alloy capable of being subjected to rapid high-temperature solution treatment and preparation method of high-toughness cast magnesium-rare earth alloy

ActiveCN114686711AShorten the high temperature solid solution timeImprove solution treatment process efficiencySolution treatmentUltimate tensile strength

The invention discloses a high-toughness cast magnesium-rare earth alloy capable of being subjected to rapid high-temperature solution treatment and a preparation method of the high-toughness cast magnesium-rare earth alloy. The magnesium alloy comprises the following components in percentage by mass: 5.6-10.8% of Gd, 2.2-3.2% of Y, 0.1-0.4% of Zn, 0.1-0.4% of La, 0.3-0.7% of Zr, less than 0.2 wt.% of impurity elements Si, Fe, Cu and Ni, and the balance of Mg. The preparation method comprises the working procedures of material drying, magnesium melting, alloy element adding, refining, casting forming, heat treatment and the like. Through La element microalloying and subsequent heat treatment process optimization, the high-toughness cast magnesium-rare earth alloy capable of being subjected to rapid high-temperature solid solution treatment is obtained, the high-temperature solid solution time can be remarkably shortened, the solid solution treatment efficiency can be improved, and meanwhile it is guaranteed that the alloy has high strength and plasticity. The invention also provides a material basis for the implementation of the online continuous solution treatment process of the high-toughness cast magnesium-rare earth alloy.

Owner:SHANGHAI JIAO TONG UNIV

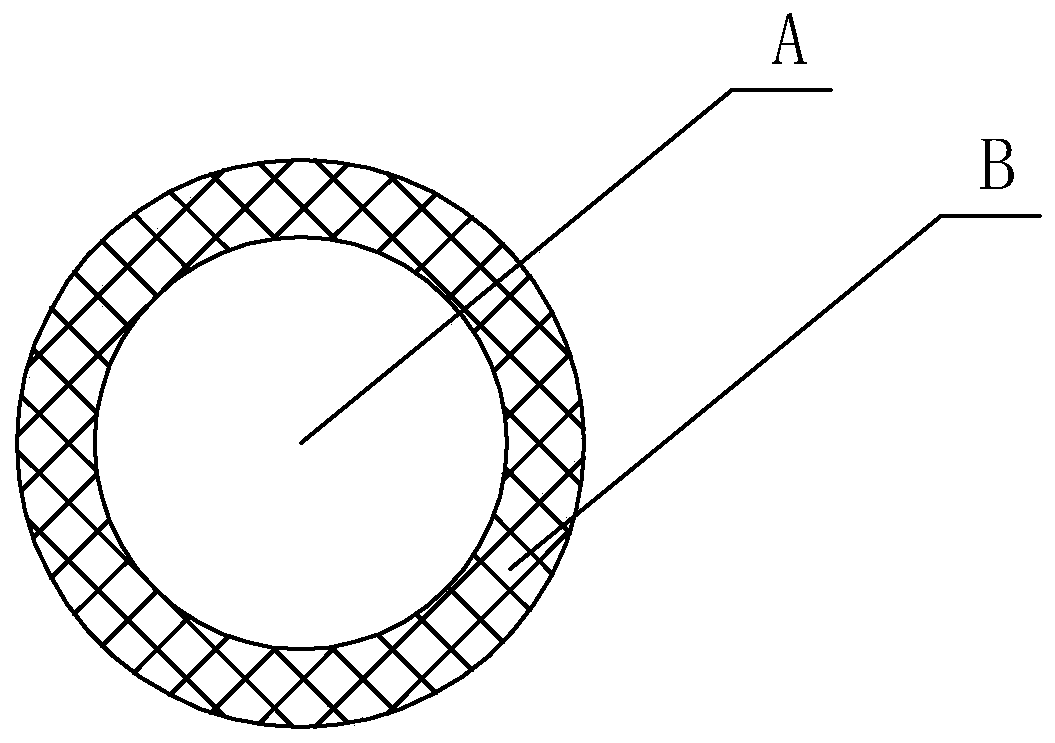

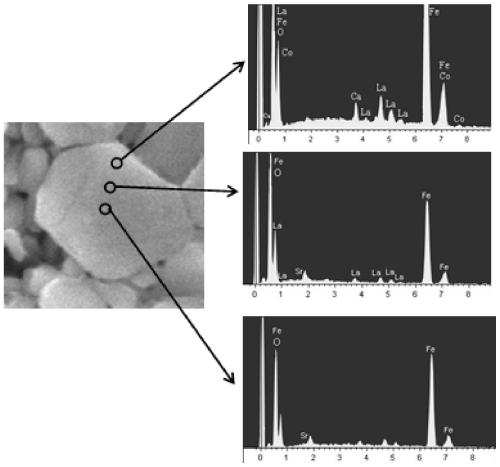

Ferrite permanent magnet material with core-shell structure and preparation method of ferrite permanent magnet material

ActiveCN110204326AReduce usageImprove coercive forceInorganic material magnetismCore componentMass content

The invention relates to the field of ferrite materials, and discloses a ferrite permanent magnet material with a core-shell structure and a preparation method of the ferrite permanent magnet material. The ferrite permanent magnet material is formed by mixing, magnetizing, molding and sintering a core component and a shell component; the mass content of elements in the core component is Sr1-xLaxFe12-yCoyO19, wherein x equals 0-0.08, and y equals 0-0.05; the mass content of elements in the shell component is Sr1-w-vLawCavFe12-zCozO19, wherein w equals 0.2-0.45, v equals 0.2-0.45 and z equals 0.15-0.35; the grain of the obtained ferrite permanent magnet material is of a core-shell structure, and the contents of La element and Co element in the grain increase from the inside to the outside with a non-uniform gradient. The ferrite permanent magnet material still can maintain higher magnetic properties under the condition that the use quantity of La-Co elements is reduced.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Rare earth-containing austenitic stainless steel for surgical implant

InactiveCN101985724AMeet the requirements of stainless steelImprove mechanical propertiesRare earthSurgical implant

The invention discloses rare earth-containing austenitic stainless steel for a surgical implant. The stainless steel comprises 0.15 to 0.50 weight percent of La, wherein in the steel, S is less than or equal to 0.005 weight percent; P is less than or equal to 0.01 weight percent; and the added La element in a stainless steel matrix is in a solid solution state and in the form of compound. The stainless steel has the advantages that: leach liquor of the stainless steel contains La ions at certain concentration to bring biological effect into play; the cell toxicity evaluation level is equivalent to that of 316L stainless steel; and the stainless steel meets the requirements of the stainless steel of the surgical implant and has superior mechanical property.

Owner:NANCHANG HANGKONG UNIVERSITY

Conductive silver paste and preparation method thereof

InactiveCN104347151AReduce corrosionControl crystallization rateNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteOhmic contact

The invention provides a conductive silver paste used for a solar cell device. The silver paste includes a silver powder, an organic carrier, and a glass powder, wherein the glass powder includes TeO2 with a weight percentage of 20-75%, PbO with a weight percentage of 20-50% and La2O3 with a weight percentage of 1-40%. The invention also provides a preparation method of the conductive silver paste. Through adoption of the conductive silver paste and the preparation method thereof, excellent ohmic contact of a positive silver grid line and a silicon wafer can be realized and particularly, better ohmic contact is formed on high sheet resistance and at the same time, the content of lead compounds in the conductive silver paste is significantly low so that a convention that traditional silver pastes are mostly high-lead glass powders is changed greatly and use of toxic compounds is reduced and pollution of environment is reduced; and at the same time, addition of the La element improves significantly the use reliability of a silicon-based solar cell.

Owner:SHANGHAI TRANSCOM ELECTRONICS TECH

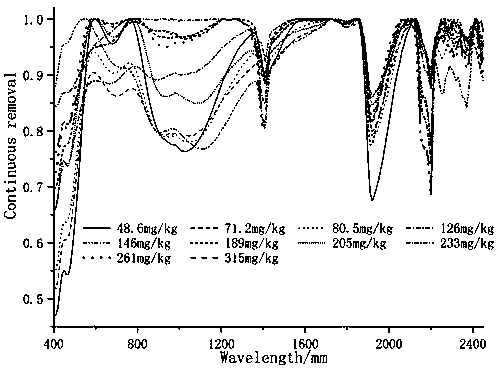

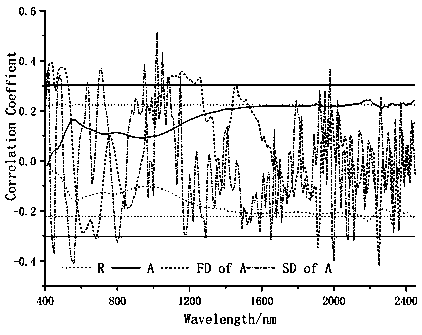

Hyperspectral inversion method of content of deposited rare earth La element

ActiveCN110596028AHigh precisionLarge coefficient of determinationMaterial analysis by electric/magnetic meansColor/spectral properties measurementsSpectral signatureLa element

