La microalloy-added hot-press formed steel plate and preparation method thereof

A technology of hot press forming and microalloying, which is applied in the field of hot press forming steel plate with La microalloying and its preparation, can solve the problems of low application pass rate, etc., achieve the improvement of product pass rate, increase production pass rate, and stabilize austenite body tissue effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0042] Example.

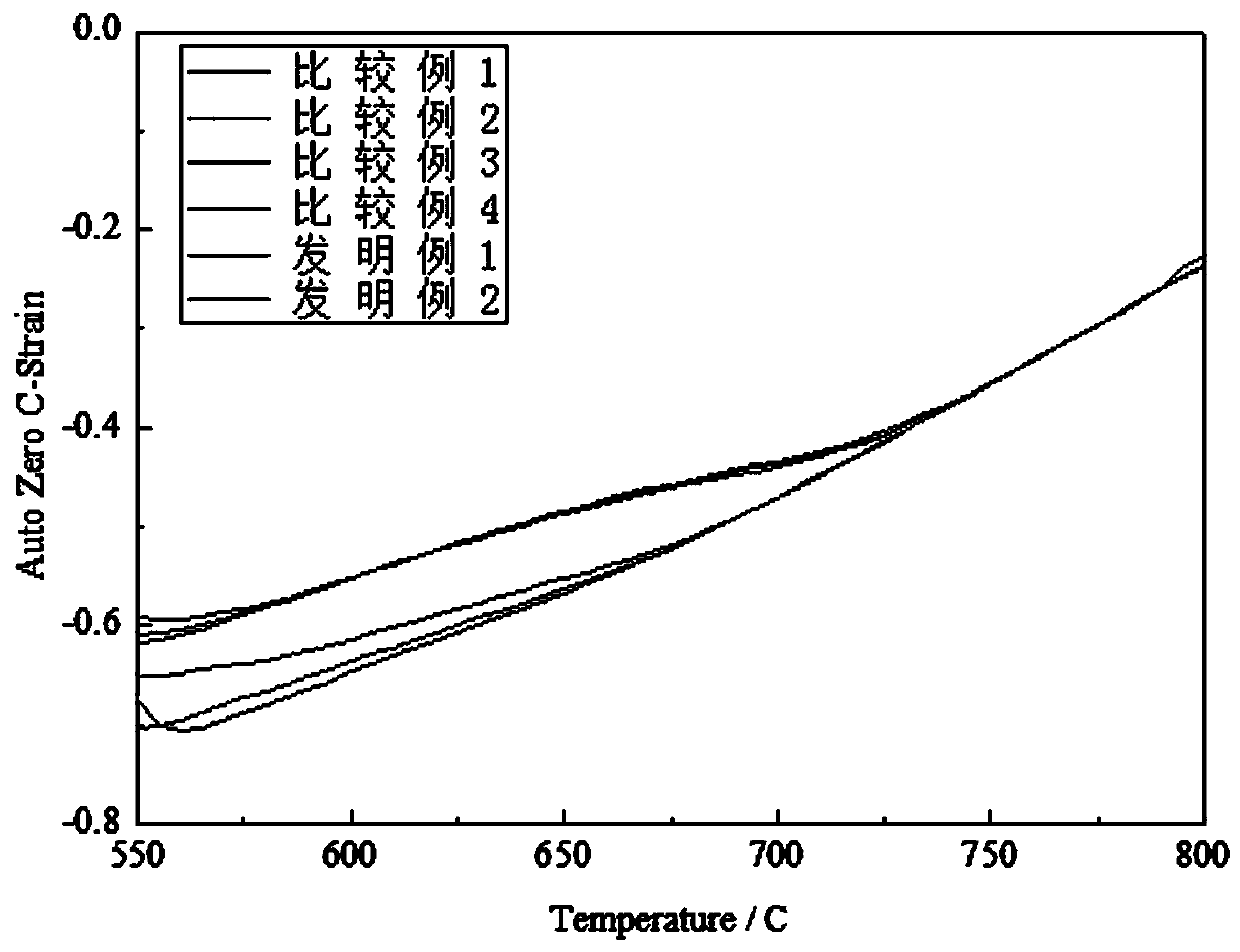

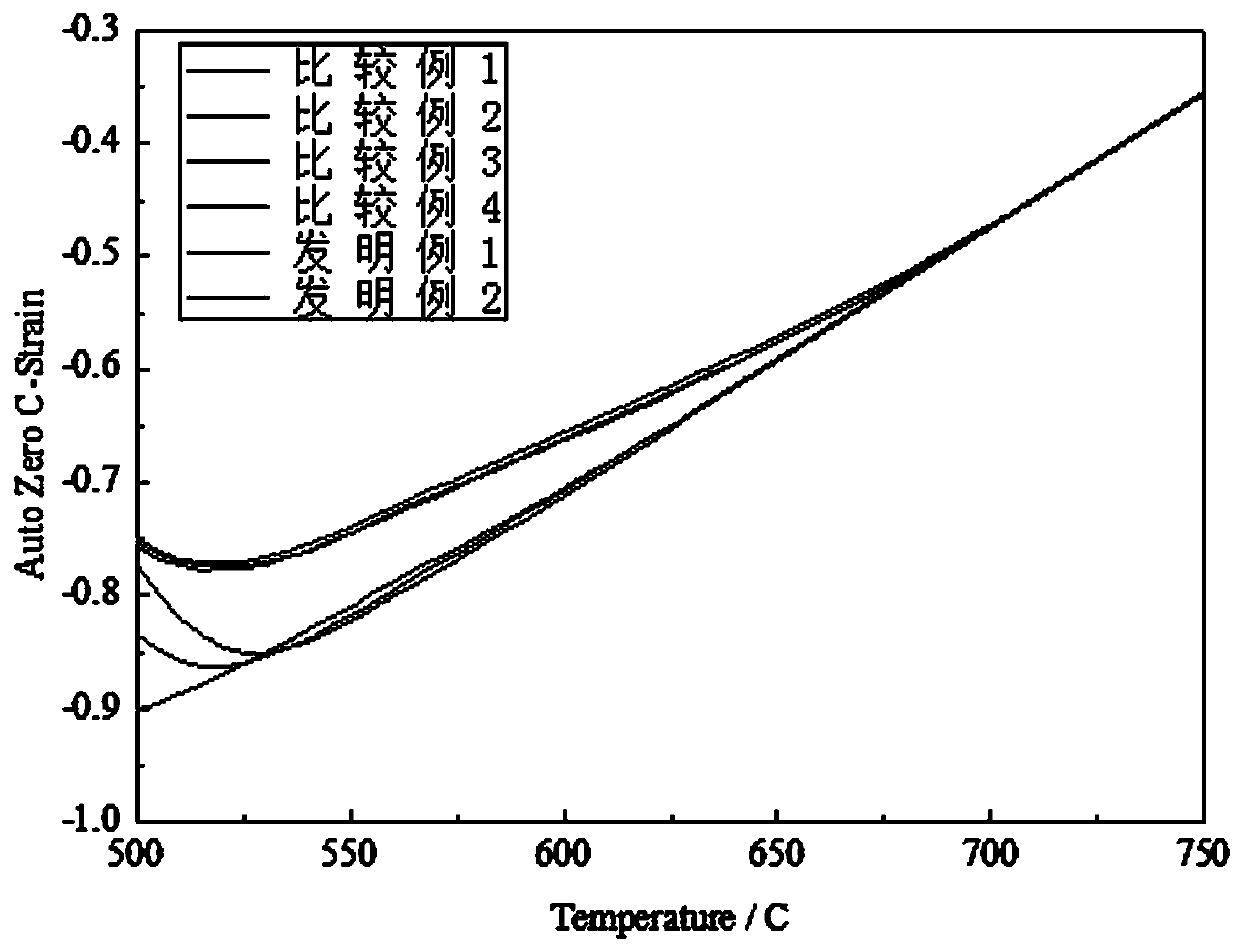

[0043] 1. Screening experiments on the chemical composition and dosage of the hot-pressed steel sheet of the present invention.

