Method for restraining leakage conductance of barium zirconate titanate ceramic

A technology of barium zirconate titanate and ceramics, which is applied in the field of ferroelectric ceramic material preparation, can solve problems such as the increase of coercive electric field, the influence of BZT ferroelectricity, and strong leakage conduction, so as to suppress leakage conduction, ensure ferroelectric performance, easy-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

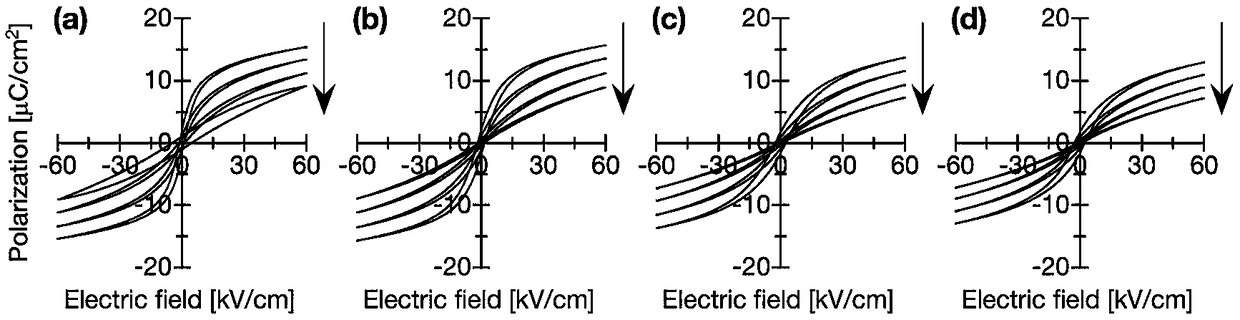

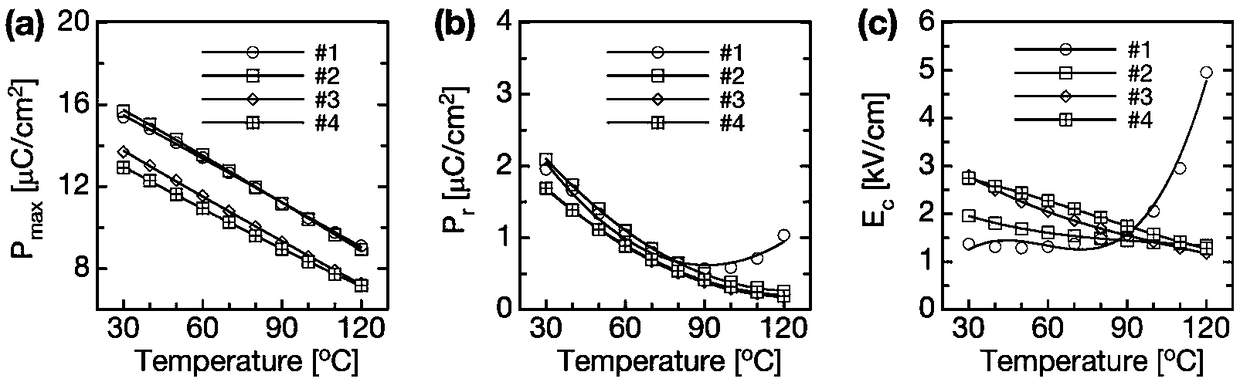

[0041] A kind of barium zirconate titanate ceramics, its chemical composition is Ba 1-x La 2x / 3 (Zr 0.2 Ti 0.8 )O 3 , the sintering temperature is 1400°C, and the doping content is 0.25%. Therefore, its chemical composition is Ba 0.9975 La 0.0017 (Zr 0.2 Ti 0.8 )O 3 , denoted as #2 ceramic sample.

[0042] Its preparation method is as follows:

[0043] 1) Weighing: according to chemical formula Ba 0.9975 La 0.0017 (Zr 0.2 Ti 0.8 )O 3 The proportion of each element in the raw material BaCO 3 , La 2 o 3 、TiO 2and ZrO 2 ;

[0044] 2) Ball milling: mix the raw materials and put them into a ball milling tank, add the ball milling solvent isopropanol and zirconia balls, fully ball mill at a speed of 250 rpm, then dry at 80°C, grind, and pass through a 60-mesh sieve;

[0045] 3) Pre-burning: Pre-burning the ground and sieved powder in step 2) at 1250° C., keeping it warm for 4 hours, and cooling to room temperature naturally;

[0046] 4) Secondary ball milling: ...

Embodiment 2

[0053] A kind of barium zirconate titanate ceramics, its chemical composition is Ba 1-x La 2x / 3 (Zr 0.2 Ti 0.8 )O 3 , the sintering temperature is 1400°C, and the doping content is 0.5%. Therefore, its chemical composition is Ba 0.995 La 0.0033 (Zr 0.2 Ti 0.8 )O 3 , recorded as #3 ceramic sample.

[0054] Its preparation method is as follows:

[0055] 1) Weighing: according to chemical formula Ba 0.995 La 0.0033 (Zr 0.2 Ti 0.8 )O 3 The proportion of each element in the raw material BaCO 3 , La 2 o 3 、TiO 2 and ZrO 2 ;

[0056] 2) Ball milling: mix the raw materials and put them into a ball milling tank, add the ball milling solvent isopropanol and zirconia balls, fully ball mill at a speed of 250 rpm, then dry at 80°C, grind, and pass through a 60-mesh sieve;

[0057] 3) Pre-burning: Pre-burning the ground and sieved powder in step 2) at 1250° C., keeping it warm for 4 hours, and cooling to room temperature naturally;

[0058] 4) Secondary ball milling: G...

Embodiment 3

[0065] A kind of barium zirconate titanate ceramics, its chemical composition is Ba 1-x La 2x / 3 (Zr 0.2 Ti 0.8 )O 3 , the sintering temperature is 1400°C, and the doping content is 1%. Therefore, its chemical composition is Ba 0.99 La 0.0067 (Zr 0.2 Ti 0.8 )O 3 , denoted as #4 ceramic sample.

[0066] Its preparation method is as follows:

[0067] 1) Weighing: according to chemical formula Ba 0.99 La 0.0067 (Zr 0.2 Ti 0.8 )O 3 The proportion of each element in the raw material BaCO 3 , La 2 o 3 、TiO 2 and ZrO 2 ;

[0068] 2) Ball milling: mix the raw materials and put them into a ball milling tank, add the ball milling solvent isopropanol and zirconia balls, fully ball mill at a speed of 250 rpm, then dry at 80°C, grind, and pass through a 60-mesh sieve;

[0069] 3) Pre-burning: Pre-burning the ground and sieved powder in step 2) at 1250° C., keeping it warm for 4 hours, and cooling to room temperature naturally;

[0070] 4) Secondary ball milling: Grind ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com