The invention discloses a hyperspectral inversion method of the content of a deposited rare earth La element. In order to realize the hyperspectral inversion of the content of the deposited rare earthLa element, after a variety of spectral transformation parameters (S-G smoothing, differential, reciprocal, continuum removal and the like) are processed, a GA-ELM (Genetic Algorithm Optimized Extreme Learning Machine) mathematical model established by a variable importance evaluation (CARS, SPA, RF) characteristic variable selection method of a measured value of the content of the La element isstudied and comapred by using reflectivity second-order differential with prominent spectral characteristic details. By adopting the hyperspectral inversion method disclosed by the invention, the content of the La element can be better detected. By adopting the hyperspectral inversion method disclosed by the invention, a new test method can be provided for the hyperspectral quantitative and fast inversion research of the deposited rare earth La element on a "point", and meanwhile, a scientific and technical basis is provided for the college implementation of the quantitative inversion evaluation of regional area hyperspectral rare earth resources.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

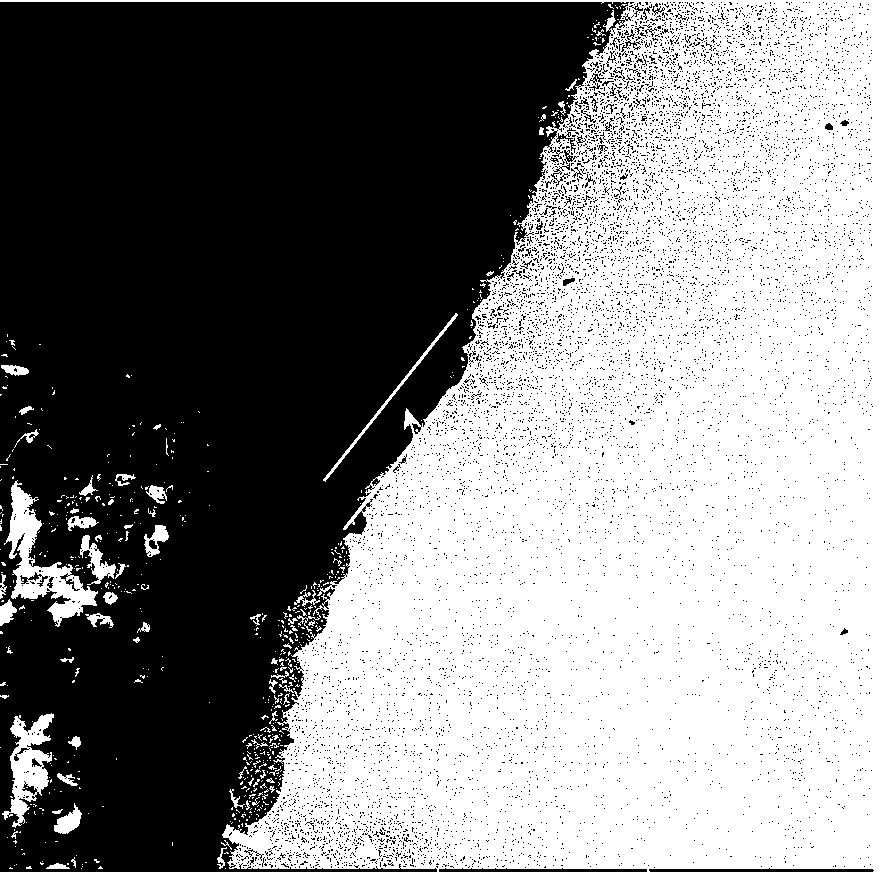

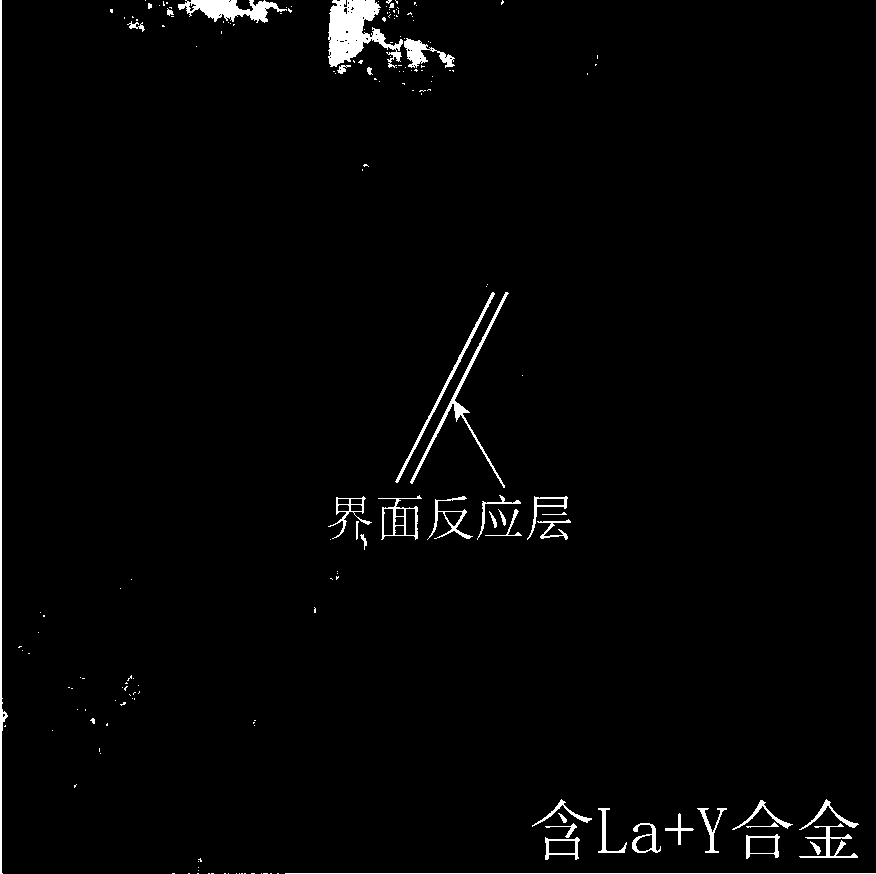

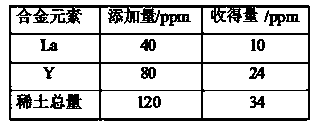

Method for stabilizing rare earth elements in nickel-based single crystal superalloy

ActiveCN107619957AStable contentImprove antioxidant capacityRare-earth elementSingle crystal superalloy

The invention relates to a method for stabilizing rare earth elements in nickel-based single crystal superalloy. Specifically, the mode of complexly adding the rare earth elements to the nickel-basedsingle crystal superalloy is adopted, wherein the content of the rare earth La element is 50+ / -10 ppm, the content of the rare earth Y element is 100+ / -20 ppm, and the content ratio of the rare earthLa element to the rare earth Y element is not lower than 1:3 but not higher than 1:2. The interface reaction between the alloy and a mold shell material is reduced, and the content of the rare earth elements in the nickel-based single crystal superalloy is stabilized. According to the method, the interface reaction between the alloy and the mold shell material is effectively reduced by adding a proper amount of the rare earth La element and the rare earth Y element to the nickel-based single crystal superalloy; and thus the content of the rare earth elements in the nickel-based single crystalsuperalloy is stable, the functions of the rear earth elements are brought into play, and the oxidation resistance, high-temperature creep resistance and the like of the nickel-based single crystal superalloy are improved.

