High-performance Al-Si welding wire alloy including trace La elements and preparation method of high-performance Al-Si welding wire alloy

An al-si, high-performance technology, applied in the field of high-performance Al-Si based welding wire alloys and their preparation, can solve problems such as difficulty in meeting plastic deformation requirements, and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

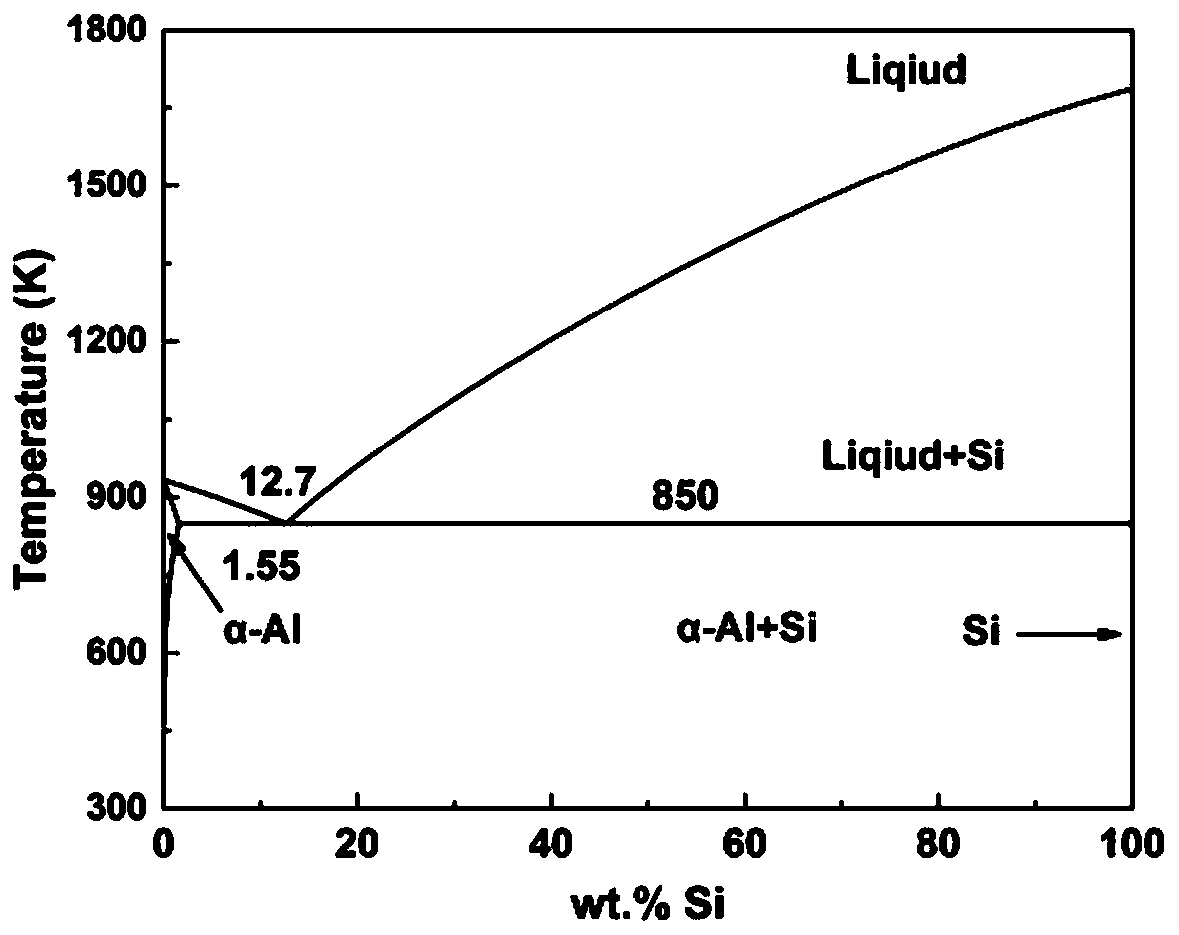

[0022] In this embodiment, the preparation process of the high-performance Al-Si-based welding wire alloy containing a trace amount of La element is as follows:

