Carbon/carbon composite material with antioxidant coating, preparation method and application thereof

A carbon composite material and anti-oxidation coating technology, which is applied in the field of long-term medium and high temperature anti-oxidation coatings, can solve the problems of difficulty in ensuring coating integrity, easy cracking and peeling, thermal shock resistance and high temperature erosion resistance, etc. , to achieve the effect of being beneficial to the protection of the environment and construction personnel, good thermal shock and thermal damage resistance, and no volatile irritating odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

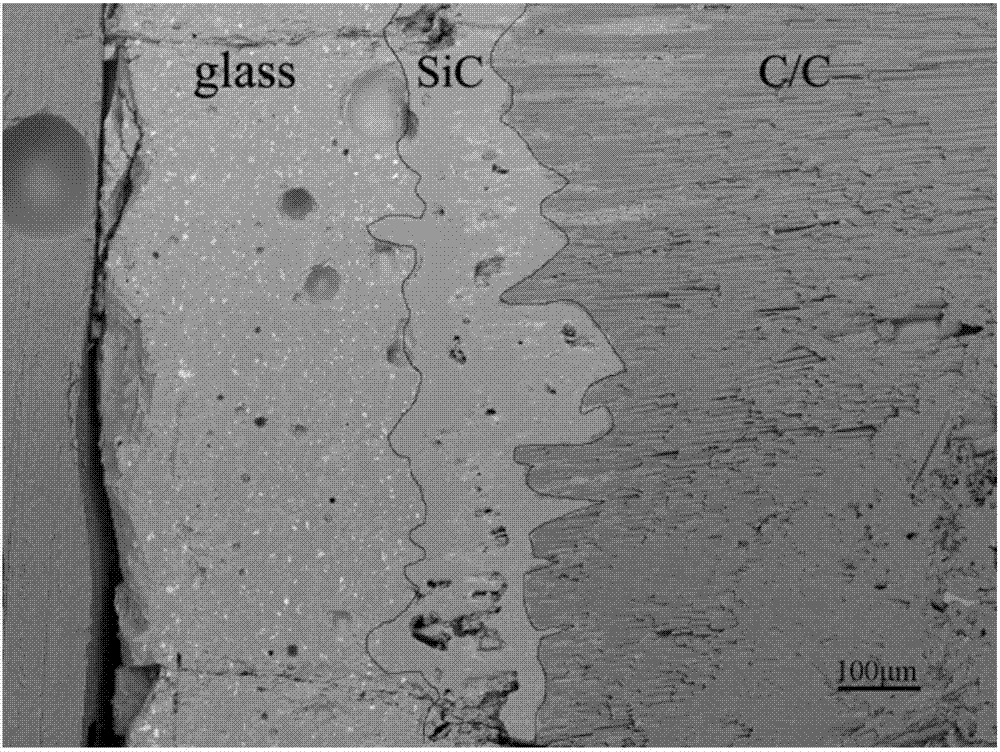

Image

Examples

Embodiment 1

[0054] Cut the three-dimensional chemical vapor deposited carbon / carbon composite matrix into different shapes as required. The density of the carbon / carbon composite matrix is 1.5g / cm 3 . Grind the surface of the substrate with 400# sandpaper to remove chamfers, and then ultrasonically clean with water and absolute ethanol for 20 minutes, and place it in a drying box at 80°C for 24 hours and take it out for use.

[0055] Weigh 85wt.% Si powder, 10wt.% C powder, 5wt.% Al 2 O 3 The powder is mixed and ball milled for 5 hours to obtain a mixed powder. Put the mixed powder into the graphite crucible, and then fill the carbon / carbon composite material sample in the mixed powder completely, then place the graphite crucible in the high-temperature furnace with graphite heating element, evacuated to 0.08Pa and flush with Ar With gas protection, the furnace temperature is increased to 1800°C at a rate of 6°C / min and kept for 2 hours. The power is turned off and the temperature is natur...

Embodiment 2

[0061] Cut the chemical vapor deposited three-dimensional finely woven carbon / carbon composite matrix into different shapes as required. The density of the carbon / carbon composite matrix is 1.6g / cm 3 . Grind and polish the surface with 100#-500# sandpaper respectively, then ultrasonically clean with water and absolute ethanol for 15 minutes, place in a drying box at 120°C for 24h, and then take it out for use.

[0062] Weigh 90wt.% Si powder, 8wt.% C powder, 2wt.% Al 2 O 3 The powder is mixed and ball milled for 5 hours to obtain a mixed powder. Put the mixed powder into the graphite crucible, and then fill the carbon / carbon composite material sample completely in the mixed powder, then place the graphite crucible in the high-temperature furnace with graphite heating element, evacuated to 0.08Pa and flush with Ar With gas protection, the furnace temperature is increased to 2000°C at a rate of 6°C / min and kept for 2 hours. The power is turned off and the temperature is naturally...

Embodiment 3

[0068] The carbon / carbon composite material matrix is made of short fiber mesh needled felt, chemical vapor deposition combined with impregnation carbonization and densification process, and cut into different shapes as required. The matrix density is 1.7g / cm 3 . Grind and polish the surface with 100#-500# sandpaper, then ultrasonically clean with water and absolute ethanol for 25 minutes, place in a drying box at 120°C for 24 hours, and take out for use.

[0069] Weigh 85wt.% Si powder, 10wt.% C powder, 5wt.% Al 2 O 3 The powder is mixed and ball milled for 5 hours to obtain a mixed powder. Put the mixed powder into the graphite crucible, and then fill the carbon / carbon composite material sample completely in the mixed powder, then place the graphite crucible in the high-temperature furnace with graphite heating element, evacuated to 0.08Pa and flush with Ar With gas protection, the furnace temperature is increased to 1900°C at a rate of 6°C / min and kept for 2 hours. The power...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com