Owner:JIANGXI UNIV OF SCI & TECH

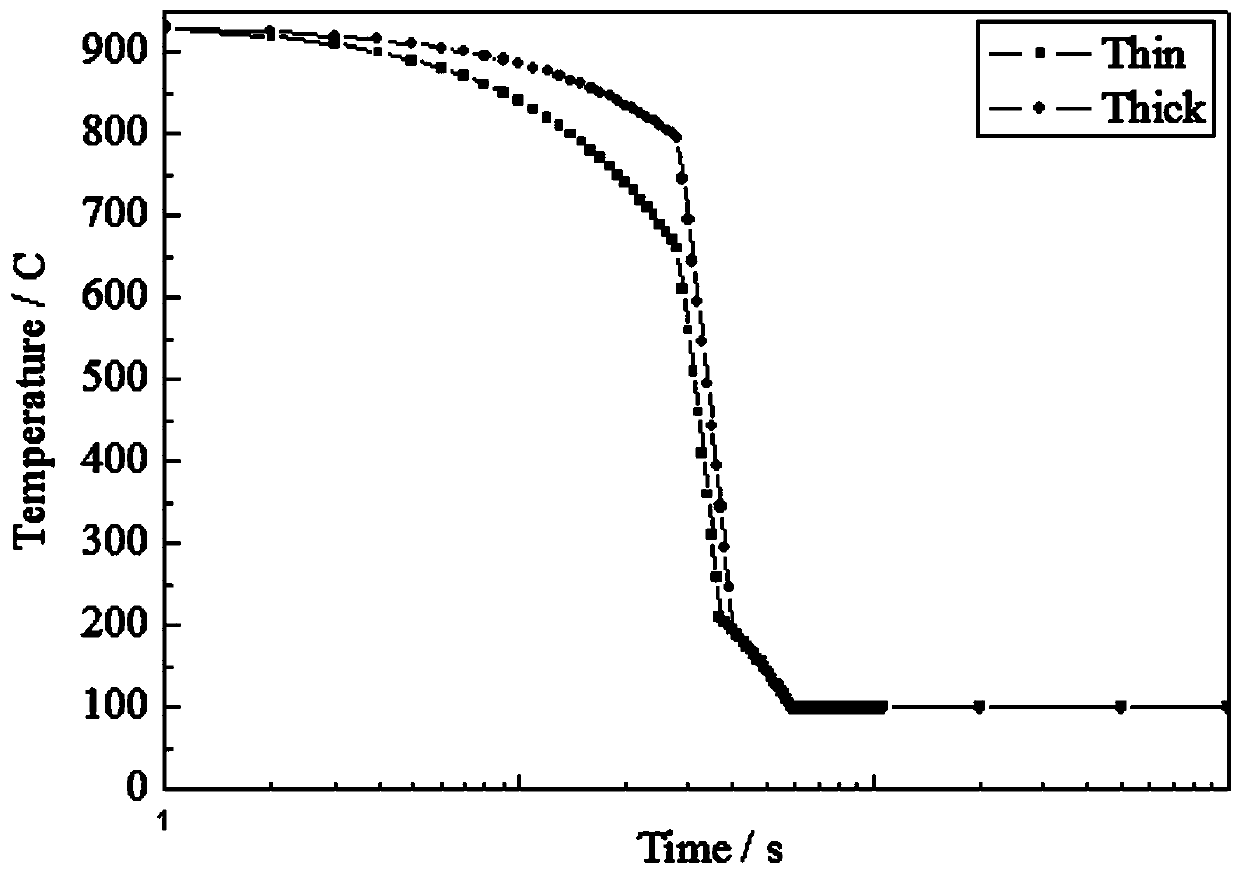

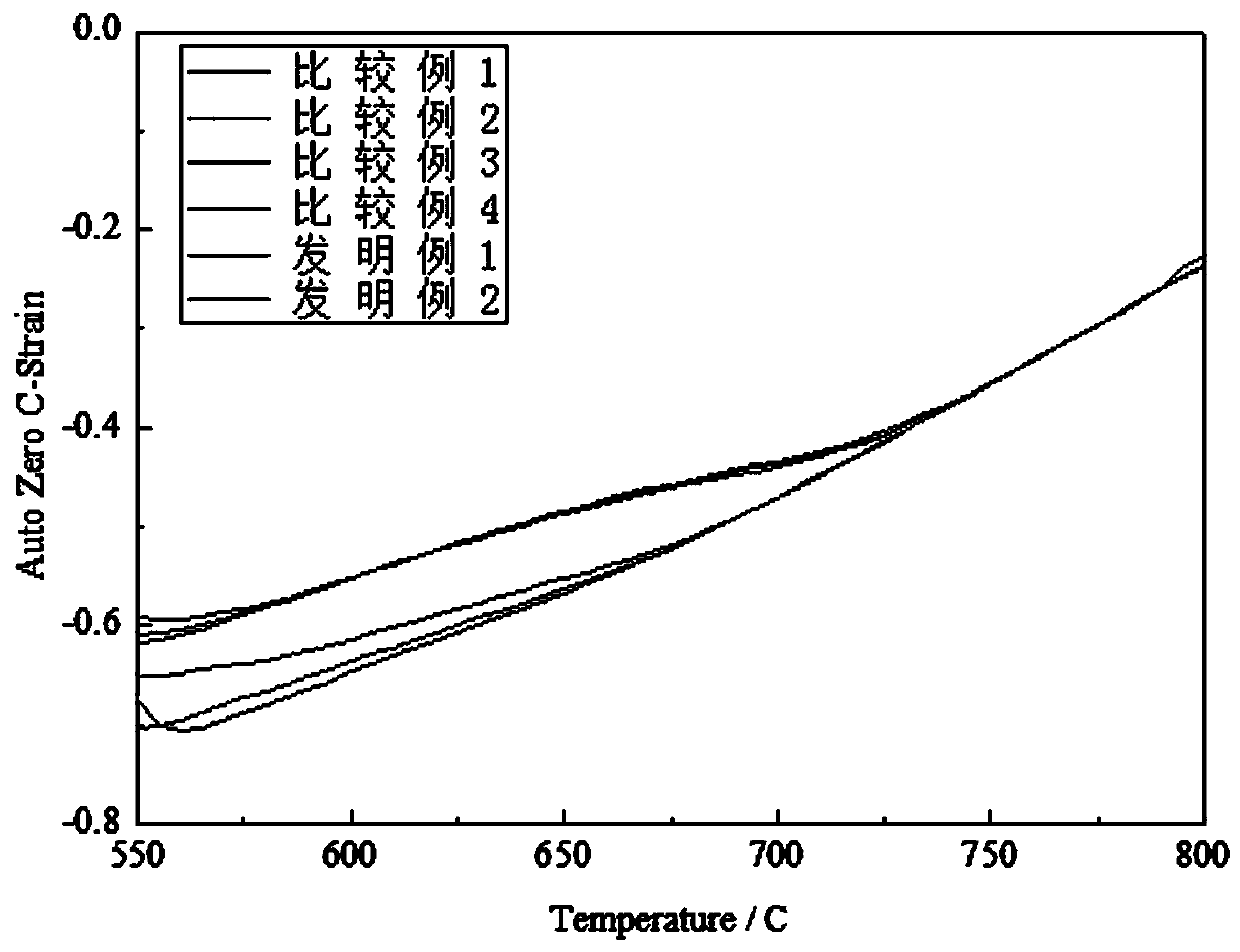

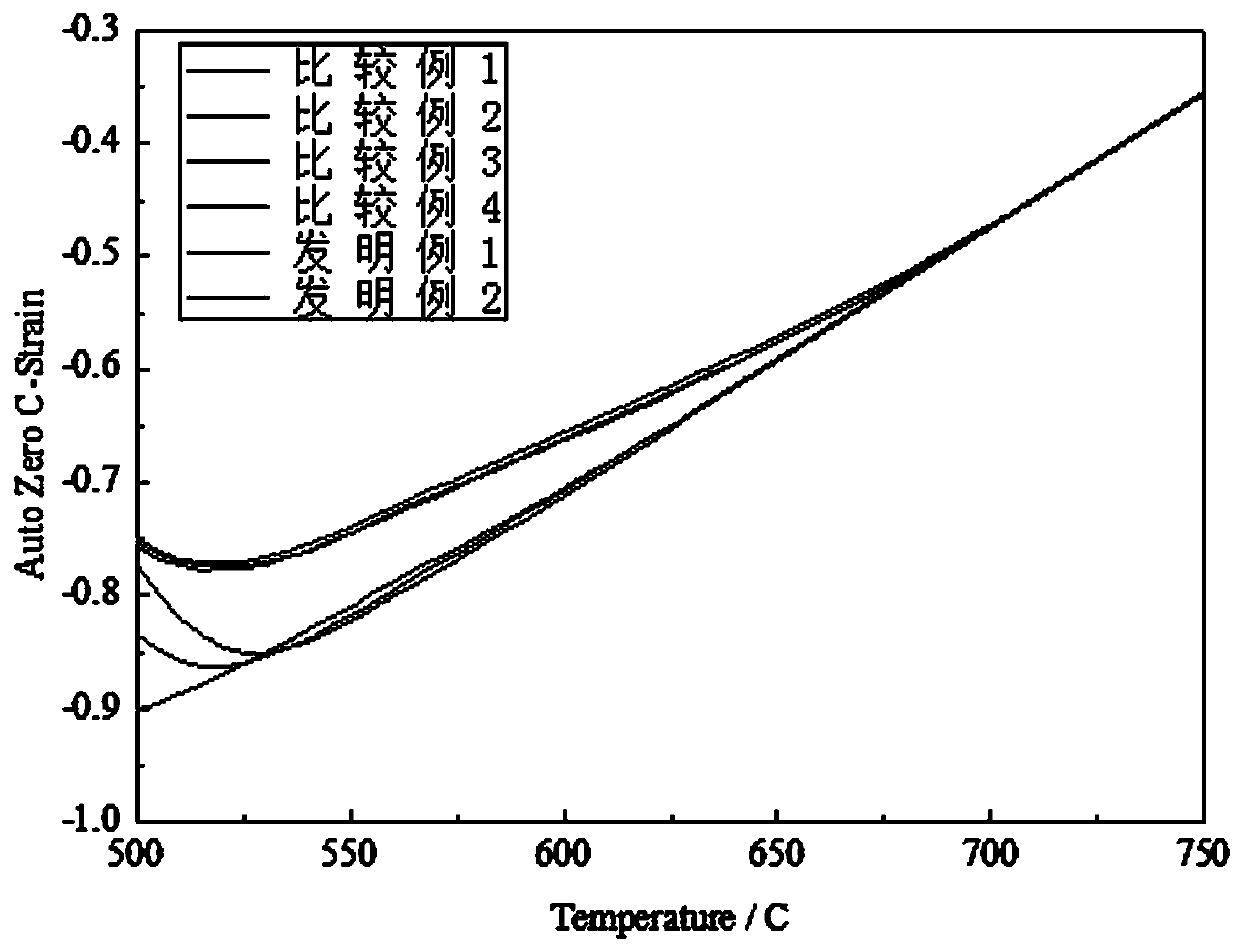

La microalloy-added hot-press formed steel plate and preparation method thereof

The invention belongs to the technical field of steel preparation, and relates to a La microalloy-added hot-press formed steel plate and a preparation method thereof. The La microalloy-added hot-pressformed steel plate is composed of the following chemical components of, in percentage by mass, 0.23% - 0.35% of C, 1.2% - 2.0% of Mn, less than 1.0% of Si, 0.05% - 0.5% of Al, less than 0.3% of Cr, less than 0.5% of Mo, less than 0.1% of Nb, less than 0.15% of V, less than 0.1% of Ti, greater than or equal to 0.0005% of B, 0.01% - 0.05% of P, less than 0.004% of O, less than 0.005% of S, 0% - 0.0005% of H, less than 0.01% of Ca, 0.0025% - 0.01% of La microalloy occurrence amount, and the balance Fe and inevitable impurities. According to the hot-press formed steel, the La element is added ina microalloy form, the La microalloy has the effect of delaying ferrite phase change, the stamping temperature can be reduced, the austenite stability can be improved, the material welding performancecannot be damaged, and the cost is low; and according to the hot-press forming process, qualified parts are stamped on existing equipment through hot-press formed steel with the specification of 1.2mm or below, and meanwhile the problem that the application qualification rate of full-size specification products is low under the condition that the environment temperature is low in winter in the north is solved.