[0023] The Al-6wt% Si alloy raw material is smelted with a resistance furnace, and the smelting temperature is 740 ° C. % sodium fluoroaluminate is uniformly mixed) to refine the Al-6wt% Si alloy melt so that the hydrogen content of the Al-6wt% Si alloy melt is 0.10ml / 100g, and the Al-La and Al-Sr master alloys are used. In the form of adding 0La+0.03wt%Sr and 0.06wt%La+0.03wt%Sr to the Al-6wt%Si alloy melt, the temperature was lowered to 720 ℃ after holding for 20 minutes, and Al-5Ti-1B master alloy was added. The content of Ti element is 0.015wt% and the content of B element is 0.003wt%, heat preservation and stirring for 10 minutes, metal mold casting is performed on the melt, and a high-performance Al-Si based welding wire alloy casting containing trace La element is obtained after solidification.

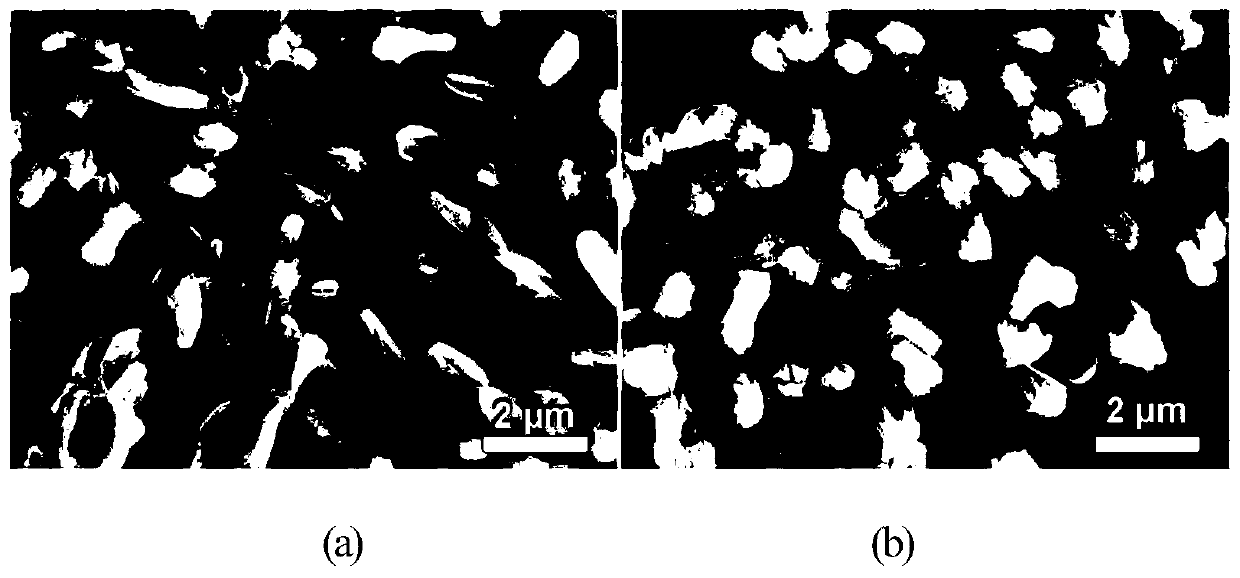

[0024] like ...

Embodiment 2

[0026] In this embodiment, the preparation process of the high-performance Al-Si-based welding wire alloy containing a trace amount of La element is as follows:

[0027] The Al-6wt% Si alloy raw material is smelted with a resistance furnace, and the smelting temperature is 740 ° C. % sodium fluoroaluminate is uniformly mixed) to refine the Al-6wt% Si alloy so that the hydrogen content of the Al-6wt% Si alloy melt is 0.10ml / 100g, in the form of Al-La and Al-Sr master alloys Add 0La+0.03wt%Sr and 0.06wt%La+0.03wt%Sr to the Al-6wt%Si alloy melt, respectively, keep the temperature for 20 minutes and then cool down to 720℃, and add Al-5Ti-1B to make the content of Ti element 0.015wt%, B element content of 0.003wt%, heat preservation and stirring for 10 minutes, metal mold casting is performed on the melt, and a high-performance Al-Si series welding wire alloy casting containing a trace amount of La element is obtained after solidification. The castings were machined into standard ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com