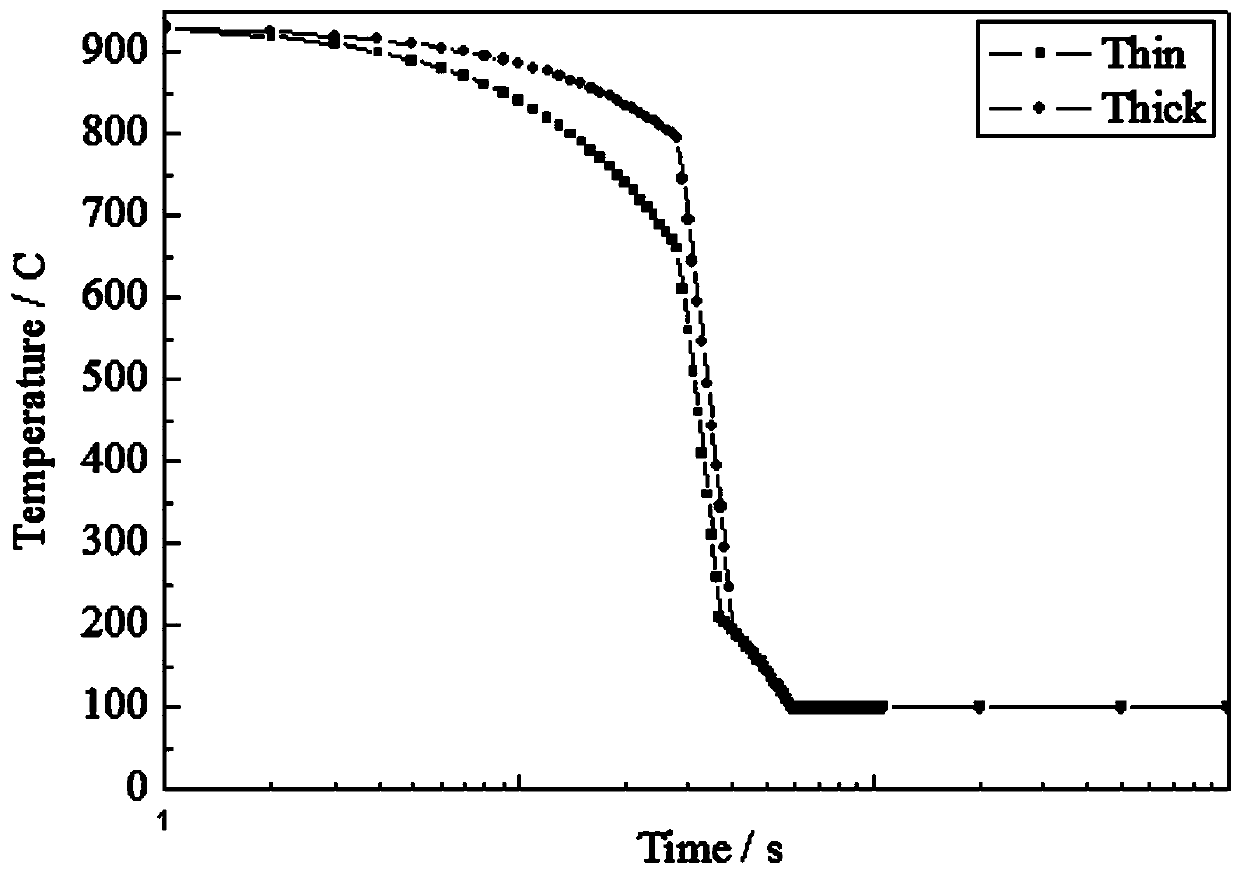

[0044] Hot press forming is divided into: heating (inert gas protection) - transfer - mold closing cooling - mold opening process. In the process of preparing parts from hot-pressed forming steel, the blank needs to be heated to the austenite state first, and the continuous strip needs to be protected by inert gas during the heating process. The blank is sent into the mold through the transfer device, and after positioning, the transfer device is withdrawn. The mold is closed and punched, and then the cooling is completed. Among them, the blank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com