Owner:LIAONING INST OF SCI & TECH

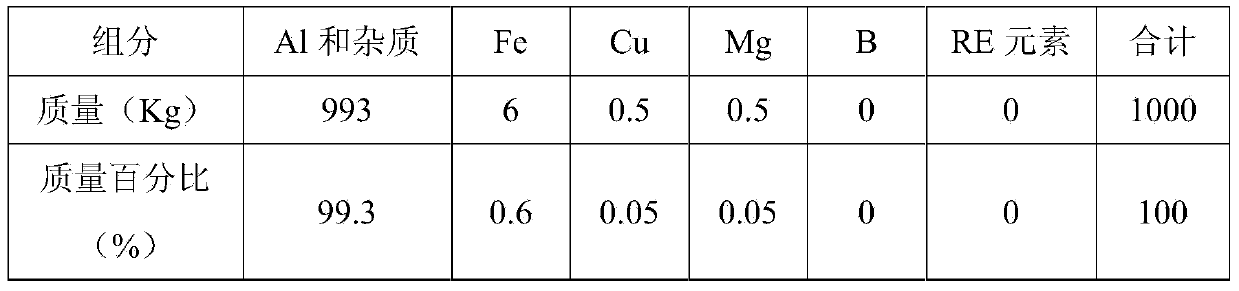

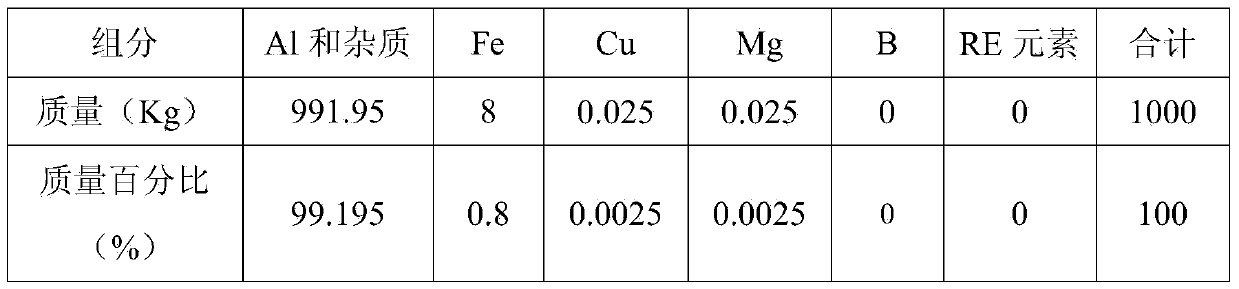

Al-Fe-Cu-Mg aluminum alloy and medium-voltage cable prepared from Al-Fe-Cu-Mg aluminum alloy

InactiveCN103725927AHigh mechanical strengthImprove tensile propertiesPower cables with screens/conductive layersMetal/alloy conductorsRare-earth elementStress concentration

The invention discloses Al-Fe-Cu-Mg aluminum alloy. The cold workability of the aluminum alloy can be significantly improved by adding B, so that an aluminum alloy rod disclosed by the invention does not generate a corrosion spot or crack in a cold-drawing process due to stress concentration, and the minimal diameter of a monofilament of the aluminum alloy after drawing can be up to 0.3mm. The content of Si is defined, the tensile property is reduced due to excessive Si, the processability of the cable is affected, the bending fatigue property of a conductor can be reduced, and the electric property also can be reduced by excessive Si. By adopting the Al-Fe-Cu-Mg aluminum alloy, an RE element is preferred, wherein Ce and Le account for over 50% of total content, so that the electric property of the alloy can be significantly improved by rare earth. The rare earth disclosed by the invention also can play a role of improving the bending fatigue resistance of the alloy, and the service life of the cable is prolonged. Ce and La are preferred due to the fact that the improvement effects of Ce and La elements in the Al-Fe-Cu-Mg aluminum alloy are more significant as compared with other rare earth elements.

Owner:ANHUI JOY SENSE CABLE

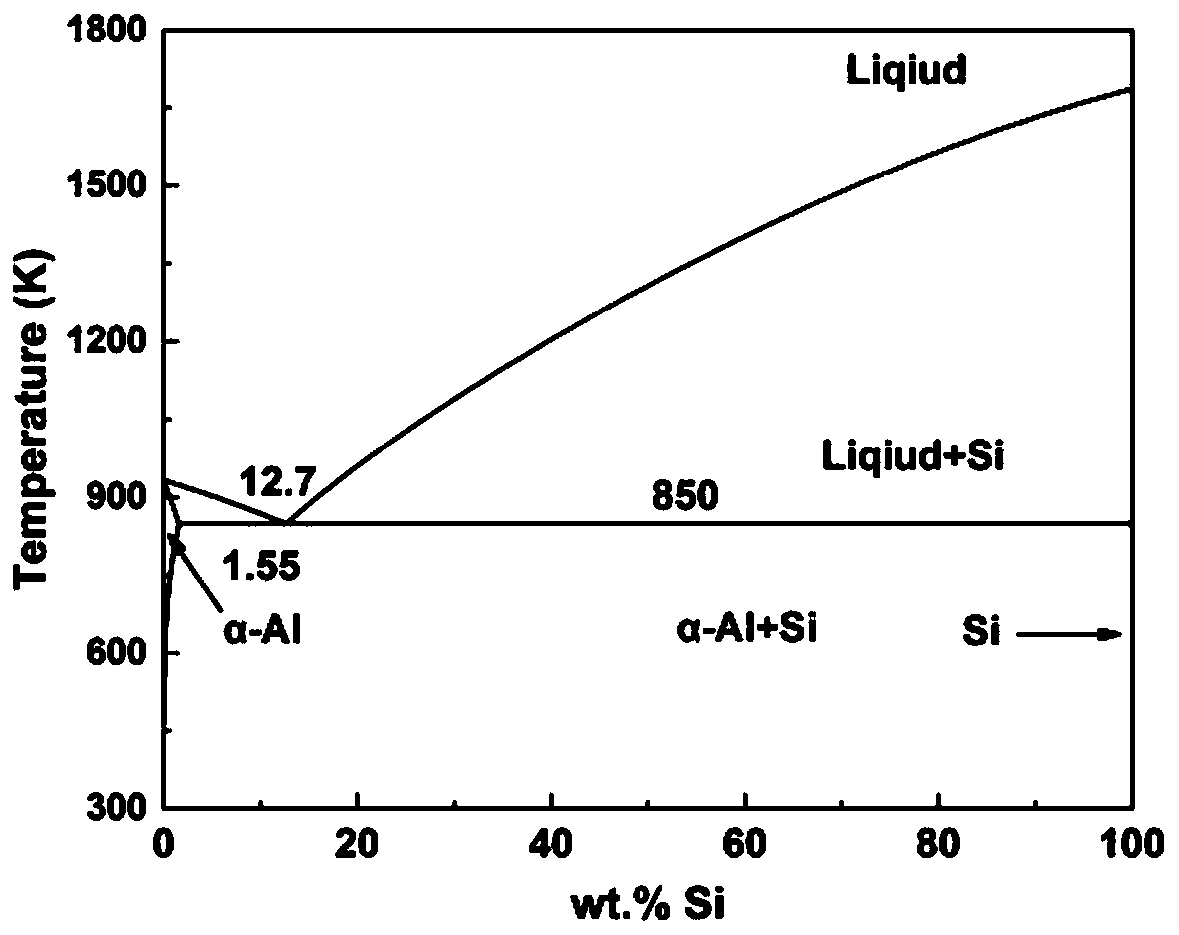

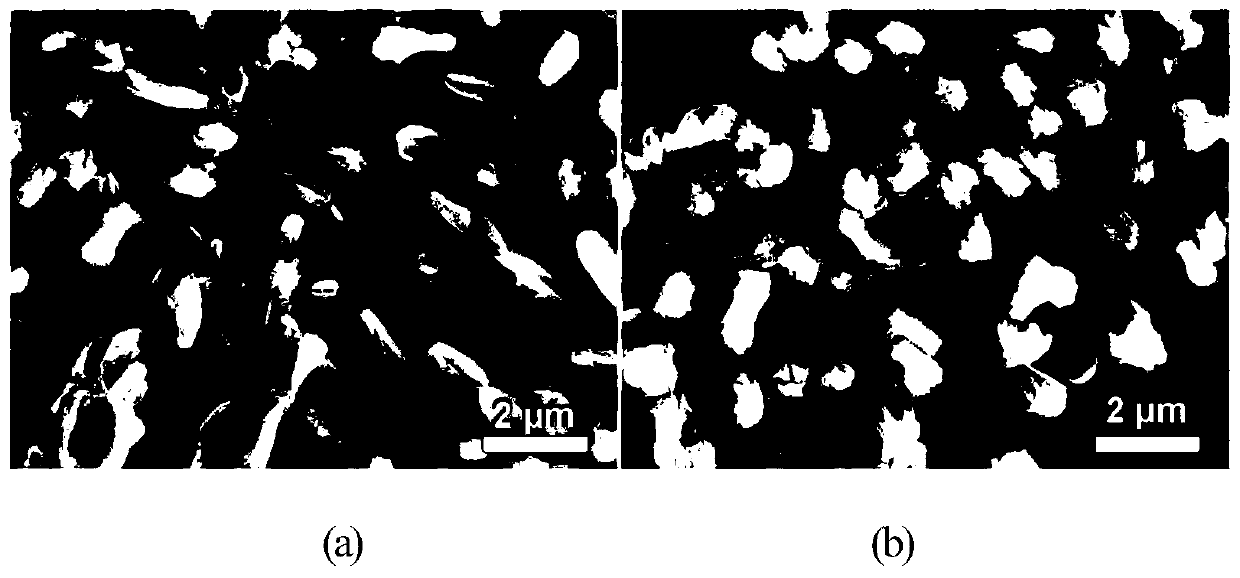

High-performance Al-Si welding wire alloy including trace La elements and preparation method of high-performance Al-Si welding wire alloy

InactiveCN110656263AImprove performanceWelding/cutting media/materialsSoldering mediaUltimate tensile strengthLa element

The invention relates to the technical field of Al-Si welding wire alloys, in particular to a high-performance Al-Si welding wire alloy including trace La elements and a preparation method of the high-performance Al-Si welding wire alloy. The trace La elements are added into Al-Si alloy melt, alloy grain refinement and eutectic silicon deterioration are achieved, and on the premise of guaranteeingthe strength performance of the alloy, the plasticity of the alloy is greatly improved. The race La elements are added into the Al-Si welding wire alloy, the refinement capacity of an Al-5Ti-1B intermediate alloy to alpha-Al grains is strengthened, the refinement effect of the alpha-Al grains is improved, nodulizing of eutectic silicon is promoted, and therefore the plasticity and drawing performance of the alloy are improved, the welding performance of the alloy is improved, and the high-performance Al-Si welding wire alloy can be used for preparing an Al-Si welding wire alloy material withgood drawing forming quality.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Magnesium alloy for negative electrode of battery

InactiveCN105609751AImprove discharge activityIncreased persistenceCell electrodesDischarge efficiencyVacancy defect

The invention discloses a magnesium alloy for a negative electrode of a battery. The magnesium alloy is prepared from the following components: 1.5wt%-2.2wt% of Zn, 1.2wt%-2.0% of Cu, 0.5wt%-1.0wt% of Ce or La, less than 0.2wt% of impurities and the balance of Mg. The Zn element is added to improve the discharge activity and continuity of the magnesium alloy; the Cu element improves a solidus temperature of the material, improves the solid solubility of the Zn, accelerates combination of solute atoms and vacancy defects, eliminates the matrix defect, improves the uniformity of the alloy material and generates an MgZnCu ternary phase; under thermal treatment, ternary phase spheroidizing dispersion distribution is formed on a grain boundary; a product is corroded to smoothly fall off in the discharge process; a magnesium hydroxide passivation layer is destroyed; and further discharge is facilitated. The rare-earth Ce or La element is added to form a few of Mg-Ce or La phases in dot diffuse distribution; balancing of over-high corrosion rate of the magnesium alloy is facilitated; and the discharge efficiency of the negative electrode is improved.

Owner:JIANGSU ZHONGKE YAMEI NEW MATERIAL CO LTD

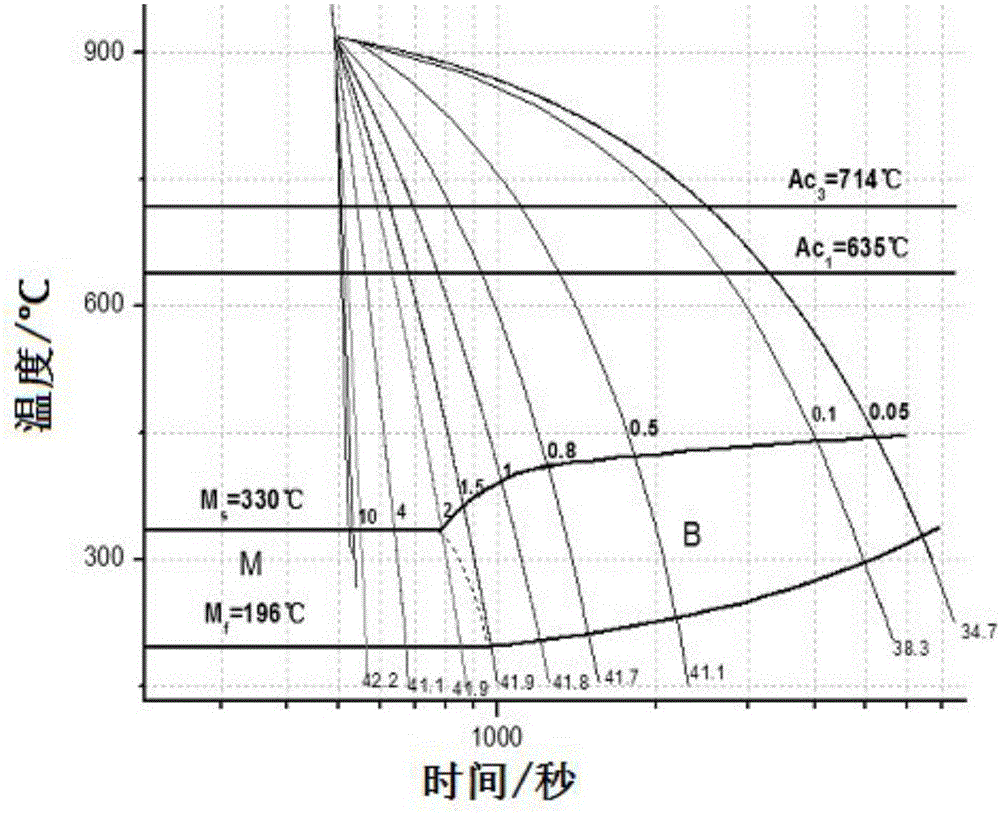

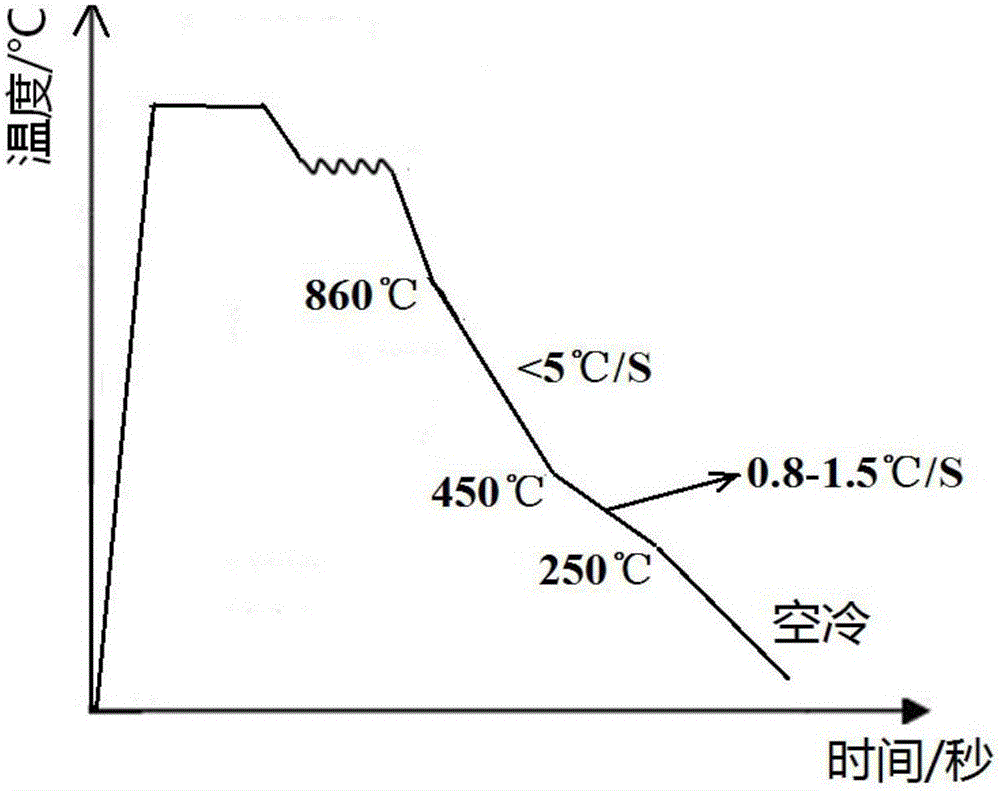

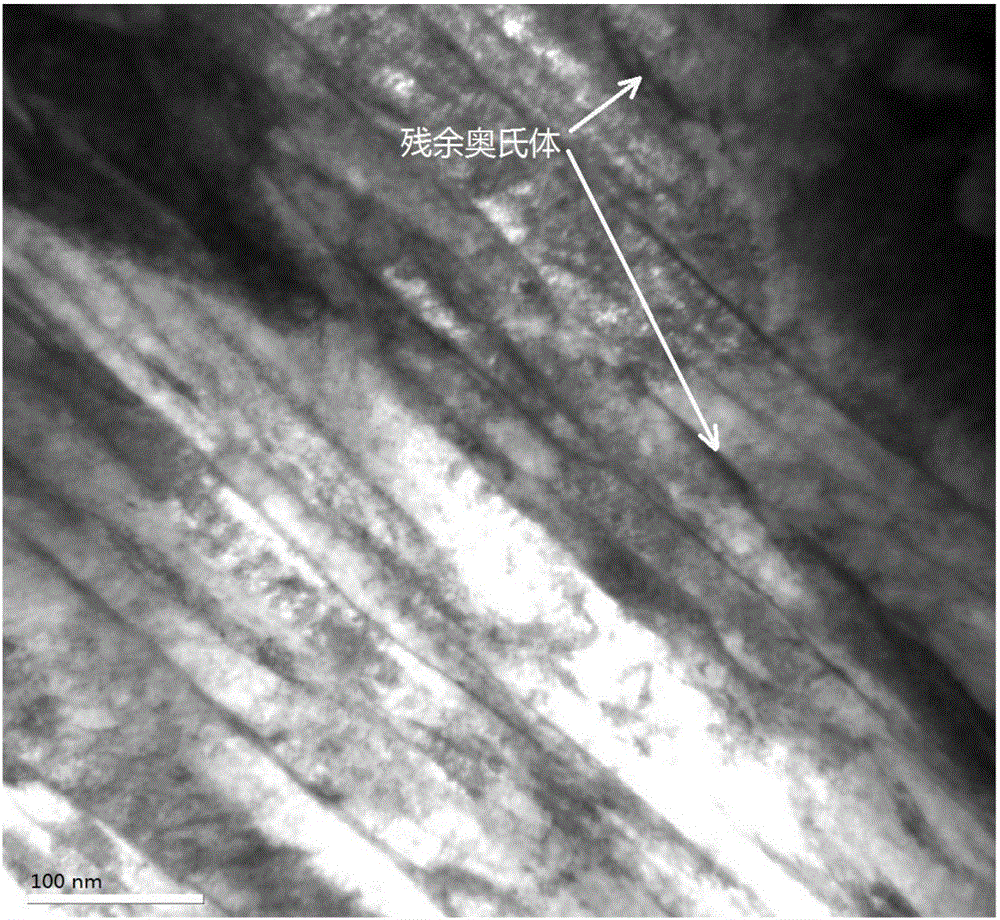

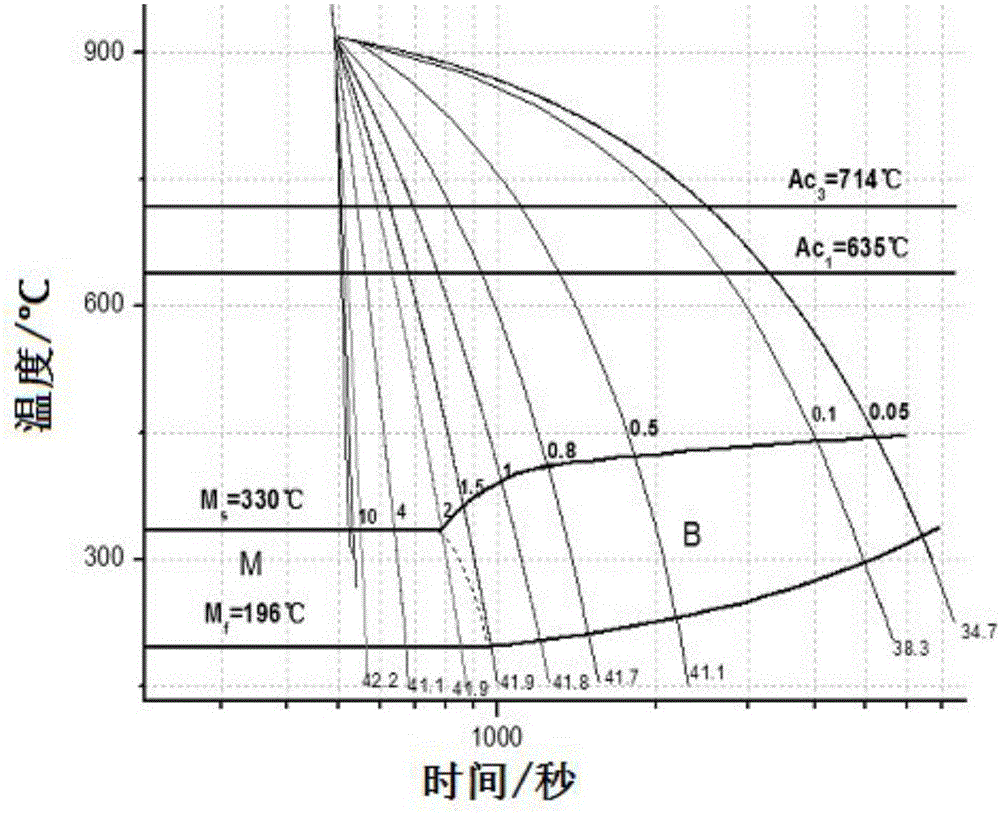

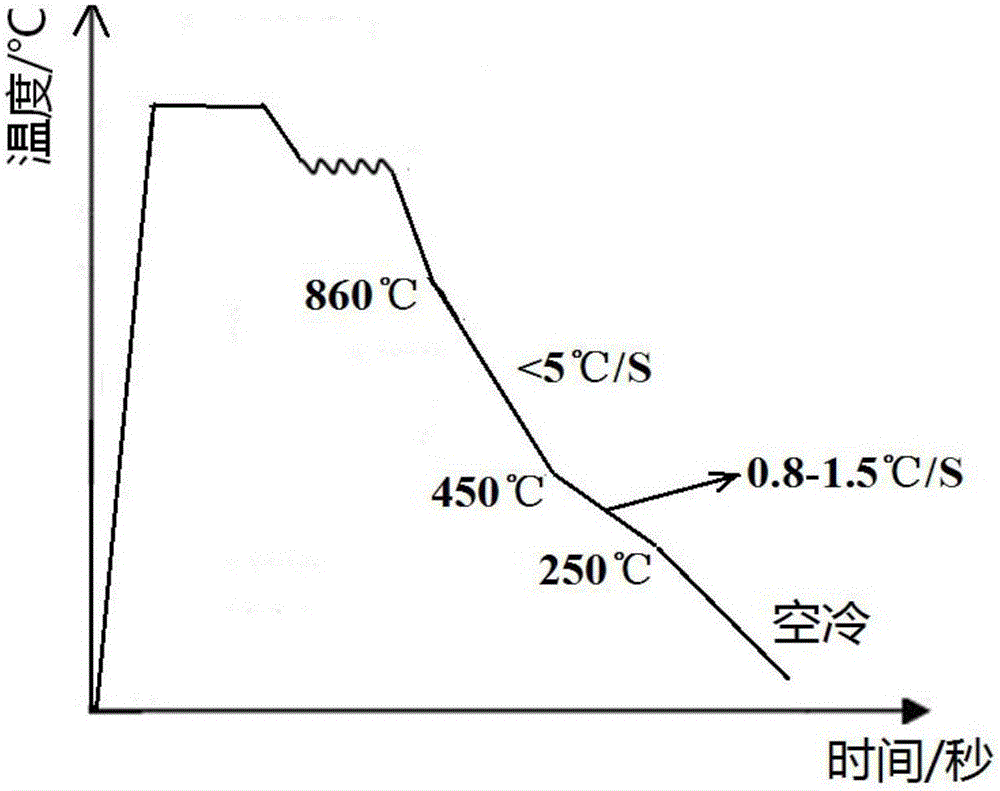

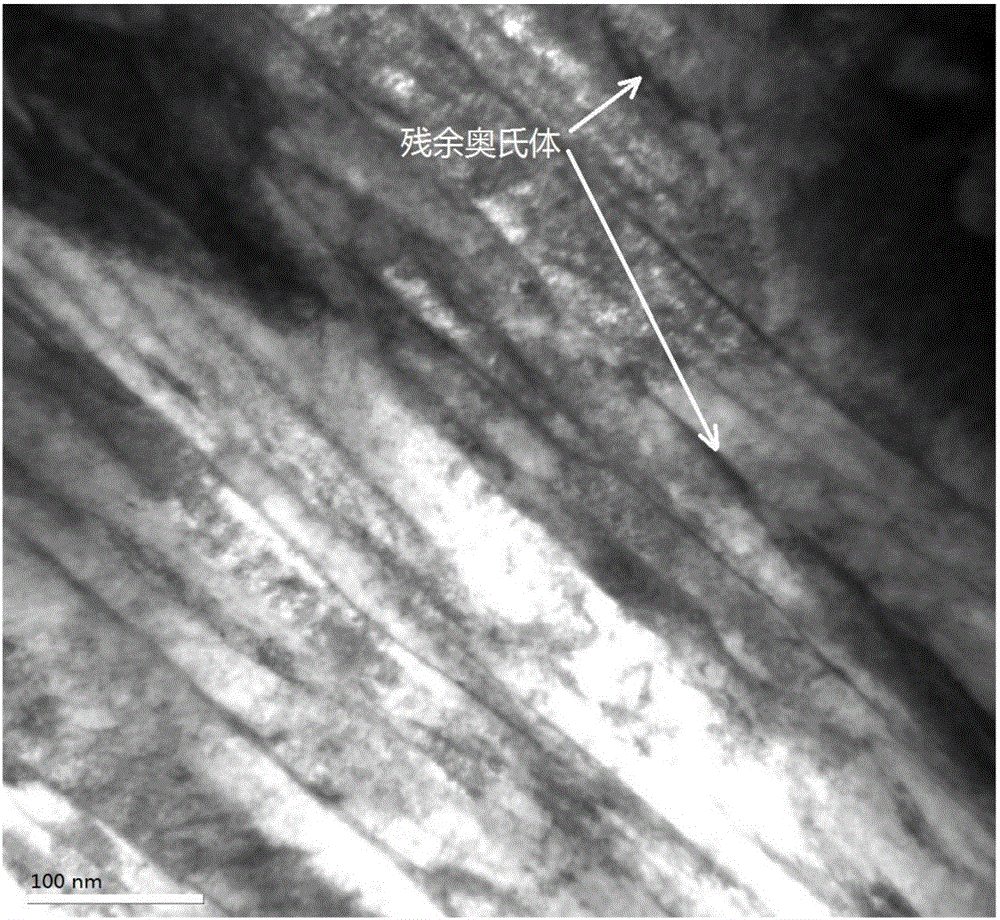

A kind of method for manufacturing steel rail and steel rail using nano-bainite material containing rare earth la element

ActiveCN105695849BLow costImprove the adaptability of production processFurnace typesHeat treatment furnacesRare-earth elementUltimate tensile strength

The invention relates to a method for manufacturing a steel rail through a nano bainite material containing the rare earth La element and the steel rail. The method includes the steps that smelting is carried out, wherein smelting comprises the deoxidation and desulfuration step, the element adding step and the refining and vacuum degassing step; rolling is carried out; and cooling is carried out. According to the preparing method, as the rare earth La is added, the rare earth La and Mn, Cr and Si alloy elements will jointly strengthen the hardenability effect, and therefore the strengthening effect is improved; in addition, expensive alloy Ni is not added, grading cooling control after rolling is used in a combined manner, and therefore the strength of steel is further improved; and meanwhile, the toughness of the steel is improved through the effects of modifying inclusion, grain boundary purification, bainite wattle refining, dislocation generation promoting and the like of the rare earth in the bainite steel, and therefore the steel rail has the excellent toughness.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Anti-radiation material for pregnant women

InactiveCN108165062AGood radiation protectionImprove absorption efficiencyCoatingsProtective garmentHigh pressureElectron density

The invention discloses an anti-radiation material for pregnant women. Yttrium nitrate, acrylic acid, lead oxide, sodium polystyrene sulfonate cation exchange resin, polyethylene, ethanol, an antioxidant 101 and other raw materials mixed, the obtained mixture is immersed in a concentrated acid, and coupling treatment is performed to obtain the anti-radiation La-cation exchange resin / nanometer leadacrylate composite maternity for maternity dresses. A La element and the cation exchange resin are subjected to high-temperature and high-pressure compounding, the obtained compound is coupled, and the coupled compound is compounded with nanometer lead polyacrylate to make particle sizes small and uniformly distributed, so the electron density of absorption atoms in the composite material is high, thereby the photon absorption efficiency is high, and the anti-radiation performance is good.

Owner:徐州创科知识产权服务有限公司

Integrally-extruded honeycomb catalyst for selective catalytic reduction (SCR) smoke denitration and preparation process of catalyst

InactiveCN102886266BEasy to shapeHigh mechanical strengthDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsStructural phaseDesorption

The invention discloses an integrally-extruded honeycomb catalyst for selective catalytic reduction (SCR) smoke denitration. The catalyst consists of the following active ingredients: 65 to 80 percent of titanium dioxide, 5 to 15 percent of ferrous sulfate, 5 to 15 percent of tungsten trioxide, 1 to 4.5 percent of vanadium pentoxide and 0.05 to 0.5 percent of lanthanum nitrate. The catalyst has the advantages of high mechanical strength, wear resistance, long service life and low cost, and the catalyst is easy to form; particularly FeSO4 is added, so that a good catalyzing effect is achieved, and a synergistic effect of FeSO4 and Ti-V-W active ingredients is also achieved; because a La element is added, structural phase transition from an anatase to a rutile is greatly restrained, a phase transition temperature is obviously increased, the catalyst can be calcined at a temperature of 800 DEG C, and the catalyst of an anatase ontology is obtained; and moreover, the catalyst has a good denitration effect, is wide in applicable temperature range, and can help to achieve a desorption efficiency of 60 to 90 percent at the temperature of between 180 DEG C and 450 DEG C.

Owner:山东蓝天节能环保科技有限公司

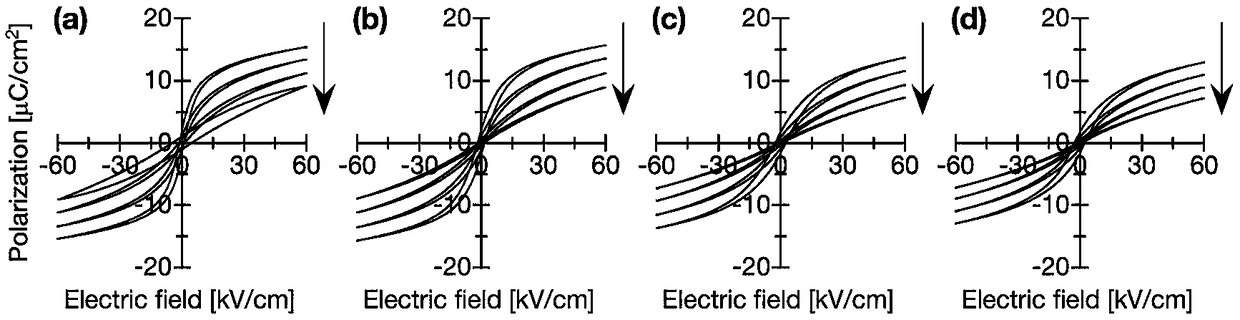

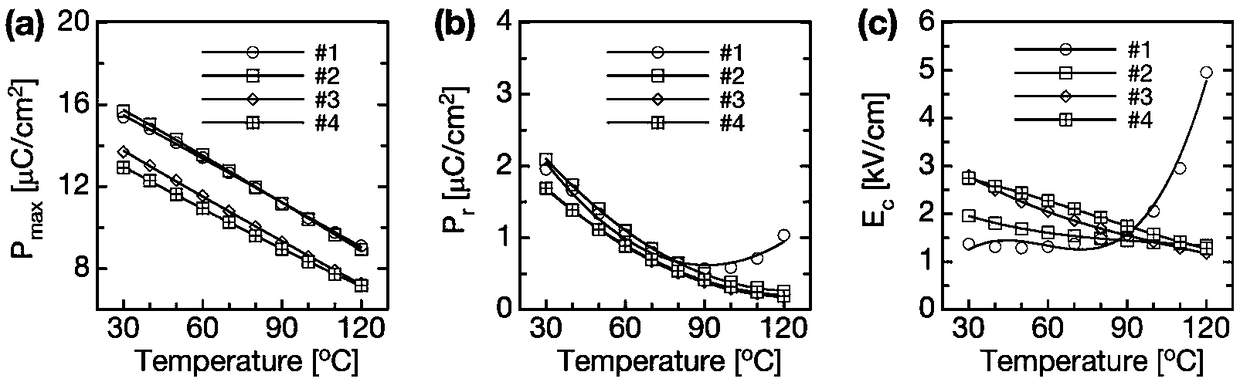

Method for restraining leakage conductance of barium zirconate titanate ceramic

The invention discloses a method for restraining leakage conductance of barium zirconate titanate ceramic and belongs to the technical field of ferroelectric ceramic preparation. The leakage conductance in non-doped barium zirconate titanate ceramic can be effectively restrained in the manner of adopting La element for A-site doping and sintering under oxygen atmosphere. Widening in a high field hysteresis loop is effectively restrained, so that the ferroelectric properties of the material under high temperature and high field can be guaranteed. The method has simple processing steps, is easyfor operation and has high repeatability. The method can be applied to the inorganic electrostriction ceramics and has a significant economic value.

Owner:XI AN JIAOTONG UNIV

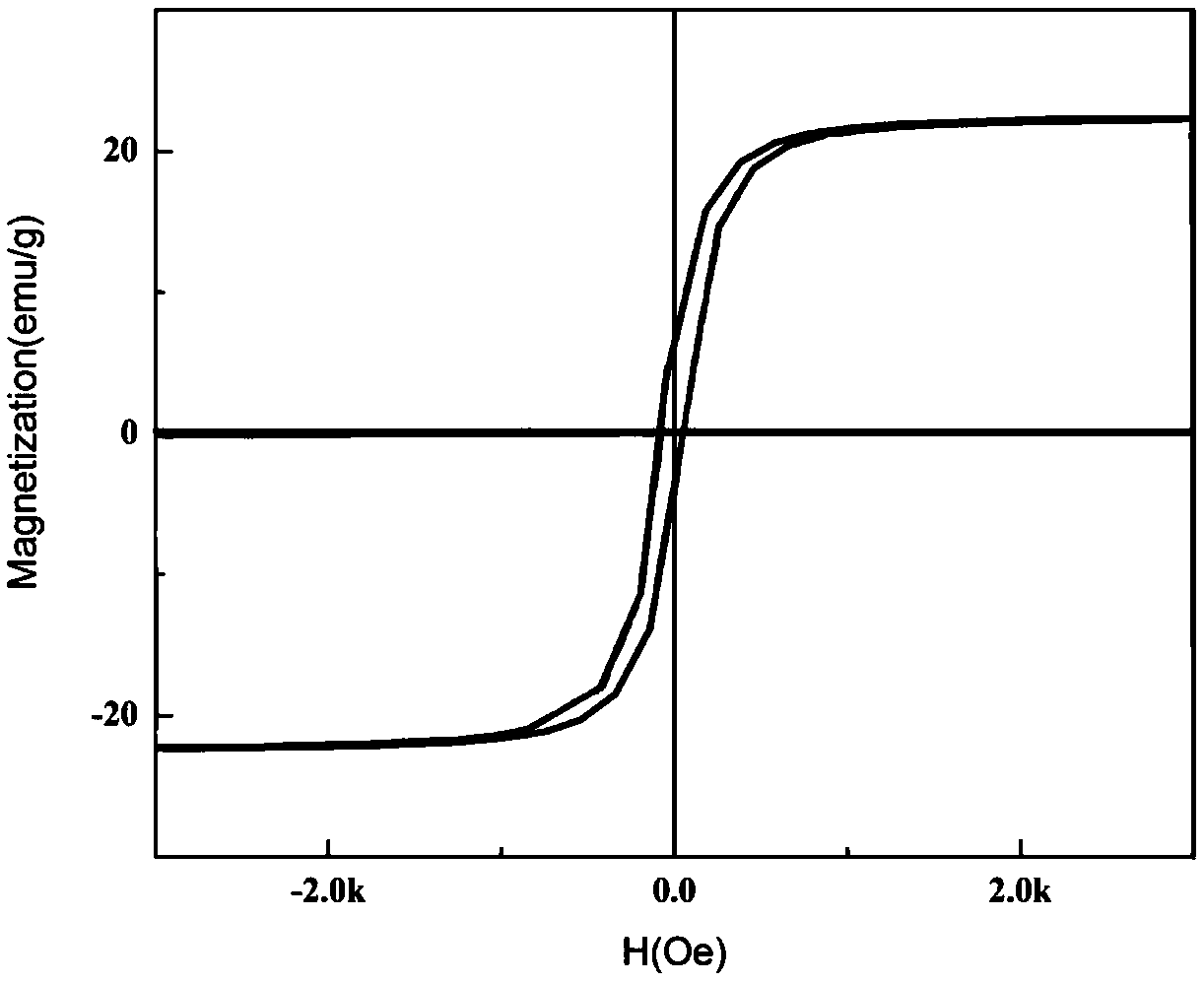

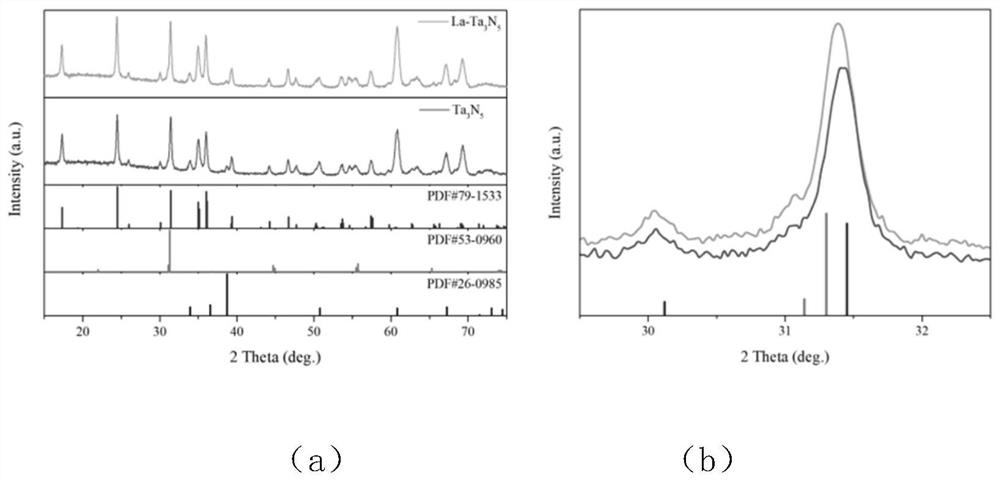

Multi-iron composite material and method for preparing flexible multi-iron composite material

The invention relates to a multi-iron composite material and a method for preparing the flexible multi-iron composite material. Two single oxide powder La0.5Y0.5FeO3 and LaY2Fe5O12 is mixed accordingto a molar ratio of 9: 1 by using a solid-phase sintering method, and an obtained multi-iron composite material is (La0.5Y0.5FeO3)0.9(LaY2Fe5O12)0.1. The flexible material is prepared by using adhesive. By doping the rare-earth La element, the magnetism of the flexible multi-iron composite material is improved, and the sintering temperature is reduced. By testing the physical properties of the flexible multi-iron composite material, the flexible material also has the ferroelectricity and ferromagnetism.

Owner:RES & DEV INST OF NORTHWESTERN POLYTECHNICAL UNIV IN SHENZHEN +1

High-rust-proof aluminum alloy and preparation method thereof

The invention discloses a high-rust-proof aluminum alloy and a preparation method thereof. According to the high-rust-proof aluminum alloy and the preparation method thereof, by optimizing Al, Mg and Ti main alloy elements and adding Mn, Fe, Si, Zn, Ni, Ga, Pb, Zr, V, B, Cr, Cu, Bi, Ca, Ce, Co, Cd, Na, Sn, Sr, Li, Ag, Be and La elements, the content of the components is scientifically regulated and controlled, and through mutual coordination of the components, the prepared aluminum alloy has excellent rust resistance, can be effectively prevented from being oxidized and rusted, has good casting performance, is easy to die-cast and form, and can be machined into objects with various shapes.

Owner:中山市银骏五金制品有限公司

Catalyst for the production of ethylbenzene from benzene and ethane

ActiveCN106582791BImprove conversion rateMolecular sieve catalystsHydrocarbon by hydrocarbon condensationMolecular sieveLa element

The invention relates to a catalyst for producing ethylbenzene from benzene and ethane. The catalyst mainly solves the problem that a Pt-loaded molecular sieve catalyst used in a reaction for producing ethylbenzene from benzene and ethane has a low conversion rate. The catalyst for producing ethylbenzene from benzene and ethane comprises the following components: (a) Pt or oxides thereof; (b) oxide of Zn; (c) simple substances or oxides of La elements; (d)molecular sieve. The technical scheme can better solve the technical problem, and is used in the reaction for producing ethylbenzene from benzene and ethane.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com